Effects of Business and Supply Chain Uncertainty to Business

Sustainability in Indonesian Coal Industry: An Exploratory Study

Firman Risqul Fidry

1

, Iwan Vanany

2

and Jerry Dwi Trijoyo Purnomo

1

1

Interdisciplinary School of Management and Technology, Institut Teknologi Sepuluh Nopember Surabaya, Indonesia

2

Industrial and Systems Engineering Department, Institut Teknologi Sepuluh Nopember Surabaya, Indonesia

Keywords: Coal Business Sustainability, Business Uncertainty, Supply Chain Uncertainty.

Abstract: There has been a significant paradigm shift with increasing awareness of environmental sustainability. It

discusses the issue of carbon emissions produced by burning fossil fuels. Besides the uncertainty of energy

needs related to fossil energy, there is also an unstable supply chain. These factors significantly influence the

business sustainability of the coal mining industry in Indonesia one of the largest coal-producing countries in

the world. Indicators of business sustainability for the coal industry include economic, social, and

environmental aspects. This research examines the uncertainty of the coal business and supply chain regarding

coal business sustainability (CBS), especially thermal coal and thermal coal supply in Indonesia. This research

uses a qualitative exploratory method. There are interviews and data analysis on two companies engaged in

the coal business. The research will reveal the factors that affects Indonesian CBS. The right solution will be

obtained, especially supply chain capabilities in upstream process efficiency due to the uncertainty of the coal

business going forward.

1 INTRODUCTION

There have been works of literature that deeply

discuss the issue of sustainability in companies (van

Kleef & Roome, 2007). However, there is still a

limited analysis of the attitude of entrepreneurs,

especially in Supply Chain (SC) activities in actual

and stated activities for sustainable business models

(Paulraj, Chen, & Blome, 2017).

Entrepreneur behavior usually reflects operational

activities, especially in business processes and value

chains. The supply chain is a structured grouping of

activities with the core company as the center

connected with others to support it (Sauer & Seuring,

2017).

Mining operations stages require reliable supply

chain sustainability. In other words, the supply chain

facilitates the coal cycle (Ding, Wang, & Zhang,

2021). Mine supply chain management (MSCM) is

not only about the implementation process but is also

related to analyzing planning, scheduling, and

evaluating all activities of the entire SC process in the

strategic, tactical, and operational fields.

The complexity of the coal supply chain is the

main topic of several supply chain concepts like the

Sustainable Supply Chain (SSC). However, many

parties in the coal supply chain also pose a high risk

of uncertainty (Peng, Tian, Zhang, Zhang, & Wang,

2020); (Wibowo & Pujawan, 2018).

The negative economic impacts of climate change

accompanied by the rapid depletion of natural capital

remain a significant problem for industrial

performance in many countries.

It is for their extreme vulnerability to climate

change and resource-based economics (Klemeš,

Varbanov, Walmsley, & Foley, 2019). The world's

energy needs increase year by year. According to the

World Energy Agency (International Energy

Agency-IEA), by 2030 world energy demand will

increase by 45% or an average increase of 1.6% per

year.

Population growth affects energy needs, where

fossil energy is still at the top of the table (80%), and

the rest is met by non-fossil fuels (Tanaka,

2011).Such conditions indicate a high level of

uncertainty in the coal business going forward.

This will affect the sustainability of the coal

business. According to (John, 1998) sustainability

consists of three principles: social, economic, and

environmental. They aim to meet current and future

human needs by maintaining environmental quality.

360

Fidry, F., Vanany, I. and Purnomo, J.

Effects of Business and Supply Chain Uncertainty to Business Sustainability in Indonesian Coal Industry: An Exploratory Study.

DOI: 10.5220/0012114200003680

In Proceedings of the 4th International Conference on Advanced Engineering and Technology (ICATECH 2023), pages 360-366

ISBN: 978-989-758-663-7; ISSN: 2975-948X

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

These principles constitute the triple bottom line

(TBL).

