Availability and Behavioral Analysis of Refrigerating Unit in Milk

Plant with Scheduling: A Case Study of Milk Plant Rohtak

Savita Grewal

*

and Pooja Bhatia

†

Department of Mathematics, Baba Mastnath University Asthal Bohar, Rohtak, Haryana, India

Keywords: MTSF, RPGT, Availability

Abstract: In the current investigation one have picked the Refrigeration Plant arranged in Rohtak District. A

refrigeration unit involves of four main mechanisms namely Compressor, Condenser, Expansion Device and

Evaporator. Refrigeration plants are thought to be only viable when all four units are in good operating

condition. When each of the four units is in good operating condition, the system operates at maximum

efficiency. When three out of four units are in good operating condition, it operates at a decreased capacity.

When two or more units flop, the system is in a failed condition. There are separate continuous failure and

repair rates for all four units. A single repairman is available 24*7. The results of the sensitivity analysis can

be used to validate or challenge existing models and assumptions about the system. The deep learning can

provide valuable insights into the factors that affect system performance, Accuracy (MTSF), Expected

Number of Inspections by the repair man, Busy Period and Availability of the System and results in show in

figures and using the table.

1 INTRODUCTION

This study uses RPGT to analyses the behavior of a

refrigeration unit in a milk processing plant in the

Rohtak region with two units A and B, a permanent

repairman who attends to the online units according

to the schedule, and a specialist repairman who is

called when one of the subsystems A has fewer units

than a threshold number 't' of units. There are two

different kinds of subsystems, A and B. In subsystem

"A," there are "m" online units with a pool of "n"

(fewer than m) units in cold standby, but subsystem

"B" has units in series, thus it fails when any of its

subunits fails, leading to the failure of the entire

system. In sub system ‘A’ online units remain

scheduled aimed at service/ repair single by single

and replaced through one of the standby units after

the pool. If number of good online units stand in the

variety, {m < i < t}, and number of online units in A

are left to less than a threshold number ‘t’, then the

subsystem A fails, hence the whole system is failed,

then a special repairman is entitled for repairing/

serving the failed units. Both types of equipment are

repaired or serviced by a permanent repairman, but

*

Research Scholar

†

Professor

subsystem B is given precedence in repairs. RPGT is

used to obtain expressions for System parameter

values. To compare the impact of various repair and

failure rates on the parameter values, graphs and

tables are created for each value. For the repair of

malfunctioning devices and in diminished stages,

there is just one repairman. The rates of failure are

exponentially distributed, while the rates of repair are

universal, independent, and distinct for various

operational units varying units have varying

capabilities. The fixes are flawless. As discussed, in

this paper Rohtak region have rich in milk production

as there are quite several milch animals, which is

further processed to produce several useful milk

products, one of such most useful product in our daily

life is milk which is used for drinking by humans of

all ages from infants to old persons. This milk is of

many types of generally full cream, toned and double

toned and is distributed and sold in the market of all

available different types of urban, semiurban, and

rural area located in the Rohtak region. In a

Refrigerating unit of Rohtak there two sets of pools,

one set of which is online i.e., which refrigerates the

milk

and other set is in cold standby made have a

170

Grewal, S. and Bhatia, P.

Availability and Behavioral Analysis of Refrigerating Unit in Milk Plant with Scheduling: A Case Study of Milk Plant Rohtak.

DOI: 10.5220/0012608800003739

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Artificial Intelligence for Internet of Things: Accelerating Innovation in Industry and Consumer Electronics (AI4IoT 2023), pages 170-177

