Exploring Determinants of Organizational Engagement in Supply

Chain Management an Integrated Approach: A Comprehensive

Literature Review

Bhavana Mathur

1

, Deepak Gupta

1

and Sonal Malhotra

2

1

Mechanical Engineering, Anand International College of Engineering/ Rajasthan Technical University, India

2

Department of CSE, Graphic Era Hill University, Dehradun, Uttarakhand-248007, India

Keywords: Performance Management, Integrated SCM, Supply Chain Management, Quality, Quality Management.

Abstract: The focus of this research is to explore the determinants that facilitate or inhibit organizations from engaging

in supply chain management initiatives. And indeed, the literature includes an abundance of studies dealing

with that. For the purpose of this study, a literate review delineates the main internal and external categories

of factors influencing SCM practices. They are organizational behavior, a framework of control, customer-

acquisition dynamics, competitive intensity, and societal expectations. Withal, there has been little research

on the role of suppliers, which can act as facilitators in areas where SCM integration could improve firm

performance. Cost constraints and a perceived lack of legitimacy are intended to be internal obstacles, whereas

regulatory constraints, lack of supplier uptake, and context-dependent conditions are external scope

limitations . Due to such differentiation, this research takes an exploratory approach and uses previous

literature and researchers’ insights in addition to interviews because the issues in the supply chain are

disciplinary and integrated. Encouragingly, across the organizations, supply chain management is seemed to

be more influenced by external rather than internal drivers. It is again concluded from the research that health

systems need to work more efficiently and effectively to met these growth targets. Therefore, it is necessary

to look for innovative solutions and appropriate modern ways to ensure that the changing needs for health

care and health systems are met.

1 INTRODUCTION

Side flicker the ever-growing demands of customers,

on the other – the imperatives of the company’s

growth and profitability. This image makes it possible

to reveal the dual nature of the SCM. It constitutes a

business process: encompassing all tasks involved in

regulating the movement of products, services, and

information from suppliers’ suppliers to customers’

customers. The supply chain is depicted as a rope,

highlighting tangible outcomes: revenue growth,

asset optimization, and cost management.

Therefore, as the degree of coordination between

departments affects a company’s success directly or

indirectly also its SCM will be influenced. When

SCM is effective, an organization will flourish, and

the service delivery system will be superior.

However, when organizational changes are made to

SCM processes, the instability that follows makes

functioning across departments chaotic. Eventually,

this turns into an existential threat to the company

(Thomas 2015). SCM is the failure of pinpointing the

sectors needing transformation, and that makes the

development of a supply chain transformation plan

critical. The word “supply chain” was developed in

the early 1980s to characterize a company’s various

actions to obtain and handle supplies. SCM is a

system of organizations, operations, and business

operations that facilitate products and services in

various sectors by providing and maximizing profits

in an enterprise. Each business will operate in various

industries or within a comprehensive supply chain

system, and each has a distinct purpose (Datta 2011).

There are three basic steps in SCM which a company

needs to decide before implementing it.

1) Suppliers (who supplies the raw product/

material)

2) Manufacturer (who assemble or arrange or

manufacture the raw material and passed it to next

step)

1710

Mathur, B., Gupta, D. and Malhotra, S.

Exploring Determinants of Organizational Engagement in Supply Chain Management an Integrated Approach: A Comprehensive Literature Review.

DOI: 10.5220/0013405600003882

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd Pamir Transboundary Conference for Sustainable Societies (PAMIR-2 2023), pages 1710-1716

ISBN: 978-989-758-723-8

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

3) Customers ( the end use of the product)

These steps may change as per of type of company

or sector in which supply chain needs to apply.

There are so many sectors today where SCM

functions logically.