(Stock & Seliger, 2016) suggested that Industry

4.0 has great potential in responding to the need for

sustainable industrial value in the TBL. Next, the

Sustainability Business Model (SBM) includes TBL

and considers other stakeholders besides the

environment and society (Bocken, Short, Rana, &

Evans, 2014).

2 LITERATURE REVIEW

Some studies have discussed business sustainability

and supply chain with an approach to environmental

issues. There are not many authors that explore

business sustainability against business and supply

uncertainties, especially in the thermal coal industry

in Indonesia.

(Bocken et al., 2014) and (Bichueti, Gomes,

Kneipp, & Da Rosa, 2015) discussed controlling

GHG emissions to minimize investment. (K. Muduli

& Barve, 2013) and (Mathiyazhagan, Diabat, Al-

Refaie, & Xu, 2015)) studied Green supply chain

management (GSCM) to improve organizational

environmental performance through cost savings.

However, they did not talk about business

sustainability going forward. (Mathiyazhagan et al.,

2015) proposed a new multi-objective model in

closed-loop supply chain problems integrated with lot

sizes while simultaneously considering lean, agility,

and sustainability factors.

(Li, Xiang, & Qu, 2016) conducted

meteorological, pademic, and economic analyses of

the macro-economy to mitigate potential losses in the

mining and agriculture industries. (K. K. Muduli et

al., 2020) analyzed the relationship between

organizational behavior and green supply chain

management (GSCM) performance. (Aguirre-

Villegas & Benson, 2017) also conducted research on

supply chain sustainability in terms of environmental

aspects using the Life Cycle Analysis (LCA) analysis

approach on the coal industry in Indonesia.

This research tries to determine the parameters of

return on energy investment. It also aims to reveal the

uncertainty factors in the coal business sustainability,

especially in the supply chain context with indicators

of business growth, profits, and net zero emission.

3 RESEARCH DESIGN

The conceptual framework is the uncertainty between

demand and supply. Demand uncertainty usually

occurs due to business uncertainty, while the

uncertainty may be due to some external factors.

Meanwhile, supply uncertainty is generally

related to the supply chain coming from internal

factors. The business and supply chain uncertainties

are the variables that determine the uncertainty of the

thermal coal business in Indonesia.

Figure 1: Conceptual framework.

Figure 1 shows that the uncertainty of the coal

business influences its sustainability. The variables

with sufficient influence include the instability of a

country's political conditions, low global and national

economic growth, restrictions on the use of fossil

energy, a high number of pandemic victims in

consumer countries, and frequent changes in

government policies regarding permits and taxes on

coal commodities.

The second influential factor in the uncertainty of

the coal business is the supply chain. There are some

interesting variables for research, including the

decreasing reserves of thermal coal in Indonesia and

the decreasing quality of thermal coal with a calorific

value of coal above 4000 Kal/gr (GAR).

Some issues like low availability of access to coal

and the availability of transportation, and a high

amount of capital in investment financing strategies

in the coal business trigger higher profitability

sensitivity in the coal industry. The large investment

value causes higher fixed costs in the cost structure of

the coal business and inefficiency of the mining

operational activities.

Those lead to higher production costs. These two

factors encourage the unsustainability of the coal

business in the future. Therefore, it is necessary to

conduct a study to obtain a coal business model that

can withstand these risks, especially the supply chain

strategy based on disruptions or changes in the coal

business.

Effects of Business and Supply Chain Uncertainty to Business Sustainability in Indonesian Coal Industry: An Exploratory Study

361

3.1 Research Methods

This is an exploratory qualitative study

(Shamsuddoha, 2015). It aims to determine business

sustainability factors in the Indonesian thermal coal

industry. This research methodology is based on

efforts to carry out research stages to achieve research

objectives. The methodology includes some case

studies at some supply chain echelons (Babaeinesami,

Tohidi, & Seyedaliakbar, 2021).

They include suppliers, producers, and users of

the coal commodity. There are also direct interviews

with key actors in the coal mining industry supply

chain. There are some case studies on the three

companies that are directly experiencing uncertainty

both from a business and supply chain perspective.

The data are obtained from the companies’ internal

data and several sources outside the companies

(Emberson, Storey, Godsell, & Harrison, 2006).