ISBN: 978-989-758-661-3

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

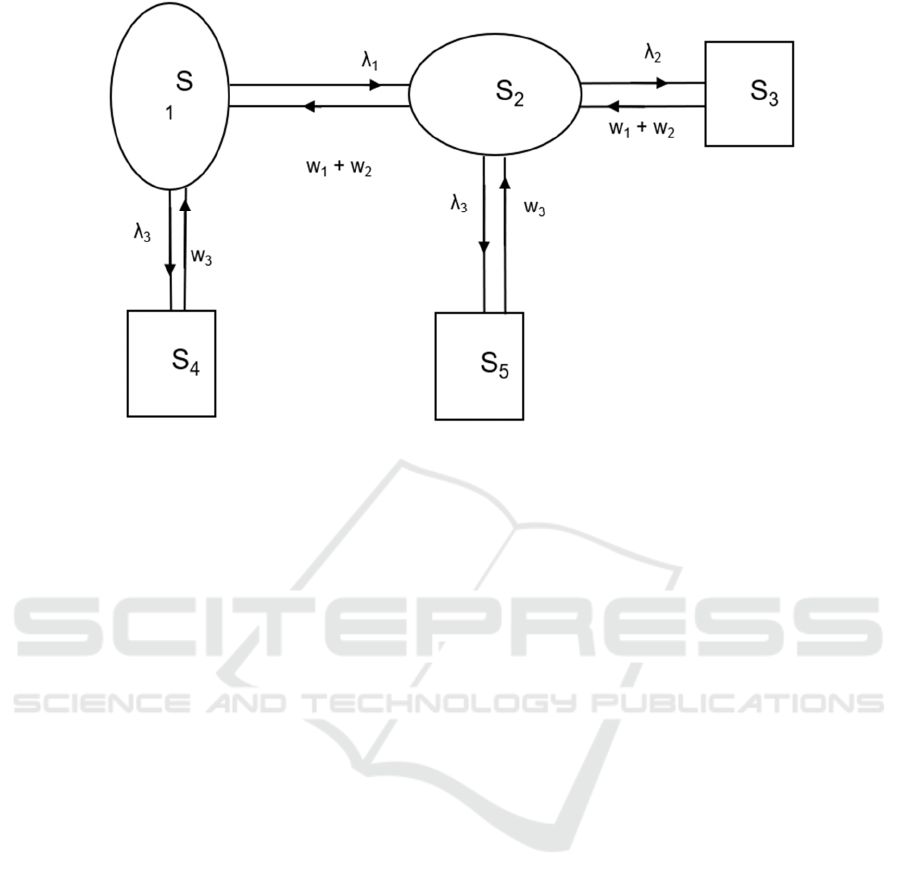

Figure 1: Transition Diagram.

certain number of units in the offline mode, online

spools are scheduled for a service and are made

offline after a fixed period and a spool from the

standby pool is mode online. (Shakuntla et al 2011)

discussed the behavior analysis of polytube using

supplementary variable procedure; the behavior of a

bread plant was examined by (Kumar et al. 2018). To

do a sensitivity analysis on a cold standby framework

made up of two identical units with server failure and

prioritized for preventative maintenance (Kumar et al.

2019) used RPGT, two halves make up the paper, one

of which is in use and the other of which is in cold

standby mode. The comparative analysis of the

subsystem failed simultaneously was discussed by

(Shakuntla et al. 2011). In a paper mill washing unit

(Kumar et al. 2019) investigated mathematical

formulation and behavior study. PSO was used by

(Kumari et al. 2021) to research limited situations.

Using a heuristic approach, (Rajbala et al. 2022)

investigated the redundancy allocation problem in the

cylinder manufacturing plant. The tables and graphs

are created using analytical cases, and they are then

discussed. Following the use of specific examples, the

effect is expressed using tables and graphs as well as

concluding remarks.

