Carbon-Aware Process Execution for Green Business Process

Management

Philipp Hehnle

1

, Maximilian Behrendt

1

, Luc Weinbrecht

1

and Carl Corea

2

1

envite consulting GmbH, Stuttgart, Germany

2

Research Group Process Science, University of Koblenz, Koblenz, Germany

Keywords:

Green BPM, Carbon-Aware Process Execution, Green ICT, Camunda.

Abstract:

Traditional business process management (BPM) focuses on the improvement of performance dimensions such

as time, costs, and quality. Ecological aspects are usually not considered as an equal performance dimension.

In this context, Green BPM approaches have been proposed to strengthen the awareness among people and

organisations about the impact of business processes on the climate. However, little research in Green BPM

covers the runtime of digitised processes, or provides concrete means to reduce carbon emissions during

process execution. Therefore, we present an approach for carbon-aware process execution, which allows to

automatically postpone energy-intensive activities to times when energy with low CO

2

emissions, e.g. solar

energy, is better available. Importantly, our approach considers and complies with external regulations such as

Service Level Agreements (SLAs) when postponing activities. Our approach is implemented in Camunda and

has been evaluated in interviews with domain experts.

1 INTRODUCTION

Climate change has the potential to cause un-

precedented natural disasters that impact, inter alia,

food production and thereby threatens livelihoods

(Matemilola et al., 2020). In result, governments

across the world adopted the Paris Agreement in 2015

(Matemilola et al., 2020), committing to implement

measures in order to keep the global temperature in-

crease below 2°C compared to pre-industrial levels.

To limit the global temperature increase, it becomes

necessary to drastically reduce carbon (CO

2

) emis-

sions, so that there are net zero emissions in the long

run (Matemilola et al., 2020). To this end, there is

a broad consensus that Information and Communi-

cation Technology (ICT) can play an important role

in reducing CO

2

emissions (Kim et al., 2009; Oloo

Ajwang and Nambiro, 2022; Gohar et al., 2020), e.g.

web meetings may reduce the need for transportation.

However, it is not safe to assume that the use of ICTs

will always save emissions. In particular, the sheer

execution of the ICTs produces emission itself. Ac-

cording to (Freitag et al., 2021), ICTs produce 2.1%-

3.9% of global green house gas emissions. There-

fore, the ICT sector itself must also strive to reduce

its emissions to contribute towards the overall goal

of the Paris Agreement. In this work, we investi-

gate how digitised business processes can contribute

towards this goal. In particular, we present an ap-

proach for carbon-aware process execution, which al-

lows to automatically execute activities of a business

process at times at which energy sources with low

CO

2

emissions (green energy) are available, e.g. so-

lar energy, lowering the CO

2

emissions. Importantly,

our approach leverages predictive insights to ensure

that the business process execution remains compli-

ant with external requirements such as service level

agreements (SLA).

In traditional BPM, the main performance dimen-

sions for which processes are optimised for are time,

cost, and quality (van der Aalst, 2013). In this work,

we aim to raise awareness that the dimension of ecol-

ogy should be seen as an equal. To this aim, our

approach supports companies in considering carbon

emissions as a process performance dimension.

Our approach is implemented in Camunda, and

can be used “out-of-the-box” by companies. We show

that our approach can be used to reduce CO

2

emis-

sions with a comprehensive case-study and evaluate

our approach in interviews with domain experts. For

our investigation, we follow a design science oriented

approach as proposed in (Peffers et al., 2007), in that

we identify important requirements (Section 3.1) and

develop/evaluate our approach based on these.

Hehnle, P., Behrendt, M., Weinbrecht, L. and Corea, C.

Carbon-Aware Process Execution for Green Business Process Management.

DOI: 10.5220/0012557100003690

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 26th International Conference on Enterprise Information Systems (ICEIS 2024) - Volume 2, pages 659-666

ISBN: 978-989-758-692-7; ISSN: 2184-4992

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

659

In Section 2, fundamentals on Sustainability,

Green BPM and Predictive Process Monitoring are

stated. In Section 3, we present our approach to re-

duce CO

2

emission during process execution and a

proof of concept implemented for the Workflow Man-

agement System (WfMS) Camunda. In Section 4, the

presented approach is evaluated. Finally, this paper

concludes with a summary and outlook.

2 FUNDAMENTALS

In this section, we introduce concepts to save carbon

when using ICTs, SLAs, predictive process monitor-

ing, and Green BPM.

2.1 Sustainability in Information and

Communication Technology

There are various approaches to operate ecologically

sustainable ICTs, mainly, by trying to improve the ef-

ficiency of the software or the hardware. As an exam-

ple, improving the hardware software is operated on

can reduce the energy consumption and thereby the

ecological impact (Freitag et al., 2021). Furthermore,

the choice of technology (e.g. programming language

(Pereira et al., 2017)) and the programming style (e.g.

used data structures (Hasan et al., 2016)) affects the

energy consumption of software.

Besides these approaches, the time when software

is executed may be chosen carbon-aware. For in-

stance, (Radovanovic et al., 2023) discusses how data

centre computing may be run in time windows when

green energy is available. For this purpose, the Green

Software Foundation’s Carbon Aware SDK

1

may be

used to get a forecast about when and where addi-

tional energy consumption causes the least CO

2

emis-

sions. The SDK takes into account whether there are

enough sustainable energy sources available for the

additional energy consumption. Building on this fore-

cast, it therefore becomes possible to execute energy-

intensive activities when green energy is available.

