Cost Analysis of Preventive Maintenance for Commercial Aircraft

Based on System Simulation

Pu Li

a

Shanghai Aircraft Design and Research Institute, China

Keywords: Preventive Maintenance, System Simulation, Cost Analysis.

Abstract: Economy plays an important role in the research and development of commercial aircraft. Under the premise

of ensuring aircraft performance and safety, manufacturers continue to pursue cost reduction. With the goal

of reducing the maintenance cost of commercial aircraft and the aircraft preventive maintenance process as

the main object, this research applies the system dynamics principle to analyze the dynamic characteristics of

aircraft maintenance costs, analyze the laws of the occurrence and development of aircraft maintenance costs,

establish a general model and conduct simulation analysis, so as to provide a way for the prediction, analysis

and control of commercial aircraft maintenance costs, and also to control the full life cycle cost of commercial

aircraft Provide effective means to meet the economic objectives of commercial aircraft.

1 INTRODUCTION

In the process of developing commercial aircraft, all

countries in the world have put forward the

requirements of safety, comfort, environmental

protection and economy without exception. Among

them, safety, comfort and environmental protection

are no longer difficult problems in technology.

Therefore, aircraft manufacturers have put economy

in an important position when developing new

generation aircraft. In short, on the premise of

ensuring aircraft performance, safety and reliability,

It has the lowest R&D cost, manufacturing cost and

operating cost.

However, some aircraft manufacturers often

focus on R&D costs and manufacturing costs for their

own interests and other factors, ignoring the overall

consideration of operating costs. As we all know,

R&D and design determine more than 50% of the cost

of products, and the proportion of aircraft products

will be higher (Pu 2014). Therefore, once the

products are finalized, the later manufacturing costs

and operating costs will be basically fixed, and it is

difficult to reduce the space, which will bring great

maintenance cost pressure to airlines after removing

variable costs such as fuel in later operations. For

example, the annual aircraft maintenance cost of the

a

https://orcid.org/0000-0002-4850-1686

US military has reached more than 20 billion US

dollars. Since the 1980s, this cost has been close to

the sum of its research and development costs and

procurement costs, accounting for 14.2% of the total

defense expenditure. At present, it is difficult to

obtain maintenance cost related data of major airlines

in the world, but the situation is generally similar.

With the goal of reducing the maintenance cost of

commercial aircraft and the aircraft preventive

maintenance process as the main object, this research

applies the system dynamics principle to analyze the

dynamic characteristics of aircraft maintenance costs,

analyze the laws of the occurrence and development

of aircraft maintenance costs, establish a general

model and conduct simulation analysis, so as to

provide a way for the prediction, analysis and control

of commercial aircraft maintenance costs, and also to

control the full life cycle cost of commercial aircraft

Provide effective means to meet the economic

objectives of commercial aircraft.

2 CAUSALITY ANALYSIS

System Dynamics (SD) is a discipline that closely

combines system engineering theory with computer

simulation to study the structure and behavior of

280

Li, P.

Cost Analysis of Preventive Maintenance for Commercial Aircraft Based on System Simulation.

DOI: 10.5220/0012073300003624

In Proceedings of the 2nd International Conference on Public Management and Big Data Analysis (PMBDA 2022), pages 280-284

ISBN: 978-989-758-658-3

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

system feedback. It absorbs the essence of chaos

theory, information theory, cybernetics, and

topology, and believes that the behavior mode and

characteristics of a system mainly depend on its

internal structure (Li 2006). Only by taking the whole

system as a feedback system can correct conclusions

be drawn. In 1999, the US military C-17 project

office first noticed that the system dynamics method

can be used in cost estimation, and the cost of

different activities under different circumstances can

be well expected.

Preventive Maintenance described in this study is

all activities to prevent aircraft failures or serious

consequences caused by failures and keep them in a

specified state. These activities include: wiping,

lubrication, adjustment, inspection, regular repair and

replacement, etc. The purpose is to find and eliminate

potential faults, which have some characteristics such

as complexity, integrity, connectivity, dynamics,

stability, etc. (Figure 1). From the perspective of cost,

the increase of preventive maintenance activities will

definitely lead to the increase of preventive

maintenance cost, and will also reduce the cost of

corrective maintenance, which will also have a

certain impact on spare parts storage costs and

maintenance personnel training costs. The theory and

method of system dynamics can solve this problem

well.

