Model-Based Auto-Commissioning of Building Control Systems

Philipp Zech

1 a

, Emanuele Goldin

1

, Sascha Hammes

2 b

, David-Geisler Moroder

2 c

,

Rainer Pfluger

2

and Ruth Breu

1

1

Department of Computer Science, University of Innsbruck, Technikerstrasse 21a, Innsbruck, Austria

2

Unit of Energy Efficient Building, University of Innsbruck, Technikerstrasse 13, Innsbruck, Austria

fl

Keywords:

Model-Based Development, Building Information Modeling, Auto-commissioning, Digital Twins.

Abstract:

Digital twins are valuable instruments for model-based design, commissioning, and operation, with signifi-

cant applicability potential in the construction industry. Whereas with Building Information Modeling (BIM)

a standard for the representation of building models has been established, these models lack (i) modeling sup-

port for building control systems, and (ii) tool-based automation support for model-based auto-commissioning

of building automation systems, an instrumental factor in putting a digital twin in operation. In this paper,

we present a domain-specific language (DSL), its modeling methodology, and tool support to augment and

condition BIM models for auto-commissioning. Preliminary results from an early prototype evaluation using

the Technology Acceptance Model demonstrate the feasibility of our proposal in contributing to the improve-

ment of building operations by facilitating auto-commissioning of building control systems and subsequent

commissioning of digital twins.

1 INTRODUCTION

Digital twins (DT) represent virtual replicas of cyber-

physical systems (CPS) comprising (Grieves and

Vickers, 2017)

• a virtual entity, i.e., the assemblage of models de-

scribing the CPS’ manifestation,

• a physical entity, i.e., the running instance of the

‚CPS, and

• interchanged data and connection between the vir-

tual and physical instance, respectively,

and represent valuable instruments the for model-

based design and operation of CPSs. DTs provide

increased planning and operational efficiency, de-

creased interruption, improved product quality, opti-

mized resource utilization, and enhanced innovation

through simulation and analysis of real-time data (Se-

meraro et al., 2021). Due to their capacity to auto-

mate building operations, the architecture, engineer-

ing, construction, and operation (AECO) domain is

increasingly interested in adopting DTs to improve

project design, planning, construction management,

a

https://orcid.org/0000-0002-4952-4337

b

https://orcid.org/0000-0001-5821-5053

c

https://orcid.org/0009-0002-3641-6182

resulting in improved collaboration, cost savings,

schedule optimization, and better asset performance

throughout the entire lifecycle of buildings (Ozturk,

2021). A DT for automating building operations

leverages a virtual representation of a building that in-

corporates building control system (BCS) data to pro-

duce an accurate digital model. It enables building

planners and operators to design, simulate and opti-

mize BCS in the planning phase and during operation

by auto-commissioning the BCS from the DT during

initial building operation and later re-commissioning.

Specifically, the integration of DTs, Building Infor-

mation Modeling (BIM), and building automation

enables stakeholders to create a model-based, dy-

namic, high-fidelity digital representation of a build-

ing for building operations and Computer-Aided Fa-

cility Management (CAFM). BIM and BCS are two

distinct, yet interdependent technologies and method-

ologies that perform complementary roles in the de-

sign, construction, and operation of buildings, viz.,

during the

• design phase, BIM can provide valuable and de-

tailed information for planning and simulation so

that calculations, system dimensioning and spec-

ifications can be substantiated and optimized. In-

formation that subsequently informs design deci-

sions for the BCS;

Zech, P., Goldin, E., Hammes, S., Moroder, D., Pfluger, R. and Breu, R.

Model-Based Auto-Commissioning of Building Control Systems.

DOI: 10.5220/0012554000003690

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 26th International Conference on Enterprise Information Systems (ICEIS 2024) - Volume 2, pages 121-128

ISBN: 978-989-758-692-7; ISSN: 2184-4992

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

121

• construction phase, coordination between BIM

and BCS trades ensures that BCS components are

installed and configured per design specifications;

• operation phase, BCS are auto-commissioned

from the BIM model and are responsible for

the surveillance, control, and optimization of the

building in real-time. They utilize sensors, con-

trols, and data analytics to manage HVAC, light-

ing, and security systems, among others. Benefi-

cially, this auto-commissioning substantially can

reduce costs and errors during initial on-site oper-

ations.

The relationship between BIM and BCS is becoming

increasingly important as organizations seek to create

smart and connected buildings (Vieira et al., 2020).

BCS data can be integrated with BIM, allowing work-

ing with a dynamic digital representation of the build-

ing. This integration enables better real-time monitor-

ing and control of BCS and can facilitate predictive

maintenance and contribute to the traceability of de-

cisions across all construction phases (Ozturk, 2021).

While BIM has led to the standardization of

the representation of building models (cf. Industry

Foundation Classes (ISO, 2018); IFC), these mod-

els lack (i) collaborative modeling support among

different trades, which encompasses BCS, and (ii)

tool-based automation support for model-based auto-

commissioning (and re-commissioning, respectively)

of BCS, an instrumental factor in automatically

putting a digital twin in operation (Ozturk, 2021).

