A Study of the Factors Influencing Labour Productivity in the

Construction Industry from a Lean Perspective: A Structural

Equation Modelling Approach

Liangqing Sun

1,*

, Lixuan Jiang

1

, Erlong Wang

2

and Wei Zeng

2

1

School of Economics and Management, Nanjing University of Technology, Pukou, Nanjing, Jiangsu, China

2

China Construction Third Bureau Group Limited, Wuhan, Hubei, China

Keywords: Labour Productivity, Resource Efficiency, Process Efficiency, Structural Equation Modelling.

Abstract: Labour productivity in the construction industry is an important factor in measuring the development level of

the construction industry. In order to better promote the development of the construction industry and to

facilitate the improvement of labour productivity in the construction industry, the study takes the influencing

factors of labour productivity in the construction industry as the object, defines the two dimensions of resource

efficiency and process efficiency of labour productivity influencing factors from a lean perspective, and

constructs the structure of "influencing factors - resource and process efficiency - labour productivity". A

structural equation model of "influencing factors - resources, process efficiency - labour productivity" was

constructed. The final results confirm the importance of resource efficiency and process efficiency in

improving labour productivity, and suggest countermeasures based on the findings of the study.

1 INTRODUCTION

As an important industrial sector of the national

economy, the construction industry plays an

immeasurable role in the stable development of the

economy. In recent years, the number of enterprises

in the construction industry has gradually expanded

in scale, but the industry as a whole has performed

with low efficiency, poor profitability, low average

technological content and, in particular, a seriously

low level of labour productivity, which is not in line

with the scale of the industry. Therefore, how to

improve labour productivity in the construction

industry has become the focus of research to promote

sustainable growth in the construction industry. A

comprehensive overview of the current state of

research at home and abroad shows that there is

currently more research on the factors influencing

labour productivity in the construction industry, but

there is a lack of research on the loss of labour

productivity due to the waste that exists in the

process. Therefore, from a lean perspective, the

influencing factors of labour productivity are

distinguished into two dimensions, namely resource

efficiency and process efficiency, and the paths and

degrees of influence of each influencing factor on

labour productivity through resource efficiency and

process efficiency are studied by constructing

structural equation models, and suggestions and

countermeasures are put forward in response to the

analysis results, which are of great significance in

promoting the improvement of labour productivity in

the construction industry.

2 CURRENT STATE OF

DEVELOPMENT OF THE

CONSTRUCTION INDUSTRY

UNDER DATA ANALYSIS

2.1 Analysis of the Current Situation of

Labour Employment in the

Construction Industry

The construction industry is labour-intensive and

requires a large number of manual workers to

complete operational tasks. At the same time, the

educational level requirement is low and the relevant

positions absorb a large number of migrant workers.

Through big data analysis, in terms of age

distribution, 38.78% of labour workers in the

236

Sun, L., Jiang, L., Wang, E. and Zeng, W.

A Study of the Factors Influencing Labour Productivity in the Construction Industry from a Lean Perspective: A Structural Equation Modelling Approach.

DOI: 10.5220/0012028800003620

In Proceedings of the 4th International Conference on Economic Management and Model Engineering (ICEMME 2022), pages 236-246

ISBN: 978-989-758-636-1

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

construction industry are aged over 50, 26.94% are

aged 40-49, 22.98% are aged 30-39, 7.41% are aged

25-29, and 3.89% are aged under 24. According to the

China Human Capital Report 2020 published by the

Human Capital and Labour Economics Research

Centre of the Central University of Finance and

Economics, the average age of China's population is

38.8 years old (approximately 39 years old). It can be

seen that nearly 66% of labour workers in the

construction industry are older than the average age

of China's population, and there is a lack of young,

high-quality labour resources in the construction

labour market.

50 or more

40-49 YO

30-39 YO

25-29 YO

24 or less

38.78%

26.94%

22.98%

7.41%

3.89%

Figure 1: Construction labour age release.

