Production-Ready End-to-End Visual Quality Inspection for Defect

Detection on Surfaces Based on a Multi-Stage AI System

Patrick Trampert

∗ a

, Tobias Masiak, Felix Schmidt

b

, Nicolas Thewes, Tim Kruse, Christian Witte

and Georg Schneider

Artificial Intelligence Lab, ZF Friedrichshafen AG, Scheer Tower II, Uni-Campus Nord, Geb. D5 2 66123 SB, Germany

Keywords:

Machine Learning, Artificial Intelligence, Deep Learning, Visual Quality Inspection, Defect Detection,

Windowing, Multistage Learning.

Abstract:

Quality inspection based on optical systems is often limited by the ability of conventional image processing

pipelines. Moreover, setting up such a system in production must be tailored towards specific tasks, which is

a very tedious, time-consuming, and expensive work that is rarely transferable to different inspection prob-

lems. We present a configurable multi-stage system for Visual Quality Inspection (VQI) based on Artificial

Intelligence (AI). In addition, we develop a divide-and-conquer strategy to break down complex tasks into

sub-problems that are easy-to-handle with well-understood AI approaches. For data acquisition a human-

machine-interface is implemented via a graphical user interface running at production side. Besides facilitated

AI processing the evolved strategy leads to a knowledge digitalisation through sub-problem annotation that

can be transferred to future use cases for defect detection on surfaces. We demonstrate the AI based quality

inspection potential in a production use case, where we were able to reduce the false-error-rate from 16.83%

to 2.80%, so that our AI workflow has already replaced the old system in a running production.

1 INTRODUCTION

The fast-developing ecosystem of the fourth indus-

trial revolution with its ongoing digital transformation

brings a lot of challenges and opportunities (Schwab,

2017). Hereby, intelligence-driven production is a

central building block for success. Artificial Intel-

ligence (AI) has empowered autonomous decision-

makings in a production environment since the break-

through of deep neural networks in 2012 (Krizhevsky

et al., 2012). Production performance can benefit in

multiple ways, for instance increasing transparency,

higher efficiency, more flexibility, lightweight recon-

figuration, easier controllability as well as cost opti-

mization (Azamfirei et al., 2021a).

AI based production systems are subject to man-

ufacturing prerequisites and have to fulfil many con-

ditions to be integrated into an everyday shop floor.

This starts at quality assurance regulations, includes

cycle times and low scrap rates, and ends at employee

empowerment. Important is not only a robust automa-

a

https://orcid.org/0000-0002-1065-4345

b

https://orcid.org/0009-0008-3010-8385

∗

Corresponding author

tion but also an integrated human machine interaction

process to foster acceptance and scalability of AI. A

tight intertwining of AI applications and shop floor

workers ensures continuous monitoring and enhance-

ment of implemented solutions to hold high quality

standards, hence, a decrease of human imperfection

(See et al., 2017).

Particularly in the context of Visual Quality In-

spection (VQI) based on image processing, such a

cooperation is extremely beneficial. An AI system

can ask a human operator in case it is not confident

about a decision. An initial uninformed AI will ask

for help each time it gets presented an item to be anal-

ysed. With growing number of examples, the AI in-

ternalises human knowledge and needs less help. Fur-

thermore, knowledge will be able transferable to sim-

ilar problems.

Most VQI is based on specialised camera sys-

tems with built in or connected conventional image

processing capabilities (Golnabi and Asadpour, 2007;

Huangpeng et al., 2018). At Start of Production

(SOP) for a new product great effort is needed to

achieve full functioning of an image analysis system,

for example to detect defects. Systems must be cal-

ibrated exactly for the new product or even for new

Trampert, P., Masiak, T., Schmidt, F., Thewes, N., Kruse, T., Witte, C. and Schneider, G.

Production-Ready End-to-End Visual Quality Inspection for Defect Detection on Surfaces Based on a Multi-Stage AI System.

DOI: 10.5220/0012536500003720

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Image Processing and Vision Engineering (IMPROVE 2024), pages 55-66

ISBN: 978-989-758-693-4; ISSN: 2795-4943

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

55

types or variants of already known products. In many

cases, this is a tedious endeavour based on the knowl-

edge and experience of the employee conducting this

task. Invested time to guarantee a proper working

of the system postpones the SOP and, hence, is very

costly in terms of working time and lost production

time. Technical changes in the production pipeline,

like replacing a conventional oven for an induction

oven, may require a recalibration as the altered sys-

tem could fail to handle the resulting changes in error-

patterns. Authorisation and approval granted to such

a system each time involves many human experts, es-

pecially quality assurance personnel.

In this article we show how to replace this pro-

cess with an AI based system for VQI of surfaces.

The presented approach reduces calibration times to

a minimum from several weeks to few hours, in par-

ticular for new types and variants of already known

products, as the knowledge of associated AI models

can be utilised. Our contributions are (i) introducing

a workflow for learning an AI model for defect detec-

tion, which can assist from the start in examining pro-

duced parts by gathering and annotating data during

production, (ii) AI supported interactive learning via

Human Machine Collaboration (HMC) to digitalise

process know-how, (iii) a flexible Graphical User In-

terface (GUI) for annotating images captured at pro-

duction time as interface for the HMC, (iv) a multi-

stage AI approach based on Deep Learning (DL) for

optimised inference and cycle times, (v) cutting-edge

AI technology combined with traditional manual de-

sign and modelling to have the advantages of both

worlds while reducing the individual disadvantages,

and (vi) end-to-end integration of the AI system into

a shop floor.

Following, we conduct an exhaustive analysis of

production research. We investigate the current state-

of-the-art (SOTA) based on a use case explaining the

motivation behind our work. This leads to the pro-

posal of the developed workflow. The experimental

setup as well as evaluation results follow afterwards.

The article finishes with a discussion and conclusion

of the presented work.

2 LITERATURE REVIEW

There is a wide range of applications, methods, and

workflows for VQI at production lines. (Inman et al.,

2003) performed a literature review on the intersec-

tion of quality and production system design and ar-

gue that the production system itself has a major im-

pact on the quality. Hence, integrating an AI includ-

ing a human machine interaction loop will improve

quality. (Yazidi et al., 2018) designed and developed

a distributed ontology-based quality control system

and showed its feasibility for printed circuit boards.

The approach enables autonomous quality control but

lacks transferability to problems that are not covered

by the ontology. (Raabe et al., 2017) proposed to in-

troduce zero defect strategies or cyber physical sys-

tems to minimise scrap rates by use of self-correcting

and autonomous systems. This reduces the depen-

dence on manual decision-making processes and pre-

dictive condition-based maintenance to decrease hu-

man imperfection. An exhaustive review on the SOTA

of quality control methods in the automotive manu-

facturing industry is presented in (Hafizi et al., 2019).

Furthermore, the work of (Knop, 2020) gives very in-

teresting insights into visual inspection methods and

even investigates further concepts regarding the term

“visual”.

