Ultrasonic Cleaning of Ore Particles and Disintegration of Flocculation

Formations

Vladimir Morkun

1 a

, Natalia Morkun

1 b

, Vitalii Tron

2 c

, Oleksandra Serdiuk

2 d

,

Iryna Haponenko

3 e

and Alona Haponenko

3 f

1

Faculty of Engineering Sciences, Bayreuth University, Universit

¨

atsstraße, 30, Bayreuth, 95447, Germany

2

Department of Automation, Computer Science and Technology, Kryvyi Rih National University,

11 Vitalii Matusevych Str., Kryvyi Rih, 50027, Ukraine

3

Research Department, Kryvyi Rih National University,

11 Vitalii Matusevych Str., Kryvyi Rih, 50027, Ukraine

Keywords:

Ultrasonic Cleaning, Ore Particles, Disintegration, Flocculation, Ore Processing.

Abstract:

The research is aimed at increasing efficiency of magnetite concentrate flotation by cleaning the surface of

useful component particles through disintegrating ore flocculated formations. The generalized model of bub-

ble motion dynamics with time-dependent pressure and bubble size is presented. Computer modelling of

bubbles behaviour under the action of ultrasonic radiation is performed. The high-energy ultrasound power is

calculated to maintain cavitation modes in the iron ore slurry. The research into flocculation and defloccula-

tion considers the dependence of magnetic susceptibility on duration of magnetization. The modelling results

enable the conclusion that in order to improve quality of cleaning ore particles before flotation, it is advisable

to apply a spatial effect to the iron ore slurry by means of high-energy ultrasound of 20 kHz in the cavitation

mode modulated by high-frequency pulses of 1 MHz to 5 MHz.

1 INTRODUCTION

In the liquid medium, some physical, chemical and

physicochemical processes occur including cavita-

tion, radiation pressure and ultrasonic flows under the

influence of ultrasound (Gubin et al., 2017; Morkun

et al., 2014). Since liquids are sensitive to stretching

forces, therefore, under powerful ultrasonic oscilla-

tions, compression and liquefaction zones arise in the

liquid. During the wave phase, which creates lique-

faction, there are many gaps in the form of cavitation

bubbles in the liquid, which close abruptly in the sub-

sequent phase of compression.

Different effects of ultrasound on individual min-

erals, are used to achieve high dispersion (Soyama

and Korsunsky, 2022; Golik et al., 2015; Morkun

et al., 2017), for example, for grinding schistose min-

a

https://orcid.org/0000-0003-1506-9759

b

https://orcid.org/0000-0002-1261-1170

c

https://orcid.org/0000-0002-6149-5794

d

https://orcid.org/0000-0003-1244-7689

e

https://orcid.org/0000-0002-0339-4581

f

https://orcid.org/0000-0003-1128-5163

erals (graphite, molybdenite). The process of grind-

ing molybdenite under excessive static pressure re-

sults in manufacturing a product, the dispersion of

which is 2-3 times higher than that of the product ob-

tained under atmospheric pressure (Soyama and Kor-

sunsky, 2022).

Application of ultrasound to processing ore raw

materials has been an urgent research problem for a

long time. In particular, introduction of ultrasound

into the water system of ore processing provides spe-

cific activation based on two physical phenomena –

acoustic cavitation and acoustic wind (Ambedkar

et al., 2011; Ambedkar, 2012; Morkun et al., 2015a;

Morkun and Morkun, 2018). Gas discharge in acous-

tic cavitation is most preferable at lower frequency

within 20kHz-40kHz, while the acoustic wind domi-

nates at frequencies above 400kHz and1MHz in ultra-

sonic and megasonic systems, respectively (Ambed-

kar et al., 2011).

The experiment results in (Harrison et al., 2002)

reveal an increase in the clean coal yield from 3 % to

10 %, greater production of clean coal and a decrease

in the content of sulfur, mercury, ash and moisture in

the processed coal. These results are associated with

78

Morkun, V., Morkun, N., Tron, V., Serdiuk, O., Haponenko, I. and Haponenko, A.

Ultrasonic Cleaning of Ore Particles and Disintegration of Flocculation Formations.

DOI: 10.5220/0012009900003561

In Proceedings of the 5th Workshop for Young Scientists in Computer Science and Software Engineering (CSSE@SW 2022), pages 78-85

ISBN: 978-989-758-653-8; ISSN: 2975-9471

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

ultrasonic shock waves generated by bubble cavita-

tion that contributes to breaking natural relationships

between coal and ash-forming mineral impurities and

cleaning of coal particles from impurities. Cavitation

also enhances removal of unwanted particles of clay,

slime and oxidation products covering the surface of

coal.