The primary data are interview results from

several companies' internal sources (Aguirre-Villegas

& Benson, 2017) with a minimum position of the

general manager. The two data sources above

complement and confirm each other. In the end, the

purpose is to conclude the factors that influence coal

business sustainability (CBS).

The results of interviews with several

respondents need to be validated in this study. The

validation method used is the source triangulation

method. This method compares information obtained

several different sources based on standardized

source rules. Some sources used are the results of

interviews with several respondents who have been

determined, among others, current information from

observations (Table 3) and information from

respondents. Information from respondents

compared with observational data (Table 3). The

combination of observational data and interview

results gives confident in research regarding the level

of data validity. Observational data based on time

series of business uncertainty and coal supply chain

in the previous period. The interview data validated

by the observation data above.

3.2 Data Collection

The data are from primary and secondary sources.

The primary sources are the interview results from

two companies. Meanwhile, the secondary ones are

from internal and previous studies. The primary data

is conducted through direct interviews with some

informants from the supply chain and businesses in

the coal industry.

The interviews are open-ended with exploratory

questions so that the results are detailed and

consistent. The table below presents the informants’

profiles:

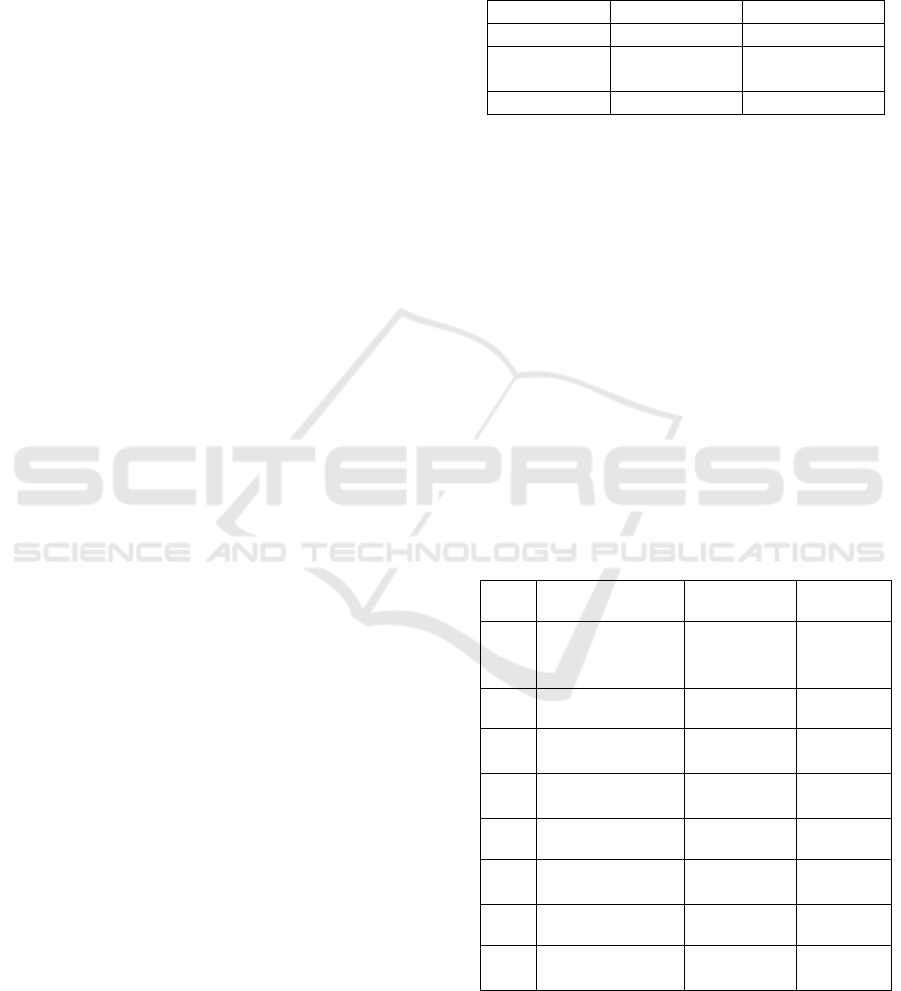

Table 1: Informants' profiles.

