RAMOM: A Reference Architecture for Manufacturing Operations

Management Activities in Industry 4.0

Gonc¸alo Freire

a

and Andr

´

e Vasconcelos

b

INESC-ID, Instituto Superior T

´

ecnico, Universidade de Lisboa, Portugal

Keywords:

Industry 4.0, Enterprise Architecture, Job Profiles, Reference Architecture and Manufacturing Operation

Management Activities.

Abstract:

Industry 4.0 has revolutionized manufacturing by introducing technologies such as Cyber-Physical Systems,

Internet of Things and others that make manufacturing more efficient and dynamic. Despite these benefits,

Industry 4.0 has a high barrier to entry. The complexity of manufacturing systems will inevitably increase,

and it is also necessary to redesign existing manufacturing processes to take advantage of Industry 4.0. In this

paper we use Enterprise Architecture to help companies to deal with the increasing complexity when adopting

Industry 4.0. In our research, we found that many solutions have been developed to help companies make the

technological transition to Industry 4.0, but none helps companies align their newly acquired technological

capabilities with their production processes. To address this gap, we developed RAMOM, a reference archi-

tecture for manufacturing operation management activities in Industry 4.0. RAMOM is composed of several

views, developed in the Archimate language, that provide information on the actors, functions, data types and

how these relate to manufacturing operation management activities, thus guiding organizations in their imple-

mentation. To confirm its validity, we conducted an evaluation of RAMOM based on expert knowledge and

an application of RAMOM in a Portuguese industry case study. We concluded that is useful to use RAMOM

to help organizations adapt their processes to Industry 4.0.

1 INTRODUCTION

The introduction of the Industry 4.0 concept in the

manufacturing industry has created new challenges

for companies. Industry 4.0 introduces new key tech-

nologies that enable more efficient, personalized and

dynamic production (Lasi et al., 2014). The intro-

duction of Industry 4.0 in a company entails up-

dating technology, production and support systems,

which leads to an increase in complexity and is one

of the main obstacles in the transition to Industry 4.0

(Luthra and Mangla, 2018). We have found that one

possible way to overcome this obstacle is to study

Enterprise Architecture (EA) in the context of Indus-

try 4.0, as this discipline can help organizations align

people, processes, and technology with their business

goals and provide methods for dealing with increas-

ing complexity. EA can provide the aforementioned

values by presenting already proven models that pro-

vide organizations with recommendations on how to

structure themselves (Bernard, 2012). During the de-

a

https://orcid.org/0009-0002-1731-9192

b

https://orcid.org/0000-0003-0038-7199

velopment of this work, we were part of an Indus-

try 4.0 transition project. In this project, we found

that many problems resulted from a lack of adapta-

tion of production and support processes to the intro-

duced Industry 4.0 technologies. Although we noted

this difficulty in our research on EA in Industry 4.0,

little information was found on this topic. For this rea-

son, we decided to develop a Reference Architecture

(RA) that can help companies adapt their processes in

the transition to Industry 4.0. This paper is organized

in six sections. First we present the theoretical basis

of our proposal; next we described how we realized

a Systematic literature review on the topic of Industry

4.0 job profiles; then we present our proposal address-

ing the problems that we identified RAMOM; after

we apply RAMOM in Portuguese industry case study;

after we provide a theoretical evaluation of RAMOM;

finally we conclude our work and provide a glimpse

of future work that remains to be done.

Freire, G. and Vasconcelos, A.

RAMOM: A Reference Architecture for Manufacturing Operations Management Activities in Industry 4.0.

DOI: 10.5220/0012173700003690

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 26th International Conference on Enterprise Information Systems (ICEIS 2024) - Volume 2, pages 595-602

ISBN: 978-989-758-692-7; ISSN: 2184-4992

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

595

2 BACKGROUND

This section presents all the research and analysis

performed that corresponds to all the knowledge ob-

tained to reach the solution definition.

2.1 Industry 4.0

Industry 4.0 is a term used to describe the 4th

industrial revolution that brings digitization for-

wards within factories by integrating information and

communication technologies with industrial technol-

ogy (Lasi et al., 2014).

2.2 Enterprise Architecture

ISO 42010:2011 describes architecture as the “pro-

cess of conceiving, defining, expressing, document-

ing, communicating, certifying proper implementa-

tion of, maintaining and improving an architecture

throughout a system’s life cycle” (ISO/IEC, 2022).

Architecture applied at the level of an entire organi-

zation is referred to as EA.

2.2.1 Architectural Description

ISO 42010:2011 (ISO/IEC, 2022) describes an ar-

chitectural description as the “work product express-

ing the architecture of a system from the perspec-

tive of specific system concerns”. “An architecture

description shall identify the system of interest and

include supplementary information as determined by

the project and/or organisation” (ISO/IEC, 2022) and

can consist of at least one architectural view or (view).

2.2.2 Architectural Views and Viewpoints

An architectural view frames one or more concerns

from one of the system’s stakeholders, and the view

can frame one or more architectural viewpoints (or

viewpoints). A viewpoint is described as a “work

product establishing the conventions for the construc-

tion, interpretation and use of architecture views to

frame specific system concerns” (ISO/IEC, 2022).