Specifically, BIM models lack

• modeling support for BCS,

• tool support for the processing of BCS trades in

BIM models, i.e., BCS information is locked in-

side closed tools, and

• tool support for collaborative work among differ-

ent trades over the building lifecycle.

Motivated by these conceptual and technological

gaps, this paper explores the extension of BIM to in-

clude modeling and pre-configuration support of BCS

for model-based auto-commissioning as a precursor

for establishing a DT. We propose a modeling for-

malism with appropriate tool support for conditioning

BIM models for model-based auto-commissioning of

BCS. Specifically, we propose a graphical domain-

specific language (DSL) and its implementation atop

an existing BIM modeling tool that enables the afore-

said scenarios. The DSL is equipped with the

necessary tooling regarding the extraction of BCS

trades from the BIM model as required for auto-

commissioning. The feasibility of our proposal is

evaluated using a survey grounded in the Technology

Acceptance Model (TAM).

Organization. Sec. 2 presents the challenges and

contributions of our work. Sec. 3 introduces our pro-

posed solution. Sec. 4 discusses our proposed model-

ing methodology and the tool implementation of our

DSL. Sec. 5 evaluates our proposal and positions it

w.r.t. related work. We conclude in Sec. 6.

2 CHALLENGES AND

CONTRIBUTIONS

In light of our discussions in Sec. 1 we identify the

following obstacles currently impeding model-based

auto-commissioning of buildings for DTs, viz.:

1. Little to no interaction between stakeholders (e.g.,

building designers, building physicists, and build-

ing operators) as of lacking modeling formalisms

for BIM-based configuration of BCS.

2. No tool support for model-based auto commis-

sioning.

3. No foundation for establishing a BIM-based DT

for tracing and optimizing a building’s perfor-

mance throughout its life cycle.

Commensurate with these, we introduce a DSL with

an accompanying modeling methodology and appro-

priate tool support for the systematic conditioning of

BIM models for model-based auto-commissioning of

BCS. In synopsis, we deliver a model-based tool en-

vironment for

• modeling BCS components and their topology in

buildings,

• describing runtime properties of BCS, and

• model-based auto-commissioning of BCS, i.e.,

automated deployment of runtime artifacts into

BCS as a foundation for commissioning DTs

thereby targeting the following research questions:

RQ1. How can collaboration between experts in

various trades for building design and build-

ing operation be improved?

RQ2. How to implement pre-configuration of BCS

in BIM models?

RQ3. How to auto-commission BCS from BIM

models for ultimately establishing BIM-

based DTs?

We have structured our contribution as Design Sci-

ence Research (DSR) (Wieringa, 2014) and produced

a tool environment as an artifact. The development

of our artifact follows a systematic process, starting

with gathering requirements and ending with creating

prototypes, tool evaluations, and obtaining feedback

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

122

from experts. Our artifact is implemented as a solu-

tion to the following design science problem, outlined

using the DSR template:

Improve BIM-based DTs for building control (context)

by designing a modeling methodology for conditioning

BIM models for building control (artifact)

that satisfies pre-configuration of BCS (requirement)

to deliver model-based auto-commissioning of BCS. (goal)

DSR usually refers to an artifact as a prototype

at Technology Readiness Level 3 (TRL3), represent-

ing a conceptual solution at an early stage of tech-

nology development. Using model-based engineer-

ing and a cyber demonstrator, our proposal achieves

TRL5 (c.f. Sec. 3).

3 MODEL-BASED

AUTO-COMMISSIONING

Our proposed solution has its roots in BIM-based

auto-commissioning. Demand for BIM-based auto-

commissioning is rapidly growing because of its ben-

efits regarding enhancing efficiency, collaboration,

compliance, and the overall quality of building op-

eration processes (Vieira et al., 2020). In the follow-

ing, we elicit actors and use cases in BIM-based auto-

commissioning (denoted UCX), and their associated

requirements (denoted RX) as to be delivered by our

proposed solution (c.f. Sec. 3.3).

3.1 Use Cases, Actors, Requirements

Usually, building designers start with the design of

the building [UC1] thereby creating the initial BIM

model. During this early design phase, the model

repeatedly is exchanged [UC4] among building de-

signers and building physicists and operators to con-

dition the model for auto-commissioning by extend-

ing it with BCS data [UC2] and necessary configura-

tions [UC3]. Model exchange is done using the IFC

which provide a vendor-neutral standard for the ex-

change of data and models in the AECO domain. A

dedicated BIM model repository (Zech et al., 2024)

provides the necessary technical infrastructure to real-

ize such model-based collaboration. During the con-

struction phase, the BCS-enabled BIM model pro-

vides the single source of truth regarding how to in-

stall and wire BCS components inside the building.

