Benchmarking Automated Machine Learning Methods for Price

Forecasting Applications

Horst Stühler

1 a

, Marc-André Zöller

2 b

, Dennis Klau

3 c

,

Alexandre Beiderwellen-Bedrikow

1 d

and Christian Tutschku

3 e

1

Zeppelin GmbH, Graf-Zeppelin-Platz 1, 85766 Garching, Germany

2

USU Software AG, Rüppurrer Str. 1, 76137 Karlsruhe, Germany

3

Fraunhofer IAO, Nobelstraße 12, 70569 Stuttgart, Germany

Keywords:

Construction Equipment, Price Forecasting, Machine Learning, ML, AutoML, CRISP-DM, Case Study.

Abstract:

Price forecasting for used construction equipment is a challenging task due to spatial and temporal price

fluctuations. It is thus of high interest to automate the forecasting process based on current market data. Even

though applying machine learning (ML) to these data represents a promising approach to predict the residual

value of certain tools, it is hard to implement for small and medium-sized enterprises due to their insufficient

ML expertise. To this end, we demonstrate the possibility of substituting manually created ML pipelines with

automated machine learning (AutoML) solutions, which automatically generate the underlying pipelines. We

combine AutoML methods with the domain knowledge of the companies. Based on the CRISP-DM process,

we split the manual ML pipeline into a machine learning and non-machine learning part. To take all complex

industrial requirements into account and to demonstrate the applicability of our new approach, we designed

a novel metric named method evaluation score, which incorporates the most important technical and non-

technical metrics for quality and usability. Based on this metric, we show in a case study for the industrial use

case of price forecasting, that domain knowledge combined with AutoML can weaken the dependence on ML

experts for innovative small and medium-sized enterprises which are interested in conducting such solutions.

1 INTRODUCTION

Price forecasting is crucial for companies dealing

with used assets whose price depends on availabil-

ity and demand varying spatially and over time. Es-

pecially the sector of heavy construction equipment

dealers and rental companies relies heavily on accu-

rate price predictions. Determining the current and

future residual value of their fleet allows construc-

tion equipment dealers to identify the optimal time

to resell individual pieces of machinery (Lucko et al.,

2007; Chiteri, 2018). Although several data-driven

methods have been proposed to forecast the heavy

equipment’s residual value (Lucko, 2003; Lucko and

Vorster, 2004; Fan et al., 2008; Lucko, 2011; Zong,

a

https://orcid.org/0000-0002-7638-1861

b

https://orcid.org/0000-0001-8705-9862

c

https://orcid.org/0000-0003-3618-7359

d

https://orcid.org/0000-0001-7934-8410

e

https://orcid.org/0000-0003-0401-5333

2017; Miloševi

´

c et al., 2020), price forecasting in

practice is still mainly performed manually due to

the lack of sufficiently skilled employees. Conse-

quently, it is a time-consuming and inflexible process

that highly depends on the domain expertise of the

employees. Due to these substantial time, cost, and

knowledge factors, the manual process is generally

carried out irregularly and infrequently, maybe even

fragmentary. This may lead to partially outdated or

even obsolete prices, as current market price fluctu-

ations are not taken into account (Ponnaluru et al.,

2012). To reflect current market prices while support-

ing domain experts and digitalization of price predic-

tion in general, it is desirable to automate the forecast-

ing process and update the forecastings periodically.

Using machine learning (ML) methods to calcu-

late the residual value of construction equipment has

already been tested in the past (Zong, 2017; Chiteri,

2018; Miloševi

´

c et al., 2021; Shehadeh et al., 2021;

Alshboul et al., 2021). While the results of these

studies and general developments in the field of ML

30

StÃijhler, H., ZÃ˝uller, M., Klau, D., Beiderwellen-Bedrikow, A. and Tutschku, C.

Benchmarking Automated Machine Learning Methods for Price Forecasting Applications.

DOI: 10.5220/0012051400003541

In Proceedings of the 12th International Conference on Data Science, Technology and Applications (DATA 2023) , pages 30-39

ISBN: 978-989-758-664-4; ISSN: 2184-285X

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

are very promising, a substantial portion of the ex-

isting work originates from academic institutes, tech

companies, start-ups, or large international corpora-

tions. Meanwhile, small and medium-sized enter-

prises (SMEs), while accounting for 90% of all busi-

nesses (Ardic et al., 2011), are not represented. Even

though SMEs generate large amounts of data and have

significant domain knowledge, ML applications are

less common there. One of the main challenges for

these organizations is the lack of skilled employees

with ML knowledge (Bauer et al., 2020).

As an alternative to the manual creation of ML

models, automated machine learning (AutoML) has

been proposed in the last years (Hutter et al., 2019;

Yao et al., 2018; Zöller and Huber, 2021). AutoML

aims to reduce and partially automate the necessary

manual work carried out by humans when creating

ML solutions. It has already been proven to achieve

good performance with a significantly smaller degree

of human effort and a high computational efficiency

(Yao et al., 2018). This provides a possible solution

for SMEs to the severe shortage of professionals with

in-depth ML knowledge.

