Mathematical Modeling and Optimization of System Parameters of

Feed Plant Using Machine Learning

Shakuntla Singla

a

and Komalpreet Kaur

b

Department of Mathematics and Humanities, MMEC, Maharishi Markandeshwar (Deemed to be University),

Mullana, Ambala, India

Keywords: Machine Learning Algorithms, Regenerative Point Graphical Technique (RPGT).

Abstract: In this study, RPGT is applied for mathematical modelling system constraints of cattle, poultry, and fish feed

plant and stand optimized by machine learning. The plant is made up of three grinder units (A1A2A3) that

grind three distinct raw materials into precipitate depending on the type of feed that needs to be prepared, as

well as a single cold standby (A) aimed at aimed at all these grinders, each of these grinders has a common

standby grinder that is operated by an imperfect switch-over device whose probability of successful replacing

is p, so that, if any one of the three grinders fails, the standby grinder can still input the ingredients into the

system, a mixer (B) that combines the powder by syrup, using stuffing unit and a packing (D). Optimization

of system parameters is carried out using Machine Learning Algorithms as Linear SVC Classifier (LC),

Logistic Regression (LR), and Decision Tree Classifier (DT). Tables and charts are likewise created to explain

the system's practical trend using specific situations.

1 INTRODUCTION

Due to religious restrictions, the beef and pork feed

industries in India are nonexistent, and these only

produce dairy, poultry, and aqua feeds. Numerous

feed plants have sprouted up in the NCR region

(especially Rohtak-Haryana) because of the high

standard and international standard of the feeds

produced there, as well as the abundance of materials

readily available for their production. Maize, rice

bran, groundnuts, and other raw materials are utilized

in a chicken, cow, and fish feed facility. Due to the

fertile soil and numerous rivers that bring water to the

region, the agriculture industry in the Rohtak region

is thriving. Farmers grow a wide variety of crops,

including Makka, barely, maize, wheat, and rice.

They are also engaged in fish farming and work in

other sectors. Numerous cattle feed plants, or cattle

feed plants, have sprung up in the region to

supplement the cattle feed. In addition, since fish

require water to grow and the Yamuna, and Ghaggar

rivers provide abundant water; many farmers in the

region have chosen to pursue fish farming as a

profession.

a

https://orcid.org/0009-0000-5659-2330

b

https://orcid.org/0000-0002-5713-2982

System Description. In a feed plant, there are

typically three grinders that grind the different

ingredients. Each of these grinders has a common

standby grinder that is operated by an imperfect

switch-over device whose probability of successful

replacing is p, so that, if any one of the three grinders

fails, the standby grinders can still input the

ingredients into the system. Following processing in

mixtures, the feed is transported via conveyor belts to

open fields where it is derivate, cold weighed, and

packaged. These ground in grinded are mixed with a

bonding material. Thus, in a feed plant, there are three

different types of unit grinder’s mixture and packing

units arranged in series. If any one of these flops, the

organization is in a down state, or fails. However, the

standby unit has a lower working capacity than the

main grinders, so when it is online, the plant's

working capacity is decreased.

The plant has three grinders, A

1

, A

2

, A

3

which

mills the uncooked resources there is a cold stand-in

grinder; it is swapped in through an imperfect switch-

over device to altogether these three grinders, a

blender unit B which mixes the raw resources in the

obligatory 0fraction by treacle and a considering of

158

Singla, S. and Kaur, K.

Mathematical Modeling and Optimization of System Parameters of Feed Plant Using Machine Learning.

DOI: 10.5220/0012608200003739

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Artificial Intelligence for Internet of Things: Accelerating Innovation in Industry and Consumer Electronics (AI4IoT 2023), pages 158-162

ISBN: 978-989-758-661-3

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

stuffing unit. When the backup unit is online, the

classification operates at a reduced rate. The

arrangement malfunctions when a standby unit,

mixer, or packing repair unit fails. Performance

analysis also identifies the primary contributors to

repairable spinning machines. It has been created to

increase system availability by managing

maintenance factors and minimum maintenance and

repair rates, which are crucial to system availability.