Application of the above methods is a promis-

ing approach to improving efficiency of technologi-

cal processes of iron ore beneficiation (Morkun et al.,

2015b,c).

The research aims to increase efficiency of flota-

tion of magnetite concentrates by disintegrating ore

flocculated formations and cleaning particle surfaces.

To achieve the set aim, it is necessary to investigate

peculiarities of formation of cavitation modes in iron

ore slurry by applying high-energy ultrasound.

2 MATERIALS AND METHODS

Let us consider mathematical description of cavitation

processes in the heterogeneous medium. The gener-

alized model of bubble motion dynamics dependent

on the pressure time and the size of bubbles is pre-

sented as a Rayleigh-Plesset equation (Gubin et al.,

2017; Kozubkov

´

a et al., 2012). Solving the Rayleigh-

Plesset equation for a certain pressure value p

∞

(t) en-

ables obtaining the value of the bubble radius dR

b

(t)

dR

b

dt

=

s

2

3

p

vap

(t) − p

∝

(t)

ρ

1

, (1)

where R

b

is the bubble radius, µm; p

∝

is pressure in

the medium at perpetuity, Pa; p

vap

is vapour pressure,

Pa; ρ

1

is liquid density, kg/m

3

.

The results of Singhal et al. (Singhal et al., 2002)

suggests a cavitation model based on a complete cav-

itation model. The density of the mixture is defined

as

ρ = αρ

vap

+ (1 −α) ρ

1

, (2)

where α is the volumetric fraction of vapour; ρ

vap

is

vapour density, kg/m

3

; ρ

1

is liquid density, kg/m

3

.

The ratio between density of the mixture and the vol-

umetric fraction of vapour α has the form:

∂

∂t

(ρ) = −(ρ

1

−ρ

vap

)

∂

∂t

(α), (3)

where ρ is density of the mixture, kg/m

3

; α is the

volumetric fraction of vapour; ρ

vap

is vapour density,

kg/m

3

; ρ

1

is liquid density, kg/m

3

. The volumetric

fraction of vapour α is determined from f as

α = f

ρ

ρ

vap

. (4)

According to the cavitation model proposed in

(Schnerr and Sauer, 2001), the equation for the par-

ticle volumetric fraction of vapour α is obtained from

the expression

R =

∂

∂t

(ρ

vap

α) +

∂

∂x

j

(ρ

vap

αu

j

), (5)

where R is the evaporation rate, kg/h.

R =

ρ

vap

ρ

1

ρ

∂α

∂t

+

∂(u

j

α)

∂x

j

(6)

When substituting equation (5) in (6) we obtain

R =

ρ

vap

ρ

1

ρ

α(1 −α)

3

R

b

s

2

3

(p

vap

−p)

ρ

1

(7)

The bubble radius is determined from the expres-

sion

R

b

=

α

1 −α

3

4π

1

n

b

1

3

. (8)

Also in this model, the only parameter to be deter-

mined is the number of spherical bubbles in the vol-

ume of liquid n

b

.

Equation (7) is also used to simulate the conden-

sation process. The final form of the model is as fol-

lows:

if p ≤ p

vap

R

e

=

ρ

v

ρ

1

ρ

α(1 −α)

3

R

b

s

2

3

(p

vap

−p)

ρ

1

. (9)

if p ≥ p

vap

R

c

=

ρ

v

ρ

1

ρ

α(1 −α)

3

R

b

s

2

3

(p − p

vap

)

ρ

1

. (10)

If ultrasonic frequency is small (< 1MHz) and

pressure amplitude is much smaller than the atmo-

spheric static pressure (101 kPa), a bubble will be in

the state of stable cavitation (Hu, 2013), i.e. fluctu-

ate around its initial radius in the periodic mode pe-

riodically. This process should be described using

an empirical equation based on the simplified Keller-

Herring model (Carvell and Bigelow, 2011)

R

0

∼

=

3

{

MHz

}

µm

f

lin

0

, (11)

where R

0

is the radius of the bubble, µm; µ is the

shearing viscosity coefficient, f

lin

0

is ultrasonic fre-

quency, MHz.

It should be noted that at higher pressure, the bub-

ble reaction also largely depends on the ultrasonic

field pressure amplitude and, therefore, equation (11)

is no longer possible in this “inertial cavitation” sce-

nario.

Ultrasonic Cleaning of Ore Particles and Disintegration of Flocculation Formations

79

There are expressions in (Carvell and Bigelow,

2011) to calculate the optimal initial radius of the bub-

ble for maximum expansion depending on ultrasonic

frequency and pressure amplitude

R

optimal

=

1

√

0.0327F

2

+ 0.0679F + 16.5P

2

, (12)

where P is the pressure amplitude for the ultrasonic

sinusoidal wave, MPa; f is frequency, MHz; R

optimal

is the optimal bubble radius, µm.

