Advancing Flotation Process Optimization Through Real-Time Machine

Vision Monitoring: A Convolutional Neural Network Approach

Ahmed Bendaouia

1,2 a

, El Hassan Abdelwahed

1 b

, Sara Qassimi

4 c

, Abdelmalek Boussetta

3

,

Intissar Benzakour

3

, Oumkeltoum Amar

2

, Franc¸ois Bourzeix

2

, Khalil Jabbahi

1

and Oussama Hasidi

1,2

1

Computer Systems Engineering Laboratory (LISI), Computer Science Department, Faculty of Sciences Semlalia,

Cadi Ayyad University, Marrakech, Morocco

2

SEIA Departement, Moroccan Foundation for Advanced Science Innovation and Research (MAScIR), Rabat, Morocco

3

R&D and Engineering Center, Reminex, Managem Group, Marrakech, Morocco

4

Computer and Systems Engineering Laboratory (L2IS), Computer Science Department,

Faculty of Science and Technology, Cadi Ayyad University, Marrakech, Morocco

Keywords:

Machine Vision, Deep Learning, Industry 4.0, Flotation Froth, Mining Industry, Monitoring.

Abstract:

The mining industry’s continuous pursuit of sustainable practices and enhanced operational efficiency has

led to an increasing interest in leveraging innovative technologies for process monitoring and optimization.

This study focuses on the implementation of Convolutional Neural Networks (CNN) for real-time monitoring

of differential flotation circuits in the mining sector. Froth flotation, a widely used technique for mineral

separation, necessitates precise control and monitoring to achieve maximum recovery of valuable minerals

and separate them from gangue. The research delves into the significance of froth surface visual properties

and their correlation with flotation froth quality. By capitalizing on CNN’s ability to identify valid, hidden,

novel, potentially useful and meaningful information from image data, this study showcases how it surpasses

traditional techniques for the flotation monitoring. The paper provides an in-depth exploration of the dataset

collected from various stages of the Zinc flotation banks, labeled with elemental grade values of Zinc (Zn),

Iron (Fe), Copper (Cu), and Lead (Pb). CNNs’ implementation in a regression problematic allows for real-

time monitoring of mineral concentrate grades, enabling precise assessments of flotation performance. The

successful application of CNNs in the Zinc flotation circuit opens up new possibilities for improved process

control and optimization in mineral processing. By continuously monitoring froth characteristics, engineers

and operators can make informed decisions, leading to enhanced mineral recovery and reduced waste.

1 INTRODUCTION

The mining industry is undergoing a transformative

phase driven by the advent of the 4th industrial rev-

olution, which is becoming a pivotal factor in ensur-

ing sustainability, success, and competitiveness. The

depletion of mineral resources over the past decade

has spurred the minerals engineering community to

explore innovative exploitation techniques. Conse-

quently, there has been a paradigm shift in the mining

sector, with an increasing focus on industrial inno-

vation in mining, exploration, process optimization,

logistics, and marketing, aimed at addressing chal-

a

https://orcid.org/0000-0003-0017-9285

b

https://orcid.org/0000-0002-2786-6707

c

https://orcid.org/0000-0002-9441-986X

lenges such as depleting mineral reserves, rising en-

ergy costs, and unpredictable fluctuations in raw ma-

terial availability.

Among various strategies employed to separate

valuable minerals from ore, flotation stands out as

the most common and widely utilized technique in

the mining industry. However, the advanced model-

ing of flotation processes has long been constrained

by classical mathematics and modeling techniques.

Recognizing the need for transformative solutions,

the mineral engineering community has recently em-

braced the application of emerging technologies in

flotation processes. These disruptive mining tech-

nologies, driven by innovative Information Technolo-

gies (IT), have paved the way for enhanced energy

efficiency and sustainable practices in the mining in-

dustry.

Bendaouia, A., Abdelwahed, E., Qassimi, S., Boussetta, A., Benzakour, I., Amar, O., Bourzeix, F., Jabbahi, K. and Hasidi, O.

Advancing Flotation Process Optimization Through Real-Time Machine Vision Monitoring: A Convolutional Neural Network Approach.

DOI: 10.5220/0012237300003598

In Proceedings of the 15th International Joint Conference on Knowledge Discovery, Knowledge Engineering and Knowledge Management (IC3K 2023) - Volume 1: KDIR, pages 429-436

