ARTHUR: Machine Learning Data Acquisition System with Distributed

Data Sensors

Niels Schneider

a

, Philipp Ruf, Matthias Lermer and Christoph Reich

b

Institute for Data Science, Cloud Computing and IT Security, Furtwangen University of Applied Science,

Robert-Gerwig-Platz 1, 78120 Furtwangen im Schwarzwald, Germany

Keywords:

Distributed Monitoring System, Machine Learning, Cloud, Data Acquisition, IoT-Cloud Integration.

Abstract:

On the way to the smart factory, the manufacturing companies investigate the potential of Machine Learning

approaches like visual quality inspection, process optimisation, maintenance prediction and more. In order

to be able to assess the influence of Machine Learning based systems on business-relevant key figures, many

companies go down the path of test before invest.

This paper describes a novel and inexpensive distributed Data Acquisition System, ARTHUR (dAta collec-

toR sysTem witH distribUted sensoRs), to enable the collection of data for AI-based projects for research,

education and the industry. ARTHUR is arbitrarily expandable and has so far been used in the field of data

acquisition on machine tools. Typical measured values are Acoustic Emission values, force plate X-Y-Z force

values, simple SPS signals, OPC-UA machine parameters, etc. which were recorded by a wide variety of sen-

sors. The ARTHUR system consists of a master node, multiple measurement worker nodes, a local streaming

system and a gateway that stores the data to the cloud. The authors describe the hardware and software of this

system and discuss its advantages and disadvantages.

1 INTRODUCTION

The competitiveness of manufacturing companies

stands and falls with efficiency in production. Col-

lecting relevant production data in combination with

Machine Learning (ML) can contribute to increasing

efficiency in many areas of manufacturing. When

integrating and implementing Artificial Intelligence

(AI)-based systems, production facilities often have

to be costly adapted in a time-consuming process to

enable a systematic data collection. It is a challenge

to assess in advance the impact of ML-based systems

on business-relevant key figures. However, such pre-

dictions must be made at the latest for the release of

funds for larger investments. Therefore, test before

invest is a good approach to be able to assess the influ-

ence of ML-based systems on business-relevant key

figures. Especially for small and medium-sized en-

terprises (SME)s a low-cost solution, like proposed

in this paper, is of particular interest (Kaiser et al.,

2021).

Typical ML based systems for manufacturing are

visual quality inspection, process optimization and

a

https://orcid.org/0000-0002-1341-2704

b

https://orcid.org/0000-0001-9831-2181

maintenance prediction (Cioffi et al., 2020). Imple-

menting such ML solutions requires obtaining the ap-

propriate data, which can be a costly and difficult

problem. Production and automation engineers have

a lot of experience and knowledge about possible

data collection options. However, there is a lack of

ML expertise, which is usually provided by external

companies with data scientists in a test before invest

project. A typical scenario for testing ML approaches

in production is to collect the data at the shop floor,

and transfer the data to an on-premise or external

cloud storage solution. Data scientists work with the

provided data to train ML models and show the re-

sults and possible improvements to the manufactur-

ing company. While there are many professional so-

lutions for a Data Acquisition System (DAQ) to en-

able this workflow, these usually involve high costs

and the use of expensive predefined hardware which

is compatible with the individual ecosystem (Haizad

et al., 2016). The work on hand proposes a low-cost,

fast, dynamic, easily adaptable Data Acquisition Sys-

tem, that sends the collected data into a Cloud, where

it can further be processed by data scientists. The

distributed DAQ, dAta collectoR sysTem witH dis-

tribUted sensoRs (ARTHUR), collects data from spa-

Schneider, N., Ruf, P., Lermer, M. and Reich, C.

ARTHUR: Machine Learning Data Acquisition System with Distributed Data Sensors.

DOI: 10.5220/0011747100003488

In Proceedings of the 13th International Conference on Cloud Computing and Services Science (CLOSER 2023), pages 155-163

ISBN: 978-989-758-650-7; ISSN: 2184-5042

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

155

tially distributed different sources and ensures the re-

liability of the system, its scalability and the time syn-

chronization of the individual data collection compo-

nents. Monitoring ensures the data quality inspection.

The paper is structured as the following: Section

2 gives an overview of the related work. The require-

ments for a distributed DAQ are defined in Section 3.

Section 4 presents and describes the ARTHUR sys-

tem. After the evaluation in Section 5 a conclusion is

drawn in Section 6.

2 RELATED WORK

The main advantages of distributed measurement sys-

tems have been known for some time. The authors

in (Grimaldi and Marinov, 2001) describe those ad-

vantages where they point out that improved scalabil-

ity, fault tolerance of singular instances, real-time ca-

pabilities, and the collaboration of parallel processes

will be the enabler for using new and upcoming soft-

ware technologies in such distributed environments.

The advantages which are described build the basis

for modern and distributed Industry 4.0 environments.

In most use cases, the biggest entry barrier, when

adapting an existing environment to a distributed en-

vironment with Industry 4.0 capabilities and going

into the direction of a smart factory, is the high cost of

retrofitting older machines and infrastructures. It has

been shown, in recent years, that cost-effective solu-

tions can be achieved. One of the solutions is to use

systems like a Raspberry Pi, which is expected to hit

a market size of 385 million dollar by 2026 in the in-

dustry according to (IndustryARC, 2021). Raspberry

Pis are used in many different domains, since they

are cost-effective, suited for prototyping, and perfor-

mant IoT devices are stated in a survey of (Saari et al.,

2017).