To evaluate this potential solution, we conduct a

case study in the context of used machinery valua-

tion. Using the well-established Cross Industry Stan-

dard Process for Data Mining (CRISP-DM) (Shearer,

2000), we divide the different steps of creating an ML

pipeline into a non-ML and an ML part. The non-ML

part can be executed by domain experts, while for the

ML part, we examine different AutoML frameworks

and compare them with the traditional, manual de-

velopment. The case study investigates if AutoML is

a viable alternative to manual ML methods and how

domain experts can fuel the ML process. To easily

assess our approach and create a general multimodal

assessment method, we introduce the novel method

evaluation score (MES), which incorporates different

application-based metrics into one single number.

The work is structured as follows: Section 2

presents related work. Section 3 describes the idea of

splitting the ML pipeline into a data domain and ML

phase, introduces the manual ML and AutoML meth-

ods, and describes the new MES. The main findings

are presented in Section 4 followed by a conclusion.

2 RELATED WORK

2.1 Automated Price Prediction for

Used Construction Machines

Several works have been published that use ML to

calculate the residual value of construction equip-

ment. (Zong, 2017) estimates the residual value of

used articulated trucks using various regression mod-

els. Similarly, (Chiteri, 2018) analyses the residual

value of

3

⁄

4

ton trucks based on historical data from

auctions and resale transactions. (Miloševi

´

c et al.,

2021) construct an ensemble model based on a di-

verse set of regression models to predict the resid-

ual value of 500 000 construction machines advertised

in the USA. (Shehadeh et al., 2021) and (Alshboul

et al., 2021) use various regression models to predict

the residual value of six different construction equip-

ment types based on data from open-accessed auction

databases and official reporting agencies.

While the results of these studies have shown first

ML successes, creating the proposed models requires

ML expertise. Our case study focuses on the potential

of AutoML and how SMEs with limited ML expertise

can benefit from automated approaches in the field.

2.2 Automated Machine Learning

AutoML aims to improve the current way of build-

ing ML applications manually via automation. While

ML experts can increase their efficiency by automat-

ing tedious tasks like hyperparameter optimization,

domain experts can be enabled to build ML pipelines

on their own without having to rely on a data scientist.

Currently, those systems mainly focus on supervised

learning tasks, e.g., tabular regression (Zöller et al.,

2021) or image classification (Zoph and Le, 2016).

From tuning the hyperparameters of a fixed model

over automatic ML model selection up to generat-

ing complete ML pipelines from a predefined search

space, AutoML mimics the way how humans grad-

ually approach ML challenges today. Virtually all

AutoML approaches formulate the automatic cre-

ation of an ML pipeline as a black-box optimization

problem that is solved iteratively (Zöller and Huber,

2021): potential model candidates are drawn from the

underlying search space, and the performance on the

given dataset is calculated. This procedure is repeated

until the optimization budget, usually, a maximum op-

timization duration, is depleted. Often this optimiza-

tion is implemented via Bayesian optimization (Fra-

zier, 2018), which utilizes a probabilistic surrogate

model, like a Gaussian process, to predict the perfor-

mance of untested pipeline candidates and steer the

optimization to better-performing regions.

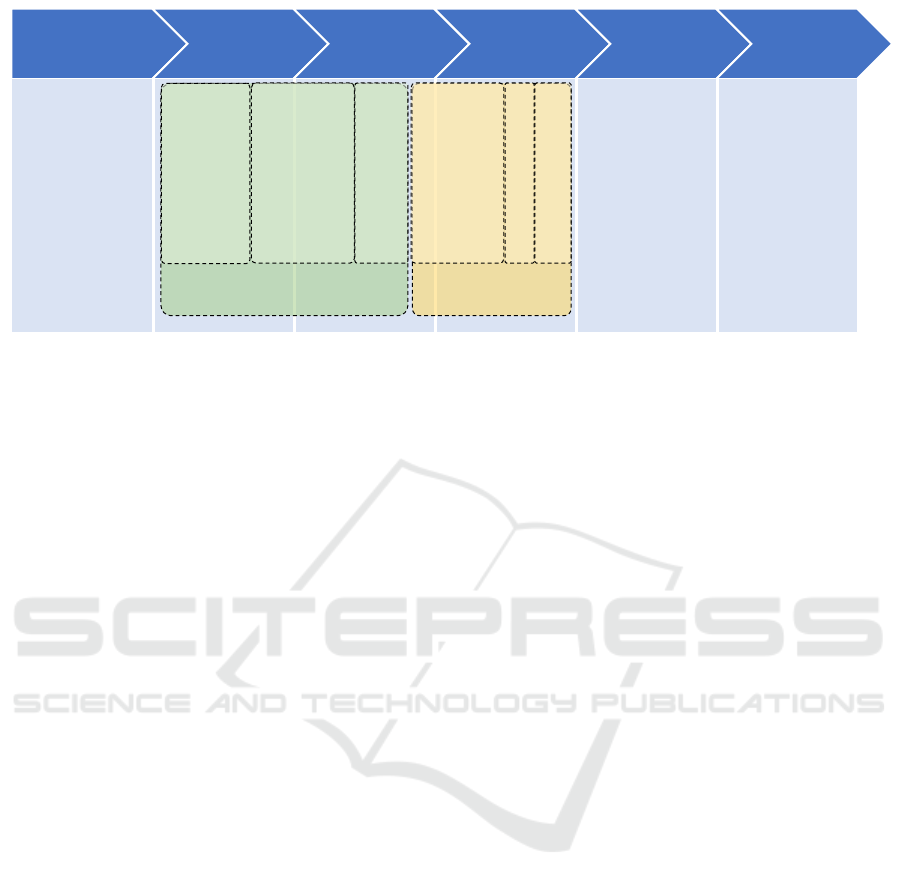

2.3 CRISP-DM

Due to its widespread dissemination and acceptance

in data-driven development, CRISP-DM is often used

in the ML context, for example, to develop quality as-

Benchmarking Automated Machine Learning Methods for Price Forecasting Applications

