Analysis of Reduced Performance of 7.5 kW Hydraulic Pump Motor

on Telescopic Spreader Quayside Container Crane (QCC)

Erman Suherman

a

and Ahmad Rofii

b

Department of Electrical Engineering, Universitas 17 Agustus 1945 Jakarta, Jl. Sunter Permai Raya, Sunter Agung,

Tanjung Priok, Jakarta Utara, Indonesia

Keywords: Hydraulic Motor, Telescopic Spreader, Varnishing.

Abstract: Quayside Container Crane (QCC) is one of the heavy equipment used by the Nusantara Port Handal company.

The Telescopic Spreader is one of the equipment found on the Quayside Container Crane (QCC). The

mechanical power for the QCC work process comes from an induction motor or asynchronous motor. In

operation, lifting power often weakens, causing business processes to idle. QCC mechanical resources come

from induction motors or asynchronous motors, of course the work process depends on the reliability of the

motor. Based on monitoring and recording, the induction motor used by QCC with a capacity of 7.5 kW often

experiences a weakening of rotational power during busy work activities. After measuring the temperature

when the induction motor was loaded, the temperature reached 44

0

C and after measuring the motor stator

resistance value, it was 1200MΩ. Based on the analysis, the increase in motor temperature caused a decrease

in lifting power due to a decrease in the Insulator Resistance value which caused voltage leakage between the

armature windings. Motor resistance decreases due to the reduced ability of the stator insulator due to

increased heat, with a decrease in lifting capacity based on measurement results causing the vibration value

to increase from the threshold, thereby disrupting the construction of the stator armature. To overcome this,

re-varnishing of the insulator has been carried out which results in an increase in the resistance value of the

stator insulator.

1 INTRODUCTION

Indonesia is the largest archipelagic country in the

world. For this reason, Indonesia needs to manage

and develop a well-managed and developed port

industry (Setiono, 2010).

Handling of loading and unloading goods must be

in accordance with the provisions that have been set.

With these provisions, it is hoped that all stevedoring

companies can implement these provisions in order to

create a smooth flow of goods and harmony in work.

But in practice the handling of loading and unloading

is not always carried out smoothly and correctly, but

few of them ignore it. Most of these stevedoring

companies are only concerned with profits without

paying attention and thinking about the impacts that

will arise if the handling of loading and unloading is

carried out unsafely and incorrectly or not in

accordance with the provisions (Triatmodjo, 2006).

a

https://orcid.org/0009-0001-9164-1641

b

https://orcid.org/0009-0006-0677-9846

Quayside Container Crane (QCC) is one of the

heavy equipment used by Nusantara Pelabuhan

Handal. This tool stands and runs on rails on the edge

of the dock with a power source from a power plant

on land or with the power plant's own diesel engine.

The working principle is simple, the container from

the ship's hold is lifted up by a telescopic spreader

using a hoist system, then with horizontal movement

is carried using a trolley system towards the dock and

stops between the two crane legs (legs) to lower the

container until it is right above the truck chassis body.

The next movement is to return the empty telesopic

spreader from its position on the dock to the ship's

hold, and land the telescopic spreader on top of the

container to be unloaded next. (Lasse, 2012).

Container loading and unloading activities on

ships often occur system failures in the telescopic

spreader area. Especially often trips occur on spreader

pumps, telescopic positions from 20 feet to 40 feet

Suherman, E. and Rofii, A.

Analysis of Reduced Performance of 7.5 kW Hydraulic Pump Motor on Telescopic Spreader Quayside Container Crane (QCC).

DOI: 10.5220/0012584600003821

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Seminar and Call for Paper (ISCP UTA ’45 JAKARTA 2023), pages 449-457

ISBN: 978-989-758-691-0; ISSN: 2828-853X

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

449

often cannot or jam, twistlocks that cannot rotate from

the unlock position to the lock position even until the

replacement of the spreader pump motor because its

performance has dropped.

2 LITERATURE REVIEW

2.1 Telescopic Spreader

Telescopic Spreader is one of the equipment

contained in Quayside Container Crane (QCC).

Telescopic Spreader is made of steel structure

consisting of 4 twistlocks on the head block, 4

twistlocks for locking corner containers, 4 flippers

installed in each corner of the spreader connected to

a gearbox and actuator that functions as a guide,

telescopic device and hydraulic system, with

automatic opening and locking based on several

proximity sensors.

Telescopic mechanism with an expansion range

of 20 feet to 45 feet, controlled by the Siemens 7 PLC

system integrated with all other devices.

Figure 1: Telescopic Spreader.

2.2 Asynchronous Motor

Induction motors are the most widely used alternating

current (AC) motors. Its naming comes from the fact

that the rotor current of this motor is not obtained

from a specific source, but is an induced current.

