Optimization of Direct Transportation Flows for the Removal of

Construction Waste Bins with both Resource and Task Availability

Interval Constraints

Safae Abderebbi and Wahiba Ramdane Cherif-Khettaf

a

LORIA, UMR 7503, Mines Nancy, Lorraine University, Nancy, France

Keywords: Waste Transportation, Waste Bin Removal, Parallel Machine Scheduling Problem, Multiple Availability

Interval Constraints, Mixed Integer Programming.

Abstract: This study focuses on a new real-word problem encountered in the construction sector, which concerns the

optimization of the removal of construction waste bins from construction sites to a massification platform,

where a limited heterogeneous fleet of tipper trucks (vehicles) must perform direct trips from the platform to

the construction sites to collect the waste bins. Each vehicle has a capacity of one bin, it leaves the platform

with an empty bin, travels to the construction site, drops off the empty bin in the construction site, collects

the full bin and returns to the platform to unload the full bin. The issue is that the vehicles and the construction

sites have one or more periods of availability, and thus are not available any time. This problem is modeled

as a parallel machine scheduling problem of bin removal tasks on non-identical machines (vehicles), with

new constraints that concern the presence of multiple availability intervals for both vehicles and tasks. Two

mixed-integer programming (MIP) models are presented and evaluated on 18 new instances derived from real

industrial case study.

1 INTRODUCTION

As the construction industry develops, it generates an

enormous quantity of materials and a very large

quantity of waste. In France

1

, the construction sector

is responsible for almost 45% of national energy

consumption, over 25% of greenhouse gas emissions,

and generates over 42 million tons of waste per year.

Legislation in France proposes a more global

approach to the environmental impact of the

construction sector including a better management of

the construction supply chain. Thus, sorting,

recycling and valorization of construction waste has

become important for improving the environmental

and ecological performance of the construction

industry. This issue is studied in the French

framework of the R&D project DILC which refers to

“demonstrator innovations logistic sites”, whose aim

is to design an innovative platform for optimizing

construction site logistics, that is adapted to multi-site

a

https://orcid.org/0000-0002-2822-0262

1

https://www.optigede.ademe.fr/outils-multi-acteurs/ba

timents-et-travaux-publics/dechets-du-batiment/cadre-

reglementaire

ecocity construction projects. The DILC project

focuses on the consolidation of transport flows and

human resources through a physical platform that is

modular, removable, and mobile, and the

development of decision support tools to help the

platform managers to optimize their logistics.

The platform must also manage the removal of

waste from construction sites to the platform. The

platform offers a recycling area to sort and recycle the

collected waste, and a material shop for the reuse of

some of this waste. Better management of waste

transport flows from the sites to the platform will

permit to extend the ecological efforts of the building

sector to the construction phase. It should be noted

that there are two types of waste: Big-bag waste and

waste bin. Big-bag wastes are packed on pallets and

concern wastes that are produced with small and

medium quantities such as soft plastic, hard plastic,

and cardboard. Waste bin concerned the wastes that

are produced in large quantity like wood and metals.

Abderebbi, S. and Ramdane Cherif-Khettaf, W.

Optimization of Direct Transportation Flows for the Removal of Construction Waste Bins with both Resource and Task Availability Interval Constraints.

DOI: 10.5220/0011821900003396

In Proceedings of the 12th International Conference on Operations Research and Enterprise Systems (ICORES 2023), pages 221-228

ISBN: 978-989-758-627-9; ISSN: 2184-4372

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

221

The optimization of the Big-bag removal is studied in

(Jaballah and Ramdane Cherif-Khettaf, 2021;

Ramdane Cherif-Khettaf et al., 2022) where a new

vehicle routing model called the Multi-Trip Pickup

and Delivery Problem, with Split loads, Profits and

Multiple Time Windows was proposed. This model

allowed mutualization of material delivery with Big-

Bag waste removal, using tail-lift truck fleet. In this

study, we focus only on waste bin removal, which

consists in performing a set of direct trips from the

platform to the construction sites to satisfy

construction site requests for full bins removal and

their replacement by empty bins. The remainder of

the paper is organized as follows. Section 2 describes

the problem and related literature; two MIP models

are presented in section 3. Experimental results with

the definition of benchmarks are given in section 4.

Finally, concluding remarks are given in section 5.

