Multi-Modal Artificial Intelligence in Additive Manufacturing:

Combining Thermal and Camera Images for 3D-Print Quality

Monitoring

Markus Bauer

1,∗

, Benjamin Uhrich

2,∗

, Martin Sch

¨

afer

3

, Oliver Theile

3

, Christoph Augenstein

2

and Erhard Rahm

2

1

Institute for Applied Informatics, Goerdelerring 9, Leipzig, Germany

2

Center for Scalable Data Analytics and Artificial Intelligence, Humboldtstraße 25, Leipzig, Germany

3

Siemens AG, Siemensdamm 50, Berlin, Germany

Keywords:

Artificial Intelligence, Additive Manufacturing, Physics-Informed Neural Networks, Multi-Modal Imaging,

Quality Monitoring.

Abstract:

With emerging technologies such as high-precision Laser Powder Bed Fusion (LPBF), rapid prototyping has

gained remarkable importance in metal manufacturing. Furthermore, cloud computing and easy-to-integrate

sensors have boosted the development of digital twins. Such digital twins use data from sensors on physical

objects, to improve the understanding of manufacturing processes as a whole or of certain production param-

eters. That way, digital twins can demonstrate the impact of design changes, usage scenarios, environmental

conditions or similar variables. One important application of such digital twins lies in early detection of man-

ufacturing faults, such that real prototypes need to be used less. This reduces development times and allows

products to be individually, affordable, powerful, robust and environmentally friendly. While typically simple

USB-camera setups or melt-pool imaging are used for this task, most solutions are difficult to integrate into

existing processes and hard to calibrate and evaluate. We propose a digital-twin-based solution, that leverages

information from camera-images in a self-supervised fashion, and creates a heat transfer based AI quality

monitoring. For that purpose, artificially generated labels and physics simulation were combined with a multi-

sensor setup and supervised learning. Our model detects printing issues at more than 91% accuracy.

1 INTRODUCTION

The virtual world of development, testing, and opti-

mization of complex products and processes nowa-

days precedes production processes in the real world.

Future components and operations are created and

simulated as software models – a so-called digital

twin. Digital twins are virtual equivalents of products,

machines, processes, or even entire production plants

that contain all relevant data and simulation models.

To ensure precise simulation throughout the life of a

product or its production, digital twins use data from

sensors on physical objects, to determine real-time

performance, operating conditions, and changes to

the system over time. By incorporating multi-physics

simulation, data analysis and machine learning capa-

bilities, digital twins can demonstrate the impact of

*

M. Bauer and B. Uhrich contributed equally to this

work as first authors.

design changes, usage scenarios, environmental con-

ditions or similar variables. Hence, excessive usage

of real prototypes is avoided, which offers advantages

in cost reduction and sustainability.

In the special case of metal additive manufactur-

ing (MAM), avoiding faulty prints is a crucial factor,

especially for the case of rapid prototyping, where

production time and material usage are key perfor-

mance indicators, and must be kept low. Further-

more, the influence of misjudged printing parameters

such as laser power must be reduced, to make a valid

estimate of the final product’s quality, based on the

prototypes. Digital twins are an adequate option, to

build up a quality monitoring, that ensures a high stan-

dard throughout the MAM process. Hence, they have

gained popularity in MAM.

Recent work has shown, that AI can support the

simulation of complex physical processes such as

fluid dynamics and heat transfer, which are of con-

Bauer, M., Uhrich, B., Schäfer, M., Theile, O., Augenstein, C. and Rahm, E.

Multi-Modal Artificial Intelligence in Additive Manufacturing: Combining Thermal and Camera Images for 3D-Print Quality Monitoring.

DOI: 10.5220/0011967500003467

In Proceedings of the 25th International Conference on Enterprise Information Systems (ICEIS 2023) - Volume 1, pages 539-546

ISBN: 978-989-758-648-4; ISSN: 2184-4992

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

539

siderable relevance for successfully printing layers in

MAM without issues such as porosity. This especially

accounts for the use of physics-informed neural net-

works (PINNs), which have been shown to provide

competitive simulation results to standard approaches

such as the finite element method (FEM) (Zhu et al.,

2021). In addition, there is a large trend in fusing

multiple sources of information in a single AI model,

which aids in manufacturing applications that typi-

cally utilize multiple sensors of different types. An-

other recent development in AI is the use of self-

supervised models that can significantly reduce the

training effort, by superseding the need for manual

annotation.

In this work, we are using AI methods, to demon-

strate how a quality monitoring can be implemented,

without the need for time- and cost expensive sen-

sor setups and manual data analysis. Our approach

aims for applicability in small to medium enterprises,

where access to specialist equipment (such as CT- or

X-ray scanners) often is limited, and labelling proce-

dures (required for supervised AI approaches) are un-

feasible, as it would require too much time of highly

skilled experts. For our solution, we thus create print

quality pseudo labels in a self-supervised fashion us-

ing only one reference build part (BP) and a sim-

ple USB-camera together with an autoencoder model.

We then proceed to combine the pseudo labels with

the output of a PINN that was applied to a pyrometer’s

measurements, to build a BP-quality-classifier. Our

model achieves state-of-the-art results as presented in

section 4.

To the best of our knowledge, our approach is the

first leveraging physics simulation, high-speed cam-

era imaging and AI together with widespread, inex-

pensive sensor setups for high accuracy error detec-

tion. The contribution of our work are as follows:

• We present a setup, which is easy to integrate, in-

expensive, and thus is a feasible solution for small

to medium enterprises (SMEs).