ISBN: 978-989-758-671-2; ISSN: 2184-3228

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

429

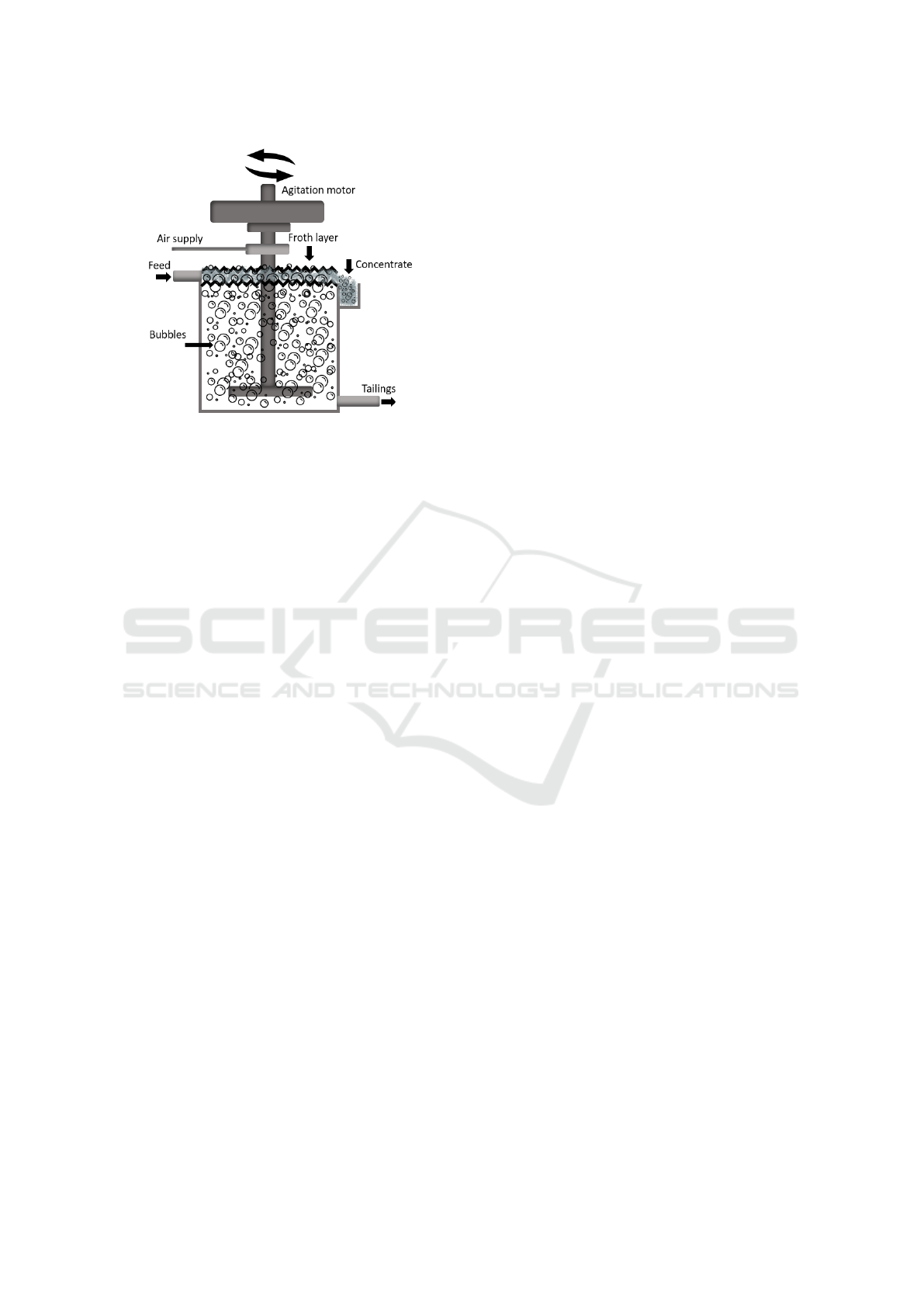

Figure 1: Froth flotation separation technique.

The need for optimizing and controlling the flota-

tion process is further intensified by the complexity

of diverse minerals’ separation based on their varying

hydrophobicity levels (Rajapakse et al., 2022). As

a result, real-time monitoring and precise control of

the flotation circuit have become increasingly chal-

lenging. To address this crucial issue, this paper ex-

plores the application of Convolutional Neural Net-

works (CNN) for real-time monitoring of the zinc

flotation circuit in the mining industry. By harness-

ing the power of CNN, this study aims to provide an

innovative and efficient solution for enhancing, in real

time, the flotation process’s effectiveness and sustain-

ability in the mining sector.

The paper is structured as follows: Section 1

provides an introduction to the context and problem

statement; Section 2 presents a literature review en-

compassing similar applications in mineral process-

ing and flotation froth analysis; Section 3 describes

the methodology for data collection and preparation;

Section 4 provides the results and evaluation of our

proposed method, followed by a discussion; and fi-

nally, Section 5 concludes the paper and offers per-

spectives for future research.

2 STATE OF THE ART

2.1 Machine Vision for Flotation

Monitoring

The mineral engineering community has been in-

creasingly captivated by the potential of utilizing

Machine Vision (MV) techniques to monitor flota-

tion processes (Aldrich et al., 2022)(Jovanovi

´

c et al.,

2015). These methods have shown promising appli-

cations in optimizing various stages of the flotation

circuit, enabling more efficient mineral separation and

recovery.

Machine Vision techniques offer an innovative

and non-invasive means to capture and analyze froth

properties in real-time. By continuously monitoring

bubble size, texture, and color changes during the

flotation process, engineers and operators can make

informed decisions and adjustments to enhance over-

all process efficiency. The integration of MV with

advanced control systems can lead to a more sophis-

ticated and adaptive flotation process, one that can

adapt to varying ore conditions and achieve optimal

mineral recovery under different operating scenarios.