Priority in repair to the three units is in order A>B>D

taking single repair facility is who is always available

carries out all types of repairs. System parameters are

obtained using RPGT. (Shakuntla et al., 2011)

discussed the behavior analysis of polytube using

supplementary technique; the behavior of a bread

plant was examined by (Kumar et al. 2018). To do a

sensitivity analysis on a cold standby framework

made up of two identical units with server failure and

prioritized for preventative maintenance, (Kumar et

al. 2019) used RPGT. The comparative analysis of the

subsystem failed simultaneously was discussed by

(Shakuntla et al. 2011). In a paper mill washing unit,

(Kumar et al. 2019) investigated mathematical

formulation and behavior study. PSO was used by

(Kumari et al. 2021) to research limited situations.

Using a heuristic approach, (Rajbala et al. 2022)

investigated the redundancy allocation problem in the

cylinder manufacturing plant. The tables and graphs

are created using analytical cases, and they are then

discussed and concluded.

2 ASSUMPTION AND

NOTATIONS

1. There is single repairman who is always presented.

2. The circulations of failure/repair periods are

constant and diverse.

3. Nothing can flop when organization is in

unsuccessful state.

4. The organization is conferred on behalf of

steady-state circumstances.

R

i

(t) : Reliability of the organization at

period t, specified that classification go in the un-

failed Re-forming state ‘i’ at t = 0.

μ

i

: Mean sojourn time expended in state i,

previously visiting several additional states.

𝜇

=

𝑅

𝑡

𝑑𝑡

ξ : Base state of the organization.

f

j

: Fuzziness portion of the j-state.

A/a : Unit in working state / failed state,

correspondingly for other units.

w

i

/ λ

i

: Denote repair failure rates of units

p: probability of switching successfully

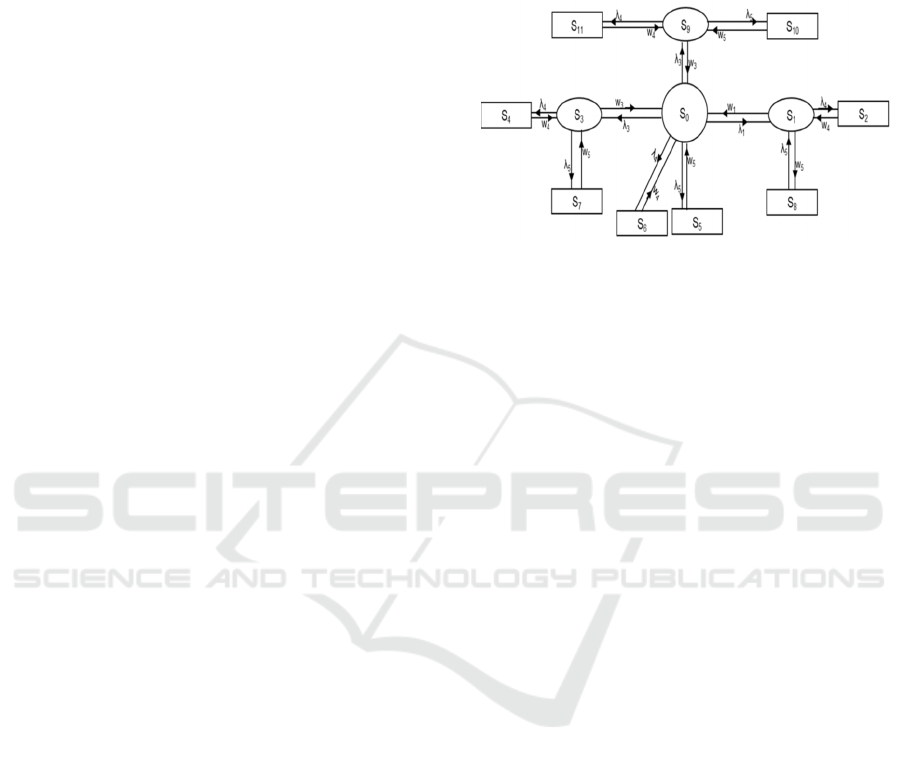

3 TRANSITION DIAGRAM

Figure 1: Transition Diagram of the feed plant.

