Production Quality Control Analysis

in Battery Product Quality Improvement Efforts

Sajiyo, Jaka Purnama, Siti Mundari,

,

Hery Murnawan and Elvia Defitriana

Industrial Engineering, University of 17 August 1945, Surabaya, Indonesia

1412000189@srel.untag-sby.ac.id

Keywords: Quality, Control, Repair, Batteries.

Abstract: Product quality improvement is carried out continuously to reduce defective products. Many factors affect the

quality of battery products not in accordance with the desired planning in the production department. Quality

control is used to measure the requirements that must be met in forming product specifications according to

actual standards. The process of controlling the quality of battery products is used to measure the quality

characteristics of the products produced and compare them with the specifications or product quality

requirements set by the company, as well as to analyse the quality of the products produced using statistical

methods. Analysis of product quality control is able to improve quality improvement. Data patterns from

statistical methods show patterns that can be used as a basis for determining battery product standards. Based

on the analysis of the data on the factors that affect the cause of product defects, the machine factor has a

probability of 66.25%, the human factor has a probability of 27.50%, the material factor has a probability of

3.75% and the method factor has a probability of 2.25%. Improvements in battery product quality control that

need to be prioritized are machine and human factors.

1 INTRODUCTION

PT. TBA is a company engaged in the manufacturing

industry that produces battery products. These battery

products can be used for industrial and motor vehicle

purposes. Battery production activities are carried out

on Jl. Raya Trosobo Krian-Sidoarjo. Production

results are used to meet local and international

markets in the form of exports to several countries.

After the end of the Covid 19 pandemic, orders for

battery products have increased.

Increasing orders from several countries has

forced companies to increase battery production, K.

Turcheniuk, (2021). In fulfilling the demand for

ordering battery products, the company added a lot of

new workers. Most of the new workers do not have

good skills in the field of battery production so that

many reject (defective) products are found.

According to Kampker, (2012), the product quality

control section pays little attention to the

specifications required for the product. According to

product standardization that is not going well, the

product that has been sent to the customer must be

returned to the company and must be re-processed.

According to Rahul Panat, VD (2014), the re-

production process makes product prices cheaper and

has an impact on reducing profits that will be received

by the company.

PT. TBA is a company that manufactures

batteries. Starting in 2022 the export market will

increase, but many buyers complain, because the

product quality is not as expected. From the

observation results it is known that the data on

production defects shows a positive trend (tends to

increase).

Analysis of production quality control is carried

out by companies in an effort to improve the quality

of battery products, Pearn WL, Shu MH, Hsu BM,

(2005) . The factors that influence the rejected

product are carried out to improve production results.

Factors that affect production in producing defective

products include humans, machines, methods,

materials and the environment. The company

conducts analysis and looks for the root causes of the

increase in the number of defective products, so that

in the coming year it is expected that sales can be

increased. According to M. Duquesnoy, (2021), that

presumption was that before carrying out the analysis,

an evaluation was carried out that the main cause of

product defects was due to equipment that needed to

Sajiyo, ., Purnama, J., Mundari, S., Murnawan, H. and Defitriana, E.

Production Quality Control Analysis in Battery Product Quality Improvement Efforts.

DOI: 10.5220/0012101900003680

In Proceedings of the 4th International Conference on Advanced Engineering and Technology (ICATECH 2023), pages 285-291

ISBN: 978-989-758-663-7; ISSN: 2975-948X

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

285

be repaired, a large number of new workers, and work

methods that were not yet well standardized. The

company seeks to find out the main causes of

defective products by using the cause and effect

diagram method.

Based on the problems that occurred in the

company, it shows that the increase in the production

time period experienced an increase in rejects that

occurred even though it was still within control limits.

Many factors that affect the cause of product defects

when carrying out production activities have not been

identified in detail. The company is trying to take

action to reduce the number of rejected products

which continues to increase. The company strives to

be able to fulfil all product requests according to

consumer needs.

