RoboToy Demoulding: Robotic Demoulding System for Toy

Manufacturing Industry

Daniel S

´

anchez-Mart

´

ınez

1 a

, Carlos A. Jara

1

and Francisco Gomez-Donoso

2 b

1

Human Robotics, University of Alicante, Alicante, Spain

2

University Institute for Computer Research, University of Alicante, Alicante, Spain

Keywords:

Robotic, Soft Object, Flexible, Manufacturing, Toy Industry, Automation, Production, Computer Vision.

Abstract:

Industrial environments and product manufacturing processes are currently being automated and robotized.

Nowadays, it is common to have robots integrated in the automotive industry, robots palletizing in the food

industry and robots performing welding tasks in the metal industry. However, there are many traditional and

manual sectors out of date with technology, such as the toy manufacturing industry. This work describes a

new robotic system able to perform the demoulding task in a toy manufacturing process, which is a tedious

labor-intensive and potentially hazardous task for human operators. The system is composed of specialised

machinery about the rotational moulding manufacturing process, cameras, actuators, and a collaborative robot.

A vision-based algorithm makes this system capable of handling soft plastic pieces which are deformable and

flexible during demoulding. The system reduces the stress and potential injuries to human operators, allowing

them to perform other tasks with higher dexterity requirements or relocate to other sub-tasks of the process

where the physical effort is minor.

1 INTRODUCTION

Nowadays, there is a growing trend towards the au-

tomation and robotization of industrial processes. The

automotive industry, for example, has embraced the

use of assembly line robots to streamline their man-

ufacturing processes. Similarly, production factories

have integrated industrial robots to handle palletizing

tasks efficiently. Moreover, various other robotized

industrial applications, including welding, painting,

inspection, and quality control, have become increas-

ingly common. This technological progress has re-

placed human operator of the line production process.

However, the toy manufacturing sector is completely

manual, making the operators to carry out high-effort

demanding tasks such as demoulding of hot plastic

pieces of dolls and managing ovens at elevated tem-

peratures. This manual process consists of the follow-

ing steps. First, the operators fill a mould with liquid

plastic material. Then, they introduce it into the oven

at more than 250 degrees Celsius; once the oven has

finalized rotating, operators move the mould to an air

cooler; finally, they place the mould in the demould-

a

https://orcid.org/0009-0008-2279-3503

b

https://orcid.org/0000-0002-7830-2661

ing zone to extract all the soft pieces.

This work presents a novel robotic approach for

the demoulding task in the toy manufacturing process

using a vision-based algorithm and force control to

avoid damaging or breaking parts. Furthermore, this

system is collaborative, so as not to replace the human

factor in the process but to relocate it. The robot per-

forms the demoulding task which requires both high

force and dexterity, while the operator is still required

for the other steps mentioned above, reducing the pos-

sibility of injury or stress in the human operator.

The main contribution of this work is the develop-

ment of a robotic system able to perform the demould-

ing of plastic and soft pieces, which manual perfor-

mance requires the operators to apply high forces in

short cycle times. In addition, a vision-based algo-

rithm has been developed to improve the accuracy and

repeatability of the task execution, which is an impor-

tant fact in industrial tasks. Finally, this collaborative

system allows the operators to perform other dexter-

ous tasks instead of this physical demanding one.

This document is structured as follows. First, in

Section 2 some related works with similar contribu-

tions are presented. In Section 3 the manual and tradi-

tional manufacturing process of the toy sector are ex-

plained and detailed. In Section 4, the developments

546

Sánchez-Martínez, D., Jara, C. and Gomez-Donoso, F.

RoboToy Demoulding: Robotic Demoulding System for Toy Manufacturing Industry.

DOI: 10.5220/0012154200003543

In Proceedings of the 20th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2023) - Volume 1, pages 546-553

ISBN: 978-989-758-670-5; ISSN: 2184-2809

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

and contributions of this work are presented. Then,

in Section 5 different experiments of the approach are

exposed. Finally, in Section 6, some conclusions are

described.

2 RELATED WORKS

Nowadays, the manipulation of soft and flexible

pieces is a common research field which covers many

different kind of objects, as described in (Lahoud

et al., 2021), where authors developed a robotic sys-

tem to manipulate fabric clothes to perform the stitch-

ing task. Similarities can be observed in relation to the

demoulding task, given that the precision required for

its execution must be exceptionally elevated. How-

ever, the stitching task does not require high forces

and it is more difficult to damage or to break the ob-

ject, in contrast to the demoulding task.