2.2 Analysis of the Current State of

Materials Utilization in the

Construction Industry

Rough construction is widespread, leading to a

serious waste of materials, energy and human

resources. In addition, the various segments of the

construction industry are disconnected from each

other and building materials are basically supplied in

the form of raw materials, resulting in a large amount

of manual reprocessing of raw materials once they

arrive at the construction site and a large amount of

actual loss of materials. For example, raw materials

of various sizes are delivered to the construction site,

"dismembered" to form a large amount of

construction waste and then shipped out of the city.

Statistical analysis of the data shows that, compared

to the construction of buildings in developed

countries, the use of steel is 10% to 25% higher per

square metre and the use of cement is 80 kg higher

per square metre. It can be seen that although China's

construction industry is developing rapidly, the

transition process from rough construction to fine

construction has been relatively slow.

2.3 Analysis of the Current State of

Management in the Construction

Industry

On the one hand, there are deficiencies in the

management system of construction enterprises,

leading to the emergence of poor execution,

especially by those located at the end of management.

On the other hand, basic aspects of the system of

ownership, distribution, personnel and operating

procedures of the enterprise are not adapted to the

increasingly competitive environment. In addition,

the regulations and technical specifications

governing the conduct of the construction market are

still imperfect, the appraisal system lacks objective

criteria, and employees are not motivated to work

efficiently.

3 FACTORS AFFECTING

LABOUR PRODUCTIVITY IN

THE CONSTRUCTION

INDUSTRY

Analysing the current state of development of the

construction industry provides a basis for studying

labour productivity in the construction industry.

From the level of the construction industry, domestic

and foreign researchers based on a large number of

analyses and studies have obtained the factors

influencing labour productivity in the construction

industry such as technology level, management

capacity, wage level, labour force, material and

equipment, external environment and capital

investment.

Huo Chunting (2013) analysed the factors

influencing labour productivity in construction

enterprises by building a structural equation model,

and the results showed that human resources and

material inputs have an indirect positive impact on

labour productivity in enterprises. Li Qingxiu (2017)

used DEA-Malmquist index and multiple regression

models to evaluate the total factor productivity,

technical efficiency and technology level of China's

construction industry. The factors affecting the

technological progress of the construction industry in

different regions were identified, and the evaluation

results showed that technological investment and

asset investment promote the development of total

factor productivity and put forward rationalization

suggestions. Liu Guiwen et al. (2011) established a

labour productivity growth function model to analyse

the degree of influence of technological progress and

A Study of the Factors Influencing Labour Productivity in the Construction Industry from a Lean Perspective: A Structural Equation

Modelling Approach

237

capital deepening on labour productivity growth, and

concluded that the positive influence of technological

progress on labour productivity is greater than that of

capital investment, and the actual growth rate of

average labour productivity in China's construction

industry is lower. Liu and Qin (2010) used a linear

regression model to analyse the impact of wages on

labour productivity in the construction industry, and

concluded that wages have a facilitating effect on

labour productivity, and each increase of 1 yuan in

wages can lead to an increase of 1.45 yuan in labour

productivity.

From the perspective of construction

professionals, foreign scholars DBH (2009)

identified constraints that negatively affect labour

productivity such as skills shortages in the sector,

procurement methods for construction projects, the

impact of regulations and lack of innovation in

certain sectors of the industry, particularly in relation

to construction materials.Jarkas (2012) et al.

identified factors that affect labour productivity,

which were further divided into Bekr (2016) found

that poor planning and scheduling, shortage of

materials on project sites, shortage of equipment and

tools, lack of skilled labour, poor site management,

rework due to construction errors, obsolete and

inefficient equipment, lack of supervisory

experience, delayed payments to suppliers, and slow

response from consultants inspecting the work can

lead to labour productivity losses in the construction

industry. Loss of labour productivity. Shamil (2016),

through literature research, came up with 46 factors

that affect labour productivity. 36 engineers were

interviewed face-to-face through questionnaires and

interviews, and analysis of the questionnaire data

revealed that project management factors such as

efficiency of project planning, working environment,

procurement methods, experience of managers,

technical knowledge, and inefficient site layout all

affect labour productivity. On the other hand, found

through questionnaires that the management level of

managers had a significant impact on labour

productivity (Almeida and Carneiro 2009; Alinaitwe

and Mwakali 2007; Abdulaziz and Bitar 2012).