Many examples of conventional image processing

algorithms that aim to detect defects exist. (Tsai et al.,

2012a) used an independent component analysis to

identify errors in solar cells. This approach requires a

lot of additional processing and relies on image recon-

structions of defect-free images as baseline to clas-

sify unseen images. Besides big initial effort the ap-

proach is not flexible for similar problems and, hence,

could only be evaluated on 80 test images resulting

in a mean recognition rate of 93.4%, which is insuf-

ficient. Further approaches for solar panel defects,

e.g., wavelet transforms (Li and Tsai, 2012) or Fourier

transforms (Tsai et al., 2012b) could not increase per-

formance significantly. (Chao and Tsai, 2010) pro-

posed anisotropic diffusion to identify defects in low-

contrast images. They applied their approach to ma-

terial surfaces in liquid crystal displays. Such kind of

model-based approaches require time-consuming ad-

justments per use-case. They are limited in terms of

flexibility, computing demands, and applicability on

production lines with short cycle times. (Jia et al.,

2004) developed a system based on manually defined

features as input for a support vector machine. Ad-

ditional filtering is needed before using the system to

find defects on surfaces of rolled steel. The perfor-

mance and speed of the system made it real-time ap-

plicable. However, a huge effort was needed for im-

plementation including manual modelling and human

decisions intrinsic to the system. The presented ap-

proaches share several drawbacks. Such approaches

often (i) only aim at a final step that makes a binary

decision, which means it is not possible to extend the

classification to more than two classes, (ii) require a

huge effort to make them work, and (iii) are tailored

towards one use case and application so that a transfer

to other use cases is hardly possible.

IMPROVE 2024 - 4th International Conference on Image Processing and Vision Engineering

56

Since the rise of DL in 2012 (Krizhevsky et al.,

2012), many novel methods were investigated for the

deployment to production. However, a lot of research

remains on an experimental level or does not exploit

its full potential. (Soukup and Huber-M

¨

ork, 2014)

used Convolutional Neural Networks (CNNs) to find

rail surface defects. They used photometric dark-field

stereo images. They showed that CNNs distinctly out-

perform model-based approaches, nevertheless, their

setup is not suited to be used in day-to-day applica-

tions. (Du et al., 2019) used Faster R-CNN, which

is an object detection approach, to detect casting alu-

minium defects based on X-ray images. They could

increase accuracy in detection, yet the X-ray setup is

quite expensive and very limited to specific applica-

tions. The lack of suitable datasets and the problem

that new data is hard to obtain narrow down the us-

age further. A more elaborated example was shown

by (Mueller et al., 2019b). They developed a binary

real-time quality inspection powered by AI and vali-

dated the approach in an aerospace assembly to clas-

sify rivet connections during their joining process as

OK or not OK (NOK). Besides the benefits, a disad-

vantage of their system is the limitation to only iden-

tify good and faulty parts, as it can’t be extended to

identify additional features, such as part numbers, en-

gravings, or other features.

3 INTELLIGENCE-DRIVEN

PRODUCTION

Nowadays, systems need high effort to be calibrated

for a single use case for – at least partly – autonomous

workflows. This involves a lot of tedious steps by-

hand as well as testing to make sure that a single use

case runs as it should (Malamas et al., 2003). Trial-

and-error processes instead of an elaborated develop-

ment for a defect detection pipeline are not rare. Qual-

ity control must ensure many sub-steps and regularly

validate the system. In the worst case, this must be

repeated every time something gets altered in the pro-

duction (Kopardekar et al., 1993), for example if a

new induction oven instead of a conventional is in-

stalled in a production line. A further problem is that

many calibrated systems still perform quite average,

so that additional manual re-inspections must be car-

ried out. Even if the human effort at a production line

is reduced by up to some percentage, the remaining

percentage of re-inspection means additional work for

unnecessary checking (Azamfirei et al., 2021b). An

exhaustive review on the current SOTA in defect de-

tection can be found in (Ren et al., 2021). The authors

present a plethora of approaches that use machine

learning. However, most of the presented methods

are quite complex and require much time in advance

to a possible usage. Besides all the semi-automatic

workflows, there are even use cases in VQI that are

completely manual human tasks without the help of

cameras, or any autonomous system (Nessle

˚

Asbrink,

2020).

3.1 Current Production Setting

Based on a use case analysis and the planning ap-

proach “product – production process – production

equipment” (Mueller et al., 2019a, cf.), the depen-

dencies between a product, the current production or

inspection process, and the current production equip-

ment must be considered to derive a holistic solution

concept (cf. Figure 1).

Example characteristics of a product can be shape,

size, or material. Especially a multi-variant produc-

tion as well as the production volume have an impact

on the later process and, thus, on the selection of the

production equipment needed for inspection. This use

case is based on the manufacturing of a spring from

the clutch pack of commercial vehicles. Springs are

produced in many different variants. These variants

can differ in terms of product size and the character-

istics of various features, such as diameter, material

thickness, or number of shaped holes.

The production process has constraints, e.g., cycle

time. One process is an inspection task that analyses

the surface of each spring to identify scratches, pres-

sure marks, or material spelling and classifies these as

NOK in comparison to OK parts with no faults (cf.

Figure 2). In a non-digitalised environment, the in-

spection process was performed manually by humans

in a monotonous and error-prone process. Since the

advent of Industry 4.0, an increasing amount of in-

spections is handled by an automated cell. Such cells

mostly use conventional image processing for work-

piece classification.

The inspection cell consists of the following pro-

duction equipment: A robot system for manipulating

the components, a camera dome as well as a sub-

sequent image processing system, and a human for

re-inspection by-hand. The spring is delivered via a

conveyor belt and automatically positioned under the

camera dome with the robotic system. Several images

are recorded from both sides of the component to cap-

ture the whole surface of each spring. The resulting

images are prepared for further processing applying

shape from shading (Zhang et al., 1999, cf.). This

technique enhances small surface defects by exposing

them from different angles with a flash, so that a three-

dimensional impression of the surface is provided.

Production-Ready End-to-End Visual Quality Inspection for Defect Detection on Surfaces Based on a Multi-Stage AI System

57

(a) In this use case a commercial vehi-

cle spring is considered as a product.

(b) The production process is repre-

sented by an automated inspection at

the production line.

(c) Used production equipment:

robot, camera dome, conventional

image processing, and human opera-

tors for re-inspection.

Figure 1: Planning approach for the development of an automated inspection process.

(a) pressure marks (b) scratches (c) material spelling (d) material inclusion

Figure 2: Examples of possible error features that need to be detected by the inspection system.

Image data is evaluated by a conventional image

processing software and the classification result is re-

ported to the cell controller. Depending on the result,

in this case OK or NOK, the component is released for

further assembly or made available to a human opera-

tor for re-inspection. The operator performs a final in-

spection of the spring via haptic feedback through pal-

pating any scratches and grooves, or via visual feed-

back by means of a close investigation of the object.

In case the component is defective, it is rejected and

thrown away, otherwise it is released for further as-

sembly. The current approach is far from being robust

in terms of a high accuracy in part classification. Due

to the complexity and individuality of possible de-

fects, classical image processing has reached its lim-

its. This results in a large number of parts incorrectly

classified as NOK, also called false-NOK, which in

turn leads to a time-consuming manual re-inspection.

