Corrosion Rate of A36 Plate with Zinc Anode and Combination of

Zinc Anode with Continuous Direct Current

Sri Endah Susilowati

a

and Didit Sumardiyanto

b

Universitas 17 Agustus 1945, Jakarta, Indonesia

Faculty of Engineering and Informatics, Universitas 17 Agustus 1945, Jakarta, Indonesia

Keywords: Corrosion Rate, Zinc Anode, DC Current, ASTM A36 Plate.

Abstract:

Corrosion, in general is a process through which refined metals are converted into more stable compounds

such as metal oxides, metal sulfides, or metal hydroxides. Likewise, the rusting of iron involves the formation

of iron oxides via the action of atmospheric moisture and oxygen. Iron is a metal that rusts easily. Iron rust is

a substance produced in corrosion events, which is in the form of a reddish-brown solid substance that is

brittle and porous. The chemical formula of iron rust is Fe2O3 x H2O. The impact of corrosion events is

detrimental. This corrosion rate research uses ASTM A36 plate (steel with low carbon content max 0.17 %C)

for venture floating dock deck with three kinds of treatment: plate without corrosion protection (A), with zinc

anode protection (B) and combined protection from zinc anode and DC electric (C). The corrosion rate is

calculated using the weight loss method. The results showed the magnitude of corrosion rates in treatment A,

B and C respectively: 0.66 mpy, 0.22 mpy and 0.17 mpy. Treatment with zinc anode protection and DC

current produces the smallest corrosion rate value among others. Hardness values tested using Brinnnel with

the values: 136.3 BHN, 205.2 BHN and 202.9 BHN respectively. The highest hardness value on the plate

with zinc anode protection treatment.

1

INTRODUCTION

In recent years, weathering steel has been widely used

in marine engineering structures, such as railway

vehicles, bridges and berths (Yang, F. et al., 2022).

Recently, a lot of efforts have been put into studying

the corrosion process of steel. These include studies

on metal corrosion in various indoor and outdoor

environments and the influence of temperature,

humidity, and corrosion ions on the corrosion rate and

products (Di Sarno et al., 2021), (Ma, Y. et al., 2009),

(Fan, Y. et al., 2020). Indoor environmental

experiments are used to control the experimental

variables and decouple the effects of different factors

on corrosion behaviour (Wu, H. et al., 2019), (Irshad,

H. M. et al., 2022). The marine atmosphere can

significantly accelerate the corrosion rate of carbon

steel. Various studies have discussed the relationship

between chloride ions, water, oxygen, corrosion

products, and corrosion rate in marine atmosphere

through indoor accelerated corrosion experiments

a

https://orcid.org/0000-0003-2284-9235

b

https://orcid.org/0000-0002-0837-8011

(Alcántara, J. et al., 2017), (Zhang, X. et al., 2019),

(Zhang, Z. et al., 2023). Ma et al. (Zhang, B. et al,

2020) proposed that in an atmospheric environment,

chloride ions can penetrate through the rust layer and

accelerate corrosion rate, and that different chloride

ion contents have different effects on the generation

of corrosion products. Fan et al. (Ohtsuka, T. and

Tanaka, S., 2015) analysed the rust layer structure and

proposed that the delamination of the rust layer has

different effects on the penetration of corrosive ions.

The dense rust layer can effectively slow the

corrosion rate, and the density of the inner rust layer

increases with increasing corrosion time. Wang et al.

(Kamimura, T. et al., 2006) suggested that there are

many types of FeOOH in corrosion products and the

proportion of different components changes with the

corrosion duration, and γ-FeOOH gradually changes

into α-FeOOH under the influence of corrosive ions

and oxygen, which causes the rust layer to become

dense and slows down the corrosion rate. Although

various studies on the corrosion of carbon steel in a

432

Susilowati, S. and Sumardiyanto, D.

Corrosion Rate of A36 Plate with Zinc Anode and Combination of Zinc Anode with Continuous Direct Current.