In (Navarro-Alarcon et al., 2016), it is presented

an automatic method to compute the parameters of

the deformation model of the soft object in real time

with an external camera. They prepared a clear set-

up where the piece is always visible. However, in

our use case, the soft piece is inside the mould and

when the robot is demoulding it, the piece is occlud-

ing all possible views, so it is needed to estimate the

applied force before the performance of the task. In

(Ubeda et al., 2021), authors present a development

based on a collaborative robotic system able to per-

form sanding tasks using a force control loop with the

feedback of a force sensor. Force control is an impor-

tant fact when manipulating soft objects, but they ap-

plied the sanding task to rigid materials, so they had

not to worry about deformations. In (Ortenzi et al.,

2018), a vision-based manipulation system of plas-

tic objects was developed. In that paper, it is sum-

marized clearly the challenges of the manipulation of

soft pieces: the lack of deformation models for the

pieces, the difficulty to perform a visual tracking, and

the drawbacks to generate inputs and outputs for the

visual error obtained. In addition, the paper describes

how to handle kinetic sand whose dynamic model is

unknown. However, they manipulate the material in

the same temperature conditions, which makes easier

the estimation of the deformation model. In the case

of our approach, the deformation level depends on the

temperature of the pieces which varies a lot during the

extraction.

Regarding the manipulation of soft objects, there

are many different applications. In (Herguedas et al.,

2019), authors classify soft objects in groups depend-

ing on the deformation model used, dimension of

the object, the control strategy followed, perception-

based classification and predominant actions they

deal with. In this description, the use case faced in

this paper is classified in some of the most compli-

cated groups because we are handling 3D shaped ob-

jects with no previous deformation model and the per-

ception system is only about the feedback force of the

own robot due to the occlusions during the task. To

solve problems related to the lack of knowledge about

the deformation model, in (Navarro-Alarc

´

on et al.,

2013), authors propose a vision-based method to

servo control the deformation of a deformable object

applying a model-free method that estimates the ob-

ject’s deformation Jacobian matrix in real time. They

detect some points of interest of the piece to carry out

the manipulation. However, this work presents the

same drawback regarding the field of view and the

approach does not face the problem of partially oc-

cluded objects as in this case, and it is necessary to

control the force without any visual feedback.

In contrast to the classic control methods to ap-

ply force during the robot manipulation, in (Lin et al.,

2019) authors present a safe control system based on

Reinforcement Learning and force sensors to improve

the control and to avoid dangerous and unpredictable

situations, especially in the simulation - real world

transition. Implementing this kind of algorithms is

really useful to obtain general solutions; however, sta-

bility and reliability are not usually guaranteed. The

problem of this work is clearly delimited, so the accu-

racy, stability and repeatability of the trajectories are

priority. Another similar case is explained in (Huang

et al., 2019), where authors apply Deep Reinforce-

ment Learning to improve the interaction between the

robot and fragile objects based on curiosity (reward-

ing the robot the exploring actions) in pushing tasks.

The main disadvantage of the possible application of

this system in our work is the penalization of large

forces its algorithm uses to learn, because the avail-

ability of huge forces are really important for us, as

will be explained in the following sections. Main dis-

advantage is the penalization of large forces, which

are important parameters to consider for the develop-

ment of this work.

In conclusion, nowadays there are many contribu-

tions related to the manipulation of deformable ob-

jects, integration of collaborative robots in industrial

environments and force controllers. However, cur-

rently, there is not any significant advance in a real in-

dustrial case which involves the robotic manipulation

of soft pieces with high force requirements in collab-

orative tasks of the toy manufacturing process. This

work aims to fill this gap and brings about a relevant

improvement in this sector.