The presented use case clearly shows the need for

a more sophisticated workflow and enhanced algorith-

mic performance. Production should aim at a classifi-

cation error rate converging towards zero eliminating

many drawbacks mentioned before moving towards

a fully automated production line. As a first step in

this direction, we develop a workflow called Artificial

Intelligence based Quality Inspection (AIQI). With

AIQI we introduce AI to the production floor utilis-

ing new ideas of classical visual computing before AI

processing to digitally optimise the data without the

need of any optical requirements engineering in ad-

vance to image acquisition (Ren et al., 2021). Fur-

thermore, we introduce a during production annota-

tion via a GUI, which is developed from scratch and

integrated into the production line. Combining SOTA

AI techniques, we use the collected and annotated

data to train a powerful and fast inferencing system

that is deployed in production replacing outdated sys-

tems. As proof for the superior performance of our

new workflow we conduct an evaluation of the old

system against AIQI and show its significant impact

on future production.

3.2 Material & Methods

AI systems usually need huge amounts of data to be

trained from scratch, at the same time events of in-

terest, here NOK-patterns, are seldom encountered

and consequently under-represented in a collected

dataset. To increase the amount of such data a tech-

nique called Data Augmentation (Wong et al., 2016;

Xu et al., 2016) is used. Hereby, transformed versions

of the original data are added to the training dataset.

Common transformations from image processing can

be used, like flipping, translations, zoom, lightning

changes and many more.

DL for image processing mainly uses CNNs,

which consist of many layers that can learn features,

like low-level edges or mid-level characteristics of a

provided problem (Yosinski et al., 2014). Based on

this fact, such already trained features can be trans-

ferred to new, similar tasks, so that CNNs do not

have to be trained from scratch, this process is called

Transfer Learning (Shin et al., 2016). We identify

three main CNN architectures through extensive ex-

IMPROVE 2024 - 4th International Conference on Image Processing and Vision Engineering

58

periments to be used in the production line, namely

ResNet (He et al., 2016), SqueezeNet (Iandola et al.,

2016), and AlexNet (Krizhevsky et al., 2012), as they

offer the best trade-off between performance and run

time to guarantee short cycle times with high detec-

tion quality.

FastAI

1

serves as basis for our development

(Howard and Gugger, 2020). This is a DL library

that provides high-level components to easily use and

apply AI techniques. Furthermore, low-level compo-

nents are provided to add new functionality. PyTorch

2

(Paszke et al., 2019) serves as the AI backend frame-

work to perform trainings. For being able to evaluate

many different CNN architectures, we use the Timm

library

3

(Wightman, 2019) as well as Torchvision

4

.

These libraries offer a collection of image models and

utilities to pull together a wide variety of SOTA archi-

tectures with the ability to reproduce ImageNet train-

ing results. All our trained models are exported to

the exchange format Open Neural Network Exchange

(ONNX) and executed in production with the runtime

accelerator ONNX Runtime

5

to ensure fast inferenc-

ing times. Communication between the peripheries

of the production station such as the Programmable

Logic Controller (PLC) and our annotation tool or the

inferencing application is realised with the integration

of the multi-platform Ethernet communication suite

Snap7

6

. The application and all its dependencies are

bundled with the help of PyInstaller

7

. We bundle ev-

erything this way to guarantee isolation of system de-

pendencies, and to ensure reproducibility.

3.3 AIQI Workflow

We present AIQI in this section. The main workflow

consists of two pipelines, one for the collection of

high-quality data in the production environment (Fig-

ure 3a and b) and one for the inference deployment at

production lines (Figure 3c).

Before an AI can accurately classify the surface

of, e.g., springs it is indispensable to acquire data and

help the system to gather correct annotations. Hu-

man experts, like line operators or quality assurance

staff, are involved in assisting an untrained AI to clas-

sify workpieces via inspection by-hand. Human in-

volvement gradually decreases over time until an ad-

ditional manual inspection is only required whenever

1

https://github.com/fastai/fastai

2

https://github.com/pytorch/pytorch

3

https://github.com/rwightman/pytorch-image-models

4

https://github.com/pytorch/vision

5

https://github.com/microsoft/onnxruntime/

6

http://snap7.sourceforge.net/

7

https://pypi.org/project/pyinstaller/

new features arise, respectively when the AI is not

confident about a classification. To accurately deter-

mine the confidence of an AI we also developed a

method that enables the confidence estimation of an

arbitrary CNN at run-time based on black-box access

to the CNN. This method is used in AIQI, for further

information have a look at (Woitschek and Schneider,

2022). The described data acquisition results in a data

set that is put into the system by means of a HMC

using an interface. This interface is tightly coupled

within the production process via a GUI, developed

especially for this purpose. Inspired by visual com-

puting, images are split into small sub-images, also

called patches, using a divide-and-conquer strategy

adapted from sliding window approaches, called Win-

dowing. First, the whole image of the workpiece is

presented to a human operator. For critical surface de-

fects the operator can select the image region that con-

tains an anomaly. The resulting marked area is then

split into patches, and these are presented to the oper-

ator besides the full view of the image. The operator

must select and classify each patch as OK (marked

green) or NOK (marked red) via a click operation in

the GUI. The results of the human classification and

the corresponding image data are used afterwards for

AI model training. Each generated data point allows

to improve the current classification accuracy via ad-

ditional training of existing models.

We introduce a visual computing step called Win-

dowing (Schneider et al., 2023) as an additional stage

in an AI based classification pipeline (see Figure 4).

The grey coloured window at the top of Figure 4 a-c

is moved with a defined step size over a defined re-

gion and determines sub-images of that region. Step

size of the window in x- and y-axis direction as well

as the size of the window h × w pixels can be modi-

fied at any time. However, the size of a single patch

must be decided once and stays fixed. The objective

of Windowing is to break down a large problem into

many small entities as shown at the bottom of Fig-

ure 4a-c. Instead of searching for complex error fea-

tures in high-resolution images, this approach allows

the error features to be located and classified in very

small sub-images. Thus, it is not necessary to specify

each feature at a whole. It is sufficient to assign each

sub-feature to its corresponding class.

The process therefore reduces the amount of data

to be analysed in each case while keeping the origi-

nal pixel resolution, which means there is no transfor-

mation of the data. The high-resolution sensor data

is broken down into many small patches at original

pixel resolution. In the workflow, as also shown in

the use case, Windowing is applied to each large-scale

image of the workpiece, so that many small patches,

Production-Ready End-to-End Visual Quality Inspection for Defect Detection on Surfaces Based on a Multi-Stage AI System