Crucially, the BIM model allows operators to infer

the BCS topology and wiring diagram [UC5] which

acts as the blueprint for the aforesaid installation. Fi-

nally, at the beginning of the operation phase, op-

erators deploy the BCS configuration contained in-

side the BIM model (cf. the operating model) into the

BCS to auto-commission the building’s initial oper-

ation [UC6]. During operation, any changes in the

building’s design and consequently the BCS readily

can be re-commissioned. Tbl. 1 summarizes our dis-

cussion of use cases and actors.

Table 1: Use cases and actors in BIM-based BEM.

Use case Actor

UC1 Design Modeling Building designer

UC2 BCS Modeling Building physicist, Operator

UC3 BCS Configuration Building physicist, Operator

UC4 Model Exchange Building designer, Building

physicist, Operator

UC5 BCS Topology Extraction Operator

UC6 BCS Configuration Deployment Operator

3.2 Requirements

The use cases from Tbl. 1 readily define the basis

for inferring the requirements our solution has to de-

liver. Building designers and building physicists need

means to (i) create and evolve the building model,

thereby conditioning it for auto-commissioning. This

not only comprises the structural modeling of a build-

ing but in addition the placement of BCS controllers,

sensors and actuators as well as their connectivity

[RQ1]. This emphasizes the collaborative working

aspect where building designers and building physi-

cists work on the same model, yet using different

tools, which implies the need for a tool infrastructure

that allows for the seamless mapping and exchange of

building models among involved actors’ tools [RQ2].

Observe however that this exchange has to work in

both directions, e.g., from building designers to build-

ing physicists and vice-versa, as BCS modeling may

require design modifications. Given the fully BCS-

conditioned BIM model, as a next step, wiring and

topology diagrams are to be exported [R3] for that in-

stallation proceeds along the specified design. This is

especially crucial for building automation. At present,

this installation step is usually completely decoupled

from any building design and done on a best-practice.

This readily results in buildings not meeting their ini-

tial planning and design objectives. Crucially, for

that this installation and subsequent initial building

operation during auto-commissioning proceed with-

out any issues, the validity of the modeled BCS pre-

configuration needs to be checked inherently to en-

sure sound BCS pre-configuration [R4], i.e., only al-

lowed devices are connected. Finally, as a last step

with the building constructed and the BCS in place,

building operators automatically deploy, i.e., auto-

Model-Based Auto-Commissioning of Building Control Systems

123

commission any runtime artifacts, e.g., control code

or other parameterizations of the BCS, directly into

the building [R5], rendering building-side commis-

sioning superfluous. Tbl. 2 summarizes our require-

ments.

3.3 Proposal

BIM ModelBIM Tool

Develop BIM

model

Read & write

Building Designer

BIM Model

BIM

Repository

BCS

Deployer

Condition BIM model for

auto-commissioning

Building Phycisist

Read & write

Building

Auto-commission

Operator

Topology/2D

Wiring Plan

BAS

Configuration

Read & write

DSL for

Auto-

commissioning

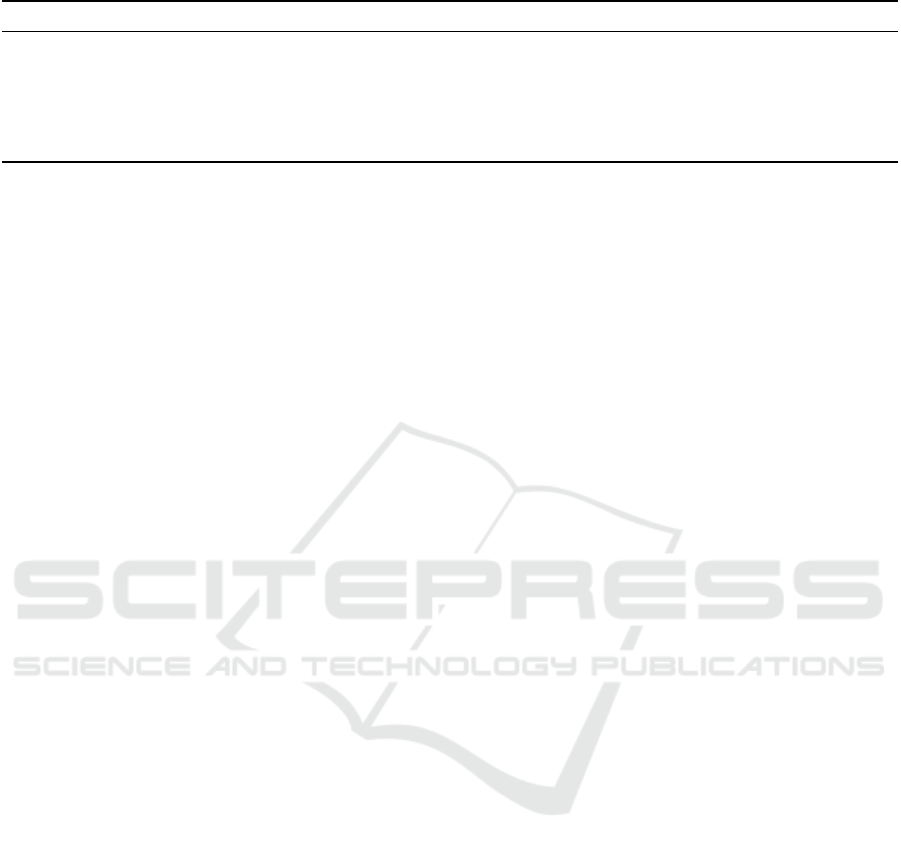

Figure 1: Conceptual model of our solution proposal.