As a result of the relative difference between the

rotation of the rotor and the rotating magnetic field

generated by the stator current. Induction motors are

the most commonly used motors in various industrial

equipment. Its popularity is due to the design it gets,

and it can be directly connected to an AC power

source.

Figure 2: Three Phase Induction Motor on hydraulic pump

Telescopic Spreader.

2.3 Stator

In the stator section there are several slots that are

where the wire (conductor) of three coils each

different phase and receive current from each phase

called the stator coil. The stator consists of iron plates

arranged as large as the rotor and on the inside has

many grooves that are given coils of insulated copper

wire.

Figure 3: Stator.

If the stator coil gets a three-phase current supply,

the coil will generate a rotary magnetic flux. Due to

the rotating magnetic flux in the stator coil, it causes

the rotor to rotate due to magnetic induction with the

rotational speed of the syncon rotor with the

rotational speed of the stator.

Where:

ns = Synchronous speed (rpm)

ƒ = Magnitude of frequency (Hz)

P = Number of poles

The construction of the induction motor stator itself

consists of several parts:

1. Motor body (axle)

2. Magnetic polar core and magnetic amplifier

circumference

3. Slip ring

ISCP UTA ’45 JAKARTA 2023 - THE INTERNATIONAL SEMINAR AND CALL FOR PAPER (ISCP) UTA ’45 JAKARTA

450

2.4 Rotor

Based on Faraday's law of magnetic impact, the

rotating field, which is relatively a magnetic field

moving against the rotor conductor, will wave the

electromotive force (ggl). The frequency of this

impact emf is the same as the frequency of the mesh.

The magnitude of this impact is directly

proportional to the relative speed between the rotating

field and the rotor conductor. Conductor - a conductor

in the rotor that forms a closed circuit, is a driving

circuit for rotor current and is in line with the

applicable law, particulary the law of lenz.

The direction is against the impacting fluctuation,

in this case the rotor current is caused by the

difference in speed between the fluctuation or

rotational field of the stator and the conductor at rest.

The rotor will rotate in the same direction as the

direction of the stator rotation field, to reduce the

speed difference above. If the rotor is loaded, then the

rotation of the rotor will drop so that there is a

difference in rotation speed between the rotor and

stator, this difference in rotation speed is called slip.

Figure 4: Rotor.

2.5 Working Principle of Induction

Motor

The induction motor works on the basis of

electromagnetic induction from the stator coil to its

rotor coil. When the stator coil of a 3-Phase induction

motor is connected to a 3-Phase voltage source, the

stator coil will produce a rotating magnetic field. Flux

force lines The data induced from the stator coil will

cut the rotor coil so that emf (ggl) or induced voltage

arises. Because the conductor (coil) of the rotor is a

closed circuit, current will flow on the rotor coil. The

conductor (coil) of the rotor that is supplied by this

current is in the line of flux force coming from the

stator coil so that the rotor coil will experience

Lorentz force which causes torque that tends to move

the rotor according to the direction of movement of

the stator induction field.

2.6 Calculation Procedure

In the research analysis of the performance of the 3

Phase induction motor on the loading of telescopic

spreader pressure, data will be taken based on current

and voltage variations, specifically minutes to 09.00,

minutes to 11.00, minutes to 14.00, and minutes to

16.00, This data collection aims to obtain the value of

losses on the motor based on pressure variations,

determine efficiency based on pressure variations,

and to obtain Power factor (PF) = 95%. So data

collection is carried out including:

1. Find the input power based on the formula

below. In this case, measurements are made

directly on the motor. To find out the input

power value, calculations are carried out with

the equationv(Rofii, A. 2018):

Pin =

(2)

Information:

P in = Input power (Watts)

V = Voltage (Volt)

I = Current (Ampere)

= power factor

2. Determine the value of losses in a 3 Phase

induction motor as a telescopic spreader

drive. Calculation of losses on the motor

using the equation:

P loses = mechanical (3)

Electricity loses (Stator winding) =

(4)

Electrical loses (Rotor winding) =P

Nominal losses

3. Finding the output power of a 3 phase motor

P Out = P in – P loses (5)

Information:

P in = Daya input (watt)

P Out = Daya output (watt)

P loses = total loses (watt)

4. Determine the efficiency value of motor

performance degradation based on the input

and output power of the motor.