DOI: 10.5220/0012584300003821

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Seminar and Call for Paper (ISCP UTA ’45 JAKARTA 2023), pages 432-436

ISBN: 978-989-758-691-0; ISSN: 2828-853X

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

marine atmosphere exist, some unique environments

need to be considered, such as the influence of strong

electric field (Cheng, X. et al., 2017).

The unique environmental characteristics of

different marine zones are responsible for the corrosion

behavior distinctions. In the atmosphere, the

environment corrosivity is determined by the

temperature, relative humidity, chloride deposition

rate, and pollutants (Jeffrey, R., & Melchers, R. E.,

2009), (Feng, X. et al, 2020), resulting in the corrosion

occurrence under the adsorbed thin electrolyte layer

(Bhandari, J. et al, 2015). In the splash zone, the typical

characteristics are the intermittent wave splashing and

the sufficient oxygen (Xu, Y. et al, 2022), (Yusoff, N.

H. N. et al, 2013). The tidal zone also experiences fluid

erosion because of the seawater scouring (Wang, Y. et

al, 2023). Besides, it also includes the full immersion

stage during a single tidal cycle (Gao, F. et al, 2023).

Moreover, the wet-dry cycles are the common

characteristics of the above three zones, while the

wetting time, frequency, and electrolyte thickness are

different. The distinct feature of the full immersion

zone is the difficulty in oxygen availability. In addition,

the sediment and accumulation of the organisms

contribute to the corrosion process underneath them

(Situmeang, I. D. R., and Heltina, D., 2020).

The use of steel plates on the deck floating dock

of ships is a common thing used as a shipbuilding

material because it is quite adequate. But iron and

steel are so reactive that they have a tendency to

corrode in corrosive areas, namely seawater.

Corrosion is a natural symptom that commonly

occurs in ship plates as a result of interaction with the

surrounding environment so that it undergoes mass

changes in corrosive environments. This study tested

the corrosion rate on the ship's floating dock deck

plate with Zinc Anode and DC electric current. The

determination of the exact protection on the ship's

floating dock deck plate was tested using the

experimental method of seawater solution and Zinc

Anode with electric current. The addition of DC

electric current to the Zinc Anode will increase higher

protection on steel plates so that the risk of damage is

lower and can be used longer.

This study aims to analyze corrosion rate by

calculating weight loss and testing hardness on A36

plate for deck floating dock venture 3 with zinc anode

protection and DC current and zinc anode without

using DC current.

2

METHODS

The steps carried out in this experiment are as

follows:

1. Prepare tools, equipment that will be used to make

corrosion rate test experiments, starting from

preparing plastic measuring cups, sea water,

plates, USB Port cables, and Zinc Anode

2. The first experiment is a corrosion rate

experiment with a plate and seawater put into a

measuring cup and then calculated the corrosion

rate every 168 hours (7 days), 336 hours (14 days),

504 hours (21 days), up to 720 hours (30 days).

3. The second trial was with the plate method

protected with Zinc Anode from 168 hours (7

days), 336 hours (14 days), 504 hours (21 days),

to 720 hours (30 days).

4. The third trial is that the plate is protected with

DC Electric Current and Zinc Anode along 168

hours (7 days), 336 hours (14 days), 504 hours (21

days), up to 720 hours (30 days).

5. After 720 hours (30 days) the results were

calculated using the corrosion rate formula with

the weight loss method.

Figure 1: A36 Plate Material with treatment: A Without

Corrosion Protection, B. With Zinc Anode Protection, C.

With Zinc Anode Protection and DC Current, D A36 Plate

Experimental Results.

3

RESULTS AND DISCUSSION

3.1 Corrosion Rate

Figure 1 shows a comparison of corrosion rate of

protected versus unprotected carbon steel A36. The

result of corrosion rate experiments with plates

without using protection resulted in the greatest

corrosion rate of 0.66 mpy. Corrosion protection the

best is to use protection with zinc anode fed by DC

current. The corrosion rate on this plate is 0.17 mpy

(the lowest). The results of the immersion test without

the protection tested on sodium chloride solution for

30 days showed the greatest weight loss and the

Corrosion Rate of A36 Plate with Zinc Anode and Combination of Zinc Anode with Continuous Direct Current