For example, if f = 1MHz, P = 1MPa, the opti-

mal bubble radius is 0.2454m.

Calculation covers the frequency range, MHz,

pressure amplitudes, MPa and radii, µm used in mod-

elling (Hu, 2013) (table 1). It should be noted that

at f = 0.5MHz and pressure P = 8.0MPa the initial

radius is R = 30.75nm.

After converting dependence (12), we get a square

equation that includes the function of optimal fre-

quency for a certain size of bubbles from where F (R)

at the known pressure P can be determined from the

expression

F (R) =

−0.068 ±

q

0.068

2

−4 ·0.034 ·

6.5P

2

−

1

R

2 ·0.033

. (13)

where R

optimal

is the optimal bubble size, µm; F () is

frequency of high-energy ultrasound, MHz.

Consequently, the cavitation mode with the known

bubble size is formed by impacting the slurry with

high-energy ultrasound with F

R

optimal

frequency.

We denote the function of distributing bubbles

by size by f (R), then the value f (R)dR determines

the fraction of bubbles within the size range of R to

R + dR.

Table 2 demonstrates the value of the function

used in calculations.

The obtained dependences allow determining op-

timal frequency of high-energy ultrasound to main-

tain cavitation in the iron ore slurry depending on pa-

rameters of its components. Therefore, to form con-

trolled cavitation processes and acoustic flows in the

iron ore slurry, it is necessary to model dynamic ef-

fects of high-energy ultrasound in the heterogeneous

medium.

3 RESULTS AND DISCUSSION

Bubble behavior under the influence of ultrasonic ra-

diation is modelled by using a specialized software

package Bubblesim in MATLAB (Hoff et al., 2000).

Dynamics of air bubble sizes during the modelling

process is determined through the modified Rayleigh-

Plesset equation (Hoff, 2001):

¨aa +

3

2

˙a

2

+

p

0

+ p

i

(t) p

L

ρ

−

a

pc

˙p

L

= 0 (14)

where a is the bubble radius, m; p

0

is hydrostatic pres-

sure, Pa; p

i

is acoustic pressure, Pa; p

L

is pressure on

the bubble surface, Pa; ρ is fluid density, kg/m3; c is

the sound speed, m/s.

The following dependence is used to determine

the value of the bubble surface pressure p

L

:

p

L

= −4η

L

˙a

a

−(T

2

−T

1

) + p

g

a

e

a

3k

(15)

where ν

L

is the internal friction coefficient; T

1

, T

2

are

tension of the inner and outer bubble walls, respec-

tively; p

g

is internal pressure of gas bubbles, Pa; k is

the gas constant of the polytropic process.