2 PROBLEM DESCRIPTION AND

RELATED LITERATURE

A limited heterogeneous fleet of tipper trucks

(vehicles) situated at the platform must perform

multiple direct trips between the platform and the

construction sites. The vehicles differ by their speed

and their distance limit. Each trip consists of loading

an empty bin at the platform, delivering it to a given

construction site, collecting a full waste bin from this

construction site, and unloading it in the recycling

center located just next to the platform. Each vehicle

has one or more periods of availability, which

represent the time windows when the vehicles are

available at the platform and so can move to the

construction sites to collect waste bins, outside of

these periods of availability, the vehicles can be

mobilized for other tasks external to the platform and

can’t satisfy the request of bin removal. The platform

also has a period of availability, that is given by the

platform's opening hours. The construction sites have

one or more types of bins depending on the specificity

of the works in progress in the construction site (bin

for wood, bin for metals, bin for plaster, bin for inert

materials, etc.). Each site has only one bin per type,

and must therefore send to the platform requests for

bin removal. The platform must manage the bins

waste removal with the available resources and

ensure the replacement of each full bin with an empty

one. The construction sites also have one or more

periods of availability during which vehicles access is

allowed, and thus the arrival and departure of vehicles

at the construction site location must be within one of

the availability time windows allowed by the

construction site. We denote by a bin removal task,

all operations that consists of loading the vehicle with

an empty bin at the platform, travelling from the

platform to the construction site, unloading the empty

bin at the construction site, loading the full bin,

travelling back to the platform and unloading the full

bin at the platform's recycling center. Platform

service time is the time required for loading and

unloading the bin on the platform.

This problem can be modelled as unrelated

parallel machine scheduling problem in which the

vehicles can be represented as machines with multiple

periods of availability and the bin removal tasks as

jobs that have one or multiple periods of availability,

and require a certain amount of processing time, that

depends on the vehicle that is used. In addition, the

constraint of availability of the tasks in our case

concerns only a part of the task processing time, it is

the loading and unloading part at the location of the

construction site and does not concern the part of the

travel to and from the site. The objective is to perform

the maximum number of bin removal tasks, to

determine the assignment of tasks to the availability

intervals of the vehicles; and to define the sequence

of satisfied tasks per available interval of each used

vehicle.

In terms of computational complexity (Lenstra et

al., 1977) proved that the single machine scheduling

problem with only release dates, which is a special

case of our problem is NP-hard. In literature,

extensive studies have been conducted in the area of

parallel machine scheduling with time constraints

without availability constraints (Arik et al.,2022;

Osorio-Valenzuela et al., 2019). In most of the

research reviewed in the area of parallel machine

scheduling, the availability constraints are defined on

resources (Such-Jeng, 2013). Very few studies

consider the availability intervals of tasks as in

(Gedik et al.,2016). A survey on parallel machine

scheduling under availability constraints can be found

(Kaabi and Harrath, 2014).

Despite the abundant literature on parallel

machine scheduling, the problem that we present here

is in our knowledge a novel one and allows us to

model a new constraint in unrelated parallel machine

scheduling problems, that is both resource and task

multiple availability interval constraint. Our

contribution can be summarized in the two following

issues:

─ Modeling a real problem of direct transportation

of bin waste in the construction sector as a

parallel machine scheduling problem with a new

specific constraint that is multiple periods of

ICORES 2023 - 12th International Conference on Operations Research and Enterprise Systems

222

availability of both resources and tasks. In

addition, the period of availability of tasks in our

case concerns only a part of the task processing

time, it is the loading and unloading part in the

construction site. The travel time which is a part

of the processing time is not concerned by the

task availability interval.

─ Proposing of two mixed-integer programming

(MIP) models, and analysis of results on 18

instances provided by our industrial partners.

3 NOTATION AND

MATHEMATICAL

PROGRAMMING MODELS

For a given time horizon specified by the platform's

opening time window, we seek to assign n non-

identical jobs (bin removal tasks) to K non-identical

machines (vehicles). The objective is to provide the

best sequence of bin removal tasks on each vehicle

to perform a maximum of bin removal tasks.

Moreover, the processing time of each bin removal

tasks depends on the type of vehicle that is assigned

to it. Each bin removal task has a processing time, that

includes loading and unloading time in the platform,

travel time from the platform to the construction site

and from the construction site to the platform. Note

that task service time represents only loading and

unloading at the construction site. Each task has DC

periods of availability intervals for its task service,

and each vehicle has DV periods of availability

intervals. The objective is to maximize the total

number of tasks to be performed within a given time

horizon.

We first define the parameters and decision

variables, and then present the two proposed

mathematical models.