The company continuously improves the quality

of battery products according to the set targets, K o

lmel A , (2014) . Many problems occur in improving

product quality in accordance with consumer

expectations. The research objectives to be achieved

are to analyze rejects that occur even though they are

still within control limits, find out the factors that

cause defective products, and improve production

activities in an effort to reduce the number of rejects.

2 RESEARCH METHODS

2.1 Quality

Quality is basically conformity to requirements or

requests, suitability for use, continuous improvement

or improvement, and something that can satisfy

customers. Many also define that quality is the totality

of features and characteristics of a product or service

that has the ability to satisfy needs, either stated

explicitly or impliedly. The term requirements are

defined as the specifications stated in the contract as

well as the criteria that must be defined beforehand.

Quality also means fitness for use. Quality is anything

that fulfills a want or satisfies a customer's need.

According to Goodenough J.B., Kim Y., (2009),

quality is conformity with market or consumer needs.

A quality company is a company that controls market

share because its production results are in accordance

with consumer needs, resulting in consumer

satisfaction. If consumers are satisfied, they will be

loyal in buying the company's products in the form of

goods or services.

Product quality needs to pay attention to the

production process, to guarantee the resulting product

is free from defects. According to J. Schmitt et.al.,

(2014) , there are several dimensions of quality as

follows: (a) Performance is the suitability of the

product with the main function, (b) Features are

product characteristics, (c) Reliability is customer

trust in the product, ( d) Conformance is the

suitability of the product with certain requirements or

sizes, (e) Durability is the level of product durability

or product longevity, (f) Servicebility is the ease of

the product to be repaired, (g) Aesthetics is the beauty

or attractiveness of the product, (h) Perception is

consumer fanaticism or product reputation

2.2 Factors Affecting Quality

According to Suyadi (2002: 16) product quality is

determined by several factors, including: (a) Design,

(b) Raw materials, (c) Manufacturing methods or

processes, (d) Shipping and packaging methods, (e)

Technological developments and service method.

The various levels of quality standard control must

conform to the planned quality standard. According

to Suyadi (2002: 7) product quality standards can be

determined as follows: (a) raw material quality

standards, (b) process quality standards, (c) semi-

finished goods quality standards, (d) finished goods

quality standards, and (e ) Standard administration,

packing, and product delivery.

The objectives of quality control in general are (a)

The final product has specifications in accordance

with established quality standards, (b) So that design

costs, inspection costs, and process costs become

more efficient. According to Kampker , (2012),

inspection or checking is an important part of quality

control. Inspection includes determining whether

inputs or outputs meet company quality standards.

The purpose of inspection is to stop processes that

cause defective products, stop services (services) that

are not useful. Inspections can be carried out at the

workplace (floor inspection) or at a central inspection

site.

2.3 Quality Improvement Techniques

A causal diagram, also known as a fishbone chart, is

a tool for identifying process elements (causes) that

might influence outcomes, Sakti A, (2015) This

diagram depicts a diagram (shaped like a fishbone)

for the everyday quality control problems of a

dissatisfied company customer. Each "bone"

represents a source of error. The Operations Manager

starts with five categories, namely Man (people),

Machine (equipment), Material, Method, and

Environment referred to as 5M which is the cause.

A fishbone diagram is a method/tool that helps

identify, sort, and display various possible causes of

ICATECH 2023 - International Conference on Advanced Engineering and Technology

286

a problem or certain quality characteristics. The

fishbone diagram illustrates the relationship between

the problem and all the causal factors that influence

the problem that occurs.

M

a

n

Reason

Reason

M

a

n

Reason

Reason

E

n

v

i

r

o

n

m

e

n

t

Reason

Reason

M

e

t

h

o

d

Reason

Reason

M

a

t

e

r

i

a

l

Reason

Reason

Quality

Problem

Conse-

quence

Figure 1: Cause and effect diagram.

The function of the fishbone diagram is to identify

and organize the possible causes of a specific effect

and then isolate the root causes. The causal conditions

that may be carried out in the analysis are to enlarge

or reduce the desired result.

The manufacturing industry in production

activities greatly benefits by conducting a hypothesis

using a fishbone diagram, Shinde, VM (2014).