59

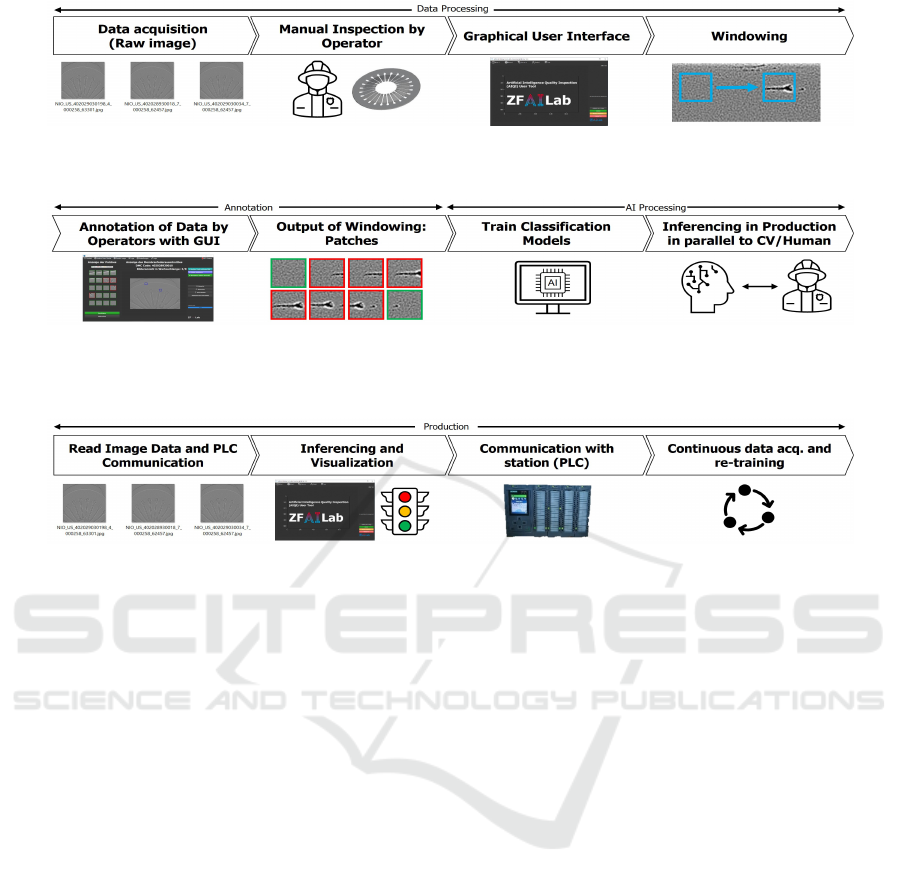

(a) Data Processing in advance of applying our workflow is composed of data acquisition, manual inspection by

human operators, setting up the annotation tool, and performing Windowing of the high-resolution large-scale

images.

(b) Assisted by the implemented GUI, human operators annotate the sub-images coming from Windowing as

OK or NOK. As soon as sufficient data has been collected, classification models can be trained and installed

into production lines, where AI inference can run in parallel to the old computer vision (CV) system and human

operators assist when AI lacks confidence.

(c) Each production line works independently now. Image data is acquired and read by the system via a PLC. The

production version of our GUI takes care for AI processing, that means inferencing as well as visualisation. The

PLC processes the results and saves them to a database. During this process additional data may be generated

and used for continuous monitoring and training to enhance current models.

Figure 3: Artificial Intelligence based Quality Inspection (AIQI) Workflow.

which are assigned to the OK or NOK class, are gen-

erated. Theoretically, Windowing is not only applica-

ble to image data but can also be transferred to other

sensor data.

Each individual patch is annotated and evaluated

by-hand at the production start-up phase, as shown

in Figure 4. The evaluation into class 1 and class 2,

which means OK and NOK within the scope of qual-

ity inspection, is performed online during production

via a GUI. The generated data and the associated

classification labels are used for model training. Dur-

ing data annotation it is important to determine the

ground truth based on the judgement of multiple hu-

man experts independently. Then, only data annotated

consistently by everyone is kept ensuring increasing

data quality for the ground truth as basis for AI train-

ing. At this point we want to emphasise once more the

importance of data quality as already a small number

of wrongly annotated data can disrupt AI model train-

ing significantly (Beggel et al., 2020, cf.).

In the presented workflow, a high quality of col-

lected data and corresponding annotations must be en-

sured, which means each classification of each sub-

image must represent the truth as defined by quality

assurance. Each miss-classified data point will lead

to a decrease in AI model performance. Hence, dif-

ferent procedures are integrated into the data quality

process, which are applied to known annotated data

as well as to unknown not yet annotated data. Exam-

ples are filtering based on high loss values both dur-

ing training and validation, or confidence analyses of

each pair of ground truth and predicted outcomes, for

example each NOK that is really predicted as NOK.

As soon as a trained model is available, the clas-

sification of the patches is no longer performed by a

human operator, but autonomously by the AI. In cases

where the AI is unsure about the assignment as OK or

NOK, e.g., because the error is a novel and very indi-

vidual feature, the AI can ask the operator for advice

and obtains help. The operator inputs the feedback via

the GUI. The associated data is collected in the back-

ground and will be available for future model training.

Through this approach, the accuracy of the model can

be continuously improved.

Obviously, it does not suffice to classify only a

single patch of several high-resolution images to as-

sign the result with certainty to the workpiece. Hence,

we developed a multi-stage inferencing pipeline for a

IMPROVE 2024 - 4th International Conference on Image Processing and Vision Engineering

60

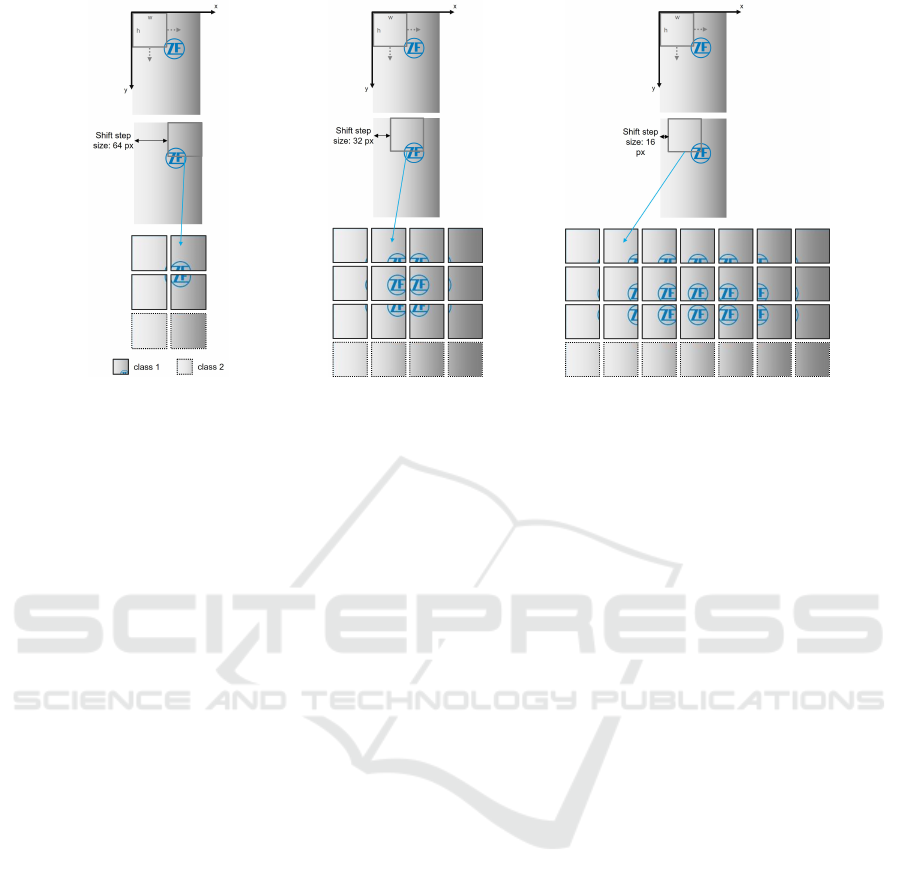

(a) (b) (c)