Fig. 1 outlines our proposal. We employ DSLs

for advancing BIM modeling towards the use case

of model-based auto-commissioning of buildings.

Specifically, we develop a graphical DSL for abstract-

ing BCS and their components which is directly em-

bedded into an existing BIM tool (cf. Autodesk Re-

vitx). This readily enables buildings physicists the

conditioning of a BIM model for auto-commissioning

by augmenting it with BCS-relevant data [R1]. The

BIM repository thereby enables collaboration [R2]

by allowing for the seamless exchange of BIM models

among different actors, e.g., building designers can

share models which can then be retrieved by build-

ings physicists and vice-versa. Building operators

on the other side retrieve the BIM model from the

repository for both extracting a 2D wiring diagram

and the BCS topology [R3] for installing the BCS as

designed. Our proposal continuously checks and as-

sures BIM model validity in that only sound config-

urations of BCS can be established [R4] (cf. Sec. 4).

Finally, with the physical BCS in place, building op-

erators eventually deploy any BCS runtime artifacts

that are inferred from the BIM model (e.g., BCS con-

figurations) [R5] into the building using a dedicated

BCS Deployer which handles necessary conversion

of BIM-based BCS data into runtime artifacts.

4 MODELING METHODOLOGY

Commensurate to our solution proposal, the follow-

ing sections provide an in-depth discussion of the

artifacts developed to address our research problem

(cf. Sec. 2).

Scope. The modeling methodology covers the pre-

configuration of BCS in BIM models which in-

cludes the definition of devices and their connections.

Model-based development of BCS control algorithms

is out of the scope of this work and will be addressed

in future extensions.

Modeling Languages. Eclipse Ecore is used for for-

malizing the abstract syntax of our DSL, whereas

its concrete syntax, i.e., the graphical representa-

tion of the DSL, is implemented using Revit families

(cf. Sec. 4.3).