• We use a self-supervised autoencoder to create la-

bels for classification as high, medium and low-

quality layers, whereas data exploration is re-

duced to evaluating few representative samples.

• We demonstrate the use of PINNs for quality as-

surance in LPBF processes.

• We show that pseudo labels taken from camera-

images and thus reflecting the BP’s quality can

be used to directly build a classifier upon highly

informative temperature field information. This

way, the model may be used to identify critical

parts in the temperature field images and then re-

fined to more sophisticated models.

2 RELATED WORK

To understand the scientific background of our pro-

posed solution, related work in the domains of MAM

and AI needs to be considered. In this section, rele-

vant literature is provided, to gain a good overview of

the work’s fundamentals.

2.1 Metal Additive Manufacturing

Recently, MAM has experienced a significant up-

swing, as it offers great potential in reducing the effort

required to build metal parts. This can be especially

useful where iterative development of certain parts is

required, for example in the field of rapid prototyp-

ing. Several efforts have been made in MAM mon-

itoring and computer-assisted process controlling by

various scientific and industry teams. To this end,

Praveena et al. provide a comprehensive review of

MAM, particularly on methods, applications, materi-

als, challenges, trends and future potentials (Praveena

et al., 2022). Nevertheless, MAM is a highly complex

process, that requires controlling of various parame-

ters such as laser-power, scan velocity etc. (Knaak

et al., 2021). Additionally, melting and fusing metal

leads to heating and cooling cycles that significantly

affect component quality. A research milestone in the

field of numerical simulation from Mukherjee et al.

made it possible to get a more in-depth understand-

ing of heat and fluid flow in MAM (Mukherjee et al.,

2018).

2.2 Machine Learning

Due to AI’s increasing popularity, various conceptu-

alizations have been proposed for automated or AI-

driven quality assurance in MAM. The most popular

approaches extract their information from melt pool

images or characteristics (Akbari et al., 2022; Kunkel

et al., 2019) or high-speed camera setups (Kwon et al.,

2018). Promising results could be achieved that way.

For example, Kunkel et al. (Kunkel et al., 2019)

achieve an accuracy of 99.7% in classifying four cat-

egories of yield strength (good, average, bad, and

mapping failure). Inspired by the success of ana-

lytic approaches that operate on melt pool shape or

layerwise camera-imaging, recent work includes se-

tups that combine multiple domains for even better

model accuracies. Shen et al. (Shen et al., 2022) pro-

pose a system for weld reinforcement. Their solution

includes multi-modal information given by the melt

pool camera images, as well as heatmap images of

different parameter groups.

We adapt the basic ideas and core findings of the

ICEIS 2023 - 25th International Conference on Enterprise Information Systems

540

referenced work and transfer them to our use case. In

addition, we extend the existing approaches, by pay-

ing particular attention to self-supervised learning and

heat flow simulation, to achieve comparable results

with less effort on the industry-practitioner side.

2.2.1 Autoencoder

Autoencoders (AEs) consist of two phases, the encod-

ing step and the decoding step. In the encoding step, a

non-linear function is learned that transforms the in-

put into a low-dimensional vector space, and in the

decoding step, an inverse transformation is learned

that reconstructs the input from this low-dimensional

vector space. AEs are an effective method for de-

tection of anomalies in unlabelled data. Bel-Hadj et

al. presented an AE for anomaly detection in vibra-

tion signals for structural health monitoring of an off-

shore wind turbine (Bel-Hadj and Weijtjens, 2023).

The principle also works in physics, as Ngairangbam

et al. have recently shown in an application using a

quantum AE (Ngairangbam et al., 2022).

In our case, autoencoders are used as a tool to au-

tomatically extract print quality labels from diverg-

ing representations of different BP’s layers, which is

a scenario comparable to referenced works.

2.2.2 Physics-Informed Neural Networks

Heat transfer during melting in 3D printing is one

of the most important factors influencing part qual-

ity in MAM. To monitor MAM processes, heat trans-

fer must be considered and understood. Such a

natural phenomenon based on physical laws is well

known. Researchers have been studying thermal be-

haviour more than 100 years and have formalized

their knowledge in the form of partial differential

equations (PDEs). There is an opportunity to incor-

porate this knowledge into classical deep learning al-

gorithms such as neural networks (NNs) to increase

prediction accuracy with the data-driven capabilities

of NNs. Raissi et al. were the first to show that PINNs

are a viable alternative method to obtain an approxi-

mation for solving these PDEs, using several time-

dependent benchmark problems (Raissi et al., 2019).

A good overview of the possibilities of PINNs for heat

transfer problems is given by Cai et al. (Cai et al.,

2021). Zhu et al. presented first results for heat trans-

fer and fluid flow in MAM using PINNs and compare

the solutions with finite element method.

PINNs are used in our work to generate input

for the error classifier. We assume that deviations

between the estimated temperature profiles and the

measured ones will help to indicate emerging prob-

lems such as delamination. As PINNs embed existing

physical knowledge, possibly more meaningful infor-

mation can be supplied than using just the raw data.

