IoT Based Efficient Hydroponics System

P Usha

1 a

, Uday Malagar

1 b

, Yashwanth Reddy V

1 c

, Sanjay C K

1 d

, Vishnu Prasad

1 e

1

Electrical and Electronics Engineering, Dayananda Sagar College of Engineering, Karnataka, India.

vishnuprasad2704@gmail.com

Keywords: Hydroponic system, lettuce plant, Artificial light, Automated nutrient Supply, IoT, Arduino Uno, ESP32.

Abstract: Hydroponics is a method of growing plants in water based nutrient solution instead of soil. The key to

sustainable agriculture is hydroponic farming, this saves water, land, and resources, gives better yield than

conventional method. The integration of IoT in hydroponics improves intelligence, accuracy, and efficiency.

The results of IoT based efficient hydroponic system developed for lettuce plant is illustrated in this paper.

1 INTRODUCTION TO

HYDROPONICS

Due to rapid increase in population, urbanization,

and industrialization the per capita land is decreasing.

The soil fertility has reached saturation level, because

of this crop yield is not increasing even after the

increased application of fertilizers (Ayaz M,2019).

The unpredictable weather and climate conditions,

rise in temperatures and poor water management are

posing menace to food production by conventional

method of agriculture (Harikrishna R B,2021).

Hydroponics is a method of growing plants

without soil, where plants are grown in nutrient-rich

water-based solutions (Palande,2018). In hydroponic

systems, plants receive their essential nutrients

directly from the water, which is carefully balanced

and supplied to the plant roots. The roots are initially

grown by an inert growing medium like coconut coir.

This soil-less cultivation technique allows for precise

control over plant nutrition, water usage, and

environmental conditions such as temperature,

humidity, and lighting. Hydroponics can be

implemented in various setups, including vertical

towers, nutrient film technique (NFT) channels, or

deep-water culture (DWC) systems (Ramos C,2019).

It offers advantages such as efficient resource

utilization, faster growth rates, higher crop yields, and

the ability to grow plants in areas with limited access

a

https://orcid.org/0000-0003-3621-0942

b

https://orcid.org/0009-0001-9663-7297

c

https://orcid.org/0009-0009-5158-2956

d

https://orcid.org/ 0009-0003-4474-7536

e

https://orcid.org/0009-0009-0276-0373

to arable land.NFT in hydroponics refers to the

Nutrient Film Technique, a hydroponic system where

a thin film of nutrient-rich water flows over plant

roots. It promotes optimal nutrient uptake and root

development, especially for leafy greens and herbs.

The integration of IoT (Internet of Things)

technology has revolutionized hydroponics by

offering greater control, automation, and efficiency in

managing hydroponic systems (Chetan D M,2015).

This paper demonstrates the results of IoT based

hydroponics systems developed for lettuce plant.

2 METHODOLOGIES

The methodology followed for the mechanical

construction of hydroponics system is explained

below.

2.1 Mechanical construction of

hydroponics system

Fig 1: Mechanical construction.

100

Usha, P., Malagar, U., V., Y., K., S. and Prasad, V.

IoT Based Efficient Hydroponics System.

DOI: 10.5220/0012522200003808

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Intelligent and Sustainable Power and Energy Systems (ISPES 2023), pages 100-106

ISBN: 978-989-758-689-7

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

The mechanical construction of an IoT-based

NFT (Nutrient Film Technique) hydroponics system

typically involves several key components:

1. Growing/NFT Channels: The NFT

hydroponics system consists of 3 channels with 6

holes each with a distance of 15cm from centre to

centre, where the plants are placed. These channels

are typically made of food-grade PVC or other

suitable materials that are resistant to water and

nutrient solutions.

2. Support Structure: A sturdy support

structure which is made up of supporting rods are

connected with the help of the clamp and the rods are

made up of galvanized iron. These supporting

structure is needed to hold the NFT channels in place.

This structure should be able to withstand the weight

of the plants, nutrient solution, and other system

components.

3. Pump and Reservoir: A submersible pump of

14W power which can pump water up to a height of

1.4m is used to circulate the nutrient solution from a

reservoir to the top of the NFT channels. The

reservoir which can hold up to 30L of nutrient

solution, which is continuously recirculated through

the system. The pump ensures a steady flow of the

nutrient solution over the plant roots.