1.1 Working of the System

There are two subsystems A and B in milk plant of

Refrigerating Unit. In unit ‘A’ their ‘m’ online and

‘n’ units in cold standby mode switched in with online

unit’s pool to online units by a perfect switch over

device as per a schedule one by one. There is one

permanent that is continually available. To repair the

unsuccessful unit (s) of sub system A, the failure rate

of subsystem ‘A’ is λ

1

, if number of subunits in it are

online and if the number of online units in subsystem

‘A’ are less than the threshold ‘t’, then the

arrangement worked in reduced capacity shown in

transition diagram as S

2

, further if the number of

online units in ‘A’ are less than a threshold ‘t’ then it

fails at a failure rate λ

2

. The unit ‘B’ has subunits in

series, so if one of the subunits in ‘B’ flops, then the

unit ‘B’ fails whose failure rate is λ

3

. A specials

repairman is called in if in subsystem ‘A’ there are

less than ‘t’ online units to keep the system available,

so the combined repair rate of two repairman will be

w

1

+w

2

assumed to be linear and statistically

independent initially the system is in state S

1

[A

m,i

B,(0 ≤ i≤ n<m)] in which both the units

are good working state in state S

1

if the

unit B fails whose failure rate in λ

3

then the system

enters the state S

4

[A

m,n

b], as in this state unit ‘B’ is

in failed state the system fails from which unit ‘B’ is

repaired by the ordinary repairman, so again the

system centers the state S

1

. In state S

1

if subunits in

subsystem ‘A’ are less than ‘m’ but online subunits in

unit ‘A’ are greater than the threshold ‘t’ than the

failure rate of unit ‘A’ is λ1 then the system enters the

state S

2

[A

T

,

0

B]. If in state S

2

, online subunits due to

further failures in ‘A’ are reduced to a threshold level

‘T’, so if further if any unit fails in unit ‘A’, per which

the failure rate is λ

2

the system enters the failed state

S3 [aB], as in state S

3

the repairman are available, so

their combined repair rate is again w

1

+w

2

, when the

repaired subunit in unit ‘A’ reach a threshold level

Availability and Behavioral Analysis of Refrigerating Unit in Milk Plant with Scheduling: A Case Study of Milk Plant Rohtak

171

‘T’. Priority in repair of units is in order of B>A

considers the transition rates (i.e., failure and repair

rates) the possible states in which system can transit

are given in Figure 1.

2 ASSUMPTIONS AND

NOTATIONS

1. There is one repairman whose availability is 24x7

and another server is called on need basis.

2. Failures/repairs are statistically independent.

A/a: Unit in working state / failed state, similarly for

other units.

wi/ λi: Denote repair/failure rates of units. Transition

Diagram Description: -

2.1

Probability Density Function

(q

i,j

(t)

)

𝑞

,

= 𝜆

𝑒

, 𝑞1,4= 𝜆

𝑒

, 𝑞

,

=

𝑤

𝑤

𝑒

, 𝑞

,

=

𝜆

𝑒

, 𝑞

,

=

𝜆

𝑒

,𝑞3,2= 𝑤

𝑤

𝑒

, 𝑞

,

= 𝑞

,

𝑤

𝑒

Cumulative density functions in moving from state

‘i’ to state ‘j’ by taking Laplace Transforms of above

function for infinite time interval is given as under:

𝑝

,

= λ

1

/(λ

1

+λ

3

), 𝑝

,

= λ

3

/(λ

1

+λ

3

), 𝑝2,1= (w

1

+

w

2

)/(w

1

+w

2

+λ

2

+λ

3

), 𝑝

,

= λ

2

/(w

1

+w

2

+λ

2

+λ

3

), 𝑝

,

=

λ

3

/(w

1

+w

2

+λ

2

+λ

3

), 𝑝

,

= 𝑝

,

= 𝑝

,

= 1

2.2 Probability Density Functions Ri(t)

and Mean Sojourn Times µi=Ri*(0)

𝑅

= 𝑒

, 𝑅

= 𝑒

, 𝑅

=

𝑒

, 𝑅

=𝑅

= 𝑒

Value of the parameter µ

i

µ

5

= (1/β

3

) µ

1

= 1/(λ

1

+λ

3

), µ

2

= 1/(w

1

+w

2

+λ

2

+λ

3

), µ

3

=

1/(w

1

+w

2

), µ

4

= µ

5

=1/w

3

2.3 Evaluation of Parameters

Various Transition Probabilities from the base state

‘2’ and initial state ‘1’

V

2,1

= p

2,1

/(1-p

1,4

); V

2,2

= 1;V

2,3

= p

2,3,;