Classic problems that often occur will be more visible

including: production delays, high product defect

rates, production machines often experience trouble,

unstable production line output which results in

chaotic production planning, productivity that does

not reach targets and customer complaints which

keeps repeating.

2.4 Process Capability

Process Capability is the ability of a process to

produce a product/service that meets consumer

needs/requirements or expected specifications. So

process capability analysis is a step that must be taken

when carrying out process quality control.

Requirements for the implementation of process

capability analysis. If we already know how our

process is (voice of process), of course we want to

compare it with the specifications set by the customer

(voice of customer). According to Shinde, VM (2014)

, process capability analysis describes process

performance in producing products according to the

desired specifications. Process capability analysis can

be expressed as the probability of producing

unsuitable characteristics when the process is in

control.

Process capability analysis using the "Process

Capability Ratio". A symmetrical process capability

ratio has a symmetrical distribution which is

calculated by the following formula:

𝐶𝑝

(1)

The results of the analysis are known for Cp =

process capability, USL = Upper Specific Limit, LSL

= Low Specific Limit, σ = process standard deviation

value, µ = process average value, if Cp value > 1

means the natural tolerance limit is still within control

limits.

2.5 Data Collection

The research was conducted at a battery production

company, PT. TBA domiciled in Sidoarjo, research

was conducted for 2 months starting from September

1

st

2022 to October 30

th

2022. Data collection was

carried out by observation and interview methods to

obtain data about the general description of the

company, the production process, the amount of

production, and the number of defective products at

each stage of work.

2.6 Data Analysis Methods

Analysis of data uniformity is also called data

distribution analysis, to determine data uniformity,

Zhang ZJ , et.al., (2013) . Data is called uniform if the

spread of data does not exceed predetermined control

limits, both upper control limits, Rifan Hariri, RA

(2013). To find out whether the data is uniform or not,

the "P-Chart Diagram" formula is used as follows:

UCL X

kδ (2)

X

∑

(3)

LCL X

kδ (4)

The control limit of the graph is known from the

value of UCL = upper control limit, LCL = low

control limit, X ̅= average measurement data, k =

adjustment constant for the confidence level of the

data, if the data confidence level is 99% then k =

3.95% then k = 2 , and below 95% then k = 1. Data

distribution is controlled by an X-Chart Diagram as

shown in Figure 2. as follows:

Figure 2: X–diagram.

Production Quality Control Analysis in Battery Product Quality Improvement Efforts

287

According to Zhang ZJ , et.al. (2013), the percentage

of damage (reject) is analyzed using a pareto chart, if

it turns out from the results of the X-Chart diagram

the data is outside the control limits, then the data

needs to be analyzed using a pareto chart to sort.

based on the level of proportion of damage, starting

from the highest level of damage to the smallest.

According to Rukmana, PW (2015), This pareto plan

will help to focus on the more common and

significant product defect issues or those that will

provide major benefits. The data is processed to

determine the percentage of damage which is

calculated by the formula:

Tk =

𝑥 100% (5)

The value of Tk = Damage level, Σkj = Total

damage of a certain type, ∑k = total damage. If the

damage level is Tk ≤ 2.5% = Mild, Tk > 2.5 - 5.0 =

Moderate, Tk > 5.0 – 7.5 = High, Tk > 7.5 = extreme.

Causal analysis of a quality problem using a

causal diagram. cause and effect diagram is used as a

technical guideline for the operational function of the

production process to maximize the success value of

the quality level. Cause and Effect Diagram or often

referred to as a cause and effect diagram.

This analysis is to determine the process potential

index or known as Process Capability (Cp) which is

obtained by comparing the specification range with

the process range with the following formula:

Cp

(6)

The analysis is carried out by knowing the value,

Cp = symmetric process capability ratio value, UCL

= upper specification limit, LCL = lower specification

limit, δ = process standard deviation value. If the Cp

value > 1 means that the natural tolerance limits are

within the UCL and LSL, or within the control limits.

2.7 Research Flow Chart

Research Flowchart to find out the flow of research

implementation as shown below:

Figure 3: Research flowchart.