Consequently, in this work, we focus on this latter line

of approaches, i.e. trying to reduce emissions by op-

timising the execution time.

2.2 Service Level Agreements in

Business Process Management

An SLA (Frankova et al., 2011) constitutes a contract

between a service provider and a consumer describ-

1

https://github.com/Green-Software-

Foundation/carbon-aware-sdk

ing a non-functional requirement. SLAs of a business

process may be the maximal execution time of the en-

tire (Frankova et al., 2011) or parts of the business

process (del R

´

ıo-Ortega et al., 2015). By monitoring

the SLAs of a business process, it becomes possible to

prevent a violation of an SLA, e.g. by alerting experts

or by automatically removing/adding activities of the

business process (del R

´

ıo-Ortega et al., 2015).

In the context of this work, we implement an SLA-

based demand shifting to ensure that any alterations in

process execution (in favour of less CO

2

emissions)

still remain compliant to the SLAs.

2.3 Predictive Process Monitoring

Predictive Process Monitoring (PPM) (Di Francesco-

marino and Ghidini, 2022) is a discipline aimed at

predicting future aspects of running business pro-

cesses. Here, history data from process executions

(event logs) are considered to train machine learn-

ing models. These models can then take as input a

running instance and predict different aspects such as

the next activity, the remaining time, or possible out-

comes (Di Francescomarino and Ghidini, 2022).

To train the models, traces from the event log, i.e.

a sequence of executed activities, are usually consid-

ered to recognise emerging patterns and behaviours.

To this end, process variables can be taken into ac-

count, such as the assigned employee.

In the approach presented in this work, remain-

ing time predictions (i.e. the time until the end of the

entire process instance) are leveraged to estimate the

potential degree of freedom for postponing current ac-

tivities (e.g. the postponement of an activity plus the

estimated remaining time should not exceed SLAs).

As our approach is applied to WfMSs, event logs

tracked by a WfMS can be used for model training.

For this work, we build on our previous results for

training machine learning models in Camunda (Bart-

mann et al., 2021). The tool presented in that work

can be used to train models in a user-friendly way and

provides an interface to predictions in Camunda.

2.4 Green Business Process

Management

In broad terms, Green BPM is a specialisation of tra-

ditional BPM, aimed to lessen the impact of processes

on the natural environment (Seidel et al., 2012). Due

to an increasing societal and organisational attention

on topics such as climate change (cf. e.g. (Couckuyt

and van Looy, 2021)), the topicality of “Green BPM”

has again gained some recent momentum, with recent

works broadly agreeing on potential benefits and the

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

660

need for future research in this area (Couckuyt, 2018;

Couckuyt and van Looy, 2021). Also, there seems

to be a growing awareness that organisations do in

fact contribute to environmental degradation through

their processes and should therefore aim to implement

more environmentally sustainable processes (Seidel

et al., 2012; Couckuyt and van Looy, 2021). Follow-

ing (Opitz et al., 2014), Green BPM can be described

to have two main goals, namely 1) the reduction of the

environmental impact of business processes, and 2)

inducing cultural change w.r.t. more eco-friendly be-

haviour. This work focuses on the first goal, namely

means for reducing the environmental impact, con-

cretely, reducing the carbon footprint.

Regarding the existing works on reducing the en-

vironmental impact of business processes, most re-

search can be found in the area of design-time anal-

ysis (cf. (Maciel, 2017; Couckuyt and van Looy,

2020; Roohy Gohar and Indulska, 2020; Hoesch-

Klohe and Ghose, 2010; Ghose et al., 2010)). That

is, most works focus on facilitating means for mod-

elling processes in a more eco-aware way, for exam-

ple, by means of extensions of modelling notations

to indicate fuel consuming activities (Recker et al.,

2011), or design patterns for modelling processes in a

more ecologically sustainable way (Alexander Nowak

et al., 2014). Works such as (Ghose et al., 2010)

and (Hoesch-Klohe et al., 2010) annotate activities

in process models with carbon emissions at design

time to substitute fragments of the process models

with ones that preserve the behaviour but reduce the

carbon impact. However, the authors (Ghose et al.,

2010) acknowledge the fact that, at runtime, carbon

emissions may vary depending on the execution time.

Despite the clear benefits of such approaches, we do

see a current lack of Green BPM research in the area

of runtime monitoring, i.e. support for Green BPM

once processes are actually running. And in fact,

this research gap has also been identified in recent re-

search agendas, i.e. (Maciel, 2017; Couckuyt, 2018)

state that more attention should be paid to “[green]

process implementation and execution”, and the “de-

velopment of instruments”. Further, the authors in

(Ghose et al., 2010) argue that “process execution

management can also contribute to carbon footprint

minimization”. To close this existing research gap,

in this work, we develop new means for the opera-

tional support of reducing the environmental impact

of running processes, concretely, by developing eco-

aware monitoring techniques in combination with re-

sults from prescriptive process monitoring.

The Activity-Based Emissions (ABE) approach

presented in (Recker et al., 2011) is developed for

analysing the carbon footprint of processes and allows

to conceptualise the emissions of individual activities.