Characteristics of preventive

maintenance elements

Complexity

Wholeness

Relational

Dynamicity

Constancy

Tasks

Object

Elements of Maintenance

System are Complex

Relationship Between

Elements is Complex

1+1>2

Interrelation and Interaction

Aggregation of Processes

Establish and Maintain a Steady State

Figure 1: Characteristics of Preventive Maintenance Elements.

Preventive maintenance is generally divided into

four forms: regular maintenance, condition based

maintenance, advance maintenance, and failure

inspection, which will consume corresponding

resources and may be different from each other (Gan

2005). Therefore, in order to accurately estimate the

preventive maintenance cost, it is necessary to first

understand the preventive maintenance support

activities of similar commercial aircraft models

through the maintenance plan, then model the

maintenance support activities of newly developed

models, and apply the system dynamics method to

evaluate the maintenance support cost of the whole

life cycle. The influencing factors of preventive

maintenance cost are shown in Figure 2.

Preventive

Maintenance Cost

Number of Preventive

Maintenance

Number of Times

Single Preventive

Maintenance Cost

Life Time

Purchase Cost

Number of

Aircra ft in a Fleet

Preventive

Maintenance Cost

of Repairable Life

Parts

Repairable Non

Life Parts

Number of All

Parts of a Single

Aircraft

Non Repairable

Parts

Instantaneous

Failure Rate

Instantaneous

Failure Rate

Instantaneous

Availability

Number of Preventive

Maintenance

Replacement Cost

Single Preventive

Maintenance Cost

Instantaneous

Failure Rate

Instantaneous

Availability

Figure 2: Influencing Factors of Preventive Maintenance Cost.

Causality analysis is very important to establish

an accurate and reasonable system dynamics model

(Li 2006). The causal loop diagram (CLD) is an

important tool to represent the feedback structure of

the system. It contains multiple variables, and the

variables are connected by arrows indicating the

causal relationship. The causal loop of the preventive

maintenance cost influencing factors listed in Figure

2 is shown in Figure 3. The NRP means Non

Repairable Parts, RLP means Repairable Life Parts

Cost Analysis of Preventive Maintenance for Commercial Aircraft Based on System Simulation

281

and RNLP means Repairable Non life Parts of the

aircraft are all maintained in a fixed time interval. In

the early stage of aircraft operation, the failure rate is

relatively low, and the time interval between

scheduled maintenance can be relatively long; After

a long period of aircraft operation, with aging and

frequent failures, the preventive maintenance interval

should be reduced. In the figure, there are 7 stocks

and 7 flows, a constant number of organic groups of

aircraft, preventive maintenance costs for single

repairable life parts, etc.

Preventive

Maintenance Cost

Number of Preventive

Maintenance of RNLP

Number of Preventive

Maintenance of NRP

Single Preventive

Maintenance Cost

of RNLP

Life Time

of RLP

Purchase Cost

of NRP

Number of

Aircra ft in a Fleet

Preventive

Maintenanc e

Cost of RLP

Preventive

Maintenance

Cost of RN LP

Number of All

Parts of a

Single Aircraft

Preventive

Maintenance

Cost of NRP

Failure Rate

of RNLP

Instantaneous

Failure Rate

of RNLP

Repairable

Maintenance

Times of RLP

Replacement

Cost of RLP

Instantaneous Failure

Rate of RLP

Failure Rate

of RLP

Number of Preventive

Maintenance of RLP

Average

Availability of

RLP

Instantaneous

Failure Rate

of NRP

Replacement

Times of NRP

Average

Availability

of RNLP

Failure Rate

of NRP

Number of

Corrective

Maintenance of

RNLP

Single

Maintenance

Cost of RLP

-

+

+

+

++

+

+

+

+

+

+

+

+

+

-

-

-

-

-

-

-

-

-

-

+

Figure 3. Cause and Effect Loop Diagram of Preventive

Maintenance Cost.

3 CASES AND MODELS

The relevant boundary conditions in this study are

as follows:

All expenses incurred are present value,

without considering inflation;

The fleet has 24 single channel trunk aircrafts,

each of which has a service life of 20 years,

and each aircraft has an average annual flight

time of 300 hours;

The preventive maintenance of the fleet only

considers scheduled maintenance, and the

time interval will be adjusted as the aircraft

ages; Corrective maintenance only includes

repair and replacement of parts; The storage

management cost of spare parts is only

affected by the number of spare parts, that is,

the storage cost of each spare part is a fixed

value; The annual personnel training cost is

fixed.