The possibility of using a Raspberry Pi cluster as

a backbone for a smart factory has been surveyed in

(Kim and Son, 2018). The authors identify the ba-

sic functions, which can be implemented by using

a Raspberry Pi cluster: Data collection, monitoring,

preprocessing and processing, time synchronization,

and the secure communication of data. In the out-

look, they conclude that an experiment for speed and

accuracy has to be conducted. The approach proposed

in this paper implements all the basic functions to en-

sure the integrity and accuracy of heterogeneous data

and additionally provides an evaluation that includes

the speed. ARTHUR is also part of the ML pipeline

but concentrates on distributed data collection and ex-

pandability.

Another data acquisition showcase is described in

(Kamat et al., 2021). It is shown, that in the smart

manufacturing domain it is possible and efficient to

use low-cost Raspberry Pis in combination with cloud

storage for implementing a predictive maintenance

and fault detection solution. The successful usage

of Raspberry Pis for different problems in the in-

dustry has been proven in many inherently different

use cases, compare (Ravindran et al., 2021), (Rama-

lingam et al., 2019), (D., 2017), (Chu and Yap, 2021),

(Song and Moon, 2022). The approach proposed in

this paper is conditionally used case-independent, as

heterogeneous data is supported and the time con-

straints are clearly defined.

In (Anik et al., 2022), a cost-effective, scalable

and portable open-source Internet of Things (IoT) in-

frastructure for indoor environment sensing is pre-

sented. As multiple Raspberry Pi enabled systems

are placed in different areas of an apartment, local

databases are synchronized with a central server. Al-

though the basic architecture is similar to the one

described in the work on hand, ML-related opera-

tions were not considered. Furthermore, the individ-

ual Raspberry Pi nodes in this work have their own

database which is then synchronized with a central

SQL database after a certain time. ARTHUR, on the

other hand, sends recorded data from the individual

sensor nodes directly to a NoSQL database via an

event stream.

In (Ferencz and Domokos, 2018) the authors pro-

pose a Java based application used for sensor data

collection in combination with Raspberry Pis. The

backbone is built on the use of a multi-node Apache

Cassandra cluster with a replication factor of 3. It

has been shown that the Redis database is superior

to Apache Cassandra in many use cases, comparing

(Seghier and Kazar, 2021), (Reichardt et al., 2021).

Additionally, it has been demonstrated in (Parks et al.,

2022) that Redis streams are future proof when de-

signing systems with real-time constraints. After see-

ing those results, it was then decided that our ap-

proach should use the Redis database with its stream-

ing capabilities.

3 REQUIREMENTS FOR A

DISTRIBUTED MEASURING

SYSTEM

Measurement technology must keep up with the ML

task for manufacturing in terms of flexibility and

adaptability to varying measurement tasks. Above all,

this means effortless expandability in the number of

sensors to be integrated, as well as the understand-

CLOSER 2023 - 13th International Conference on Cloud Computing and Services Science

156

ing of common protocols in production (e.g., OPC-

UA, CAN, Profibus, etc.). These numerous require-

ments have been investigated during the development

of ARTHUR and will be presented and examined in

more detail in the following paragraphs.

R1: Easily Extendable. The system must be eas-

ily extendable with additional sensor components for

collecting data in order to have the freedom of inte-

grating the needed data sources for the ML applica-

tion. It should be possible to connect a data source to

ARTHUR using various technologies such as OPC-

UA, CAN, Profibus, MQTT, REST, TCP, a digital

signal, an analog signal, a switch, and much more.

The ARTHUR system should provide an abstract pro-

gramming model that supports the implementation of

new interfaces and protocols, respectively, without in-

fluencing or disturbing existing components of the

system.

R2: Data Pre-Processing on the Edge. Data sci-

entists usually like to work on raw data, but in cases

of data privacy, amount of data, timing conditions, or

noise, the raw data has to be pre-processed. Typical

examples of pre-processing are cleaning, normaliz-

ing, aggregation, or building the average of a value

across a dataset. When pre-processing the data as

close to the respective source as possible, the net-

work load can be drastically reduced (Hafeez and

Kathirisetty, 2022). The disadvantages are that the

amount of resulting data will contain a lower infor-

mation density and that errors during pre-processing

cannot be corrected afterwards.

R3: Data Quality Assessment. The quality of an

ML solution correlates strongly with the quality of

the dataset that was used for its training. Ensuring the

quality of an acquired dataset within a distributed sys-

tem brings additional complexity to the overall sce-

nario, as unreliable network transactions must be con-

sidered. To ensure the quality of the data, threshold

values can be used, for example, to check the data

stream for anomalies like sensor failures. (Keijzer and

Ferrari, 2022). The ARTHUR system should allow

for the extension and utilization of further and cus-

tomizable quality control tests.

R4: Affordable Data Acquisition. The system

should be inexpensive, easy to build, and easy to im-

plement in existing environments. For this purpose,

the use of open-source technologies should be favored

over expensive licensing or proprietary solutions. The

overall system should be reasonably stable, but not

implemented in terms of a complete industrial solu-

tion and therefore be in line with the motto: “test

before invest”. This principle has been touted as a

strategic means for driving the digital transformation

of European SMEs by European Commission Digital

Innovation Hubs (Asplund et al., 2021).

R5: Heterogeneous Collaboration. As there is of-

ten an absence of expert data scientists in SMEs, the

utilization of gathered data within ML systems is not

trivial. To overcome such boundaries, a common col-

laboration platform for the respective domain experts,

e.g., mechanics, shopfloor workers and collaborating

data scientists, is required. A data scientist may ob-

tain the sensed data by performing Application Pro-

gramming Interface (API) calls to the cloud environ-

ment.

When ML workflows are made configurable for

a respective task, domain experts become more inde-

pendent with respect to the ad-hock training and as-

sessment of models.