Case 1 Case 2

Position Director General Manager

Working

duration

>15 years > 15 years

Education Master/S2 Master/S2

There is a systematic interview protocol to guide

the researcher to stay focused and make it easier to

conduct interviews with the respondents. The

interview protocol contains questions about the

importance of business sustainability, business

uncertainty effects, and supply chain uncertainty

effects.

3.3 Case Profiles

The respondents come from the companies involved

in the coal supply chain. They are the companies with

private ownership status that have Mining Business

Permits and Mining Service Business Permits. The

three companies produce for a production target of

over 100 million BCM per year with coal production

of over 15 million.

Table 2: Case Profile.

No Profiles Case 1 Case 2

1 Business Portfolio Mining

Services

Mining

Services &

producer

2 Commodity OB & Coal OB & Coal

3 Production

(Million BCM)

729,5 178,56

4 Total asset (USD

Mio)

435.85

5 Firms Scale Big Big

6 Employees >10.000 10.000-

5000

7 Ownership Private Private

8 Position General

Manager

Director

The production capacity classifies the level of a

large company. They have more than 5.000

employees. The respondents have working

ICATECH 2023 - International Conference on Advanced Engineering and Technology

362

experience more than 15 years with different

positions, including directors and general managers.

Table 2 displays the details of the case profiles.

3.4 Case Analysis

This section discusses some factors and variables that

influence business sustainability. Business

sustainability is interesting to study. The concept of

business sustainability must be seen as a solution to

the problems currently faced by the business world

amid the disruptions at global and national levels.

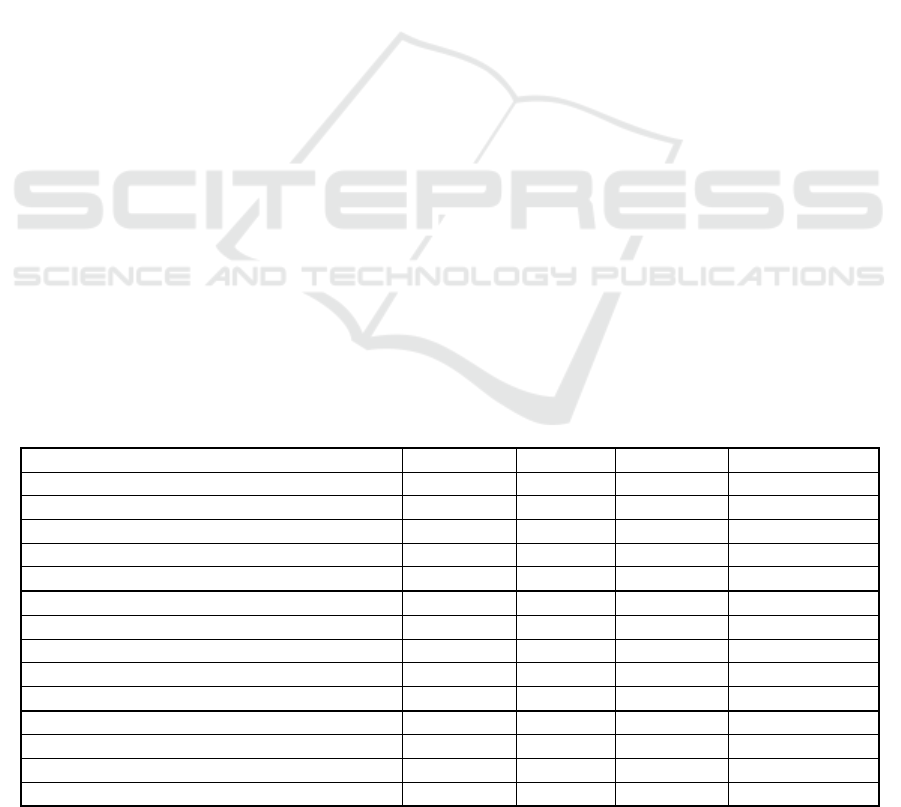

Table 3: Business and supply chain uncertainty factors.