31

Business

Understanding

Data

Understanding

Data

Preparation

Modeling Evaluation Deployment

Determine Business Objectives

Assess Situation

Determine Data Mining Goals

Produce Project Plan

Evaluate Results

Review Process

Determine Next Steps

Plan Deployment

Plan Monitoring and Maintenance

Produce Final Report

Review Project

Data Processing Phase ML Phase

Collect Initial Data

Describe Data

Explore Data

Verify Data Quality

Select Data

Clean Data

Construct Data

Integrate Data

Format Data

Select Modeling Tech.

Generate Test Design

Build Model

Assess Model

Level 1

Level 2 Level 3

Level 4

L. 5

L. 6

Figure 1: Adaptation of the CRISP-DM process neglecting the loop from the original process for visual simplicity. The data

understanding, preparation, and modeling steps are divided into a data processing and ML phase; individual steps are further

grouped into knowledge levels. Tasks within the data processing phase require basic programming and data processing skills

and highly benefit from domain expertise. In contrast, ML expert knowledge is mandatory for the steps within the ML phase.

surance methodologies (Studer et al., 2021) or to in-

vestigate the interpretability of machine learning so-

lutions (Kolyshkina and Simoff, 2019).

According to CRISP-DM, building ML models

can be divided into six steps with associated sub-

tasks, as highlighted by the blue area in Figure 1. The

Business Understanding step investigates the business

needs, goals, and constraints to formulate a data min-

ing problem and develop a project plan. During the

Data Understanding phase, actual datasets are identi-

fied and collected. Also, a first analysis is conducted

to understand the data and assess its quality. These

datasets are further manipulated in the Data Prepa-

ration step to properly prepare them for modeling.

This includes, e.g., selecting meaningful attributes,

performing data cleaning, and integrating different

data sources. Based on this final data set, the actual

generation of the models is executed in the Model-

ing step. Different models and configurations are ex-

plored, trained, and evaluated iteratively. The Evalu-

ation step complements the CRISP-DM loop by veri-

fying whether the goals defined in the business under-

standing step have been achieved. If the requirements

are satisfied, next steps are discussed in the Deploy-

ment phase to deploy the models to production.

3 METHODOLOGY

3.1 Knowledge Bottleneck and Potential

for Automation

CRISP-DM requires various roles—namely business

analyst, data scientist, big data developer, and busi-

ness owner (De Mauro et al., 2018)—to conduct a

project. Yet, the role of a data scientist, which covers

most of the data understanding, data preparation, and

modeling steps of the CRISP-DM process, is often not

filled in SMEs. To give a clear separation between

tasks that can be performed by domain experts and

tasks for which ML expertise is needed, we divided

these steps, including their associated sub-tasks, into

a Data Processing Phase and an ML Phase, as high-

lighted in Figure 1. Furthermore, the tasks in the two

phases can be assigned ML knowledge levels that are

required to perform them. A higher level corresponds

to more required expertise. We propose the following

knowledge levels for the data processing phase:

Level 1. Collect, describe and explore data: The

users can collect and store business data. They

understand the data and can explore it.

Level 2. Verify, select and clean the data: The users

understand the implications of data distributions,

outliers, and missing values.

Level 3. Construct and integrate data: The user can

construct new features out of existing data, which

are potentially meaningful for the expressiveness

of the dataset.

In contrast, the ML phase requires knowledge lev-

els with a profound ML expertise:

Level 4. Format data, select a model and generate

test design: The user knows how to prepare the

data for ML methods, knows the difference be-

tween problem classes like classification and re-

gression, and can use established ML libraries.

Level 5. Model assessment: The user knows the

functionality and meaning of different models

DATA 2023 - 12th International Conference on Data Science, Technology and Applications

32

and can assess the impact of their hyperparam-

eters. They must also have an understanding of

the different performance metrics in regard to the

dataset.

Level 6. Model creation: The user has a deep ML un-

derstanding, can create new models from scratch,

and can optimize them via different search algo-

rithms like grid or random search (Bergstra and

Bengio, 2012).

After splitting the ML pipeline into an ML and a

non-ML phase, we analyze how AutoML can replace

the manual labor in the ML phase. This may enable

data domain experts to use ML techniques and, con-

sequently, speed up the development of ML solutions

within the organization significantly. AutoML is sup-

posed to handle as many of the more sophisticated

knowledge levels as possible. Therefore, in the next

sections, we explain the individual steps in more de-

tail in the context of the residual value case study.

3.2 Data Processing Phase

Collect, Describe & Explore Data. The initial data

was obtained by regularly collecting all advertise-

ments from seven major construction equipment mar-

ket portals

1

over a time period of seven months. In

total, 11 606 162 entries from different manufacturers

have been collected. The collected features, selected

by data domain experts a priori, are shown in Table 1.

Verify Data Quality. A drawback of collecting data

automatically by web-scraping is the resulting dataset

quality. Regular collection of advertisements from

web portals leads to duplicated data points, as the

same construction machine can be offered on differ-

ent platforms and for longer periods. Furthermore, the

quality and completeness of the dataset depend on the

input of the portal users, which may lead to incorrect

or missing attributes. Outliers were primarily present

Table 1: Collected dataset features with types and examples.