To inspect and assess flotation froth, conventional ap-

proaches have often relied on RGB-based methods,

which offer valuable insights into bubble size and tex-

ture. Bubble size and shape hold significant impor-

tance, as they significantly impact the efficiency and

effectiveness of the process. Various factors influ-

ence these characteristics, including the rate of the

gas stream, dosage of reagents, particle granularity,

hydrophobicity of minerals, and the pH of the pulp.

Understanding the interplay of these factors is essen-

tial for achieving optimal flotation performance, as it

directly affects the recovery of valuable minerals and

the rejection of gangue.

Since the flotation froth is heavily influenced by

froth concentrate grade, and bubble deformation is

positively correlated to the flotation froth quality,

many froth image inspection systems were devel-

oped (Ai et al., 2018)(Liu et al., 2020)(Zhang and

Xu, 2020)(Massinaei et al., 2019)(Tang et al., 2021).

Bubble size detection, which is the main technique

to obtain information of flotation cells has taken the

biggest portion of the flotation froth inspection(Ai

et al., 2018)(Zhang and Xu, 2020)(Kaartinen et al.,

2006).

2.2 Deep Learning for Flotation Froth

Features Extraction

Traditional texture and bubble size extraction meth-

ods consider limited feature types. The developed

froth image inspection systems has responded to the

real time challenge but stills on the way to be more

accurate. Deep learning methods are an alternative

which does not suffer these disadvantages. The qual-

ity of convolutional neural networks (CNN) features

was compared to those from traditional texture fea-

ture extraction methods(Horn et al., 2017)(Bendaouia

et al., 2022). Performance of CNN as feature ex-

tractors was found to be competitive, showing sim-

ilar performance to the other texture feature extrac-

tors. A classification CNN algorithm was compared

KDIR 2023 - 15th International Conference on Knowledge Discovery and Information Retrieval

430

to a conventional artificial neural network (ANN).

The results show that the flotation froth classifica-

tion model CNN-based significantly outperforms the

ANN classifier in terms of accuracy and computation

time(Zarie et al., 2020).

The predominant applications in this domain pri-

marily revolve around froth classification using Con-

volutional Neural Networks (CNN). This preference

stems from the CNN’s inherent ability to learn in-

tricate hierarchical features from image data. Addi-

tionally, CNN’s computational power in deep learning

facilitates effective feature extraction from froth im-

ages, enhancing the classification process (Zhang and

Gao, 2021), (Zarie et al., 2020), (Cao et al., 2022),

and (Wen et al., 2021).

In the context of supervised learning for regres-

sion tasks, previous studies has explored the use of

ConvLSTM on video data(Bendaouia. et al., 2023a)

and Fast Fourier based features extraction along with

Machine Learning(Bendaouia. et al., 2023b). This

study aims to capitalize on the capabilities of CNNs,

aiming to revolutionize real-time monitoring of the

Zinc flotation circuit. We present a CNN-based im-

age analysis soft sensor designed for online moni-

toring of industrial flotation. Our proposed analyzer

not only classifies froth images accurately, but pre-

dicts the grades of four minerals: Zn, Cu, Fe, and Pb

in the cleaners of the Zinc circuit. The objective is

to achieve more precise and efficient assessments of

mineral concentrate grades and overall flotation per-

formance. By leveraging the potential of CNNs in

this regression-based problem, this research opens up

new avenues for enhancing mining industry practices

through improved process monitoring and optimiza-

tion.

3 METHODOLOGY

3.1 The Differential Flotation Circuit at

CMG Morocco

The flotation circuits employed at CMG (Compagnie

Mini

`

ere de Guemassa) in Morocco for processing a

complex ore from two extraction sites, ”Daraa Las-

far” and ”Kodiat Aicha,” located around the city of

Marrakech, are known as a complex differential flota-

tion circuit. At the CMG flotation site, three miner-

als are valuated: CuFeS2 Copper sulphide (Chalcopy-

rite), ZnS Zinc sulphide (Sphalerite) and PbS Lead

sulphide (Galena). Each of these minerals follows

a specific flotation circuit consisting of three stages:

roughing, scavenging, and cleaning. The primary ob-

jective of these consecutive cells is to maximize the

concentrate grade and recovery of valuable minerals

while effectively separating them from the gangue.