The use of views and viewpoints provides many ad-

vantages to the architecture definition process, includ-

ing the proposed solution. Separating the solution

into distinct descriptions will aid its design, analy-

sis, and communication process by making it possible

to approach different parts of the system individually,

reducing the complexity of the architecture definition

process

2.3 Reference Architectures

”A Reference Architecture is, in essence, a prede-

fined architectural pattern, or set of patterns, pos-

sibly partially or completely instantiated, designed

and proven for use, in particular, business and tech-

nical contexts, together with supporting artifacts to

enable their use.” (Kruchten, 2004). Due to their

usefulness and high coverage of RAs, this tool has

been studied and applied in a variety of fields result-

ing in several different definitions and an increased

number of RAs for other domains (Nakagawa et al.,

2014). RAs can be classified as research-driven or

practical-driven.“Practice-driven reference architec-

tures are defined when sufficient knowledge has been

accumulated in a domain to propose the “best of best-

practices” architecture. Research-driven reference ar-

chitectures provide a “futuristic” view on a class of

systems that are expected to become important in the

future, but by the time of the architecture definition

are seen as hard to build. These architectures aim at

facilitating the design of the first systems from a class

of systems” (Angelov et al., 2008).

2.4 Reference Architectures in Industry

4.0

Since Industry 4.0 is a new phenomenon, RAs has an

increased value in this area, since it hasn’t reached a

maturity level where widely practiced standards exist,

for the same reason not many RA have been devel-

oped in this area. In this section, we will go through

the most popular Industry 4.0 to see how these are

built and what topics they cover.

2.4.1 Reference Architecture Industry 4.0

(RAMI 4.0)

Reference Architecture Industry 4.0 (RAMI 4.0) is a

reference architecture model developed by the Ger-

man Electrical and Electronic Manufacturers’ Asso-

ciation (ZVEI) to support Industry 4.0 initiatives. The

RAMI 4.0 Reference Architectural Model gives com-

panies a framework for developing future products

and business models. The model “consists of a three-

dimensional coordinate system that describes all cru-

cial aspects of Industry 4.0” (Hankel and Rexroth,

2015).

2.4.2 Industrial Internet Reference Architecture

(IIRA)

The Industrial Internet Reference Architecture (IIRA)

is a reference architecture to enable the implemen-

tation of IIoT (Industrial Internet of things) archi-

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

596

tectures in a wide variety of industries (Moghaddam

et al., 2018). For this purpose, the “architecture de-

scription and representation are generic and at a high

level of abstraction to support the requisite broad in-

dustry applicability” (Consortium, 2019). The IIRA

model consists of four viewpoints, business, usage,

functional and implementation viewpoints, that frame

different concerns of Industry 4.0.

2.5 The ”human element” in Reference

Architectures for Industry 4.0

From our research into reference architectures in

Industry 4.0, we could observe there isn’t enough

detail regarding the human component of Industry

4.0 (Sharpe et al., 2019). In the current literature re-

lating to Industry 4.0 and automation, there is a con-

sensus that despite the technological advances in the

manufacturing industry, humans will still maintain a

relevant role in this industry (Sharpe et al., 2019). So

these should also be considered in system modeling

regarding Industry 4.0. In RAMI 4.0, personnel is

part of the Asset layer, which is then seen as phys-

ical components by RAMI 4.0, such as linear axes,

metal parts, documents, circuit diagrams, ideas, and

archives (Adolphs et al., 2015). While this might be

sufficient for some scenarios, this isn’t enough, as

proven by the article An industrial evaluation of an

Industry 4.0 RA demonstrating the need for the in-

clusion of security and human components. In this

article, the authors try to model three scenarios from

the manufacturing industry that include the human el-

ement using RAMI 4.0 (Sharpe et al., 2019). The

authors found that all scenarios showed uncertainties

when modeling the human part. The authors then con-

clude that a more significant focus is on the human el-

ement in the future of RAMI 4.0 (Sharpe et al., 2019).

IIRA acknowledges that humans can play a role in

the several domains of IIoT systems, briefly describ-

ing what role these can have in the operations, infor-

mation, application, and business domains. Despite

knowing that it is crucial and challenging to under-

stand “what capabilities a given person will provide,

how those capabilities fit into the system design as a

whole and assuring that person is actually providing

those capabilities when needed” (Consortium, 2019)

IIRA, other than what was already mentioned, doesn’t

provide much more details regarding the human ele-

ment in IIoT.

2.6 IEC 62264

IEC 62264, is the international standard for integrat-

ing enterprise and control systems. This standard was

developed to provide a model that end-users, integra-

tors, and vendors can use when integrating new ap-

plications in the enterprise. IEC 62264 defines five

different levels with their respective problems and

challenges when implementing applications using an

SOA-based approach (Delsing et al., 2012). This

work will mainly focus on IEC 62264-3, which cor-

responds to the third part of this standard. This part

defines activity models of manufacturing operations

management that enable enterprise systems to control

system integration and includes a model of the activ-

ities associated with manufacturing operations man-

agement, Level 3 functions, and an identification of

some of the data exchanged between Level 3 activi-

ties (Commission et al., 2016).