Feature Type Example

Brand Categorical Caterpillar

Model Categorical M318

Series Categorical E

Construction year Numerical 2018

Working hours Numerical 8536

Location Categorical Germany

Price Numerical 59.000 C

1

The market portals are Mascus, Catused, Mobile, Ma-

chineryLine, TradeMachines, Truck1, and Truckscout24.

0 2 4 6 8 10

Working hours

10

4

0

2

4

6

8

10

Price in Euros

10

5

Data points

Outliers

Figure 2: Working hours versus price where detected out-

liers are highlighted.

in the attributes working hours and price, as displayed

in Figure 2.

Select & Clean Data. Duplicate entries are elimi-

nated by an iterative comparison of different feature

combinations. In the Working hours feature, outliers

were identified through reviews by the respective do-

main experts, considering the average number of op-

erating hours for the given model and year of manu-

facture. For instance, some machines were advertised

with operating hours much larger than their expected

lifetime. For outliers regarding the price feature, the

main source of noise was traced back to a missing cur-

rency conversion for one of the biggest dealers from

Poland. These outliers were detected by a plausibility

check—namely, removing values outside a 99% con-

fidence interval—considering the working hours and

price. Errors in the series attribute are also mainly

caused by incorrect inputs by the selling dealer. If the

underlying reason for errors or outliers could not be

determined, the sample was dropped.

Dealing with missing values depends on the at-

tribute. Samples are dropped if a value of the fea-

tures model, construction year, or location is miss-

ing. Missing values for the working hours attribute

will be substituted via stochastic regression imputa-

tion (Newman, 2014). Values for the series attribute

are optional. The entries for brand and price are

mandatory on all portals for creating advertisements.

Construct & Integrate Data. Finally, to ensure

sufficient data for each construction machine model,

only model types with more than 150 samples were

added to the dataset, resulting in 10 different machine

models and 2910 samples in total. As all remaining

machine models are manufactured by Caterpillar, the

brand feature, depicted in Table 1 is thus obsolete. An

Benchmarking Automated Machine Learning Methods for Price Forecasting Applications

33

Table 2: Excerpt of the final dataset.

Brand Model Series Construction year Working hours Location Price

Caterpillar 308 D 2010 4865 BE 38500

Caterpillar D6 T 2016 11851 NL 112000

Caterpillar 330 F 2015 4741 CH 126056

Caterpillar M318 F 2016 8920 PL 99000

Caterpillar 966 K 2012 10137 FR 82000

excerpt of the resulting dataset is shown in Table 2. To

also account for and investigate the impact of single

features, data subsets with individual feature combi-

nations are created. The subset consisting of the ma-

chine model, working hours, and construction year is

used as the baseline feature set (subsequently referred

to as basic subset). In addition, this basic subset was

extended by the series and/or location feature, result-

ing in four data sets.