Based on an in-depth study of the relevant

literature, the various factors affecting labour

productivity performance can usually be categorised

into five areas, referred to as the 5Ms, namely

management and control, labour, materials and

equipment, external factors and incentives, which

further provides the basis for constructing the

research model for the thesis.

4 A THEORETICAL MODEL OF

THE FACTORS INFLUENCING

LABOUR PRODUCTIVITY IN A

LEAN PERSPECTIVE

4.1 Application of Lean Construction

Theory

Lean construction is derived from lean production,

which is a successful application of the principles of

economic production in the field of building

construction. This new construction management

model can effectively help construction companies to

reduce costs, improve the quality of their work,

increase their real profitability and play a huge role in

the process of schedule control, safety management

and environmental management.

Furthermore, researchers of lean construction

argue that the labour production process in the

construction industry focuses only on the resource

level of utilisation and lacks attention to the waste

that exists in a large number of processes, resulting in

low labour productivity. Resource efficiency and

process efficiency is an important aspect of lean

construction, where resource rationalisation and

reliable processes not only improve labour

productivity and project performance, but also lead to

faster delivery of construction projects at lower cost

and higher quality.

4.2 Resource Efficiency and Process

Efficiency

Efficiency is the amount of work done per unit of

time. In management terms, efficiency refers to the

ratio between the various inputs and outputs of an

organisation in a given time.

Resource efficiency refers to the efficiency of the

input and output of resources, usually using human

resources, capital resources and natural resources as

input factors. In the concept defined in this paper,

resource efficiency refers to the maximisation of the

value created given the input conditions of various

resources (labour, materials and equipment, etc.) and

examines the value created in the process of

development and utilisation of resources in an

integrated manner. The input indicators for

measuring resource efficiency are natural resources,

human and capital resources, etc., and the output

indicator is the useful value created.

Process efficiency is the amount of compliant

product or service that a process can deliver in a given

amount of time given a certain amount of resources

ICEMME 2022 - The International Conference on Economic Management and Model Engineering

238

invested. In Lean thinking, the variability of work

processes increases the amount of waste and hinders

the performance of the system, so labour productivity

losses can be reduced by improving process

efficiency and eliminating waste.

This study addresses the topic of workforce

management, focusing on site productivity

improvements. exploratory research by Kisi (2017)

and others identifies system and operational

inefficiencies to estimate optimal labour productivity.

modig and Ahlström (2015) propose 'process

efficiency' to reflect the relationship between time

spent creating value and total time. while 'resource

efficiency' focuses on maximising the utilisation of

machines and individual workers. Therefore, this

paper uses 'process efficiency' and 'resource

efficiency' to distinguish between two different

sources of labour productivity. Time-motion studies

and PPC metrics are used to measure both 'resource

efficiency' and 'process efficiency'.

4.3 Theoretical Model of Factors

Influencing Labour Productivity

At the individual project level, there are two branches

of productivity performance measurement. The Lean

approach focuses more on performance measures

based on project schedule, processes and procedures

than the traditional approach which focuses only on

the optimisation of resource utilisation, providing a

useful framework for the industry to improve labour

productivity. Based on this logic, 'resource efficiency'