R6: Time Constraints. A prompt reaction to

events that occur within an ARTHUR system can be

very important, which is why a high data throughput

must be ensured throughout the system and bottle-

necks have to be eliminated. The speed of the sys-

tem should also not be affected by a growing num-

ber of nodes. Further, the Nyquist Sampling Theorem

(Shannon, 1984) requires that the sample rate should

be greater than twice the amount of analog signals,

which has to be taken into account.

4 ARTHUR A DISTRIBUTED

DATA ACQUISITION SYSTEM

ARTHUR is a distributed DAQ system, which has

been developed during the research project ”DQ-

Meister: quality assessment - predictive quality as-

sessment for complex production processes” and is

used in the model factory at the Furtwangen Univer-

sity. The following subsections describe the require-

ments as well as the architectural structure of the sys-

tem.

4.1 Machine Learning Infrastructure

In order to fulfill the previously described require-

ments for the distributed DAQ, a hierarchical ap-

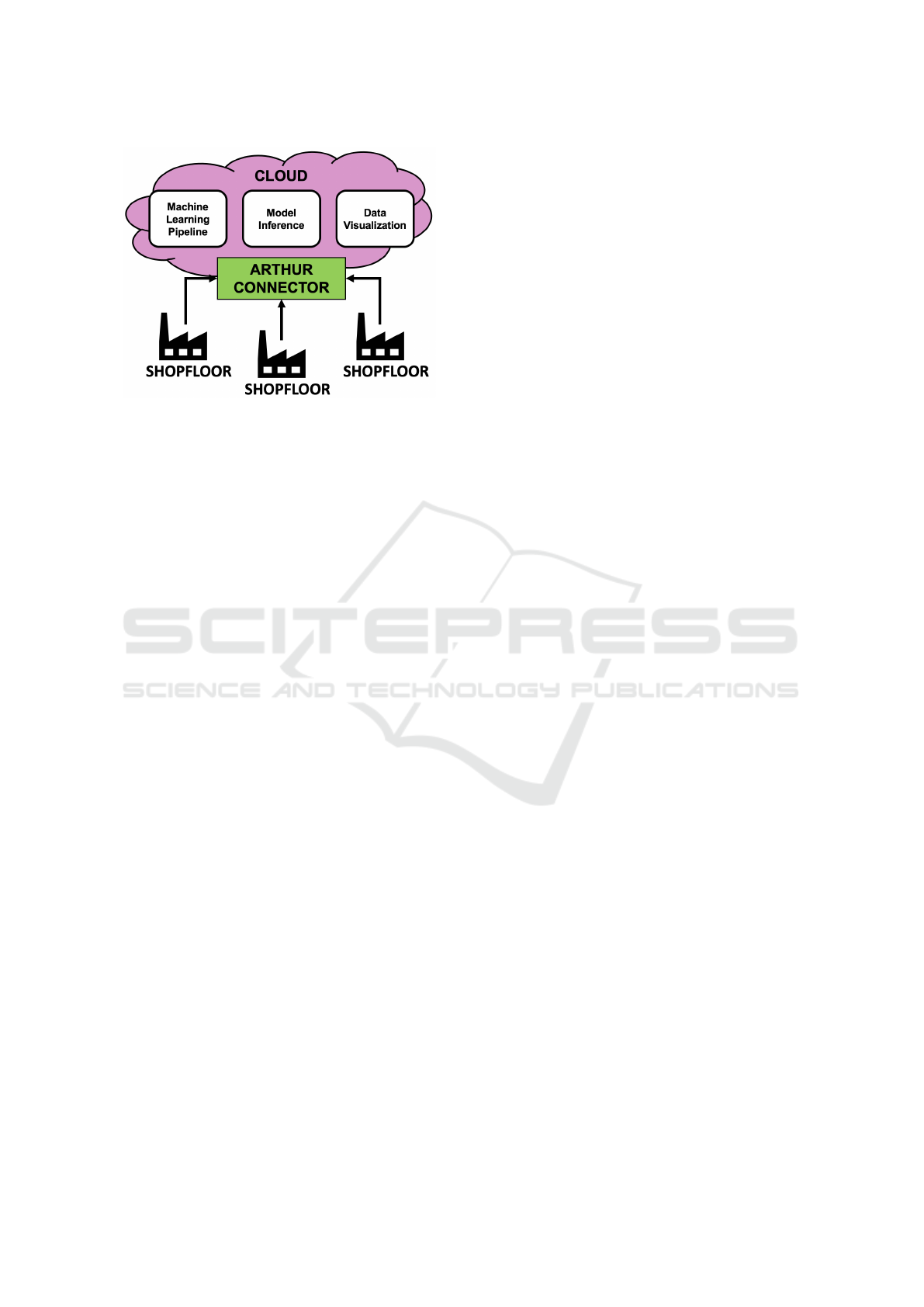

proach is presented in Fig. 1, where domain experts

and data scientists can have access in order to gener-

ate models for their specific ARTHUR systems.

ARTHUR: Machine Learning Data Acquisition System with Distributed Data Sensors

157

Figure 1: High-level Perspective of the ML Infrastructure.

Data from a shopfloor is collected from a cloud

environment using the ARTHUR Connector and per-

sisted for future access (see Fig. 1). A web interface

as part of the Data Visualization module allows vi-

sualizing and monitoring the particular datasets. The

resource-intense training of a respective model is car-

ried out in a scalable cloud solution, where the Ma-

chine Learning Pipeline is integrated. Peaks during

learning utilization can be tolerated by such a cloud

infrastructure in principle. The configuration and im-

plementation of such a ML pipeline is primarily in-

tended for a collaborating ML expert. Trained mod-

els are also inferred in this central environment repre-

sented in Fig. 1 as Model Inference, where the results

can also be visualized and compared.