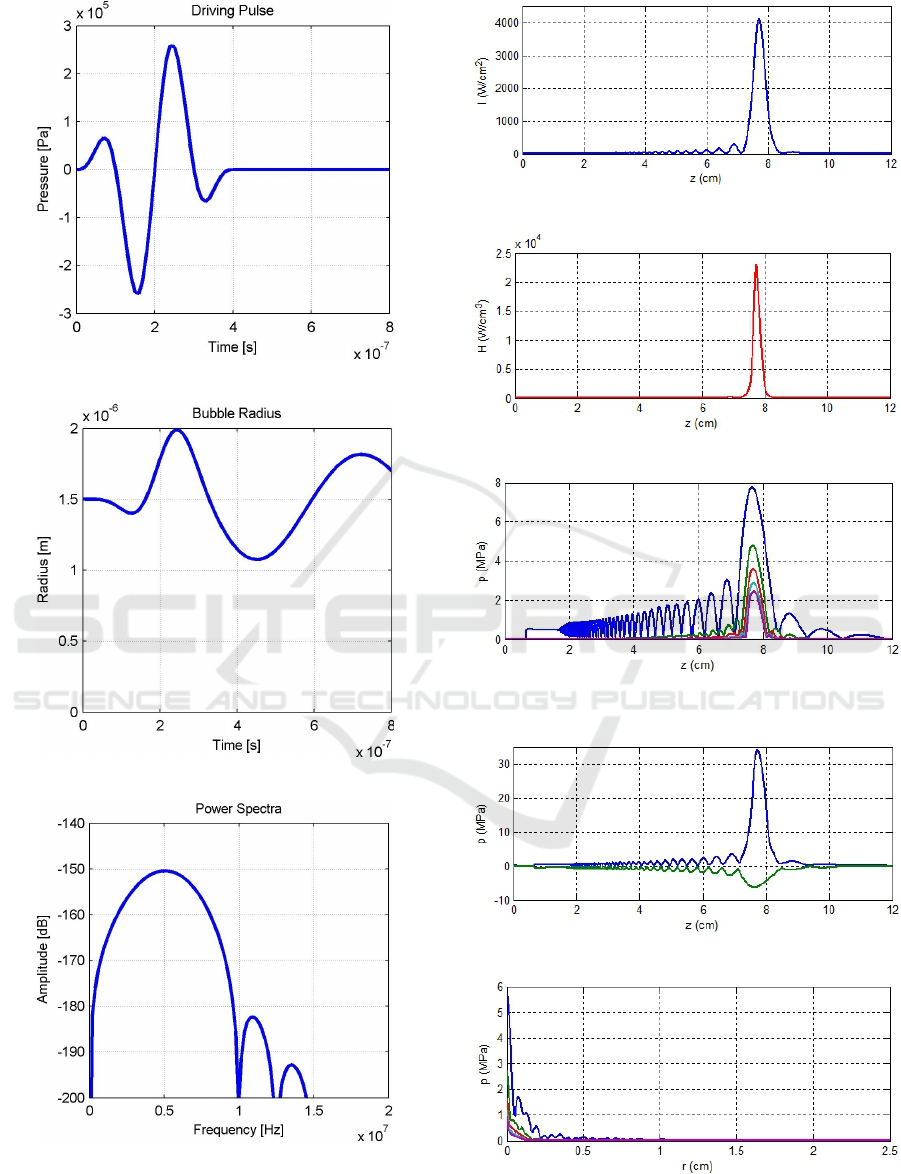

The modelling results with nonlinear effects of

high-energy ultrasound considered are presented in

(figure 1): the driving pulse (figure 1, a), changes of

the bubble radius (figure 1, b), the signal spectrum

(figure 1, c).

During the study, the radiation pressure amplitude

is 0.3 MPa, while the ultrasound frequency changes

and makes 1 MHz, 3 MHz, 5 MHz.

To model the process of ultrasonic signal propa-

gation in the liquid medium when changing the sound

propagation rate and density, the 1st and 2nd-order

k-space method is used based on the 1st-order linear

equations (Tabei et al., 2002; Mast et al., 2001).

To apply the k-space method to the system of the

1st-order equations describing wave propagation, the

2nd-order k-space operator can be used by dividing it

into parts associated with each spatial direction. For a

two-dimensional case, this procedure is performed as

follows

∂p(r,t)

∂

(c

0

∆t)

+

x

≡

= F

−1

ik

x

e

ik

x

∆

x

/

2

sin

c

0

∆t k

2

c

0

∆t k

2

F (p (r,t))

!

; (16)

∂p(r,t)

∂

(c

0

∆t)

+

y

≡ F

−1

ik

y

e

ik

y

∆

y

2

sin

c

0

∆t k

2

c

0

∆t k

2

F (p (r,t))

!

;

∂p(r,t)

∂

(c

0

∆t)

−

x

≡ F

−1

ik

x

e

ik

x

∆

x

/

2

sin

c

0

∆t k

2

c

0

∆t k

2

F (p (r,t))

!

;

∂p(r,t)

∂

(c

0

∆t)

−

y

≡ F

−1

ik

y

e

ik

y

∆

y

2

sin

c

0

∆t k

2

c

0

∆t k

2

F (p (r,t))

!

;

CSSE@SW 2022 - 5th Workshop for Young Scientists in Computer Science Software Engineering

80

Table 1: Parameters of ultrasonic cavitation modes.

f, MHz

P, MPa

0.01 0.1 0.3 0.5 0.7 1.0 3.0 5.0 8.0

0.5 4.779 2.197 0.809 0.489 0.350 0.245 0.082 0.049 0.031

1.0 3.127 1.940 0.794 0.486 0.349 0.245 0.082 0.049 0.031

3.0 1.414 1.228 0.710 0.465 0.341 0.242 0.081 0.049 0.031

5.0 0.929 0.869 0.615 0.435 0.328 0.238 0.081 0.049 0.031

Table 2: Values of the function of distributing bubbles by size.

R,m ×10

−6

3 5 10 20 50

f (R),m

−1

0.0054 0.0273 0.0545 0.330 0.545

R,m ×10

−4

1.5 2.0 2.5 3.0 3.5

f (R),m

−1

×10

−3

49 21.2 10.9 6.5 4.1

so that

∂p (r,t)

∂

(c

0

∆t)

+

x

∂p (r,t)

∂

(c

0

∆t)

−

x

+

∂p (r,t)

∂

(c

0

∆t)

+

y

∂p (r,t)

∂

(c

0

∆t)

−

y

p(r,t) =

=

∇

(c

0

∆t)

2

p(r,t) (17)

Spatial-frequency components k

x

and k

y

are deter-

mined so that k

2

= k

2

x

+ k

2

y

. The use of equation op-

erators (16) in (15) enables formation of the 1st-order

k-space method which is equivalent to equation (14).