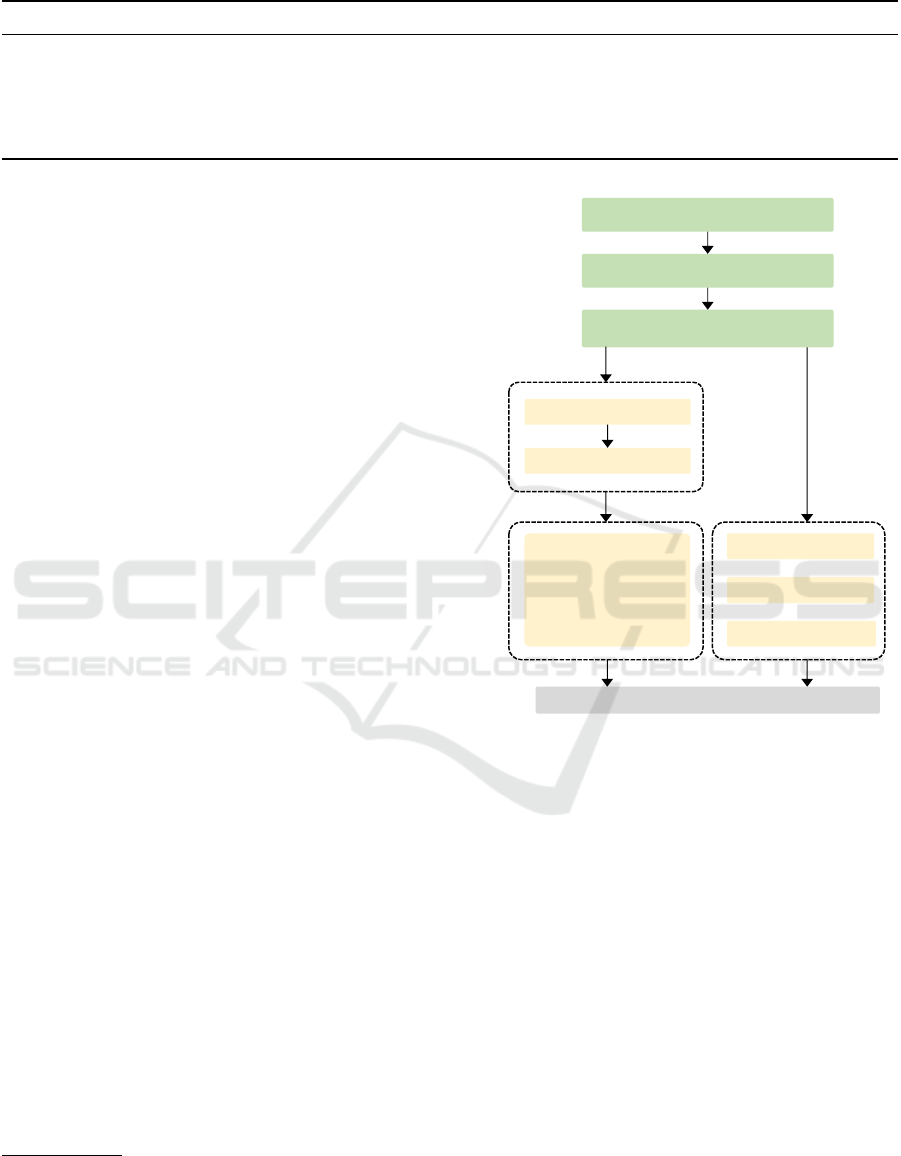

3.3 ML Phase

As we want to test whether AutoML can be a po-

tential substitution for manual ML, we describe the

manually implemented pipeline and selected AutoML

frameworks in more detail below. An overview of the

whole ML pipeline for the case study is depicted in

Figure 3 and the source code is available on Github

2

.

3.3.1 Manual ML

The manually created pipeline closely resembles a

best-practice pipeline (Géron, 2022). All features are

pre-processed using one-hot encoding for categori-

cal features and standard scaling for numerical fea-

tures. Next, seven different state-of-the-art and well-

established ML methods are used for predicting the

residual values:

• Polynomial Regression

• Tree-based regression: decision tree, random for-

est (RF) & adaptive boosting (AdaBoost)

• Kernel-based regression: support vector regres-

sion (SVR) & k-nearest neighbors (kNN)

• Deep learning: multi-layer perceptron (MLP)

For each of those methods, selected hyperparameters

are tuned via random search

3

. For more information

on those ML methods, we refer the interested reader

to (Géron, 2022).

2

See https://tinyurl.com/4wt2hp2y.

3

The list of hyperparameters is available within the on-

line source code.

Clear dataset of duplicates

Remove outliers

Generate dataset with different

feature combinations

One-hot encoding

Standard scaling

auto-sklearn

FLAML

manual ML:

Polyn. Regression,

Decision Trees, RF,

AdaBoost, SVR,

kNN, MLP

AutoGluon

Evaluate models and document results

for each feature combination

Format Data

Train Models

Figure 3: The case study pipeline illustrates the steps of the

data processing phase in green and the ML phase in yellow.

One-hot encoding and standard scaling are only applied to

the manually implemented ML methods.

3.3.2 Automated ML

The manual approach is compared with the three

open-source AutoML frameworks AutoGluon (Erick-

son et al., 2020), auto-sklearn (Feurer et al., 2020),

and FLAML (Wang et al., 2022). We chose those

AutoML frameworks as they are 1. simple to use,

2. well documented, 3. easy to integrate, 4. have

achieved good performances in the past (Gijsbers

et al., 2019), and 5. have a broad user base and,

therefore, good support. To ensure a fair compari-

son, we restricted the selection of algorithms to the

ones with implementation in the same underlying ML

library, namely scikit-learn (Pedregosa et al., 2011),

and omitted, for example, Neural Network Intelli-

gence (NNI) (Microsoft, 2021) as it uses additional

frameworks, e.g., PyTorch (Paszke et al., 2019).

DATA 2023 - 12th International Conference on Data Science, Technology and Applications

34

The selected frameworks promise an end-to-end

creation of ML pipelines, including all necessary pre-

processing steps, for tabular regression tasks. Conse-

quently, data is not manually pre-processed.

3.4 Criteria

To determine the relative performance of the models,

we define a novel benchmarking scheme. In literature

and practice, a multitude of commonly used evalu-

ation criteria—such as mean absolute error (MAE),

root mean squared error (RMSE), and mean abso-

lute percentage error (MAPE)—are well known and

widely adopted to assess the performance of an ML

regressor. To account for industrial requirements,

these technical metrics have to be complemented by

further non-technical ones. Consequently, multiple

factors have to be integrated into the algorithm selec-

tion process. Following (Ali et al., 2017), we define

quality metrics with application-based meanings that

domain experts can understand:

Correctness (s

corr

) measures the predictive power of

an ML model. This corresponds to typical metrics

used in supervised learning. In the context of this

work, the MAPE

MAPE =

1

n

n

∑

i=1

|y

i

− ˆy

i

|

|y

i

|

is used to calculate the performance, with y

i

be-

ing the true value, ˆy

i

the predicted value and n the

number of samples.

Complexity (s

comp

) measures the training complex-

ity of an ML model. In this work, we use the CPU

wall-clock time as a proxy for this metric.

Responsiveness (s

resp

) measures the inference time

of an ML model by determining the CPU wall-

clock time required to create a single prediction.

This aspect may be especially important for inter-

active and real-time systems. Following (Nielsen,

1993), runtimes are mapped into a real-time (un-

der 0.1 seconds), fast (under 1 second), and slow

(above 1 second) category.

Expertise (s

exp

) measures the knowledge level, as in-

troduced in Section 3.1, required to be able to cre-

ate the according ML solutions in the first place.

Reproducibility (s

repr

) measures the stability of the

ML model regarding the other criteria by deter-

mining the standard deviation if retrained on the

exact same data again.