In this work, we follow the ABE approach and focus

on activities with high emissions due to high energy

consumption. Our work lifts the ABE approach to a

runtime perspective. In particular, our approach al-

lows to reduce the environmental impact of carbon-

aware process models at runtime, by orchestrating the

execution of individual activities s.t. these activities

are executed in time windows where green energy is

better available. This is mainly done by postponing

activities, as has also been proposed by (Zhu et al.,

2015). While other approaches comprise manufactur-

ing business processes (Ghose et al., 2010; Hoesch-

Klohe et al., 2010), we focus on digitised business

processes only.

Importantly, by leveraging predictive insights, ac-

tivities are postponed while still ensuring that pro-

cesses remain compliant, e.g. are in line with SLAs.

In such, our approach represents a novel form of

“Carbon-Aware” Prescriptive Process Monitoring.

Note that CO

2

emissions are not the only KPI

measurable in regard to the environmental impact (cf.

e.g. the dimensions mentioned in (Roohy Gohar and

Indulska, 2020) like water consumption, waste, etc.).

However, reducing CO

2

can be seen as an important

part of lowering the environmental impact of pro-

cesses (Roohy Gohar and Indulska, 2020), which is

why we focus on this aspect in this work.

3 CARBON-AWARE PROCESS

EXECUTION

In this section, we will present our approach to reduce

the environmental impact of business processes. We

begin by exploring important requirements for such

an approach and then continue with the concrete pre-

sentation and discussion.

3.1 Requirements

The main goal of our approach is to reduce the CO

2

emissions of digitised business processes. We pro-

pose to shift the execution of energy-intensive activi-

ties to time windows when green energy is available.

For such a run-time approach, we see the following

general requirements:

Typically, a WfMS is used to orchestrate various

services. The required energy for these services varies

widely. Getting an entry in a database might not use

much energy compared to complex tasks such as im-

age processing. Therefore, an approach is required

that is simple to use and takes a holistic view of the

business process instead of single services separately.

Carbon-Aware Process Execution for Green Business Process Management

661

Furthermore, the process instances need to con-

tinue to comply with the specified SLAs. In result,

when moving the execution of an activity to a later

time window, the overall process execution has to re-

main within these bounds.

Based on these observation, we therefore raise the

following requirements.

R1: The adjustment effort must be low. In princi-

ple, it would be possible to configure every ser-

vice orchestrated by a process individually to con-

sider the carbon intensity of the current energy

supply. However, that would entail a lot of ad-

justment efforts in many services. Ideally, only

small changes to the original process model are

required.

R2: The business process must be optimised holisti-

cally. Rather than optimising services individu-

ally, the optimisation should aim for the business

process as a whole.

R3: The process instances need to comply with speci-

fied SLAs. When business processes are executed,

the specified SLAs must be adhered to. For ex-

ample, if the maximal allowed execution time for

a process instance is 3 hours, the approach needs

to ensure that even if execution is postponed in

favour of carbon savings, the process instance is

executed within this frame.

3.2 Proposed Approach for

Carbon-Aware Process Execution

To reduce CO

2

emissions produced by energy-

intensive activities, we propose to shift the execution

of these activities to time windows where green en-

ergy is available. For instance, before executing an

energy-intensive activity (e.g. image processing), it is

verified if green energy is available entailing immedi-

ate execution or otherwise it may be postponed.

Two main problems in this use-case are 1) get-

ting data on the availability of green energy, and 2)

deciding if and how long to postpone activities. For

problem 1), we build on the publicly available Car-

bon Aware SDK by the Green Software Foundation

(cf. Section 2.1). Regarding problem 2), a method is

needed for deciding how to postpone activities, e.g.

SLAs must be kept. In the following, we present our

proposed method for this decision task. See process

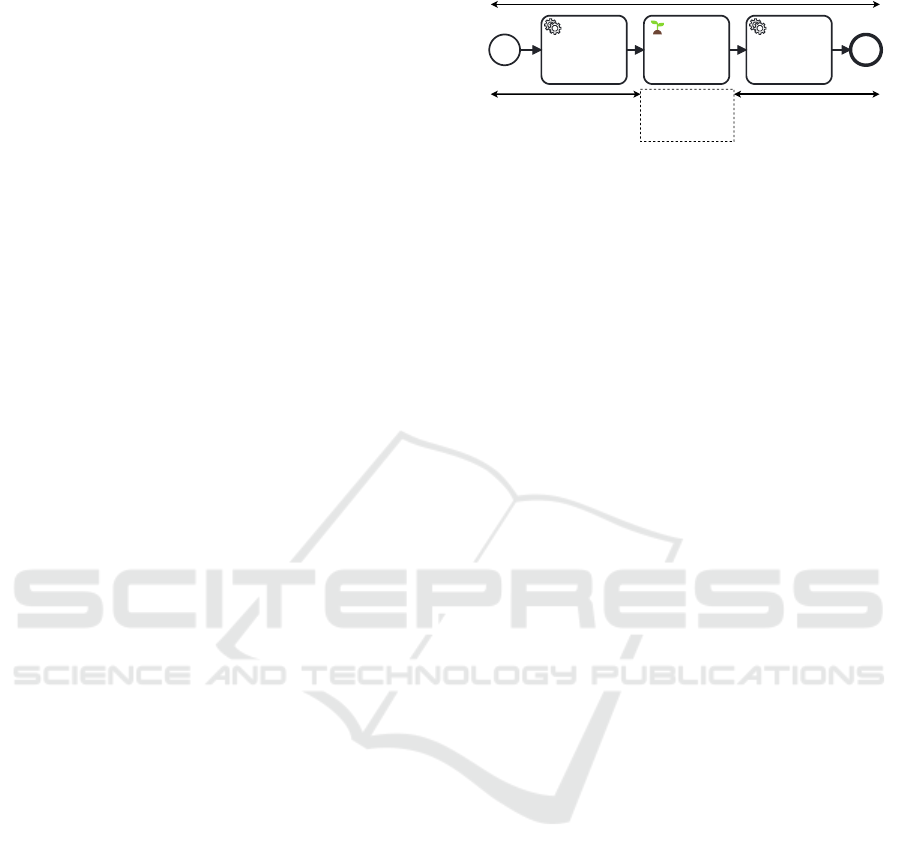

model in Figure 1 as a running example.