There have been studies on several topics of

business sustainability in the mining industry.

However, they only discuss more from one side,

namely internal or external. Therefore, there are still

research gaps to be studied deeply.

Business Uncertaint

y

Description Author(s)

1. Political

instability

Political stability, economic stability, stakeholder

pressure, competition, energy transition, and

regulations.

Wan Ahmad, W.N.K

2. Low global and

national economic

g

rowth

The economic slowdown will lead to a decrease in

energy demand and prices

Correljé and van der

Linde, 2006

3. Renewable Energy Top management support, teamwork, workplace

culture, resistance to change, green innovation, and

g

reen motivation.

Muduli K.K et al. (2020)

4. Effects of the Covid

19 Pandemic

Local response to the covid-19 pandemic resulted in

a drastic drop in energy deman

d

IMF. World Economic

Outlook, 2020

5. Government Policy These policy uncertainties, along with the rising

sentiment of resource nationalism, have resulted in

forei

g

n miners sellin

g

their o

p

erations

Mining in Indonesia

Investment and Taxation

Guide June 2019,

Supply Chain

Uncertaint

y

1. Coal reserves Major sources of uncertainty that were considered

are the reserves and the quality of the lignite.

MichaelGaletakis (2012)

2. Quality Eco-geo-environment quality generally has been

declining since the development and utilization of

coal resources

ZhiYang et al (2019)

3. Transportation

model and

infrastructure

Improve management of sub-processes in the coal

supply chain and reduce costs along the supply

chain.

James M. Ekmann et

al.(2004)

4. Financing strategy The expected lifespan of a newly built plant is

estimated in carbon pricing scenarios.

Jianlei Mo et al (2021)

5. Operational strategy to minimize the expected cost to the economy and

environment driven by the production capacity (PC)

under energy securit

y

QingYang et al (2020)

Coal Business

Sustainabilit

y

1. Economical: Market

share, profit.

2. Environmental:

Carbon foot

p

rint

Components of business sustainability, including

environmental, social, and governance components,

linked to various stakeholders

Rezaee, (2016); Zhao et

al., (2021)

3. Growth Index Businesses can grow in four directions: (1) growth

within their current market, (2) sales of new products

in their current market, (3) sales of existing products

to new markets, and (4) sales of new products to new

markets.

Ansoff (1957)

Effects of Business and Supply Chain Uncertainty to Business Sustainability in Indonesian Coal Industry: An Exploratory Study

363

This research tries to make a thorough analysis

that combines internal and external factors by

considering the risk of some variables in it.

Table 3 presents the details of the variables that

were the topic of previous research. Table 3 shows the

factors and dimensions of uncertainty as risks from

business and supply chain uncertainties. Several

variables of business uncertainty include political

instability, low global and national economic growth,

restrictions on fossil fuels, the COVID-19 pandemic,

and uncertainty over government policies.

The supply chain uncertainty starts from declining

coal reserves, relatively declining coal quality, the

difficulty of access and transportation, errors in coal

mining financing schemes, and low work efficiency

in mining operations.

The following describes the results of the

interviews in case 1 and 2 to find out whether political

instability affects coal business sustainability

Case 1: -'-political stability in the coal industry is

very crucial because we work in areas within political

territories of the Head of Territory.

Case 2: - Political stability influences business

sustainability, especially the process of changing

leaders and changing policies.

Low Global and national economic growth affects

coal business sustainability

Case 1: Economic growth is very crucial for our

needs, so if we look at a country that has high

economic growth, it means that energy needs are

high, and the demands for coal are also high. If

economic growth is low, the demand will also be low.

That is what creates a disruptive relationship in our

supply chain

Case 2: As we know, economic growth greatly

influences a country's energy needs. Apart from that,

fossil and non-fossil energy are currently

experiencing significant growth

Renewable Energy affects coal business

sustainability.

Case 1: Indeed, it is affected by renewable energy.

The renewable energy that will later replace or

become very competitive with coal is sunlight. We

can see many industries have started to use solar

panels. They can be effective and common. There

must also be batteries for solar cell.