Before data analysis is carried out, the data taken

from the observations is tested to find out whether the

amount of data is sufficient and uniform, as a

reference for fact indicators, if the numbers are

considered not representative of facts, then additional

observation data. added, as well as if the data

distribution is not normal or not. If the data is

uniform, then data that is outside the control limits is

considered defective data and must be discarded and

replaced with new ones.

3 RESULTS AND DISCUSSION

Data analysis based on production output obtained

from data processing shows that the total production

output, including the number of good products and

the number of defective products is shown in the

following table 1.

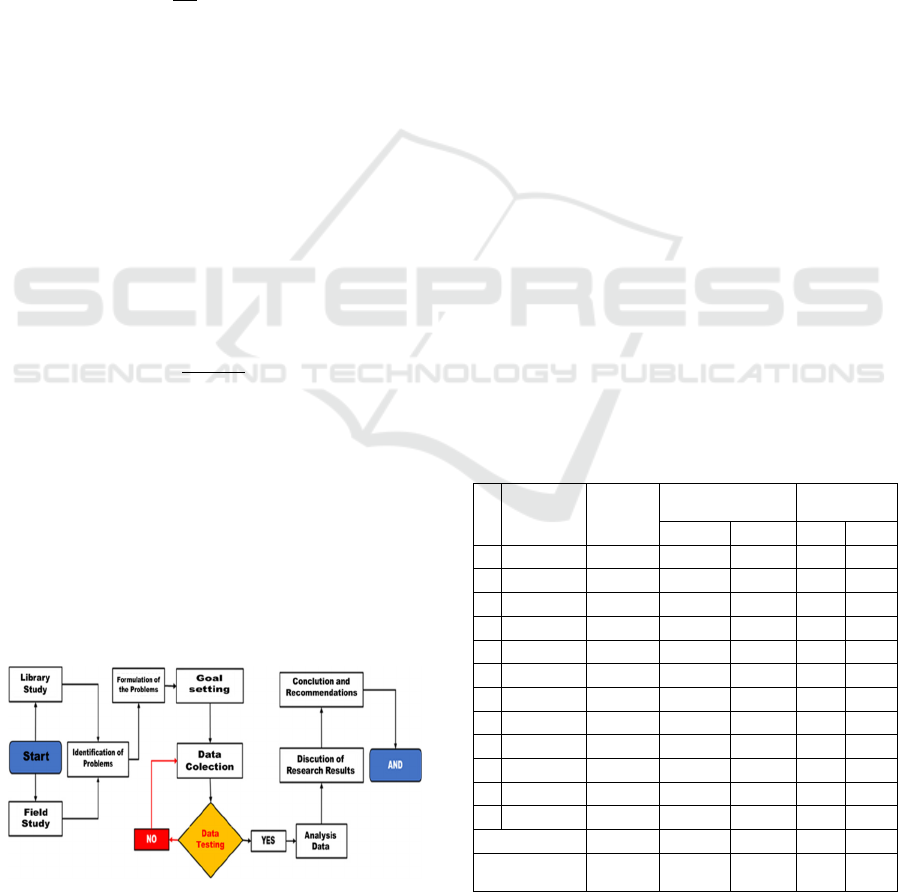

Based on the data in table 1. above, it can be

concluded that the average production yield is

54,237/month, the average number of defective

products is 515 (0.94%)/month. Analysis of the Trend

of Defective Products based on data on the number of

defective products as shown in the following figure 4.

Based on Figure 4 above, it can be concluded that

the average defective product is 0.94%, in terms of

the relatively small percentage of defects, but the

number of defects tends to form a positive trend

(increases every month). Means there is a process

change that causes an increase in the number of

defects.

Table 1: Production data.

N

o.