Following the ABE approach (Recker et al.,

2011), activities causing high emissions have to be

identified by domain experts, e.g. based on met-

rics such as energy consumption. In Figure 1, this

① maximum execution time

④

time window for

postponement

② duraon of the

remaining tasks

③ duraon since

process start

Start

...

postpone

execution for

greener energy

energy intense

work

End

Figure 1: Exemplary process model containing energy-

intensive activity adapted from (Hehnle et al., 2023).

is schematically shown as the activity “energy in-

tense work”. In case of such an activity, a new

model element, denoted a postponement activity, can

be added before this element (see “postpone execu-

tion for greener energy” in Figure 1). The postpone-

ment activity decides whether to postpone subsequent

activities to time windows when energy is less carbon-

intensive. To allow for making this decision, the post-

ponement activity is called with the following data:

• the region in which the process is executed

• the start time of the process instance

• the maximal runtime until the end of the process

instance (SLA)

• the (predicted) duration of the remaining activities

(cf. Section 2.3)

The region is required to determine the carbon-

intensity in the energy forecast. It is assumed that the

entire process and its called services are executed in

the same region. The time information (start time,

maximal execution time according to SLA, predicted

remaining time) are needed to calculate the possible

time window for postponing the carbon-intensive ac-

tivity. To prevent SLA violations, the execution may

not be postponed arbitrarily. Equation (1) describes

how the time window for postponement is calculated:

t

P

= t

MET

− (t

PS

+t

RA

) (1)

• t

P

: time window for postponement, i.e. the maxi-

mal time subsequent activities may be postponed.

• t

MET

: maximal execution time of the business

process (i.e. the SLA)

• t

PS

: duration since process start

• t

RA

: predicted duration of the remaining activities

The calculation of the time window for postpone-

ment is visualised in Figure 1. The maximal execu-

tion time of a process instance, which must not be ex-

ceeded, can be seen at the arrow with the mark

1

⃝ (e.g.

according to an SLA). The (predicted) duration of the

remaining activities following the postponement-task

(mark

2

⃝) as well as the time since the process in-

stance start (mark

3

⃝) need to be deducted from this

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

662

maximal execution time, which results in the time

window for the postponement (mark

4

⃝). In result,

the execution of activities can be postponed within

this time window while still considering the specified

maximal execution time. This ensures that carbon op-

timisation does not result in SLA violations.

Finally, the API by the Green Software foundation

is used to retrieve a forecast of the carbon-intensity

within the time window for the postponement. Based

on this forecast, the WfMS postpones the execution

of the energy-intensive activity until the optimal time

with regard to green energy.

3.3 Proof of Concept

To demonstrate our approach, we implemented a

proof of concept (PoC) using Camunda together

with the Green Software Foundation’s Carbon Aware

SDK. In the following, we refer to our PoC as the

Camunda Carbon Reductor. The Camunda Carbon

Reductor is publicly available

2

and can be used “out-

of-the-box” with any Camunda (7 or 8) installation.