Indices:

i, j : task index (1, . . ., n)

k : vehicle index, k = 1, . . ., K

α : task availability interval index,

α = 1,.., DC

l : vehicle availability interval index,

l = 1, . . ., DV

Parameters:

n : total number of tasks

K : total number of vehicles

DC : total number of tasks’ availability

intervals

DV : total number of vehicles’ availability

intervals

M : a very large number

CP : platform loading time

DP : platform unloading time

rp : release date of the platform’s time

window

dp : due date of the platform’s time

window

timePC

ik

: duration between the platform and the

construction site i, using vehicle k

CS

i

: site i loading time

DS

i

: site i unloading time

timeTask

ik

: processing time of task i using vehicle

k, such that:

timeTask

ik

= CP + 2

×

timePC

ik

+CS

i

+DS

i

+DP

rs

iα

: release date of availability interval α of

task i

ds

iα

: due date of availability interval α of

task i

dist

i

: round-trip distance between the

platform and the construction site i

distmax

k

: maximum distance of each vehicle k

timeInter

kl

: duration of availability interval l of

vehicle k

rv

kl

: release date of availability interval l of

vehicle k

dv

kl

: due date of availability interval l of

vehicle k

Decision Variables

V

k

: 1, if vehicle k is used; 0, otherwise

Y

iαkl

: 1, if task i is scheduled using its

availability interval α on availability

interval l of vehicle k; 0, otherwise

Z

ij

: 1, if task i precedes task j; 0,

otherwise

T

i

: task i start time; 0 if i is not assigned

to any vehicle

3.1 Mixed Integer Programming

(MIP1)

The first mathematical model that will be referred to

as MIP1 is given below:

(MIP1) Maximize

∑∑ ∑ ∑

𝑌

iαk

(1)

St.

∑∑∑

𝑌

iαkl

1

, ∀𝑖 (2)

V

k

≤

∑∑ ∑

𝑌

iαkl

, ∀𝑘

(3)

Optimization of Direct Transportation Flows for the Removal of Construction Waste Bins with both Resource and Task Availability Interval

Constraints

223

∑∑ ∑

𝑌

iαkl

𝑀

4

*V

k

,∀𝑘

,

𝑀

4

= n

(4)

T

i

𝐶𝑃 𝑡𝑖𝑚𝑒𝑃𝐶

ik

𝑟𝑠

iα

𝑀

5

∑

𝑌

iαkl

1

∀𝑖,𝛼,𝑘, M

5

= DP (5)

T

i

𝐶𝑃 𝑡𝑖𝑚𝑒𝑃𝐶

ik

𝐶𝑆

i

𝐷𝑆

i

𝑑𝑠

iα

𝑀

6

*

(1

∑

𝑌

iαkl

),

∀𝑖

, α,

𝑘, M

6

= DP + timeTask

ik

(6)

T

i

𝑟𝑣

k

𝑀

7

∑

𝑌

iαkl

1, ∀𝑖, 𝑘, 𝑙, M

7

= DP

(7)

T

i

𝑡𝑖𝑚𝑒𝑇𝑎𝑠𝑘

ik

𝑑𝑣

kl

𝑀

8

1

∑

𝑌

iαkl

)

∀𝑖

,

𝑘

,

l

, M

8

= 1.5

DP (8)

∑∑ ∑

𝑑𝑖𝑠𝑡

i

𝑌

iαkl

𝑑𝑖𝑠𝑡𝑚𝑎𝑥

k

V

k

,∀𝑘

(9)

∑∑

𝑌

iαkl

𝑡𝑖𝑚𝑒𝑇𝑎𝑠𝑘

ik

𝑡𝑖𝑚𝑒𝐼𝑛𝑡𝑒𝑟

kl

,∀𝑘,𝑙 )

(10)

∑∑∑

𝑌

iαkl

T

i

,∀𝑖 (11)

T

i

𝑀

12

∑∑∑

𝑌

iαkl

,∀𝑖, M

12

= DP

(12)

T

i

∑

𝑌

iαkl

timeTask

ik

)

T

j

𝑀

13

(3

∑

𝑌

iαkl

∑

𝑌

jαkl

- Z

ij

),

∀𝑖 𝑗,𝑘,𝑙, M

13

= DP (13)

T

j

∑

𝑌

iαkl

timeTask

jk

)

T

i

𝑀

14

(2

∑

𝑌

iαkl

∑

𝑌

jαkl

+ Z

ij

),

∀𝑖 𝑗,𝑘,𝑙, M

14

= DP (14)

V

k

∈

0, 1

,∀𝑘 ; 𝑌

iαkl

∈

0, 1

,∀𝑖,𝑘,𝑙,𝛼 ; 𝑍

ij

∈

0, 1

,∀𝑖,𝑗 ;

T

i

0, ∀𝑖 (15)

The objective function (1) maximizes the number

of tasks. Constraint (2) guarantees that each task is

scheduled at most once, fulfilling one task availability

interval and one vehicle availability interval.

Constraints (3) and (4) ensure the coherence between

Yiαkl and Vk . Constraints (5) and (6) state that the

start time of the task, which represents the beginning

of the loading of an empty bin at the platform must

allow the vehicle to arrive at the site i and to perform

the service on the site i (unloading the empty bin and

loading the full bin) while meeting one of the task

availability intervals. Constraint (7) and (8) guarantee

that the start time of the task must respect the release

date and the due date of one of the interval

availabilities of the vehicle that is selected. Constraint

(9) means that each vehicle must satisfy its maximum

distance. Constraint (10) ensures that the sum of the

processing times of all tasks assigned to a given

interval must satisfy the time duration of this interval.