and 'process efficiency' were selected as key

antecedent variables affecting labour productivity in

the construction industry, based on the relationship

between the influencing factors and the resource

efficiency input indicators and process efficiency

influencing factors, including management and

control, labour, external factors and incentives. Based

on the relationship between the influencing factors

and resource efficiency input indicators and process

efficiency influencing factors, the five key factors of

management and control, labour, materials and

equipment, external factors and incentives are further

divided into two dimensions: resource and process,

and the differences between the influencing factors of

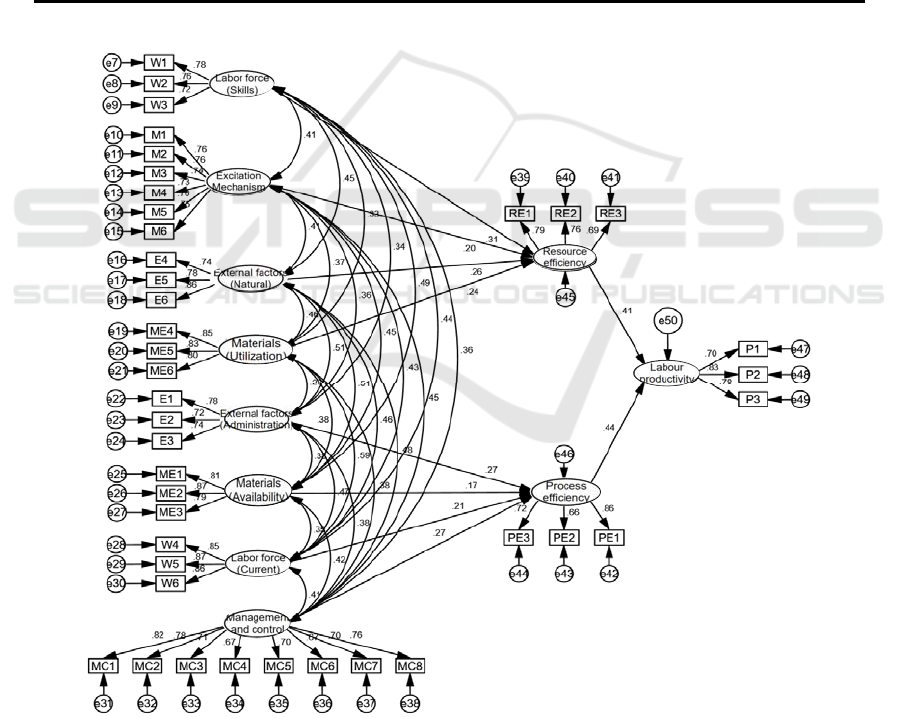

different dimensions are analysed to draw a labour

productivity model mediated by resource efficiency

and process efficiency. The research model of this

paper is shown in Figure 1.

Figure 2: Research model.

5 RESEARCH DESIGN AND

DATA COLLECTION

5.1 Questionnaire Design

By consolidating several literature descriptions of the

same variable differentiation and distinguishing

between factors that fall under resource efficiency

and process efficiency, specific measures of each

variable and literature sources were derived as shown

in Table 1. The study was conducted on the basis of a

questionnaire with questionnaire measure items using

a 5-point Likert scale to assess the likelihood of

influencing factors (1=very unlikely, 5=very likely)

that determine productivity. The completed

questionnaire was reviewed, progressively revised

and refined and finally validated. The final

questionnaire consisted of 11 factors and 41

measures.

Table 1: Construction of variables and sources of factors influencing labour productivity.

Potential variables Measurement problem items Source

Management factors

(MC)

MC1 Construction Management Capability Doloi et al. (2012), Dai et al.

(2009), Huang et al. (2008),

Ibbs and McEniry (2008),

Bernold and AbouRizk

(2010), and Ghoddousi and

Hosseini (2012)

MC2 Site Management

MC3 Communication

MC4 construction method

MC5 rework

MC6 Lack of supervision

A Study of the Factors Influencing Labour Productivity in the Construction Industry from a Lean Perspective: A Structural Equation

Modelling Approach

239

MC7 overtime

MC8 on-site storage

Workforce (skills)

(W)

W1 Workforce Training Kazaz and Ulubeyli (2004),

Hanafi et al. (2010), Durdyev

et al. (2013)

Bernold and AbouRizk

(2010), and Mojahed and

Aghazadeh (2008)

W2 Worker experience and skills

W3 Education level of the workforce

Labour force (mobility)

(W)

W4 Production technology and process changes

W5 Change in labour capacity

W6 Workers' personal wishes

Materials and equipment

(availability)

(ME)

Availability of ME1 equipment tools Alonso et al. (2007), Pratibha

and Gaikwad (2015), Kazaz

et al. (2008), and Page (2010)

Availability of ME2 materials

Suitability or adequacy of the plant and equipment

used for ME3

Materials and equipment

(utilisation)

(ME)

ME4 Delayed supply of construction materials

Shortage of materials on site for ME5 project

Lack of tools and equipment on the ME6 market

External factors

(administrative)

(E)

E1 Economic situation Ghoddousi and Hosseini

(2012), Moselhi and Khan

(2010), Durdyev et al. (2017),

and Ratcliffe and Stubbs

(2003)

E2 Excessive influence of the owner on the

construction

p

rocess

E3 regulations and laws

External factors (natural)

(E)

E4 Health and safety conditions

E5 Meteorological conditions

E6 accident

Incentives

(M)

Amount of M1 compensation Van Tam et al. (2018).