4. Return System: At the end of the channels, a

return system collects the excess nutrient solution that

has passed through the root zone. This solution is then

redirected back to the reservoir with the help of PVC

pipes which will be recirculated.

5. Sensors and Control System: IoT integration

involves the installation of sensors to monitor various

parameters such as pH, EC (Electrical Conductivity),

temperature, and humidity (Michael G W,2021).

These sensors transmit data to a control system,

which can be a microcontroller or a central computer.

The control system processes the data and triggers

appropriate actions, such as adjusting nutrient levels

or activating irrigation cycles.

6. Lighting System: In indoor or low-light

environments, an artificial lighting system (PAR

spectrum light) is installed to provide the necessary

light intensity and spectrum for optimal plant growth.

The mechanical construction of an IoT-based NFT

hydroponics system should prioritize durability,

functionality, and ease of maintenance. It is essential

to ensure proper sealing, secure connections, and

efficient nutrient circulation to create an effective and

reliable system.

2.2 Proposed IoT based hydroponics

system

IoT sensors enable real-time monitoring of

parameters such as water pH, nutrient solution levels,

temperature, and humidity, providing instant access

to vital information for timely interventions.

Automation and remote-control capabilities allow

for tasks such as water pump scheduling and nutrient

adjustment based on plant needs, while remote

monitoring facilitates system management from

anywhere. The data collected by IoT sensors enables

data-driven decision-making, optimizing cultivation

strategies and effective resource usage.