Constraints (11) and (12) represent coherence

constraint between Ti and Yiαkl . Constraints (13)

and (14) force a precedence relation between two

tasks if they use the same vehicle availability period.

Constraints (15) are the set constraint.

3.2 Mixed Integer Programming

(MIP2)

In this section, we present another version of MIP1,

in which constraints (1)-(15) are maintained except

constraints (5) and (6) which will be reformulated in

another way:

T

i

𝐶𝑃

∑

𝑡𝑖𝑚𝑒𝑃𝐶

ik

∑

𝑌

iαkl

) 𝑟𝑠

iα

𝑀

5’

∑∑

𝑌

iαkl

1, ∀𝑖, 𝛼, M

5’

= DP (5’)

T

i

𝐶𝑃

∑

𝑡𝑖𝑚𝑒𝑃𝐶

ik

∑

𝑌

iαkl

) 𝐶𝑆

i

𝐷𝑆

i

𝑑𝑠

iα

𝑀

6’

1

∑∑

𝑌

iαkl

, ∀𝑖, 𝛼,

M

6’

= DP (6’)

4 EXPERIMENTAL RESULTS

To solve our two models, we use Pyomo, an open-

source constrained optimization library and GLPK

solver. All tests were carried out on MacBookPro18,3

at 2.66 GHz, with 16 GB RAM. We conducted

numerical experiments on 18 new instances which are

inspired by real case studies given by our industrial

partners.

In this section, we give a general description of

the studied instances, we present the results that

allowed us to validate our models. We first analyze

the detailed results of the two models on an

illustrative example, then we give a comparison of the

two models and evaluate their limit on all instances.

4.1 Instance Description

The studied instances simulate a real case study

provided by our industrial partners. The number of

sites for the considered instances is 10. Each site can

have one or several requests for bin waste removal,

which gives a total number of tasks that ranges

between 10 and 20. The characteristics of the

instances are given in table 8a. Column1 indicates the

instance, this name starts with R, followed in order by

the number of sites, the instance index, the letter ‘F’

to indicate that the number of vehicles is fixed, then a

letter (U or P) means that the vehicles have only one

interval of availability (U), or multiple interval of

availability (P). The last position in the instance name

is a group number. Instances with the same group

number have the same characteristics except the total

number of tasks. i.e. the number of requests per

ICORES 2023 - 12th International Conference on Operations Research and Enterprise Systems

224

construction site is different, which results in a

different number of tasks. The two other columns

give the characteristics of each instance, which are the

following in column order: the number of sites (NS),

the number of tasks (n), the number of vehicles (K),

minimum and maximum number of availability

intervals of tasks (DC), and finally the minimum and

the maximum number of availability intervals of

vehicles (DV).

4.2 An Illustrative Example

In this section, the instance R10_1_F_P is given to

illustrate the problem environment and the solution

structure. This instance considers 10 sites, and 5

vehicles. Each site has one demand for bin removal

(1 task per site). The number of availability intervals

per site (respectively per vehicle) is between 1 and 4

(respectively between 2 and 3). All details of this

instance are given in tables 1, 2, 3, 4 and 5.

Table 1: R10_1_F_P_1 size.

K

NS

n

[Min, Max] DC

[Min, Max] DV

5

10

41

[1, 4]

[2, 3]

Table 2:

R10_1_F_P_1 instance - vehicle features.

V

Distmax

(km)

Speed

max

(Km/h)

DV

TimeInter

{Min(h),

Max (h)}

Intervals

V1

800

80

3

{3, 6}

[6, 12],

[14, 17],

[18, 21]

V2

600

70

2

{3,3}

[14, 17],

[18, 21]

V3

600

60

3

{3, 6}

[6, 12],

[14, 17],

[18, 21]

V4

500

50

3

{3, 6}

[6, 12],

[14, 17],

[18, 21]

V5

800

80

2

{3, 6}

[6, 12],

[14, 17]

Table 3: R10_1_F_P_1 instance - site features (DSP:

Distance between sites and the platform, the length of

intervals is equal to 1h for all sites).