433

corrosion rate was 0.66 mpy. This is due to the high

dissolved salts causing an increase in the conductivity

of the salt solution (Irshad, H. M. et al., 2022), the

steel undergoes corrosion due to the presence of the

Cl- ion where the Cl- ion will break the passive layer

on carbon steel or prevent the formation of a passive

layer on carbon steel (Situmeang, I. D. R., and

Heltina, D., 2020). On protected carbon steel, less

weight loss was observed than the unprotected carbon

steel. It can be seen from Figure 1 that the rate of

corrosion of steel protected by an anode of zinc

sacrificed and DC current was slower compared to the

rate of corrosion of unprotected carbon steel plate A

36. The results of the calculation of corrosion rates

with time and treatment variations are presented in

Table 1 and Figure 2 below:

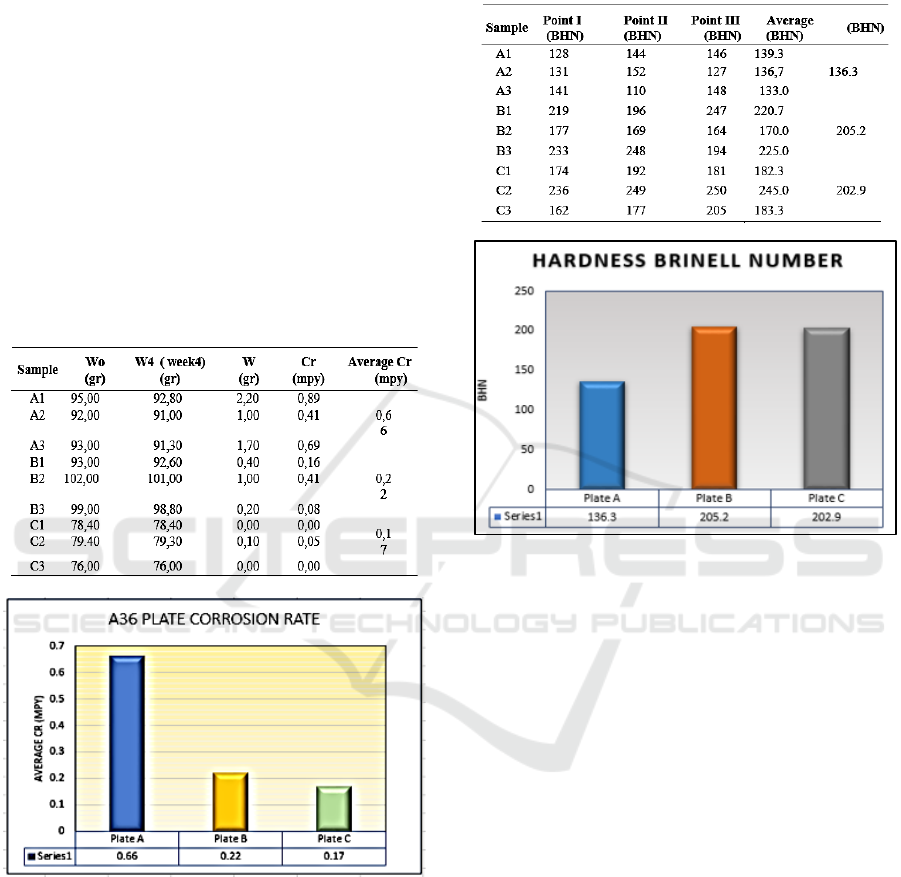

Table 1: Calculation of Corrosion Rate of A36 plate.

Figure 2: Corrosion Rate on Various Treatments.

A zinc anode's protective properties result from a

strongly negative reduction potential, which is more

negative than the metal it is protecting. Oxidants,

which corrode metals, will oxidize the zinc anode

rather than the protected metal structure, thus

preventing the structure from being corroded.

3.2 Hardness Test

The results of the hardness test calculation can be

seen in Table 2 and Figure 3 below:

Table 2: The Hardness Brinnel Number.

Figure 3: A36 plate hardness test on various treatments.