4.2 Architecture

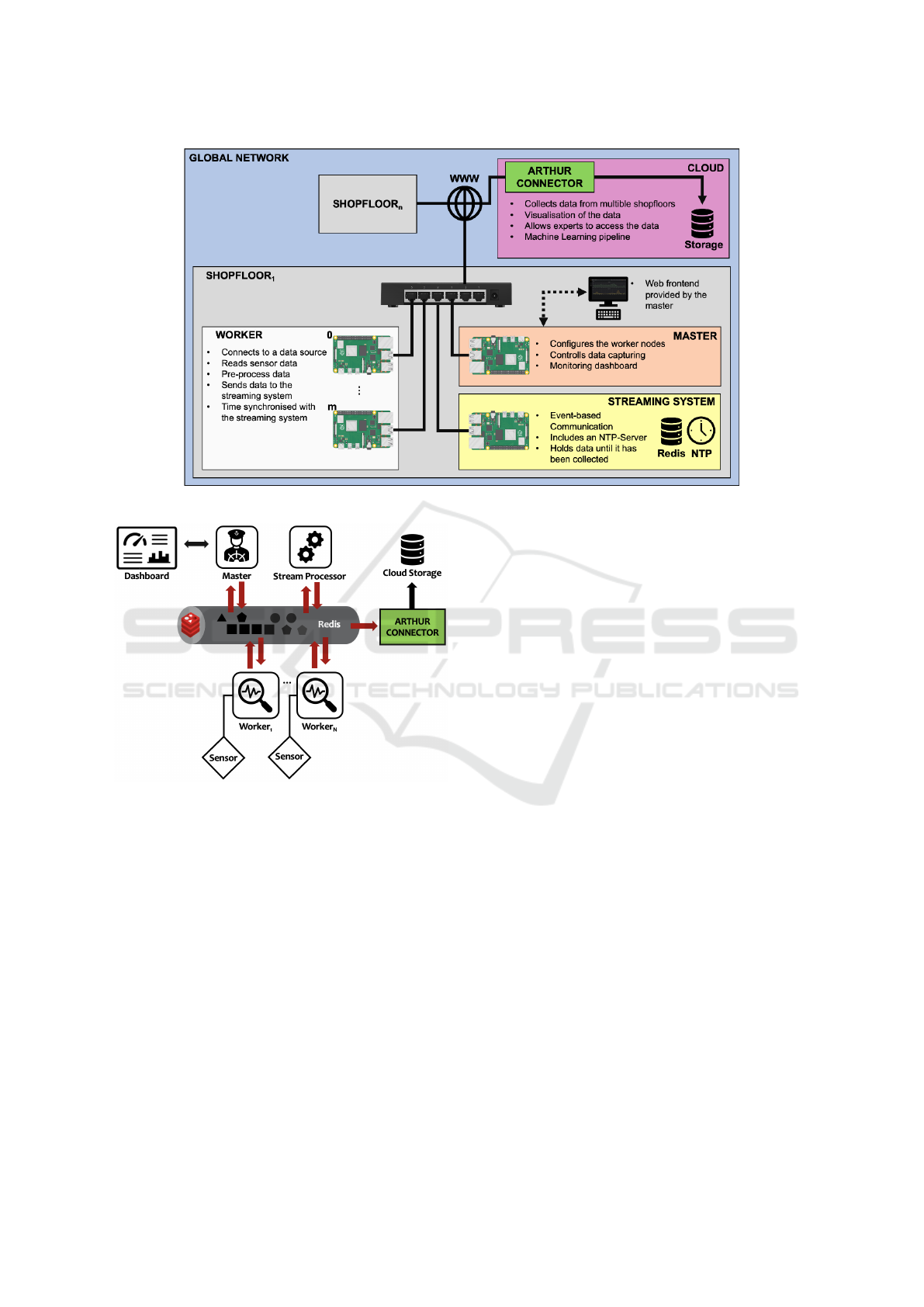

ARTHUR was developed with Python, but its open ar-

chitecture allows the implementation of components

with any other programming language. ARTHUR is

made up of distributed computing nodes with prede-

fined roles, typically with one master, several work-

ers, and a streaming system node at the local and

global layer (see Fig. 2). A node can take on any of

these roles simultaneously if its computing power and

local dependence allow it to do so. ARTHURs open

architecture makes it easy to add more roles to the

system and to increase the number of nodes at will.

The following subsections present existing roles and

layers of the system in detail.

4.2.1 Redis Database as Middleware

In order to enable a high degree of decoupling of in-

dividual roles, the communication between individual

nodes was developed on an event-based architecture

realized through the streaming system role. ARTHUR

uses Redis to implement this role (see Fig. 3). The ar-

chitectural concept of ARTHUR is not bound to the

use of Redis, other streaming systems such as e.g.,

Kafka can be used instead. Redis is a key value based

open source (BSD licensed) multi-model in-memory

database with a very high read and write speed. Re-

dis collects events of the same type in a stream de-

fined by a unique key name. A key is structured

in a similar way as a file path. It is a string con-

sisting of words and separators e.g., ”MEASURE-

MENT:START”. All measurement events of the type

”START” can be found under this key. The payload

of an event also consists of a combination of key-

value pairs. To ensure the order of multiple events

in a stream, each event is assigned a UNIX timestamp

as well as a sequence number. If the timestamp of

an event is lower than the timestamp of the last added

event resulting due to the clock drift between different

nodes, the largest timestamp of the last added event

with an increased sequence number is used. To min-

imize such occurrences, the streaming system node

also includes an NTP server, which all local nodes

use for time synchronization.