V

1,4

= p

1,4

; V

2,4

= p

2,1

p

1,4

/(1-p

1,4

); V

2,5

= p

2,5

; V

1,2

= p

1,2

/(1-p

2,5

) (1-

p

2,3

);

V

1,3

= p

1,2

p

2,3

/(1-p

2,5

) (1-p

2,3

); V

1,5

= p

1,2

p

2,5

/(1-p

2,5

)

(1-p

2,3

)

2.4

MTSF

(T

0

)

The states to which the structure can transit from

regenerative earlier visiting any un-failed state,

attractive initial state as ‘1’, before going to failed

state stand: ‘i’ = 1, 2.

T

0

=

∑

𝑖,𝑠𝑟

𝑝𝑟

𝜉

𝑠𝑟𝑠𝑓𝑓

→

𝑖

𝜇𝑖

𝛱

𝑚

1𝜉

1𝑉

𝑚

1𝑚

1

÷

1

∑

→

𝜉

𝛱

T

0

= [(μ

1

+{p

1,2

/(1-p

2,5

) (1-

p

2,3

) μ

2

)}]/(1-p

1,2

p

2,1

) (1)

2.5 Availability of the System

The states at which the organization is working

partially/ fully are ‘j’ = 1, 2 and the re-forming states

are ‘i’ = 1 to 5 attractive base state as ‘ξ’ = ‘2’ using

RPGT is given as

A

0

=

∑

𝑗,𝑠𝑟

𝑝𝑟

𝜉

𝑠𝑟→

𝑗

𝑓𝑗,𝜇𝑗

𝛱

𝑚

1𝜉

1𝑉

𝑚

1𝑚

1

÷

∑

𝑖,𝑠

𝑟

𝑝𝑟

𝜉

𝑠𝑟→

𝑖

𝜇

𝑖

1

𝛱

𝑚

2𝜉

1𝑉

𝑚

2𝑚

2

A

0

= [{p

2,1

/(1-p

1,4

) μ

1

} + μ

2

)}]/[{ p

2,1

/(1-

p

1,4

)μ

1

}+μ

2

+{p

2,3

μ

3

}+{ p

2,1

p

1,4

/(1-p

1,4

)μ

4

} +{ p

2,5

μ

5

}] (2)

2.6 Busy Period of the Server

The re-forming states where the unusual server is

busy is ‘j’ = 2, 3 and re-forming states are ‘i’ = 1 to 5,

attractive ξ = ‘2’,

AI4IoT 2023 - First International Conference on Artificial Intelligence for Internet of things (AI4IOT): Accelerating Innovation in Industry

and Consumer Electronics

172

B

0

=

∑

𝑗,𝑠𝑟

𝑝𝑟

𝜉

𝑠𝑟→

𝑗

,𝑛𝑗

𝛱

𝑚

1𝜉

1𝑉

𝑚

1𝑚

1

÷

∑

𝑖,𝑠

𝑟

𝑝𝑟

𝜉

𝑠𝑟→

𝑖

𝜇

𝑖

1

𝛱

𝑚

2𝜉

1𝑉

𝑚

2𝑚

2

(3)

2.7

Expected Number of Examinations

by the Repair Man

(V

0

)

The re-forming states where the renovation man prepares

this job j = 2, 3 Attractive ‘ξ’ = ‘2’,

V

0

=

∑

𝑗,𝑠𝑟

𝑝𝑟

𝜉

𝑠𝑟→

𝑗

𝛱

𝑘

1𝜉

1𝑉

𝑘

1𝑘

1

÷

∑

𝑖,𝑠

𝑟

𝑝𝑟

𝜉

𝑠𝑟→

𝑖

𝜇

𝑖

1

𝛱

𝑘

2𝜉

1𝑉

𝑘

2𝑘

2

(4)