3 SYSTEMATIC LITERATURE

REVIEW

The introduction of Industry 4.0 technologies means

that the complexity of the shop floor will increase,

and the organization’s manufacturing operations will

change. This, coupled with the organizational

changes, means that there is a need for new actors

with new roles and the revamp of old ones in Indus-

try 4.0 able organizations. In order to fully explore

these topics an Systematic Literature Review (SLR)

was conducted. For this purpose, the following Re-

search questions were developed.

• Research Question 1: What are the main traits of

Industry 4.0 job profiles ?

• Research Question 2: What new or updated job

profiles were developed for Industry 4.0?

• Research Question 3: What standards or propos-

als exist connecting organizational structure, job

profiles, and the activities they perform in the con-

text of Industry 4.0?

To ensure that our research is conducted properly

we defined a review protocol with the research strings,

the databases used for the research and inclusion cri-

teria such as papers with titles related to our research

strings, with a publishing date after 2011, written in

English and free to access. From our research we re-

covered 774 papers that fit the proposed criteria. Then

we further reviewed these papers and selected 24 to

utilize in the SLR.

From our research, we were able to take the fol-

lowing conclusions.

• The key traits that Industry 4.0 job profiles have

are High IT skills, Improved soft skills, More fo-

cus on cognitive skills, and a High focus on mul-

tidisciplinary skills.

RAMOM: A Reference Architecture for Manufacturing Operations Management Activities in Industry 4.0

597

• There has already been some research done in cre-

ating and updating job profiles in Industry 4.0.

Although research on job profiles in Industry 4.0

hasn’t reached maturity, this should be compre-

hensive enough to start architecture, how these

should be organized, and the task these should

carry out.

• We have reviewed two proposals by Garc

´

ıa de

Soto et al. (Garc

´

ıa de Soto et al., 2019) and Silvia

Fareri et al. (Fareri et al., 2018) that address job

profiles, their roles, and activities. However, we

have found that these proposals are not relevant

enough to our work as they do not emphasize this

topic adequately and fail to develop it effectively.

4 TOWARDS A REFERENCE

ARCHITECTURE FOR

MANUFACTURING

OPERATIONS MANAGEMENT

ACTIVITIES IN INDUSTRY 4.0

Considering the open issues identified in the SLR we

propose a research-driven RA, focused on manufac-

turing operation management activities and its actors:

RAMOM. In this work, the choice was made to only

focus on level 3 activities, since this was the only

level where we explicitly found a set of activities (IEC

62264-3). The focus of this RA is to provide organi-

zations a tool to adapt their business side, to be more

in line with Industry 4.0 ways of operating. To guide

the development of RAMOM we followed a method-

ology for the development of RAs named ProSA-

RA (Nakagawa et al., 2014). This is divided into

four stages, Information Source Investigation, Archi-

tectural Analysis, Architectural Synthesis, and Archi-

tectural Evaluation, which we will follow.

4.1 Information Source Investigation

In this phase, the primary sources for constructing the

RA are selected. The chosen sources must provide in-

formation about processes and activities supporting a

system of the target domain (Santos et al., 2013). This

was already done in the Background, Related Work

and Systematic literature review chapter, so instead in

this section, we will organize the recovered informa-

tion in a more digestible way.

4.1.1 Industry 4.0 Job Profiles

During the SLR, we discovered several works that

identified or adapted existing job profiles for Indus-

try 4.0. In this section, we organize the job profiles

that we found in our research. From these we derived

and introduced in RAMOM the following job pro-

files: Data Scientist, Maintenance Operator, Produc-

tion Operator, Production Manager, Logistics Opera-

tor, Supply Chain manager, Production manager, En-

vironmental technician, Quality manager, and Quality

operator.

4.2 Architectural Analysis

Following the ProSA-RA methodology, after realiz-

ing an Information Source Investigation an architec-

tural analysis is made. In this the system requirements

are identified, then based on these the architectural re-

quirements of the RA are identified and finally we es-

tablished the set of concepts that must be considered

in this reference architecture.

4.3 Architectural Synthesis

In this step, following the ProSA-RA methodology,

the architectural description of the reference archi-

tecture is built by describing the goals of RAMOM,

its stakeholders, its concerns and the viewpoints and

view that are present in RAMOM.

Goals of the RAMOM: 1. Support the implemen-

tation of Industry 4.0 systems in organizations; 2. Re-

duce the entry barrier for the implementation of In-

dustry 4.0 systems by providing a baseline model of

activities and resources; 3. Allow to detect points of

failure in Industry 4.0 systems; 4. Increase the suc-

cess and effectiveness of the implementation of In-

dustry 4.0 components in organizations;

Stakeholders: Operation managers, Process ar-

chitects, Data architects, Domain architects and Re-

cruiters.

Concerns from the stakeholders: 1.What are the

main manufacturing operation management activities

to support smart factories; 2.What tasks composed

the manufacturing operation management activities;

3.What actors should be responsible for the man-

ufacturing operation management activities; 4.What

characteristics should the actors possess to effec-

tively realize the activities they are responsible for;

5.What data/artifacts are required for the realization

of the manufacturing operation management activi-

ties; 6.What data/artifacts result from the realization

of the activities; 7.What are the required artifacts/data

that the different actors must have access to effec-

tively realize their responsibilities;

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

598

4.3.1 Architectural Viewpoints and Views

In this section, we present the viewpoints and views

that will compose RAMOM.