Application of exponential coefficients from equation

(16) requires evaluation of ultrasonic wave velocities

u

x

and u

y

at the grid points at intervals ∆x

2 and

∆y

2, respectively. The resulting algorithm has the

form

u

x

(r

1

,t

+

) −u

x

(r

1

,t

−

)

∆t

=

1

ρ(r

1

)

∂p (r,t)

∂

(c

0

∆t)

+

x

;

u

y

(r

2

,t

+

) −u

y

(r

2

,t

−

)

∆t

=

1

ρ(r

2

)

∂p (r,t)

∂

(c

0

∆t)

+

y

;

p(r,t + ∆t) − p(r,t)

∆t

=

= −ρ(r ) c(r)

2

∂u

x

(r

1

,t

+

)

∂

(c

0

∆t)

−

x

+

∂u

y

(r

2

,t

+

)

∂

(c

0

∆t)

−

y

(18)

where

r

1

≡

x + ∆x

2,y

, r

2

≡

x,y + ∆x

2

,

t

+

≡t + ∆t

2, t

−

≡t −∆t

2.

(19)

In equation (18), the coefficients c

0

and ρ

0

are

replaced spatially and transformed by values of the

sound speed and density c (r) and r (r) . Spatial dis-

tribution in equation (18) is implicitly introduced into

spatial derivatives of the operators considered. For

example, operators

∂

.

∂

(c

0

∆t)

+

x

and

∂

.

∂

(c

0

∆t)

−

x

determined by formula (16) correspond to derivatives

calculated after spatial shifts according to the Fourier

transformation shift property ∆x

2 and −∆x

2 , re-

spectively.

High-energy ultrasound power, which allows

maintaining cavitation modes in the iron ore slurry, is

calculated on the basis of the above results of studying

distribution of the ultrasonic pulse front by using HI-

FUSimulator v1.2 (Soneson, 2011). The calculation

results are given in figures 3, 4, 5, 6, 7.

The modelling results enable us to conclude that

in order to improve quality of cleaning ore particles

before flotation, it is advisable to apply a spatial effect

to the iron ore slurry by means of high-energy ultra-

sound of 20kHz in the cavitation mode modulated by

high-frequency pulses of 1 MHz - 5 MHz.

At the same time, the reasons for forming floc-

cules from particles of magnetite iron ore slurry,

which being beneficiated move relative to each other

and interact with their poles, include movement of

ferromagnetic particles in the magnetic field to re-

duce total magnetostatic energy (energy of free poles)

(Karmazin and Karmazin, 2005). This phenomenon

is an integral part of beneficiation of fine materials

with significant magnetic properties and directly af-

fects efficiency of beneficiation. The size of floccules

can vary from 2 to 1000 diameters of the particles

forming them.

The phenomenon of fluctuations of monopolar

blast furnace boundaries under the action of ultrasonic

waves propagating along them is explained by the fact

that ultrasound causes variable mechanical stresses in

iron particles, which leads to an increase in magnitude

of magneto-elastic energy U

d

generally determined

from the expression (Vlasko-Vlasov and Tikhomirov,

1991)

U

d

= −σ ·λ (20)

Ultrasonic Cleaning of Ore Particles and Disintegration of Flocculation Formations

81

(a)

(b)

(c)

Figure 1: Modelling results of cavitation processes under

high-energy ultrasound.

Figure 2: Radial intensity in the ultrasound focus.

Figure 3: Intensity in the ultrasound focus.

Figure 4: Axial distribution of pressure of the first five har-

monics of ultrasonic radiation.

Figure 5: Axial pressure peaks in ultrasonic radiation.

Figure 6: Distribution of radial pressure of the first five har-

monics in the ultrasonic radiation focus.

CSSE@SW 2022 - 5th Workshop for Young Scientists in Computer Science Software Engineering

82

Figure 7: Shape of the ultrasonic wave along the radiation

axis at the distance (z=7.73 cm), which corresponds to the

peak intensity.

where λ is magnetostriction; σ is tension.

According to the Akulov anisotropy law, the ex-

pression for U

d

has the following form (Chikazumi,

2009):

U

d

= −σ·

a

1

∑

i=1,2,3

S

2

i

β

2

i

−

1

3

+ a

2

∑

i̸= j

S

i

S

j

β

i

β

j

!