Product

Period

Number

of

Product

Good

Produc

t

Product

Defects

Total % Total %

1 january 33862 33706 99.54 156 0.46

2 February 43754 43457 99.32 297 0.68

3 march 63577 63097 99.25 480 0.75

4 April 56643 56206 99.23 437 0.77

5 may 66325 65772 99.17 553 0.83

6 june 57874 57354 99.10 520 0.90

7 July 45673 45256 99.09 417 0.91

8 August 65276 64662 99.06 614 0.94

9 September 57802 57151 98.87 651 1.13

10 October 62975 62249 98.85 726 1.15

11 November 43826 43233 98.65 593 1.35

12 December 53255 52528 98.63 727 1.37

Total Product 650842 644671 1188.75 6171 11.25

Average

Produc

t

54237 53722.58 99.06 515 0.94

ICATECH 2023 - International Conference on Advanced Engineering and Technology

288

Figure 4: Graph of defective product trends.

Based on Figure 4 above, it can be concluded that

the average defective product is 0.94%, in terms of

the relatively small percentage of defects, but the

number of defects tends to form a positive trend

(increases every month). Means there is a process

change that causes an increase in the number of

defects.

Analysis of Defective Product Control Limits

based on data on the number of defective products as

in table 1. above, then analysed with an X-Chart

diagram as shown in the following figure 5.

Figure

5: X -chart

diagram

.

Based on the X-Chart Diagram above, it can be

seen that the average number of defective products =

515, Upper Control Limit (UCL) = 781.49 (782),

Lower Control Limit (LCL) = 247.01 (248), there is

1 (one) data that is outside the control limits, and the

chart shows a positive (increasing) trend. This

indicates a continuous change of process equipment

which causes product defects. For this reason, product

quality control needs to be improved in the

production process tool.

Analysis of the Causes of Product Defects based

on the fishbone diagram (Ishikawa) is used to explore

the causes of defects in detail, the data on the causes

of product defects as shown in table 2 below.

Table 2: Causes of Product Defects.

No

Causative

factor

Type

Because

Score

(0–

100)