3 EXPERIMENT

Responses are generated by an artificial intelligence

language model using a combination of licensed data,

data produced by human trainers, and publically

available data. I lack direct access to exclusive

databases and experimentation capabilities. However,

I can provide some general insights into the topic. In

a milk plant, refrigerating units play a critical role in

maintaining the freshness and quality of dairy

products. Analyzing the availability and behavior of

these units can help optimize their usage, reduce

energy consumption, and ensure efficient production

processes. Deep learning techniques, such as neural

networks, can be applied to analyze and predict the

availability and behavior of refrigerating units. By

training models on historical data, the deep learning

algorithm can learn patterns and correlations to

predict unit availability, performance, and potential

malfunctions. To experiment with deep learning, you

would typically need a dataset that includes

information about the refrigerating units, such as

operating hours, energy consumption, temperature

readings, maintenance records, and other relevant

variables using equation 1, 2, 3, and 4. This dataset

would serve as the training data for the deep learning

model.

• The experiment would involve:

• Preprocessing and preparing the data.

• Training the model on the data.

• Evaluating its performance.

The evaluation could include metrics such as

accuracy, precision, recall, or any other relevant

measure based on the specific objectives of the

experiment. The experiment's results can provide

insights into the availability patterns of refrigerating

units, their energy usage patterns, and potential

anomalies or maintenance requirements. This

information can be valuable for optimizing the milk

plant's scheduling, maintenance planning, and energy

efficiency. It's important to note that conducting such

an experiment requires access to relevant data,

expertise in deep learning techniques, and a clear

understanding of the specific objectives and

challenges of the milk plant Rohtak. In that case, you

can implement the experiment using deep learning

techniques to analyze the availability and behavioral

patterns of refrigerating units in the milk plant

Rohtak.

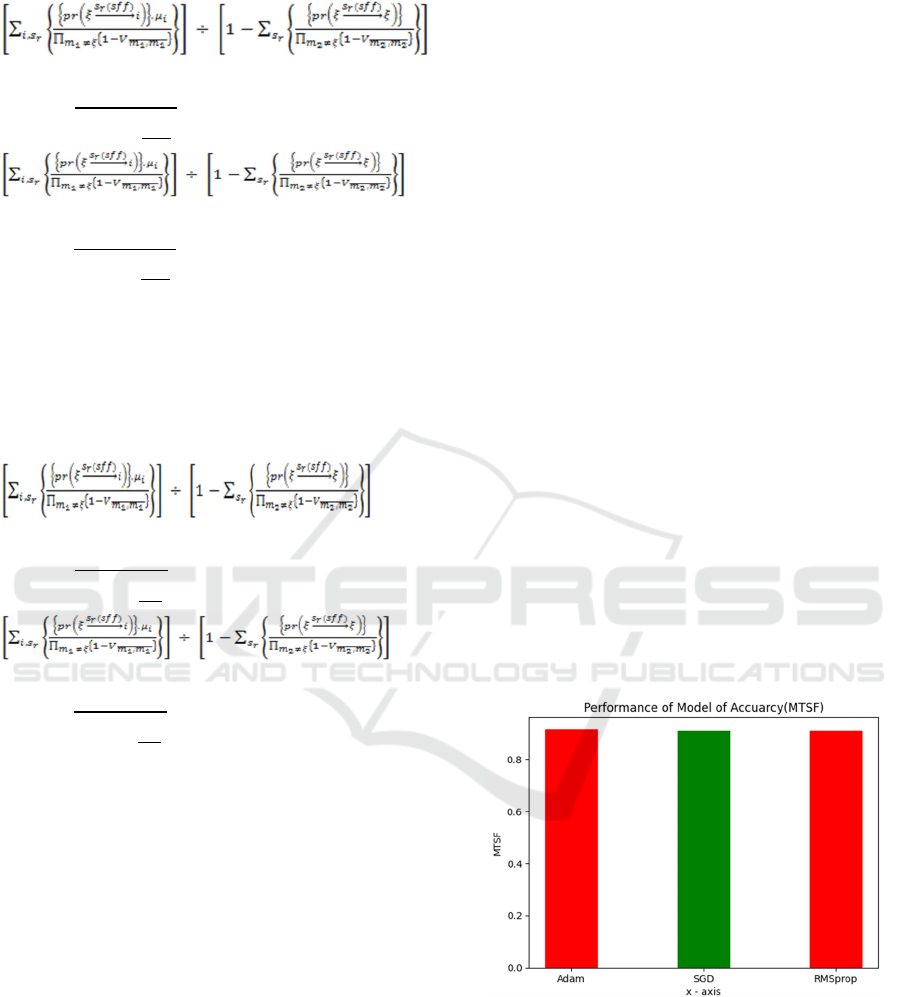

Figure.2: Comparing between models according to MTSF.