Each aircraft has 100000 parts, and there are

only three types of parts: 60000 repairable

parts with life, 20000 repairable parts without

life, and 20000 non repairable parts. The

failure rate of all parts is the same. The cost of

a single repair is a fixed value, and the cost of

tools/facilities for inspection and repair is also

a fixed value.

The field maintenance rate of aircraft fault

parts is a fixed value.

When a component fails, the improvement of

reliability after repair or replacement is

considered as the improvement of the

reliability of the original component and the

continuation of the original component, but

the instantaneous failure rate is reduced.

Other detailed assumptions will not be elaborated.

The preventive maintenance interval of the

aircraft is determined by the method of timing

maintenance interval T:

()

T

e

T

A

λ

λ

−

−= 1

1

Where

A

is the average availability, λ Is the

failure rate. In engineering calculation, the time

interval T is not easy to express, so the

T

e

λ

−

in the

formula is decomposed by Taylor:

()() ()

!!3!2!1

1

32

n

TTTT

e

n

T

λλλλ

λ

−

++

−

+

−

+

−

+=

−

Generally, according to the requirements of

airworthiness regulations, the failure rate of aircraft

components λ Are extremely low, even reaching 10-

9, so λ 3 It is small enough, so the first three terms of

T

e

λ

−

Taylor decomposition formula are

approximated:

()

()

()

λ

λλ

λλ

λ

A

T

TT

T

e

T

A

T

−

≈

−

+

−

+−≈−=

−

12

!2!1

11

1

1

1

2

Then, the DAPCA analysis model of RAND

Company in the United States is used for simulation

analysis and estimation, and the PRICE model is used

for parameter estimation and verification.