2.2.3 Multi-Modal Machine Learning

Multimodal ML is important if there is more than

one data representation or modality for the same real-

world application, respectively. This could be the

combination of text and images or images of different

types, such as greyscale and thermal images. Similar

to our work, Gaikwad et al. (Gaikwad et al., 2020)

incorporate information from a pyrometer as well as

a high speed video camera to characterize the quality

of single tracks printed using LPBF. They extract var-

ious statistical features for each sensor measurement

and process them using a set of echelon artificial neu-

ral networks. Using quality metrics generated from

profilometer measurements, their approach provides

state-of-the-art results for detecting and pairing errors

(e.g., balling, keyholding) to critical process param-

eters (e.g., laser velocity and laser power). More re-

cent work of the authors (Gaikwad et al., 2022) on

the effects of melt pool characteristics (e.g., tempera-

ture, spatter, and size) on build part porosity presents

a similar approach. The main difference to our work

lies in the more time-, knowledge- and resource ex-

pensive setup, which may be impractical for small to

medium enterprises.

As described in section 4, multi-modal machine

learning is a good strategy to increase the perfor-

mance of a printing error classifier. We thus make

use of this technique in our work.

3 METHODS

Our proposed architecture features the application of

supervised CNN learning, Autoencoders for label-

generation and process simulation using PINNs. Be-

low, those methods’ theoretical background is pro-

vided.

3.1 Laser Powder Bed Fusion

For our experiments, we use the LPBF procedure,

which is one of the most widespread and industrially

used additive manufacturing processes. It is based on

the melting of single metal powder layers using a laser

beam. The laser energy is focused on the powder sur-

face and the powder is melted at the focal point due

to the high energy-density. The laser “scans” the geo-

metric shape of the component to be produced in each

powder layer, i.e., the laser beam is deflected by a mir-

ror system and the focal point is guided over the pow-

Multi-Modal Artificial Intelligence in Additive Manufacturing: Combining Thermal and Camera Images for 3D-Print Quality Monitoring

541

der surface according to a predefined pattern. After

melting a layer, the build platform is lowered, usu-

ally approx. 50 µm, powder is reapplied through a re-

coating system and afterward the next layer is melted.

The laser energy is sufficient to create a melt pool

that extends over several layer thicknesses. However,

the resulting melt pool must be adapted to both the

material and the process settings to ensure optimal,

true-to-shape solidification of the metal without de-

fects such as cracks or flaws. It is thus similar to the

welding process, but more complex, as not only indi-

vidual traces are melted, but flat areas besides small

zones are created without interruptions. The melting

and cooling behaviour of the process is more compre-

hensive and dependent on a variety of process condi-

tions.

3.2 Multimodal Dataset

To develop and test a real-time data processing work-

flow, EOS M 290 and SLM 280 laser melting ma-

chines were used. In total, nine different specimens

of pillars have been built in two distinct print jobs

with AISI 316L (1.4404), and IN718 (2.4668) pow-

der. For each print job, 382 × 288 pixels greyscale

images and pyrometer heatmaps of λ = 7 µm to 14 µm

were recorded with f

record

= 3 Hz. While for the first

job only smaller printing errors could be observed

qualitatively, the second print job contained signifi-

cant warping / delamination issues. The quality of

the first build job was evaluated by manufacturing ex-

perts, using surface roughness and shape deviation

measurements, and found to be on a par with the man-

ufacturer’s quality standards. For the second build

job, no further part evaluation was done, as severe is-

sues were clearly visible.

3.3 Machine Learning Methods

Multiple machine learning methods have been ap-

plied, to create the error classifier, including an au-

toencoder, PINNs and convolutional neural networks

(CNNs) trained with supervision.

An Autoencoder, as described in section 2.2.1 is a

special kind of NN that uses an encoder E to create

vector representations z (:= embeddings) from input

data X (i.e., camera images), and a decoder D to re-

store the original images. The output image

ˆ

X thus is

created by:

ˆ

X = D(z ∼ E(X, ω), θ) (1)

where ω refers to the encoder’s and θ to the decoder’s

parameters. As the decoder is simply the inverse of

the encoder, weights can be shared between them. In

this case, ω is identical with θ. For training, a re-

construction error between X and

ˆ

X is calculated and

used to optimize the parameters ω of the network by

solving:

argmin

ω,θ

∑

(X −

ˆ

X)

2

N

(2)

with N as the total number of input samples. The cre-

ated embeddings z can then, as in our case, be used

as pseudo labels to train further models, or directly to

perform tasks like clustering etc.

PINNs describe a special form of NNs that incor-

porate PDEs as a mathematical formalism of knowl-

edge about physical behaviour. A neural network is

trained to learn a function T

NN

(t,x, y, z,W, b) that can

approximate a scalar temperature field while consid-

ering the energy conservation equation. t,x,y,z de-

scribes the spatial-temporal domain of the BP and W ,

b are the trainable weights and bias of the neural net-

work. The optimization of the weights and biases W,

b are driven by initial and boundary value conditions

as well as by the PDE of energy conservation. If any

of the three restrictions is not satisfied, this is penal-

ized in the form of the loss function (3) and optimized

by backpropagation.

Loss = λ

1

R

1

+ λ

2

R

2

+ λ

3

R

3

(3)

Here R

1

and R

2

are initial and boundary conditions,

and R

3

describes the energy conservation equation.

To obtain the derivatives of the learned function T

NN

,

automatic differentiation is used. λ

1

− λ

3

are weights

of the individual loss terms, ranging from 0-1, prior-

itizing the loss terms differently. Using the pseudo

labels created from the autoencoder and the images

created with the PINNs, a CNN M(X , ψ) is trained in

a supervised fashion. This is done by optimizing the

parameters ψ using the cross entropy loss between the

outputs of M and the pseudo labels

ˆ

X.