This study focuses specifically on the Zinc flotation

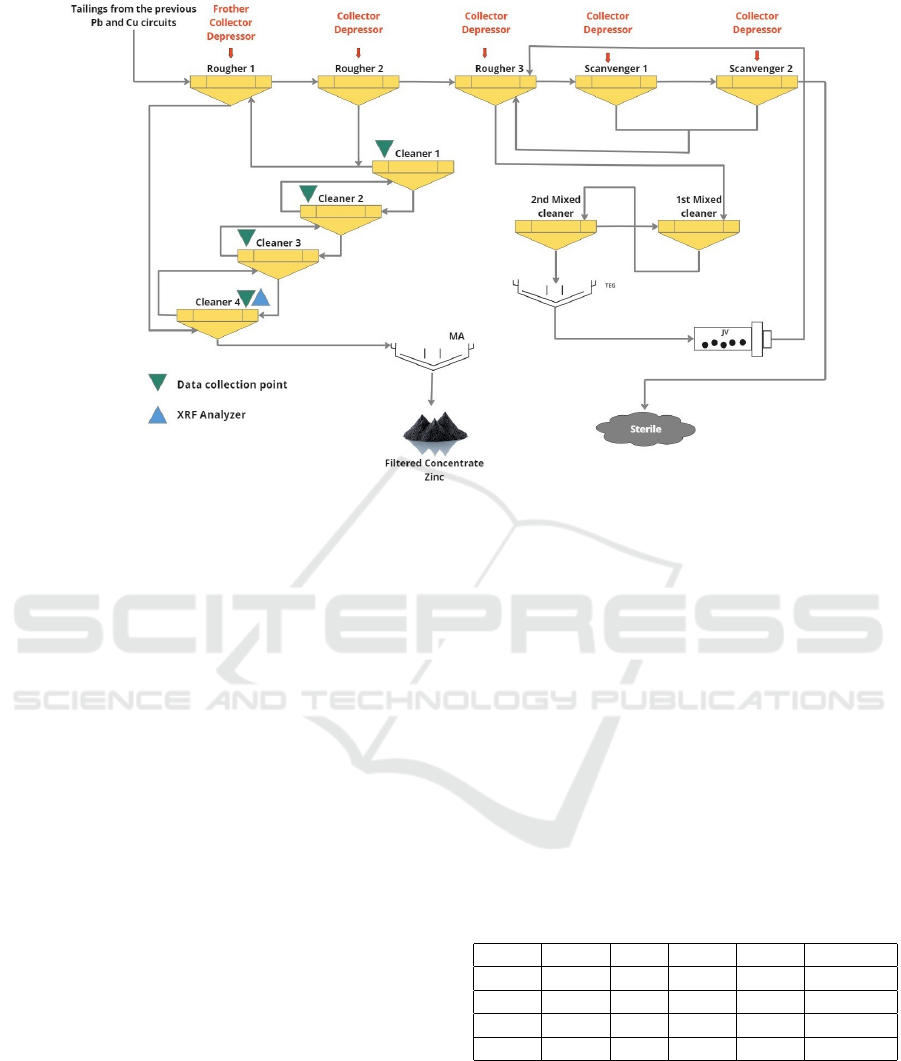

circuit, as presented in Figure 2. The Zinc flotation

circuit comprises three roughers, two scavengers, and

six cleaners. For each type of flotation bank, specific

reagents, such as frothers, collectors, and depressors,

are added. The roughing stage initiates the flotation

process, with the primary aim of separating as much

valuable mineral as possible from the initial ore feed.

The scavenging stage is intended to recover any re-

maining valuable mineral that might not have been

separated during the roughing stage. Lastly, the clean-

ing stage produces the concentrate with the highest

achievable grade of the valuable mineral. These three

stages play a pivotal role in optimizing the grade and

recovery of valuable minerals while efficiently isolat-

ing them from the gangue.

3.2 CNN for Knowledge Discovery and

Features Extraction

Convolutional Neural Networks (CNN) can play a

crucial role in extracting Knowledge Discovery (KD)

from froth flotation data. By leveraging their power-

ful capabilities in image processing and pattern recog-

nition, CNNs can uncover valid, hidden, novel, po-

tentially useful, and meaningful information from the

froth images obtained during the flotation process.

CNNs can be applied to extract KD from froth flota-

tion data in by different aspects:

• Froth Image Analysis: CNNs can process and an-

alyze the froth images captured during the flota-

tion process. By learning hierarchical features

from these images, CNNs can identify important

patterns and structures within the froth, including

bubble sizes, textures, and color variations.

• Froth Segmentation: CNNs excel at froth segmen-

tation, accurately distinguishing between valuable

minerals and gangue particles present in the froth.

This segmentation provides valuable insights into

the distribution of minerals within the froth, aid-

ing in the evaluation of flotation performance and

mineral recovery.

• Feature Extraction: CNNs are adept at feature ex-

traction, allowing them to identify relevant char-

acteristics in the froth images that might not be

apparent through traditional algorithms. This ex-

traction process helps uncover hidden patterns and

correlations, contributing to a deeper understand-

ing of the flotation process.

• Predicting Mineral Grades: With the knowledge

gained from froth image analysis and feature ex-

Advancing Flotation Process Optimization Through Real-Time Machine Vision Monitoring: A Convolutional Neural Network Approach

431

Figure 2: Flowchart of the Zinc flotation circuit in the differential flotation plant at CMG Morocco.

traction, CNNs can predict mineral grades more

accurately than traditional methods. This predic-

tive capability is vital in optimizing the flotation

process and maximizing the recovery of valuable

minerals.

• Process Optimization: By providing insights into

froth behavior and mineral distribution, CNNs as-

sist in process optimization. They can recommend

adjustments in gas flow rates, reagent dosages,

and other process parameters to enhance flotation

efficiency and overall performance.

• Identifying Anomalies: CNNs can detect anoma-

lous froth behavior, indicating potential issues or

deviations from expected flotation patterns. Early

detection of anomalies allows for timely correc-

tive actions, preventing potential process ineffi-

ciencies or disruptions.

• Real-time Monitoring: CNNs can facilitate real-

time monitoring of the flotation process, enabling

continuous data analysis and feedback. This real-

time monitoring ensures prompt decision-making

and adaptive control, enhancing process stability

and productivity.