Sites

DSP

(Km)

DC

CS

(h)

DS

(h)

Intervals

S1

187.24

4

0.17

0.17

[7, 8],

[11, 12],

[14, 15],

[17, 18]

S2

194.82

2

0.08

0.12

[14, 15],

[17, 18]

S3

150.26

3

0.10

0.10

[7, 8],

[14, 15],

[17, 18]

S4

32.42

2

0.13

0.10

[7, 8],

[14, 15]

S5

104.86

4

0.15

0.10

[7, 8],

[11, 12],

[14, 15],

[17, 18]

S6

140.45

2

0.17

0.17

[14, 15],

[17, 18]

S7

142.93

3

0.17

0.10

[7, 8],

[11, 12],

[14, 15]

S8

127.90

3

0.17

0.12

[11, 12],

[14, 15],

[17, 18]

S9

169.06

2

0.17

0.15

[14, 15],

[17, 18]

S10

86.62 1

0.15

0.12

[11, 12]

Table 4: R10_1_F_P_1 instance-platform features.

rp dp CP

(h)

DP

(h)

6

21

0.10

0.13

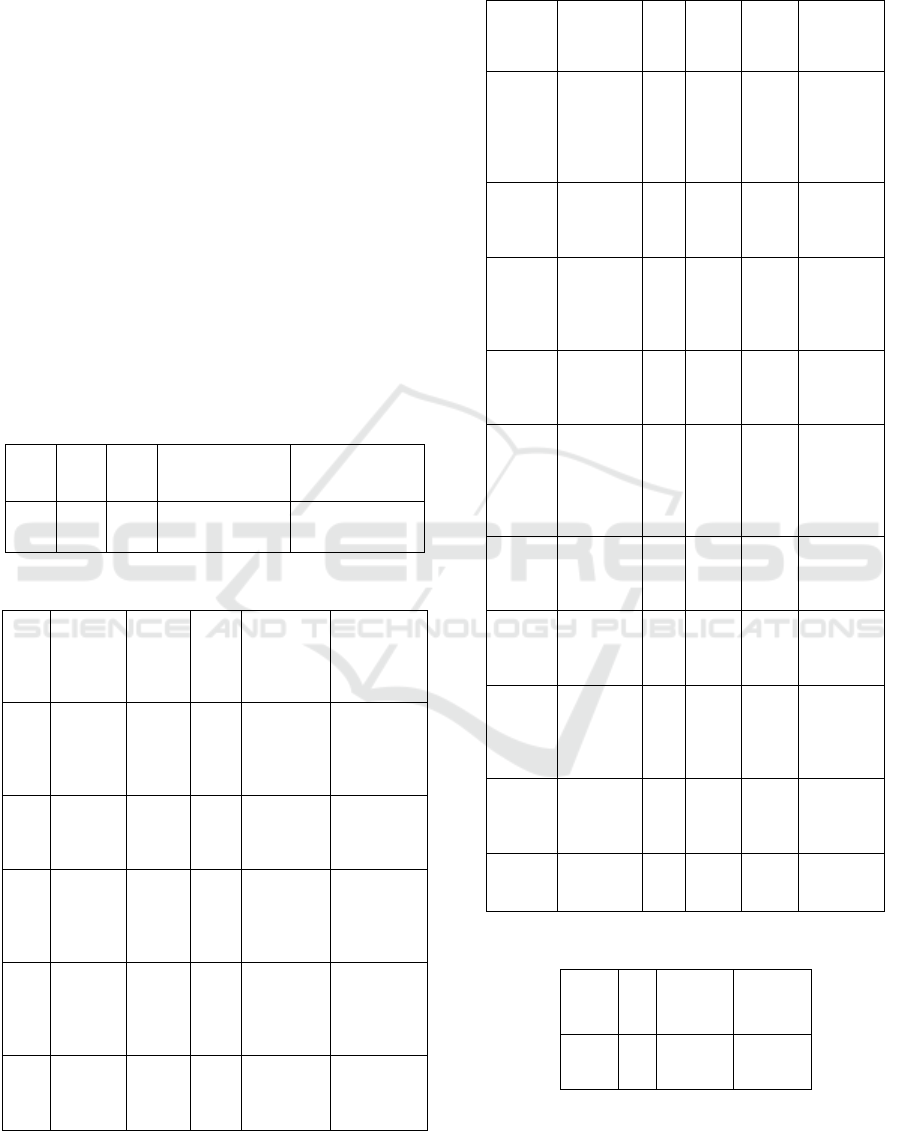

The availability interval constraints are shown in

figure 1 for the construction site 7. We can notice for

site 7 and if we consider only vehicle 1, only the first

Optimization of Direct Transportation Flows for the Removal of Construction Waste Bins with both Resource and Task Availability Interval

Constraints

225

availability interval of site 7 can be feasible, because

the second and the third interval does not allow

vehicles to perform the travel time, when respecting

these vehicle availability intervals even if we start the

task as soon as possible (see figure 2.a and figure 2.b

for more details). If task 7 is selected in the solution,

the beginning of the service of this task will be

scheduled using the first availability interval of the

site [7h, 8h]. The task will be assigned to the

availability interval [6h, 12h] of the vehicle 1.

Table 5: R10_1_F_P_1 instance - travel time between the

platform and the sites (h).