Where various states are as under,

S

0

= A

1

A

2

A

3

BD(a); S

1

= AA

2

A

3

BD(a

0

); S

2

=

AA

2

A

3

bD; S

3

= A

1

AA

3

BD(a

2

); S

4

= A

1

AA

3

bD(a

2

); S

5

= A

1

A

2

A

3

Bd; S

6

= A

1

A

2

A

3

bD; S

7

= A

1

AA

3

Bd(a

2

); S

8

= AA

2

A

3

Bd(a

1

); S

9

= A

1

A

2

ABD(a

3

); S

10

=

A

1

A

2

ABd(a

3

); S

11

= A

1

A

2

AbD(a

3

)

3.1 Probability Density Function (Q

i,j

(t)

)

𝑞

,

= 𝜆

𝑒

𝑞

,

= 𝜆

𝑒

𝑞

,

= 𝜆

𝑒

𝑞

,

= 𝜆

𝑒

𝑞

,

= 𝜆

𝑒

𝑞

,

= 𝜆

𝑒

;𝑞

,

= 𝜆

𝑒

𝑞

,

= 𝑤

𝑒

; 𝑞

,

= 𝑤

𝑒

𝑞

,

= 𝜆

𝑒

; 𝑞

,

= 𝜆

𝑒

𝑞

,

𝑞

,

𝑞

,

= 𝑞

,

= 𝑤

𝑒

𝑞

,

𝑞

,

𝑞

,

𝑞

,

= 𝑤

𝑒

𝑞

,

= 𝑤

𝑒

; 𝑞

,

= 𝜆

𝑒

𝑞

,

= 𝜆

𝑒

Cumulative Density Functions in moving from

state ‘i’ to state ‘j’ by taking Laplace Transform

of above functions, P

ij

= q*

i,j

(t)

, for infinite time

intervals is given as under: -

𝑝

,

= λ

1

/(λ

1

+λ

3

+λ

4

+λ

2

+λ

5

),; 𝑝

,

=

λ

5

/(λ

1

+λ

4

+λ

3

+λ

2

+λ

5

),; 𝑝

,

= λ

6

/(λ

1

+λ

3

+λ

4

+λ

2

+λ

5

)

;

𝑝

,

= λ

2

/(λ

1

+λ

3

+λ

4

+λ

2

+λ

5

); 𝑝

,

=

λ

3

/(λ

1

+λ

4

+λ

3

+λ

2

+λ

5

); 𝑝

,

= λ

4

/(λ

5

+λ

2

+w

1

)

;

𝑝

,

=

λ

5

/(λ

5

+λ

2

+w

1

); 𝑝

,

= w

1

/(λ

5

+λ

2

+w

1

); 𝑝

,

=

w

2

/(w

2

+λ

4

+λ

5

); 𝑝

,

= λ

5

/(w

2

+λ

4

+λ

5

)

;

𝑝

,

=

Mathematical Modeling and Optimization of System Parameters of Feed Plant Using Machine Learning

159

λ

4

/(w

2

+λ

5

+λ

4

); 𝑝

,

= w

3

/(w

3

+λ

4

+λ

5

); 𝑝

,

=

λ

5

/(w

3

+λ

5

+λ

4

), 𝑝

,

= λ

4

/(w

3

+λ

5

+λ

4

)

3.2 Probability Density Functions Ri(t)

and Mean Sojourn Times µi=Ri*(0)

𝑅

= 𝑒

; 𝑅

= 𝑒

;

𝑅

= 𝑒

; 𝑅

= 𝑒

; 𝑅

𝑅

𝑅

= 𝑒

; 𝑅

𝑅

𝑅

𝑅

= 𝑒

;

𝑅

= 𝑒

Value of the parameter µ

i

giving Mean Sojourn

Times

µ

0

= 1/(λ

1

+λ

5

+λ

4

+λ

2

+λ

3

); µ

1

= 1/(λ

4

+λ

5

+w

1

); µ

3

=

1/(w

2

+λ

5

+λ

4

); µ

2

=µ

4

=µ

11

=µ

6

= 1/(w

4

); µ

7

=µ

5

=µ

10

=µ

8

= 1/w

5

; µ

9

= 1/(w

3

+λ

5

+λ

4

)

3.2.1 Transition Probabilities from the

Initial Vertex ‘0’ (or Base State)

V

0,0

= 1 (Verified); V

0,1

= p

0,1

/(1-p

1,2

p

2,1

) (1-p

1,8

p

8,1

)

V

0,2

=

[{λ

1

/(λ

1

+λ

5

+λ

2

+λ

4

+λ

3

)}{λ

4

/(λ

5

+λ

4

+w

1

)}]/[{1-

(λ

5

/λ

4

+λ

5

+w

1

)}]; V

0,3

= ………..Continuous

MTSF (T

0

): The working states to which system can

join from primary state ‘0’, earlier going one down

state are: ‘i’ = 2, 4, 5, 6, 7, 8, 10, 11. Taking initial

state or base state as ‘ ’ = ‘0’.