Hiyassat et al. (2016),

Mahamid (2013a) Hiyassat

et al. (2016) Mahamid et al.

(2013), Jarkas (2015)

M2 creates competition

M3 job satisfaction

Motivation of M4 workers

M5 facilitation opportunities

M6 Awards and Punishments

Resource efficiency

(RE)

RE1 Programme Completion Rate (PPC) Buchan et al. (2006), Kazaz

et al. (2008), Smith (2013),

Gouett et al. (2011),Hwang et

al. (2018),Neve et al. (2020a)

RE2 Direct working time (DW)

RE3 Non-value added working time (NVAW)

Process efficiency

(PE)

PE1 Programme Completion Rate (PPC)

PE2 direct working time (DW)

PE3 Non-value added working time (NVAW)

Labour productivity

(P)

P1 project duration Soekiman et al. (2011) and

Kazaz et al. (2016)

P2 Quality objectives achieved

P3 Projected cost of quality

5.2 Results of Data Collection

The data collection process took the form of a

professional questionnaire published on a website

and the information required from those working in

the construction industry (skilled workers, architects,

builders, engineers, quantity surveyors and project

managers). A total of 300 questionnaires were

distributed (50 face-to-face and 250 via an online

questionnaire). At the end of the survey, a total of 201

valid questionnaires were identified and the sample

size met the basic requirements. Based on the 201

collected data, a questionnaire reliability analysis was

carried out through SPSS software, and the results

showed that the Cronbach's alpha value for the whole

questionnaire reached 0.937, indicating that the

questionnaire had good reliability.

ICEMME 2022 - The International Conference on Economic Management and Model Engineering

240

6 RESEARCH FINDINGS AND

ANALYSIS

6.1 Reliability and Validity Tests of the

Measurement Model

Firstly, the suitability test of the model. Suitability

tests were carried out by SPSS 22.0 to reduce the data

set dimensional data according to principal

components, where the KMO test value was 0.901

and the statistical value of Bartlett's sphere test had a

probability of significance of 0.000, indicating that

the questionnaire data met the prerequisite

requirements for factor analysis.

Secondly, the reliability of the model was tested

using the widely used criterion of Cronbach's alpha

coefficient greater than 0.7, and then the reliability of

the model was tested according to the criterion that

the overall correlation coefficient (CITC) of the items

should not be less than 0.5 as proposed by the scholar

Churchill. The analysis showed that the Cronbach's

alpha coefficient for each construct was greater than

0.8 and the CITC values were all above 0.5,

indicating that the questionnaire had high reliability.

Finally, the model convergent validity was tested.

The convergent validity of the measurement model

was subjected to a validation-type factor analysis.

Further assessment of the structural model could only

be performed if the fit of the measurement model met

acceptable criteria. As can be seen from Table 2

below, the standardised factor loadings for each

question were greater than 0.5 or more, and the

residuals were positive and significant. The

composite reliability (C.R.) values were greater than

0.7 and the average variance extracted (AVE) values

were greater than 0.5, all of which met the criteria for

convergent validity and the fit was within acceptable

limits. The model was retained for subsequent

analysis.

Table 2: Results of the validation factor analysis.

Structure

Title

item

Non-

standardised

factor loadin

g

s

Standard

Error S.E.

C.R. (t-

value)

P

Standardise

d factor

loadin

g

s

CR AVE

Workforce

(Skills)

W1 1 0.788

0.801 0.573

W2 1.091 0.098 11.127 *** 0.753

W3

0.988 0.091 10.901 *** 0.729

Incentives

M1

1 0.759

0.88 0.551

M2

1.056 0.083 12.716 *** 0.768

M3

1.034 0.084 12.26 *** 0.742

M4

1 0.083 12.051 *** 0.73

M5

0.957 0.083 11.562 *** 0.703

M6

1.044 0.084 12.404 *** 0.75

External factors

(Nature)