RoboToy Demoulding: Robotic Demoulding System for Toy Manufacturing Industry

547

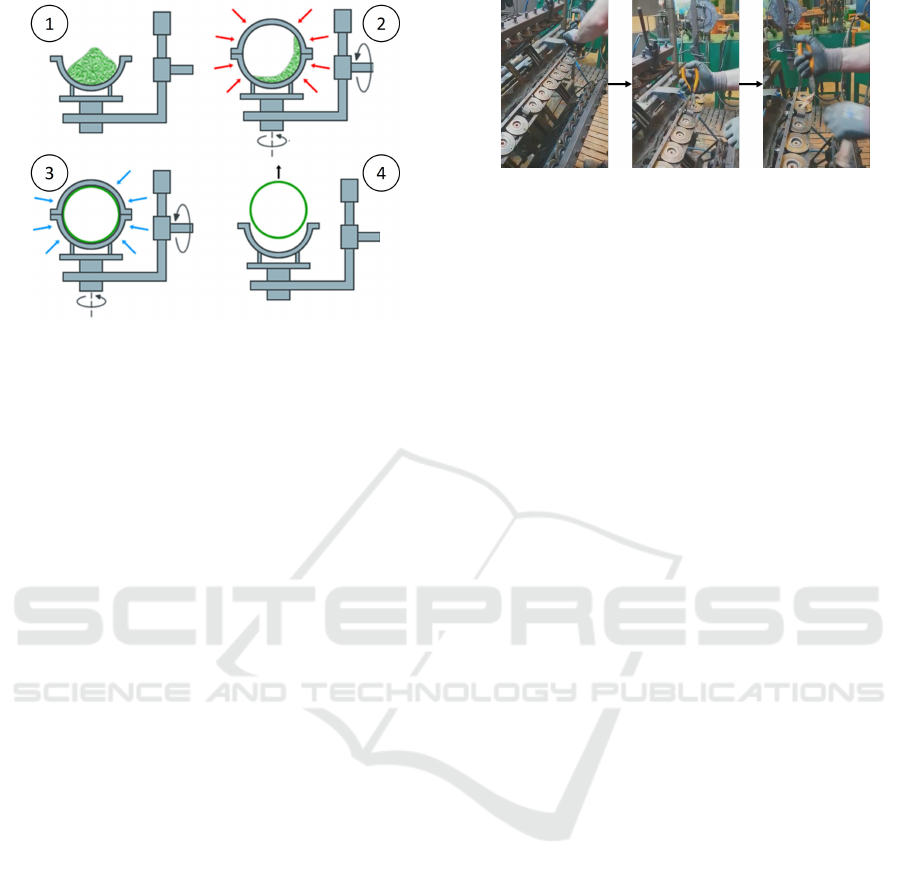

Figure 1: Rotomoulding manufacturing process.

3 MANUAL TASK

Toy industry is a really manual sector which involves

several tasks such as the demoulding of plastic pieces,

painting, assembly, packaging and many others. In

this case, the project is focused on the demoulding

task which is the most physically demanding one.

The extraction of the pieces is just one task of the

complete process shown in Figure 1 and explained as

follows.

• 1. Substance Pouring: the process begins with

carefully pouring the desired substance into the

mould. The amount of liquid plastic material de-

pends on the specific kind of manufactured piece.

• 2. Sealing, Placement and Rotational Heat-

ing: once the mould is filled, this is tightly closed

to avoid any leakage or escape of the substance.

Then, the operator places the mould inside a ro-

tomoulding oven. The rotomoulding oven is spe-

cially designed to facilitate rotational movement

along two distinct axes. Once the mould is placed

inside the oven, the rotation starts. This rota-

tional movement serves for two purposes; firstly,

it ensures the uniform distribution of the material

across the entire inner surface of the mould, elim-

inating any inconsistencies or air pockets. Sec-

ondly, the rotation helps in heating the mould, al-

lowing the substance to melt, fuse, and adhere to

the mould’s inner surface. The heating tempera-

ture and duration vary depending on the material

being processed.

• 3. Air Cooling: after finishing the heating pro-

cess, the operator moves the mould to an air cool-

ing system. This system helps to rapidly decrease

the temperature of the mould by the circulation of

ambient or chilled air around the mould surface.

Figure 2: Manual demoulding task.

The cooling process is carefully controlled to so-

lidify the substance within the mould.

• 4. Mould Unsealing and Extraction of Pieces:

once the substance has solidified (the piece is not

rigid and it stills soft) and reached the desired tem-

perature, the seal on the mould is carefully re-

moved. Special attention is given to avoid any

damage to the mould or the formed pieces. With

the mould unsealed, the resulting pieces are ex-

tracted.

By following these steps, the rotomoulding pro-

cess ensures the creation of uniformly distributed and

accurately formed objects with desirable properties.

Distinctive types of pieces necessitate varying quanti-

ties of material, distinct heating and cooling duration,

as well as different demoulding forces. As illustrated

in Figure 2, skilled operators use pliers to extract the

components since both the pieces and the mould re-

tain elevated temperatures. Prompt demoulding is es-

sential to prevent the pieces from an excessive cool-

ing, because prolonged cooling compromises their

malleability and complicates the extraction process.