The result of hardness testing without protection

is 136.3 BHN, while with Zinc Anode protection is

205 BHN and on a combined treatment between Zinc

Anode and DC Current is 202.9 BHN (Fig. 3). This

result is above the minimum limit of marine plate

hardness. Cathodic protection is an effective way to

prevent stress corrosion cracking (cracking due to

corrosion), by restoring the direction of the corrosion

current to restore electrons that decompose from

certain metals, which are immune or immune so that

the corrosion process on metals can be reduced or

eliminated.

The principle of cathodic protection is to provide

electrons for the metal structure to be protected. The

underlying theory is that if current flows from the

positive pole to the negative pole (conventional

electrical theory) the structure will be protected if

current enters from the electrodes. Conversely, the

corrosion rate will increase if the current enters

through the metal to the electrode. In the process of

corrosion in case of scratches or peeling of the

coating. The presence of water vapor, CO2 gas in the

air and other particles, a mini voltaic cell occurs with

Zn as the anode and Fe as the cathode. Zn will

oxidize first because its Eo value is smaller than Fe,

ISCP UTA ’45 JAKARTA 2023 - THE INTERNATIONAL SEMINAR AND CALL FOR PAPER (ISCP) UTA ’45 JAKARTA

434

so electrolytic corrosion (an electrochemical reaction

that oxidizes metals) does not occur.

From the calculation of the corrosion rate of

plates using protection, better results are obtained

compared to no protection. This happens because of

the potential difference, then the electron current will

flow from the installed anode and will resist the

electron current from the nearby metal, so that the

metal turns into a cathode region. This is what slows

down the plate experiencing the corrosion rate while

on the contrary the plate without protection will

release electrons causing damage to the plate so that

it is easy to corrode.

4 CONCLUSION

1. From the results of the three experiments,

results were obtained that showed that

corrosion occurred which was characterized by

a decrease in the weight of objects.

2. After calculating the corrosion rate value using

the weight loss, the result is a slower corrosion

rate when using zinc anode protection and DC

current, followed by zinc anode protection and

finally without using protection.

3. From the three experiments, it was obtained that

the value of corrosion rate with protection with

zinc anode and DC current was 0.17 mpy or

corrosion rate was 17%, then with zinc anode

protection with a value of 0.22 mpy or corrosion

rate was 22% and the last one was without

protection the value obtained was 0.66 mpy or

corrosion rate was 66%.

4. With this research, it has become the initial stage

to be applied directly, so that the use of this

method can save routine repair costs in the

shipping industry.

REFERENCES

Yang, F., Yuan, M. M., Qiao, W. J., Li, N. N., & Du, B.

(2022). Mechanical degradation of Q345 weathering

steel and Q345 carbon steel under acid corrosion.

Advances in Materials Science and Engineering, 2022.

Di Sarno, L., Majidian, A., & Karagiannakis, G. (2021).

The effect of atmospheric corrosion on steel structures:

A state-of-the-art and case-study. Buildings, 11(12), 571.

Ma, Y., Li, Y., & Wang, F. (2009). Corrosion of low carbon

steel in atmospheric environments of different chloride

content. Corrosion science, 51(5), 997-1006.

Fan, Y., Liu, W., Li, S., Chowwanonthapunya, T.,

Wongpat, B., Zhao, Y., ... & Li, X. (2020). Evolution of

rust layers on carbon steel and weathering steel in high

humidity and heat marine atmospheric corrosion.

Journal of Materials Science & Technology, 39, 190-199.

Wu, H., Lei, H., Chen, Y. F., & Qiao, J. (2019). Comparison

on corrosion behaviour and mechanical properties of

structural steel exposed between urban industrial

atmosphere and laboratory simulated environment.

Construction and Building Materials, 211, 228-243.

Irshad, H. M., Toor, I. U., Badr, H. M., & Samad, M. A.

(2022). Evaluating the Flow Accelerated Corrosion and

Erosion–Corrosion Behavior of a Pipeline Grade

Carbon Steel (AISI 1030) for Sustainable Operations.

Sustainability, 14(8), 4819.