4.1 Graphical DSL

To enable the model-based pre-configuration of BCS

we have developed a graphical DSL for Autodesk Re-

vit (cf. Sec. 4.3) for augmenting BIM models with

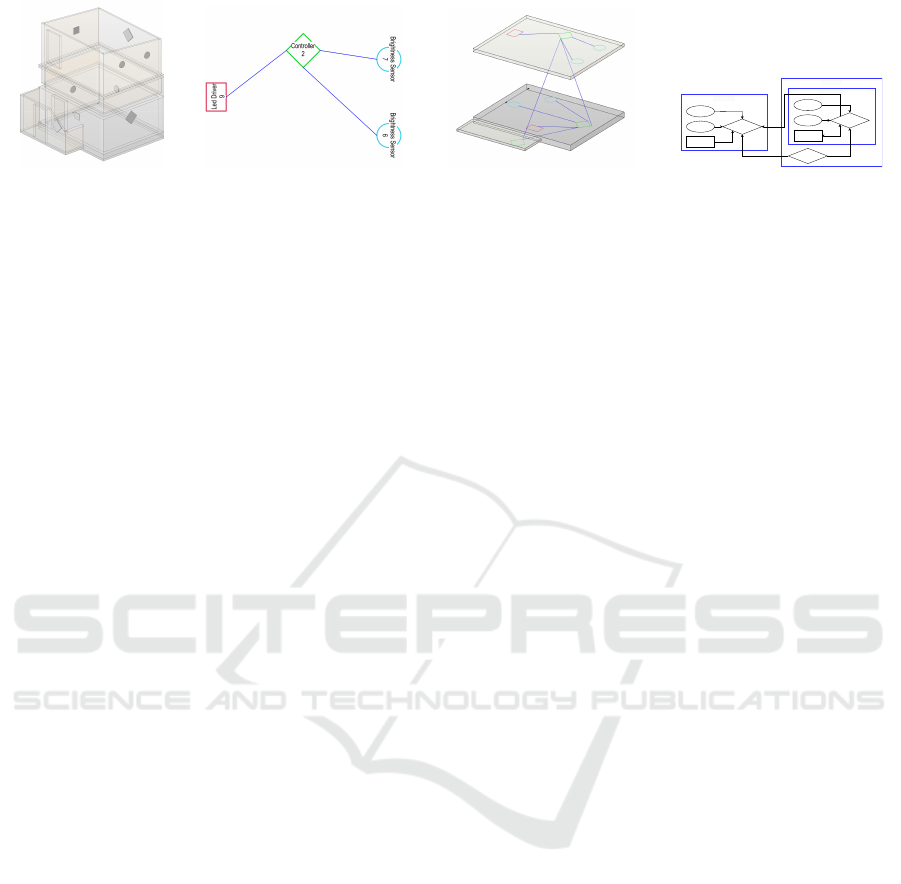

BCS data (cf. Fig. 2). The top-level element of our

DSL is a Device, e.g., a sensor, a controller (which

houses the control logic), or an actuator (e.g., a mo-

tor to drive a blind), whereas sensors and actuators

are further modeled as interacting devices, i.e., they

measure or modify the environment. Crucially, each

device has associated a unique id used for addressing

it at runtime. Controllers can have attached up to N

devices (where address ranges are bound in the inter-

val [1, N]). Sensors and actuators can only be con-

nected to controllers but not directly to each other.

For each device, we also model its readable and con-

figurable parameters that allow both monitoring the

runtime state of the device and re-commissioning it at

runtime by overwriting parameter values. We further

model devices’ specifications, e.g., voltageType, res-

olution, or setpoint. For both sensors and actuators,

our metamodel provides predefined concrete classes,

e.g., BrightnessSensor or LedDriver which describe

common BCS components. Finally, our model also

Device

id: int

provider: Provider

type: ElementType

ParametermodifiableParams

readonlyParams

Controller

endpoint: String

InteractingDevice

accuracyClass: AccurracyClass

voltageType: VoltageType

ioProtocol: IOProtocol

mounting: Mounting

connection: ConnectionType

powerSupply: PowerSupply

Gateway

type: GatewayType

Actor

resolution: double

output: double

Sensor

setpoint: double

protectionClass: ProtectionClass

drift: double

range: double

Motor

motorType: MotorType

powerInput: double

readings: [double]

Relais

frequency: double

numChannels: int

LEDDriver

dimmingLevel: DimmingLevel

colorTemp: ColorTemperature

PresenceSensor

runOnTime: double

BrightnessSensor

coverage: double

WeatherStation

readings: [double]

Switch

position: Position

output: [byte]

device

id

Device2DeviceMap

connectedDevices

Figure 2: Metamodel specifying BCS components for BIM

models.

implements a Gateway that allows for interconnect-

ing devices from different vendors in one BCS instal-

lation.

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

124

Table 2: Requirements as prompted by the use cases from Tbl. 1.

Requirement Prompting use case(s)

R1 Modeling and configuration support to enable pre-configuration of BCS [UC1], [UC2], [UC3]

R2 Model exchange to enable building designers the sharing of BIM models with buildings physicists and BCS experts

for BCS modeling and configuration

[UC1], [UC2], [UC3], [UC4]

R3 BCS topology/wiring diagram extraction to enable general constructors to install the BCS according to the design [UC5]

R4 Model validity assurance to establish sound and complete BCS pre-configurations [UC2], [UC3]

R5 BCS deployment to enable building physicists and BCS experts model-based auto-commissioning of buildings [UC6]

4.2 Modeling Steps

The modeling procedure for model-based pre-

configuration of BCS comprises 3 steps: (1) speci-

fying the BCS devices in the BIM model, (2) creating

topology views for different stories, and (3) specify-

ing inter-story (e.g., within a story) and intra-story

(e.g., between stories) connections among devices.

Crucially, the below steps need to be followed in or-

der.

(1) Specifying BCS Devices. To begin, BCS devices

(e.g., controllers, sensors, actuators, and gateways)

are placed in the BIM model through the utilization

of the provided Revit families whose implementation

follows our metamodel (cf. Fig. 2). Fig. 3a shows a

3D view of a building with multiple modeled devices.

(2) Creating Topology Views. To draw connec-

tions between devices, the second step involves creat-

ing a topology through the Create Topology com-

mand which is part of the developed tooling for our

DSL (cf. Sec. 4.3). The resulting topology view is

created along the selected room, story, or the en-

tire model which eventually determines the selection

of displayed devices within the view. Room and

story topologies are 2D views, whereas the full model

topology is a 3D view allowing the establishment

of connections between devices on different stories

(cf. Fig. 3b).

(3) Inter-Story and Intra-Story Connections. Once

in the topology view, devices can be connected us-

ing the Connect device command and subsequently

selecting the source and target device. Crucially,

our tooling restricts selectable target devices to avoid

erroneous connections, e.g., between two sensors.

Only valid I/O connections between the individual de-

vices are permitted. In the event of removing a con-

nection, Revit automatically handles model updates.

In addition, our tooling environment provides com-

mands for managing connection visibility: (i) Hide

connections to hide all connections in the view, (ii)

Show connections to reveal existing but (yet hid-

den) connections, and (iii) Highlight connection

to maintain visibility of connections among currently

selected devices. Fig. 3c shows a reduced view on the

building model (walls removed) from Fig. 3a with de-

vices and their connections. The Export topology

command generates a 2D topology plan of all devices

and their directed connections from the BIM model

(cf. Fig. 3d).