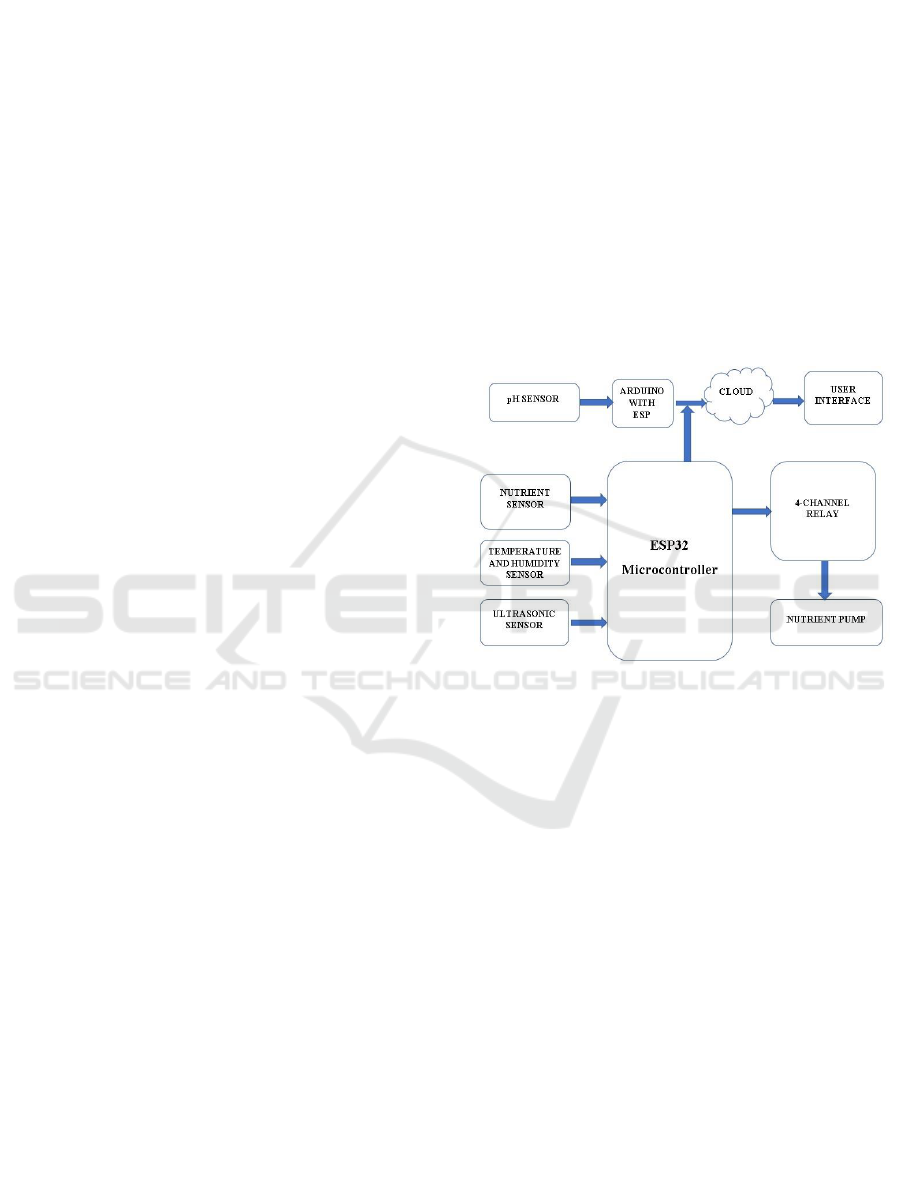

The Fig.2 shows the block diagram of the IoT

based hydroponics system:

Fig 2: Block diagram of proposed hydroponics system.

ESP32 microcontroller - Used as a

microcontroller to store data and also helps the

system to connect to Wi-Fi through which monitoring

and controlling of sensor values is possible. In this

project, data from ultrasonic sensor, EC sensor and

temperature and humidity sensor is uploaded to blynk

application using esp32 board.

Ultrasonic sensor - Ultrasonic sensors are

electronic devices that utilize emitted ultrasonic

sound waves to determine the distance to a target,

subsequently converting those waves into electrical

signals. In this project, it is used to measure water

level in the container. As water reaches to a level

which is 7cm from the sensor, nutrients will be

dispensed into the container.

EC sensor or Nutrient sensor - An EC

(Electrical Conductivity) sensor is a device used to

measure the electrical conductivity of a solution. EC

sensors are commonly used in hydroponics,

aquaponics, and other applications where precise

monitoring of nutrient levels in water is essential.

IoT Based Efficient Hydroponics System

101

pH sensor - A pH sensor is a device used to

measure the acidity or alkalinity of a solution by

determining its pH value. pH is a measure of the

concentration of hydrogen ions (H+) in a solution and

indicates the level of acidity or alkalinity on a

logarithmic scale from 0 to 14. pH value of 7 is

considered neutral, and values less than 7 indicate

acidity. Values above 7 indicate alkalinity. In

hydroponics, pH sensor is used to measure pH of

nutrient solution.

ESP8266 microcontroller - Used as a

microcontroller to store data and also helps the

system to connect to Wi-Fi through which monitoring

and controlling of sensor values is possible. In this

project, data from pH sensor is uploaded to blynk

application using esp8266 board.

4-Channel relay module - A 4-channel relay

module is a device that allows you to control multiple

electrical circuits using a microcontroller or other

control signal. In this project, this device is used to

control nutrient dispenser pumps and pH up and down

solutions.

Nutrient pump - Used to dispense nutrients

(NPK) into the main container of the hydroponics

system. These pumps are also used to dispense pH up-

down solutions into the container to balance pH.

Blynk application - Blynk is a popular IoT

(Internet of Things) platform that allows us to easily

create mobile applications to control and monitor our

connected devices. In this project, Blynk application

is used to monitor and control nutrient dispensing, pH

values, EC values in real time.

Arduino uno - The Arduino Uno is a

microcontroller board based on the ATmega328. In

this project, Arduino uno is used to store data from

pH sensor and transmit the data to esp8266. Since

Arduino uno does not have Wi-Fi connecting

capability, we use serial communication between

Arduino uno and esp8266.

BME280 - The BME280 is a temperature and

humidity sensor particularly developed for mobile

uses and wearables where size and low power

consumption are crucial design parameters.

2.3 Circuit connections of the proposed

hydroponics system

Fig 3: Circuit connection of hydroponics system.

Circuit diagram consists of ESP32

microcontroller and ultrasonic sensor, RTC module

and two 4-channel relay modules are connected to

esp32 microcontroller. Nutrient dispenser pumps are

controlled using relay module. RTC module is used

to get real time data which is used to dispense

nutrients. Battery is connected in series between

pump and relay module.