To get the efficiency value of the

performance of the induction motor on the

telescopic spreader, calculations are carried out

using the equation:

Efficiency =

(6)

Information:

: daya output (Watt)

: input power (Watts)

Analysis of Reduced Performance of 7.5 kW Hydraulic Pump Motor on Telescopic Spreader Quayside Container Crane (QCC)

451

2.7 Equivalent Circuit of Three-Phase

Induction Motor

The equivalent circuit of a three-Phase induction

motor is expressed in a one-Phase circuit, consisting

of:

A. Stator Equivalent Circuit

If the resistance of the stator winding per phase is Rs,

and the reactance is Xs, while the core losses are

expressed in parallel to a resistance Rc and reactance

Xc, then the equivalent circuit of the stator can be

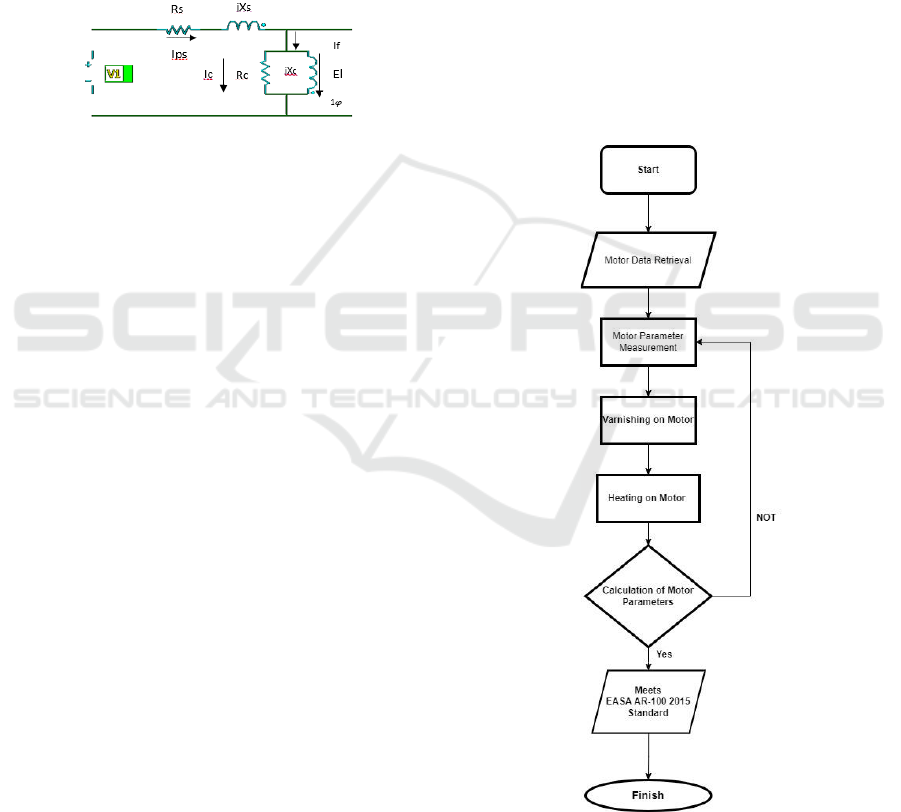

illustrated in Figure 5 below.

Figure 5: Stator Equivalent Circuit.

The impact voltage on the stator is:

(7)

Where:

Kw1 = Stator winding factor

F = Stator Voltage Frequency

φm = Maximum Fluctuation in the Stator Gap

N1 = Number of Stator Windings

In Figure 5, V1 is the voltage source per Phase on

the stator of the induction motor and E1 is the impact

voltage on the stator then:

(8)

3 RESEARCH METHODS

3.1 Place and Time of Research

This research was conducted at PT. Parvi Indah

Persada NPH Building Jl. Kebon Bawang 1 No.45,

Kebon Bawang Tanjung Priok, North Jakarta, 14320.

The time used by the researcher for this research is

carried out from the date of issuance of the research

permit within a period of approximately 2 (two)

months.

3.2 Research Tools and Materials

Telescopic spreader hydraulic pump motor as

material / object of research, Megger to measure

insulation resistance (Insulation Resistance),

Multitester to measure resistance value (resistance),

Temperature Gun to measure motor temperature and

Vibartion Meter to measure motor vibration.

3.3 Research Variables

a. Phase to phase isolation resistance

b. Isolation Resistance with phase to ground

c. Source voltage (droop or stable)

d. Motor temperature

3.4 Data Collection Techniques

In terms of collecting this data, the author plunges

directly into the object of research to get valid data,

then the researcher uses direct observation methods

and documentation observation. The following are

the steps to obtain data by taking direct prisoner

measurements.

Figure 6: Research Flowchart.

ISCP UTA ’45 JAKARTA 2023 - THE INTERNATIONAL SEMINAR AND CALL FOR PAPER (ISCP) UTA ’45 JAKARTA

452

3.5 Discussion Method

Based on the availability of calculated data,

measuring data and standard data, discussions are

carried out:

1. The effect of decreasing insulation resistance

on the rotating power of the motor

2. Effects of temperature rise on insulation

resistance

3. The effect of vibration on the rotating power of

the motor

Then analysis can be done from these three

influences, which one has the most potential to cause

a decrease in the performance of the hydraulic pump

motor on the telescopic spreader.

