Revolutionizing Efficiency in Smart Manufacturing Trough IoT and

Predictive Maintenance

Mohan Kumar S

*

and Anitha G

†

Department of Computer Applications, Karpagam Academy of Higher Education, Coimbatore, India

Keywords: Smart Manufacturing, AI-Based Technology, Scheming the Product Design, Market and Safeguarding.

Abstract: The Internet of Things (IoT) has emerged as a catalyst for providing a competitive edge to companies through

its diverse applications and tools. One prominent application is within the domain of smart manufacturing,

which harnesses the power of the Industrial Internet of Things (IIoT) to streamline operations, enhance

efficiency, and curtail costs by automating tasks that were previously manual. A pivotal focus of this paradigm

is predictive maintenance, aimed at reducing downtime and optimizing equipment reliability. Predictive

maintenance operates on the premise that issues can be foreseen and addressed before they disrupt operations.

For instance, it encompasses preventive maintenance strategies such as scheduled inspections and the testing

of critical engine components to mitigate unscheduled downtime. In the context of high equipment volumes

and energy consumption, even marginal efficiency gains wield significant influence on operational costs and

overall energy consumption.

1 INTRODUCTION

The Internet of Things (IoT) offers companies a

competitive edge through its diverse applications and

tools. Smart manufacturing harnesses the Industrial

Internet of Things, automating tasks to enhance

efficiency and reduce costs previously handled

manually. Predictive maintenance aims to minimize

downtime and enhance equipment reliability by

proactively identifying issues before they arise. For

instance, preventive maintenance reduces

unscheduled downtime by implementing strategies

like scheduled inspections and testing of major engine

components. In a high operating unit count scenario

with high energy consumption, even a slight increase

in inefficiency significantly impacts operational costs

and total energy consumption. Equipment Health

Monitoring and Prediction technology, employing

AI-based apps, aids factories in meeting the demands

of the rapidly expanding intelligent manufacturing

sector. By amalgamating human expertise with

cutting-edge engineering automation, these

applications mitigate equipment failure and

downtime, resulting in considerable time and cost

savings for producers. Leveraging sensor data,

*

PG Student

†

Assistant Professor

learning algorithms identify optimal settings and

guide systems effectively. Meaningful insights mined

from extensive datasets further enhance the efficiency

of machine learning algorithms. AI-based HMP

technology mitigates risk across industrial sectors,

including steel, pharmaceuticals, automotive, and

energy, fostering a safer environment for

manufacturers and reducing risk across the industrial

landscape.

2 METHODOLOGY

Stage 1 Scheduling and Requisite Investigation:

Within the Software Development Life Cycle

(SDLC), the requirement analysis phase stands as the

pivotal cornerstone. This critical step involves

collating inputs from clients, the sales department,

market surveys, and domain specialists, led by senior

team members. This gathered data forms the basis for

shaping the project's fundamental strategy and

conducting comprehensive technical, operational,

and financial feasibility analyses. Throughout the

planning phase, the emphasis also lies on pinpointing

S, M. and G, A.

Revolutionizing Efficiency in Smart Manufacturing Through IoT and Predictive Maintenance.

DOI: 10.5220/0012613500003739

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Artificial Intelligence for Internet of Things: Accelerating Innovation in Industry and Consumer Electronics (AI4IoT 2023), pages 271-275

ISBN: 978-989-758-661-3

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

271

project risks and outlining the prerequisites for

quality assurance. The technical feasibility study

serves to delineate various strategies available for

executing the project efficiently while mitigating

potential risks, offering a refined conclusion on the

optimal technical approaches.

Stage 2: Significant Necessities:

Once the requirement analysis phase concludes, the

subsequent step entails securing precise analyst

approval. This critical milestone is achieved by

consolidating all product requisites essential for

planning and development across the project's life

cycle within the Software Requirement Specification

(SRS) document.

Stage 3: Scheming the Product Design:

Product architects advocate that the ideal product

architecture hinges upon the Software Requirement

Specification (SRS). Typically, multiple design

approaches for the product's architecture are

suggested and documented within a DDS (Design

Document Specification), aligned with the criteria

outlined in the SRS. The DDS undergoes thorough

scrutiny by key stakeholders, evaluating various

factors such as risk analysis, product resilience,

design modularity, budget constraints, and time

limitations. Following this comprehensive review,

the most suitable design approach is selected for the

product, considering a blend of these critical factors.

Stage 4: Structure or Mounting the Product:

At this stage in the SDLC, the genuine development

process commences, where products are constructed

based on the finalized design specifications (DDS).