In the following, the functionality of the Camunda

Carbon Reductor is described in interaction with Ca-

munda 8. Connectors are a special type of task in

Camunda. They act as reusable templates consisting

of a model element and a small application that inter-

acts with third party systems. For our PoC, the Ca-

munda Carbon Reductor is implemented via a con-

nector. It can be added to a process model before

energy-intensive activities. Configured accordingly,

it can automatically decide to postpone the energy-

intensive activity to a better time window, while still

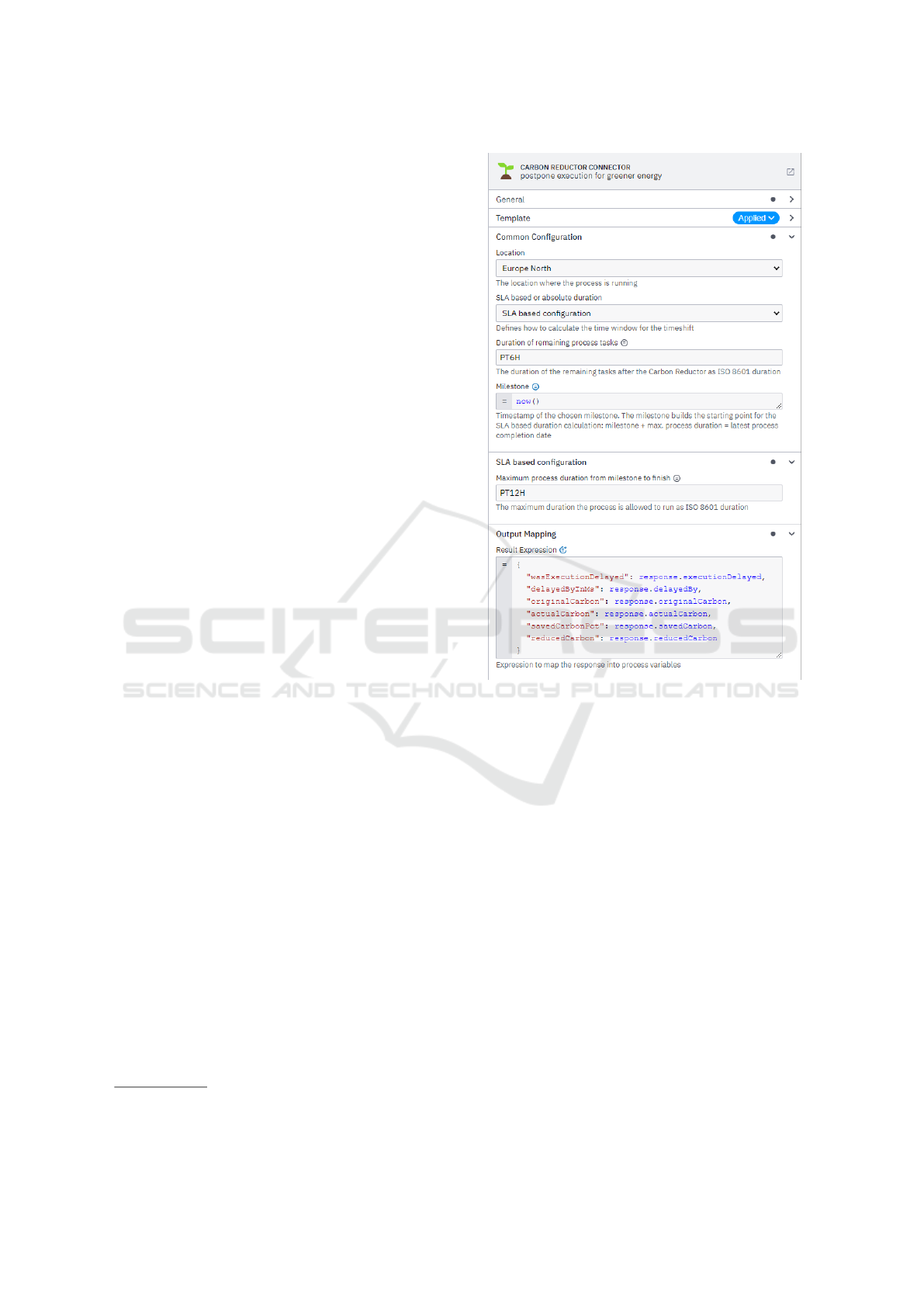

ensuring the SLAs. Figure 2 highlights the configura-

tion possibilities of the Camunda Carbon Reductor:

1. The location where the energy-intensive activity

is executed in, which is required for the forecast.

2. An estimated duration of the remaining activities,

which may be specified manually or retrieved via

a remaining time prediction. The concrete meth-

ods for obtaining such a prediction are beyond the

scope of this report. We build on our previous tool

presented in (Bartmann et al., 2021), which allows

to retrieve such predictions directly in Camunda.

3. The milestone is a timestamp and the starting

point for the SLA based duration calculation.

4. The maximal duration of a process instance from

the milestone to finish to be SLA compliant.

Once the Camunda Carbon Reductor determined

the optimal time window for execution, a timer is set

to pause the execution until green energy is available.

2

https://github.com/envite-consulting/

camunda-carbon-reductor

Figure 2: Showcase of configuration possibilities of the Ca-

munda Carbon Reductor adapted from (Hehnle et al., 2023).

For analysis in the monitoring tool Camunda Op-

timize, results are written as variables into the process

instance (also shown in Figure 2)

3.4 Discussion

In the following, we discuss the fulfilment of the re-

quirements (cf. Section 3.1) as well as limitations.

3.4.1 Requirements Fulfilment

The benefit of the proposed approach is that only

the process model has to be adjusted in order to

save carbon emissions, and no further adjustments

are necessary for the called services. Therefore, R1

is met. The Camunda Carbon Reductor orchestrates

the called services and is thus able to achieve the

maximum carbon reduction for the business process

through carbon-aware optimisation. Here, R2 is sat-

isfied as well. The developer can specify the SLA

of the maximal execution time of the business pro-

cess, which is considered when postponing energy-

Carbon-Aware Process Execution for Green Business Process Management

663

intensive activities. Based on the specified SLA, the

predicted remaining time, and the duration since a

specified milestone, the time window for postpone-

ment is calculated. In result, R3 is met as well.

3.4.2 Limitations

If a business process is run in a region where the de-

mand of energy is higher than green energy is avail-

able postponing activities will not reduce emissions.

Furthermore, only activities whose consumption is

higher than that of the Camunda Carbon Reductor

should be postponed or otherwise more carbon emis-

sions are produced than saved. However, measuring

the energy consumption of software is difficult and

still a subject of research (Ardito et al., 2019). Inte-

grating the Camunda Carbon Reductor multiple times

in one process model may result in SLA violations

as all Camunda Carbon Reductors might exploit the

maximal execution time. When subsequent activi-

ties after the Camunda Carbon Reductor include user

tasks it becomes difficult to predict the remaining time

of the process. When the Camunda Carbon Reductor

postpones the execution of a business process and in

addition to that later on in the business process it takes

more time than anticipated for a human to complete a

user task it may result in an SLA violation as well.