Local Caching. To ensure fast communication,

ARTHUR provides at least one local streaming sys-

tem node for each shopfloor. When using a single

streaming system node instance, a single point of fail-

ure occurs. To avoid this, several replication strategies

are possible depending on the use case. In order to en-

able global access to the recorded data of a shopfloor

streaming system node, ARTHUR Connectors exists

for transferring the local data to a cloud storage (see

Fig. 2). For the implementation of an ARTHUR

Connector with Redis, Redis consumer groups can

be used. With them, it is possible to track the infor-

mation about already consumed data between several

consumers of a group. This makes it possible to use

a consumer group to consume the data from the lo-

cal Redis node and automatically remove what has al-

ready been consumed. The local Redis instance thus

has similar properties to a limited queue. By persist-

ing individual events with ARTHUR, a historical view

of a shopfloor can be made possible and a dataset for

a ML task can be acquired.

Stream Processing. Redis supports the use of

stream processors with RedisGears. These allow op-

erations to be performed directly on a stream of data.

For this, RedisGears runs a python code directly in a

Redis instance. For example, a stream processor can

be used to check an event stream for a threshold vi-

olation. If a threshold violation is detected, another

event can be generated to react to it. Stream proces-

sors are used on the shopfloor level to process the data

CLOSER 2023 - 13th International Conference on Cloud Computing and Services Science

158

Figure 2: ARTHUR Structure with Nodes (Master, Worker, etc.).

Figure 3: Redis as streaming middleware.

stream as early as possible. Furthermore, Redis also

enables the direct deployment of an ML model within

the streaming system via RedisML. The proximity to

the data enables a fast execution time which can be

needed for application use cases with strong time con-

straints.

4.2.2 Node Event Handler

If a node is interested in a certain type of event, for

example, the arrival of an event to start the data ac-

quisition, it observes a corresponding stream for the

arrival of this event with an event handler. Event han-

dlers can be used to define the reaction of a node to an

event that occurs or fails to occur. If a node crashes

and then comes back online, it looks at missed events

and decides what to do next. In principle, the infor-

mation about who created an event and who reacted

to it is irrelevant for an individual node. A single

node therefore only needs the information about the

IP address to connect with the streaming system to be

part of ARTHUR. This can be determined as a con-

figuration when setting up a node. This property en-

ables considerable simplification in comparison to a

request-response system.

4.2.3 Master Node

The role of the master node provides a central control

unit for configuring the individual worker nodes via

the following events:

• StartEvent(startTime: UNIX Nanosecond

timestamp)

• StopEvent(stopTime: UNIX Nanosecond

timestamp)

• ConfigChangeEvent(diviceID: Unique

device ID, config: JSON)

An important role of the master is the transmis-

sion of a start event for the simultaneous start of the

data recording. Furthermore, the master functions

as a dashboard for monitoring the system. Grafana,

an open-source dashboard, is used for this purpose.

Grafana enables the connection of the local Redis in-

stance as a data source from which data is constantly

read out. Such a dashboard can be adapted to any use

case and is recommended to monitor the status of the

database. With the dashboard, it is possible to mea-

sure the network load caused by the communication

and to observe the available memory of the local Re-

dis instance.