E4

1 0.742

0.84 0.637

E5

1.089 0.089 12.296 *** 0.784

E6

1.232 0.094 13.068 *** 0.864

Materials and

equipment

(Utilisation)

ME4

1 0.855

0.866 0.684

ME5

0.999 0.065 15.303 *** 0.826

ME6

0.931 0.063 14.78 *** 0.799

External factors

(Administrative)

E1

1 0.782

0.792 0.56

E2

1.026 0.097 10.549 *** 0.715

E3

1.055 0.097 10.845 *** 0.747

Materials and

equipment

(Availability)

ME1

1 0.816

0.867 0.685

ME2

1.211 0.079 15.378 *** 0.873

ME3

1.145 0.081 14.123 *** 0.791

Workforce

(Mobility)

W4

1 0.846

0.896 0.741

W5

1.168 0.066 17.651 *** 0.876

W6

1.119 0.065 17.296 *** 0.861

A Study of the Factors Influencing Labour Productivity in the Construction Industry from a Lean Perspective: A Structural Equation

Modelling Approach

241

Management and

control

MC1

1 0.818

0.899 0.529

MC2

1.033 0.07 14.661 *** 0.786

MC3

0.884 0.069 12.747 *** 0.707

MC4

0.774 0.065 11.856 *** 0.667

MC5

0.908 0.072 12.596 *** 0.7

MC6

0.833 0.07 11.877 *** 0.668

MC7

0.916 0.073 12.503 *** 0.696

MC8

0.915 0.065 14.017 *** 0.76

Resource

efficiency

RE1

1 0.802

0.789 0.557 RE2

0.956 0.088 10.872 *** 0.757

RE3 0.919 0.091 10.086 *** 0.674

Process efficiency

PE1

1 0.867

0.792 0.563

PE2

0.723 0.072 10.015 *** 0.648

PE3

0.804 0.074 10.867 *** 0.719

Labour

productivity

P1 1 0.698

0.822 0.608 P2 1.312 0.121 10.844 *** 0.861

P3 1.218 0.112 10.884 *** 0.772

6.2 Studies Based on Structural

Equation Modelling

6.2.1 Evaluation of the Overall Fit of the

Model

Table 4 details the key fit indicators from the

structural model tests. When compared to the

recommended values given for the fitness indicators,

the fitted values for the fitness indicators fall within

the recommended values. It can be seen that the

setting of the theoretical model is acceptable.

Table 3: Model fit.

Fitted

indicators

Acceptable range

Measured

values

CMIN - 941.357

DF - 741

CMIN/DF <3 1.270

GFI >0.8 0.868

AGFI >0.8 0.847

RMSEA <0.08 0.031

IFI >0.9 0.966

TLI(NNFI) >0.9 0.962

CFI >0.9 0.966

6.2.2 Results of Testing the Research

Hypothesis

The structural relationships between the latent

variables and the estimates of their standardised path

coefficients, t-values and hypothesis testing results

are shown in 5. As can be seen, all hypotheses passed

the t-test and the path coefficients were significant at

the confidence level of α = 0.001. The final model of

the factors influencing labour productivity in the

construction industry (path relationship) and the

standardised path coefficients between each of its

internal variables are obtained, as shown in Figure 2.

Table 4: Structural equation model path coefficients.

Path relationships

Standard

i-sation

factor

Non-

standardized

coefficients

Standard

error

T-

value

P

Assuming

establishment

of support

Resource

efficienc

y

<--

Workforce

(skills)

0.313 0.358 0.084 4.275 *** Support

Resource

efficienc

y

<-- Incentives 0.203 0.214 0.071 3.032 0.002 Support

Resource

efficiency

<--

External

factors

(

natural

)

0.26 0.308 0.088 3.502 *** Support

ICEMME 2022 - The International Conference on Economic Management and Model Engineering

242

Resource

efficiency

<--

Materials and

equipment

(utilisation)

0.235 0.213 0.061 3.499 *** Support

Process

efficiency

<--

External

factors

(administrative

)

0.266 0.321 0.091 3.529 *** Support

Process

efficiency

<--

Materials and

equipment

(

availabilit

y)

0.171 0.221 0.087 2.526 0.012 Support

Process

efficienc

y

<--

Labour force

(

mobilit

y)