Finally, the current approach favours only the process

performance dimension of emitted carbon. However,

it might be necessary to consider a trade-off among

time, cost, quality, and carbon emissions.

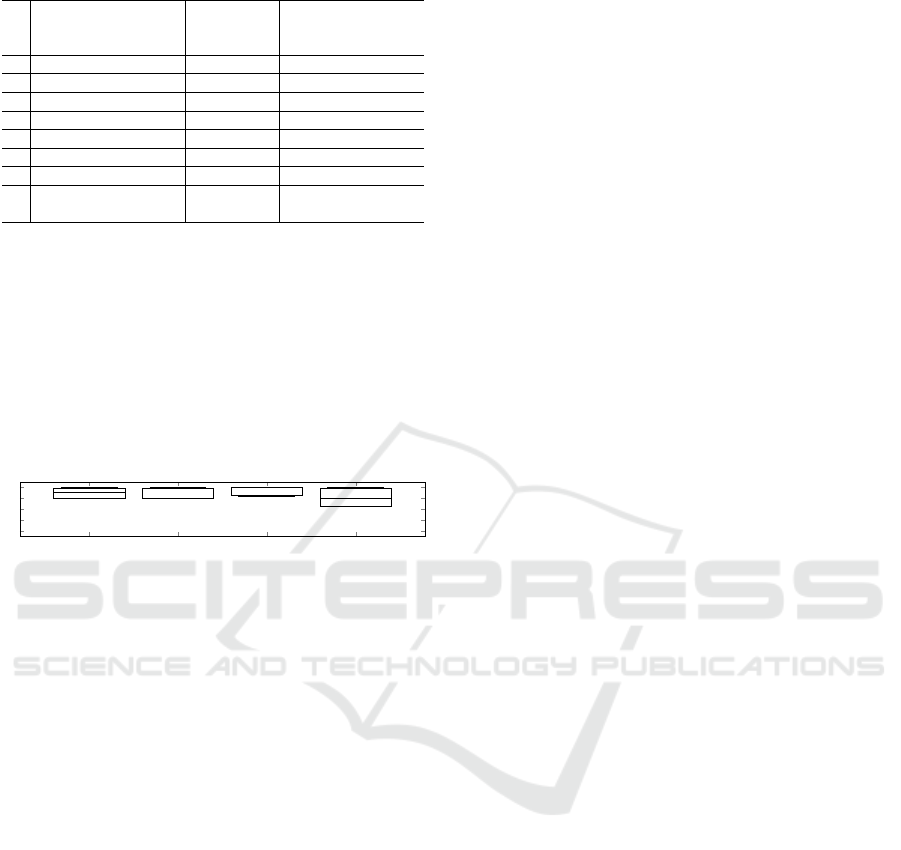

4 EVALUATION

The approach as well as the Camunda Carbon Re-

ductor are evaluated in the following. First, a case

study explores the fitness in production use. Then, we

present feedback from experts gained in interviews.

4.1 Case Study

We conducted a case-study to investigate the poten-

tial benefits of our approach. For this, we created

an exemplary process model and simulated its exe-

cution within a Camunda installation. The process

model (shown in Figure 3) consists of a start event,

an energy-intensive activity and an end event. The

Camunda Carbon Reductor was included as a prede-

cessor activity of the energy-intensive activity. We

then used Camunda to run concrete process instances

of this process over the course of one week (every 30

minutes, a process instance was started). Importantly,

the execution was performed in real-time, allowing to

also obtain real-time energy forecasts (meaning the

data obtained from the case study reflects the actual

CO

2

savings!). In total, 173 process instances were

executed in this time. For the energy-intensive ac-

tivity, an execution time of one hour was assumed.

Furthermore, an exemplary SLA of 23 hours was as-

sumed. In result, there is a time window of 22 hours

to postpone the energy-intensive activity. The activity

was assumed to be run in a data centre in the region

West US. The results of the case study are depicted in

Figure 3.

Figure 3: Case study results (Camunda Optimize Dash-

board) adapted from (Hehnle et al., 2023).

The data collected by the Camunda Carbon Recu-

tor allow to report KPIs such as the amount of emis-

sions reduced per kWh. As can be seen, 17.9 thou-

sand gCO

2

/kWh could be saved over all instances. On

average, 103.4 gCO

2

/kWh were saved.

Furthermore, the dashboard allows to track the

progress of goals, e.g. an instance should ideally save

at least 10% of carbon. 74.72% of all (173) instances

satisfied this goal. Among all instances on average

23% CO

2

emissions could be saved.

4.2 Expert Interviews

To evaluate the plausibility of our approach, we con-

ducted interviews with eight domain experts who

were approached from a pool of industrial partners,

but not associated with the affiliations of the authors.

An overview of the experts is shown in Table 1.

As can be seen, all experts had a strong back-

ground in BPM and Camunda. Especially, inputs

from experts A, B, D, E and H, who explicitly work on

implementing Camunda in industrial settings, make

us confident the interview partners were very suitable

to provide feedback. With each expert, we conducted

an interview via Microsoft Teams. At least two re-

searchers were present in every interview and an pro-

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

664

Table 1: Expert panel overview.