T

0

=

∑

⎯

⎯

⎯

⎯

⎯

Π

-

,

÷ 1-

∑

⎯

⎯

⎯

⎯

⎯

Π

-

(1)

= (μ

0

+{p

0,1

/(1-p

1,2

p

2,1

) (1-p

1,8

p

8,1

) μ

1

}

+{[{λ

2

/(λ

1

+λ

3

+λ

5

+λ

4

+λ

2

)}]/[{1-λ

5

(w

2

+λ

5

+λ

4

)} {1-

λ

4

(w

2

+λ

5

+λ

4

)}] μ

3

} +{[{λ

3

/(λ

1

+λ

4

+λ

3

+λ

2

+λ

5

)}]/[{1-

λ

5

(w

3

+λ

5

+λ

4

)} [{1-λ

4

(w

3

+λ

4

+λ

5

)}] μ

9

)}

Availability of the System: The states (regenerative)

classification is in partial / full working state are ‘j’ =

0, 1, 3, 9 and all states are regenerative, taking ‘ξ’ =

‘0’ the total fractional availability using RPGT is

given by

A

0

=

∑

→

,

Π

-

,

÷

∑

→

Π

-

,

(2)

=

∑

𝑉

,

,𝑓

,𝜇

∑

𝑉

,

,𝑓

,𝜇

Busy Period of the Server: The states in which

server is busy for inspection/ repairing the units are

‘j’ = 1 to 11, taking ξ = ‘0’, the using RPGT is given

by

B

0

=

∑

→

,

Π

-

,

÷

∑

→

Π

-

,

(3)

=

∑

𝑉

,

,𝑛

∑

𝑉

,

,𝜇

Expected Number of Examinations by the repair

man (V

0

): The situations where the overhaul man

visits anew are j = 1, 3, 9 the reformative states stand

i = 0 - 11, and ‘ξ’ = ‘0’,

V

0

=

∑

→

Π

-

,

÷

∑

→

Π

-

,

(4)