4 ANALYSIS OF SIMULATION

RESULTS

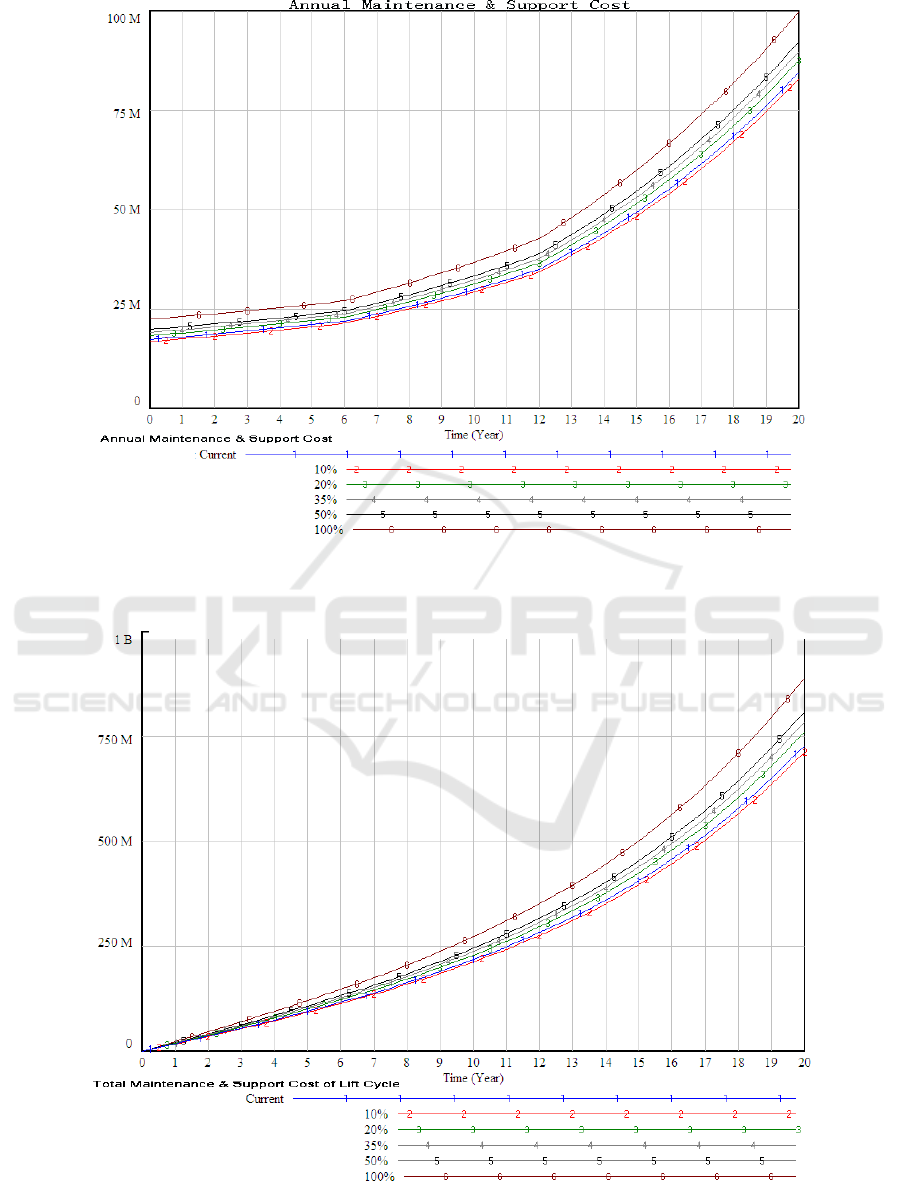

This study observed the change of maintenance

support cost by increasing the frequency of

preventive maintenance (Figures 4 and 5): when the

maintenance frequency increased by 10%, the

maintenance support cost decreased; When the

maintenance frequency is increased by more than

20%, the maintenance support cost will increase

significantly, which deviates from the traditional

understanding. Therefore, it is suggested that the

higher the preventive maintenance frequency is, the

better. A more reasonable cycle balance point needs

to be found.

PMBDA 2022 - International Conference on Public Management and Big Data Analysis

282

Figure 4: The Influence of Preventive Maintenance Frequency Change on Annual Maintenance Support Cost.

Figure 5: Influence of Preventive Maintenance Frequency Change on Total Life Cycle Cost.

Preventive Maintenance

Frequency Increased by

Total Maintenance & Support Cost of Life Cycle

Preventive Maintenance Frequency

Increased by

Cost Analysis of Preventive Maintenance for Commercial Aircraft Based on System Simulation

283

5 CONCLUSION

This study provides an effective method to solve the

cost estimation of aircraft maintenance support

system with complex influencing factors and long

duration by applying system dynamics. Through case

based simulation analysis, the impact of failure rate

and preventive maintenance rate on maintenance cost

is analyzed, and suggestions are put forward to reduce

the failure rate of aircraft parts and determine

reasonable preventive maintenance frequency, This

will enable the winning manufacturer to pay full

attention to the aircraft development process and take

effective measures to reduce the life cycle cost to

achieve the purpose of economy.

REFERENCES

C. D. Purvis. (2001). Estimating C-17 Operating and

Support Costs: Development of a System Dynamics

Model. R. Air force institute of technology.

Gan M., Kang J. (2005). Military Equipment Maintenance

Engineering. M. Beijing: National Defense Industry

Press.

Guo S. H. (2013). Thoughts on Effectively Controlling

Airline Aircraft Maintenance Costs. J. Foreign

Investment in China (20), 130-131.

Jia R. A., Hu L., Ding R. H., et al. (2001). System

Dynamics Simplified Flow Rate Basic Tree Entry

Model and Application. J. System Engineering Theory

and Practice, 21 (10): 137-144.

Jia R. A., Wu F., Xu N. S. (1998). SD flow rate basic tree

modeling method. J. System Engineering Theory and

Practice, 18 (6): 90-95.

Li Z. Q., Chen Y. L. (2011). Research on aircraft condition

based maintenance strategy and model. J. Aviation

Science and Technology, 2011 (03): 28-30.

Macia N. F. , Thaler G. J. (2006). Dynamic System

Modeling and Control. M. Translated by Li Naiwen and

Sun Jianghong. Tsinghua University Press.

Pu L., Huang Z. D. (2014). System dynamics analysis of

aircraft maintenance training cost. J. Civil Aircraft

Design and Research, 4 (2): 48-50.

Shao G. X., Qiu J. C., Li Z. & Liu J. (2012). System

dynamics analysis of aviation equipment preventive

maintenance cost. J. Aerospace Science and

Technology (03), 65-70.

Xu Z. Y., Peng Y. M. (1997). Research on Life Cycle Cost

Analysis of Aeroengines. J. Aviation Systems

Engineering, 1997 (5): 39-44.

PMBDA 2022 - International Conference on Public Management and Big Data Analysis

284