The programming code is crafted in strict alignment

with the DDS, expediting code generation when the

design is meticulous and organized. A suite of

programming tools like compilers, interpreters,

debuggers, and similar aids are employed to produce

the code, adhering rigorously to the coding standards

set forth by the organization. Diverse high-level

programming languages such as C, C++, Pascal, Java,

and PHP are utilized for coding purposes.

Stage 5: Testing the Product:

This phase usually functions as part of the entire

SDLC, as modern models integrate testing operations

throughout. However, this specific stage is dedicated

solely to the product's testing phase. Here, product

flaws are identified, meticulously documented,

corrected, and repeatedly retested until rectified,

ensuring alignment with the quality requirements

specified in the SRS.

Stage 6: Consumption in the Market and

Safeguarding:

Upon completion of testing and readiness for

deployment, the product undergoes formal release

into the pertinent market. Occasionally, deployment

occurs in phases aligning with the organization's

commercial strategy. Initially, the product might be

accessible to a select group of customers, undergoing

User Acceptance Testing (UAT) in an authentic

business environment. The released product could be

distributed either in its current state or with suggested

improvements tailored for the intended market.

Subsequent to the product's market launch,

maintenance is conducted to cater to the existing

clientele.

3 EXISTING SYSTEM

Information-driven prognostics face a persistent

challenge in the absence of comprehensive failure

data. Often, genuine data includes markers of

potential issues but fails to capture the full evolution

of a problem until it leads to failure. While periodic

maintenance occurs, real-time conditions are solely

recorded without extensive automation, relying more

on manual calculations for error resolution, which

may lack accuracy. Gathering precise system flaw

progression data is typically time-consuming and

expensive. Most handled systems lack adequate

instrumentation for comprehensive data collection.

Those capable of collecting long-term fleet data often

opt to withhold it due to proprietary or sensitive

reasons.

4 PROPOSED SYSTEM

Commonly used across various factory settings,

overhead hoist transports greatly benefit from HMP

equipment. These transports, ubiquitous in assembly

lines, serve as a preventive measure against accidents

and cost-saving mechanisms. Leveraging HMP

equipment, users can establish standardized hoists for

the factory floor effortlessly, ensuring all transports

align with this benchmark post-maintenance and

promptly notifying users of any deviations. To

enhance maintenance efficiency, Equipment HMP

monitors the Remaining Useful Life (RUL) of each

individual overhead hoist transport by employing

unsupervised learning methodologies on large-scale

data, preempting errors or faults before their

occurrence. Unlike conventional systems, HMP's

AI4IoT 2023 - First International Conference on Artificial Intelligence for Internet of things (AI4IOT): Accelerating Innovation in Industry