These criteria are combined into a novel score to

create a ranked list of ML models. It is, therefore,

mandatory to normalize all criteria values to [0, 1] us-

ing min-max scaling. Furthermore, the actual met-

rics in each criterion have to be compatible with each

other by having identical optimization directions; in

our case smaller values being better. Preferences re-

garding the weighting of individual criteria should be

incorporated into the final score. This can be done

by assigning weights w

c

to each criterion leading to

the final method evaluation score (MES) using the

weighted average

MES =

∑

c∈C

w

c

˜s

c

∑

c∈C

w

c

(1)

with C = {corr, comp, resp, exp, repr} and ˜s

c

being the

normalized values. By design, the MES is bound to

[0, 1], where zero indicates a perfect and one the worst

performance with regard to all individual metrics. To

ensure reliable results and make the calculation of re-

producibility even possible, models need to be fitted

multiple times.

4 RESULTS

This section presents the results of the experiments.

For a better overview, we only present the two best

(in terms of correctness) ML models, RF and MLP,

out of the seven examined manual methods and use

them as a baseline for comparison against the investi-

gated AutoML frameworks. All measurements were

performed on a Ubuntu Linux 20.04.5 LTS system

with 32 GB RAM and an Intel i7-4790 Processor. We

conducted five independent measurements with fixed

90% / 10% holdout training/test split.

4.1 Correctness

The correctness, in form of the MAPE, of the differ-

ent approaches is depicted in Figure 4. AutoGluon

delivers the best results for all feature combinations.

For the rest of the methods, there is no clear trend

or order. Thus, concerning the prediction quality, the

AutoML methods are comparable to or even better

than the manual ML methods. The best results with

respect to minimal predictive error for all methods are

achieved with the entire feature set.

4.2 Expertise

Implementing and tuning the seven manual ML meth-

ods presumes expertise of level 5 and requires ap-

proximately 50 lines of code (LOC) on average. The

manual approaches must be implemented and config-

ured by hand and require a profound understanding

Benchmarking Automated Machine Learning Methods for Price Forecasting Applications

35

Figure 4: Correctness, in form of MAPE. Diamonds depict the average results over 5 repetitions. Single measurements are

displayed as dots. Due to low variance, single measurements are often not visible. For better visibility, only the winning RF

method is shown for the set of the manual ML methods.

of the different ML libraries, their functionalities, and

when and how to use them. On the other hand, train-

ing and predicting using AutoGluon, auto-sklearn, or

FLAML can be implemented within 5 LOC and with-

out any ML expertise. This demonstrates that ba-

sic programming knowledge is sufficient to use the

AutoML frameworks. Yet, generating and storing the

data is still necessary (knowledge level 1). The same

holds true for verifying and cleaning the data (knowl-

edge level 2). Thus, the knowledge demands for the

AutoML methods, with level 2, and the manual ML

methods, with level 5, are quite different, with a clear

advantage for the AutoML methods.

4.3 Responsiveness

Responsiveness is measured as the average prediction

time over all samples. Predictions of a single sample

are always in a millisecond range. Consequently, all

methods fall in the real-time application category.

4.4 Complexity

The results for the method complexity, in terms of

training duration, are depicted in Figure 5. Auto-

Gluon has the lowest training time with about 15 sec-

onds, being much better than RF coming in second

place. In contrast to all other analyzed methods, Au-

toGluon does not search for an optimized model but

trains only a single predefined ensemble. FLAML

and auto-sklearn fully utilize the specified training

budget of 1800 seconds, whereas the manual ML

methods are controlled by an iteration number and not

by a time limit. The detailed algorithmic analysis of

these findings is further analyzed in a follow-up work.

4.5 Reproducibility

As the values of the expertise (s

exp

) and responsive-

ness (s

resp

) are categorical measurements, we did not

observe any variance making these criteria unsuited.

Both correctness (s

corr

) and complexity (s

comp

) ex-

pressed usable variance. In the context of this work,

we decided to use correctness as the basis for repro-

ducibility (s

repr

). A variance of performance can be

Table 3: MES with unnormalized underlying criteria for all methods on the complete feature set. Smaller values are better.

The best results are highlighted in bold. The observed differences in the results for each criterion were significant according

to a Student’s t-test with α = 0.05. Reproducability, defined as the standard deviation of Correctness, is not depicted as its

own column. Results marked by * did produce constant results.

Method Correctness [MAPE] Complexity [sec.] Expertise Responsiveness MES

MLP 0.1570±0.0049 2308.1±354.70 5 real-time 0.977±0.0130

RF 0.1482±0.0009 1067.6±29.93 5 real-time 0.896±0.0138

auto-sklearn 0.1506 * 1806.1±3.52 2 real-time 0.696±0.0160

AutoGluon 0.1389 * 14.2±0.17 2 real-time 0.583±0.0101

FLAML 0.1646 ± 0.0042 1801.5 ± 0.71 2 real-time 0.738 ± 0.0108

DATA 2023 - 12th International Conference on Data Science, Technology and Applications

36

Figure 5: Model complexity, in terms of training duration, for all feature set combinations. The AutoML frameworks are

configured to optimize for 1800 seconds. Diamonds depict average results over 5 repetitions. Single measurements are

displayed as dots. Due to low variance, single measurements are often not visible. For better visibility, only the winning RF

method is shown for the set of the manual ML methods.

observed for FLAML, RF, and MLP, while both auto-

sklearn and AutoGluon produced constant results.