4 ROBOTIC SYSTEM

In order to develop a robotic cell with all the needed

capabilities, the first step is to design and simulate the

mock-up, in order to set the layout of the elements. In

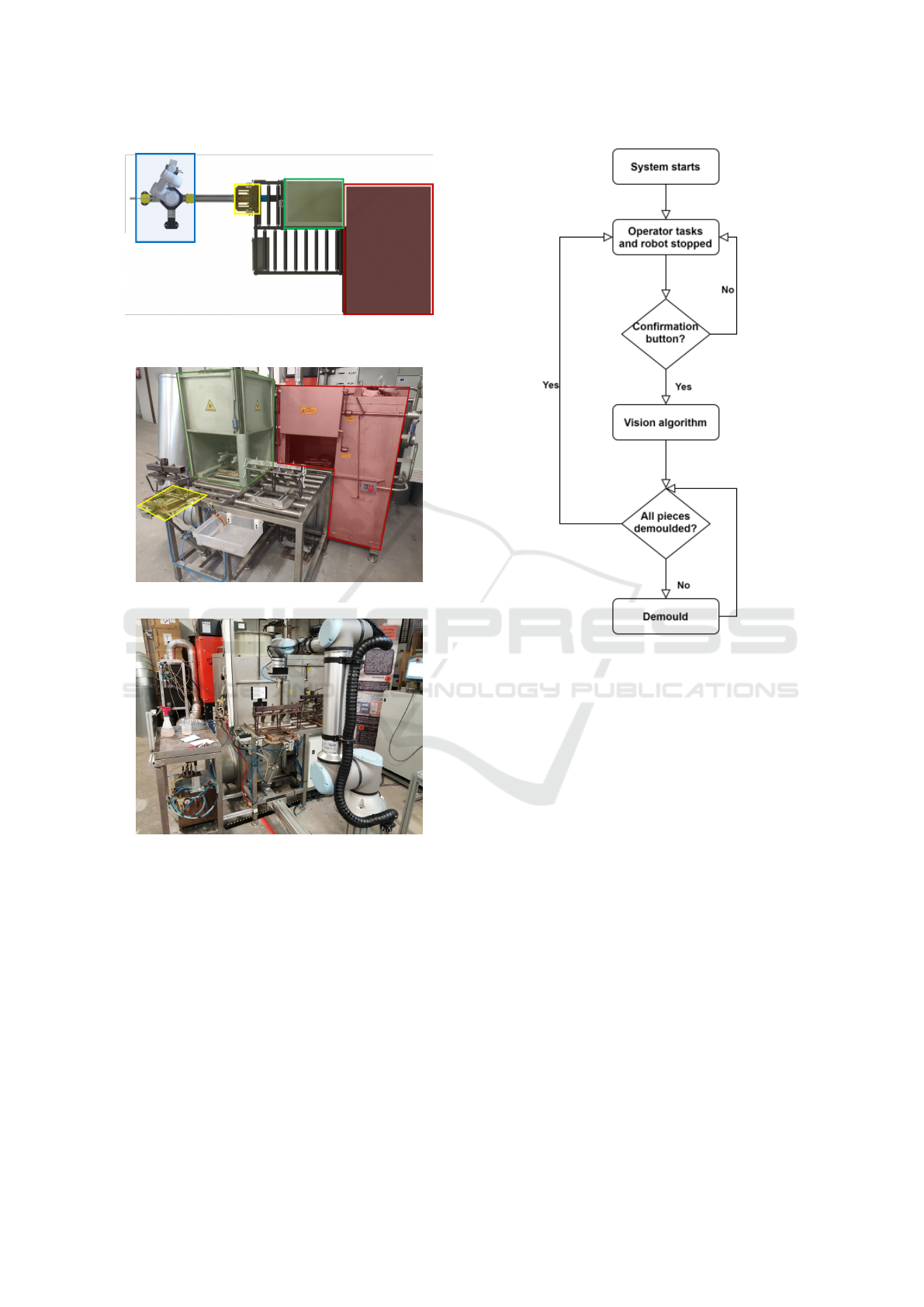

Figure 3, it is shown the distribution of the different

elements of the robotic cell: the rotomoulding oven is

marked as the red area, the air cooler is marked as the

green area, the demoulding zone is marked in yellow,

and finally, the robot (UR10e) is marked in blue.

From the simulation, the developed mock-up was

developed and it is illustrated in Figure 4 where color

areas show the different elements mentioned above.