Capability Map Viewpoint. The capability map

viewpoint allows the Business Architect to create a

structured overview of the capabilities of the enter-

prise. A capability map typically shows two or three

levels of capabilities across the entire enterprise.

• Stakeholders: Business managers, enterprise,

business architects, recruiters

• Concerns: Architecture strategy and tactics, mo-

tivation

• Purpose: Designing, deciding

• Scope: Strategy

• Archimate elements: Resources, Capabilities

and Outcome

Business Function, Objects, and Actors/Roles

Viewpoint. The Business function, objects, and

actors/roles viewpoint focus on identifying the ac-

tors/roles that are responsible for executing the busi-

ness functions of the organization as well as the busi-

ness objects that are inputted into the function and that

result from it.

• Stakeholders: Operation managers, Process ar-

chitects, Data architects, and Domain architects

• Concerns: Identification of execution responsi-

bility and artifacts input and output

• Purpose: Designing, deciding, informing

• Scope: Single layer/Single aspect

• Archimate elements: Actor, Function and Busi-

ness object

Actor’s Business Objects Viewpoint. The actor data

and artifacts viewpoint focuses on what data/artifacts

inside an organization should be available to the ac-

tors for them to be able to effectively exercise their

tasks.

• Stakeholders: Data architects, Domain archi-

tects, and Operation managers

• Concerns: Data architecture, security and man-

agement

• Purpose: Designing, deciding, informing

• Scope: Single layer/Single aspect

• Archimate Elements: Actor and Business object

From the viewpoints presented before we derived

five views that adequately represent RAMOM. Each

of the selected views addresses the concerns of the

stakeholders that were raised earlier.

Job Profiles Capabilities View. This view is derived

from the Capability map viewpoint. This view will

display the different job profiles necessary to effec-

tively run manufacturing operation management ac-

tivities in a smart factory as well as the capabilities

that these must have to execute the functions that will

be attributed to them. These job profiles will serve as

the source of information for the actors presented in

the RA. This view will address the fourth raised con-

cern “What characteristics should the actors possess

to effectively realize the activities they are responsi-

ble for”.