Figure 4: Divide-and-conquer approach via Windowing. (a) A window of size h × w pixels moves horizontally and vertically

over a selected area with a configurable but fixed step size, which is also specified in pixels. Thereby, the image is split into

many sub-images, also called patches. Patches are annotated by a human operator into classes, e.g., OK and NOK. Non-

overlapping patches are generated in the initial Windowing step. (b) Stage two of our multi-stage classification of patches is

shown. By altering the step size to a smaller value than the patch size, overlapping patches are generated. (c) The final stage

with even smaller step size is shown. Combining these three, or even more, stages leads to enhanced feature detection.

reliable usage at production lines as depicted in Fig-

ure 4 as sketch. An initial inspection of each high-

resolution image is performed by applying Window-

ing with maximal step size, so that non-overlapping

patches are generated as shown in Figure 4a. The

subsequent classification uses a fast AI model with a

high false-NOK rate, which means many patches are

identified as NOK although they are OK. The goal

behind this procedure is to detect each possible de-

fective patch, so that the likelihood to miss a NOK

workpiece tends towards zero. All areas around iden-

tified NOK patches are analysed at least once more.

These areas are sub-sampled with a smaller step size,

so that overlapping patches are generated as shown in

Figure 4b. Now, a slower more precise AI model is

used to identify only patches that are really NOK, as

it should be prevented to generate a lot of additional

manual work due to unnecessary re-inspections. De-

pending on production constraints like cycle-times the

procedure can be extended with a third stage as shown

in Figure 4c. Subsequent stages are executed at differ-

ent granularity applying AI models with varying ac-

curacy towards less false-NOK predictions. The final

patch classification can be further adjusted in terms

of sensitivity. As example, a workpiece can be cate-

gorised as NOK based on a defined minimum of NOK

patches, which could be one for a very high sensitiv-

ity and possibly more false-NOKs or five within a de-

fined area size for less sensitivity. This number can be

calibrated according to different workpieces and situ-

ations. The multi-stage procedure allows features to

be inspected from different perspectives and provides

a more accurate classification result adaptable to the

needs of individual use cases. At this point AIQI ben-

efits from the usage of small patches in contrast to

whole high-resolution images because novelties can

be analysed completely isolated from workpiece ge-

ometries and image sizes The AI is not confused and

mislead from the surrounding environment near any

anomaly, which often is a problem when applying DL

(Heaven et al., 2019).

A running production line incorporates additional

modules (cf. Figure 3c). An additional production-

ready version of our GUI is installed and serves as

brain of the quality inspection. Besides running the

AI inference, results are visualised and the HMC

takes place when the AI asks for it. Furthermore,

results are processed and saved to a database via a

PLC. Additional data may be generated at this point

for continuous monitoring or to enhance current mod-

els.

4 USE CASE RESULTS

We show the usefulness and impact of the developed

workflow by means of the presented workpiece pro-

duction of springs. Two production lines were se-

lected as basis for the AIQI development and eval-

uation. Besides the already described workflow, we

Production-Ready End-to-End Visual Quality Inspection for Defect Detection on Surfaces Based on a Multi-Stage AI System

61

used SOTA techniques from AI research and devel-

opment to ensure that no potential is wasted. Before

presenting the setup and results the most important

ingredients will be recapped.

We selected PyTorch and FastAI as main develop-

ment frameworks for implementation as well as train-

ing and evaluation of our AIQI workflow. Due to low

data availability and faster convergence rates all mod-

els were learned with pre-trained architectures.

As already shown before, cf. Figure 3, we had

to start with data acquisition as not a single image

was available at that time. The whole pipelines in-

cluding annotation routines, image data quality assur-

ance, and the GUI were developed upfront and set up

in production. During data collection we developed

the training and inferencing routines and tested these

regularly with increasing data availability to ensure

robust working of the software.

For the experiments we used 19,265 patches parti-

tioned into the classes OK and NOK with 15,600 OK

and 3,665 NOK. As AIQI is able to include an arbi-

trary number of classes with no additional effort, we

tweaked the training utilizing this fact. OK patches

were split into the classes OK and false-NOK, which

resulted in 12,638 OK and 2,962 false-NOK. The

AI was then trained with three classes, and a sub-

sequent inference was mapped onto the classes OK

and NOK again for decisions on large-scale images

in production. The applied trick halved the error-rate

in upcoming results. Due to production constraints,

in particular cycle times, not only the best perfor-

mance in terms of accuracy was important, but also

a runtime smaller than allowed. Hence, we evaluated

1065 different CNN architectures to identify an opti-

mal trade-off. We refrain from presenting all of these

results, as this would not add any value to the pre-

sented work. The data patches were split into a train-

ing and a validation set with an 80 to 20 ratio and

equally distributed classes in both sets. For testing we

gathered additional data sets of workpieces that were

completely independent of the training patch data set.

The whole inferencing workflow was applied to all

high-resolution images.

Based on the experiments, we identified three ar-

chitectures for the final inferencing pipeline used in

the described multi-stage approach. The multi-stage

approach was fixed using SqueezeNet in round one,

AlexNet in round two, and ResNet as final decision

step for the classification. This results in a very fast

first stage and a very accurate last stage. We only re-

port performance in terms of accuracy for ResNet, as

stage three determines the final classification. For the

training set an error rate of 0.0325% was achieved,

which shows that training converged quite well. The

validation set delivered an error rate of 3.5%, which

was the best possible trade-off between accuracy and

run-time also incorporating the additional stages as

pre-selection and acceleration steps.

Before installing the AI in production as indepen-

dent system, we had to convince quality assurance

that our workflow outperforms the old one. Hence, a

quality assurance approved data set of 386 whole im-

ages, which consisted of 298 OK and 88 NOK work-

pieces, was composed and approved for a final test.

The old system was compared against AIQI. An im-

portant remark here is, that both systems did not con-

fuse real NOK workpieces as OK, so that no defective

parts passed the quality check. Hence, the goal was to

reduce the false-NOK rate while keeping the false-

OK rate at zero. The old system had an error rate

of 27%, whereas our AI workflow had an error rate

of 3.1%. This convinced quality assurance to install

the AI in parallel to the old system for a long-term

test. The following months a long-term test was per-

formed running both systems in parallel. The long-

term evaluation was based on 9,020 workpieces. The

old system performed at an error-rate of 16.83% and

the AI at 2.80%. In sum, the validation set, the test

set, as well as the long-term test set performed con-

sistently in terms of error rates, which is a strong hint

for a well-trained AI. Consequently, the old system

was shut down after the evaluation.