=

∑

𝑉

,

∑

𝑉

,

,𝜇

4 MODEL EVALUATION

To evaluate the implementation of our model

performance, we have estimated different execution

evaluation confusion matrix (Recall, Accuracy

Precision, and F1- Measure). The evaluation of model

phase proposes to appraise the generalization

precision exactness of the design model on an

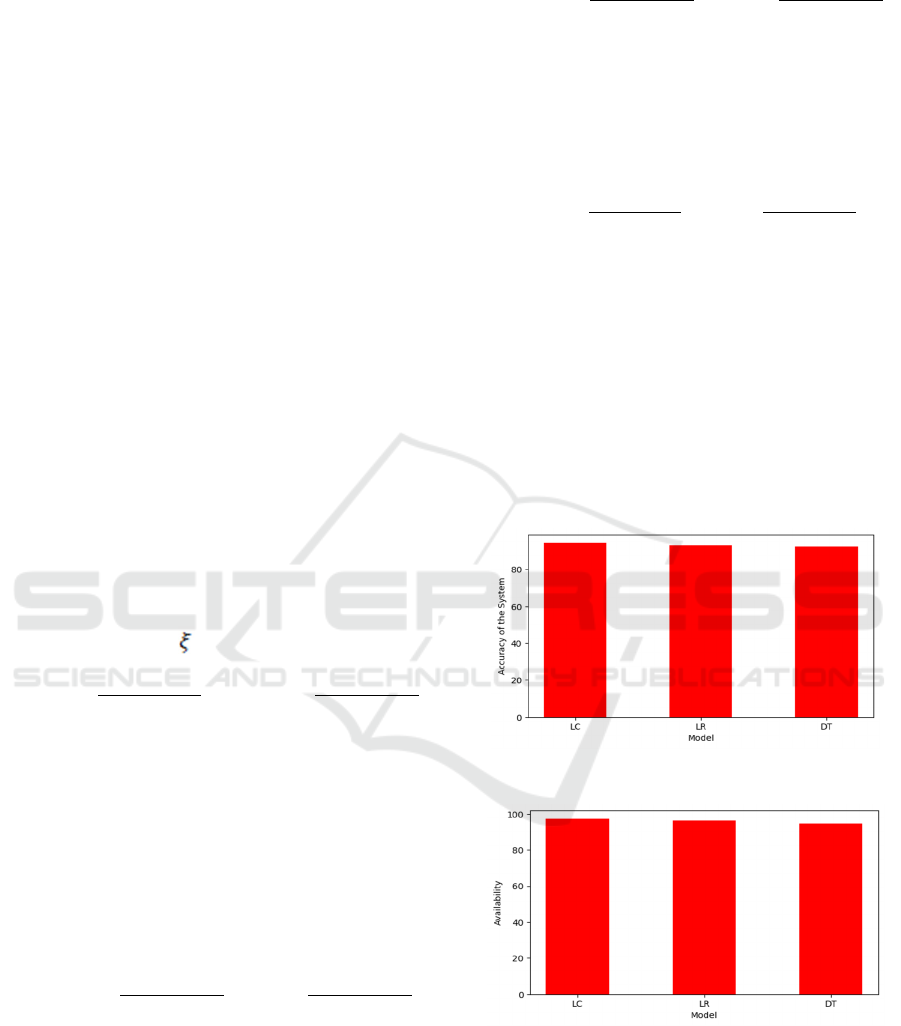

Figure 2: Comparison between Accuracy of models.

Figure 3: Comparison between Availability of models.

AI4IoT 2023 - First International Conference on Artificial Intelligence for Internet of things (AI4IOT): Accelerating Innovation in Industry