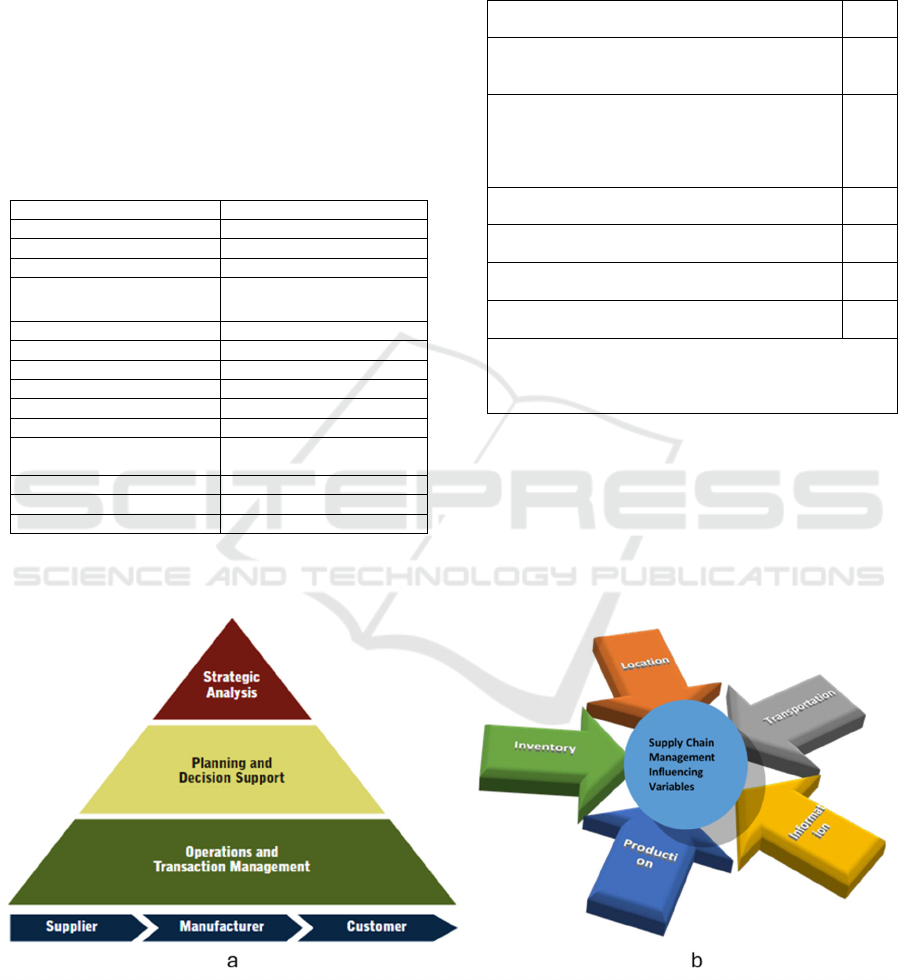

Supply Chain Influencing Factors: Even for the

industry SCM is the best tool for providing better

service to the customers and enhancing the profit for

itself, SCM is standing over some pillars. These

pillars always influences to the SCM. Profitable SCM

and poor SCM all are the reflection of these pillars.

Table 1: List of sectors where SCM is in functioning today.

Secto

r

SCM applies in terms of as

Communication information transfe

r

Manufacturing secto

r

Material handling

Field Marketing Transportation

Online marketing Transportation

Online services Transportation

Production Material handling

Logistics Transportation and services

Banking Services

Education Services

Health care secto

r

Services

Wall-Marts and

Malls/shopping complexes

Product handling and

services

Traffic syste

m

transportation

Railways Transportation and services

Metro Train Transportation and services

So the effecting “SCM is nothing but the managing

balance over these pillars in a best of best way”

(Figure1a & b, and Figure 2).

Table 2: Supply Chain implementation year to year.

The earliest form of supply chain was likely the

b

arter system.

1904

The origins of outsourcing can be traced back to

instances such as Charles S. Rolls acting as a selling

agent for cars manufactured by F. Henry Royce.

1960-

1975

The foundational understanding of Supply Chain

Management (SCM) emerged during its initial phase,

characterized by an inventory 'push' era that

emphasized the physical distribution of finished

goods.

1975-

1990

Businesses started transitioning from an inventory

push model to a customer pull approach.

1980

Wal-Mart pioneered the introduction of the concept

of cross-docking.

1985

The internet revolutionized business distribution

systems.

1996

The concept of e-commerce redefined the business

landscape.

1998

Since 1998, Supply Chain (SC) involvement has expanded

into numerous sectors including services, production, material

handling, healthcare, logistics & distribution, and various

other integrated fields.

Figure 1: a. SCM Steps, b. SCM influencing factor.