3.4 Proposed Training Architecture

To create an error classification model, we are using

a procedure as depicted in Fig. 1. We are combining

both the thermal and greyscale records in the created

dataset. For that purpose, first, we train an autoen-

coder to a set of hold-out patches taken from the suc-

cessful BPs greyscale images, with the objective to

reduce the mean squared error of the reconstruction

vs. the input image.

The greyscale data consists of 110 × 110 pixels

patches x and x

re f

(15112 patches in total), cropped

from the full-size images, around the individual pil-

lar’s centre. Additionally, as the pillars are of different

shape and thus may never fill the whole image patch

area, the final row of pixels was repeated to the edge

ICEIS 2023 - 25th International Conference on Enterprise Information Systems

542

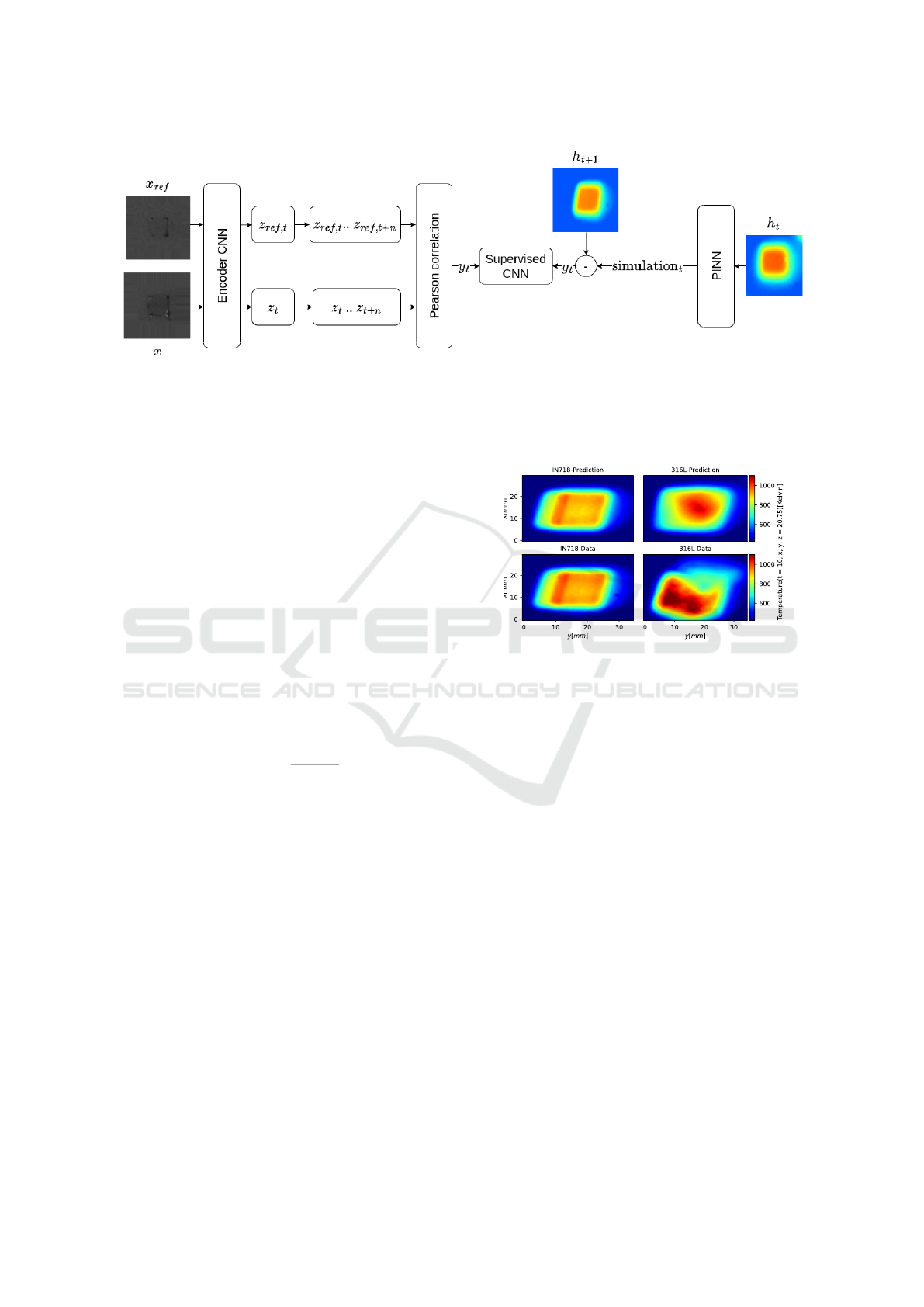

Figure 1: Architecture of the proposed training method - Camera images x

t

are collected and processed using a NN

encoder, together with a reference image. After buffering a certain number of images, a pseudo label is created using the

Pearson correlation between reference and current images. As soon as pseudo labels y

t

are created for a layer, referring images

g

t

are provided, which are created by subtracting the currently predicted temperature profile from the measured temperature

field image. That way, a neural network is trained, to later predict, whether a layer was printed successfully.

of the patch according to the actual build parts shape,

rather than applying zero padding. Our autoencoder

uses a Resnet18-like architecture (He et al., 2016) for

the encoder and decoder.