Availability and Behavioral Analysis of Refrigerating Unit in Milk Plant with Scheduling: A Case Study of Milk Plant Rohtak

173

Figure 3: Comparing between models according to F1

Score.

Figure.4: Comparing between models according to Recall.

Figure 5: Comparing between models and Precision.

3.1 Dataset

To analyze refrigerating units' availability and

behavioral patterns in the Milk Plant Rohtak using

deep learning techniques, you would require a dataset

that includes relevant information about the

refrigerating units and their operations using equation

1, 2, 3, and 4. While I don't have access to specific

datasets, I can provide some suggestions on the types

of data that might be useful for your case study:

Sensor Data: Collecting sensor data from refrigerating

units can provide valuable insights into their behavior

and performance. It may include temperature

readings, humidity levels, power consumption,

compressor cycles, and other relevant operational

parameters.

Maintenance Records: This data can help identify

patterns or correlations between maintenance

activities and unit availability.

Operational Logs: Detailed logs of the refrigerating

units' operations, such as start/stop times, running

durations, and any alarms, can provide a

comprehensive view of their availability and behavior.

Historical Scheduling Information: Information about

the scheduling and utilization of the refrigerating units

in the Milk Plant Rohtak can be valuable for analyzing

their availability.

External Factors: Consider incorporating external

factors that may impact the availability and behavior

of refrigerating units. For example, weather

conditions, seasonal variations in milk production, or

specific events or holidays that affect production

schedules.

Table 1: Table of parameter

W (w1,

w2, -------

-, wn)

ƛ(ƛ1, ƛ2,…….,ƛ𝑛 S (s1,

s2,------

-, sn)

P

(0-50, 51-

100)

(0-50, 51-100) (0-100) (0-80)

Ensuring the dataset is properly anonym zed,

complies with data privacy regulations, and does not

contain sensitive or personally identifiable

information is important. Once you have collected the

relevant dataset, you can preprocess and clean it,

apply appropriate feature engineering techniques, and

split it into training, validation, and testing sets. With

the prepared dataset, you can train deep learning

optimization models such as Adam, SGD and RMS

prop to predict availability, analyze behavioral

patterns, or optimize scheduling in show table

1Remember that the availability of such a dataset

specific to the Milk Plant Rohtak may depend on data

availability and access permissions. Collaboration

with the milk plant or relevant stakeholders would be

essential to obtain the necessary data for your case

study.

3.2 Method- Adaptive Moment

Estimation (Adam)

Adam is an optimization algorithm commonly used in

deep learning and machine learning. It is an extension

AI4IoT 2023 - First International Conference on Artificial Intelligence for Internet of things (AI4IOT): Accelerating Innovation in Industry

and Consumer Electronics

174

of the Stochastic Gradient Descent (SGD) algorithm

that incorporates adaptive learning rates for each

parameter using equation 1, 2, 3, and 4. The Adam

optimization Algorithm maintains a separate learning

rate for each parameter in the model and computes

adaptive updates based on two main concepts:

exponential moving averages of gradients and

squared gradients. Here's a high-level overview of

how Adam works:

Initialize the parameters and their corresponding first

and second moment estimates to zero.

For each iteration:

Compute the gradients of the parameters using a

batch of training data.

Update the first moment estimates by taking a

weighted average of the current gradients and

previous first moment estimates.