Exploring Determinants of Organizational Engagement in Supply Chain Management an Integrated Approach: A Comprehensive Literature

Review

1711

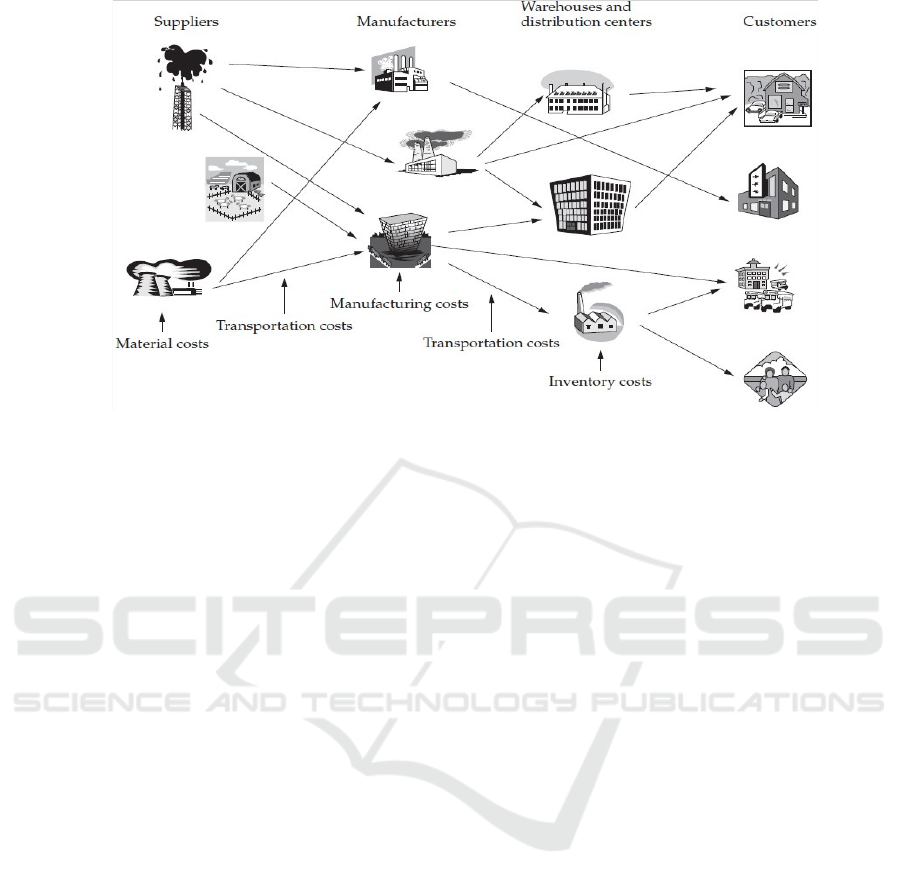

Figure 2: The hierarchical network of SCM.

2 LITERATURE REVIEW

SCM has evolved directly or indirectly in qualitative

performance of industry over the last 20-25 years.

Studies over the past researchers have investigated

the relationships qualitative performance with supply

chain management. Therefore an integrating

approach of SCM upon the different sector apart of

the manufacturing fields has been useful and famous

over the researcher’s perspectives and that’s why

integrated SCM will be important for future

competitiveness (Shah 2023).

In the literature researchers found a number of

fields where SCM has been involved a part of the

common fields like manufacturing, information and

material handling etc. So many integrated approaches

are using by the researchers in various fields. Accept

these, there are many review papers which also has

been reviewed by the author during the research. The

scope of supply chain performance measurement

studies includes a variety of models, methods, and

frameworks. There are models such as Supply Chain

Partnership , Supply Chain Integration , Supply Chain

Interaction, Supplier Relations and Selection , Supply

Chain Information , and Quality Improvement (Joshi

2022).

Supply chain quality management is described as

all partner organizations in the supply channel

formally coordinating and integrating business

processes. The primary goal is to measure, analyze,

and continuously enhance product reliability,

serviceability, and customer satisfaction at the

intermediate stages and final consumption stages.