4.3 Implementation

Our prototype has been implemented as a series of

Revit families and a dedicated plugin that implements

the necessary tooling support. The choice for Au-

todesk Revit is due to both (i) our own experience in

developing Revit plugins and (ii) our project partners’

reliance on Revit as their commonly used planning

tool.

Revit families – broadly spoken – allow the defi-

nition of a group of model elements with a common

set of parameters, behavior, and graphical represen-

tation apart from what Revit innately offers. At this,

Revit distinguishes between system and component

families, whereas the latter are intended for our use

case by extending Revit’s innate modeling capabili-

ties. Fig. 3 shows the graphical representation of our

DSL as currently implemented in Revit.

Aside from the graphical syntax, dedicated tooling

to support the modeling procedure was implemented

in a Revit plugin. Specifically, this plugin implements

the generation of topologies as part of the BCS De-

ployer, the checking of connection validity, and hid-

ing and showing connections depending on the se-

lected model view, e.g., in the 3D view of Revit, we

deliberately hide connection as this would drastically

congest the view on the model. Instead, connections

are visible in the dedicated topology views. An ex-

ception to this are intra-story connections which also

need to be visible in the 3D view, as they are not part

of story-specific topologies.

Finally, the plugin implements a feature for gener-

ating a 2D topology diagram for BCS installation. We

extract this plan directly from the BIM model inside

Revit and store it as a graphviz file. Fig. 3d shows

a sample 2D topology plan for the model depicted in

Fig. 3.

Model-Based Auto-Commissioning of Building Control Systems

125

(a) 3D view of a building

with devices (lozenges

denote controllers, cir-

cles sensors, and squares

actuators) placed on dif-

ferent floors.

(b) 2D topology view of the

first floor from the building

from Fig. 3a.

(c) 3D view with walls and doors

hidden showing inter- and intra-

story connection between differ-

ent devices from Fig. 3a.

EG- OK RD

Empfangsraum 2

OG1- OK RD

Sensor: 6

Sensor: 7

Actuator: 9

Controller: 2

Sensor: 5

Sensor: 4

Actuator: 8

Controller: 3

Controller: 1

(d) Exported topology for the

building from Fig. 3d

Figure 3: Example 3D planning views of a building with devices.

5 EVALUATION

We evaluated our proposal using the Technology Ac-

ceptance Model (TAM) (Davis et al., 1989). The

TAM holds considerable importance in the evaluation

of tool utilization by providing a methodical structure

for understanding user perceptions, attitudes, and in-

tentions regarding the adoption of technology.

5.1 Method

From our research questions (c.f. Sec. 2) we created

a user survey (cf. Riemenschneider and Hardgrave

(2001)) to be administered to our sample. The sam-

ple in this case comprises representatives from the

construction domain with both academic and indus-

trial backgrounds. Specifically, after an interactive

tool demonstration, we administered our survey to the

19 representatives, among them researchers (9), light-

ning planners and consultants (6), and building de-

signers (4). The reported average age of participants

is 39,5 years with an average of 9 years of experi-

ence. Two participants did not disclose their gender,

among the remaining 19 participants, there were 14

males and three females.

5.2 Model Evaluation

To thoroughly assess the implementation of our sug-

gested tool environment, we utilize a methodical

approach to estimate and analyze the correspond-

ing structural equation model (Hair Jr et al., 2021).

Structural equation modeling (SEM) is a power-

ful tool for evaluating complex theoretical relation-

ships, especially among latent variables. PLS-SEM is

particularly beneficial in situations where the goal of

the structural model is to predict and explain desired

outcomes, such as technology acceptance (Hair Jr

et al., 2021).

5.2.1 Measurement Model Evaluation

Starting with the evaluation of the dependability and

accuracy of our reflective measurement, as per the ap-

proach outlined by Hair Jr et al. (2021), we analyze

the reliability of each construct by analyzing respec-

tive indicator loadings, (ii) evaluate the reliability of

the measurement instrument by calculating composite

reliability (ρ

c

), Cronbach’s alpha (ρ

T

), and the relia-

bility coefficient (ρ

A

), (iii) assess the convergent va-

lidity by calculating the average variance extracted

(AVE), and (iv), verify the discriminant validity by

examining the Heterotrait-Monotrait (HTMT) ratios.

Concerning (i), all the loadings of the four con-

structs, viz. Training (TRA), Ease-of-Use (EOU), Use-

fulness (USF), and Use (USE), which were measured

reflectively, exhibit statistical significance at a confi-

dence level of CI

α

= .05 or below. Furthermore, being

above the threshold value of .708 (Hair Jr et al., 2021),

they suggest a sufficient level of indicator reliability.

Concerning (ii), all four constructs measured demon-

strate a substantial level of internal consistency, with

ρ

c

, ρ

T

, and ρ

A

all surpassing .7 and slightly exceeding

.95 (Hair Jr et al., 2021). Moreover, w.r.t. (iii), it is im-

portant to mention that all the Average Variance Ex-

tracted (AVE) values significantly surpass the thresh-

old of .5, indicating a high level of convergent valid-

ity for the measures of the four constructs (Hair Jr

et al., 2021). Concerning (iv), all HTMT ratio values

are below the liberal cut-off threshold of .85 (Hair Jr

et al., 2021), indicating discriminant validity among

the four constructs.