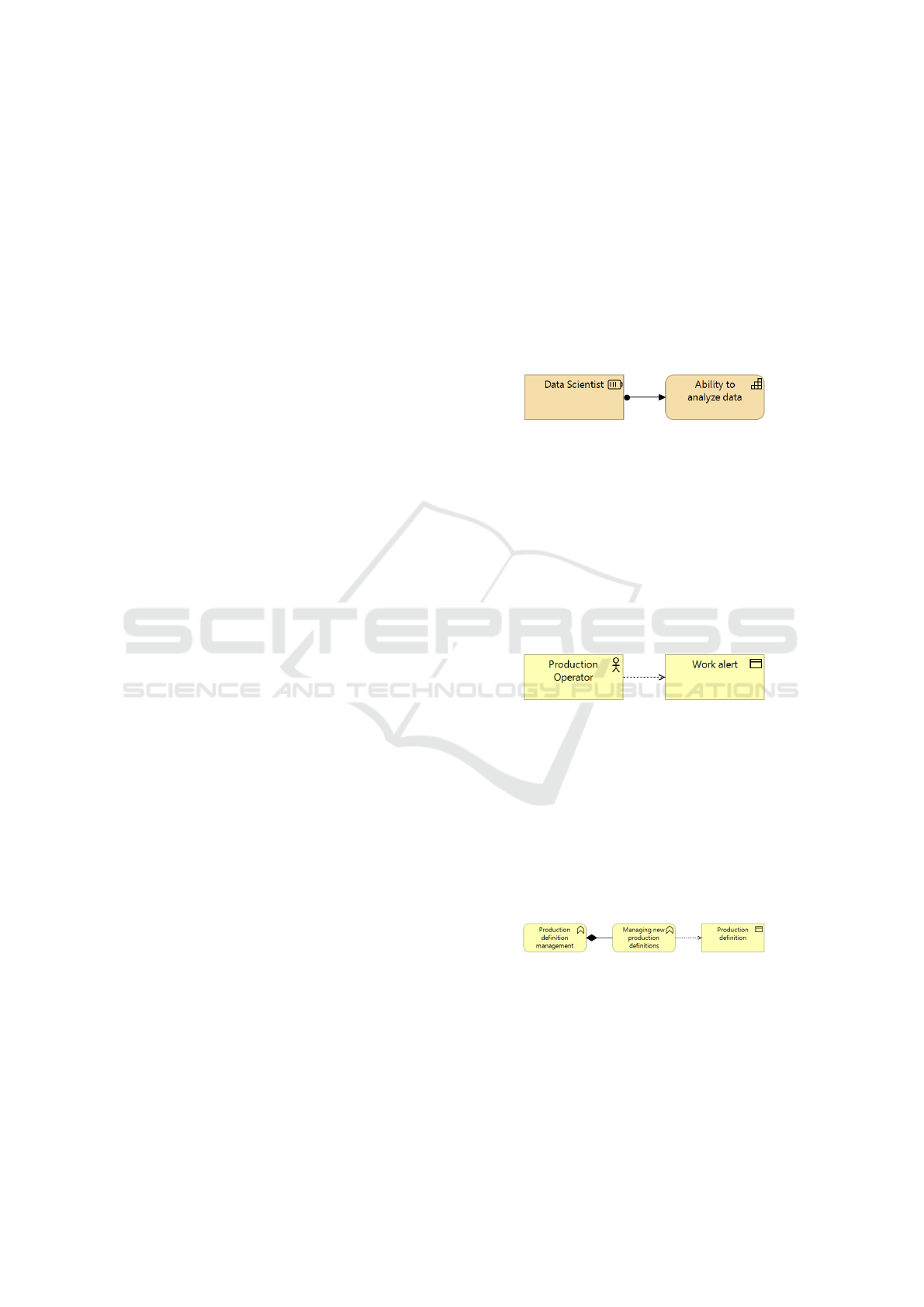

Figure 1: Job profiles capabilities view example.

Actor’s Data/Artifacts View. This view is de-

rived from the Actor’s business objects Viewpoint.

This view will display the different data/artifacts that

should be made available to the actors responsible

for the manufacturing operation management activ-

ities, this will facilitate both data and security archi-

tecture. This view will address the seventh raised con-

cern “What are the required data/artifacts that the dif-

ferent actors must have access to effectively realize

their responsibilities”.

Figure 2: Actor’s data/artifacts view example.

Business Function’s Data/Artifact View. This view

is derived from the Business function, objects, and

actors viewpoint. This view identifies both the

data/artifacts that are inputted into the function as well

as the data/artifacts that result from it. This view

addresses the fifth and sixth raised concerns “What

data/artifacts are required for the realization of the

manufacturing operation management activities” and

”What data/artifacts result from the realization of the

activities”.

Figure 3: Business function’s data/artifact view example.

Business Function Responsibility View. This view

is derived from the Business function, objects, and ac-

tors viewpoint. This view identifies what actors are

responsible for manufacturing operation management

activities. The objective of this actor is to indicate

which activities are mainly the responsibility of the

information system inside organizations instead of the

RAMOM: A Reference Architecture for Manufacturing Operations Management Activities in Industry 4.0

599

job profiles that have been identified in this work.