Quality-SCM is integral to academic research and

industrial practice, and a conceptual framework for

Quality-SCM will enhance quality initiatives in the

field of SCM. Standardization, through norm

adherence (for example, to ISO 9001:2000) to

establish management systems, has a significant role

in identifying critical supply chain processes and

Drivers (Robinson 2005). TQM and supply chain

management systems have a lot in common because

of a common goal of satisfying customers. Effective

quality management in the supply chain can be

defined through three central dimensions: supplier

selection, supplier, and supplier development, and

supplier integration. The Quality and Technology

framework highlights the relationship between

supply quality, supplier quality, and buyer quality.

Quality relationships between suppliers and buyers

can be captured in the terminology and are defined in

two stages. The first stage is supply chain quantity, a

collection of buyer-specific qualities, and the second

stage is supply chain technology, a reflection of

supply quality (Mahdiraji 2012).

A quality management QM model recommended by

Kaynak and Hartley emphasizes internal and external

integration to drive quality performance (Kaynak

2008). The quality performance stems from studies

that highlight initiatives to focus on improving and

controlling the supply chain. Integrated SCM systems

led to attempts to improve the quality of all processes

in the supply chain. These initiatives resulted in cost

reductions, better use of resources, and increased

process performance. Proposed conceptual models

for measuring quality of service in the supply chain

PAMIR-2 2023 - The Second Pamir Transboundary Conference for Sustainable Societies- | PAMIR

1712

identified areas of future research on the selected

domains of service quality. They also played a vital

role in other organizational components. The

performance measurement systems help direct

actions and enable the implementation of strategies

that drive the quality of the organization. In

measuring and relying on performance measurement,

the data is commonly utilized in public reporting,

provider incentive programs, and quality

improvement initiatives. Efficiency of performance

depends on how prepared the organization’s culture

is across its life cycle. Performance measurement

systems are balanced and dynamic systems that aid

decision-making processes by collecting, processing,

and analysing data, focusing on efficiency and

effectiveness (Kaynak 2008).

The next approach to be considered as dynamicity.

Dynamicity is related to the adaptability and

capability of changes in the established system. It

means that the system can be changed and adjusted

with time and in response to changes in the internal

and external environment. The first two perspectives

ensure that the measurement system can change and

met the current needs and the challenging market

conditions. The supply chain in the healthcare sector

is an inherently complicated system due to its direct

influence on patient care. Poor SC performance is a

significant source of avoidable cost for healthcare

delivery facilities and could account for a

considerable portion of their operating expenditure.

Other problems associated with SC in the health

sector include communication failure, patient

accidents, long waiting times, and inadequate

integration. Therefore, integration between

businesses units and facilities is essential to providing

high-quality patient outcomes. The data quality is

another significant problem in the health sector. The

lack of data quality reduces the potential of SC data

to address the system’s problems, as to ensure that

better data quality, SC management must follow

quality-related procedures (Burgess 2023, Emir

2024).

3 GAPS IN LITERATURE

Reviewed current researches in SCM, Integrated

SCM, and performance management and identified

some themes which are actually variables of SC. The

variables under consideration encompass customer

focus, quality practices, supplier relations, leadership,

HR practices, business results, and aspects related to

safety, transportation, healthcare, and artificial

intelligence. Even after the literature review of many

research papers author made a survey also on SCM.

Several industries (Dell, Amazon, Saras Dairy, Amul

Dairy, Local manufacturers & suppliers) directly and

indirectly are involved in that survey. Survey initiated

with direct meeting to the departmental head and

workers and their customers of respective

organization as well as at some stage telephonic

survey has also been conducted. Likert scale of 1 to 5

marking is used for rating the SCM performance in

the respective organizations and the service received

by the customers of respective organization (Table 3).

Table 3: Some important organizations which are involved

in survey.

Name of

Organization

ICICI Bank

LOCAL

SUPPLIERS

INFOSYS Axis Bank LOCAL

MANUFACTURES

HCL Info

systems

DELL BOSCH

Wipro GENPACT Apollo Hospital

Life Insurance

Corporation of

India

AMUL DAIRY APEX HOSPITAL

HDFC Bank SARAS DAIRY FORTIS

HOSPITAL

EHCC

HOSPITAL

MAHATMA

GANDHI

MEDICAL

COLLEGE

SWAI MAN

SINGH

HOSPITAL

Organizations on table can be clustered in the five

groups as per of their service provided to the

customers for representing the responses of the

customers. Total score from all the responses is

counted separately for the services provided with

respective questions.