5.2.2 Structural Model Evaluation

Having proved the reliability and validity of the con-

structs, we investigate the structural component of

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

126

our instance of the TAM. Following Hair Jr et al.

(2021)’s recommendations, we (i) examine the struc-

tural model for collinearity issues based on the vari-

ance inflation factor (VIF), (ii) assess the significance

and relevance of the structural model relationships,

i.e., the path coefficients, using bootstrapping, and

(iii), assess the explanatory capability of the structural

model using the coefficient of determination (R

2

) and

the effect size ( f

2

).

Regarding (i), the VIF analysis reveals that our

model does not exhibit any evidence of collinearity

among the four constructs, as the greatest VIF values

are well below the threshold of 5 (Hair Jr et al., 2021).

Regarding (ii), we assess the significance and the rel-

evance of the structural model paths by bootstrapping

the sampling distribution to test the structural model’s

relationship coefficients for statistical significance at

CI

α

= .05. Finally, concerning (iii), the R

2

values

for the endogenous constructs USF, EOU, and USE are

moderate being located close to the moderate thresh-

old of 0.5 (Hair Jr et al., 2021). This suggests that our

instance of the TAM has a satisfactory ability to pre-

dict outcomes within the sample (Hair Jr et al., 2021).

5.3 Interpretation of Results

The results of our data analysis have verified the ac-

curacy of our implementation of the TAM and have

shown a significant level of acceptability for the pro-

posed tool environment. Our analysis suggests that

the initial TRA has a significant influence on EOU. To

put it succinctly, being trained in the utilization of a

technology diminishes the level of proficiency needed

to employ it efficiently. Nevertheless, it is crucial to

acknowledge that TRA has an insignificant impact on

USF. This implies that the mere benefit of adopting a

new technology is sufficient for its implementation,

even without any prior training, despite thereby rais-

ing the level of difficulty for newcomers. Based on

these observations, it is evident that the impact of EOU

on USF is considerable. This suggests that possessing

the knowledge of how to utilize a particular technol-

ogy enhances its utility, provided that it is advanta-

geous for the task at hand.

When it comes to the concept of USE, it is evi-

dent that USF has a considerable impact. In addition,

EOU has only a weak influence of USE implying that

ease-of-use fosters technology acceptance but does

not seem to be the driving force behind acceptance.

This reinforces our prior assertion regarding the sole

benefit of adopting a novel technology. Put simply,

the weak impact of EOU on USE serves as more evi-

dence that professionals are eager to embrace a new

technology, regardless of the effort involved, as long

as it is advantageous for their work. Overall, our anal-

ysis demonstrates a robust reception of our proposal

and its modeling methodology.

Regarding RQ1, our proposal effectively show-

cases the utilization of model repositories for model

exchange, model-based development, and language

engineering to advance existing modeling formalisms

towards novel use cases.

As for RQ2, our graphical DSL and its accompa-

nying modeling methodology illustrate the process of

pre-configuring BCS in BIM models. In our current

work, we use this information to subsequently infer a

2D topology (cf. Fig. 3d) as a blueprint for the instal-

lation of the BCS.

Finally, in the event of RQ3, the combination of

model-based development for BCS pre-configuration

and the subsequent capitalization on models for au-

tomatically extracting relevant information thereof

(cf. Fig. 3d) delivers the necessary foundation for es-

tablishing BIM-based DTs in the future.

5.4 Related Work

Tang et al. (2020) - similar to our approach - embed

BCS-specific information into a BIM model. How-

ever, contrary to us, their approach does not support

direct data extraction from the BIM model but instead

leverages the IFC in combination with an additional

tool, thus impeding an integrated workflow. The work

of Dave et al. (2018) describes a concrete implemen-

tation of a framework that integrates IoT and BIM.

Specifically, they export an IFC model from Revit

which is subsequently extended with BCS data for

further use (e.g., visualization). This heavy reliance

on the IFC by export-edit-import however repeatedly

results in errors due to information loss during export

and import and the IFC not being designed for edit-

ing (Mirarchi et al., 2017). Louis and Rashid (2018)

propose to leverage BIM models as operating sys-

tems for smart homes by extending the BIM model

with relevant IoT-device data. By then loading the

model into the Unity Game Engine, they create a plat-

form for click-control of IoT devices in smart build-

ings. Contrary to our work, Louis and Rashid how-

ever only support locating IoT devices in BIM mod-

els but do not address the pre-configuration of BCS

devices (e.g., establishing connections) as done in our

work. Finally, the work of Tan et al. (2022) - similar

to ours - also addresses the configuration of artificial

lighting and daylighting. Yet, in their case models of

the building and embedded BCS are established post

factum only, thus not addressing initial model-based

pre-configuration for initial building operations.