4 DISCUSSION

4.1 Data Standard Insulation

Resistance

The following is a list of the use of Insulation

resistance Test direct voltage against each winding

rated voltage based on EASA (Electrical Apparatus

Service Association) AR100-2015 Standard

Insulation.

Table 1: Standard Insulation Resistance at PT. Parvi Indah.

Recommended Minimum Insulation Resistance Values at

400C

Minimum Insulation

Resistance After 1 min

Test Specimen

IR 1 min = kV + 1

Mega Ohm Unit

Most windings were made

before about 1970, all terrain

windings and others are not

described below

IR = 100 M

Most AC rolls were built after

about 1970 (coil roll form)

IR = 5 M

As a large machine with

random winding stator coil,

forming a coil roll with a

voltage below 1 kV DC

armature

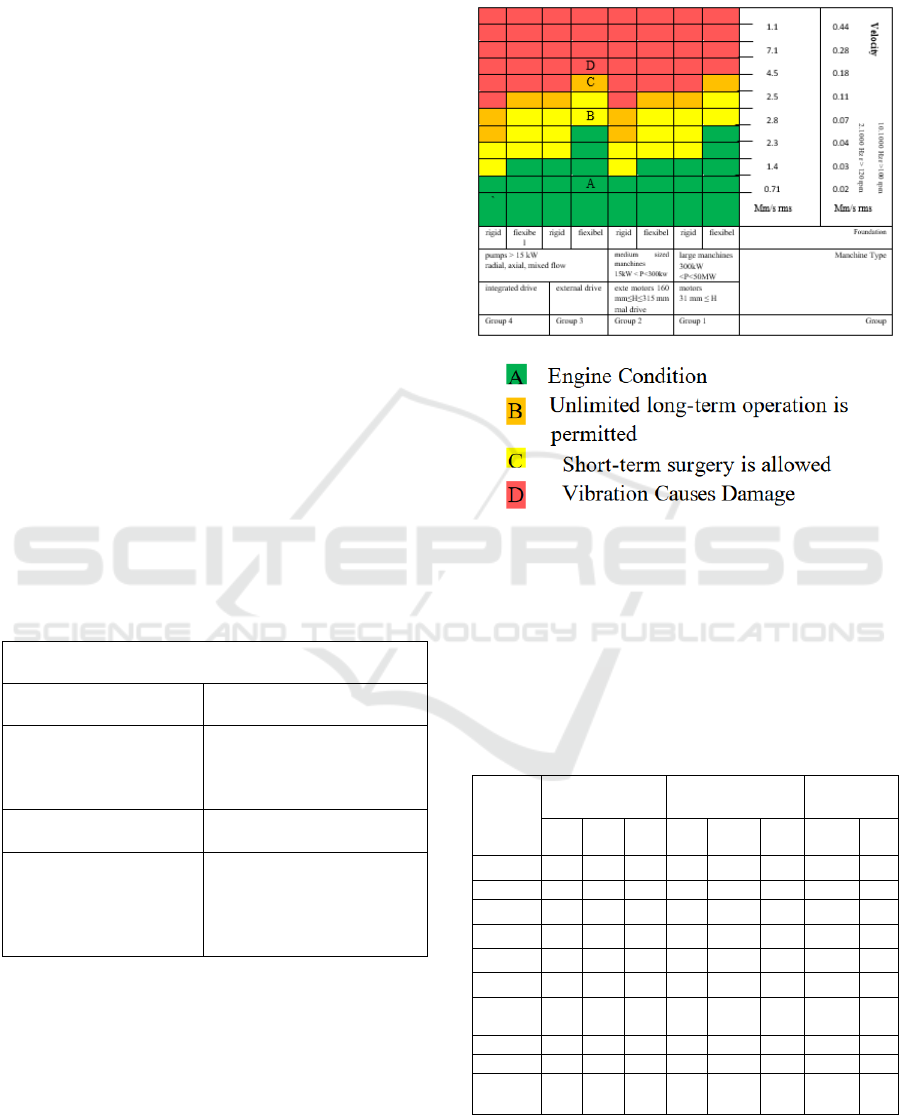

4.2 Vibration Standards

Table 2: Vibration Standards at PT. Parvi Indah Persada.

In the table above where the green color has good

engine condition and dark yellow color has

unlimited long-term operation allowed while light

yellow has short-term operation allowed and pink

has vibration causing damage.

A. Vibration Motor Pump Spreader Telescopic

Table 3: Vibration Tests on No-Load Telescopic Spreader

Pump Motors.