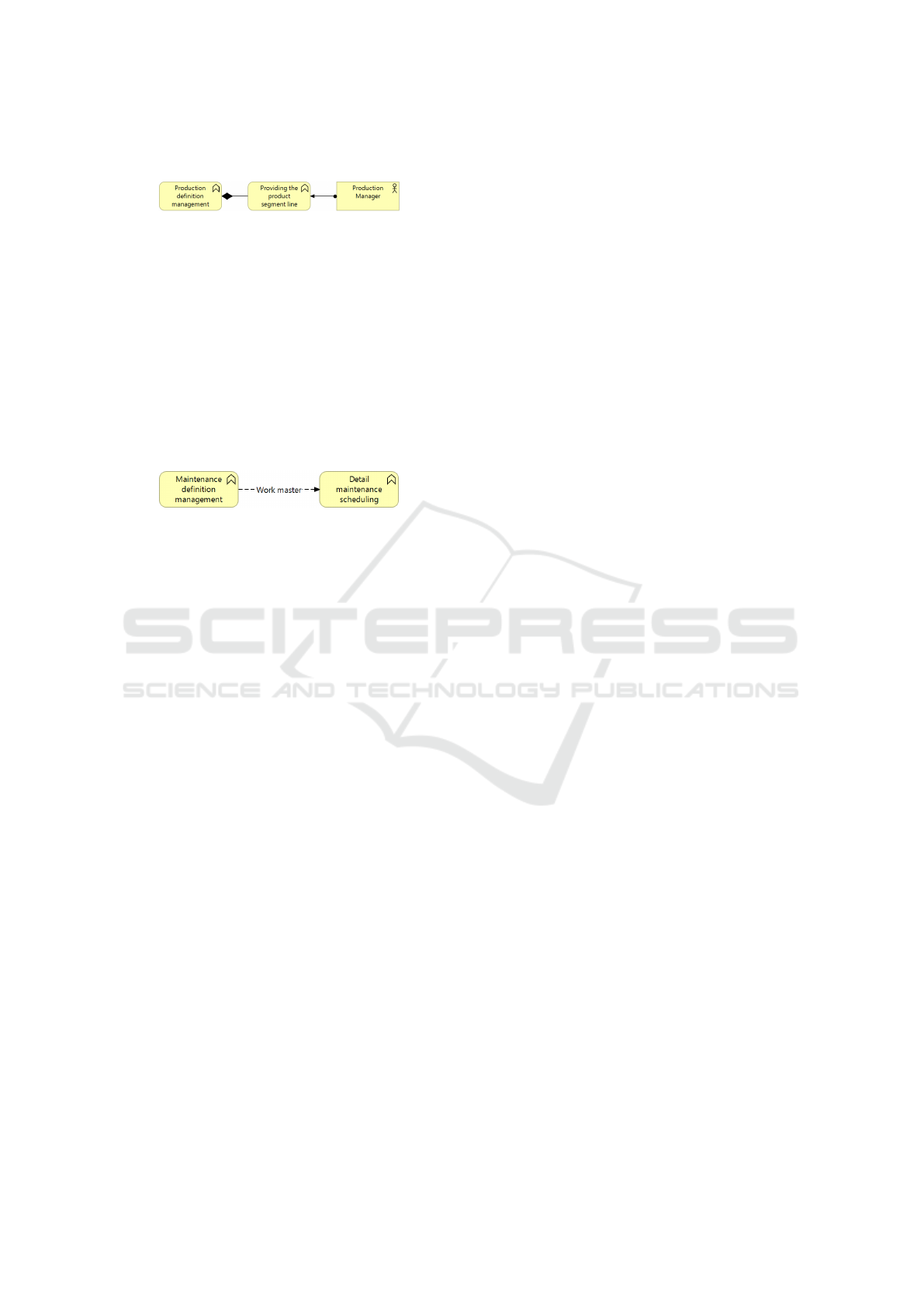

Figure 4: Business function responsibility view example.

Business Function General View. This view is de-

rived from the Business function, objects, and actors’

viewpoint. This view has the objective of providing a

more general vision of the system by combining both

data/artifacts and actors of the manufacturing opera-

tion management activities in the same view, facili-

tating the overall communication of the architecture

with stakeholders. This view addresses the first and

second raised concerns “What are the main manu-

facturing operation management activities to support

smart factories” and ”What tasks composed the man-

ufacturing operation management activities.”

Figure 5: Business function general view example.

5 RAMOM IN A PORTUGUESE

INDUSTRY CASE STUDY

In this section, we described how a use case as used

to show how RAMOM can be used in a real project.

During the development of RAMOM, one of the

possible use cases that we envisioned for it is to vali-

date the architecture of a manufacturing area that has

converted to Industry 4.0. This might be necessary to

evaluate if the architecture meets industry best prac-

tices or to identify why the manufacturing area is not

functioning as intended after the transition. To per-

form this validation a trusted architecture in this topic

is necessary to recognise if the best industry practices

are followed or to pinpoint the issues faced by the cur-

rent architecture. RAMOM would serve as the trusted

architecture that would guide this analysis. The archi-

tecture chosen for this analysis belongs to a Demo-

corp, which faces some issues after starting its transi-

tion to Industry 4.0. The demonstration has two main

phases. First, we modelled the Democorp architec-

ture following the RAMOM views and viewpoints en-

abling its analysis using RAMOM. After this, we start

comparing the Democorp and RAMOM view by view

identifying factors that contribute to the challenges

that Democorp is facing in its transition to Industry

4.0.

Where we only present the analysis made to the

job profiles capabilities view of the Democorp. Simi-

lar analysis were done to remaining views.

In job profiles capabilities view two main chal-

lenges were found. The first is the lack of profiles

specialized in handling data. During our research on

Industry 4.0, we have found that many of the ben-

efits can only be achieved by handling and process-

ing the large amounts of data obtained from produc-

tion equipment so that it is possible to draw conclu-

sions from this data and make the production process

more efficient (Dalenogare et al., 2018). In the current

Democorp architecture, no profile can perform these

tasks, which means that the transition to Industry 4.0

is not possible. The clear solution to this problem is to

create a profile identical to the RAMOM data scientist

to fulfill the activities of this profile. The second prob-

lem is the lack of capabilities of the operations pro-

files in dealing with technologically advanced equip-

ment. In both the maintenance and production oper-

ator profiles in RAMOM, the emphasis is that they

should be able to interact with digital tools, and the

production operator should be able to use software to

monitor activities and program and interact with au-

tomated systems. Currently, profiles similar to those

in Democorp do not have these skills, which keeps

them from iterating with Industry 4.0 equipment and

makes the transition more difficult. One possible so-

lution would be to train operators in these areas so

they can handle high-tech systems, or hire employ-

ees with these skills. These were the two biggest

challenges we identified in our analysis. In addition,

other issues that, while not as relevant as those pre-

viously mentioned, Democorp should also be aware

of, namely the lack of maintenance profiles equipped

to deal with automation and the fact that they use a

more vertical hierarchical structure. In the Democorp

nothing is mentioned about automation, which may

become a challenge in the transition to Industry 4.0

as it relies heavily on automation. The use of a more

vertical hierarchical structure can be problematic in

the transition to Industry 4.0, as it makes it difficult

to implement various Industry 4.0 values (R

¨

ußmann

et al., 2015).

From this type of analysis on all of RAMOM

views, we were able to identify the several issues in

the Democorp architecture. In the Job profiles capa-

bilities view we discover a lack of profiles special-

ized in data usage, a lack of capabilities in operational

profiles, a lack of maintenance profiles equipped to

deal with automation and the use of a more verti-

cal hierarchical structure. In the Business function’s

data/artifact view we found that analysis activities

missing and not systematically performed in the De-

mocorp and that maintenance and inventory tracking

activities not performed. Finally in the Business func-

tion responsibility view exist a lack of automatization

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

600

of activities, an unhelpful separation of activities and

that performance analysis activities are not realized

by profiles proficient in data. By identifying these is-

sues we have proven how RAMOM has practical util-

ity since we were able to successfully identify impor-

tant elements that were lacking in the Democorp ar-

chitecture for this to be able to transition to Industry

4.0.