2.4 Flow chart of control mechanism of

IoT based hydroponics system

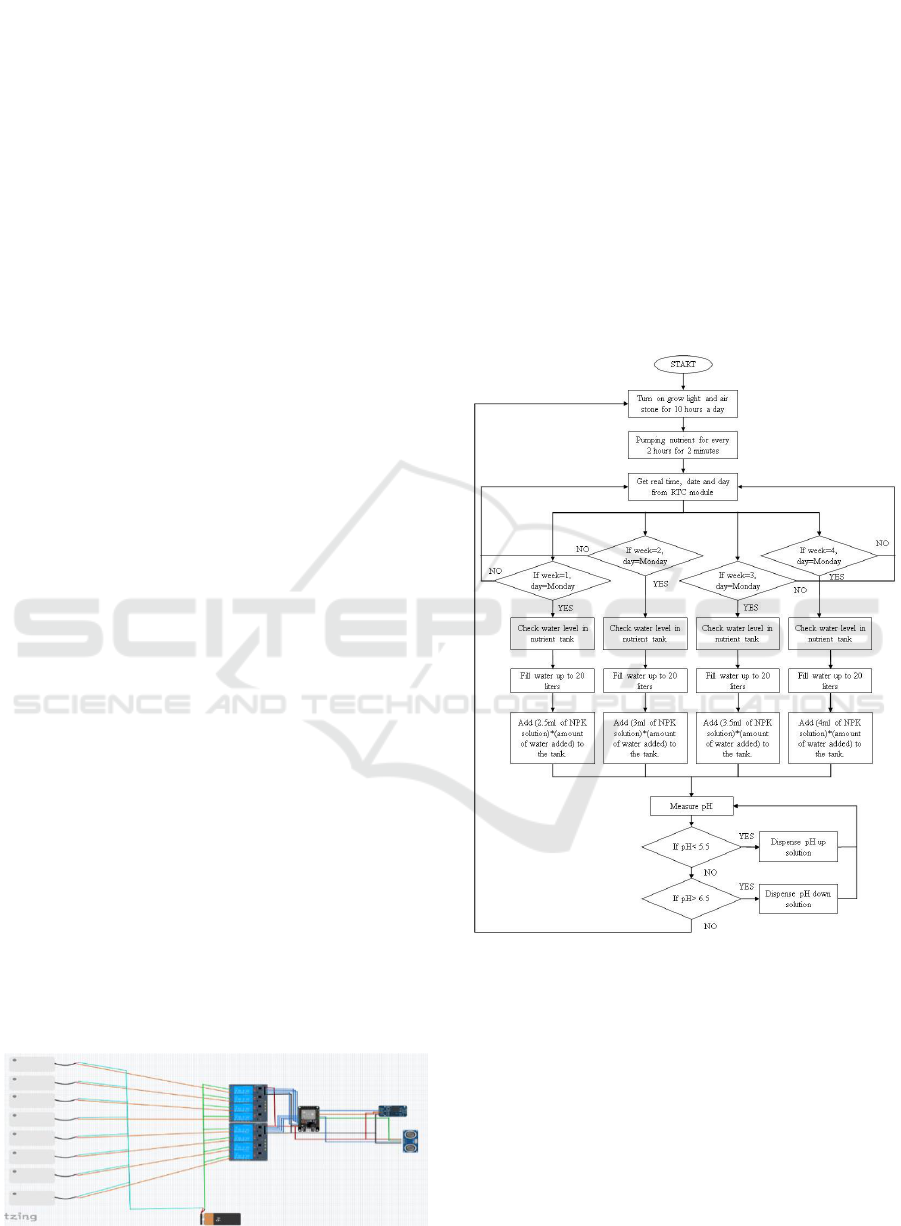

Fig 4: Flow chart of control mechanism proposed

hydroponics system.

Lights (PAR Spectrum lights) and air stone are

turned on, which will be continuously switched ON

for 10 hours per day. These lights are an alternative

for sunlight, which helps the plants to grow. Hence

both turn on and turn off periods are equally

important. Pump the nutrient water from the reservoir

to the NFT channel for 2 minutes every 2 hours. This

nutrient water forms a thin layer in NFT channel

which touches the root of the plants and nutrients is

absorbed by these roots which helps in plant growth.

ISPES 2023 - International Conference on Intelligent and Sustainable Power and Energy Systems

102

By using RTC module, we get the real time, date,

and day. Data from the RTC module is used to

dispense nutrients and nutrient requirement will

increase week by week as the plant grows. So, it is

suggested to increase the nutrient concentration by

0.5ml of NPK every week. After one week, the

quantity of nutrient solution decreases in nutrient tank

(reservoir), then we add water till it reaches 20 litres

in the tank and it is measured by using an ultrasonic

sensor. Based on the amount of water added in the

tank, we calculate the amount of nutrients (NPK) that

has to be dispensed for the present week by using the

formula: (amount of water added) * (an increment of

0.5ml of NPK solution that was dispensed in to the

tank in previous week). Dispensing of nutrients is

achieved by controlling relay modules. Air stone

helps in mixing of nutrients with water in the nutrient

tank.