Case 2: The trend of using renewable energy is

indeed increasing especially in 2030. However, until

now we still rely on fossil energy, especially coal. The

cost constraints of alternative energy are still more

expensive than coal.

Case 1: The influence is quite significant. There

will be a balance where everyone gets vaccinated,

everyone is arrested, and people are all strong.

Case 2: - The covid pandemic which has been

running for almost two years has had a huge impact

on coal demands, especially at the beginning of the

pandemic when almost coal importing countries

carried out lockdowns and decreased demands for

coal, but this only lasted until the end of 2020.

Government Policy

Case 1: The"less pro" policies towards fossil

energy in the future, especially in coal, will also affect

business sustainability in the coal industry - Very

Important

Case 2: -Government policies towards the use of

fossil energy are very far ahead and affect the coal

business in the future, where the current government

also needs coal revenue.

Table 4: Assessing business, supply chain uncertainty, and sustainable factors.

Business uncertainty factors Case 1 Case 2 Average Criteria

1. Unstable Political condition 5 5 5,0 Very Important

2. Low economical growth in national and global 5 5 5,0 Very Important

3. Fossil Fuel restriction 4 3 3,5 Moderate

4. Long Pandemics 3 4 3,5 Moderate

5. Government Policy ambiguity 4 4 4 Important

Supply chain uncertainty factors Case 1 Case 2 Average Criteria

1. Coal reserves reduced 5 5 5,0 Very Important

2. Decreased coal quality 4 4 4 Important

3. Low accessibility and transportation 4 4 4,0 Important

4. Low operational efficiency 5 5 5,0 Very Important

Sustainable factors Case 1 Case 2 Average Criteria

1. Economics: Market share 5 5 5 Very Important

2. Economics: Profit 4 5 4,5 Important

3. environment: Carbon footprint 4 4 4,0 Important

ICATECH 2023 - International Conference on Advanced Engineering and Technology

364

4 RESULTS AND DISCUSSIONS

The uncertainty score of the supply chain in case 1

and case 2 is higher (4.5) than the score of business

uncertainty (4.2) means supply chain uncertainty has

a greater risk than business uncertainty.

Cases 1 and 2 assume supply chain uncertainty is

more important than business uncertainty. The

important factors in supply chain uncertainty are coal

reserves and operational efficiency.

The coal business sustainability strategy in

overcoming supply chain uncertainties in case 1 and

2 is to find new coal reserves in large quantities with

reduced mining operational costs that are more

environmentally friendly.

5 CONCLUSIONS

Political instability and economic slowdown at

national and global levels significantly influence the

growth of energy needs. Energy demand will keep

increasing in the future. The ability of the supply

chain related to the decreasing amount of coal

reserves and the low efficiency of operational

activities to produce thermal coal is a very vital

variable in the supply chain. There must be

operational efficiency to fulfill one of the indicators

for the sustainability of the thermal coal business in

achieving net zero emission. To improve coal

business sustainability (CBS), there should be an

accurate mathematical model, especially for the

optimization of uncertainty factors for improving coal

supply chain capability.

REFERENCES

Aguirre-Villegas, H. A., & Benson, C. H. (2017). Case

history of environmental impacts of an Indonesian coal

supply chain. Journal of Cleaner Production, 157, 47–

56. doi:10.1016/j.jclepro.2017.03.232

Babaeinesami, A., Tohidi, H., & Seyedaliakbar, S. M.

(2021). Designing a data-driven leagile sustainable

closed-loop supply chain network. International Journal

of Management Science and Engineering Management,

16(1), 14–26. doi:10.1080/17509653.2020.1811794

Bichueti, R. S., Gomes, C. M., Kneipp, J. M., & Da Rosa,

L. A. B. (2015). Strategic management of the use of

water in mining: A study in Brazilian Multicases.

Revista de Gestao Social e Ambiental, 9(2), 102–119.

doi:10.5773/rgsa.v9i2.986

Bocken, N. M. P., Short, S. W., Rana, P., & Evans, S.