and Consumer Electronics

272

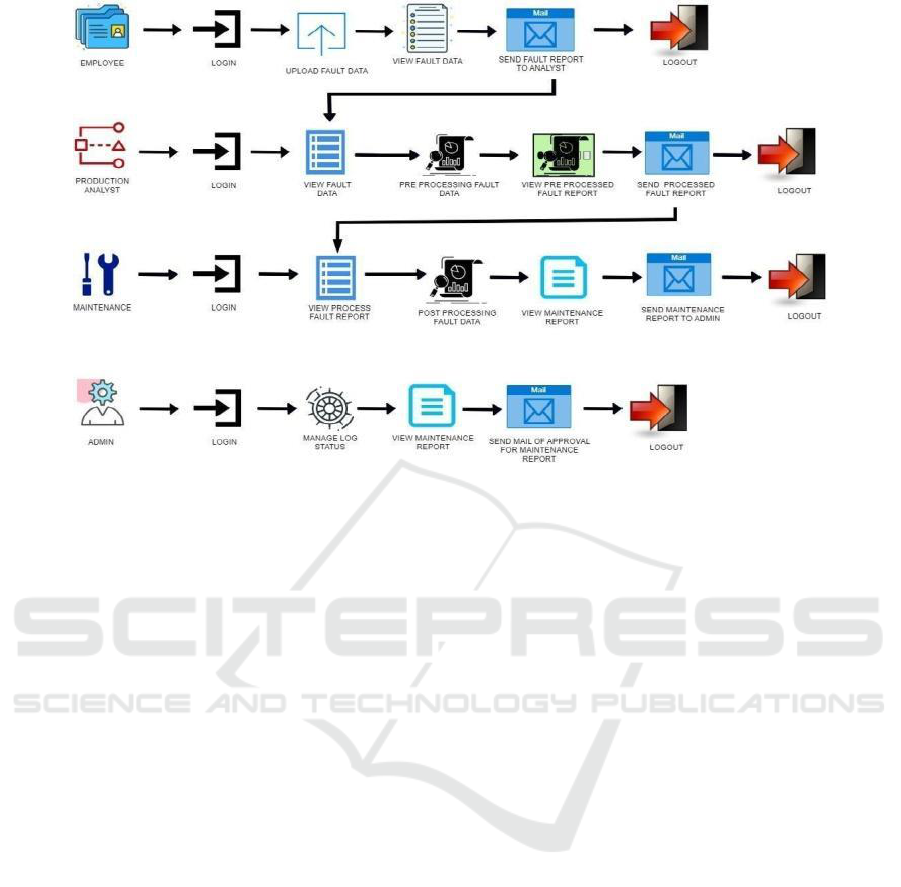

Figure 1.

fault detection dynamically defines control limits by

analyzing the entire spectrum of generated data,

encompassing sensor data from the equipment and

quality data from the output, resulting in a more

comprehensive fault detection approach.

Advantage of Proposed System:

The dataset will undergo rigorous training on a model

to enable automation, streamlining processes. This

approach facilitates swift identification of downtime,

expediting solutions to arising issues. Consequently,

the reduction in repair and maintenance costs

becomes a tangible benefit. Additionally, the

integration of learning methodologies simplifies error

handling, ensuring smoother operations. Particularly

efficient for managing extensive datasets, this

methodology proves highly effective in optimizing

operations at scale.

5 MODULES

1. Employee

2. Production Analyst

3. Maintenance

4. Admin

Module 1: Employee

Employees input their details into this module,

undergoing verification before receiving a password

via email. Only analysts can access the module with

this password. Subsequently, employees can solely

log in to their designated homepage using their

passwords; failure to do so restricts access to the

module. Within the module, employees oversee

transports, mitigating failure-prone errors such as belt

cutting or motor speed reductions, crucial in averting

potential downtime leading to significant financial

losses. Leveraging vibration data and the admin-

assigned password, the HMP system preempts

failure, issuing an alarm an hour prior. Any

alterations in reported production times are logged by

employees, with the data uploaded to the associated

web application for the production line, such as in car

manufacturing, where conveyor belts move at fixed

intervals. Subsequently, this data is forwarded via

email to Production Q/A before employees are logged

out of the module.

Module 2: Production Analyst

Within this module, the analyzer registers details and,

upon verification, receives a password via email. This

password grants exclusive access, allowing only the

analyzer's login. Using the admin-allocated

password, the analyzer accesses the module,

reviewing data uploaded by employees pinpointing

errors in conveyor belts or overhead hoist transport

timings. The analyzer preprocesses this data,

assessing faults in the systems. Post-processing, the

results are displayed; if a fault is detected, the data is

forwarded to Maintenance for further action.

Conversely, in the absence of faults, the analyzer

Revolutionizing Efficiency in Smart Manufacturing Through IoT and Predictive Maintenance

273

notifies employees via email. Subsequently, the

analyzer logs out of the module.

Module 3: Maintenance

Within this module, maintenance team members

register their details and upon verification, receive

login credentials via email. Utilizing the admin-

allocated password, the team accesses the module to

view fault data shared by the production analyst.

Subsequently, maintenance members undergo post-

processing of this data, conducting maintenance

checks on identified faults. Following post-

processing, the output presents tolerance timings

crucial for maintaining the conveyor belt system.

Additionally, the conveyor belt systems undergo a

structured maintenance check guided by a predefined

list. Upon authorization, maintenance technicians

update problem details, issue reports, and

maintenance check specifics within the main

module's admin section. Finally, maintenance team

members log out of the module.

Module 4: Admin

Within this module, the admin utilizes the admin

password to access it. Their role includes reviewing

employee details and sending acceptance or rejection

emails to respective employees seeking authorization

for access to the Employee module. Additionally, the

admin evaluates production analyzer details, issuing

acceptance or rejection emails, thus enabling

authorization for login to the Production Analyst

module. Similarly, after scrutinizing maintenance

team member details, the admin sends acceptance or

rejection emails for authorization to access the

Maintenance module. Subsequently, the admin

reviews a report from the maintenance team,

examining faults in the conveyor belt system on the

production line and the planned repairs.