CNNs contribute significantly to Knowledge Discov-

ery in froth flotation data by effectively processing

and analyzing froth images, identifying valuable pat-

terns, predicting mineral grades, optimizing process

parameters, and enabling real-time monitoring. Their

ability to extract meaningful information from froth

images revolutionizes the way the mining industry ap-

proaches flotation monitoring and process optimiza-

tion, leading to increased efficiency, improved min-

eral recovery, and sustainable mining practices.

3.3 Data Collection and Image

Capturing

To effectively apply Convolutional Neural Networks

(CNN) for real-time monitoring of the Zinc flotation

circuit, comprehensive data collection and image cap-

turing procedures were conducted. The dataset used

in this study was collected from different cleaner cells

of the Zinc flotation circuit in an actual industrial

flotation setting.

Table 1: Statistical analysis of the different mineral grades

of the collected samples.

Mean Std Min Max Variance

Cu % 0.98 0.36 0.41 1.86 0.13

Fe % 15.00 3.60 8.77 21.24 12.93

Pb % 1.34 0.46 0.60 2.70 0.22

Zn % 42.17 5.18 30.59 51.95 26.81

The data is collected from the cleaners of the Zinc

flotation banks within a real-industrial mining envi-

ronment Figure 3. It comprised a total of 6462 froth

flotation images utilized for the training phase, along

with an additional 1738 images for testing purposes.

Each image was meticulously labeled with four ele-

mental grade values: Zinc (Zn), Lead (Pb), Iron (Fe),

and Copper (Cu) (See Figure 1). To ensure uniformity

KDIR 2023 - 15th International Conference on Knowledge Discovery and Information Retrieval

432

Figure 3: The data acquisition system of the flotation froth

image data from the Zinc circuit.

Figure 4: The image capturing characteristics during data

collection.

in the visual aspect parameters, the images were cap-

tured using an RGB camera under stable luminosity

conditions as described in the Figure 4.

The data collection process was from different

shifts, encompassing different operational settings.