6 EVALUATION

This section describes how we evaluate RAMOM fol-

lowed by ther conclusions that we took from this pro-

cess. For a RA to be considered fit for purpose it must

be proven that it is built correctly (this means with-

out any architectural flaws) and that its content must

be theoretically correct. For these reasons, there is

an inherent need of evaluating RAs (Angelov et al.,

2008). To evaluate RAMOM we opted to used FERA

methodology as this is a suitable evaluation method-

ology for RAs. FERA was developed as a way to

evaluate RAs for embedded systems but that could

be personalized to fit other subjects. For this pur-

pose, a questionnaire was built based on current lit-

erature available on embedded systems, reference ar-

chitectures, and software architecture and already de-

veloped research on this topic (Santos et al., 2013).

Because FERA focuses on RAs for embedded sys-

tems we removed questions specific to this topic, the

remaining questions were deemed relevant to evaluat-

ing the developed RA. We saw no need to add ques-

tions to the base questionnaire, since the remaining

questions already covered all relevant topics to our

project, since these cover the completeness of the RA,

if its construction is correct, and if the contents pre-

sented in the RA are valid, resulting in a 71 questions

questionnaire with questions such as:

• Do the selected viewpoints frame the concerns of

all stakeholders (including domain-specific stake-

holders)?

• Does each view correctly represent its viewpoint?

• Is the reference architecture consistent with the

domain’s practices and mandated standards?

The inspection of RAMOM was done by 3 roles,

one specialist in industry 4.0, project management

and familiar with Enterprise Architecture, an indus-

trial engineer working on Industry 4.0 projects, and

an IoT project manager working on Industry 4.0

projects that did not have previous involvement with

RAMOM. The results show that RAMOM is able to

obtain a majority of ”Completely satisfactory” in the

questionnaire with the lowest percentage of ”Com-

pletely satisfactory” responses by a participant be-

ing 71 percent. The main problems identified in

RAMOM are related to the lack of guidelines when

it comes to implementing concrete instances of the

architecture described in RAMOM, some details in

RAMOM that do not comply with international stan-

dards, best practices, and guidelines, and some infor-

mation that was missing in the architectural descrip-

tion of RAMOM.

The criticism of the lack of guidelines is to be ex-

pected due to the fact that RAMOM is a research-

driven RA, i.e., it was developed based on research

done on these topics and not on a concrete archi-

tecture, so the lack of concepts such as guidelines

for its implementation, knowledge of how the vari-

able part interacts with the non-variable part in be-

cause of the architecture, or how to implement the

architecture in instances is normal, since this knowl-

edge is gained only after implementing a concrete

instance of RAMOM. The non-compliance with in-

ternational standards, best practices, and guidelines

was discussed with the experts involved in the evalua-

tion and based on their feedback and further research,

changes were made to RAMOM to correct these non-

compliances. Finally, we also received feedback that

certain aspects of RAMOM lacked information, such

as a version identifier in each model or the lack of ar-

ticulation of open decisions. Based on these results,

we improved the architectural views to provide a more

consistent and complete architectural description of

RAMOM and facilitate its dissemination. After re-

ceiving this feedback we dicussed based on the evalu-

ation carried out and the further discussion and treat-

ment of the problems encountered, we can conclude

that RAMOM is theoretically sound.

7 CONCLUSIONS

In this work, we explored how EA is used in the field

of Industry 4.0 and contributed to this research topic

in several forms. First, we identified a gap in this re-

search topic, by identifying a lack of EA resources on

how organizations could adapt their operational pro-

cesses to the technological innovations originated by

Industry 4.0. We reached this conclusion by look-

ing at the most popular Industry 4.0 RAs’ and how

these dealt with this topic. After determining this we

decided to approach this topic with the development

of a RA that supports organization’s transition to In-

dustry 4.0, leading to the development of RAMOM.

RAMOM is a RA focused on manufacturing opera-

tions management in Industry 4.0 that aids organiza-

RAMOM: A Reference Architecture for Manufacturing Operations Management Activities in Industry 4.0

601

tion’s adjustment to Industry 4.0 by providing a set of

generic actors, functions and data required for manu-

facturing operations management activities. Despite

considering this work a success there are several lim-

itations of this work that should be considered. The

first is limitation is that Industry 4.0 is a relatively

new phenomenon, meaning that RAMOM should be

qualified as a research-driven RA, meaning that the

best practices described in RAMOM might change

in the future with further developments in the area.