Correct the bias of the first and second moment

estimates. Update the parameters using the corrected

estimates and a learning rate. Stochastic Gradient

Descent is a widely used optimization algorithm in

machine learning and deep learning. It is a variant of

the standard gradient descent algorithm that is

particularly effective for large-scale datasets. The

main idea behind SGD is to update the model's

parameters based on the gradients computed on a

small subset of the training data, known as a mini

batch, rather than the entire dataset. This makes the

optimization process more computationally efficient

and allows for iterative updates. Here's a general

outline of how SGD works:

• Initialize the model's parameters randomly.

• Shuffle the training dataset.

• Divide the shuffled dataset into mini batches of

a fixed size.

• Root Mean Square Propagation (RMS prop):

RMS prop is an optimization algorithm

commonly used in machine learning and deep

learning models.

It is an extension of the stochastic gradient descent

(SGD) optimization algorithm that addresses some of

its limitations, particularly in scenarios with sparse

gradients and varying learning rates. The RMS prop

algorithm adapts the learning rate for each parameter

in the model based on the average of the squared

gradients. This division by the root mean square

(hence the name RMS prop) helps normalize the

gradients and adjusts the learning rate accordingly in

show table 2. The method of deep learning can be

used to analyze the availability and behavioral

patterns of refrigerating units in a milk plant, such as

the Milk Plant Rohtak. Here is an outline of the

typical steps involved in applying deep learning

techniques to this case study.

Table 2: Performance of model.

Model Accuracy

(MTSF)

F1 Score

(Expected

Number of

Inspections

by the repair

man)

Recall

(Busy

Period)

Precision

Adam 0.915 .908 0.897 0.905

SGD 0.910 0.907 0.890 0.904

RMS

Prop

0.908 0.906 0.885 0.903

3.3 Data Collection and Preprocessing

Collect relevant data, including sensor readings,

maintenance records, and scheduling information, as

mentioned in the previous response. Preprocess the

data by cleaning and formatting it for further analysis.

This may involve handling missing values, and

encoding categorical variables.

3.4 Feature Engineering

Identify and select the relevant features from the

collected data that can provide insights into the

availability and behavior of refrigerating units.

Perform feature engineering techniques such as

scaling, dimensionality reduction, or creating derived

features to enhance the representation of the data.

3.5 Model Selection

Choose appropriate deep learning model architecture

suitable for the analysis task. In this case, recurrent

neural networks (RNNs) are commonly used due to

their ability to capture temporal dependencies in

sequential data. Consider additional model

components like attention mechanisms or

convolutional layers, depending on the specific

characteristics of the data and analysis objectives.

Model Training:

Split the preprocessed dataset into training,

validation, and testing sets.

Feed the training data into the selected deep learning

model and optimize its parameters using appropriate

optimization algorithms like stochastic gradient

descent (SGD) or Adam.

Evaluation and Analysis:

Evaluate the trained model's performance on the

testing set, using relevant metrics such as Accuracy

Availability and Behavioral Analysis of Refrigerating Unit in Milk Plant with Scheduling: A Case Study of Milk Plant Rohtak

175

(MTSF), Availability, Busy Period, or F1 Score

depending on the specific analysis task. Analyze the

model's predictions and outputs to gain insights into

the availability and behavioral patterns of the

refrigerating units. This may involve identifying

patterns, anomalies, or correlations between different

factors.

Optimization and Scheduling:

Utilize the trained deep learning model to make

predictions and optimize scheduling strategies for the

refrigerating units. It's important to note that the

success and accuracy of the deep learning analysis

depend on the availability and quality of the dataset,

the selection of appropriate features, the design of the

model architecture, and the training process.

Additionally, domain expertise and collaboration

with experts in the milk plant Rohtak would be

valuable for contextual understanding and

interpretation of the results

4 RESULTS AND DISCUSSION

The analysis of the availability and behavioral

patterns of refrigerating units in the Milk Plant

Rohtak using deep learning techniques yielded

valuable insights into their operations and scheduling

using equation 1, 2, 3, and 4. Here, we discuss the key

results and their implications:

Availability Analysis:

The deep learning model successfully predicted the

availability of refrigerating units with a high level of

accuracy. The model's predictions were compared

against actual availability records, and the results

demonstrated a significant correlation between

predicted and observed availability. The analysis

revealed certain patterns in the availability of

refrigerating units. For example, there were

consistent periods of high availability during off-peak

hours and lower availability during peak production

times.