(2014). A literature and practice review to develop

sustainable business model archetypes. Journal of

Cleaner Production, 65(February), 42–56.

doi:10.1016/j.jclepro.2013.11.039

Ding, S., Wang, M., & Zhang, H. (2021). Intergenerational

externalities influence for exploitation process of rare

metal minerals. Processes, 9(5).

doi:10.3390/pr9050883

Emberson, C., Storey, J., Godsell, J., & Harrison, A. (2006).

Managing the supply chain using in-store supplier

employed merchandisers. International Journal of

Retail and Distribution Management, 34(6), 467–481.

doi:10.1108/09590550610667056

John, E. (1998). Accounting for the Triple Bottom Line.

Measuring Business Excellence, 2(3), 18–22.

Klemeš, J. J., Varbanov, P. S., Walmsley, T. G., & Foley,

A. (2019). Process Integration and Circular Economy

for Renewable and Sustainable Energy Systems.

Renewable and Sustainable Energy Reviews, 116.

doi:10.1016/j.rser.2019.109435

Li, C., Xiang, X., & Qu, Y. (2016). Product quality

dynamics in closed-loop supply chains and its

sensitivity analysis. Journal of Grey System, 28(1),

180–190.

Mathiyazhagan, K., Diabat, A., Al-Refaie, A., & Xu, L.

(2015). Application of analytical hierarchy process to

evaluate pressures to implement green supply chain

management. Journal of Cleaner ….

Muduli, K., & Barve, A. (2013). Establishment of a

sustainable development framework in small scale

mining supply chains in India. International Journal of

Intelligent Enterprise. doi:10.1504/IJIE.2013.057340

Muduli, K. K., Luthra, S., Kumar Mangla, S., Jabbour, C.

J. C., Aich, S., & de Guimarães, J. C. F. (2020).

Environmental management and the “soft side” of

organisations: Discovering the most relevant

behavioural factors in green supply chains. Business

Strategy and the Environment. doi:10.1002/bse.2459

Paulraj, A., Chen, I. J., & Blome, C. (2017). Motives and

Performance Outcomes of Sustainable Supply Chain

Management Practices: A Multi-theoretical

Perspective. Journal of Business Ethics, 145(2), 239–

258. doi:10.1007/s10551-015-2857-0

Peng, J.-J., Tian, C., Zhang, W.-Y., Zhang, S., & Wang, J.-

Q. (2020). An integrated multi-criteria decision-making

framework for sustainable supplier selection under

picture fuzzy environment. Technological and

Economic Development of Economy, 26(3), 573–598.

doi:10.3846/tede.2020.12110

Sauer, P. C., & Seuring, S. (2017). Sustainable supply chain

management for minerals. Journal of Cleaner

Production, 151, 235–249.

doi:10.1016/j.jclepro.2017.03.049

Shamsuddoha, M. (2015). Integrated supply chain model

for sustainable manufacturing: A system dynamics

approach. Advances in Business Marketing and

Purchasing. doi:10.1108/S1069-09642015000022B003

Stock, T., & Seliger, G. (2016). Opportunities of

Sustainable Manufacturing in Industry 4.0. Procedia

CIRP, 40(Icc), 536–541.

doi:10.1016/j.procir.2016.01.129

Effects of Business and Supply Chain Uncertainty to Business Sustainability in Indonesian Coal Industry: An Exploratory Study

365

Tanaka, K. (2011). Review of policies and measures for

energy efficiency in industry sector. Energy Policy,

39(10), 6532–6550. doi:10.1016/j.enpol.2011.07.058

van Kleef, J. A. G., & Roome, N. J. (2007). Developing

capabilities and competence for sustainable business

management as innovation: a research agenda. Journal

of Cleaner Production, 15(1), 38–51.

doi:10.1016/j.jclepro.2005.06.002

Wibowo, A. B., & Pujawan, I. N. (2018). Procurement

strategy and supply risk analysis of coal by considering

price fluctuation and supplier delivery time.

Proceedings of the International Conference on

Industrial Engineering and Operations Management,

2018-March, 2903–2913.

ICATECH 2023 - International Conference on Advanced Engineering and Technology

366