5 DISCUSSION

After having presented AIQI and an use case appli-

cation that is already deployed at a production floor

including superior results compared to a traditional

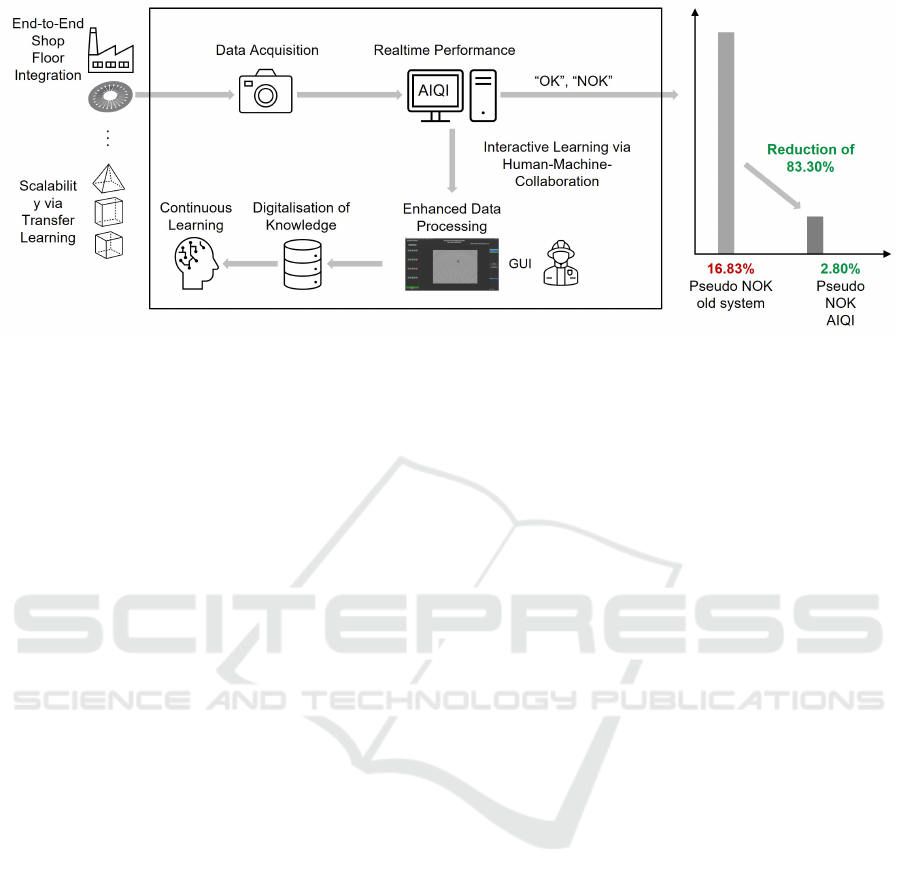

workflow (cf. Figure 5), we concentrate on the indi-

vidual steps and work out the benefits and limitations

of AIQI.

Compared to more complex AI methods, e.g.,

bounding box annotation in object detection, initial

data collection and the connected annotation work-

flow during production are much easier with AIQI.

Firstly, due to system design as annotation and pro-

duction are not separated processes, secondly, as the

annotation workflow itself exhibits a strongly reduced

complexity. Looking at bounding boxes, tagging fea-

tures does not lead to unique results for different an-

notators as the variability in bounding box sizes needs

much more tedious work and, hence, is more error

prone despite a higher effort. In our approach there

is a clearly defined workflow to generate distinct sub-

images and it is only needed to assign them to a class.

Furthermore, the reduced complexity makes our ap-

proach less data hungry than standard bounding box

IMPROVE 2024 - 4th International Conference on Image Processing and Vision Engineering

62

Figure 5: Summary of our contributions and achievements as workflow for AI based defect detection. Enhanced data pro-

cessing via Windowing is one of the crucial steps within a shop floor integration to deliver an End-to-End solution. Acquired

sensor data is analysed in real time by AIQI utilising its multi-stage AI approach based on DL. Cutting-edge AI technologies

in combination with conventional methods integrate the advantages of both worlds. Hereby, interactive learning is realised via

HMC to digitalise process know-how by means of a GUI and its annotation functions. The system is easily scalable because

of integrated transfer learning methods toward further applications. In the presented use case, AIQI reduced the pseudo error

rate, depicted as Pseudo NOK, of the old system by 83.30% from 16.83% down to 2.80%.

approaches. Other ways of defect identification are at

least as complex as object detection which highlights

the importance of our AIQI approach.

The proposed annotation workflow developed in

our GUI profits from an effect called Gaming With

A Purpose (GWAP) as described in (Venhuizen et al.,

2013). Hereby, labelling tasks are presented as games

to the user, but serve a purpose to the owner of the

product, respectively the principal of the annotation

task. Such GWAP’s are nowadays used in the form of

captchas where each user identifies objects by click-

ing on boxes. Compared to bounding box approaches,

where it is needed to draw appropriate boxes for de-

fects, clicking on readily prepared boxes is much eas-

ier. This increases the motivation of the user for the

data labelling task to do a good job. The authors have

shown that an increased motivation results in higher

quality when annotating data, which was one more

reason we developed AIQI. We are aware that the

facilitated annotation workflow does not solve each

kind of problem. Humans still suffer from imperfec-

tion, and it is quite likely that errors occur during

labelling that can mislead any AI training. Hence,

ground truth data must be independently validated

by different persons and the current workflow must

be challenged and developed further. AI-based sup-

port via trained models as well as semi-automated la-

belling assistance can also be enhanced further to re-

duce labelling errors and effort.

Besides the advantages for data labelling, Win-

dowing also brings significant algorithmic advan-

tages. Identifying defects and anomalies on

large-scale images without losing pixel resolution

and, hence, detection quality is very challenging.

Analysing whole images as basis for classification

is very compute intensive and requires a lot of data

covering the possible space of occurring situations

like specific errors. Applying Windowing, which is a

divide-and-conquer inspired splitting of a large-scale

image into smaller sub-images, resolves such issues

and facilitates many tasks. Hereby, a large complex

problem is broken down into many small and simple

problems that can be classified more easily and ef-

ficiently. Furthermore, training an AI with patches

that are context independent of its environment pre-

vents focusing on the surroundings, which increases

the ability to learn what is expected.

When cutting an image into many small pieces

to find erroneous spots it is important to create some

logic around the whole system arising from this idea.

Classification of a single patch isn’t enough to deter-

mine the quality of a produced part robustly. Conse-

quently, we developed a multi-stage approach, which

has the advantage to be more reliable due to multiple

factors used for a decision, so that more knowledge

than only single patch classifications is incorporated.

The multi-stage approach also has a higher degree of

flexibility to adapt to the classification process. For

example, sensitivity can be varied in subsequent steps

by refining the minimum error size or the number of

patches with detected errors that are needed to judge

a whole image as containing at least one defect or

anomaly. Nevertheless, a multi-stage AI is often not

usable out of the box, hence, additional work may be

Production-Ready End-to-End Visual Quality Inspection for Defect Detection on Surfaces Based on a Multi-Stage AI System

63

needed to modify AIQI.

Windowing is tailored towards basic classification

tasks, which are well researched, fast, robust, and do

not require complicated workflows or architectures.

In a production setup, image processing speed is one

of the main bottlenecks that influences real-time per-

formance of vision systems (Ren et al., 2021). The

simplicity of our approach to break down a hard task

into many easy tasks delivers a huge benefit towards

this problem, as we showed in the depicted use case.

It may be misleading that we argue with shorter run-

times and easier application, as there are additional

steps involved that cost time and need to be integrated.

However, the developed multi-stage pipeline makes

it possible to identify important areas of large-scale

images to only concentrate on small percentages for

the complex operations. The need for such an initial

search may require some time but saves much more

time in subsequent steps. Furthermore, we sped up in-

ferencing times by converting models to the exchange

format ONNX. Utilizing the ONNX format and its

runtime environment ONNX Runtime provides fast

computation times, so that the inferencing time can be

sped up drastically compared with data formats from

other frameworks, like PyTorch or TensorFlow. This

is crucial in time sensitive applications, especially on

the production floor, where each part has a predeter-

mined cycle time for each step to minimise delays and

maximise the number of produced parts.