and Consumer Electronics

160

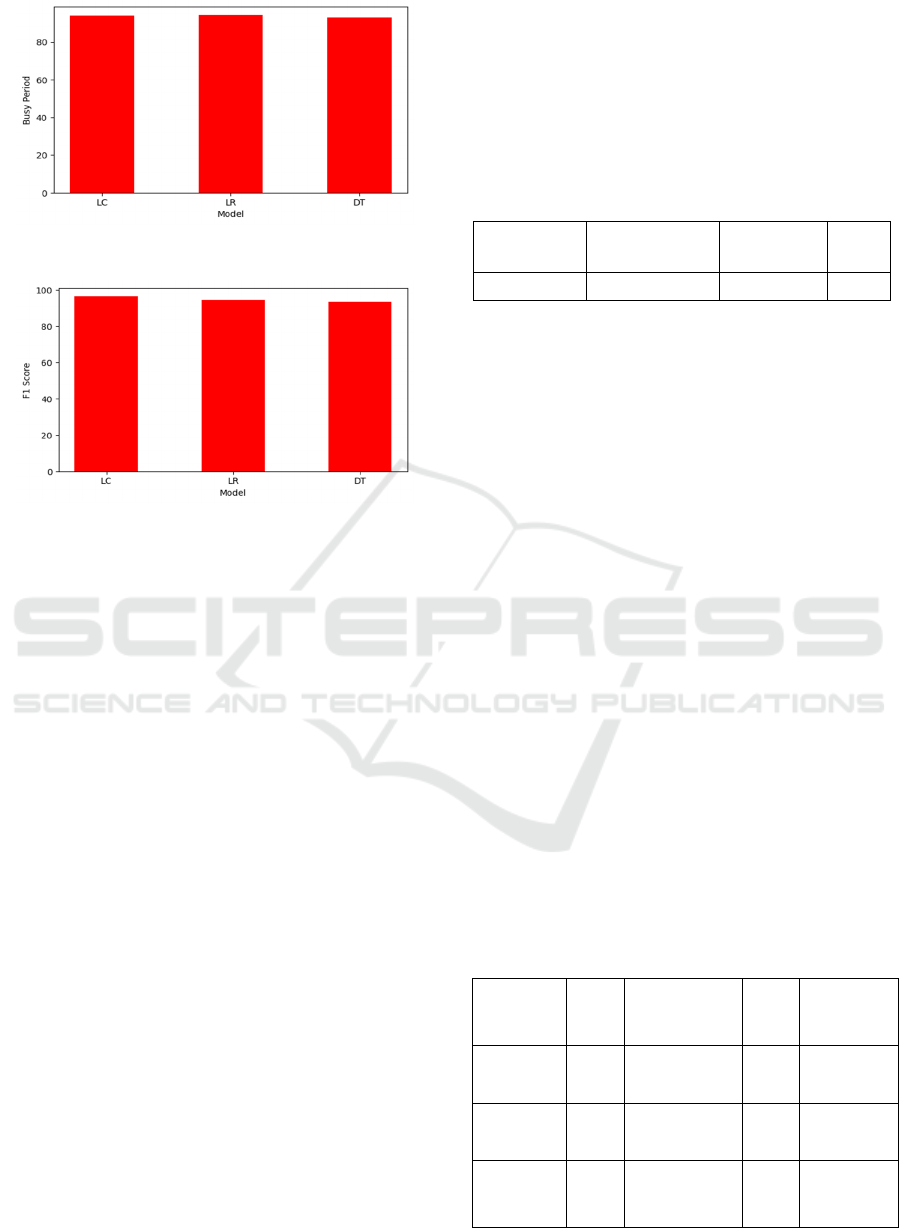

Figure 4: Comparison between Busy periods of models.

Figure 5: Comparison between F1 score of models.

Availability of the System by applying the precision,

MTSF, Busy Period, Expected Number of repair

man, that are imported from the metrics module

available into the Scikit-learn Python library that

depends on the following formula in equations 1, 2, 3

and 4 respectively. Overall, the availability analysis

is an important tool for identifying the factors that

impact the production and profitability of a feed plant

[1, 2, 3]. By understanding these factors, plant

managers can make informed decisions about

investments in equipment, raw materials, and labor

that can improve production efficiency and

profitability [4, 5, 6,].

Dataset: Availability analysis of a fish feed plant can

benefit from the use of machine learning for dataset

analysis. Machine learning algorithms can assistance

to identify decorations and trends in large datasets

that may not be closely apparent to human analysts.

This can help to improve the accuracy of the

availability analysis and enable plant managers to

make more informed decisions about how to improve

production efficiency and profitability. For example,

machine learning algorithms can be trained on

historical data from the plant to predict future demand

for feed products. This can help managers to adjust

production levels and raw material orders to match

expected demand, reducing waste and improving

profitability. Similarly, machine learning can be used

to identify patterns in raw material availability and

price fluctuations, enabling managers to optimize

purchasing decisions and reduce costs [4, 5, 6,].

Another potential application of machine learning in

availability analysis is predictive maintenance. By

scrutinizing statistics from machine beams and added

fonts, machine learning algorithms dismiss identifies

patterns that could indicate an impending breakdown

or maintenance issue.

Table 1: Table of parameter.

This can enable plant managers to schedule

maintenance proactively, reducing downtime and

improving overall equipment availability. Overall,

machine learning can remain a commanding tool for

educating the accuracy and efficiency of availability

analysis for poultry, cattle, and fish feed plant. By

enabling more accurate predictions and insights,

machine learning can help plant managers to optimize

production, reduce costs, and improve profitability in

Table 1.

5 RESULTS AND DISCUSSION

In general, availability analysis involves examining

the factors that influence the availability of a

particular product or service. For a poultry, cattle, or

fish feed plant, these factors might include the

availability of raw materials, labor, equipment, and

other resources required for production. The analysis

would also consider any constraints that might limit

the plant's ability to produce feed, such as market

demand or regulatory requirements. According to

Table 2, fig. 2, Fig. 3, Fig. 4 and Fig. 5 show,

comparison among model of linear classifier is better

than other model of machine learning.

Table 2: Performance of model.

Model MTSF

Expected

Number of visits

by repair man

Busy

Period

Availability

Linear SVC

Classifier

0.941 0.961 0.941 0.97

Logistic

Regression

0.9312 0.9412 0.942 .96

Decision

Tree

Classifier

0.9234 0.9323 0.932 .94

W (w1, w2, -----

--, wn)

ƛ

(

ƛ

1, ƛ2,…….