Vehicles

Sites

V1 V2 V3 V4 V5

S1

1.17

1.34

1.56

2.27

1.17

S2

1.22

1.39

2.02

2.35

1.22

S3

1.34

1.07

1.25

1.50

1.34

S4

0.20

0.23

0.27

0.32

0.20

S5

1.06

1.15

1.27

1.05

1.06

S6

1.28

1.00

1.17

1.40

1.28

S

7

1.29

1.02

1.19

1.43

1.29

S8

1.20

1.31

1.07

1.28

1.20

S9

1.06

1.21

1.41

2.09

1.06

S10

0.54 1.02

1.12

1.27

1.54

Figure 1: R10_1_F_P_1 instance – illustration of the

availability interval constraints on task 7.

Table 6: R10_1_F_P_1 – comparison between MIP1 and

MIP2.

Model Obj K

Time

(min)

MIP1

6

4

3

MIP2

6

4

1.3

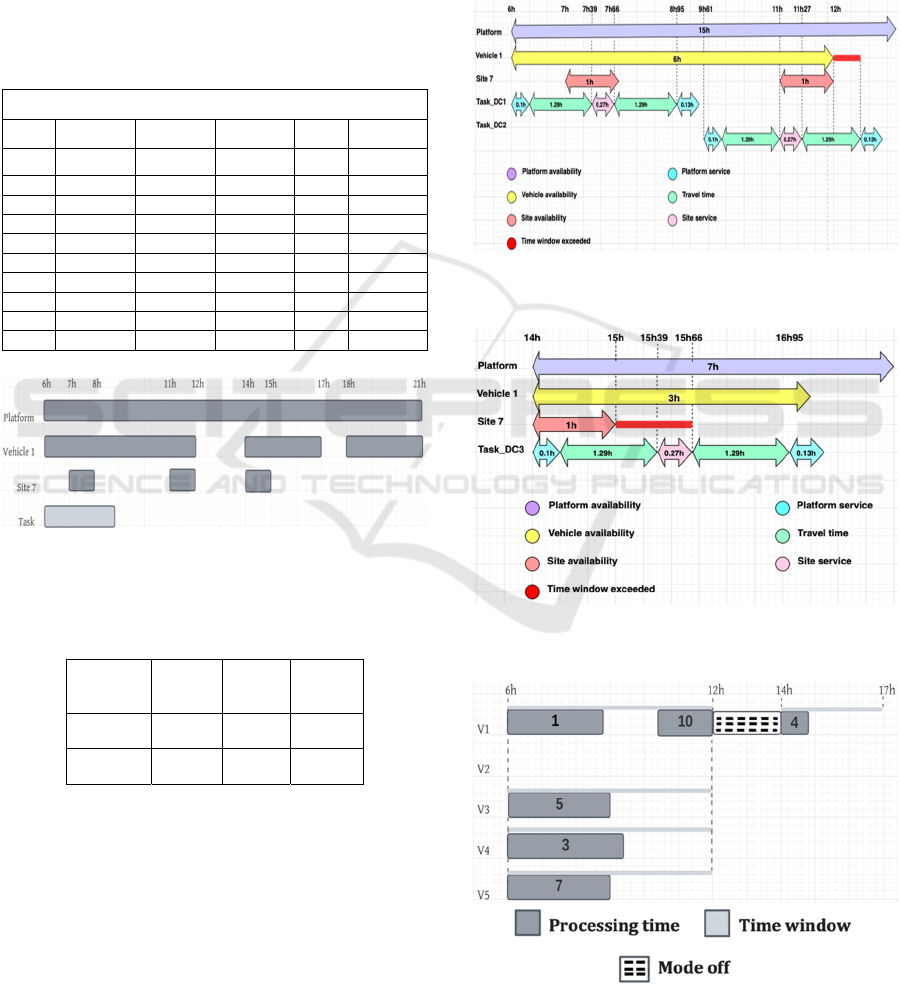

The results obtained for instance R10_1_F_P by

model 1 (respectively model 2) are illustrated by a

Gantt chart in figure 3 (respectively in figure 4). The

results show that an optimal solution was found by

both models. 6 tasks were scheduled among the 10

tasks using 4 vehicles among the 5 available. Vehicle

2 is not used in both solutions, because none of the

remaining tasks is compatible with the availability

intervals of this vehicle. The two solutions one

interval for each selected vehicle except for vehicle 1

and vehicle 3, where a second interval was chosen

only for vehicle 1 in the first solution and only for

vehicle 3 in the second solution. The other selected

intervals are the same for each vehicle in the two

solutions. The tasks that have not been assigned in the

optimal solution are tasks 2, 6, 8 and 9. We can notice

that the availability intervals of these tasks are

incompatible with all the remaining availability

intervals of the vehicles.