Additional benefits emerge that make future de-

velopments easier and more reliable in terms of tack-

ling new use cases. Patches can be collected as kind

of an error catalogue for surface defects and anoma-

lies. This offers an adaption onto other variants from

a workpiece, like springs with a varying diameter or

differing holes, out of the box with minimal additional

effort. Furthermore, other produced workpieces also

share properties regarding their surface, like the ma-

terials they consist of, hence, also errors occurring on

such surfaces look similar. Consequentially, a knowl-

edge transfer from collected and annotated data of

workpieces to new or not yet included workpieces is

possible. Due to the splitting into small sub-images

the collected error catalogue becomes even more in-

formative. Instead of templates for complete errors,

we collect subsets or fragments from varying angles

and positions. Using such sub-error parts or sub-

anomaly parts the developed multi-stage approach

makes it possible to put these together like in a jigsaw

and recognise even unseen complete errors that con-

sist of the sub-parts. That means, scalability becomes

simpler, and it is like working on the same data as size

of images and defects does not play an important role

for sub-images of the same small size. With a grow-

ing number of use cases this leads to a comprehensive

error database for surface defects and anomalies as a

digitalization of human knowledge that can be utilised

for the development of powerful AI methods.

Where there is light, there is also shadow. We

should not expect to have solved all problems regard-

ing the detection of surface errors and anomalies as

soon as we identified a use case. There will always

occur defects never seen before, or materials that look

the same when OK may develop different properties

and challenge the AI based quality inspection. Close

monitoring and regular human quality controls still

need to be performed besides the ability of the AI to

ask for help and additional data that can be added to

the models via continuous learning strategies. Exactly

such strategies were put into practice in the spring

use case during the last year. Additional data was

collected and annotated based on uncertainties from

AI as well as from observed problems for continu-

ously updating running models. Based on the most

recently produced 16,153 workpieces we performed

a long-term comparison of the initially deployed and

latest up-to date models. The initial setup led to an er-

ror rate of 4.42%, which shows that over time models

can decrease as well as that not all kind of errors had

been covered. The latest setup led to an error rate of

2.58%, which is even better than the final evaluation.

Summarizing based on the discussed advantages

and limitations, AIQI turned out to be a promising ad-

dition to a digitalised production incorporating com-

puter vision and machine learning. Realising more

use cases and utilising the capabilities already present

will give additional insights to further extensions and

a rich database for surface defect recognition.

6 CONCLUSION

The main contribution of our work is a multi-stage AI

system for image processing tasks. Instead of using a

sophisticated black box like end-to-end algorithm that

is not configurable in between, we propose to break-

down a complex task into small and easy sub-tasks

that can be handled with well-understood basic AI ap-

proaches. Besides enhanced control over data collec-

tion and training, AIQI is more flexible due to manual

modelling and configurability. This makes it possible

to introduce additional steps based on, e.g., defined

metrics and confidences to control the behaviour of

the whole process. Furthermore, it is easier to under-

stand the inner workings and, hence, to explain the

system to operators that use it in day-to-day produc-

tion. The ability to explain, what the AI is doing and

why, increases transparency and hence acceptance of

IMPROVE 2024 - 4th International Conference on Image Processing and Vision Engineering

64

the system. The interwoven human machine collab-

oration ensures both digitalisation of human knowl-

edge and high-quality performance due to continu-

ously updated data and trained models. The AI sys-

tem asks for help if unclear instances are detected and

incorporates the human answers into future assess-

ments.

The presented workflow can be extended in sev-

eral ways, like introducing a higher degree of de-

tail than only OK and NOK labels as we did by in-

troducing false-NOK labels, adding more stages if

needed, changing the basic AI algorithm, adapting ex-

isting models to similar problems via transfer learn-

ing, or tuning sensitivity based on various metrics

and defined confidence measures. Numerous options

for manual modelling combined with SOTA AI algo-

rithms make the process versatile. A further option is

the generation and use of synthetic data, which could

be incorporated into future models. Such data could

even enforce a deployment at production start without

ever having produced any part before.

Scalable and accurate quality inspection with lit-

tle maintenance effort is fundamental for production.

The implemented workflow and all the automated

processes as well as the easy deployment as appli-

cation make our AI-based quality inspection work-

flow a great tool for a fast time-to-market due to short

and efficient development cycles. The knowledge dig-

italisation of human experts offers a huge business

value. There is no need to artificially define any er-

ror catalogue of what could happen but rather it suf-

fices to collect and annotate data based on a running

production line. The resulting knowledge database is

not only more precise than predicted anomalies for a

workpiece but also is transferable to all kind of similar

problems in the future.

We conclude that our workflow is suited for a wide

range of applications and, hence, should be taken into

consideration for VQI tasks in a production setting.

ACKNOWLEDGEMENTS

We thank the shop floor in Schweinfurt, especially

Michael Huebner and Daniel Joerg for the close col-

laboration and their continuous availability. Fur-

thermore, we thank Andreas Dorsch who made this

project possible with his enthusiasm and ongoing sup-

port.

7 FUNDING

The research was supported by funding from Bun-

desministerium f

¨

ur Wirtschaft und Klimaschutz

(BMWK) in the project Vernetzter digitaler Assistent

f

¨

ur das Datengetriebene Engineering von Roboter-

basierten Produktionsanlagen (VADER, 01.01.2023 –

31.12.2025).

REFERENCES

Azamfirei, V., Granlund, A., and Lagrosen, Y. (2021a).

Multi-layer quality inspection system framework for

industry 4.0. International Journal of Automation

Technology, 15(5):641–650.

Azamfirei, V., Granlund, A., and Lagrosen, Y. (2021b).

Multi-layer quality inspection system framework for

industry 4.0. International journal of automation

technology, 15(5):641–650.

Beggel, L., Pfeiffer, M., and Bischl, B. (2020). Robust

anomaly detection in images using adversarial au-

toencoders. In Brefeld, U., Fromont, E., Hotho, A.,

Knobbe, A., Maathuis, M., and Robardet, C., edi-

tors, Machine Learning and Knowledge Discovery in

Databases, pages 206–222, Cham. Springer Interna-

tional Publishing.

Chao, S.-M. and Tsai, D.-M. (2010). Anisotropic diffusion

with generalized diffusion coefficient function for de-

fect detection in low-contrast surface images. Pattern

Recognition, 43(5):1917–1931.

Du, W., Shen, H., Fu, J., Zhang, G., and He, Q. (2019).

Approaches for improvement of the x-ray image de-

fect detection of automobile casting aluminum parts

based on deep learning. NDT & E International,

107:102144.

Golnabi, H. and Asadpour, A. (2007). Design and appli-

cation of industrial machine vision systems. Robotics

and Computer-Integrated Manufacturing, 23(6):630–

637.