ID Job Title Experience

with BPM/

Camunda

Company/Sector

A Developer Advocate 9 years Software Vendor

B Developer Advocate 1 years Software Vendor

C Senior Consultant 12 years IT Consulting

D BPM Consultant 6 years IT Technology

E IT Consultant 5 years IT Consulting

F Principal Scientist 11 years Software Vendor

G Data Scientist 3 years Tech Company

H Software Architect

Process Development

3 years Insurance Company

tocol was followed to support internal validity: First,

the general approach was motivated. Then, the PoC

was shown to the experts, followed by a roughly 20-

30 minute discussion. After the interview, the ex-

perts were shown four statements (e.g. “I found the

tool useful”), to which they should indicate whether

they agreed or not (on a 5-point Likert scale from

strongly agree to strongly disagree). The statements

were based on the technology acceptance model. Fig-

ure 4 shows our survey results.

useful

easy to

use

well

integrated

quickly

learnable

-2

-1

0

+1

+2

Figure 4: Results of the conducted user survey (Statements:

“I found the tool...”), on a 5-point Likert scale from strongly

agree (+2) to strongly disagree (-2).

As can be seen from Figure 4, our approach was

uniformly seen as useful and easy to use. It was es-

pecially mentioned that the approach was very well

integrated, which is in line with requirement R1. The

experts did see a slight need for training when using

such a tool, but this was seen as expectable.

Also from the open questions/interview, the over-

all approach was uniformly well-received. The ex-

perts were specifically asked whether they could

imagine to use the PoC in one of their industrial

project, to which five experts answered yes. Expert

C emphasised that the PoC is especially useful and

necessary in sectors that run huge simulations, e.g in-

surance companies run simulations before many con-

tracts. Expert D indicated that the approach should

also be able to transfer the execution of an activity to

a different location where green energy is available.

Experts F and G proposed a configuration to specify

a minimum saving of CO

2

which need to be achieved

to postpone the execution or otherwise the execution

will be continued immediately. Expert B argued that it

might become necessary for a human process partici-

pant to manually resume a paused process instance.

5 SUMMARY AND OUTLOOK

Climate change is a challenge for society as a whole.

The ICT Sector also needs to contribute to overcome

it by reducing carbon emissions (Gohar et al., 2020;

Seidel et al., 2012). Research has unveiled various

strategies to reduce carbon emissions of ICTs, one of

which is them being executed carbon-aware , i.e. time

windows can be chosen for running the ICT solutions

in which green energy is available.

In this work, we applied the well-established ap-

proach of carbon-aware execution from the field of

sustainable ICTs to business processes, i.e. energy-

intensive activities are executed in time windows in

which green energy is available. While traditional

BPM focuses on the performance dimensions time,

cost, and quality, Green BPM has evolved to reduce

the environmental impact of business processes. Pre-

vious approaches of Green BPM push for design time

optimisation, whereas we focus on the runtime.

The Camunda Carbon Reductor is a proof of con-

cept that implements the presented approach and is

publicly available. A case study revealed that the use

of the Camunda Carbon Reductor can achieve sub-

stantial CO

2

reduction. In this context, the conducted

expert interviews underline these findings, where the

majority of experts confirmed the need, usefulness

and plausibility of our approach.

Despite the achievements in the case study and the

good response in the expert survey, the Camunda Car-

bon Reductor may be improved. Currently, an ele-

ments needs to be integrated into the process model,

whereas in the future, no element shall be needed.

Also, in future work, the Camunda Carbon Reductor

shall be able to relocate the execution of business pro-

cesses to data centres where green energy is available.

Currently, it is reasonable to pause the execution of a

business process only at one position. However, mul-

tiple energy-intensive activities in a process model

shall be considered. Also, we plan to integrate results

from multi-instance predictive process monitoring to

verify whether activities from parallel instances can

be postponed in a batch, e.g. image processing tasks

from different process instances can be batched, s.t.

the hardware used for the image processing does not

have multiple (energy-intensive) “cold-starts”.

As stated, CO

2

emissions are not the only KPI in

regard to the environmental impact (e.g. water con-

sumption, waste (Roohy Gohar and Indulska, 2020)).

However, reducing the carbon footprint is uniformly

viewed as important in the context of Green BPM

(Gohar et al., 2020), which makes us confident that

the presented approach is a step towards improving

the environmental impact of business processes.

Carbon-Aware Process Execution for Green Business Process Management

665

REFERENCES

Alexander Nowak, Uwe Breitenb

¨

ucher, and Frank Ley-

mann (2014). Automating green patterns to compen-

sate co2 emissions of cloud-based business processes.

In Proc. 8th Int. Conf. ADVCOMP., pages 132–139.

Xpert Publishing Services.

Ardito, L., Coppola, R., Morisio, M., and Torchiano, M.

(2019). Methodological guidelines for measuring en-

ergy consumption of software applications. Scientific

Programming, 2019:1–16.

Bartmann, N., Hill, S., Corea, C., Drodt, C., and Delfmann,

P. (2021). Applied predictive process monitoring and

hyper parameter optimization in camunda. In Proc.

CAiSE Forum 2021, pages 129–136. Springer.

Couckuyt, D. (2018). An overview of challenges and re-

search avenues for green business process manage-

ment. In On the move to meaningful internet systems,

volume 10697 of LNCS Inf. sys and applications, incl.

internet/web, and HCI, pages 270–279. Springer.

Couckuyt, D. and van Looy, A. (2020). A systematic review

of green business process management. Business Pro-

cess Management Journal, 26(2):421–446.