Figure 2a: R10_1_F_P_1 - compatibility of availability

intervals [7h, 8h] and [11h, 12h] of task 7.

Figure 2b: R10_1_F_P_1- compatibility of availability

interval

[14h, 15h]

of task 7.

Figure 3: R10_1_F_P_1 - Gantt chart of the optimal

solution obtained by MIP1.

ICORES 2023 - 12th International Conference on Operations Research and Enterprise Systems

226

Figure 4: R10_1_F_P_1 - Gantt chart of the optimal

solution obtained by MIP2.

Table 7: R10_1_F_P_1-evaluation of MIP2 limit by

varying the number of tasks (NTF number of feasible

tasks).

Instances

NS-n-NTF Obj Time (min)

R10_1_F_P_1

10-10-6

6 1.3

R10_1_F_P_2

10-15-10

10 30

R10_1_F_P_3

10-20-14 12

>120

R10_1_F_P_4 10-25-19 16 >120

R10_1_F_P_5 10-30-21 18 >120

Table 6 reveals that model 1 is more efficient in

computational time than model 2 on the illustrative

instance. We then investigated the limit of model 2 on

the same instance by duplicating the number of

requests of some sites to increase the number of tasks.

The results are summarized in table 7. The solutions

in bold are optimal, the others indicate the best

feasible solutions found by the solver while limiting

the computation time to 2h. We can see that model 2

can solve instances up to 15 tasks, 5 vehicles, 4 task

availability intervals and 3 vehicle availability

intervals. On instances with 20 tasks, the model

returns a feasible solution with about 85% of

completed tasks among all feasible tasks.

4.3 Comparison of MIP1 and MIP2

The purpose of this section is to study the limit of the

two models on 18 instances derived from a real case

study, and to compare their performance. Table 8

summarizes the obtained results. The columns MIP1-

obj and MIP2-obj give the percentage of tasks

performed in relation to the total number of tasks. It

can be noticed that both models have the same limit,

they succeed in solving optimally instances with up

to 15 tasks, 10 vehicles, 4 vehicle availability

intervals, and 3 task availability intervals. For

instances with 20 tasks, the table illustrates the best

feasible solutions found within a time limit of 2h.The

results show that model 2 performs better than model

1, the computation time on instances up to 15 tasks of

model 2 is on average 19% better compared to the

computation time of model 1. Model 1 takes from 3

to 90 minutes of computation time, while model 2

takes from 0.7 minutes to 37 minutes.

On the instances with 15 tasks, the computation

times are more important when using multiple

availability intervals compared to the instances with

only one vehicle availability interval. On instances

with 20 tasks, model 2 is able to satisfy up to 6% more

tasks compared to model 1. We can conclude that

model 2 is more efficient, and allowed us to solve up

to 15 tasks in a more reasonable time. We are

currently analyzing the obtained results, by

computing for each instance the real number of

feasible tasks, this will be used to adjust the objective

according to the feasible tasks, which is more

representative than using the total number of tasks.

These results have been validated by our industrial

partner. The obtained results are important for further

research which aims to solve larger instances. The

results of the MIP models will allow us to evaluate

heuristic approaches under development.

5 CONCLUSIONS

In this paper, we have presented a detailed study of a

new real problem encountered in the construction

sector on the optimization of waste bin transportation

in the framework of an organization with a

massification platform. The platform has a limited

Table 8a: Instances characteristics.

Instances NS-n-K

[Min,Max]

DC, DV

R10_1_F_P_1 10-10-5

[1, 4]

-

[2, 3]

R10_2_F_P_1 10-10-5

[1, 4]

-

[2, 3]

R10_3_F_P_1 10-10-5

[1, 4]

-

[2, 3]

R10_1_F_U_1 10-10-5

[1, 4]

-

[1, 1]

R10_2_F_U_1 10-10-5

[1, 4]

-

[1, 1]

R10_3_F_U_1 10-10-5

[1, 4]

-

[1, 1]

R10_1_F_P_2 10-15-10

[1, 4]

-

[2, 3]

R10_2_F_P_2 10-15-10

[1, 4]

-

[2, 3]

R10_3_F_P_2 10-15-10

[1, 4]

-

[2, 3]

R10_1_F_U_2 10-15-10

[1, 4]

-

[1, 1]

R10_2_F_U_2 10-15-10

[1, 4]

-

[1, 1]

R10_3_F_U

_

2 10-15-10

[1, 4]

-

[1, 1]

R10_1_F_P_3 10-20-10

[1, 4]

-

[2, 3]

R10_2_F_P_3 10-20-10

[1, 4]

-

[2, 3]

R10_3_F_P_3 10-20-10

[1, 4]

-

[2, 3]

R10_1_F_U_3 10-20-10

[1, 4]

-

[1, 1]

R10_2_F_U_3 10-20-10

[1, 4]

-

[1, 1]

R10_3_F_U_3 10-20-10

[1, 4]

-

[1, 1]

Optimization of Direct Transportation Flows for the Removal of Construction Waste Bins with both Resource and Task Availability Interval

Constraints

227

Table 8b: Comparison of the performance of MIP1 and

MIP2.