%

Score

%

Factor

Score

1 Man

Untrained 60 15.00

27.50

No briefing 50 12.50

2 Ingredients

Not according to

specifications

10 2.50

3.75

Raw material

defects

5 1.25

3 Machine

Breaks

frequently

80 20.00

66,25 Not exactly 90 22.50

Rarely

calibrated

95 23.75

4 Method

Not Standard

Operational

Process

5 1.25

2.50

No form of

activity

5 1.25

TOTAL 400 100 100

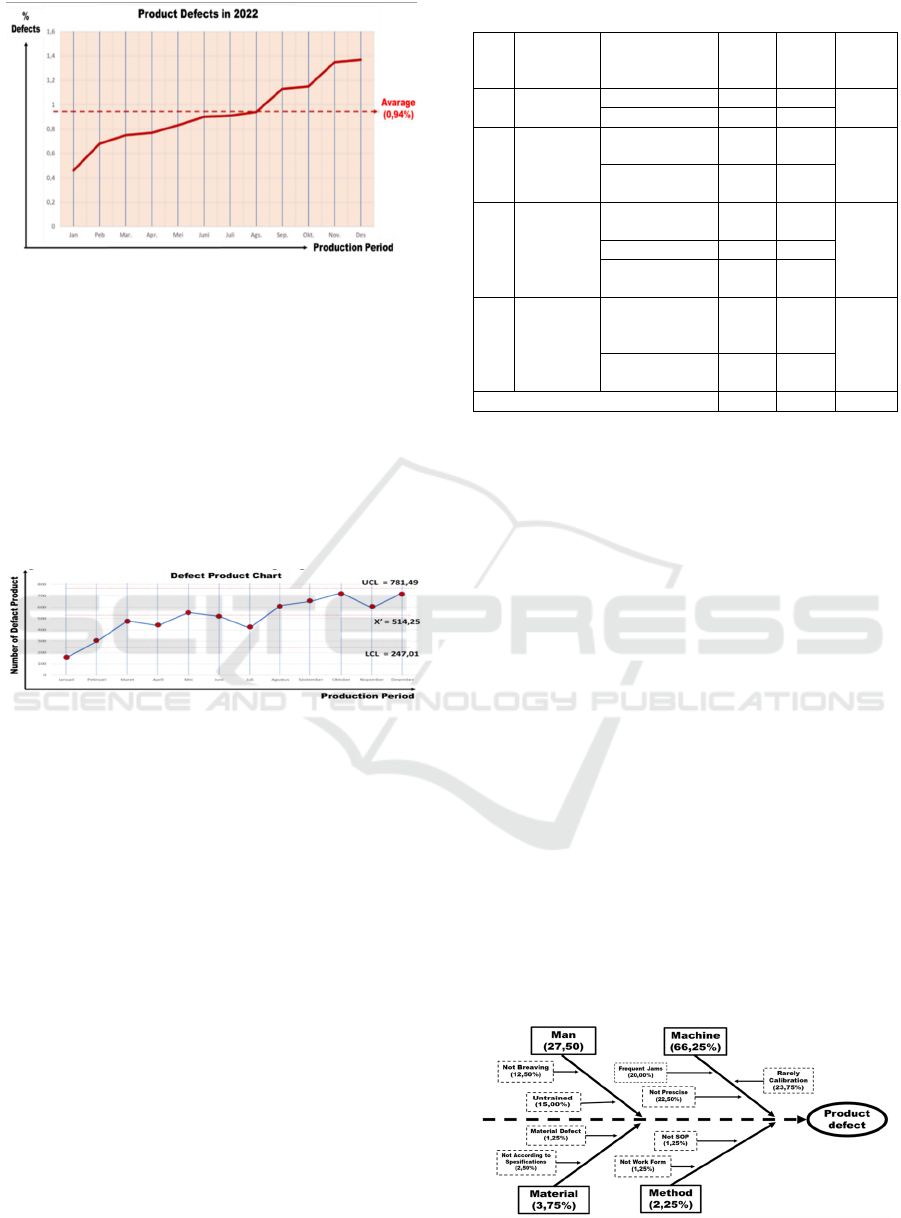

Based on Table 2. it can be concluded that there

are 4 factors that cause product defects, namely: the

human factor consists of 2 variables that cause many

product defects, namely an untrained workforce and

no breaving/coordination before work. Material

factors consist of 2 variables that cause product

defects, namely materials not according to

specifications, and raw materials used in defective

conditions. The engine factor consists of 3 variables

that cause product defects, namely the machine often

jams, the machine placement is not precise, and the

machine is not calibrated. The method factor consists

of 2 variables that cause defective products, namely

there is no Standard Operating Procedure (SOP), and

there is no work form.

Based on the analysis, it shows that work

environment factors do not have much effect on

production results. A work environment that meets

predetermined standards, so that the workforce is able

to carry out production activities properly. The work

environment does not affect the use of work

equipment and materials used to make battery

products.

The Fishbone Diagram is used to explore the

causes of defects in detail as shown in Figure 6 below:

Figure 6:

Fishbone

Diagram

Production Quality Control Analysis in Battery Product Quality Improvement Efforts

289

Today Ishikawa diagram analysis can be

concluded that of the 4 causes of product defects the

biggest causes are machines with a probability value

of 66.25% and humans with a probability value of

27.50%. Improvements are a priority scale in the

process of product quality control, it is necessary to

increase machines and humans. Machine and human

factors have the greatest probability of causing

defective products.

Product quality control is carried out by

improving machine factors, namely minimizing the

occurrence of machine stops when carrying out

production activities, setting the machine according

to the desired product standard so that production

results have a high precision value. The next engine

factor improvement is to periodically re-calibrate

(calibrate) so that the size of the machine is always

precise. Product quality control is carried out by

treating the workforce to training and direction from

leaders every time they do work in the form of

coordination. The human factor requires high work

experience so that production results get better by

increasing skills, motivation, and selecting foremen

who are able to influence subordinates to improve

product quality.