ARTHUR: Machine Learning Data Acquisition System with Distributed Data Sensors

159

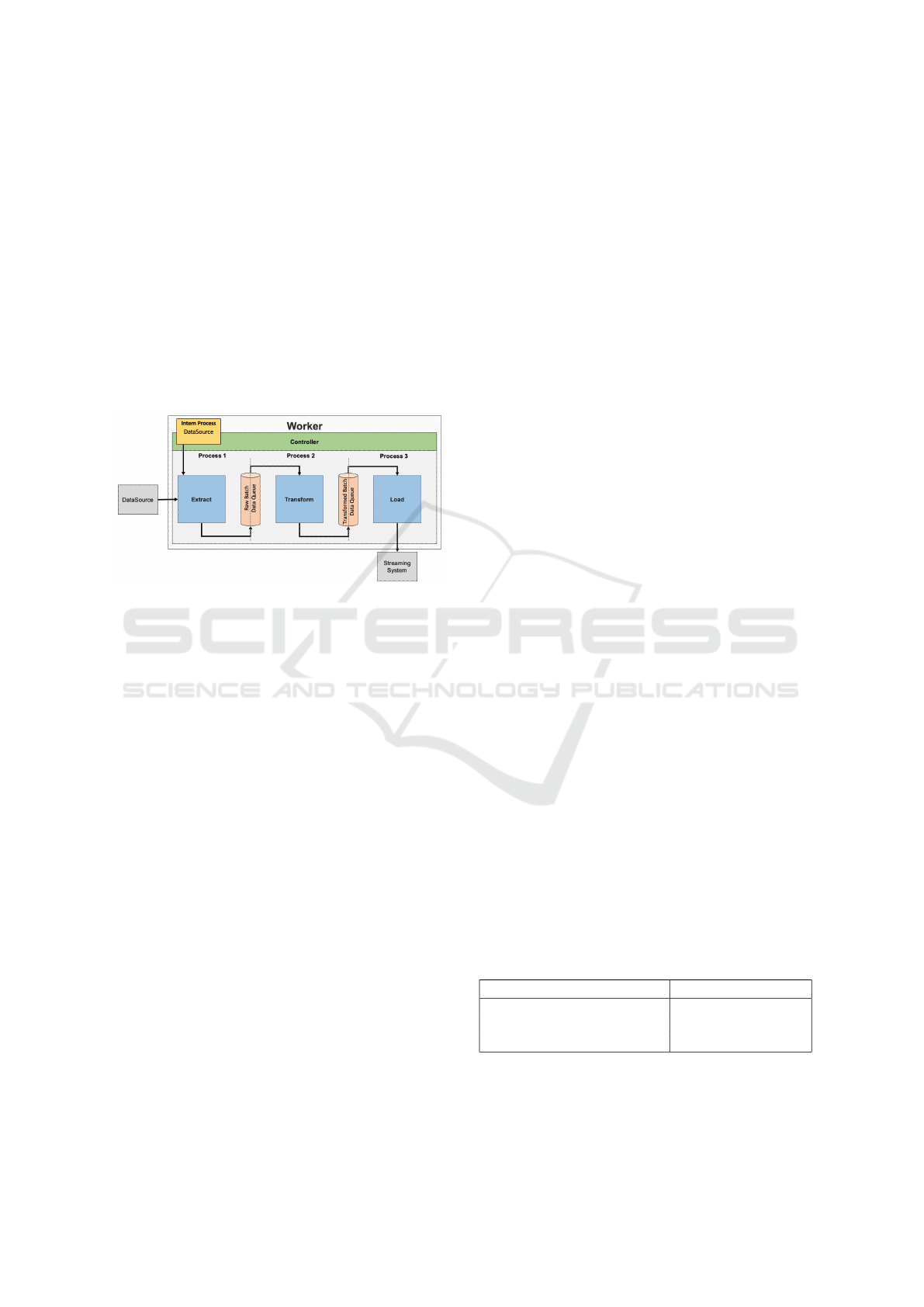

4.2.4 Worker Node

The worker role serves as an adapter between

ARTHUR and various data sources. A worker is con-

trolled by several event handlers who constantly wait

for events like:

• MEASUREMENT:START

• MEASUREMENT:STOP

• WORKER:CONFIG:CHANGE

To achieve optimal hardware utilization and to

guarantee a high data acquisition rate, the worker

starts several processes inspired by the Extract Trans-

form Load (ETL) design pattern (see Fig. 4). All pro-

Figure 4: Dataflow in a worker node.

cesses are started and managed from a main process,

called controller and communicate with each other

over first in first out (FIFO) queues. Synchronous pro-

cessing of the data in a queue is necessary to ensure

its correct order. The following sections discuss the

individual ETL processes in more detail.

Extract Process. The extract process receives data

from a connected data source. This can be done in

different ways and is strongly dependent on the use

case of the worker. Data can be directly produced by

an intern worker process or be obtained from external

sources e.g., OPC-UA.

If the master starts data acquisition by sending a

start event, all distributed workers react to the event

with their corresponding event handlers and inform

the controller. The controller of a worker forwards

the start signal to the extractor process. During data

acquisition, the extractor continuously reads one ore

multiple targets and writes the recorded data batches

into the Raw Batch Queue for further processing.

Transform Process. The transform process reads

incoming batches from the Raw Batch Queue and pro-

cesses them further. After the data has been success-

fully processed, it is transferred to the Transformed

Batch Queue. This process can be used to enable in-

dividual data pre-processing at the edge. For example,

averages can be formed from the raw data to minimize

the number of data points resulting in a reduced load

for the system.

Load Process. The load process is responsible for

persisting incoming data batches from the Trans-

formed Batch Queue by sending them to the streaming

system. The streaming system further takes care of

the received data (see section 4.2.1). For this purpose,

the load process uses the Redis interface to attach data

batches as events to the MEASUREMENT:DATA stream.

.

5 EVALUATING THE

REQUIREMENTS

In this section, the implemented ARTHUR system

is evaluated and discussed according to the require-

ments stated in section 3.

Description of the Used Hardware. ARTHUR has

been successfully used to acquire data from multiple

data sources in a grinding process on a CNC machine

tool. All worker nodes as well as the master node and

the streaming system node were setup on a Raspberry

Pi 4 with 8GB RAM. The usage of a Raspberry Pi

is not mandatory. ARTHUR can easily be deployed

on different hardware if e.g., a use case requires more

computational power. The choice of the Raspberry Pi

was made for several reasons. The connection of dif-

ferent data sources to a Raspberry Pi is easily possible

through already existing expansion cards. The Pi also

has an ethernet port that allows a direct network con-

nection.

In the experiments, we used a separate worker

node (see Fig. 5), a master node, and a streaming sys-

tem node for each data source. To evaluate the max-

imum sample rate, data synchronization, etc. during

the experiment we used a signal generator instead of

the CNC machine.

The following Table 1 provides an overview of the

data sources in the real manufacturing process. Both

Table 1: Overview of all data sources.

Data source Signal

Dittel AE6001 acoustic emission

Kistler force plate X-Y-Z force values

Simens SIMATIC IPC227E machine tool values

the acoustic emission and force values were recorded

via the GPIO HAT MCC118 analog-to-digital con-

verter mounted on the Raspberry Pi. The MCC118

CLOSER 2023 - 13th International Conference on Cloud Computing and Services Science

160

Figure 5: Experimental Setup.

HAT of the Raspberry Pi is able to acquire data at a

sample rate of 100 kHz per second with a resolution

of 12-bit in a value range of +-10 volts and has 8 input

channels. The maximum recording rate of 100 kHz

is divided equally between several channels. Thus,

when using two channels, a maximum data recording

rate of 50 kHz per channel is possible. The MCC118

Python library daqhat was used to implement the ex-

tract process described in the section 4.2.4. The same

extract process implementation was used to read AE

and force values.