Instances

NS-n-K

MIP1

Obj.

MIP2

Obj.

MIP1

time

(min.)

MIP2

time

(min.)

R10_1_F_P_1

10-10-5

60%

60%

3 1.3

R10_2_F_P_1

10-10-5

50%

50%

5 1.5

R10_3_F_P_1

10-10-5

30%

30%

3 1.1

R10_1_F_U_1

10-10-5

10%

10%

4 1

R10_2_F_U_1

10-10-5

20%

20%

3.5 0.7

R10_3_F_U_1

10-10-5

20%

20%

3.7 0.9

R10_1_F_P_2 10-15_10

13% 13%

90 37

R10_2_F_P_2 10-15-10

33% 33%

66 30

R10_3_F_P_2 10-15-10

13% 13%

78 32

R10_1_F_U_2 10-15-10

7% 7%

57 28

R10_2_F_U_2 10-15-10

13% 13%

43 21

R10_3_F_U_2 10-15-10

7% 7%

53 26

R10_1_F_P_3 10-20-10 -

5%

>120 >120

R10_2_F_P_3 10-20-10 -

10%

>120 >120

R10_3_F_P_3 10-20-10 5%

5%

>120 >120

R10_1_F_U_3 10-20-10 5%

10%

>120 >120

R10_2_F_U_3 10-20-10 10%

15%

>120 >120

R10_3_F_U_3 10-20-10 5%

10%

>120 >120

fleet of heterogeneous vehicles available during

certain periods, the sites have a bin for each type of

waste and negotiate contracts with the platform for

the bin waste removal. The sites limit access to

vehicles at certain time windows periods. The

platform must manage the waste bin removal by

replacing each full bin with an empty bin. The

construction site may have multiple bin removal

requests (one request per bin waste type). We

modeled this problem as a scheduling problem on

non-identical parallel machines with new constraints

that concern the presence of multiple availability

intervals for both vehicles and tasks. We presented

two mathematical integer models, which we

compared and evaluated using 18 instances derived

from a real case study. The test results allowed us to

optimally solve instances up to 15 tasks, 10 vehicles,

4 task availability intervals and 3 vehicle availability

intervals. Currently, we are improving the

mathematical model by integrating the interval

incompatibility. The obtained results will allow us to

evaluate the quality of the heuristic approaches that

are under development.

REFERENCES

Jaballah, A., Ramdane Cherif-Khettaf, W. (2021). Multi-

trip Pickup and Delivery Problem, with Split Loads,

Profits and Multiple Time Windows to Model a Real

Case Problem in the Construction Industry. Proceeding

of ICORES 2021,pp. 200-207.

Ramdane Cherif-Khettaf, W., Jaballah,A, Ferri, F.(2022).

ILS-RVND Algorithm for Multi-trip Pickup and

Delivery Problem, with Split Loads, Profits and

Multiple Time Windows. ICCL 2022: 105-119 In: De

Armas, J., Ramalhinho, H., Voβ, S., (eds.), ICCL2022,

LNCS, vol 13557, pp.105-119, Springer.

Lenstra, J. K., Kan, A. R., & Brucker, P. (1977).

Complexity of machine scheduling problems. Annals of

Discrete Mathematics, 1, pp. 343–362.

Arık, O. A., Schutten, M., & Topan, E. (2022). Weighted

earliness/tardiness parallel machine scheduling

problem with a common due date. Expert Systems with

Applications, 187, 115916.

Osorio-Valenzuela, L., Pereira, J., Quezada, F., & Vásquez,

S. C. (2019). Minimizing the number of machines with

limited workload capacity for scheduling jobs with

interval constraints. Applied Mathematical Modelling,

74, pp. 512-527.

Suh-Jeng Yang (2013), Unrelated parallel-machine

scheduling with deterioration effects and deteriorating

multi-maintenance activities for minimizing the total

completion time, Applied Mathematical Modelling,

vol. 37-5, pp. 2995-3005.

Kaabi, Jihene, and Youssef Harrath (2014). A survey of

parallel machine scheduling under availability

constraints." International Journal of Computer and

Information Technology 3.2 pp. 238-245.

Gedik, R., Rainwater, C., Nachtmann, H., Pohl Ed A.,

(2016). Analysis of a parallel machine scheduling

problem with sequence dependent setup times and job

availability intervals. European Journal of Operational

Research 251.2, pp. 640-650.

ICORES 2023 - 12th International Conference on Operations Research and Enterprise Systems

228