Finally, the robot was integrated in order to final-

ize the construction of the robotic cell as shown in

Figure 5. This configuration enables the robot only to

access the demoulding area in order to execute the ex-

traction using the robotic gripper equipped with cus-

tomized fingers and an integrated vacuum system.

ICINCO 2023 - 20th International Conference on Informatics in Control, Automation and Robotics

548

Figure 3: Layout of the simulated robotic cell with marked

elements.

Figure 4: Real developed mock-up.

Figure 5: Final robotic cell.

Once the hardware of the robotic cell has been in-

tegrated, the developed software of the system must

ensure the safety of the operators and achieve the de-

moulding without damaging the pieces. In Figure 6,

it is explained the workflow of the system.

First of all, the system is initialized and the robot

is stopped until its action is required, so the operator

carries out the other tasks of the process (filling the

mould, putting in the oven, insertion in the cooler and

placing the mould in the demoulding zone) safely and

securely. Then, the operator goes out the robotic cell

and presses an external button to send the confirma-

tion to the robot in order to start the program. Next,

four pneumatic actuators fix the mould and the inte-

Figure 6: Automatic demoulding pipeline.

grated camera (Real Sense d435i) of the robot grip-

per detects the pieces. The computer vision algorithm

computes the grasping point to perform the demould-

ing. Then, the robot starts the demoulding trajectory

as shown in Figure 7. It introduces the vacuum sys-

tem equipped finger of the gripper into the detected

extraction point, closes the gripper and the air inside

the piece is removed to make easier the extraction.

After demoulding all the pieces from the mould, the

robot moves to the initial position and the cycle of

the system starts again. These steps ensure the op-

erator will be out of the robotic cell during the robot

performance, avoiding risk of injuries. Nevertheless,

a pair of laser scanners have been integrated around

the robotic cell to slow down or stop the robot in any

unforeseen situation. The security insurance and the

removal of the direct physical effort of the task reduce

the stress of the operators.

4.1 Vision Algorithm

As explained previously, the operator places the

mould in the demoulding zone and four pneumatic ac-

tuators fix it. However, the human error when placing

RoboToy Demoulding: Robotic Demoulding System for Toy Manufacturing Industry

549

Figure 7: Demoulding process.

the mould produces small variations in the positions.

The vision algorithm has been developed in order to

detect the extraction point of the pieces before the de-

moulding and to correct these small variations.

Figure 8 provides a comprehensive overview of

the entire algorithmic process, encompassing the ac-

quisition of the initial image to the detection of hole

coordinates. The process unfolds as follows.

• 1: in the initial step, the camera captures both the

initial RGB image and the point cloud of the en-

vironment.

• 2: next stage involves the removal of background

points from the point cloud to optimize computa-

tional efficiency and eliminate non-relevant data

for the algorithm. A defined threshold will elimi-

nate points that are outside, in order to minimize

the area of interest for detection.

• 3: after reducing the point cloud, the target is

to detect the top of the mould, where pieces are

located. In order to achieve it, RANSAC al-

gorithm is employed to identify the best-fitting

plane, which corresponds to the top surface of the

mould. RANSAC is an iterative method for es-

timating the parameters of a mathematical model

of an observed data set containing outliers. In this

case, the observed data set is the point cloud, the

estimated model a plane (top of the mould) and

removed outliers are the points out of that plane.

• 4: subsequently, any data outside the bounding

box of the identified plane is discarded from the

initial image. This step changes the data managed

from 3D to 2D to improve computational cost.

• 5: by narrowing down the focus to the region of

interest, the center of the piece can be readily de-

tected (green circles at the center of the pieces).

• 6: finally, the robot moves towards these coordi-

nates and introduces the vacuum finger into the

identified extraction hole. Then, the robot follows

the demoulding process shown in Figure 7.

This sequence of steps ensures a comprehensive

and accurate algorithmic process for the detection of

the extraction hole, facilitating the subsequent robotic

manipulation.

The accuracy of the vision algorithm is crucial in

identifying the extraction hole of the pieces since it

closely matches the dimensions of the gripper’s fin-

ger. This gripper incorporates a vacuum system which

removes the air from inside the piece, facilitating the

demoulding process. Additionally, these holes en-

able us to securely grasp the piece from its interior,

preventing any damage to the external surface of the

piece. Another important feature is the scalability of

this algorithm, which is easily modifiable to detect

other kind of pieces such as legs, bodies and arms,

instead of just doll heads.

5 EXPERIMENTATION AND

RESULTS

This work aims to achieve industrial production re-

quirements, which do not allow many failures during

the process and need really accurate actions. In order

to test the repeatability and performance level, several

tests have been carried out.