This extended duration allowed for a comprehensive

examination of the froth surface characteristics under

varying conditions, contributing to a more thorough

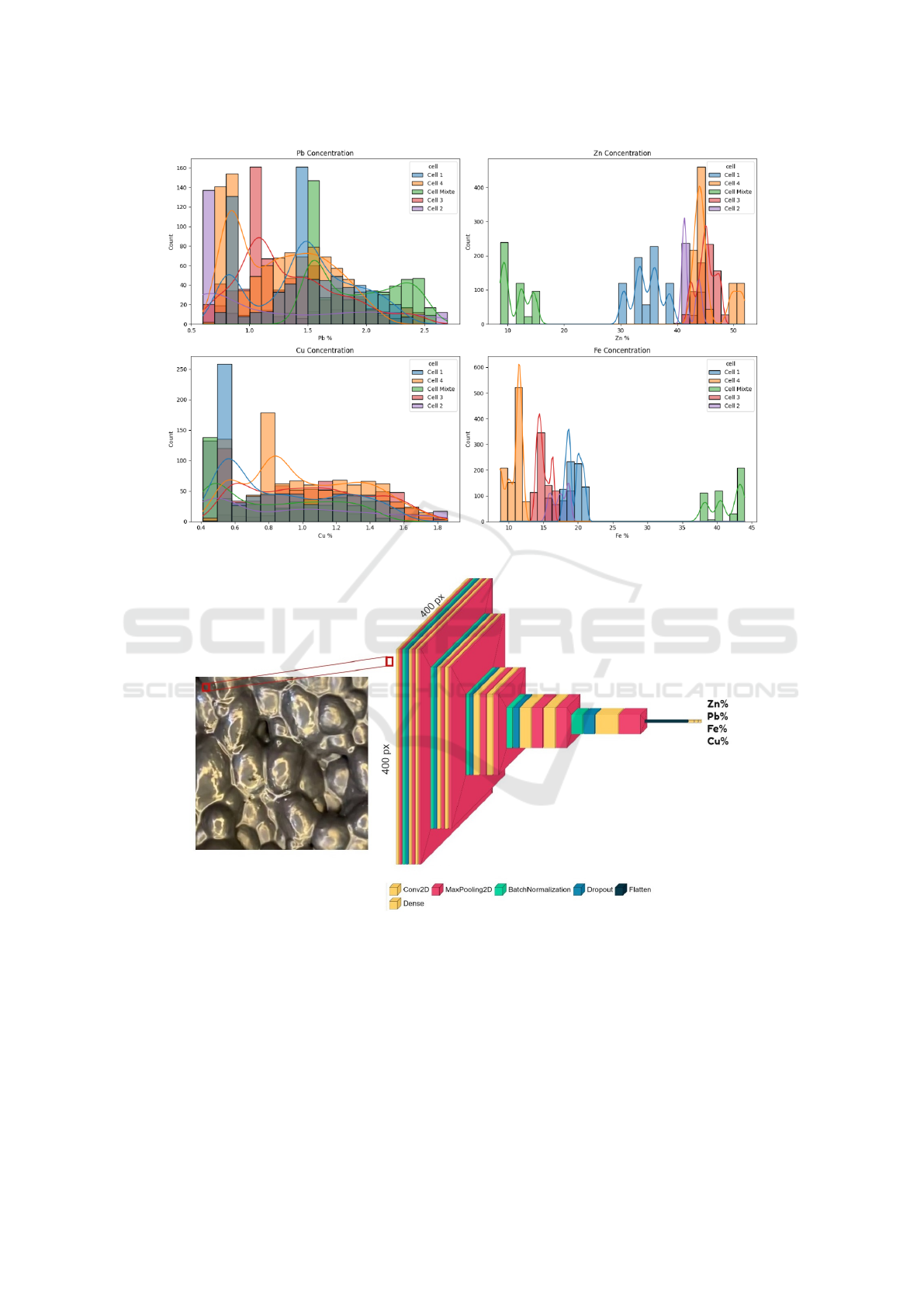

understanding of the flotation process. The Figure

5 presents the mineral grades distribution of the col-

lected samples from the cleaner of Zinc circuit.

4 FLOTATION FROTH

MONITORING CNN-BASED

4.1 CNN Architecture Description

The used CNN architecture has an input of

400x400x3 as height, weight and depth of the images

with RGB color channels Figure 6. The model uses a

rectified linear unit (ReLU) activation function, which

allows for non-linearity in the model. The Adam op-

timizer is used for training, with a learning rate of

0.001, which helps the model converge faster. The

loss function used is ’mean absolute percentage error’

which measures the mean absolute percentage error

between the predicted and actual values. The batch

size used is 32, which means that the model updates

its parameters after processing 32 images. The model

is trained for 100 epochs using a GPU. The model

has a total of 47,538,628 trainable parameters, which

represents the number of weights and biases that are

updated during the training.

4.2 Experimental Evaluation

To assess the performance of the CNN-based model

designed for predicting mineral grades in flotation

froth, we conducted an experimental process using

a new deployment dataset. The model’s evaluation

was conducted using a separate test dataset, consist-

ing of froth images, with each image labeled with cor-

responding mineral grades.

Various metrics were employed to measure the ac-

curacy of the model, including Root Mean Squared

Error (RMSE), Mean Absolute Percentage Error

(MAPE), and the average error on real deployment

data. The Mean Squared Error metric was used to

evaluate the disparity between the predicted and ac-

tual values, while the average error on real deploy-

ment data gauges the model’s ability to generalize

and predict outcomes in real-world industrial flota-

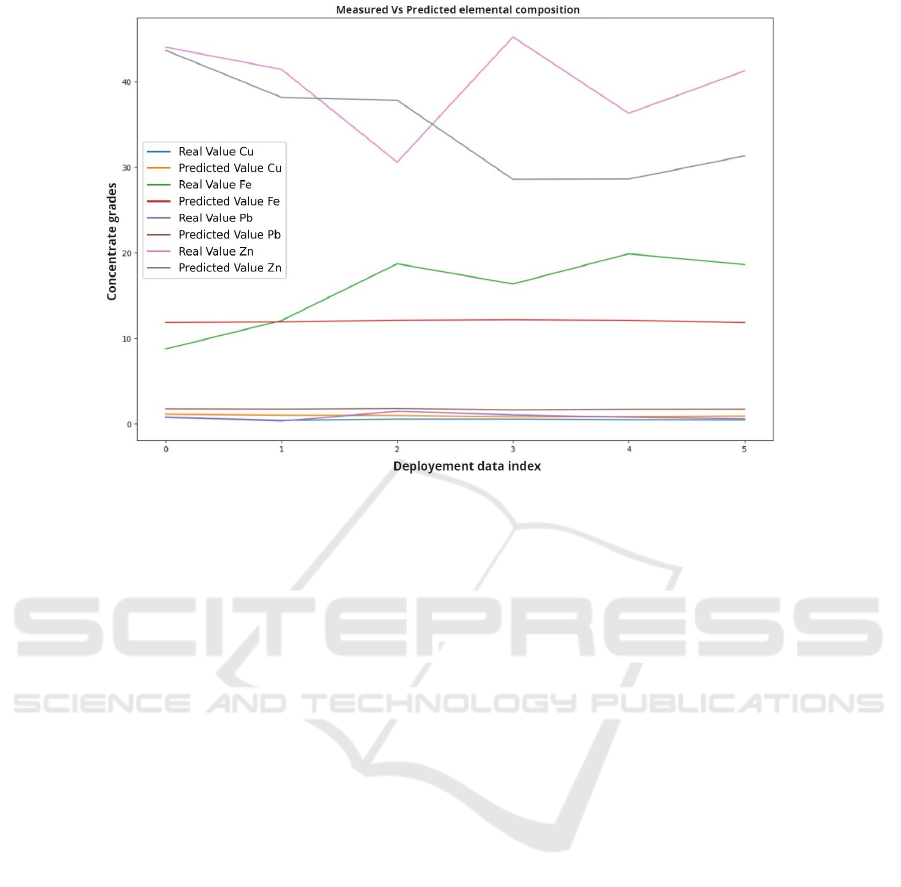

tion scenarios. Additionally, we visually represented

the prediction results of the trained models for a new

sample of image data (see Figure 7).