ƛ

𝑛 S (s1, s2, -----,

sn)

p

(0-50, 51-100) 0 to 0.1 (0-50, 51-100) (0-75)

Mathematical Modeling and Optimization of System Parameters of Feed Plant Using Machine Learning

161

Without more specific information about the plant

and the analysis conducted, it is difficult to provide a

meaningful discussion of the results. However, some

potential areas for discussion might include:

• The availability of key raw materials: If the

availability analysis identified a shortage or high

cost of key raw materials, such as soybean meal

or corn, this could have significant implications

for the plant's ability to produce feed at a

reasonable cost.

• Labor availability and skill levels: If the plant

relies on skilled labor to operate machinery and

produce feed, a shortage of qualified workers

could limit production capacity.

• Equipment availability and maintenance: If the

plant relies on specialized equipment, such as

pellet mills or extruders, any breakdowns or

maintenance issues could reduce production

capacity and profitability.

• Market demand and competition: The

availability analysis might also consider the

demand for feed products in the local market and

the level of competition from other feed

producers. If the market is saturated or demand

is low, this could limit the plant's ability to sell

its products at a profitable price.

Overall, the availability analysis is an important

tool for identifying the factors that impact the

production and profitability of a feed plant. By

understanding these factors, plant managers can make

informed decisions about investments in equipment,

raw materials, and labor that can improve production

efficiency and profitability.

6 CONCLUSION

The results of the behavior analysis can be used to

optimize the input variables for the poultry, cattle, or

fish feed plant. For poultry, cattle, or fish feed plant,

these factors might include the availability of raw

materials, labor, equipment, and other resources

required for production. By identifying which input

variables have the greatest impact on the output

variable, decision-makers can make informed choices

about which variables to prioritize for optimization.

This can help to improve the efficiency and

profitability of the industry, as well as the quality of

the final product. These insights can be used to

optimize processing parameters, improve the quality

of raw materials, and ultimately increase the

efficiency and profitability of the industry.

REFERENCES

Zhu, C. (2013). Discussion on countermeasures of supply

chain integration of fresh agricultural products in big

cities, Price Monthly, 1(1), 60–65.

Shamshirband, S, Anuar, N. B. and Patel, A. (2013). An

appraisal and design of a multi-agent system based

cooperative wireless intrusion detection

computational Intelligence technique, Engineering

Applications of Artificial Intelligence, 2105–2127.

Naphade, S. T. and Badhe, S. G. (2021). Study of smart

management system in poultry farming, Journal of

scientific Research, 65(6), 153–156.

Shalev, B. A. and Pasternak, H. (1989). Meat production

efficiencies of turkey, chicken and duck broilers,

worlds Poultry Science Journal, 45(2), 109–114.

Mosavi, A., Salimi, M., Faizollahzadeh Ardabili, S.,

R.abczuk, T., Shamshirband, S. and Varkonyi- Koczy,

A. R. (2019). State of the art of machine learning

models in energy systems, a systematic review,

Energies, 12(7), 1301.

Shakuntla, Lal, A, K., and Bhatia, S. S. (2011).

Comparative study of the subsystems subjected to

independent and simultaneous failure, Eksploatacja

INiezawodnosc-Maintenance and Reliability, 63-71.

Kumar, A., Garg, D., and Goel, P. (2019). Mathematical

modelling and behavioral analysis of a washing unit

in paper mill, International Journal of System

Assurance Engineering and Management, 1(6),

1639-1645.

Kumar, A., Garg, D., and Goel, P. (2019). Sensitivity

analysis of a cold standby system with priority for

preventive maintenance, Journal of Advance and

Scholarly Research in Allied Education, 253-258.

Shakuntla, Lal, and Bhatia S., (2011). Reliability analysis

of polytube tube industry using supplementary

variable Technique. Applied Mathematics and

Computation, 3981-3992.

Kumar, A., Goel, P. and Garg, D. (2018). Behavior analysis

of a bread making system, international journal of

Statistics and Applied Mathematics, 3(6), 56-61.

Kumari, S., Khurana, P., Singla, S., Kumar, A. (2021).

Solution of constrained problems using particle swarm

optimization, International Journal of System

Assurance Engineering and Management, 1-8.

Rajbala, Kumar, A. and Khurana, P. (2022). Redundancy

allocation problem: Jayfe cylinder Manufacturing

plant. International Journal of Engineering, Science &

Mathematic, 11(1), 1-7.

AI4IoT 2023 - First International Conference on Artificial Intelligence for Internet of things (AI4IOT): Accelerating Innovation in Industry

and Consumer Electronics

162