4.6 Method Evaluation Score

We determined the values of the weighting factors for

individual criteria by surveying six domain experts,

averaging the results, and rounding them to the near-

est tens for simplicity. In our case, w

corr

= 50, w

exp

=

40 and w

comp

= 10. While in general, all criteria are

important, w

resp

and w

repr

are set to 0 for the con-

sidered use case because they were deemed unimpor-

tant by the domain experts. The MESs, as defined in

Equation (1), are calculated for each method/feature

combination and depicted in Figure 6. For the fea-

ture subset with the lowest overall MES, the individ-

Figure 6: Method evaluation score for each method and sub-

set combination. Smaller values are better.

ual criteria scores and the final MESs are depicted in

Table 3. The winning method/subset combination is

AutoGluon and the complete subset, with an MES of

0.583. The MES drastically simplifies the methods’

comparability and shows that AutoGluon is perform-

ing best for the given data set and weighting factors.

Based on these findings, AutoML seems to be a good

alternative for this use case.

5 CONCLUSION

This work analyzed the potential of AutoML methods

and their usability for SMEs with limited ML exper-

tise. In our case study, predicting the residual value

of used heavy construction equipment, all evaluated

AutoML methods were shown to outperform man-

ually created ML pipelines regarding the newly in-

troduced method evaluation score (MES), see Equa-

tion (1). Furthermore, they are applicable with only

domain knowledge and basic data processing skills.

We, therefore, showed that separating the data under-

standing, data preparation, and modeling steps of the

CRISP-DM process into a data domain and an ML

part enables companies with limited ML expertise to

tackle ML projects by using AutoML methods. We

introduced ML expertise levels and used the MES to

enable an easy assessment of the different ML and

AutoML methods.

To transfer the results identified in this case study

to other use cases, a qualification of domain experts

for at least knowledge level 2 is necessary. In sum-

mary, the evaluation of the models created by Auto-

Gluon was deemed favorable. The predictions were

Benchmarking Automated Machine Learning Methods for Price Forecasting Applications

37

validated by the domain experts as valid and reli-

able. Consequently, the deployment phase in the

CRISP-DM process can be planned and implemented.

It has to be mentioned that we only examined a

limited number of ML and AutoML methods on four

variations of a single data set, so that general state-

ments are therefore limited by our choice of methods.

In the evaluated use case AutoML was able to pro-

vide results with a good performance, yet it still may

not be applicable for some use cases. AutoML tools

may create models with low predictive power or even

fail to generate a model at all. To resolve some of

these issues, knowledge of ML could be necessary,

which users with knowledge level three or lower do

not have.

In the future, we plan to examine the differences

between the AutoML methods in more detail and ex-

tend their usability for SMEs by adding additional

preprocessing steps like data splitting. In addition to

the MES, we aim to develop a data-centric explana-

tion of the final results to provide more insights for

domain experts. This is intended to explain the model

behavior via the dataset and should enable the domain

experts to validate the quality and reliability of the re-

sults based on the data used to train the models. These

data-centric explanations are crucial in order to gen-

erate confidence in the results and increase the will-

ingness of domain experts to use AutoML methods.

ACKNOWLEDGEMENTS

This work was partly funded by the German Federal

Ministry of Economic Affairs and Climate Action in

the research project AutoQML.

REFERENCES

Ali, R., Lee, S., and Chung, T. C. (2017). Accurate

multi-criteria decision making methodology for rec-

ommending machine learning algorithm. Expert Sys-

tems with Applications, 71:257–278.

Alshboul, O., Shehadeh, A., Al-Kasasbeh, M., Al Mam-

look, R. E., Halalsheh, N., and Alkasasbeh, M. (2021).

Deep and machine learning approaches for forecasting

the residual value of heavy construction equipment:

a management decision support model. Engineering,

Construction and Architectural Management.

Ardic, O. P., Mylenko, N., and Saltane, V. (2011). Small and

medium enterprises: A cross-country analysis with a

new data.

Bauer, M., van Dinther, C., and Kiefer, D. (2020). Machine

learning in sme: an empirical study on enablers and

success factors. AIS Electronic Library (AISeL).

Bergstra, J. and Bengio, Y. (2012). Random search for

hyper-parameter optimization. JMLR, 13:281–305.

Chiteri, M. (2018). Cash-flow and residual value analysis

for construction equipment. Master’s thesis, Univer-

sity of Alberta.

De Mauro, A., Greco, M., Grimaldi, M., and Ritala, P.

(2018). Human resources for big data professions: A

systematic classification of job roles and required skill

sets. Information Processing & Management, 54(5).

Erickson, N., Mueller, J., Shirkov, A., Zhang, H., Larroy,

P., Li, M., and Smola, A. (2020). Autogluon-tabular:

Robust and accurate automl for structured data. arXiv

preprint arXiv:2003.06505.

Fan, H., AbouRizk, S., Kim, H., and Zaïane, O. (2008).

Assessing residual value of heavy construction equip-

ment using predictive data mining model. Journal of

Computing in Civil Engineering, 22(3):181–191.

Feurer, M., Eggensperger, K., Falkner, S., Lindauer, M.,

and Hutter, F. (2020). Auto-sklearn 2.0: Hands-

free automl via meta-learning. arXiv preprint

arXiv:2007.04074.