After mixing nutrients with water, pH of nutrient

solution has to be checked which should be between

5.5 and 6.5 for lettuce plant and when the pH is less

than 5.5, pH up solution has to be added which

increases the pH values until it maintains the

optimum value. Similarly, when pH crosses more

than 6.5, pH down solution has to be added which

decreases the pH of the solution.

2.5 Control Flow of the proposed

hydroponics system

Fig 5: Control flow of hydroponics system.

The control flow of an IoT-based efficient

hydroponics system typically involves several

components working together to monitor and control

various aspects of the hydroponic setup. Here is a

general overview of the control flow. The system

utilizes various sensors to collect data about

environmental conditions such as temperature,

humidity, light, pH, and nutrient levels in the

hydroponic system. These sensors can be connected

to a microcontroller (ESP32, Arduino and ESP8266),

which gathers the sensor data. The collected sensor

data is then transmitted to a central hub or cloud

server using wireless communication protocols such

as Wi-Fi, Bluetooth, or cellular networks. This allows

for real-time or periodic data updates from the

hydroponic system to the cloud. The control actions

determined by the users are sent back to the

hydroponic system via the IoT device or

microcontroller. Actuators such as pumps or relays

are used to carry out the control actions. For example,

nutrient pumps can be activated to deliver the right

amount of nutrients to the plants. The system

continuously monitors the effects of the control

actions by collecting feedback data from sensors.

This feedback data is used to evaluate the impact of

the control actions on the hydroponic system's

performance. It allows for continuous monitoring and

adjustment of the control to ensure optimal plant

growth and resource efficiency. The IoT-based

hydroponics system often includes a user interface,

such as a mobile application in our case Blynk

application, that enables users to remotely monitor

and control the system. This allows users to access

real-time data, receive alerts or notifications, and

manually intervene if necessary.

3 ANALYSIS OF DEVELOPED

HYDROPONICS SYSTEM

Analysis of the hydroponics

system is explained below.

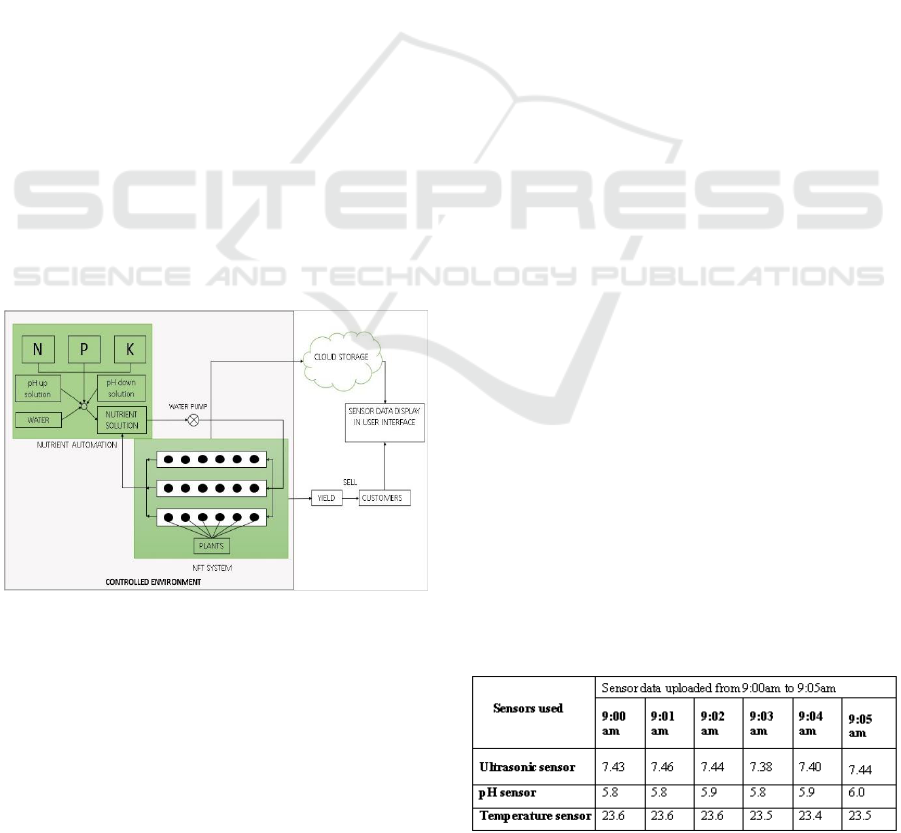

3.1 Data uploading to cloud during

specific duration

Data from sensors are uploaded to the cloud

(Blynk application) using esp32 microcontroller.