6 SYSTEM ARCHITECTURE

FEASIBILITY

Module 1: Technical Feasibility

The current system is grounded in practicality,

offering a web-based user interface tailored for audit

workflow. This interface ensures swift consumer

access while the database serves the objective of

establishing and maintaining workflow across

multiple entities, aiding users in their respective roles.

User permissions align with predefined rules,

ensuring technological reliability, correctness, and

security. The software and hardware requisites for

this project are minimal, readily accessible, and often

available as open-source, contributing to its cost-

effectiveness. Leveraging contemporary equipment

and software technologies, the project boasts ample

bandwidth to ensure prompt feedback.

Module 2: Operational Feasibility

The analyst assesses the new system's capability to

fulfill departmental requirements, scrutinizing if it

adequately addresses existing system elements and

brings substantial enhancements. Our findings

indicate that the proposed "Secure transaction"

method is poised to notably surpass the current

approach.

Module 3: Economic Feasibility

The proposed system proves economically viable as

the expenses associated with acquiring hardware and

software fall within reasonable limits. Its operation

doesn't demand highly specialized expertise, and the

operating environment costs remain minimal.

Additionally, its efficiency in saving time

significantly contributes to its economic feasibility.

7 CONCLUSION

A substantial amount of electrical energy powers

numerous operating units worldwide, making even

slight efficiency improvements pivotal for revenue

generation, global electricity consumption, and

environmental considerations. This project aims to

bolster equipment efficiency in manufacturing,

contributing to overall operational optimization.

Leveraging HMP technology, the project utilizes

sensor input, big data, and machine learning to

forecast equipment issues and strategically schedule

maintenance, shifting away from conventional time-

based approaches. HMP's inception marks the

beginning, progressing towards establishing a

dynamic knowledge base through an AI-based

solution for the next phase. This innovation enables

machines to recognize and promptly address

recurring patterns. Implementing suggested data

preparation techniques through models significantly

enhances failure count predictions, thereby elevating

precision levels. This study serves as a valuable

resource for hybrid data preparation techniques

within data mining and machine learning

applications.

AI4IoT 2023 - First International Conference on Artificial Intelligence for Internet of things (AI4IOT): Accelerating Innovation in Industry

and Consumer Electronics

274

REFERENCES

F. Nie, X. Dong, and X. Li, “Unsupervised and

semisupervised projection with graph optimization,”

IEEE Trans. NeuralNetw. Learn.Syst., earlyaccess,

Apr.23, 2020.

R. Hettiarachchiand, J. F. Peters, “Multi-manifold LLE

learning in pattern recognition,” Pattern Recognit., vol.

48, no. 9, pp.2947–2960, Sep. 2015.

F. Nie, X. Wang, and H. Huang, “Clustering and projected

clustering with adaptive neighbors,” in Proc. 20

th

ACM

SIGKDD Int. Conf. Knowl. Discovery Data Mining,

Aug. 2014, pp.977–986.

K. Xiong, F. Nie, and J. Han, “Linear manifold

regularization with adaptive graph for semi-supervised

dimensionality reduction,” in Proc. 26

th

Int. Joint Conf.

Artif. Intell., Aug. 2017, pp.3147–3153.

Y. Liang, F. Shen, J. Zhao, and Y. Yang, “A fast mani fold

learning algorithm for dimensionality reduction,” in

Proc. IEEE 28thInt.Conf. Tools with Artif. Intell

(ICTAI), Nov. 2016, pp .985–988.

S. Boyd, S. P. Boyd, and L. Vandenberghe, Convex

Optimization. Cambridge, U.K.: Cambridge Univ.

Press, 2004.

L. Zelnik-Manorand, P. Perona, “Self-tuning spectral

clustering,” in Proc. Adv. Neural Inf. Process. Syst.,

2005, pp.1601–1608.

Y. Liu, R. Zhang, F. Nie, X. Li, and C. Ding,“Supervised

dimensionality reduction methods via recursive

regression, ”IEEE Trans. Neural Netw. Learn. Syst.,

vol. 31, no.9, pp.3269–3279, Sep. 2019.

S. Balakrishnamaand A. Ganapathiraju, “Linear

discriminant analysis-a brief tutorial,” Inst. SignalInf.

Process.,vol. 18,pp.1–8,Mar.1998.

X. Li, M. Chen, F. Nie, and Q. Wang, “A multiview-based

parameter free framework for group detection,” in Proc.

AAAI Conf. Artif. Intell. (AAAI), 2017, pp.4147–

4153.

Revolutionizing Efficiency in Smart Manufacturing Through IoT and Predictive Maintenance

275