With the trained encoder, we then process the re-

maining images of both BPs to create a vectorized

version z and z

re f

of each patch, whereas z are the

vectors of the faulty BP and z

re f

are the ones of the

successful BP. Afterwards, all vectors are stored in

buffers of length n = 10 and compared using the Pear-

son correlation. That way, we identify trends of dif-

ference between the BPs, without any human supervi-

sion. With this procedure, except for an initial amount

of 10 layers, we create pseudo labels y according to

the following rule:

y =

successful, Pearson r >= 0

warning, 0 >

∂Pearson r

∂t

> −0.02

failed, otherwise

(4)

The thresholds for the pseudo labels have been set em-

pirically.

In the next step, we create input images g for train-

ing the classifier M. For that purpose, regions of the

pillars are cropped from the heatmap images. We then

create heatmap predictions h for each next layer, start-

ing with the n − 1

th

layer (as we already needed to dis-

card images for greyscale images). We then subtract

the heatmaps simulation

t

predicted from h

t

from the

previously measured ones h

t+1

and take the absolute

error to create a new training image g

t

.

4 RESULTS

To create our model, we are running three distinct

tasks. Those consist of training the PINN and AE,

creating labels and images, and finally creating the

Figure 2: Comparison of heat prediction - Heat predic-

tion for INC 718 (left) and 316L (right) in comparison with

measurement data. For the INC718 print job prediction and

measurement data match. In the case of the 316L print job

prediction and measurement data show differences indicat-

ing defective layers, as the simulations match, i.e., layers

that have been printed earlier.

classifier. Our particular results for each step are pre-

sented below.

4.1 Heatmap Simulation

Heatmap prediction is based on a fully connected,

physics-informed feed forward network. Each printed

layer is simulated by solving an initial and boundary

value problem. The NN is informed by the energy

conservation equation, which describes the physical

laws of heat transfer, and the solution domain is de-

scribed by randomly selected collocation points. On

these points, a solution is prepoints, based on a batch

size of 1000. We set initial and boundary conditions

based on real measured data. For this purpose, a train-

ing data set of a total of 1200 thermal images was

used for the entire printing process. Additionally, a

heat source position detection method is implemented

to produce comparable heatmaps. The heat source

Multi-Modal Artificial Intelligence in Additive Manufacturing: Combining Thermal and Camera Images for 3D-Print Quality Monitoring