Below table shows the data being uploaded to

blynk application for a duration of 5 minutes:

Table 1: Data uploaded from sensors to Blynk application

during 9:00am to 9:05am.

IoT Based Efficient Hydroponics System

103

From the above table it is clearly observed that

during 5 minutes duration, the data that is uploaded to

Blynk application from ultrasonic sensor, pH sensor

and temperature sensor are almost constant. Lettuce

plant requires an optimum temperature of 18-24°C

and from the table we can see that temperature sensor

is reading temperature which is within the optimum

range. The optimum pH range of lettuce plant is

between 5.5-6.5 and from the table we can verify that

the pH is within the optimum range. Ultrasonic sensor

is used to detect nutrient water level in the container.

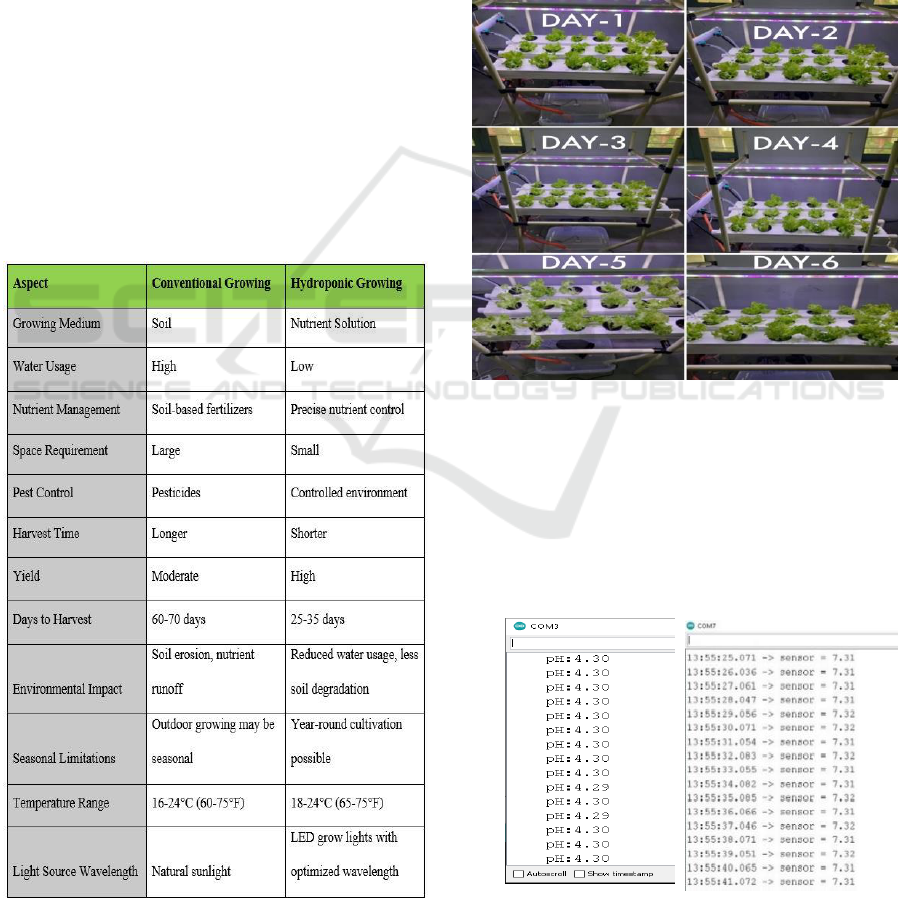

3.2 Comparison of lettuce plant growth

in soil-based agriculture and

hydroponics

Lettuce plant can grow in both soil- based

(conventional) agriculture and hydroponics and

below table represents few significant difference

among these methods.

Table 2: comparison of lettuce plant growth in soil and

hydroponics.