Alcántara, J., de la Fuente, D., Chico, B., Simancas, J., Díaz,

I., & Morcillo, M. (2017). Marine atmospheric corrosion

of carbon steel: A review. Materials, 10(4), 406.

Zhang, X., Zhou, X., & Nilsson, J. O. (2019). Corrosion

behaviour of AA6082 Al-Mg-Si alloy extrusion: The

influence of quench cooling rate. Corrosion Science,

150, 100-109

Zhang, Z., Zhang, F., Du, G., Li, G., Fan, W., Wang, Y., ...

& Wang, X. (2023). Effect of intermittent and

continuous direct current electric fields on the initial

corrosion of steel in simulated marine environment.

Materials Today Communications, 35, 105629.

Zhang, B., Wei, X. X., Wu, B., Wang, J., Shao, X. H., Yang,

L. X., ... & Ma, X. L. (2019). Chloride attack on the

passive film of duplex alloy. Corrosion Science, 154,

123-128.

Ohtsuka, T., & Tanaka, S. (2015). Monitoring the

development of rust layers on weathering steel using in

situ Raman spectroscopy under wet-and-dry cyclic

conditions. Journal of Solid State Electrochemistry, 19,

3559-3566.

Kamimura, T., Hara, S., Miyuki, H., Yamashita, M., &

Uchida, H. (2006). Composition and protective ability

of rust layer formed on weathering steel exposed to

various environments. Corrosion Science, 48(9), 2799-

2812.

Cheng, X., Jin, Z., Liu, M., & Li, X. (2017). Optimizing the

nickel content in weathering steels to enhance their

corrosion resistance in acidic atmospheres. Corrosion

Science, 115, 135-142.

Jeffrey, R., & Melchers, R. E. (2009). Corrosion of vertical

mild steel strips in seawater. Corrosion Science, 51(10),

2291-2297.

Feng, X., Yan, Q., Lu, X., Wu, T., Zhang, Y., Zuo, Y., &

Wang, J. (2020). Protection performance of the

submerged sacrificial anode on the steel reinforcement

in the conductive carbon fiber mortar column in splash

zones of marine environments. Corrosion Science, 174,

108818.

Bhandari, J., Khan, F., Abbassi, R., Garaniya, V., & Ojeda,

R. (2015). Modelling of pitting corrosion in marine and

offshore steel structures–A technical review. Journal of

Loss Prevention in the Process Industries, 37, 39-62.

Xu, Y., Huang, Y., Cai, F., Lu, D., & Wang, X. (2022).

Study on corrosion behavior and mechanism of AISI

4135 steel in marine environments based on field

exposure experiment. Science of The Total

Environment, 830, 154864.

Corrosion Rate of A36 Plate with Zinc Anode and Combination of Zinc Anode with Continuous Direct Current

435

Yusoff, N. H. N., Ghazali, M. J., Isa, M. C., Daud, A. R., &

Muchtar, A. (2013). Effects of powder size and metallic

bonding layer on corrosion behaviour of plasma-

sprayed Al2O3-13% TiO2 coated mild steel in fresh

tropical seawater. Ceramics International, 39(3), 2527-

2533.

Wang, Y., He, J., Xie, F., Zhang, Y., Wang, G., Sun, D., ...

& Jia, W. (2023). The synergistic effect of parallel

magnetic field and sulfate-reducing bacteria on stress

corrosion cracking of buried X80 pipeline steel.

Engineering Failure Analysis, 154, 107644.

Gao, F., Li, J., Zhou, N., Luo, X., Yang, H., Chai, F., &

Yang, C. (2023). Investigating the corrosion

performance of hull steel with different microstructure

in a tropical marine atmosphere. Journal of Materials

Research and Technology, 27, 2600-2614.

Situmeang, I. D. R., & Heltina, D. (2020, May). Cathodic

protection on stuctures of carbon steel using sacrificial

anode methode for corrosion control. In IOP

Conference Series: Materials Science and Engineering

(Vol. 845, No. 1, p. 012015). IOP Publishing.

ISCP UTA ’45 JAKARTA 2023 - THE INTERNATIONAL SEMINAR AND CALL FOR PAPER (ISCP) UTA ’45 JAKARTA

436