Evaluation of R1: Easily Extendable. In order to

receive data from the SIMATIC IPC, an OPC-UA

server was configured on it, which publishes the ma-

chine parameters of the machine tool. These were

then read out by a worker via OPC-UA, for which the

python library opcua was used in the reader process.

Connecting additional data sources with OPC-UA

or other technologies does not affect the recording of

existing workers. If adding a new work node, it is

sufficient to configure the IP address of the streaming

system node. The requirement for simple expandabil-

ity of the system was therefore fulfilled. How many

worker nodes can be added depends on the amount

of data collected, which is related to the sample rate

configured in the worker node.

Evaluation of R2: Data Pre-Processing on the

Edge. The analog signals recorded by the MCC118

must be further processed for their storage. The

MCC118 writes recorded values of all its channels

into a single list. The list is then pre-processed by

the transform process presented in section 4.2.4 and

thus divided into its individual channels. In addition,

the recorded force value must be converted from volt

to newton.

Pre-processing of the data can be done as desired

by the customizable transformation process and s the

requirement R2.

Evaluation of R3: Data Quality Assessment. Fig-

ure 6 shows the input data of the value of the

force plate Z direction, defining two thresholds. If

the measurement is outside the T hreshold

min

and

T hreshold

max

, the worker node of ARTHUR can sig-

nal alarms locally or/and sends an event to the cloud

to avoid failure in data collection. Due to the simple

Figure 6: Sensor input with Thresholds.

possibility of extending the system with quality mech-

anisms, requirement R3 can be considered fulfilled.

Evaluation of R4: Affordable Data Acquisition.

Although the proposed ARTHUR system consists of

multiple Raspberry Pis, other low-cost embedded de-

vices can be utilized. Low-cost sensors can be con-

nected to any device capable of acting as a worker

node, e.g., a laptop or stationary PC, where resource-

intense operations like pre-processing can be carried

out. Of disadvantage is that the operation of Rasp-

berry Pis might be inappropriate for the rough manu-

facturing environment. The presented system is indi-

vidually adaptable to the cost requirements and fulfills

the demand for a cost-effective system formulated in

R4.

Evaluation of R5: Heterogeneous Collaboration.

The collaboration of domain experts and data sci-

entists can be accomplished by granting access to

datasets in the cloud system. When the resulting ML

pipelines are being made available to the cloud en-

vironment, the re-training with new datasets and the

inference of respective models is made possible. In

principle, there can be triggers for starting a partic-

ular ML training task in the cloud, using data from

a specific ARTHUR system or a fusion of multiple

ARTHUR systems data respectively. As the cloud in-

terface can be extended with arbitrary logic, the in-

cremental training of a model can be started for ex-

ample whenever a certain amount of new data be-

comes available. At the same time, existing work-

ARTHUR: Machine Learning Data Acquisition System with Distributed Data Sensors

161

flows/pipelines can dynamically be adapted to current

situations, for example reacting to sensor drifts. This

enables heterogeneous collaboration and meets the re-

quirement of R5.

Evaluation of R6: Time Constraints. By opti-

mally utilizing the resources of the Raspberry Pi and

the MCC118 GPIO HAT, a maximum recording rate

of 80 kHz per worker, resulting in a 2 MB/sec network

load, could be achieved without causing queue jam-

ming. The CPU load of the local streaming system

node implemented with Redis was utilized by 3 work-

ers at an average of 60%, enabling fast processing of

events. A reaction to incoming events takes place im-

mediately after their occurrence. If more workers are

added in the future, Redis can be scaled both hori-

zontally and vertically to continue ensuring a fast re-

sponse time. The system met the time requirements in

the DQ-Meister project and thus fulfills requirement

R4.

6 CONCLUSION

In this work, a Data Acquisition System for dis-

tributed sensors was discussed with respect to pro-

totypical ML operations. This hierarchical system

consists of multiple embedded sensing devices, which

are synchronized. The system has been shown to be

easily extendable and it is not dependent on specific

technologies like OPC-UA. ARTHUR supports data

pre-processing close to the resource to reduce net-

work load and can additionally be tailored to spe-

cific data pre-processing use cases. The same goes

for specific data quality assessments where thresholds

for data values can be defined and acted upon on with

customized events. The proposed system was evalu-

ated with several Raspberry Pis and low cost sensors

making it affordable, even for early stages of proto-

typing. The provided interface enables a heteroge-

neous collaboration between domain experts and data

scientists. In order to uphold the time constraints of

different use cases, appropriate hardware can be used

without a problem as the architecture of the system is

hardware agnostic.

For the future, it is planned to integrate cam-

eras for visual surface quality inspection and integrate

ARTHUR into non-Raspberry Pi hardware. Addition-

ally we intend to add more complex hardware, like a

precision RTP oscilloscope with a max. sample rate

of 40 G sample/s in order to further test the limits of

the system. Furthermore a thorough security analy-

sis of the system has to be conducted in order to be

prepared for future Machine Learning audit require-

ments. Finally, the system will be evaluated with a

complex manufacturing use case.

ACKNOWLEDGMENT

This work as outcome of the project DQ-Meister*in

with the project number P2021-01-013 has received

funding from the Carl Zeiss Stiftung.

REFERENCES

Anik, S. M. H., Gao, X., Meng, N., Agee, P. R., and McCoy,

A. P. (2022). A cost-effective, scalable, and portable

iot data infrastructure for indoor environment sensing.

Journal of Building Engineering, 49:104027.

Asplund, F., Macedo, H. D., and Sassanelli, C. (2021).

Problematizing the service portfolio of digital innova-

tion hubs. In Camarinha-Matos, L. M., Boucher, X.,

and Afsarmanesh, H., editors, Smart and Sustainable

Collaborative Networks 4.0, pages 433–440, Cham.