Time

Drive End

(DE)mm/s

Non Drive End

(NDE)mm/s

Temperature

(

0C)

Horiz

ontal

Verti

cal

Axial

Horiz

ontal

Vertica

l

Axial

OF

ND

08.00

0.9

0.7

0.6

0.7

0.9

0.7

37

37

09.00

0.9

0.7

0.6

0.7

0.9

0.7

36

37

10.00

0.9

0.8

0.7

0.8

0.9

0.7

37

37

11.00

0.9

0.8

0.8

0.8

0.9

0.7

37

38

11.45

0.9

0.8

0.8

0.9

0.9

0.7

38

39

13.15

0.9

0.8

0.8

0.9

0.9

0.7

39

40

14.00

0.9

0.8

0.8

0.9

0.9

0.8

40

41

15.00

0.9

0.8

0.8

0.9

0.9

0.8

40

41

16.00

0.9

0.8

0.8

0.9

0.9

0.8

41

41

17.00

0.9

0.9

0.8

0.9

0.9

0.8

43

42

Analysis of Reduced Performance of 7.5 kW Hydraulic Pump Motor on Telescopic Spreader Quayside Container Crane (QCC)

453

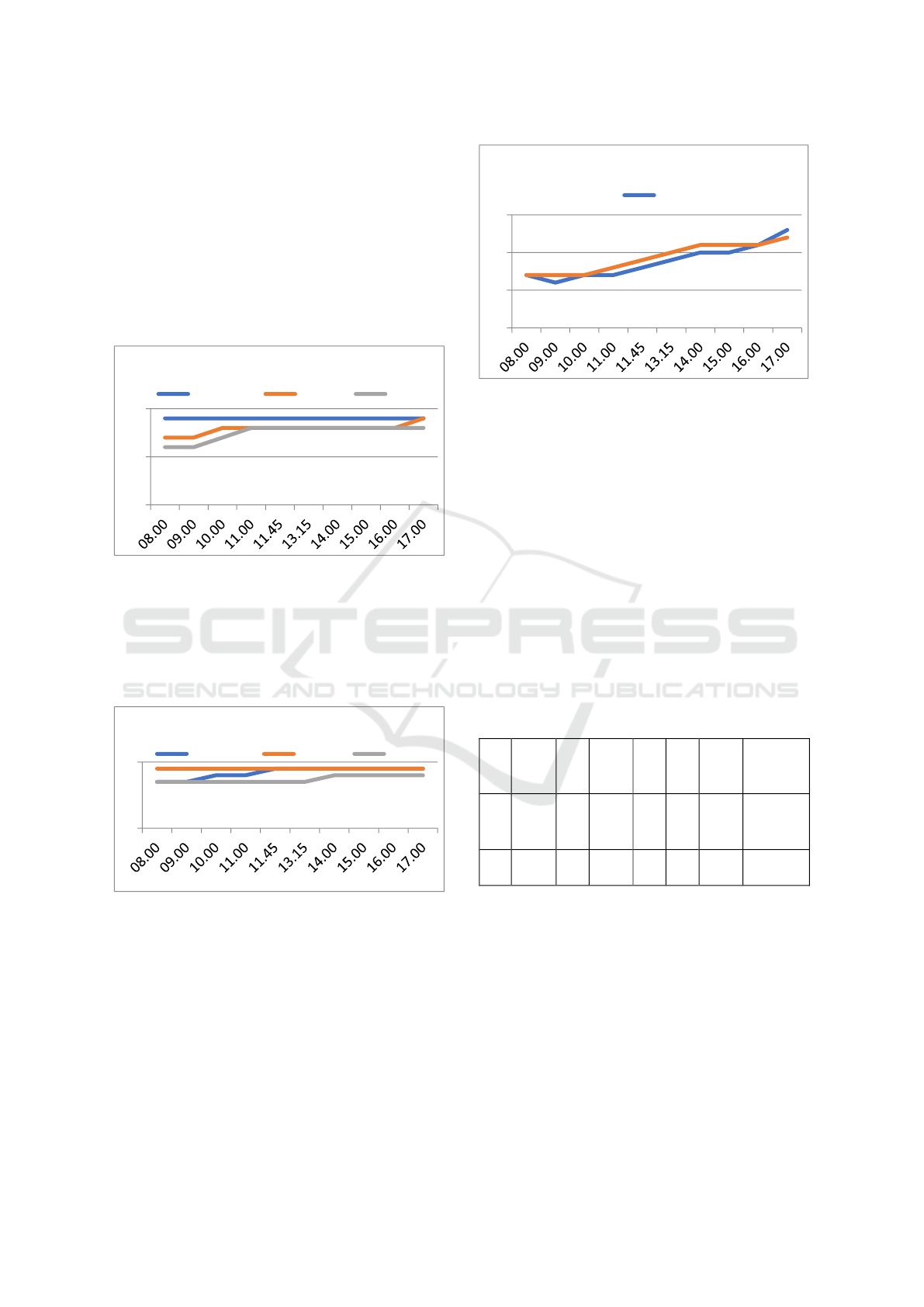

4.3 Motor Vibration Measurement

Measurement of the vibration of the telescopic

spreader hydraulic pump motor using a vibration

meter at several points on the motor body with the

position of the tip of the tool placed horizontally,

vertically and axial.