4 RESULTS

The results of the plant growth is

explained in the below sections

4.1 Results of plant growth

Duration of green leaf lettuce is between 6 to 8

weeks after its germination. Below pictures shows the

growth of lettuce plants once they are transferred to

NFT system.

Fig 6: Lettuce plants growth in 1 week duration.

4.2 Results of pH sensor

The optimum pH level for lettuce to grow in

hydroponics system is between 5.5 to 6.5 which is

slightly acidic in nature. Below picture shows the pH

output in serial monitor of Arduino IDE.

Fig 7: pH output for acid (left), pH output of distilled water

(right)

ISPES 2023 - International Conference on Intelligent and Sustainable Power and Energy Systems

104

4.3 Results for nutrient dispensing

To automate nutrient dispensing in hydroponics, a

4-channel relay and a RTC module is used and 2ml of

NPK has to be dispensed in 1 Liter of water once a

week. The below picture shows dispensing of

nutrients by controlling relay channels.

Fig 8: Nutrient dispensing using 4-channel relay and RTC

module

4.4 Results of Blynk Application

Data from the sensors and nutrient dispenser is

uploaded to a user interface called Blynk application.

Below pictures shows the Blynk application

templates and controller for nutrient dispenser.

Nutrients can also be manually dispensed using Blynk

app and user can dispense NPK solutions along with

pH up- down solutions manually based on the

requirements.

Fig 9: Nutrient pump template in Blynk application.

. Fig 10: pH monitoring template in Blynk application

5 CONCLUSION

The advantages of hydroponics are making it

more popular over soil-based cultivation. However,

integrating IoT technology into hydroponics

enhances the efficiency, precision, and scalability of

cultivation. The results of the IoT based hydroponics

system developed for Lettuce plant has been

presented here by harnessing the power of sensors,

connectivity, and data analytics, growers can

optimize resource usage, minimize manual

intervention, and achieve higher yields of quality

yield. This combination of hydroponics and IoT holds

tremendous potential for sustainable and future-

forward agriculture practices.

The future scope of IoT-based efficient

hydroponics systems is promising and holds potential

for significant advancements in sustainable

agriculture. IoT technologies can further enhance

automation in hydroponics systems. Integration with

AI algorithms and machine learning can enable

predictive analysis, optimizing resource allocation,

and decision-making. Advanced data analytics and

predictive models can be developed to analyse large-

scale data collected from IoT sensors. IoT-based

hydroponics systems can integrate with other

precision farming technologies such as drones,

robots, and hyperspectral imaging. This integration

can enable automated plant monitoring, targeted

nutrient delivery, and precision harvesting

techniques, further enhancing efficiency and

productivity.

REFERENCES

Ayaz, M., Ammad-uddin, M., Sharif, Z., Mansour, A., &

Aggoune, el-Hadi M. (2019). Internet-of-Things

(IoT) based Smart Agriculture: Towards Making

the Fields Talk. IEEE Access, 1–1.

https://doi.org/10.1109/access.2019.2932609

IoT Based Efficient Hydroponics System

105

Harikrishna, R. B., R, S., N, P. P., Anand Kumar A, A., &

Pandiaraj, S. (2021, May 1). Greenhouse

Automation Using Internet of Things in

Hydroponics. IEEE Xplore.

https://doi.org/10.1109/ICSPC51351.2021.9451

668

Palande, V., Zaheer, A., & George, K. (2018). Fully

Automated Hydroponic System for Indoor Plant

Growth. Procedia Computer Science, 129, 482–

488. https://doi.org/10.1016/j.procs.2018.03.028

Ramos, C., Nobrega, L., Baras, K., & Gomes, L. (2019).

Experimental NFT hydroponics system with

lower energy consumption. 2019 5th Experiment

International Conference (Exp.at’19).

https://doi.org/10.1109/expat.2019.8876479

Chetan D M., R, G. R., S, J., & Priyatharshini, R. (2015,

July 1). Smart farming system using sensors for

agricultural task automation. IEEE Xplore.

https://doi.org/10.1109/TIAR.2015.7358530

Michael, G. W., Tay, F. S., & Then, Y. L. (2021).

Development of Automated Monitoring System

for Hydroponics Vertical Farming. Journal of

Physics: Conference Series, 1844(1), 012024.

https://doi.org/10.1088/1742-

6596/1844/1/012024

ISPES 2023 - International Conference on Intelligent and Sustainable Power and Energy Systems

106