The other relevant limitation is the limited scope of

RAMOM since it only deals with manufacturing op-

eration management activities meaning that the topic

of levels two and four activities aren’t covered. To

deal with this research should be conducted to iden-

tify what activities belong to levels two and four ac-

tivities and then conduct a similar work as the one

done in RAMOM. Finally, further research should be

done on identifying the challenges companies face in

moving to Industry 4.0 in terms of their operating

and business models and how EA can help compa-

nies solve these challenges since the main aspiration

of this work are to demonstrate that this is a real chal-

lenge that is impeding organizations of adopting In-

dustry 4.0 and to contribute to this challenge by ex-

panding our current understanding of this topic.

ACKNOWLEDGEMENTS

This work was supported by national funds

through FCT, Fundac¸

˜

ao para a Ci

ˆ

encia e a

Tecnologia, under project UIDB/50021/2020

(DOI:10.54499/UIDB/50021/2020) and in the scope

of the project nr. 51 “BLOCKCHAIN.PT - Agenda

Descentralizar Portugal com Blockchain”, financed

by European Funds, namely “Recovery and Re-

silience Plan - Component 5: Agendas Mobilizadoras

para a Inovac¸

˜

ao Empresarial”, included in the

NextGenerationEU funding program. ”

REFERENCES

Adolphs, P., Bedenbender, H., Dirzus, D., Ehlich, M., Ep-

ple, U., Hankel, M., Heidel, R., Hoffmeister, M.,

Huhle, H., K

¨

archer, B., et al. (2015). Reference ar-

chitecture model industrie 4.0 (rami4. 0). ZVEI and

VDI, Status report.

Angelov, S., Trienekens, J. J., and Grefen, P. (2008). To-

wards a method for the evaluation of reference ar-

chitectures: Experiences from a case. In European

Conference on Software Architecture, pages 225–240.

Springer.

Bernard, S. A. (2012). An introduction to enterprise archi-

tecture. AuthorHouse.

Commission, I. E. et al. (2016). Iec 62264-3 enterprise-

control system integration—part 3: Activity models of

manufacturing operations management. International

Electrotechnical Commission: Geneva, Switzerland.

Consortium, I. I. (2019). The industrial internet of things

volume g1: Reference architecture.

Dalenogare, L. S., Benitez, G. B., Ayala, N. F., and Frank,

A. G. (2018). The expected contribution of industry

4.0 technologies for industrial performance. Inter-

national Journal of Production Economics, 204:383–

394.

Delsing, J., Rosenqvist, F., Carlsson, O., Colombo, A. W.,

and Bangemann, T. (2012). Migration of industrial

process control systems into service oriented archi-

tecture. In IECON 2012 - 38th Annual Conference

on IEEE Industrial Electronics Society, pages 5786–

5792.

Fareri, S., Chiarello, F., Coli, E., Teloni, D., Dente, G., and

Fantoni, G. (2018). Workers 4.0: skills, profiles and

jobs in different business functions. Economy, em-

ployment and skills: European, regional and global

perspectives in an age of uncertainty, page 95.

Garc

´

ıa de Soto, B., Agust

´

ı-Juan, I., Joss, S., and Hun-

hevicz, J. (2019). Implications of construction 4.0 to

the workforce and organizational structures. Interna-

tional Journal of Construction Management.

Hankel, M. and Rexroth, B. (2015). Industrie 4.0: The refer-

ence architectural model industrie 4.0 (rami 4.0). zvei.

ISO/IEC (2022). Ieee/iso/iec international standard for soft-

ware, systems and enterprise–architecture description.

ISO/IEC/IEEE 42010:2022(E), pages 1–74.

Kruchten, P. (2004). The rational unified process: an intro-

duction. Addison-Wesley Professional.

Lasi, H., Fettke, P., Kemper, H.-G., Feld, T., and Hoffmann,

M. (2014). Industry 4.0. Business & Information Sys-

tems Engineering, 6(4).

Luthra, S. and Mangla, S. K. (2018). Evaluating challenges

to industry 4.0 initiatives for supply chain sustainabil-

ity in emerging economies. Process Safety and Envi-

ronmental Protection, 117:168–179.

Moghaddam, M., Cadavid, M. N., Kenley, C. R., and Desh-

mukh, A. V. (2018). Reference architectures for smart

manufacturing: A critical review. Journal of manufac-

turing systems, 49:215–225.

Nakagawa, E. Y., Guessi, M., Maldonado, J. C., Feitosa,

D., and Oquendo, F. (2014). Consolidating a process

for the design, representation, and evaluation of refer-

ence architectures. In 2014 IEEE/IFIP Conference on

Software Architecture, pages 143–152. IEEE.

R

¨

ußmann, M., Lorenz, M., Gerbert, P., Waldner, M., Justus,

J., Engel, P., and Harnisch, M. (2015). Industry 4.0:

The future of productivity and growth in manufactur-

ing industries. Boston consulting group, 9(1):54–89.

Santos, J. F. M., Guessi, M., Galster, M., Feitosa, D., and

Nakagawa, E. Y. (2013). A checklist for evaluation of

reference architectures of embedded systems (s). In

SEKE, volume 13, pages 1–4.

Sharpe, R., van Lopik, K., Neal, A., Goodall, P., Conway,

P. P., and West, A. A. (2019). An industrial evaluation

of an industry 4.0 reference architecture demonstrat-

ing the need for the inclusion of security and human

components. Computers in Industry, 108:37–44.

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

602