4 CONCLUSIONS

The total production yield is 650,842/year with an

average of 54,237/month, good products are

644,671/year with an average of 53,723/month, and

defective products are 6,171/year with an average of

515/month. Based on the data, it can be seen that total

production in 2022 has not been achieved, and every

production period (every month) there are always

defective products with an average of 514.25

(0.94%). The trend of defective products shows an

average percentage of good products at 99.06%, and

defective products at an average of 0.94%. Judging

from the percentage of defective products of 0.94%,

it can still be tolerated, because the tolerance for the

number of defective products <2% is relatively small,

but the number of defects tends to form a positive

trend (increases every month). Means there is a

process change that causes an increase in the number

of defects

Control of Defective Products from the X-Chart

diagram shows the average number of defective

products = 514.25 (515), Upper Control Limit (UCL)

= 781.49 (782), Lower Control Limit (LCL) = 247.01

(242) , there is 1 (one) data that is outside the control

limits, and the chart shows a positive trend

(increasing). It was concluded that there was a

continuous change of process equipment which

caused product defects. For this reason, product

quality control needs to be improved in the

production process tool.

The biggest causes of product defects are the

machine factor with a probability of 66.25% and the

human factor with a probability of 27.50%. The

product quality control process needs to be improved

on machines and humans. Controlling product quality

by carrying out machine repairs, namely carrying out

repairs and calibrating machines on a regular basis.

Product quality control is carried out by treating the

workforce, namely training and directing each time

they carry out work.

REFERENCES

Gooddenough JB, Kim Y. (2009). Challenges for

rechargeable Li batteries. Chemisty of Materials 22

(2009) 3, 587-603.

J. Schmitt, A. Raatz, F. Diatrich, K. Droder, J. Hesselbach.

(2014). Process and performance optimization by

selective assembly of battery electrodes. CIRP Annals-

Manufacturing Technology 63, 2014, Pages 9-12.

K. Turcheniuk, D. Bondarev, GG Amatucci G. Yushin

(2021). Battery material for low-cost electric

Transportation Mater Today, 42 (2021), pp. 57-72.

Kampker, A.; burggraf, P.; deutskens, C.; Heimes, H.:

Schmidt, M. (2012): Process alternatives in the battery

production. Electrical Systems for Aircraft, Railway

and Ship Propulsion (ESARS). Bologna, Italy, 1-6.

Kolmel A, Sauer A, Lanza G. (2014). Quality-oriented

production planning of battery assembly system for

electric mobility. Procedia CIRP 23 149-154.

M. Duquesnoy, I. Boyano, G. Larraitz, P. Cereijo, A.

Alixabete, A. Franco (2021). Machine Learning-Based

on Assessment of the Impact of the Manufacturing

Process on Battery Electrode Heterogeneity Energy AI,

5 (2021).

Pearn WL, Shu MH, Hsu BM. (2005). Monitoring

Manufacturing Quality for Multiple Li-BPIC processes

based on capability index Cpmk. International Journal

of Production Research 43 (2005) 12, 2493-2512.

Rahul Panat, VD (2014). The Application of Lean Six

Sigma to the Configuration Control in Intel's

Manufacturing R&D Environment. International

Journal of Lead Six Sigma Vol. 5 444.

Rifan Hariri, R.A (2013). Application of the Six Sigma

Method as a Remedial Effort to Reduce

GREENFIELDS Milk Pack Defects. Journal of

Agricultural Technology Vol. 14. No. 2, 141-150.

Rukmana, PW (2015). Product quality control with a Six

Sigma Approach and Kaizen Analysis and New Seven

Tools as an Effort to Reduce Product Defects. Journal

of Technology, Vol. 8 No. 1, 65-74.

ICATECH 2023 - International Conference on Advanced Engineering and Technology

290

Sakti A, Michalek JJ, Fuchs ER, Whitacre J F. (2015) A

Techno-economic Analysis and Optimization of Li-ion

Batteries for Light-ducty Passenger Vehicle

Electrification. Journal of Power Sources 273 (2015),

966-980.

Shinde, VM (2014). Application of 7 Quality Control Tools

for Continuous Improvement of Manufacturing

Processes. International Journal of Engineering

Research and General Science Vol 2 Issue 4, 364-371.

Zhang ZJ, Ramadass P. (2013) Lithium-Ion Battery

Systems and Technology. In: Brodd R J. Batteries for

Sustainability. New York, NY: Springer New York.

319-357. ISBN: 978-1-4614-5790-9.

Production Quality Control Analysis in Battery Product Quality Improvement Efforts

291