The primary parameters to evaluate in this appli-

cation are the accuracy of the vision algorithm and

the applied force of the robot. A substantial level of

repeatability is essential to consistently identify the

identical center point of the pieces, which has been

achieved optimizing parameters of the vision algo-

rithm explained previously. Moreover, it is crucial to

ICINCO 2023 - 20th International Conference on Informatics in Control, Automation and Robotics

550

Figure 8: Vision-based algorithm process for extraction point detection.

appropriately define the force, ensuring it is sufficient

for demoulding without causing any damage. The

robot force limit is 150 Newtons (N); however, it is

possible to disable restrictions and set the maximum

force to 225N. This test is based on good accuracy of

the algorithm to carry out 30 cycles of the complete

process using the ”head” pieces mould (2 pieces per

mould), and divide the results in different situations

which depend of the temperature of the pieces and the

force applied. Possible situations to appear during the

experiments are explained below:

• Stuck: when the robot tries to demould the parts

by applying force but the part does not come off

the mould, the robot enters an elastic loop with no

end. This usually occurs when it has taken a long

time for the robot to grip the part and the part has

cooled down.

• Slip: this situation is similar to the previous one.

The robot tries to demould the piece, but it does

not come off the mould. However, in this case,

the gripping force is lower and the piece slips.

• Damaged: in this case, the robot has demoulded

the part, but has scratched it during removal, so

although the part has been demoulded, the result

is not good. This usually happens when the force

applied is sufficient to demould the piece, but it is

not very high and the robot spends a lot of time

doing it.

• Broken: when the robot applies too much force,

the soft piece breaks.

• Demoulded: if the force applied is correct, the

piece is demoulded.

As explained previously, the robot will perform

the demoulding task 30 times, which corresponds to

60 possible pieces to extract. In Table 1 results are

shown for three different force limits:

Table 1: Demoulding success rate with different forces.

Forces (N)

150 190 225

Stuck (%) 43 22 0

Slip (%) 17 12 6

Damaged (%) 0 7 3

Broken (%) 0 3 11

Demoulded (%) 40 56 80

The results lead to the conclusion that the more

force is applied, the more successful the demoulding.