(21)

To observe the condition

∂(U

K

+U

D

+U

H

)

∂α

= 0 (22)

where U

K

is magnetic anisotropy energy of a crystal;

U

H

is energy of the external magnetic field.

According to expressions (20)–(22), if energy U

H

changes, magnetism of the particles increases.

Interaction of magnetic masses in flocculation is

described in accordance with the Coulomb law to

determine the strength of flocculated formations F

f

l

(Karmazin and Karmazin, 2005):

F

f l

= σ

f l

s = kχ

2

H

2

s

2

µ

0

r

2

(23)

where σ

f l

is the floccule strength, S is the area of the

floccule cross section, k is the coefficient specifying

the coordinate of the point of magnetic mass concen-

tration, ξ is magnetic susceptibility, H is intensity of

the magnetic field, r is the distance of interaction.

The strength of floccules is determined by the ex-

pression (Karmazin and Karmazin, 2005):

σ

f l

= kJ

2

.

(1 −χN)

2

(24)

where k is the proportionality coefficient; J is floccule

magnetization; N is the floccule demagnetization co-

efficient. This characteristic is also evaluated by the

expression of ferromagnetic energy:

F

f l

= −

dU

dx

= −

d (BHV )

dx

= −0.5BHV = −0.5 µH

2

s;

σ

f l

= 0.5µH

2

.

(25)

When studying flocculation and deflocculation,

one should consider the dependence of magnetic sus-

ceptibility γ

c

on duration of magnetization t.

The dependence of the flocculation degree Ψ and

the field intensity looks like (Karmazin and Kar-

mazin, 2005):

ψ = k

1

H

2

0

+ ∆ψδ(H −H

kr

)+

+ (1 + ψ

2

)(1 −exp(−k

2

(H −H

kr

))),

(26)

where H

0

is initial intensity of the magnetic field

which causes equilibral reversible flocculation; ∆ψ =

ψ

1

−ψ

2

is an increase in the flocculation degree due

to the avalanche process; ψ

1

−ψ

2

are flocculation de-

grees at the beginning and at the end of the avalanche

process, respectively, which are functions of concen-

tration, the formfactor, size and magnetic suscepti-

bility of flocculating particles; H

kr

is critical field

tension causing avalanche flocculation H

0

< H

kr

; k

1

,

k

2

are intensity coefficients presented as functions of

concentration, magnetic susceptibility, the formfac-

tor, the Reynolds parameter for the hydromechanical

mode of the medium motion, particle size dependent

on time [k

2

= f (C, N, ℵ, R

e

,d,t)] ; δ (H −H

kr

) is the

Dirac function from tension;

R

H

kr

+∆

H

kr

−∆

δ(H −H

kr

)dH =

1, where ∆ is a small number.

The dependence of size of the narrow fraction

particle extracted from the floccule (flocculation de-

gree) E obtained in (Karmazin and Karmazin, 2005;

Chikazumi, 2009), shows a significant dependence of

flocculation on the content of the ferromagnetic com-

ponent in the iron ore slurry:

E = 1 −e

−

r

0

v

0

t

R

R

f

r

0

exp

(

−kχd

(

r

−1

0

−r

−1

)

.

(3πµD

t

)

)

rdr

(27)

noindent where r

0

is the radius of the floccule; v

0

is

the speed of particles of a narrow fraction near the

surface of the floccule; t is flocculation time; D

t

is

the turbulent diffusion coefficient. It should be noted

that with decreased size, magnetic susceptibility of

the magnetic sharply decreases, and the coercive force

increases sharply, which is explained by approxima-

tion to the monodomain size of magnetite, that com-

plicating the flocculation process.

When implementing this approach, the ultrasonic

wave radiator should be able to vary frequency during

measurements in a fairly wide range. In practice, this

can be done by means of the ultrasonic phased array.

While developing its design, the influence of the dis-

tance between elements, wavelength and the number

of elements on controllability and efficiency of ultra-

sonic radiation are investigated. Optimal parameters

of the ultrasonic phased array are selected by indica-

tors that characterize its directional diagram (Morkun

et al., 2015b,c).

Analysis of the research results enables conclud-

ing that in order to increase efficiency of the flotation

Ultrasonic Cleaning of Ore Particles and Disintegration of Flocculation Formations

83

process by disintegrating flocculated ore formations,

it is advisable to exert a spatial effect on the iron ore

slurry including a combination of high-energy ultra-

sound and the pulsed magnetic field of descending in-

tensity.

The modelling results enable concluding that to

improve quality of ore particles cleaning before flota-

tion, it is advisable to apply a spatial effect to the

iron ore slurry. This includes a combination of high-

energy ultrasound of 20 kHz in the cavitation mode

modulated by high-frequency pulses within 1 MHz-

5 MHz and the pulsed magnetic field of descending

intensity. The next stage involves calculation of char-

acteristics of these effects and determination of the

device parameters to disintegrate flocculated ore for-

mations in the slurry flow on the basis of the ultra-

sonic phased array.