The increase in temperature of the telescopic

spreader hydraulic pump motor when without load in

the table above is caused by an increase in vibration.

Figure 7: Telescopic Spreader Motor DE Vibration Graph.

In the chart above for the horizontal is the same

amount of 0.9 while the smallest vertical is 0.7 at time

08.00 and 09.00 and the greatest is 0.9 at time 17.00

for axial is the smallest 0.6 at time 08.00 and 09.00

and the greatest is 0.8 at time 11.00 to 17.00.

Figure 8: Telescopic Spreader Motor NDE Vibration

Graph.

In the chart above for the smallest horizontal is 0.7

at time 08.00 and 09.00 and the largest is 0.9 at time

11.45 to 17.00 while the vertical is the same

magnitude is 0.9 for axial, the smallest is 0.7 at time

08.00 to 13.15 and the greatest is 0.8 at time 14.00 to

17.00.

Figure 9: Telescopic Spreader Motor Temperature.

In the chart above, the smallest DE is 36 at 09.00

and the largest is 43 at 17.00, while the smallest NDE

is 37 at 08.00 to 10.00 and the largest is 42 at 17.00.

4.4 Isolation Resistance

Measurement of insulation resistance of the

telescopic spreader hydraulic pump motor using a

device, a megger, by disconnecting all cable

connections at the terminals. Select the selector on the

megger according to the voltage of the motor object.

Then check the connection between phase and phase

of each phase, and finally check the connection

between phase and ground of each phase.

Table 4: Insulation Resistance in Telescopic Spreader

Motors Before and After Varnishing &; Heating.

Test

Point

U-

Ground

V-

Groun

d

W-

Ground

U-V

V-W

W-U

Information

Main

Stator

1300

MΩ

1300

MΩ

1200

MΩ

1000

M

1000

M

1000 M

Before

Main

Stator

2000 MΩ

2000

MΩ

2000 MΩ

2000

MΩ

2000

MΩ

2000 MΩ

After

The increase in the value of insulation resistance

on the telescopic spreader motor due to the

varnishing process is carried out after which the

heating process is carried out for 48 hours with a

temperature of 110

0

C.

0

0,5

1

Drive End (DE)

Horizontal Vertikal Axial

0

1

Non Drive End (NDE)

Horizontal Vertikal Axial

30

35

40

45

TEMPERATURE

DE

ISCP UTA ’45 JAKARTA 2023 - THE INTERNATIONAL SEMINAR AND CALL FOR PAPER (ISCP) UTA ’45 JAKARTA

454

4.5 No-Load Motor Current and

Voltage Measurement

The second step in decreasing the performance of the

telescopic spreader pump motor is to test the motor so

that it can operate every hour.

Table 5: No-load Motor Voltage and Current Measurement

Results.