Table 2: The evaluation metrics of the CNN model on de-

ployment data of the Zn Cleaners of CMG flotation circuit.

Elements Evaluation metrics

MSE RMSE MAPE Average

Error

Cu 0.18 0.43 79.47 0.42

Fe 29.33 5.42 28.75 4.75

Pb 0.89 0.94 144.79 0.88

Zn 82.90 9.11 19.07 7.52

4.3 Discussion of the Results

Through rigorous evaluations and analyses, the table

2 displays the MSE, RMSE, MAPE and average error

values for each elemental composition. Concerning

the Zn mineral, and the RMSE value is 9.11, while

the variance of the Zn collected samples is 26.81.

This outcome is considered as accurate considering

the variation in Zn mineral grades observed within

Advancing Flotation Process Optimization Through Real-Time Machine Vision Monitoring: A Convolutional Neural Network Approach

433

Figure 5: Mineral grades distribution of the collected samples from the cleaner of the Zinc circuit at CMG.

Figure 6: The used CNN architecture for features extraction from the froth images.

the Zn flotation circuit. The low values of these met-

rics suggest that the model provides more precise pre-

dictions, taking into account the high standard devia-

tion of the Zn mineral grades. Furthermore, the table

underscores that the model’s performance varies de-

pending on the mineral, owing to the diverse distribu-

tions of concentrate grades. Notably, when compared

to other minerals, Copper exhibits lower MSE, and

MAPE values, indicating the model’s heightened ac-

curacy in predicting this particular low grade mineral.

This study demonstrates the reliability and accuracy

of the developed CNN-based models in predicting the

elemental composition of flotation froth. These re-

sults validate the effectiveness of the model and its

potential for enhancing process monitoring and opti-

mization in the mining industry.

In previous studies, we explored more intricate

methods for identifying mineral grades, including

KDIR 2023 - 15th International Conference on Knowledge Discovery and Information Retrieval

434

Figure 7: The measured values of zinc, iron, copper and lead with the predicted values provided by the CNN-based architecture

on deployment data from the Zn cleaners.

feature extraction based on image processing (Ben-

daouia et al., 2022), ConvLSTM (Bendaouia. et al.,

2023a) and Fourier Transform with baseline Machine

Learning methods (Bendaouia. et al., 2023b). The

CNN-based approach is considered less complex and

easier to implement in IoT systems, given its reduced

complexity and lower time consumption. While the

CNN-based solution shows promise, it is essential

to acknowledge that its accuracy may not match the

precision of traditional techniques, such as labora-

tory analysis or XRF fluorescence. These established

methods may currently yield more accurate results;

however, the CNN-based approach presents a vision

for the future of flotation monitoring. With further

advancements and accumulation of more comprehen-

sive datasets, the model’s accuracy is expected to im-

prove over time.

5 CONCLUSIONS

In this paper, we have explored the potential of

Convolutional Neural Networks (CNN) for real-time

monitoring of the Zinc flotation circuit in the mining

industry. Our research has demonstrated the signifi-

cance of froth surface visual properties in relation to

flotation froth quality, highlighting CNN’s superior-

ity in froth monitoring compared to traditional tech-

niques. By harnessing the power of CNNs, we have

successfully extracted valuable Knowledge Discovery

(KD) from froth flotation data, enabling precise as-

sessments of mineral concentrate grades and overall

flotation performance. The application of CNNs in

the Zinc flotation circuit has paved the way for en-

hanced process control and optimization in the mining

industry. The CNN model’s ability to continuously

analyze froth images, predict mineral grades, and

monitor froth behavior has led to more efficient min-

eral separation and improved recovery rates. More-

over, the simplicity and computational efficiency of

CNNs have made them an attractive feature extraction

method compared to conventional supervised tech-

niques.

By extending CNNs to other circuits, integrat-

ing the flotation Digital Twin (Hasidi et al., 2022),

designing a deployment architecture, and deploying

real-time process adjustment, future research holds

promising prospects for enhancing mining opera-

tions’ sustainability, productivity, and competitive-

ness.

ACKNOWLEDGEMENTS

This study is a part of a project supported by the Dig-

ital Development Agency (DDA), and the National

Center for Scientific and Technical Research of Mo-

rocco (CNRST) through the Al-Khawarizmi program.

The project is a collaboration between MASCIR (Mo-

roccan Foundation for Advanced Science, Innovation

and Research), REMINEX R&D (an engineering and

project management subsidiary of the MANAGEM

Advancing Flotation Process Optimization Through Real-Time Machine Vision Monitoring: A Convolutional Neural Network Approach

435

Group), UCA, ENSMR, and ENSIAS. We would like

to express our gratitude to the MANAGEM Group

and its subsidiary CMG for providing us with the

opportunity to conduct research, collect and validate

data on-site, and for being an industrial partner in this

project.

REFERENCES

Ai, M., Xie, Y., Xu, D., Gui, W., and Yang, C. (2018).

Data-driven flotation reagent changing evaluation via

union distribution analysis of bubble size and shape.

The Canadian Journal of Chemical Engineering,

96:2616–2626.