0.213 0.226 0.074 3.054 0.002 Support

Process

efficienc

y

<--

Management

and control

0.271 0.3 0.076 3.954 *** Support

Labour

p

roductivit

y

<--

Process

efficienc

y

0.411 0.338 0.061 5.57 *** Support

Labour

p

roductivit

y

<--

Resource

efficienc

y

0.441 0.326 0.055 5.97 *** Support

Note: ***=P<0.001

6.2.3 Analysis of Resource and Process

Mediation Effects

This paper applies the Bootstrap technique to re-

estimate the standard errors and confidence intervals

for the indirect effect and the results of the validation

data are shown in Table 6. Following the

determination criteria that the upper and lower

intervals of Bias-corrected and Percentile do not

contain 0 and Z > 1.96 or Z= 1.96, which proves that

the indirect effect holds, the data show that both

resource efficiency and process efficiency have

significant indirect effects.

Table 5: Resource, process efficiency intermediary validation.

Paths

Indirect effects

Bias-Corrected Percentile

95% CI 95% CI

Valuation Lower Upper Lower Upper

1 Labour force (skills)

→ resource efficiency

→

labour productivity

0.129 0.05 0.25 0.034 0.225

2 Incentives →

Resource efficiency →

Labour productivity

0.083 0.017 0.203 0.009 0.187

3 External factors

(nature) → resource

efficiency → labour

p

roductivit

y

0.107 0.016 0.263 0.011 0.249

4 Materials and

equipment (utilisation)

→ resource efficiency

→ labour productivity

0.097 0.035 0.194 0.02 0.171

5 External factors

(administrative) →

process efficiency →

0.117 0.026 0.262 0.024 0.258

A Study of the Factors Influencing Labour Productivity in the Construction Industry from a Lean Perspective: A Structural Equation

Modelling Approach

243

6 Materials and

equipment (availability)

→ process efficiency →

labour productivity

0.075 0.007 0.18 0.003 0.174

7 Labour (mobility) →

process efficiency →

labour productivity

0.094 0.03 0.191 0.019 0.171

8 Management and

control → Process

efficiency → Labour

productivity

0.119 0.043 0.244 0.032 0.227

Figure 3: Final model of factors influencing labour productivity in the construction industry.

ICEMME 2022 - The International Conference on Economic Management and Model Engineering

244

7 STRATEGIES FOR

SUSTAINABLE LABOUR

PRODUCTIVITY GROWTH IN

THE CONSTRUCTION

INDUSTRY

The final model shows that the impact of resource

efficiency and process efficiency on labour

productivity in the construction industry is verified to

exist, with the process aspect having a more

significant impact on labour productivity than the

traditional resource utilisation dimension. Factors

such as labour (skills), incentives, external factors

(nature) and material and equipment (utilisation)

affect labour productivity by influencing resource

efficiency and hence labour productivity. Of these,

labour force skills are the most important factor with

a path coefficient of 0.313 and material and

equipment utilisation with a path coefficient of 0.235.

It is therefore necessary to provide regular training

for workers and to enhance the maintenance and

renewal of materials and equipment for construction

projects. In addition, management and control,

external factors (administrative), labour (mobility)

and material and equipment availability factors have

an impact on process efficiency, with management

and control being the most important factor with a

path coefficient of 0.271. Clearly, the construction

project management team plays an important role in

conveying tasks and instructions to workers. The

results are therefore reasonable, as inadequate

management and control can lead to a reduction in

construction labour productivity.

The findings suggest that improving labour

productivity in the construction industry can be

considered from both resource and process

perspectives, with more focus on performance

measurement based on project objectives (schedule,

cost and quality), and improving resource utilisation

and optimising process efficiency based on lean

theory, thereby achieving the goal of improving

labour productivity.

8 CONCLUSION

Firstly, we systematically review and analyse the

influencing factors of labour productivity in the

construction industry, identify the potential

influencing factors of labour productivity in the

construction industry from five levels: management

and control, labour, external factors, materials and

equipment and incentives, and introduce resource

efficiency and process efficiency, transforming the

influencing factors of labour productivity from the

traditional resource utilisation perspective to the

resource-process optimisation objective The model

of labour productivity is constructed. The model

provides a reliable model basis and practical guidance

for decision-making on labour productivity in the

construction industry.