Total Score =[rating 1x no. of customers who rate it

as 1] + [rating 2x no. of customers who rate it as 2]

+[rating 3x no. of customers who rate it as 3] +[rating

4x no. of customers who rate it as 4] +[rating 5x no.

of customers who rate it as 5].

Exploring Determinants of Organizational Engagement in Supply Chain Management an Integrated Approach: A Comprehensive Literature

Review

1713

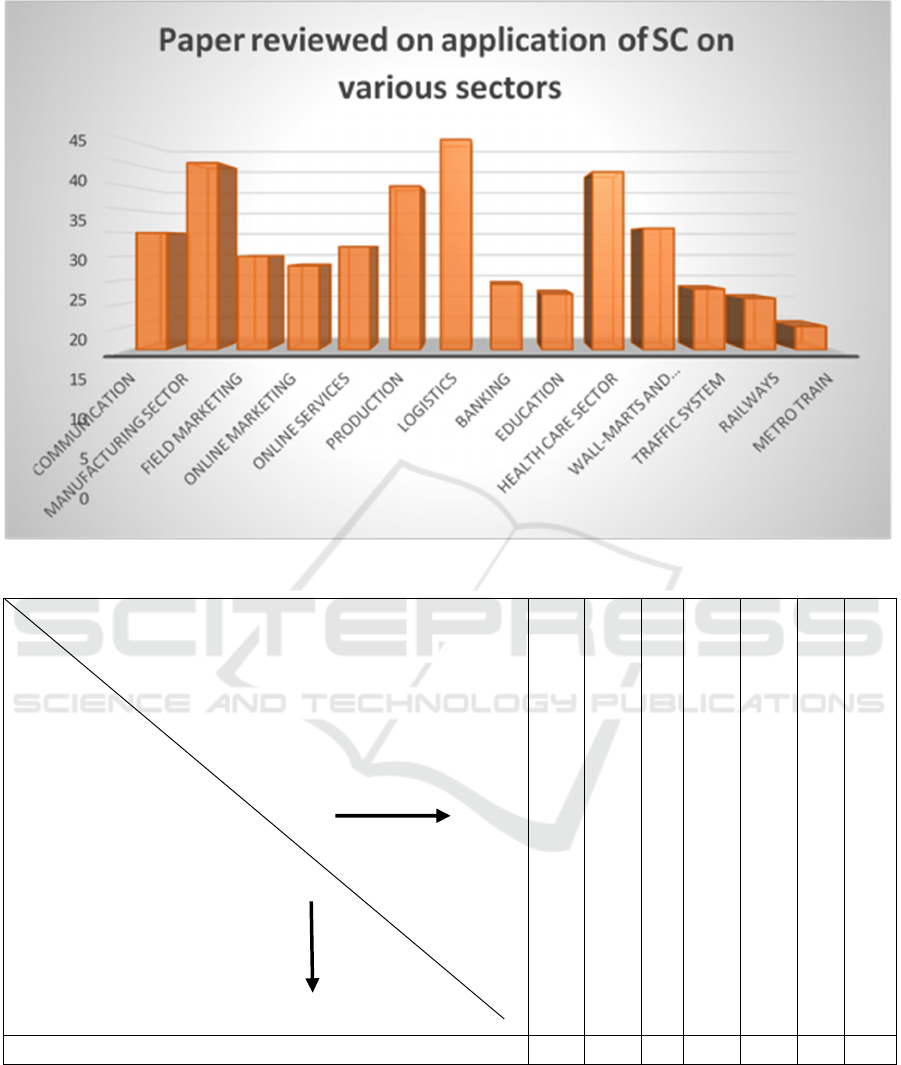

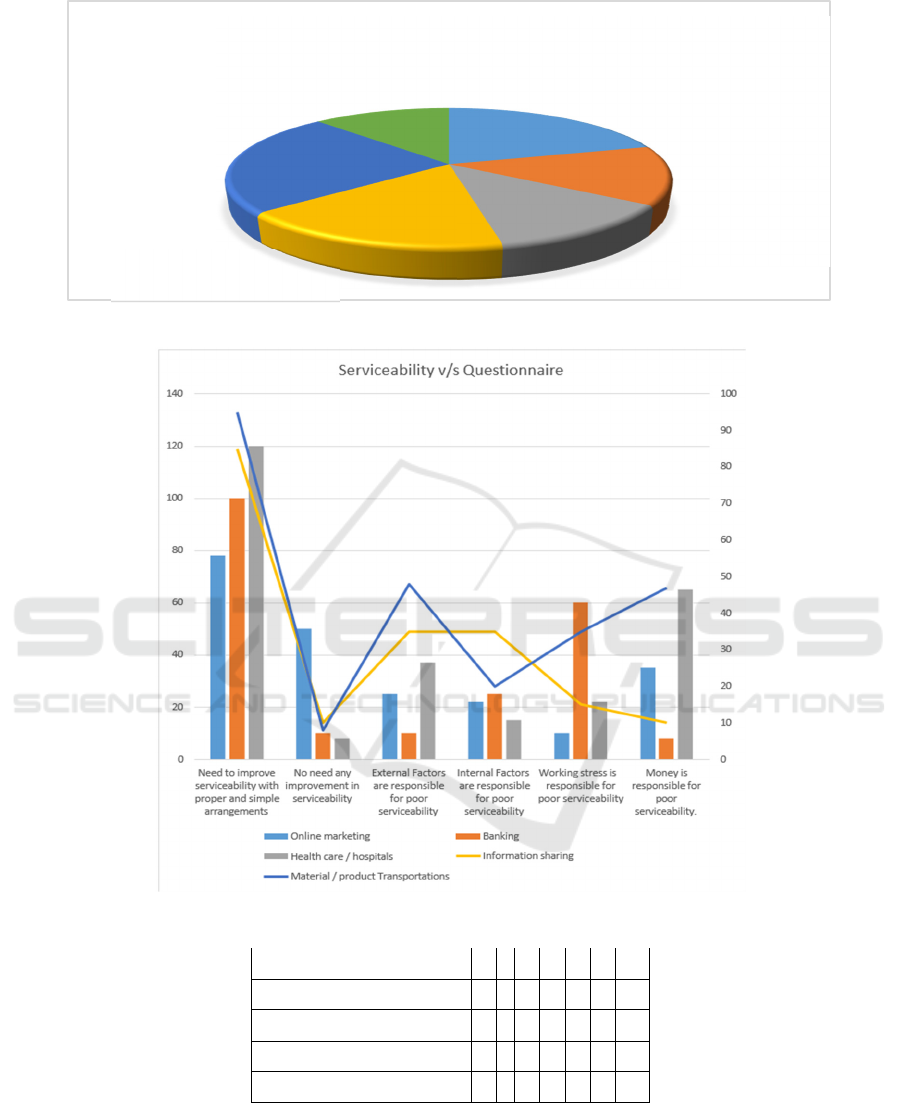

Figure 3. Sector view segregation of SC reviewed papers.

Question Asked for rating performance or

serviceability

Groups of services provided to the customers

Need to improve serviceability with proper and simple

arrangements

No need any improvement in serviceability

External Factors are responsible for poor serviceability

Internal Factors are responsible for poor serviceability

Working stress is responsible for poor serviceability

Money is responsible for poor serviceability.

Total Score

Online marketing 78 50 25 22 10 35 220

PAMIR-2 2023 - The Second Pamir Transboundary Conference for Sustainable Societies- | PAMIR

1714

Figure 4: Paper reviewed on SCM according to facility (Pie Chart).

Figure 5. Serviceability Questionnaire.

Banking 100 10 10 25 60 8 213

Health care / hospitals 120 8 37 15 22 65

267

Information sharing 85 10 35 35 15 10 190

Material / product Transportations 95 8 48 20 35 47 253

Total Score

478

86 155 117 142 165 1143

Based on the available literature and survey

results, I would like to propose the future research

direction in supply chain quality management. Much

of the supply chain’s aspects, such as performance,

coordination, integration, communication,

leadership, and best practices , have been studied in

many industries. However, what has not been given

is the serviceability quality of a supply chain in the

context of the healthcare industry. One may notice

that, while studying product quality, most research

PAPER REVIEWED ON SCM ACCORDING

TO FACILITY

Logistics information

12% transfer

21%

Services

Material

handling 14%

Transportation

and services 17%

Transportation 12

%

Exploring Determinants of Organizational Engagement in Supply Chain Management an Integrated Approach: A Comprehensive Literature