Couckuyt, D. and van Looy, A. (2021). An empirical study

on green bpm adoption: Contextual factors and perfor-

mance. J. of Software: Evolution and Process, 33(3).

del R

´

ıo-Ortega, A., Guti

´

errez, A. M., Dur

´

an, A., Resinas,

M., and Ruiz-Cort

´

es, A. (2015). Modelling service

level agreements for business process outsourcing ser-

vices. In Advanced inf. sys. eng., volume 9097 of

LNCS, pages 485–500. Springer.

Di Francescomarino, C. and Ghidini, C. (2022). Predictive

process monitoring. In Process Mining Handbook,

volume 448 of LNBIP, pages 320–346. Springer In-

ternational Publishing.

Frankova, G., S

´

eguran, M., Gilcher, F., Trabelsi, S.,

D

¨

orflinger, J., and Aiello, M. (2011). Deriving busi-

ness processes with service level agreements from

early requirements. J. Syst. and Softw., 84(8):1351–

1363.

Freitag, C., Berners-Lee, M., Widdicks, K., Knowles, B.,

Blair, G. S., and Friday, A. (2021). The real climate

and transformative impact of ict: A critique of esti-

mates, trends, and regulations. Patterns, 2(9):100–

140.

Ghose, A., Hoesch-Klohe, K., Hinsche, L., and Le, L.-S.

(2010). Green business process management: A re-

search agenda. Australasian J Inf. Sys., 16(2).

Gohar, S. R., Indulska, M., et al. (2020). Environmental

sustainability through green business process manage-

ment. Australasian J. Inf. Sys., 24.

Hasan, S., King, Z., Hafiz, M., Sayagh, M., Adams, B., and

Hindle, A. (2016). Energy profiles of java collections

classes. In Proc. 38th Int. Conf. Softw. Eng., pages

225–236. ACM.

Hehnle, P., Weinbrecht, L., and Behrendt, M. (2023). The

camunda 8 connector for carbon-aware process ex-

ecution. https://camunda.com/blog/2023/07/carbon-

aware-process-execution-connector/ (retrieved

16/02/2024).

Hoesch-Klohe, K. and Ghose, A. (2010). Carbon-aware

business process design in abnoba. In Proc. 8th

Int. Conf. Service Oriented Comp., pages 551–556.

Springer.

Hoesch-Klohe, K., Ghose, A., and L

ˆ

e, L.-S. (2010). To-

wards green business process management. In Int.

Conf. Services Comp., pages 386–393. IEEE.

Kim, S., Kim, H.-K., and Kim, H. J. (2009). Climate change

and icts. In INTELEC 09, pages 1–4. IEEE.

Maciel, J. C. (2017). The core capabilities of green business

process management—a literature review. In Proc.

Int. Conf. Wirtschatsinformatik, pages 12–15.

Matemilola, S., Fadeyi, O., and Sijuade, T. (2020). Paris

agreement. In Encyclopedia of Sustainable Manage-

ment, pages 1–5. Springer International Publishing.

Oloo Ajwang, S. and Nambiro, A. (2022). Climate change

adaptation and mitigation using information and com-

munication technology. Int. J. Comp. Sci. Research,

6:1046–1063.

Opitz, N., Krup, H., and Kolbe, L. M. (2014). Green busi-

ness process management – a definition and research

framework. In 47th Hawaii Int. Conf. Sys. Sci., pages

3808–3817. IEEE.

Peffers, K., Tuunanen, T., Rothenberger, M. A., and Chat-

terjee, S. (2007). A design science research methodol-

ogy for information systems research. J. management

inf. sys., 24(3):45–77.

Pereira, R., Couto, M., Ribeiro, F., Rua, R., Cunha, J., Fer-

nandes, J. P., and Saraiva, J. (2017). Energy efficiency

across programming languages: how do energy, time,

and memory relate? In Proc. 10th ACM SIGPLAN Int.

Conf. Softw. Language Eng., pages 256–267. ACM.

Radovanovic, A., Koningstein, R., Schneider, I., Chen, B.,

Duarte, A., Roy, B., Xiao, D., Haridasan, M., Hung,

P., Care, N., Talukdar, S., Mullen, E., Smith, K.,

Cottman, M., and Cirne, W. (2023). Carbon-aware

computing for datacenters. IEEE Transactions on

Power Systems, 38(2):1270–1280.

Recker, J., Rosemann, M., and Gohar, E. R. (2011). Mea-

suring the carbon footprint of business processes.

In BPM 2010 Int. Workshops and Education Track,

pages 511–520. Springer.

Roohy Gohar, S. and Indulska, M. (2020). Environmental

sustainability through green business process manage-

ment. Australasian J. Inf. Sys., 24.

Seidel, S., Recker, J., and vom Brocke, J. (2012). Green

business process management. In Green business pro-

cess management, Springer Management/Business for

professionals, pages 3–13. Springer.

van der Aalst, W. M. P. (2013). Business process manage-

ment: A comprehensive survey. ISRN Software Engi-

neering, 2013:1–37.

Zhu, X., Zhu, G., vanden Broucke, S., and Recker, J.

(2015). On merging business process management

and geographic information systems: Modeling and

execution of ecological concerns in processes. In Geo-

informatics in resource management and sustainable

ecosystem, volume 482 of Communications in Com-

puter and Inf. Sci., pages 486–496. Springer.

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

666