Time

Voltase

Ampere

R-S

S-T

R-T

R

S

T

09.00

381 V

380 V

380 V

8,1 A

8,2 A

8,2 A

11.00

381 V

381 V

381 V

8,3 A

8,3 A

8,1 A

14.00

382 V

381 V

380 V

8,4 A

8,3 A

8,2 A

16.00

381 V

381 V

381 V

8,3 A

8,3 A

8,2 A

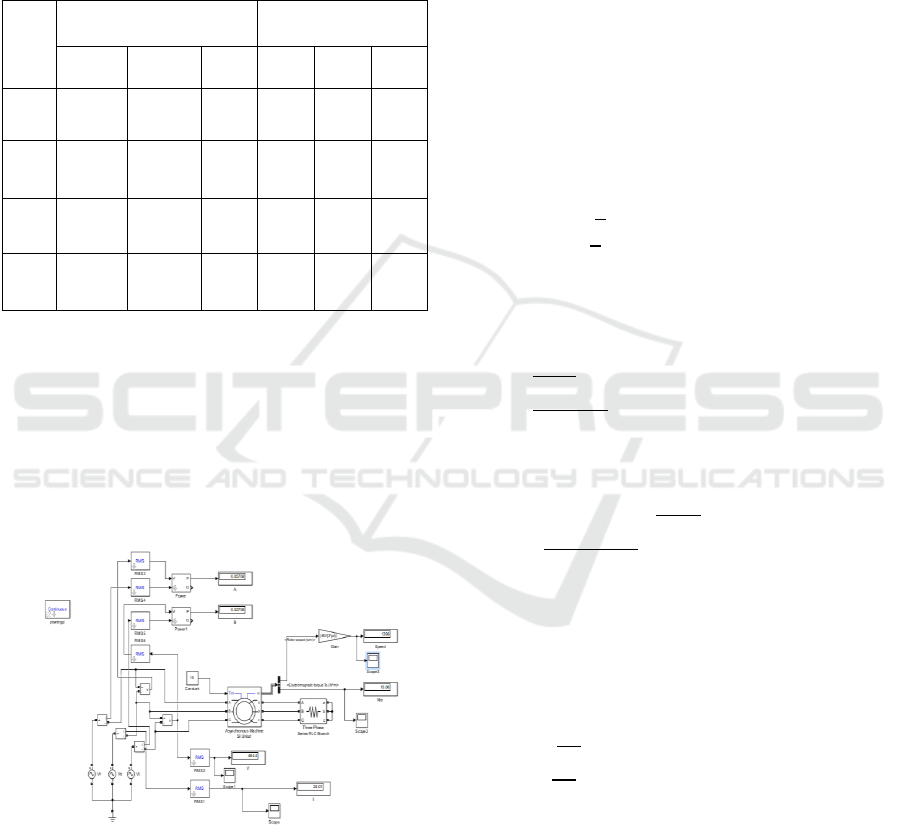

4.6 Hydraulic Motor Simulation Using

Simulink

Changes in load that occur during the operation of

Quayside Container Crane result in trips on the

hydraulic pump motor of the telescopic spreader. The

effect of the load change can be seen from the matlab

simulation as follows:

Figure 10: Hydraulic Motor Circuit.

In figure 10 the following components are used as

follows:

• Power Gui

• RMS (6)

• Power (2)

• Gain

• Display (6)

• Scope (4)

• Asynchonous Manchine

• Three-Phase series RLC Branch

• Constant

• Bus selector

• Ground

• Voltase Measurement (3)

• Current Measurement (3)

• Ac Voltase Source (3)

4.7 Calculation of 3 Phase Induction

Motor Efficiency

• Motor Efficiency Measurement Calculation

The calculation of the output power value is based

on Table 5 as follows:

P in Calculation :

P =

P =

(9)

P = 4.560 Watt

• Insulation resistance calculation formula with

3 phase motor performance

Slip i Calculation:

S =

S =

(10)

S = 3.6%

• Mechanical Loss Calculation:

P loses = T

=

=

= 151.24 rad/s (11)

P loses = 0.12 151.24

= 18.14 Watt

• Winding Loses :

P

Scl

= 3 . I

2

. R1

= 3 8.1

2

65.44 (12)

= 1.288 Watt

P

Rcl

=

P

Loses

nominal

=

62.94 (13)

= 13.217 Watt

• P

total loses

= P

m

+ P

Sc

l + P

Rcl

= 18.14 + 1.288 + 13.217 (14)

= 44.23 Watt

• P Out Calculation:

P

Out

= P

in

– P

loses

= 4.650 – 44.23 (15)

= 4.605 Watt

• Efficiency Calculation:

Analysis of Reduced Performance of 7.5 kW Hydraulic Pump Motor on Telescopic Spreader Quayside Container Crane (QCC)

455

Efficiency =

=

(16)

= 90%

• Formula between resistance and temperature

The calculation of resistance and temperature

based on tables 3 and 4 is as follows:

Find the resistance value in DE with a temperature

of 0

0

C First:

=

/ (1 + )

= / (1 + (0.0043 x 36)

= / (1 + 0.154) (17)

= / 1.154

= Ω

Find the resistance value in DE with a temperature

of 43

0

C First

=

(1 +

)

= x (1 + (0.0043 x 43)

Because

= x (1 + 0.184)

= x 1. 184

= Ω

• Find the resistance value in an NDE with a

temperature of 0

0

C First

=

/ (1 +

)

= / (1 + (0.0043 x 37)

= / (1 + 0.159)

= / 1, 159

= Ω

• Find the resistance value in an NDE with a

temperature of 42

0

C First

=

(1 +

)

= x (1 + (0.0043 x 42)

Because

= x (1 + 0.180)

= x 1,180

= Ω

• Insulation Resistance Formula

Calculation of Isolation Resistance based on table

5:

IR =

IR =

4.8 Research Analysis

The increase in temperature in the telescopic spreader

hydraulic pump motor can be seen from table 4 so that

this means that the motor insulation material will

inhibit the electric current more when the higher

temperature will cause the insulation of the stator

winding to be damaged. Based on table 5, changes in

insulation resistance have increased due to the

varnishing process and heating process with a

working temperature of 1100C for 48 hours. If the

temperature setting is too low, then the insulation

resistance can be reduced. If the temperature setting

is too hot, there is a risk of insulation becoming less

effective because it experiences thermal degradation

or can even melt.