Review

1715

has been conducted on improving performance and

time to patient in the healthcare supply chain. The

existing supply chains such as the one in hospitals and

pharmacies do not serve the customers well; that is,

the patients and, hence, need supply quality

improvement. This is because imported supply

change management practices, perhaps implemented

as an integrated approach, can help increase this

performance

4 CONCLUSIONS

Supply Chain Management is a set of integrated

processes that enables the transformation of raw

materials into valuable products and their distribution

to customers via a systematic channel. SCM

comprises a network of facilities and distribution

mechanisms, such as the process of procurement,

change of structure from materials, and circulation of

the complete product. The growth of the healthcare

industry in India is significant, driven by the high

population growth, significant government outlay on

health, and raising per capita income. The growth rate

of the industry creates the necessity to tackle such

challenges as an ability to keep up with increasingly

more demands of customers, an ability to adapt to the

market’s demands for pharmaceuticals and medical

devices, as stated by other researchers and

policymakers. There is little doubt that a more

efficient system’s performance is a necessity for

economies to hit growth targets. As such, modern

approach and innovative solutions are a must to meet

the increased demands of the system and tackle its

evolving challenges. The purpose of this study is to

present the SCM’s concept, its critical components,

and the relationships among them with an

organizational performance.

REFERENCES

A. Thomas, M. Krishnamoorthy, G. Singh, J.

Venkateswaran, Coordination in a multiple producers–

distributor supply chain and the value of information,

Int. J. Prod. Econ. 167 (2015) 63–73. https://doi.

org/https://doi.org/10.1016/j.ijpe.2015.05.020.

P.P. Datta, M.G. Christopher, Information sharing and

coordination mechanisms for managing uncertainty in

supply chains: a simulation study, Int. J. Prod. Res. 49

(2011) 765–803. https://doi.org/10.1080/00207540

903460216.

N. Singh, V. Mittal, V. Rawat, P. Malik, A. Rana, Research

Trends in Supply Chain Management: A Machine

Learning Perspective, 2023.

https://doi.org/10.1109/CISES58720.2023.10183623.

J.K. Shah, M. Sharma, S. Joshi, Digital Supply Chain

Management: A Comprehensive Review Using Cluster

Analysis, with Future Directions and Open Challenges,

Int. J. Supply Oper. Manag. 10 (2023) 337–364.

https://doi.org/10.22034/ijsom.2023.109914.2739.

S. Joshi, M. Sharma, Impact of sustainable Supply Chain

Management on the Performance of SMEs amidst

COVID-19 Pandemic: An Indian Perspective, Int. J.

Logist. Econ. Glob. 9 (2022) 248–276.

https://doi.org/10.1504/IJLEG.2022.10044917.

C. Robinson, M. Malhotra, Defining the concept of supply

chain quality management and its relevance to

academic and industrial practice, Int. J. Prod. Econ. 96

(2005) 315–337.

https://doi.org/10.1016/j.ijpe.2004.06.055.

H. Mahdiraji, M. Arabzadeh, R. Ghaffari, Supply chain

quality management, Manag. Sci. Lett. 2 (2012) 2463–

2472. https://doi.org/10.5267/j.msl.2012.07.020.

H. Kaynak, J. Hartley, A Replication and Extension of

Quality Management Into the Supply Chain, J. Oper.

Manag. - J OPER Manag. 26 (2008) 468–489.

https://doi.org/10.1016/j.jom.2007.06.002.

P.R. Burgess, F.T. Sunmola, S. Wertheim-Heck, A review

of supply chain quality management practices in

sustainable food networks, Heliyon. 9 (2023) e21179.

https://doi.org/https://doi.org/10.1016/j.heliyon.2023.e

21179.

S. Emir, N. Sulistyowati, The effect of supply chain

management and total quality management on

operational performance through competitive

advantage, Int. J. Res. Bus. Soc. Sci. (2147- 4478). 13

(2024) 27–37.

https://doi.org/10.20525/ijrbs.v13i1.3087.

PAMIR-2 2023 - The Second Pamir Transboundary Conference for Sustainable Societies- | PAMIR

1716