Springer International Publishing.

Chu, Y. B. and Yap, W. K. (2021). Raspberry pi based

wireless interface system for automated microfabrica-

tion in the context of industry 4.0. In Zakaria, Z. and

Emamian, S. S., editors, Advances in Electrical and

Electronic Engineering and Computer Science, pages

117–123, Singapore. Springer Singapore.

Cioffi, R., Travaglioni, M., Piscitelli, G., Petrillo, A.,

and De Felice, F. (2020). Artificial intelligence and

machine learning applications in smart production:

Progress, trends, and directions. Sustainability, 12(2).

D., D. (2017). Industrial automation using iot with rasp-

berry pi. International Journal of Computer Applica-

tions, 168:44–48.

Ferencz, K. and Domokos, J. (2018). Iot sensor data ac-

quisition and storage system using raspberry pi and

apache cassandra. In 2018 International IEEE Confer-

ence and Workshop in

´

Obuda on Electrical and Power

Engineering (CANDO-EPE), pages 000143–000146.

Grimaldi, D. and Marinov, M. (2001). Distributed measure-

ment systems. Measurement, 30(4):279–287.

Hafeez, S. and Kathirisetty, N. (2022). Effects and compar-

ison of different data pre-processing techniques and

ml and deep learning models for sentiment analysis:

Svm, knn, pca with svm and cnn. In 2022 First Inter-

national Conference on Artificial Intelligence Trends

and Pattern Recognition (ICAITPR), pages 1–6.

Haizad, M., Ibrahim, R., Adnan, A., Chung, T. D., and Has-

san, S. M. (2016). Development of low-cost real-time

data acquisition system for process automation and

control. In 2016 2nd IEEE International Symposium

on Robotics and Manufacturing Automation (ROMA),

pages 1–5, Ipoh, Malaysia. IEEE.

IndustryARC (2021). Industrial raspberry pi market

2022 - 2027. IndustryARC, Report Code: AIR 0372.

CLOSER 2023 - 13th International Conference on Cloud Computing and Services Science

162

https://www.industryarc.com/Report/19454/industrial-

raspberry-pi-market.html.

Kaiser, J., Terrazas, G., McFarlane, D., and de Silva, L.

(2021). Towards low-cost machine learning solutions

for manufacturing smes. AI & SOCIETY.

Kamat, P., Shah, M., Lad, V., Desai, P., Vikani, Y., and Sa-

vani, D. (2021). Data acquisition using iot sensors

for smart manufacturing domain. In Singh, P. K.,

Polkowski, Z., Tanwar, S., Pandey, S. K., Matei, G.,

and Pirvu, D., editors, Innovations in Information

and Communication Technologies (IICT-2020), pages

393–400, Cham. Springer International Publishing.

Keijzer, T. and Ferrari, R. M. (2022). Threshold design

for fault detection with first order sliding mode Ob-

servers. Automatica, 146:110600.

Kim, C.-S. and Son, S.-B. (2018). A study on big data clus-

ter in smart factory using raspberry-pi. In 2018 IEEE

International Conference on Big Data (Big Data),

pages 5360–5362.

Parks, D. F., Voitiuk, K., Geng, J., Elliott, M. A., Keefe,

M. G., Jung, E. A., Robbins, A., Baudin, P. V., Ly,

V. T., Hawthorne, N., Yong, D., Sanso, S. E., Rezaee,

N., Sevetson, J. L., Seiler, S. T., Currie, R., Pollen,

A. A., Hengen, K. B., Nowakowski, T. J., Mostajo-

Radji, M. A., Salama, S. R., Teodorescu, M., and

Haussler, D. (2022). Iot cloud laboratory: Internet

of things architecture for cellular biology. Internet of

Things, 20:100618.

Ramalingam, S., Baskaran, K., and Kalaiarasan, D. (2019).

Iot enabled smart industrial pollution monitoring and

control system using raspberry pi with blynk server.

In 2019 International Conference on Communication

and Electronics Systems (ICCES), pages 2030–2034.

Ravindran, V., Ponraj, R., Krishnakumar, C., Ragunathan,

S., Ramkumar, V., and Swaminathan, K. (2021). Iot-

based smart transformer monitoring system with rasp-

berry pi. In 2021 Innovations in Power and Advanced

Computing Technologies (i-PACT), pages 1–7.

Reichardt, M., Gundall, M., and Schotten, H. D. (2021).

Benchmarking the operation times of nosql and mysql

databases for python clients. In IECON 2021 – 47th

Annual Conference of the IEEE Industrial Electronics

Society, pages 1–8.

Saari, M., bin Baharudin, A. M., and Hyrynsalmi, S. (2017).

Survey of prototyping solutions utilizing raspberry pi.

In 2017 40th International Convention on Information

and Communication Technology, Electronics and Mi-

croelectronics (MIPRO), pages 991–994.

Seghier, N. B. and Kazar, O. (2021). Performance bench-

marking and comparison of nosql databases: Redis vs

mongodb vs cassandra using ycsb tool. In 2021 In-

ternational Conference on Recent Advances in Math-

ematics and Informatics (ICRAMI), pages 1–6.

Shannon, C. E. (1984). Communication in the presence of

noise. In Proceedings of the IEEE, volume 72, pages

1192–1201.

Song, Z. and Moon, Y. B. (2022). A cloud-fog continuum

computing architecture for cyber-manufacturing sys-

tems. Advanced Engineering Forum, 45:97 – 102.

ARTHUR: Machine Learning Data Acquisition System with Distributed Data Sensors

163