543

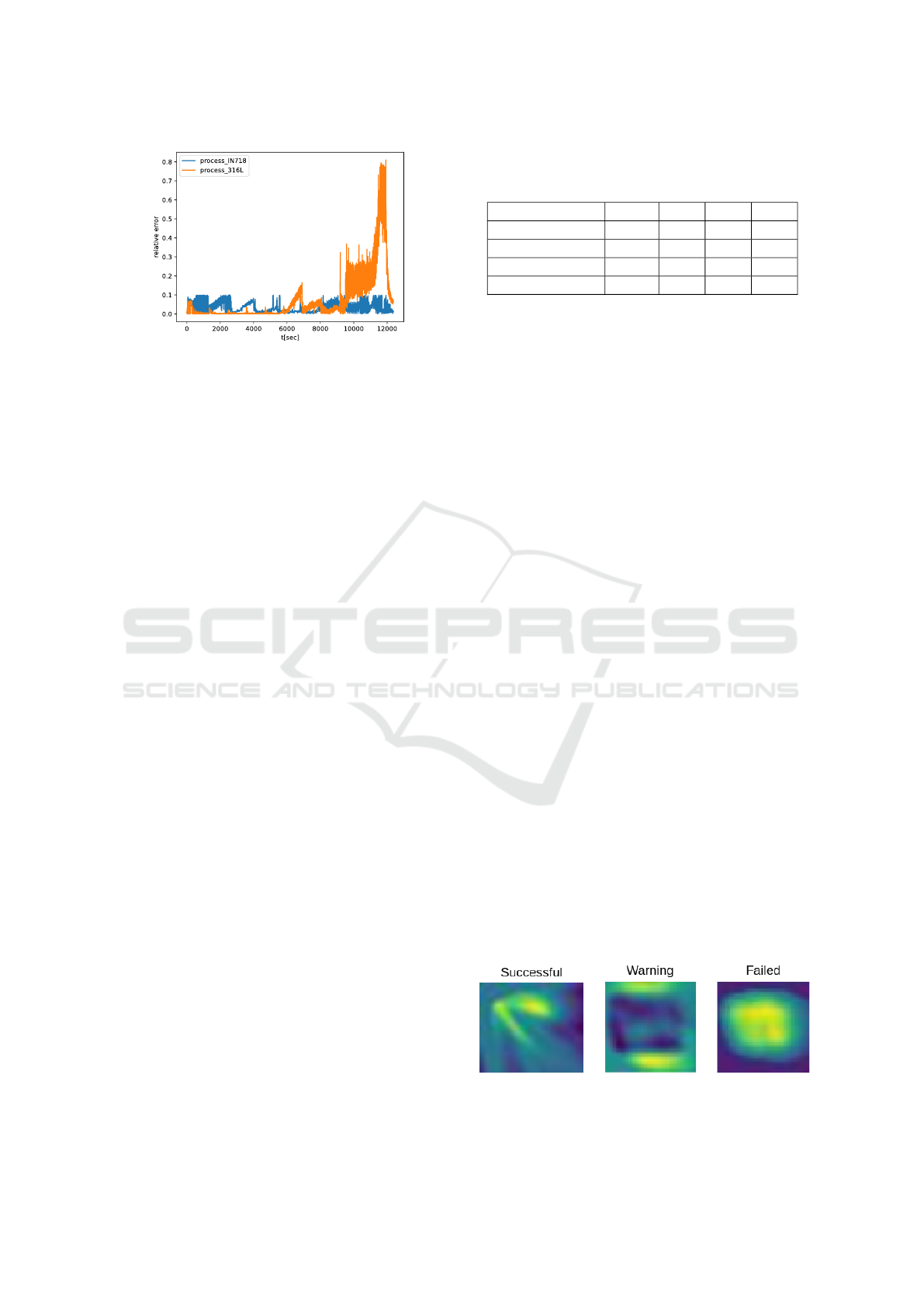

Figure 3: Error between temperature scalar field of pre-

diction and sensor data - To quantify anomalies, the rela-

tive error between prediction and sensor data is calculated

over more than three hours of printing. Irregularities can be

detected, especially in the last section of 316L.

is described analytically by a Gaussian function. A

sigmoid function was used as an activation function

in each layer and a learning rate of 10

−3

. Fig. 2

shows an example solution of a heatmap prediction

for a specific point at a time t. For the nickel-based

alloy INC718, the heatmap simulation is comparable

to the measured data of the print job. For the 316L

stainless steel, the heat simulation and the measured

data are not equivalent, significant disparities are visi-

ble. Boundary conditions are not met, and heat build-

up can be seen, affecting BP quality. These anomalies

can be quantified, as can be seen in Fig. 3. The dis-

tance between the scalar field of the temperature mea-

surement and the simulation is calculated and quanti-

fied using the relative error over a printing duration

of more than three hours. Significant differences be-

tween the simulation and the measurements can be

seen, especially in the fourth quarter.

4.2 Generated Pseudo Labels

The heatmap difference images g are matched with

the labels y to create a dataset of 37246 data pairs. As

the pyrometer-based data was recorded using a higher

sampling rate than the greyscale images, the same la-

bel y

t

has been used for a layer’s heatmap images, ac-

cording to the timestamp of the greyscale images. The

data was split into a training and test set, whereas sep-

arate layers were used in the subsets to avoid overfit-

ting. Fig. 4 shows some example images taken from

g. From the examples, it’s evident, that distinguish-

ing successful and failed layers can be a challenging

task, when considering the deviations in the simulated

and measured temperature profile. A plausible way to

interpret the data, may be that the temperature differ-

ences are generally low for successfully printed lay-

ers. In case a faulty layer or multi-layer area of the

BP is emerging, anomalous temperature spread is ris-

Table 1: Performance of different classification models -

Evaluation were done using balanced accuracy (Acc.) and

f

1

scores for successful (s), warning (w), and failed (f).

Model Acc. f

1,s

f

1,w

f

1, f

Resnet18 0.917 0.98 0.87 0.89

Resnet50 0.920 0.98 0.87 0.90

EfficientNet-B0 0.926 0.98 0.88 0.89

MobileNet-V3 0.860 0.96 0.79 0.81

ing especially at the corners of the BPs, which is the

case for the warning class. By the time a faulty layer

can even be identified by human supervision, the tem-

perature profile shows larger deviations in the area

where the BP is melted. It is, however, hard to draw a

clear border here. Thus, using self-supervised learn-

ing as a label generator and an AI-based approach to

build a classifier is a promising approach, that enables

manufacturers to create a fault prevention based on

heatmap data.

4.3 Printing Error Classifier

With the created dataset, we proceed to train a su-

pervised CNN. We use a learning rate of 5 · 10

−6

,

a weight decay of 1 · 10

−7

, and a cyclic learning

rate. We evaluated the Resnet18, Resnet50 (He

et al., 2016), EffcientNet-B0 (Tan and Le, 2019) and

MobileNet-V3 (Howard et al., 2017) architectures, to-

gether with 2D batch norm layers and Dropout of 0.1

for each convolution layer, which were pretrained to

the ImageNet dataset (Deng et al., 2009). The im-

age size was downsampled to 35 × 35 pixels, with a

batch size of 256. The cross entropy loss was used

as a cost function. We train the model until the point

of convergence, which is determined as the intersec-

tion of the training and validation loss curve. After

training the model, classification accuracy was mea-

sured using the test data and within a 5-fold cross val-

idation scenario. A maximum accuracy of 92.60%

was achieved this way by a EfficientNet-B0 (c.f. Tab.

1), which even improves earlier work of the authors

(Bauer et al., 2022). For most of the individual

classes’ f

1

scores, the EfficientNet-B0 performs best

as well, even though the residual networks achieve

comparable performance.

Figure 4: Example images - of a successful layer (left),

a layer that causes a warning (centre), and a faulty layer

(right).

ICEIS 2023 - 25th International Conference on Enterprise Information Systems

544

Further investigation indicated that most confu-

sion occurs for failed layers that have been marked as

successful. The successful layers, on the other hand,

have been classified very well. The most confusion

only occurred to the warnings, which are not critical

for practice. It should be noted that the earlier layers

recorded consist of support material, which may mis-

lead the classifier, given the fact that only few such ex-

amples are provided. Additionally, outliers in the self-

supervised labelling procedure can impose a degree of

label noise, which can’t be avoided completely. Thus,

the number of missed errors can be expected to be

lower than in Tab. 1, in practice.

In a real-world application, however, a false neg-

ative for an actually faulty layer may cause severe is-

sues within the production. The warning class serves

as a measure against missing faulty layers completely,

by smoothing the borders between successful and

failed. The high f

1,w

value (c.f. Tab. 1) indicates

that the warning class compensates most of the suc-

cessful as failed / failed as successful false positives.