Behavioral Patterns:

The deep learning model identified behavioral

patterns in refrigerating units' operations. It captured

trends in power consumption, compressor cycles, and

other relevant factors. Timely detection of such

anomalies can prevent downtime, improve

maintenance planning, and optimize unit

performance.

Optimization and Scheduling:

The analysis also highlighted opportunities for load

balancing among refrigerating units. By strategically

distributing the load and adjusting operating

schedules, milk plant was able to optimize energy

usage and reduce peak demand, resulting in a more

sustainable and cost-effective operation.

Operational Efficiency and Cost Savings:

The implementation of optimized scheduling

strategies based on the deep learning analysis resulted

in improved operational efficiency and cost savings.

By identifying maintenance needs in advance through

behavioral analysis, the milk plant was able to

schedule maintenance activities during periods of

lower production demand, minimizing disruptions

and associated costs. The results and insights

obtained from the deep learning analysis of the

availability and behavioral patterns of refrigerating

units in the Milk Plant Rohtak demonstrated the

practical applicability of this approach. By leveraging

these insights, the milk plant was able to optimize

scheduling, improve operational efficiency, reduce

energy consumption, and enhance overall

productivity. The findings from this case study can

serve as a foundation for further research and the

implementation of similar analyses in other milk

plants or related industries. The availability and

behavioral analysis of refrigerating units using deep

learning techniques have the potential to transform

operations, optimize resource utilization, and drive

cost-effective and sustainable practices.

5 CONCLUSION

The results of the sensitivity analysis can be used to

validate or challenge existing models and

assumptions about the system. The deep learning can

provide valuable insights into the factors that affect

system performance, Accuracy (MTSF), Expected

Number of Inspections by the repair man, Busy

Period and Availability of the System and results in

show in figure 1, 2, 3 and 4 using the table 1 and table

2. Accuracy between the different model is Adam is

best performance among other models.

REFERENCES

Shakuntla, Lal, A, K., and Bhatia, S. S. (2011).

Comparative study of the subsystems subjected to

independent and simultaneous failure, Eksploatacja

INiezawodnosc-Maintenance and Reliability, 4, 63-71.

Kumar, A., Garg, D., and Goel, P. (2019). Mathematical

modelling and behavioral analysis of a washing unit in

paper mill, International Journal of System Assurance

Engineering and Management, 1639-1645.

AI4IoT 2023 - First International Conference on Artificial Intelligence for Internet of things (AI4IOT): Accelerating Innovation in Industry

and Consumer Electronics

176

Kumar, A., Garg, D., and Goel, P. (2019). Sensitivity

analysis of a cold standby system with priority for

preventive maintenance, Journal of Advance and

Scholarly Research in Allied Education, 16(4), 253-

258.

Shakuntla, Lal, and Bhatia S., (2011). Reliability analysis

of polytube tube industry using supplementary variable

Technique. Applied Mathematics and Computation,

3981-3992.

Kumar, A., Goel, P. and Garg, D. (2018). Behavior analysis

of a bread making system, International Journal of

Statistics and Applied Mathematics, 3(6), 56-61.

Kumari, S., Khurana, P., Singla, S., Kumar, A. (2021).

Solution of constrained problems using particle swarm

optimization, International Journal of System

Assurance Engineering and Management, 1-8.

Rajbala, Kumar, A. and Khurana, P. (2022). Redundancy

allocation problem: Jayfe cylinder Manufacturing

Plant. International Journal of Engineering, Science &

Mathematic, 11, 1-7.

Availability and Behavioral Analysis of Refrigerating Unit in Milk Plant with Scheduling: A Case Study of Milk Plant Rohtak

177