Based on table 4, the performance of the telescopic

spreader hydraulic pump motor can be affected by

vibration enhancement. Over-vibration can cause

interference with the internal components of the motor

and cause faster wear. This can lead to a decrease in

motor efficiency and even complete failure.

So the factor that has a major influence on the

decrease in the performance of the telescopic spreader

hydraulic pump motor in this study is the decrease in

the insulation resistance value on the stator of the

spreader pump motor. The decrease in the insulation

resistance value of the spreader motor is caused by

the condition of the outside air which is quite dirty

and due to the leakage of hose hoses in the hydraulic

pump system that can penetrate the insulation of the

stator winding on the telescopic spreader motor.

5 CONCLUSION

The conclusions obtained from the study on the

analysis of the performance degradation of the 7.5

kW hydraulic pump motor on the Quayside Container

Crane telescopic spreader are as follows:

1. The results of the efficiency calculation in

chapter 4.5 of the telescopic spreader hydraulic

pump motor of 90% with different outputs of

4,605 Watts,

2. For simulated performance degradation analysis

of 7.5 kW hydraulic pump motor on Quayside

Container Crane telescopic spreader using

MATLAB R2016a,

3. The results of the data on isolation prisoners

obtained at PT. Parvi Indah Persada in table 5

(Before) in phase U - ground and phase V - ground

is the same at 1300 M, and W - ground is 1200 M,

while between phases U-V, V-W, W-V is the

same at 1000 M and Based on table 6 (After)

for solitary confinement in phases U, V, W-

Ground the isolation resistance is the same which

is 2000M there is also for isolation resistance

between phase U-V, V-W, W-U the solitary

confinement is the same i.e. 2000M. The

increase in insulation resistance value is quite

significant in the telescopic spreader hydraulic

pump motor because the Varnishing process is

carried out after which the Heating process is

carried out for 48 hours Advice.

ISCP UTA ’45 JAKARTA 2023 - THE INTERNATIONAL SEMINAR AND CALL FOR PAPER (ISCP) UTA ’45 JAKARTA

456

5.1 Suggestion

The suggestions from this study are:

1. To make it easier to learn the analysis of

electrical machines, software should be used

that can present dynamic simulations.For

example matlab/simulink

2. Multiply references in research and analysis,

This study can be a reference to analyze the

efficiency of three-phase induction motors

with the compensated ampere ratio voltage

method.

REFERENCES

Andriyadi, A. (2020). Analysis of IDF K-84-002 CDU IV

Motor Isolation Resistance Reduction at PT. Pertamina

RU III Plaju (Doctoral dissertation, 021008 Universitas

Tridinanti Palembang).

Anthony, Z. (2020). Alternating Current Electric Machine:

Revised Edition. Andy Publishers.

Apriyadi, T. (2022). Insulation resistance testing on the

stator winding of a 500 kW induction motor. FTI.

EASA AR-100, Recommended Practice for The Repair of

Rotating Electrical Apparatus, St. Lois, MO: Electrical

Apparatus Service Association, inc., 2015

Kristanto, V. H. (2018). Research Methodology Guidelines

for Writing Scientific Papers: (KTI). Deepublish.

PT. Indonesia Power, Electric Motor Maintenance Manual

Level 1,2,3., Semarang: PT. Indonesia Power Unit

Generation Semarang, 2016.

Ramdhan, M. (2021). Research methods. Cipta Media

Nusantara.

Siyoto, S., &; Sodik, M. A. (2015). Basic research

methodology. media literacy publishing.

Sulastri, D., &; Darmawan, I. A. (2022). Electrical testing

of 3 phase induction motor rotor cage 75 kW at PT

MESINDO TEKNINESIA. TESLA: Journal of

Electrical Engineering, 24(1), 47-55.

Theodore Wildi. (2017). Three-Phase Induction Motor

Theory. Ministry of Education and Culture of the

Republic of Indonesia, 2(1), 7–37.

Wicaksana, A., &; Rachman, T. (2018). Angewandte

Chemie International Edition, 6(11), 951–952., 3(1),

10–27. https://medium.com/@arifwicaksanaa/

pengertian-use-case-a7e576e1b6bf 7

Rofii, A., &; Ferdinand, R. (2018). Analysis of the use of

capacitor banks in an effort to improve the power factor.

Journal of Electrical Engineering Studies, 3(1), 39–51.

Analysis of Reduced Performance of 7.5 kW Hydraulic Pump Motor on Telescopic Spreader Quayside Container Crane (QCC)

457