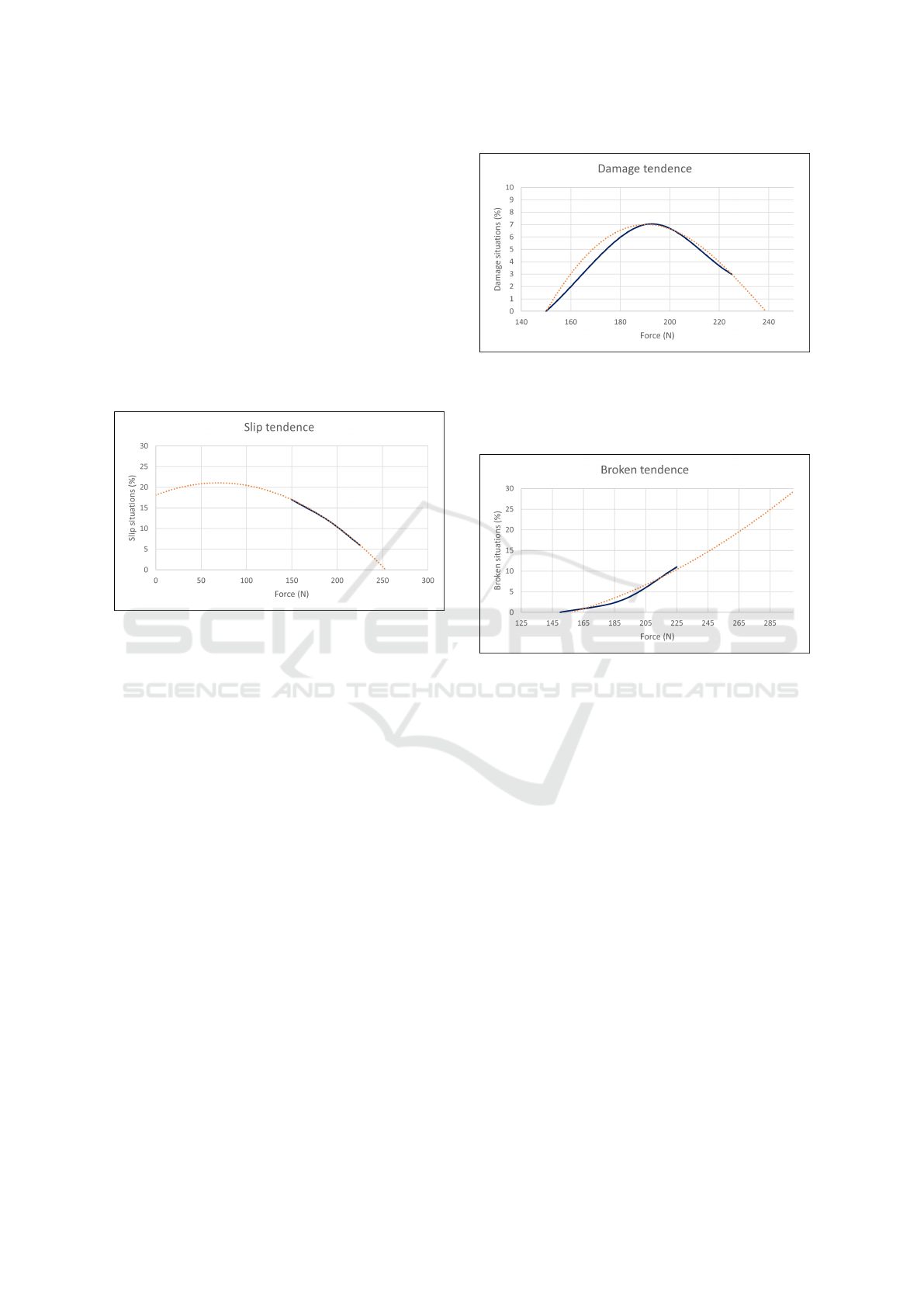

The following figures explain each result according to

the situation.

5.1 Stuck Results

As explained previously, if the robot is not applying

enough force to demould the piece, it cools, and con-

sequently the robot tries to demould it in an infinite

loop. Figure 9 shows the results obtained and the

trend of the percentage of times this situation will oc-

cur according to the force applied.

Figure 9: Trend of stuck situations as a function of the force

applied by the robot.

RoboToy Demoulding: Robotic Demoulding System for Toy Manufacturing Industry

551

It is noticeable that when the forces are high, the

parts do not get stuck, whereas when the forces are re-

duced, this situation becomes more frequent because

the robot does not manage to dislodge the parts from

the mould.

5.2 Slip Results

The piece slips from the robot during the demoulding

task due to the lack of applied force. Slip and stuck

situations are the most repeated ones when the robot

applies low forces. Figure 10 shows the results of the

test and the trend of the slip situation according to the

force applied.

Figure 10: Trend of slip situations as a function of the force

applied by the robot.

The results obtained show the relation between

low forces and slippage produced in the pieces dur-

ing demoulding task.

5.3 Damage Results

Causing harm to the pieces is a frequent occurrence

when dealing with moderate levels of force, as the

robot managed to remove the piece but encountered

challenges in doing so, resulting in damage to the

piece during the procedure. Figure 11 represents the

trend of the damage situations from the obtained data

of the tests.

By contrasting the preceding graphics, it is possi-

ble to infer that when subjected to lower forces, the

piece remains undamaged due to its inability to be re-

moved from the mould. Conversely, at higher forces

there is no damage because the robot successfully ac-

complishes the demoulding of the piece.

5.4 Broken Results

As mentioned previously, the pieces are highly soft

and malleable, which poses challenges for manipulat-

ing this material as the robot runs the risk of either

Figure 11: Trend of Damage situations as a function of the

force applied by the robot.

deforming or breaking it. Figure 12 shows the ten-

dency for part breakage situations to occur.

Figure 12: Trend of Break situations as a function of the

force applied by the robot.

These situations occur when the demoulding task

is performed with relatively higher forces. It can be

observed that with an increase in force, the probability

of breakage also tends to rise.

5.5 Demoulded Results

This situation measures the number of demoulded

pieces, which means the absolute success rate of the

task. Figure 13 represents the trend of the demoulding

success rate.

In conclusion, the results obtained indicate that

as the force increases, the probability of successful

demolding of the part also increases. However, as

mentioned in the previous graphics, if the force is

increased, the probability of breaking the piece rises

too.

To sum up, considering the three distinct forces

applied (150N for low, 190N for intermediate, 225N

for high), the potential scenarios can be categorized

as follows. At low forces, there are instances of slips

and pieces getting stuck. At intermediate forces, the

robot tend to damage the pieces. And at high forces,

ICINCO 2023 - 20th International Conference on Informatics in Control, Automation and Robotics

552

Figure 13: Trend of Demoulded situations as a function of

the force applied by the robot.

the pieces can either break or demould successfully.