4 CONCLUSIONS

To increase efficiency of magnetite concentrates flota-

tion by disintegrating flocculated ore formations and

cleaning the particle surface, it is advisable to use

nonlinear effects of the high-energy ultrasonic field to

form and maintain cavitation processes and acoustic

flows in the iron ore slurry.

Investigation into cavitation patterns results in de-

pendences obtained to determine optimal frequency

of high-energy ultrasound aimed to maintain cavita-

tion processes in the iron ore slurry depending on pa-

rameters of its components.

Based on the modelling results, it is established

that in order to improve quality of ore particles clean-

ing before flotation, a spatial effect should be ex-

erted on the iron ore slurry, which includes a com-

bination of 20kHz high-energy ultrasound in the cav-

itation mode modulated by high-frequency pulses of

1 MHz-5 MHz and the pulsed magnetic field of de-

scending intensity.

REFERENCES

Ambedkar, B. (2012). Ultrasonic Coal-Wash for De-

Ashing and De-Sulfurization: Experimental Investi-

gation and Mechanistic Modeling. Springer Theses.

Springer Berlin, Heidelberg. https://doi.org/10.1007/

978-3-642-25017-0.

Ambedkar, B., Nagarajan, R., and Jayanti, S. (2011).

Investigation of High-Frequency, High-Intensity Ul-

trasonics for Size Reduction and Washing of

Coal in Aqueous Medium. Ind. Eng. Chem.

Res, 50(23):13210–13219. https://doi.org/10.1021/

ie200222w.

Carvell, K. J. and Bigelow, T. A. (2011). Dependence of op-

timal seed bubble size on pressure amplitude at ther-

apeutic pressure levels. Ultrasonics, 51(2):115–122.

https://doi.org/10.1016/j.ultras.2010.06.005.

Chikazumi, S. (2009). Physics of Ferromagnetism, vol-

ume 94 of International Series of Monographs on

Physics. Oxford University Press, Oxford, 2 edition.

Golik, V., Komashchenko, V., Morkun, V., and

Zaalishvili, V. (2015). Enhancement of

lost ore production efficiency by usage of

canopies. Metallurgical and Mining Indus-

try, 7(4):325–329. https://www.metaljournal.

com.ua/assets/MMI 2014 6/MMI 2015 4/

047-GolikKomashchenkoMorkunZaalishvili.pdf.

Gubin, G. V., Tkach, V. V., and Ravinskaya, V. O. (2017).

Application of ultrasound for cleaning the surface of

altered mineral particles before flotation [Primene-

nie ul’trazvuka dlja ochistki poverhnosti izmenennyh

mineral’nyh chastic pered flotaciej]. The quality of

mineral raw materials, 1:341–349.

Harrison, C. D., Raleigh, Jr., C. E., and Vujnovic, B. J.

(2002). The use of ultrasound for cleaning coal.

In Proceedings of the 19th Annual International

Coal Preparation Exhibition and Conference, vol-

ume 1, page 61–67. http://web.archive.org/web/

20190713150249if /http://www.bixbydental.com:

80/about/news/coalultrasound.pdf.

Hoff, L. (2001). Acoustic Characterization of Con-

trast Agents for Medical Ultrasound Imaging.

Springer Dordrecht. https://doi.org/10.1007/

978-94-017-0613-1.

Hoff, L., Sontum, P. C., and Hovem, J. M. (2000). Oscilla-

tions of polymeric microbubbles: Effect of the encap-

sulating shell. The Journal of the Acoustical Society

of America, 107:2272–2280. https://doi.org/10.1121/

1.428557.

Hu, Z. (2013). Comparison of Gilmore-Akulichev equa-

tion and Rayleigh-Plesset equation on the rapeu-

tic ultrasound bubble cavitation. Master’s the-

sis, Iowa State University. https://doi.org/10.31274/

etd-180810-3261.

Karmazin, V. V. and Karmazin, V. I. (2005). Magnetic,

electrical and special methods of mineral processing.

Publishing house MGTU.

Kozubkov

´

a, M., Rautov

´

a, J., and Bojko, M. (2012). Math-

ematical Model of Cavitation and Modelling of Fluid

Flow in Cone. Procedia Engineering, 39:9–18. XI-

IIth International Scientific and Engineering Confer-

ence ”Hermetic Sealing, Vibration Reliability and

Ecological Safety of Pump and Compressor Machin-

ery” - ”HERVICON-2011”. https://doi.org/10.1016/j.

proeng.2012.07.002.