This would reduce the amount of manual inspection,

as well as “false alarms” in practice.

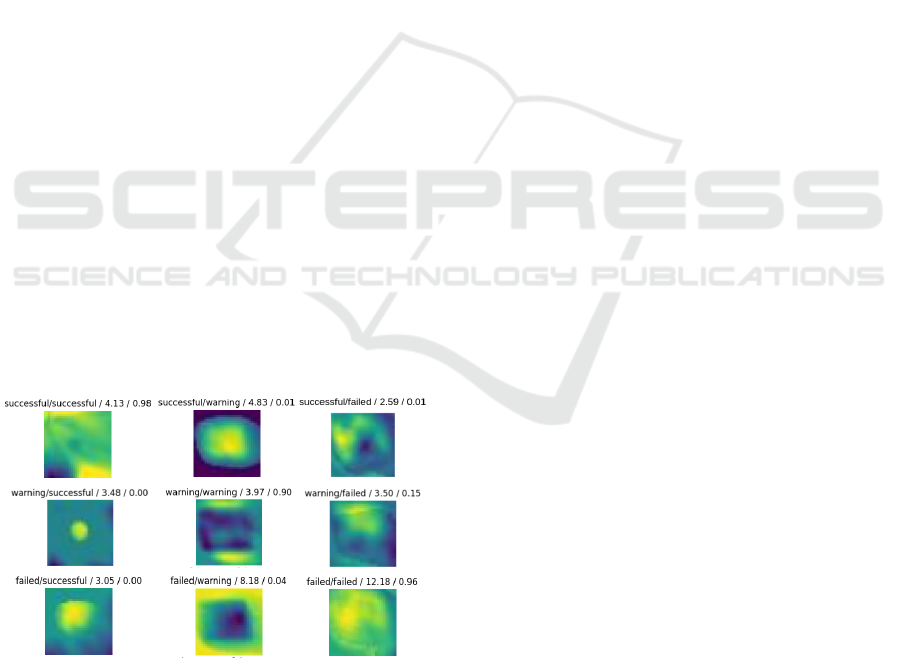

The model’s performance can be demonstrated

better, by visually investigating how certain cases

have been classified, as depicted in Fig. 5. The exam-

ple underlines the model’s capability of fine-granular

separation of different temperature profile types. For

example, the first and last image look very similar,

but show indeed a successful and failed layer. The

model successfully classifies both of them right, even

with a high probability. Confusion with the success-

ful class, as described above, often occurs during the

support layer printing. The model’s predictions thus

seem plausible.

Figure 5: Example temperature difference im-

ages – and the model’s referring prediction (ac-

tual/prediction/loss/probability) for low model loss.

5 DISCUSSION

Summarizing, it could be shown that the presented ap-

proach successfully can be used to predict a BPs cur-

rent quality, using example components. We achieve

a competitive accuracy in this task using various AI

methods. Our approach has potential to increase AM

production quality, while keeping efforts for manu-

facturers low, as only few resources are needed for

implementation.

For a more general approach, however, extensive

evaluation needs to be done on other components, es-

pecially on such with different and more complex ge-

ometries. The transferability of the approach to other

metal powder has not yet been demonstrated. Fur-

ther experiments should be conducted to determine

the limitations of the proposed approach, when the

material parameters, and thus the material behaviour

itself, change. Furthermore, the problem with the ini-

tially printed support layers has to be clarified and has

not been solved in this work so far. This will be inves-

tigated in a further approach. Possibly, the solution

can be found in an additional model trained on the

support layers. If the data quality can be improved,

especially for the greyscale images, a more detailed

analysis of the BP would be possible.

6 CONCLUSIONS AND FUTURE

WORK

In this paper, we presented an approach, to build a

simple AI-based error prevention, that combines mul-

tiple modalities of sensors. The created model can be

used to digitally clone the actual BP’s printing pro-

cedure, and to predict its current state. It therefore

serves as a first digital twin part for in-process qual-

ity assurance. We conclude that extracting relevant

information about BP quality from measured temper-

ature profiles may be difficult, but of value for var-

ious quality monitoring models. To avoid the need

for laborious annotation procedures, self-supervised

learning may be used with more comprehensive pre-

diction examples based on greyscale image data. In

the future, issues, such as the remaining failed-as-

successful classification should be investigated and

reduced, to make the model a robust variant for prac-

tical use. Besides that, different usage scenarios may

be investigated. This includes the mapping of AI and

temperature profiles using different material proper-

ties after the print. As in the presented examples, self-

supervised learning may be a good starting point here

as well. Another important aspect is the application of

such a monitoring tool as a trigger for a machine con-

Multi-Modal Artificial Intelligence in Additive Manufacturing: Combining Thermal and Camera Images for 3D-Print Quality Monitoring

545

troller. For example, errors could be minimized, if the

laser power is reduced by the time of a warning, or at

least if an error occurs. This would likely lead to an

improved BP quality and thus should be investigated.

Additionally, machine learning should be used to in-

tegrate more parts of a complete digital twin, such as

geometry optimization and material planning. Sum-

marizing, the presented approach is a vital proof of

concept for the feasibility of moving AI into practice

without too many expenses and labour time.

ACKNOWLEDGEMENTS

All results presented refer to the TWIN project

(https://websites.fraunhofer.de/TWIN), funded by the

Federal Ministry of Education and Research, Ger-

many (02K18D052).