Frazier, P. I. (2018). A tutorial on bayesian optimization.

arXiv preprint arXiv: 1807.02811, pages 1–22.

Géron, A. (2022). Hands-on machine learning with Scikit-

Learn, Keras, and TensorFlow. " O’Reilly Media".

Gijsbers, P., LeDell, E., Thomas, J., Poirier, S., Bischl, B.,

and Vanschoren, J. (2019). An open source automl

benchmark. arXiv preprint arXiv:1907.00909.

Hutter, F., Kotthoff, L., and Vanschoren, J. (2019). Au-

tomated machine learning: methods, systems, chal-

lenges. Springer Nature.

Kolyshkina, I. and Simoff, S. (2019). Interpretability of

machine learning solutions in industrial decision engi-

neering. In Australasian Conference on Data Mining.

Lucko, G. (2003). A statistical analysis and model of the

residual value of different types of heavy construction

equipment. PhD thesis, Virginia Tech.

Lucko, G. (2011). Modeling the residual market value of

construction equipment under changed economic con-

ditions. JCEMD4, 137(10):806–816.

Lucko, G. and Vorster, M. C. (2004). Predicting the residual

value of heavy construction equipment. In Towards a

vision for information technology in civil engineering.

American Society of Civil Engineers.

Lucko, G., Vorster, M. C., and Anderson-Cook, C. M.

(2007). Unknown element of owning costs - impact

of residual value. JCEMD4, 133(1).

Microsoft (2021). Neural Network Intelligence.

Miloševi

´

c, I., Kova

ˇ

cevi

´

c, M., and Petronijevi

´

c, P. (2021).

Estimating residual value of heavy construction equip-

ment using ensemble learning. JCEMD4, 147(7).

Miloševi

´

c, I., Petronijevi

´

c, P., and Arizanovi

´

c, D. (2020).

Determination of residual value of construction

machinery based on machine age. Gra

¯

devinar,

72(01.):45–55.

Newman, D. A. (2014). Missing data: Five practical guide-

lines. Organizational Research Methods, 17(4).

Nielsen, J. (1993). Usability Heuristics, chapter 5.5 Feed-

back. Morgan Kaufmann.

DATA 2023 - 12th International Conference on Data Science, Technology and Applications

38

Paszke, A., Gross, S., Massa, F., Lerer, A., Google, J. B.,

Chanan, G., Killeen, T., Lin, Z., Gimelshein, N.,

Antiga, L., Desmaison, A., Xamla, A. K., Yang, E.,

Devito, Z., Nabla, M. R., Tejani, A., Chilamkurthy, S.,

Ai, Q., Steiner, B., Facebook, L. F., Facebook, J. B.,

and Chintala, S. (2019). Pytorch: An imperative style,

high-performance deep learning library. In Advances

in Neural Information Processing Systems 32, pages

8024–8035.

Pedregosa, F., Varoquaux, G., Gramfort, A., Michel, V.,

Thirion, B., Grisel, O., Blondel, M., Prettenhofer, P.,

Weiss, R., Dubourg, V., Vanderplas, J., Passos, A.,

Cournapeau, D., Brucher, M., Perrot, M., and Duch-

esnay, E. (2011). Scikit-learn: Machine learning in

python. JLMR, 12:2825–2830.

Ponnaluru, S. S., Marsh, T. L., and Brady, M. (2012). Spa-

tial price analysis of used construction equipment:

The case of excavators. Construction Management

and Economics, 30(11):981–994.

Shearer, C. (2000). The crisp-dm model: the new blueprint

for data mining. Journal of data warehousing, 5(4).

Shehadeh, A., Alshboul, O., Al Mamlook, R. E., and Hame-

dat, O. (2021). Machine learning models for predict-

ing the residual value of heavy construction equip-

ment: An evaluation of modified decision tree, light-

gbm, and xgboost regression. Automation in Con-

struction, 129:103827.

Studer, S., Bui, T. B., Drescher, C., Hanuschkin, A., Win-

kler, L., Peters, S., and Müller, K.-R. (2021). Towards

crisp-ml (q): a machine learning process model with

quality assurance methodology. Machine Learning

and Knowledge Extraction, 3(2):392–413.

Wang, C., Wu, Q., Liu, X., and Quintanilla, L. (2022). Au-

tomated machine learning & tuning with flaml. In

Proceedings of the 28th ACM SIGKDD Conference on

Knowledge Discovery and Data Mining.

Yao, Q., Wang, M., Chen, Y., Dai, W., Li, Y.-F., Tu, W.-

W., Yang, Q., and Yu, Y. (2018). Taking human out

of learning applications: A survey on automated ma-

chine learning. arXiv preprint arXiv:1810.13306.

Zöller, M.-A., Nguyen, T.-D., and Huber, M. F. (2021).

Incremental search space construction for machine

learning pipeline synthesis. In Advances in Intelligent

Data Analysis XIX.

Zong, Y. (2017). Maintenance cost and residual value pre-

diction of heavy construction equipment. Master’s

thesis, University of Alberta.

Zoph, B. and Le, Q. V. (2016). Neural architecture

search with reinforcement learning. arXiv preprint

arXiv:1611.01578.

Zöller, M.-A. and Huber, M. F. (2021). Benchmark and sur-

vey of automated machine learning frameworks. Jour-

nal of Artificial Intelligence Research, 70:409–472.

Benchmarking Automated Machine Learning Methods for Price Forecasting Applications

39