Secondly, the relationship between labour

productivity factors was analysed using structural

equation modelling and the final structural model was

derived based on acceptable GOF measures. The

analysis of the model's parameter estimation showed

that the effects of resource efficiency and process

efficiency on labour productivity were significantly

present. In addition, among the influencing factors,

labour force skills, management and control are the

most important factors affecting resources and

processes respectively.

Finally, through quantitative research, the

relationship between labour productivity influencing

factors and resource efficiency and process efficiency

is verified, and it is proposed that the practice of

focusing on both resources and processes in the

labour production process in the construction

industry achieves improved labour productivity and

project performance to deliver construction projects

faster with lower costs and higher quality. It also

provides a theoretical basis for subsequent in-depth

research on labour productivity in the construction

industry.

ACKNOWLEDGMENTS

This study contains funds: Ministry of Housing and

Urban-Rural Development: 2019 Science and

Technology Plan Project (2019-R-017); Jiangsu

Provincial Department of Housing and Urban-Rural

Development Science and Technology Service

Project: Research on Lean Construction

Implementation Strategy and Key Benchmark

Creation in Jiangsu Province Construction Industry

(202140755). Enterprise Cooperation Project:

Research on Process Interpolation and Efficiency

Improvement of Modern General Hospital from the

Perspective of Lean Construction (202141076).

A Study of the Factors Influencing Labour Productivity in the Construction Industry from a Lean Perspective: A Structural Equation

Modelling Approach

245

REFERENCES

Abdulaziz M, Jarkas, Camille G, Bitar. Factors Affecting

Construction Labor Productivity in Kuwait[J].

Management, 2012(138):811-820.

Almeida R,Carneiro P. The Return to the Firm Investment

in Human Capital [J]. Labour Economics,2009(16):97-

106.

Alinaitwe H M, Mwakali J A, Hansson B. Factors affecting

the productivity of building craftsmen-studies of

Uganda[J]. Journal of Civil Engineering and

Management,2007, 13(3):169-176.

Bekr, G. A Mahamid.(2016). "Study of Significant Factors

Affecting Labor Productivity at Construction Sites in

Jordan: Site Survey. "Journal of Engineering

Technology (JET).4(1) 92-97.

DBH (Department of Building and Housing). (2009).

"Report of the building and construction sector

productivity taskforce." Wellington, New Zealand.

Huo Chunting. Research on the analysis of labor

productivity level of enterprises in China's construction

industry [D]. Harbin Institute of Technology, 2013.

Jarkas, A. M., and Bitar, C. G. (2012). "Factors affecting

construction labor productivity in Kuwait." J. Constr.

Eng. Manage., 10.1061/(ASCE)CO .1943-

7862.0000501, 811-820.

Kisi,K.P., N. Mani, E. M. Rojas, and T. Foster. 2017.

"Optimal productivity in labor-intensive construction

operations:Pilot study. "J. Constr. Eng. Manage.

143(3):04016107.https://doi.org/10.1061/(ASCE)CO .

1943-7862.0001257.

Li Qingxiu. Research on total factor productivity and

influencing factors of China's construction industry

[D]. Northeast University of Finance and Economics,

2017.

Liu Guiwen, Diao Yanbo, Chen Lisan. Analysis of the

impact of technological progress on labor productivity

in the construction industry[J]. Science and Technology

Progress and Countermeasures, 2011, 28(13):52-55.

Liu QJ, Qin DW. Research on the relationship between

wages and labor productivity in construction

enterprises[J]. Cooperative Economics and

Technology, 2010, (392):30-31.

Modig, Niklas; Åhlström, Pär (2015), This is Lean:

Resolving the Efficiency Paradox. Stockholm:

Rheologica Publishing.-ISBN: 978-91- 87791-09-3.

Naoum S G. Factors influencing labor productivity on

construction sites:a state-of-the-art literature review

and a survey[J].International Journal International

Journal of Productivity and Performance

Management,2016,65(3):401-421.

ICEMME 2022 - The International Conference on Economic Management and Model Engineering

246