Hafizi, M., Jamaludin, S., and Shamil, A. (2019). State of

the art review of quality control method in automotive

manufacturing industry. In IOP Conference Series:

Materials Science and Engineering, volume 530, page

012034. IOP Publishing.

He, K., Zhang, X., Ren, S., and Sun, J. (2016). Deep resid-

ual learning for image recognition. In Proceedings of

the IEEE conference on computer vision and pattern

recognition, pages 770–778.

Heaven, D. et al. (2019). Why deep-learning ais are so easy

to fool. Nature, 574(7777):163–166.

Howard, J. and Gugger, S. (2020). Fastai: A layered api for

deep learning. Information, 11(2).

Huangpeng, Q., Zhang, H., Zeng, X., and Huang, W.

(2018). Automatic visual defect detection using tex-

ture prior and low-rank representation. IEEE Access,

6:37965–37976.

Iandola, F. N., Han, S., Moskewicz, M. W., Ashraf, K.,

Dally, W. J., and Keutzer, K. (2016). Squeezenet:

Production-Ready End-to-End Visual Quality Inspection for Defect Detection on Surfaces Based on a Multi-Stage AI System

65

Alexnet-level accuracy with 50x fewer parame-

ters and¡ 0.5 mb model size. arXiv preprint

arXiv:1602.07360.

Inman, R. R., Blumenfeld, D. E., Huang, N., and Li, J.

(2003). Designing production systems for quality: re-

search opportunities from an automotive industry per-

spective. International journal of production research,

41(9):1953–1971.

Jia, H., Murphey, Y. L., Shi, J., and Chang, T.-S. (2004).

An intelligent real-time vision system for surface de-

fect detection. In Proceedings of the 17th Inter-

national Conference on Pattern Recognition, 2004.

ICPR 2004., volume 3, pages 239–242. IEEE.

Knop, K. (2020). Indicating and analysis the interrelation

between terms-visual: management, control, inspec-

tion and testing. Production Engineering Archives, 26.

Kopardekar, P., Mital, A., and Anand, S. (1993). Manual,

hybrid and automated inspection literature and current

research. Integrated Manufacturing Systems.

Krizhevsky, A., Sutskever, I., and Hinton, G. E. (2012). Im-

agenet classification with deep convolutional neural

networks. Advances in neural information processing

systems, 25:1097–1105.

Li, W.-C. and Tsai, D.-M. (2012). Wavelet-based defect

detection in solar wafer images with inhomogeneous

texture. Pattern Recognition, 45(2):742–756.

Malamas, E. N., Petrakis, E. G., Zervakis, M., Petit, L., and

Legat, J.-D. (2003). A survey on industrial vision sys-

tems, applications and tools. Image and vision com-

puting, 21(2):171–188.

Mueller, R., Franke, J., Henrich, D., Kuhlenkoetter, B.,

Raatz, A., and Verl, A. (2019a). Handbuch Mensch-

Roboter-Kollaboration. Carl Hanser.

Mueller, R., Vette, M., Masiak, T., Duppe, B., and Schulz,

A. (2019b). Intelligent real time inspection of rivet

quality supported by human-robot-collaboration. SAE

Technical Paper, 2(2019-01-1886).

Nessle

˚

Asbrink, M. (2020). A case study of how industry

4.0 will impact on a manual assembly process in an

existing production system: Interpretation, enablers

and benefits.

Paszke, A., Gross, S., Massa, F., Lerer, A., Bradbury, J.,

Chanan, G., Killeen, T., Lin, Z., Gimelshein, N.,

Antiga, L., et al. (2019). Pytorch: An imperative style,

high-performance deep learning library. Advances in

neural information processing systems, 32.

Raabe, H., Myklebust, O., and Eleftheriadis, R. (2017). Vi-

sion based quality control and maintenance in high

volume production by use of zero defect strategies. In

International Workshop of Advanced Manufacturing

and Automation, pages 405–412. Springer.

Ren, Z., Fang, F., Yan, N., and Wu, Y. (2021). State of

the art in defect detection based on machine vision.

International Journal of Precision Engineering and

Manufacturing-Green Technology, pages 1–31.

Schneider, G., Masiak, T., Trampert, P., and Schmidt, F.

(2023). Pr

¨

ufen eines pr

¨

uflings, patent number 10 2021

210 572.6.

Schwab, K. (2017). The fourth industrial revolution. Cur-

rency.

See, J. E., Drury, C. G., Speed, A., Williams, A., and Kha-

landi, N. (2017). The role of visual inspection in the

21st century. In Proceedings of the Human Factors

and Ergonomics Society Annual Meeting, volume 61,

pages 262–266. SAGE Publications Sage CA: Los

Angeles, CA.

Shin, H.-C., Roth, H. R., Gao, M., Lu, L., Xu, Z., Nogues,

I., Yao, J., Mollura, D., and Summers, R. M. (2016).

Deep convolutional neural networks for computer-

aided detection: Cnn architectures, dataset charac-

teristics and transfer learning. IEEE transactions on

medical imaging, 35(5):1285–1298.

Soukup, D. and Huber-M

¨

ork, R. (2014). Convolutional neu-

ral networks for steel surface defect detection from

photometric stereo images. In International Sympo-

sium on Visual Computing, pages 668–677. Springer.

Tsai, D.-M., Wu, S.-C., and Chiu, W.-Y. (2012a). Defect de-

tection in solar modules using ica basis images. IEEE

Transactions on Industrial Informatics, 9(1):122–131.

Tsai, D.-M., Wu, S.-C., and Li, W.-C. (2012b). Defect de-

tection of solar cells in electroluminescence images

using fourier image reconstruction. Solar Energy Ma-

terials and Solar Cells, 99:250–262.

Venhuizen, N., Evang, K., Basile, V., and Bos, J. (2013).

Gamification for word sense labeling. In Proceed-

ings of the 10th International Conference on Compu-

tational Semantics (IWCS 2013).

Wightman, R. (2019). Pytorch image models. https:

//github.com/rwightman/pytorch-image-models.

Woitschek, F. and Schneider, G. (2022). Online black-box

confidence estimation of deep neural networks. In

33rd IEEE Intelligent Vehicles Symposium (IV22).

Wong, S. C., Gatt, A., Stamatescu, V., and McDonnell,

M. D. (2016). Understanding data augmentation for

classification: when to warp? In 2016 international

conference on digital image computing: techniques

and applications (DICTA), pages 1–6. IEEE.

Xu, Y., Jia, R., Mou, L., Li, G., Chen, Y., Lu, Y., and Jin, Z.

(2016). Improved relation classification by deep recur-

rent neural networks with data augmentation. arXiv

preprint arXiv:1601.03651.

Yazidi, K., Darmoul, S., and Hajri-Gabouj, S. (2018). Intel-

ligent product quality control and defect detection: A

case study. In 2018 International Conference on Ad-

vanced Systems and Electric Technologies (IC ASET),

pages 98–103. IEEE.

Yosinski, J., Clune, J., Bengio, Y., and Lipson, H. (2014).

How transferable are features in deep neural net-

works? In Advances in neural information processing

systems, pages 3320–3328.

Zhang, R., Tsai, P.-S., Cryer, J. E., and Shah, M. (1999).

Shape-from-shading: a survey. IEEE transactions on

pattern analysis and machine intelligence, 21(8):690–

706.

IMPROVE 2024 - 4th International Conference on Image Processing and Vision Engineering

66