Target forces to achieve a successful task perfor-

mance are elevated. Indeed, it is important to consider

that the rise in the rate of broken pieces could have an

impact on the overall results. This is the reason for

research into new gripper finger designs to achieve

demoulding of pieces at medium forces or to define

new demoulding paths to avoid part breakage.

6 CONCLUSION

This paper has presented a new robotic system able to

perform the traditional demoulding task of the roto-

moulding manufacturing process of plastic toys. An

accurate vision-based algorithm detects the extraction

hole of the pieces, where the robot grasps them. The

first step to achieve this performance level was to de-

velop the accurate vision algorithm. Then, the defi-

nition of effective demoulding trajectories to achieve

the extraction of the pieces.

The results obtained allow us to understand the di-

rect relationship between the force applied and the

number of successful demouldings. However, this

fact increases the possibility of breaking the pieces

during the process. As future work, in order to im-

prove the system and to avoid failed extractions, the

fingers of the gripper could be redesigned to increase

the grasped area of the piece, to reduce the possibility

of leaving marks or to break it.

Finally, a more exhaustive study will be carried

out on the trajectories the operators make during the

manual process in order to define similar ones to the

robot. Furthermore, as this system is easily scalable,

the number of parts to be demoulded will be increased

to cover all the parts that a normal toy doll has. In-

stead of only demoulding heads, the system will also

be able to extract bodies, legs and arms. In addition,

this work has the potential to be completely adapted to

cover all the different models of toys the factory pro-

duces; however, when the need arises to extract larger

pieces, it becomes evident that the collaborative robot

may fall short in terms of force capacity. In such situ-

ations, it would be necessary to resort to an industrial

robot, which offers greater force and performance ca-

pabilities. However, making this switch would entail

losing the collaborative nature of the task since in-

dustrial robots often operate in more controlled envi-

ronments and are not safe for direct interaction with

humans. Therefore, a balance must be struck between

the size of the pieces and the robot’s capacity to main-

tain safe and efficient collaboration.

REFERENCES

Herguedas, R., L

´

opez-Nicol

´

as, G., Arag

¨

u

´

es, R., and Sag

¨

u

´

es,

C. (2019). Survey on multi-robot manipulation of de-

formable objects. In 2019 24th IEEE International

Conference on Emerging Technologies and Factory

Automation (ETFA), pages 977–984.

Huang, S. H., Zambelli, M., Kay, J., Martins, M. F., Tassa,

Y., Pilarski, P. M., and Hadsell, R. (2019). Learning

gentle object manipulation with curiosity-driven deep

reinforcement learning.

Lahoud, M., Marchello, G., Abidi, H., D’Imperio, M.,

and Cannella, F. (2021). Robotic Manipulation Sys-

tem for Multi-Layer Fabric Stitching. volume Vol-

ume 7: 17th IEEE/ASME International Conference

on Mechatronic and Embedded Systems and Appli-

cations (MESA) of International Design Engineering

Technical Conferences and Computers and Informa-

tion in Engineering Conference. V007T07A037.

Lin, N., Zhang, L., Chen, Y., Zhu, Y., Chen, R., Wu, P., and

Chen, X. (2019). Reinforcement learning for robotic

safe control with force sensing. In 2019 WRC Sym-

posium on Advanced Robotics and Automation (WRC

SARA), pages 148–153.

Navarro-Alarcon, D., Yip, H. M., Wang, Z., Liu, Y.-H.,

Zhong, F., Zhang, T., and Li, P. (2016). Automatic

3-d manipulation of soft objects by robotic arms with

an adaptive deformation model. IEEE Transactions

on Robotics, 32(2):429–441.

Navarro-Alarc

´

on, D., Liu, Y.-H., Romero, J. G., and Li, P.

(2013). Model-free visually servoed deformation con-

trol of elastic objects by robot manipulators. IEEE

Transactions on Robotics, 29(6):1457–1468.

Ortenzi, V., Corke, P., Leitner, J., and Cherubini, A. (2018).

Towards vision-based manipulation of plastic materi-

als.

Ubeda, R. P., Guti

´

errez Rubert, S. C., Stanisic, R. Z., and

Perles Ivars, A. (2021). Behavioural study of the force

control loop used in a collaborative robot for sanding

materials. Materials, 14(1).

RoboToy Demoulding: Robotic Demoulding System for Toy Manufacturing Industry

553