In the event of dedicated language extensions of

Model-Based Auto-Commissioning of Building Control Systems

127

BIM, e.g., by DSLs, the only related work we were

able to identify is by Alves et al. (2017). In particular,

Alves et al. introduce a DSL for embedding real-time

sensor data into BIM models. Yet, their work - similar

to what was discussed previously - neither addresses

pre-configuration nor subsequent model-based auto-

commissioning of BCS.

6 CONCLUSIONS

In our paper, we have presented a metamodel

with relevant tooling support for model-based

pre-configuration of BCS for model-based auto-

commissioning of BCS, a crucial precursor in estab-

lishing DTs of buildings. Our current implementation

allows for both the configuration and extraction of a

structural design plan for operators. The results of

our evaluation using the TAM are promising in that

– despite its for now limited functionality – our pro-

posal is appreciated and will be used once it reaches

the necessary TRL, e.g., TRL7.

In future work, we plan to extend our graphical

DSL to capture further relevant information regarding

auto-connecting, i.e., twinning, physical and virtual

replicas by extracting a device configuration for a DT

middleware that allows for the automated and seam-

less establishment of bidirectional data exchange with

the physical entity. Further, we plan to extend our

proposal by a textual DSL for model-based BCS pro-

gramming thereby also delivering [R5] for eventually

deploying such code-based runtime artifacts.

ACKNOWLEDGEMENTS

This research has received funding from the Aus-

trian Research Promotion Agency (FFG) under Grant

Agreement No.: 898708, TwinLight.

REFERENCES

Alves, M., Carreira, P., and Costa, A. A. (2017). Bimsl: A

generic approach to the integration of building infor-

mation models with real-time sensor data. Automation

in Construction, 84:304–314.

Dave, B., Buda, A., Nurminen, A., and Främling, K. (2018).

A framework for integrating bim and iot through open

standards. Automation in construction, 95:35–45.

Davis, F. D., Bagozzi, R. P., and Warshaw, P. R. (1989).

User Acceptance of Computer Technology: A Com-

parison of Two Theoretical Models. Management Sci-

ence, 35(8):982–1003.

Grieves, M. and Vickers, J. (2017). Digital Twin: Mitigat-

ing Unpredictable, Undesirable Emergent Behavior in

Complex Systems. In Transdisciplinary Perspectives

on Complex Systems, pages 85–113. Springer Interna-

tional Publishing.

Hair Jr, J. F., Hult, G. T. M., Ringle, C. M., and Sarstedt, M.

(2021). A primer on partial least squares structural

equation modeling (PLS-SEM). Sage publications.

ISO (2018). Industry Foundation Classes (IFC) for data

sharing in the construction and facility management

industries — Part 1: Data schema. Standard, Interna-

tional Organization for Standardization, Geneva, CH.

Louis, J. and Rashid, K. (2018). Utilizing building informa-

tion models as operating systems for smart homes. In

Proceedings of the Workshop on Human-Habitat for

Health (H3): Human-Habitat Multimodal Interaction

for Promoting Health and Well-Being in the Internet

of Things Era, pages 1–4.

Mirarchi, C., Pasini, D., Pavan, A., Daniotti, B., et al.

(2017). Automated ifc-based processes in the con-

struction sector: A method for improving the infor-

mation flow. In LC3 2017: Volume I–Proceedings of

the Joint Conference on Computing in Construction

(JC3), pages 491–498.

Ozturk, G. B. (2021). Digital Twin Research in the AECO-

FM Industry. Journal of Building Engineering, 40.

Riemenschneider, C. K. and Hardgrave, B. C. (2001). Ex-

plaining software development tool use with the tech-

nology acceptance model. Journal of computer infor-

mation systems, 41(4):1–8.

Semeraro, C., Lezoche, M., Panetto, H., and Dassisti, M.

(2021). Digital twin paradigm: A systematic literature

review. Computers in Industry, 130:103469.

Tan, Y., Chen, P., Shou, W., and Sadick, A.-M. (2022).

Digital twin-driven approach to improving energy ef-

ficiency of indoor lighting based on computer vision

and dynamic bim. Energy and Buildings, 270:112271.

Tang, S., Shelden, D. R., Eastman, C. M., Pishdad-Bozorgi,

P., and Gao, X. (2020). Bim assisted building au-

tomation system information exchange using bacnet

and ifc. Automation in Construction, 110:103049.

Vieira, R., Carreira, P., Domingues, P., and Costa, A. A.

(2020). Supporting building automation systems in

BIM/IFC: reviewing the existing information gap. En-

gineering, Construction and Architectural Manage-

ment, 27(6):1357–1375.

Wieringa, R. (2014). Design Science Methodology

for Information Systems and Software Engineering.

Springer Berlin Heidelberg.

Zech, P., Fröch, G., and Breu, R. (2024). A requirements

study on model repositories for digital twins in con-

struction engineering. In Cooperative Information

Systems, pages 459–469. Springer Nature Switzer-

land.

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

128