Aldrich, C., Avelar, E., and Liu, X. (2022). Recent advances

in flotation froth image analysis. Minerals Engineer-

ing, 188:107823.

Bendaouia., A., Abdelwahed., E., Qassimi., S., Boussetta.,

A., Benzakour., I., Amar., O., Bourzeix., F., Soulala.,

A., and Hasidi., O. (2023a). Conv-lstm for real

time monitoring of the mineral grades in the flotation

froth. In Proceedings of the 12th International Con-

ference on Data Science, Technology and Applications

- DATA, pages 89–96. INSTICC, SciTePress.

Bendaouia., A., Abdelwahed., E., Qassimi., S., Boussetta.,

A., Hasidi, I. B. O., Amar., O., and Chafiqui., Y.

(2023b). Fourier transform and machine learning for

real-time monitoring of froth flotation in mining in-

dustry. In Proceedings of the 6TH IEEE Conference

on Information and Multimedia Processing. IEEE,

Iieee xplore digital library.

Bendaouia, A., Abdelwahed, E. H., Qassimi, S., Boussetta,

A., Benhayoun, A., Benzakour, I., Amar, O., Zen-

nayi, Y., Bourzeix, F., Ba

¨

ına, K., Ba

¨

ına, S., Khalil, A.,

Cherkaoui, M., and Hasidi, O. (2022). Digital Trans-

formation of the Flotation Monitoring Towards an On-

line Analyzer. In Hamlich, M., Bellatreche, L., Sia-

dat, A., and Ventura, S., editors, Smart Applications

and Data Analysis, Communications in Computer and

Information Science, pages 325–338, Cham. Springer

International Publishing.

Cao, W., Wang, R., Fan, M., Fu, X., Wang, H., and

Wang, Y. (2022). A new froth image classification

method based on the MRMR-SSGMM hybrid model

for recognition of reagent dosage condition in the coal

flotation process. Appl. Intell.

Hasidi, O., Abdelwahed, E. H., Qazdar, A., Boulaamail,

A., Krafi, M., Benzakour, I., Bourzeix, F., Ba

¨

ına, S.,

Ba

¨

ına, K., Cherkaoui, M., and Bendaouia, A. (2022).

Digital Twins-Based Smart Monitoring and Optimi-

sation of Mineral Processing Industry. In Hamlich,

M., Bellatreche, L., Siadat, A., and Ventura, S., ed-

itors, Smart Applications and Data Analysis, pages

411–424, Cham. Springer International Publishing.

Horn, Z. C., Auret, L., McCoy, J. T., Aldrich, C., and

Herbst, B. M. (2017). Performance of Convolu-

tional Neural Networks for Feature Extraction in Froth

Flotation Sensing. IFAC-PapersOnLine, 50(2):13–18.

Jovanovi

´

c, I., Miljanovi

´

c, I., and Jovanovi

´

c, T. (2015). Soft

computing-based modeling of flotation processes – A

review. Minerals Engineering, 84:34–63.

Kaartinen, J., H

¨

at

¨

onen, J., Hy

¨

otyniemi, H., and Miettunen,

J. (2006). Machine-vision-based control of zinc flota-

tion—A case study. Control Engineering Practice, 14.

Liu, J., Gao, Q., Tang, Z., Xie, Y., Gui, W., Ma, T., and

Niyoyita, J. P. (2020). Online Monitoring of Flotation

Froth Bubble-Size Distributions via Multiscale De-

blurring and Multistage Jumping Feature-Fused Full

Convolutional Networks. IEEE Transactions on In-

strumentation and Measurement, 69:9618–9633.

Massinaei, M., Jahedsaravani, A., Taheri, E., and

Khalilpour, J. (2019). Machine vision based moni-

toring and analysis of a coal column flotation circuit.

Powder Technology, 343:330–341.

Rajapakse, N., Zargar, M., Sen, T., and Khiadani, M.

(2022). Effects of influent physicochemical character-

istics on air dissolution, bubble size and rise velocity

in dissolved air flotation: A review. Separation and

Purification Technology, 289.

Tang, M., Zhou, C., Zhang, N., Liu, C., Pan, J., and

Cao, S. (2021). Prediction of the Ash Content of

Flotation Concentrate Based on Froth Image Process-

ing and BP Neural Network Modeling. Interna-

tional Journal of Coal Preparation and Utilization,

41:191–202. Publisher: Taylor & Francis eprint:

https://doi.org/10.1080/19392699.2018.1458716.

Wen, Z., Zhou, C., Pan, J., Nie, T., Zhou, C., and Lu, Z.

(2021). Deep learning-based ash content prediction of

coal flotation concentrate using convolutional neural

network. Minerals Engineering, 174:107251.

Zarie, M., Jahedsaravani, A., and Massinaei, M. (2020).

Flotation froth image classification using convolu-

tional neural networks. Minerals Engineering.

Zhang, D. and Gao, X. (2021). Soft sensor of flotation froth

grade classification based on hybrid deep neural net-

work. International Journal of Production Research.

Zhang, L. and Xu, D. (2020). Flotation bubble size dis-

tribution detection based on semantic segmentation.

IFAC-PapersOnLine, 53.

KDIR 2023 - 15th International Conference on Knowledge Discovery and Information Retrieval

436