REFERENCES

Akbari, P., Ogoke, F., Kao, N.-Y., Meidani, K., Yeh, C.-Y.,

Lee, W., and Farimani, A. B. (2022). MeltpoolNet:

Melt pool characteristic prediction in metal additive

manufacturing using machine learning. Additive Man-

ufacturing, 55:102817.

Bauer, M., Augenstein, C., Sch

¨

afer, M., and Theile, O.

(2022). Artificial intelligence in laser powder bed fu-

sion procedures – neural networks for live-detection

and forecasting of printing failures. Procedia CIRP,

107:1367–1372. Leading manufacturing systems

transformation – Proceedings of the 55th CIRP Con-

ference on Manufacturing Systems 2022.

Bel-Hadj, Y. and Weijtjens, W. (2023). Anomaly detection

in vibration signals for structural health monitoring

of an offshore wind turbine. In Rizzo, P. and Mi-

lazzo, A., editors, European Workshop on Structural

Health Monitoring, volume 270 of Lecture Notes in

Civil Engineering, pages 348–358. Springer Interna-

tional Publishing, Cham.

Cai, S., Wang, Z., Wang, S., Perdikaris, P., and Karniadakis,

G. E. (2021). Physics-informed neural networks for

heat transfer problems. Journal of Heat Transfer,

143(6).

Deng, J., Dong, W., Socher, R., Li, L.-J., Li, K., and Fei-

Fei, L. (2009). Imagenet: a large-scale hierarchi-

cal image database. In 2009 IEEE conference on com-

puter vision and pattern recognition, pages 248–255.

IEEE.

Gaikwad, A., Giera, B., Guss, G. M., Forien, J.-B.,

Matthews, M. J., and Rao, P. (2020). Heterogeneous

sensing and scientific machine learning for quality as-

surance in laser powder bed fusion – a single-track

study. Additive Manufacturing, 36:101659.

Gaikwad, A., Williams, R. J., de Winton, H., Bevans, B. D.,

Smoqi, Z., Rao, P., and Hooper, P. A. (2022). Multi

phenomena melt pool sensor data fusion for enhanced

process monitoring of laser powder bed fusion addi-

tive manufacturing. Materials & Design, 221:110919.

He, K., Zhang, X., Ren, S., and Sun, J. (2016). Deep resid-

ual learning for image recognition. In 2016 IEEE Con-

ference on Computer Vision and Pattern Recognition

(CVPR). IEEE.

Howard, A. G., Zhu, M., Chen, B., Kalenichenko, D.,

Wang, W., Weyand, T., Andreetto, M., and Adam,

H. (2017). Mobilenets: Efficient convolutional neu-

ral networks for mobile vision applications.

Knaak, C., Masseling, L., Duong, E., Abels, P., and Gill-

ner, A. (2021). Improving build quality in laser pow-

der bed fusion using high dynamic range imaging and

model-based reinforcement learning. IEEE Access,

9:55214–55231.

Kunkel, M. H., Gebhardt, A., Mpofu, K., and Kallweit, S.

(2019). Quality assurance in metal powder bed fusion

via deep-learning-based image classification. Rapid

Prototyping Journal, 26(2):259–266.

Kwon, O., Kim, H. G., Ham, M. J., Kim, W., Kim, G.-H.,

Cho, J.-H., Kim, N. I., and Kim, K. (2018). A deep

neural network for classification of melt-pool images

in metal additive manufacturing. Journal of Intelligent

Manufacturing, 31(2):375–386.

Mukherjee, T., Wei, H. L., De, A., and DebRoy, T. (2018).

Heat and fluid flow in additive manufacturing—part

i: Modeling of powder bed fusion. Computational

Materials Science, 150:304–313.

Ngairangbam, V. S., Spannowsky, M., and Takeuchi, M.

(2022). Anomaly detection in high-energy physics

using a quantum autoencoder. Physical Review D,

105(9).

Praveena, B., Lokesh, N., Abdulrajak, B., Santhosh, N.,

Praveena, B. L., and Vignesh, R. (2022). A compre-

hensive review of emerging additive manufacturing

(3d printing technology): Methods, materials, appli-

cations, challenges, trends and future potential. Mate-

rials Today: Proceedings, 52:1309–1313.

Raissi, M., Perdikaris, P., and Karniadakis, G. E. (2019).

Physics-informed neural networks: A deep learn-

ing framework for solving forward and inverse prob-

lems involving nonlinear partial differential equations.

Journal of Computational Physics, 378:686–707.

Shen, B., Lu, J., Wang, Y., Chen, D., Han, J., Zhang, Y., and

Zhao, Z. (2022). Multimodal-based weld reinforce-

ment monitoring system for wire arc additive manu-

facturing. Journal of Materials Research and Tech-

nology, 20:561–571.

Tan, M. and Le, Q. (2019). EfficientNet: Rethinking model

scaling for convolutional neural networks. In Chaud-

huri, K. and Salakhutdinov, R., editors, Proceedings of

the 36th International Conference on Machine Learn-

ing, volume 97 of Proceedings of Machine Learning

Research, pages 6105–6114. PMLR.

Zhu, Q., Liu, Z., and Yan, J. (2021). Machine learn-

ing for metal additive manufacturing: predicting tem-

perature and melt pool fluid dynamics using physics-

informed neural networks. Computational Mechanics,

67(2):619–635.

ICEIS 2023 - 25th International Conference on Enterprise Information Systems

546