Mast, T. D., Souriau, L. P., Liu, D.-L. D., Tabei, M., Nach-

man, A. I., and Waag, R. C. (2001). A k-space

method for large-scale models of wave propagation

in tissue. IEEE Transactions on Ultrasonics, Fer-

roelectrics, and Frequency Control, 48(2):341–354.

https://doi.org/10.1109/58.911717.

Morkun, V. and Morkun, N. (2018). Estimation of the

Crushed Ore Particles Density in the Pulp Flow Based

on the Dynamic Effects of High-Energy Ultrasound.

CSSE@SW 2022 - 5th Workshop for Young Scientists in Computer Science Software Engineering

84

Archives of Acoustics, 43(1):61–67. https://doi.org/10.

24425/118080.

Morkun, V., Morkun, N., and Pikilnyak, A. (2014). The

adaptive control for intensity of ultrasonic influence

on iron ore pulp. Metallurgical and Mining Industry,

6(6):8–11. https://www.metaljournal.com.ua/assets/

MMI 2014 6/2-MorkunPikilnyak.pdf.

Morkun, V., Morkun, N., and Tron, V. (2015a). Dis-

tributed closed-loop control formation for tech-

nological line of iron ore raw materials bene-

ficiation. Metallurgical and Mining Industry,

7(7):16-19. https://www.metaljournal.com.ua/assets/

Journal/english-edition/MMI 2015 7/003Vladimir%

20Morkun%2016-19.pdf.

Morkun, V., Morkun, N., and Tron, V. (2015b). Dis-

tributed control of ore beneficiation interrelated

processes under parametric uncertainty. Met-

allurgical and Mining Industry, 7(8):18–21.

https://www.metaljournal.com.ua/assets/Journal/

english-edition/MMI 2015 8/004Morkun.pdf.

Morkun, V., Morkun, N., and Tron, V. (2015c).

Model synthesis of nonlinear nonstationary dy-

namical systems in concentrating production

using Volterra kernel transformation. Met-

allurgical and Mining Industry, 7(10):6–9.

https://www.metaljournal.com.ua/assets/Journal/

english-edition/MMI 2015 10/001Morkun.pdf.

Morkun, V., Semerikov, S., Hryshchenko, S., and Slovak,

K. (2017). Environmental geo-information technolo-

gies as a tool of pre-service mining engineer’s training

for sustainable development of mining industry. In Er-

molayev, V., Bassiliades, N., Fill, H., Yakovyna, V.,

Mayr, H. C., Kharchenko, V. S., Peschanenko, V. S.,

Shyshkina, M., Nikitchenko, M. S., and Spivakovsky,

A., editors, Proceedings of the 13th International

Conference on ICT in Education, Research and In-

dustrial Applications. Integration, Harmonization and

Knowledge Transfer, ICTERI 2017, Kyiv, Ukraine,

May 15-18, 2017, volume 1844 of CEUR Workshop

Proceedings, pages 303–310. CEUR-WS.org. https:

//ceur-ws.org/Vol-1844/10000303.pdf.

Schnerr, G. H. and Sauer, J. (2001). Physical and Numerical

Modeling of Unsteady Cavitation Dynamics. In CMF-

2001, 4th International Conference on Multiphase

Flow. New Orleans, USA, May 27 - June 1, 2001.

https://www.researchgate.net/publication/296196752.

Singhal, A. K., Athavale, M. M., Li, H., and Jiang, Y.

(2002). Mathematical Basis and Validation of the

Full Cavitation Model. Journal of Fluids Engineering,

124(3):617–624. https://doi.org/10.1115/1.1486223.

Soneson, J. (2011). High intensity fo-

cused ultrasound simulator. https://www.

mathworks.com/matlabcentral/fileexchange/

30886-high-intensity-focused-ultrasound-simulator.

Soyama, H. and Korsunsky, A. M. (2022). A critical com-

parative review of cavitation peening and other sur-

face peening methods. Journal of Materials Process-

ing Technology, 305:117586. https://doi.org/10.1016/

j.jmatprotec.2022.117586.

Tabei, M., Mast, T. D., and Waag, R. C. (2002). A k-

space method for coupled first-order acoustic propa-

gation equations. The Journal of the Acoustical So-

ciety of America, 111(1):53–63. https://doi.org/10.

1121/1.1421344.

Vlasko-Vlasov, V. K. and Tikhomirov, O. A. (1991). Oscil-

lations of monopolar domain walls in the field of ultra-

sonic waves. Solid State Physics, 33(12):3498–3501.

https://journals.ioffe.ru/articles/22125.

Ultrasonic Cleaning of Ore Particles and Disintegration of Flocculation Formations

85