Revolutionizing Vehicle Damage Inspection: A Deep Learning

Approach for Automated Detection and Classification

Onikepo D. Amodu

1

, Adel Shaban

1a

and Gbenga Akinade

2b

1

University Centre Middlesbrough, Middlesbrough College, U.K.

2

Department of Computing & Games, Teesside University, U.K.

Keywords: Vehicle Damage Detection, Deep Learning Algorithms, Machine Learning.

Abstract: In the past, fleet managers and vehicle insurance companies relied on manual methods to inspect vehicle

damage. This involved visually examining the vehicles and taking measurements manually. The aim of this

study was to explore the use of deep learning algorithms to automate the process of vehicle damage detection

and classification. By automating these tasks, stakeholders in the industry, such as fleet managers and

insurance companies, can streamline vehicle inspections, assess the extent and severity of damage, and

validate insurance claims. The research focused on three main deep learning architectures: Convolutional

Neural Networks (CNNs), Generative Adversarial Networks (GANs), and Deep Neural Networks (DNNs).

These algorithms were applied to a diverse dataset containing vehicles in different lighting conditions. The

study conducted a comprehensive evaluation of each algorithm's performance, considering factors such as

accuracy, speed, and detection rates. The goal was to assess the strengths and weaknesses of each approach.

The results of the experiment revealed significant differences in the performance of the CNN, DNN, and GAN

models. The CNN model achieved the highest accuracy rate, at 91%, followed by the DNN model at 84%.

The GAN model achieved a more modest accuracy rate of 78%. These findings contribute to the advancement

of vehicle damage detection technology and have important implications for industries, policymakers, and

researchers interested in deploying state-of-the-art solutions for faster and more precise identification of

various levels of damage and their severity.

1 INTRODUCTION

The swiftly emerging technology of identifying and

categorizing vehicular damage has garnered immense

traction due to its ability to address two primary

objectives. Firstly, it considerably reduces the

expenses related to the traditional manual inspection

of vehicles. Secondly, it provides an unfailingly

dependable methodology for detecting and classifying

damage from several factors, such as wear and tear

and collisions (Kim et al., 2013). This state-of-the-art

technology has brought about a significant

transformation in the automotive industry and

associated fields, consequently contributing to

elevated levels of safety, improved quality assurance,

and product advancement.

Damage detection was often done by hand

measurements and visual inspections prior to the

a

https://orcid.org/0000-0001-6765-3645

b

https://orcid.org/0000-0003-3950-3775

development of automated technologies. Although

this method is beneficial, it had flaws and was prone

to errors and instability. As a result, scientists have

worked to develop a more efficient method of damage

detection, as mentioned in the research by Lyu, Feng,

and Wang (2020). The study comes to the conclusion

that it is possible to precisely measure physical

deformations in an object in addition to being able to

identify them by using advanced data collection

techniques like stereo vision. Zhao et al.'s (2018)

research has provided further evidence of the

advantages of automated inspection techniques. The

study investigated the long-term benefits of automated

damage detection systems, suggesting that the risk of

human error can be eliminated entirely, resulting in

more precise estimates of vehicle damage reports.

This improvement in accuracy has been mentioned in

numerous workshop reports and was also illustrated in

the field experiment conducted by Jeon et al. (2020).

Amodu, O., Shaban, A. and Akinade, G.

Revolutionizing Vehicle Damage Inspection: A Deep Learning Approach for Automated Detection and Classification.

DOI: 10.5220/0012630700003705

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 9th International Conference on Internet of Things, Big Data and Security (IoTBDS 2024), pages 199-208

ISBN: 978-989-758-699-6; ISSN: 2184-4976

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

199

The research concluded that utilizing automated

vehicle damage recognition systems can save dozens

of man-hours, significantly reducing the time required

to diagnose vehicle problems.

Innovatively, deep learning technology has

substantially grown in recent years. Its potential as a

facilitative mechanism for various industries is

discernible through its application to identifying and

categorizing vehicular damage. This sophisticated

technology harnesses artificial neural networks'

power to detect and accurately classify damage to

vehicles (Cireşan et al., 2012). Neural networks can

assimilate information from a vast range of data

inputs, rendering a comprehensive approach to

vehicle damage classification considerably more

dependable than traditional manual inspection

methods (Nguyen et al., 2016).

Employing deep learning algorithms for vehicle

damage detection and classification is primarily

geared towards curtailing the time and expenditure

involved in evaluating, diagnosing, and rectifying

vehicular damages (Sarkar et al., 2014). Trained

networks can be proficiently utilized to expediently

and precisely recognize diverse forms of damage and

categorize them into particular classifications, such as

dents, scratches, or chip marks. This, in turn,

substantially decreases the costs and time involved in

the repair process and mitigates the likelihood of

errors. Furthermore, these algorithms can be

employed to speedily gauge the severity of the

damage and suggest potential repair methodologies,

thereby effectively streamlining the repair process

(Kim et al., 2013).

Innovatively, deep learning algorithms can detect

anomalies or discrepancies in vehicle images

(Cireşan et al., 2012).

This necessitates a substantial and heterogeneous

accumulation of datasets, including images of

vehicles exhibiting various damages. Furthermore,

the datasets must be classified with labels that specify

the types of damage visible in each image. This

greatly aids the algorithms in effectively detecting

and categorizing the diverse types of damage.

Vehicle detection using deep learning methods

such as CNNs and DNNs has achieved significant

progress and has shown promising results in recent

years. However, limitations and gaps still need to be

addressed to improve the accuracy and efficiency of

the detection process.

Deep learning-based vehicle detection heavily

relies on the quality and quantity of labeled data.

Labeling large amounts of data can be time-

consuming and expensive, limiting the ability to train

the models on a diverse data set. Additionally, the

performance of deep learning models can be affected

by the quality and accuracy of the labels, which can

be subjective and prone to errors.

Another limitation is that deep learning models

for vehicle detection may struggle to generalize to

new environments or conditions do not present in the

training data. If the model is trained on images

captured during the day, it may not perform well on

images captured at night or in bad weather conditions.

This is known as the "generalization gap" and can

limit the model's usefulness in real-world scenarios.

This study aims to address the undervaluation of

deep learning models by implementing a specialized

technical experiment for vehicle damage detection

and classification. The experiment considers factors

such as the type of vehicle, dataset size, and required

accuracy to determine the most effective technique

for identifying and categorizing vehicle damage. The

proposed solution aims to enhance customer service

and streamline the repair process by providing

necessary support resources. The paper also examines

the current state and future prospects of technology in

detecting and classifying vehicle damage, and

presents a comprehensive report with an in-depth

analysis of existing models and experimental

evaluations.

2 LITERATURE REVIEW

In recent years, vehicle damage detection and

classification has emerged as a rapidly expanding

area of interest in the automotive industry. With an

extensive body of literature spanning the past twenty

years, there has been a growing awareness of the

criticality of this field and the prospect of creating a

self-sustaining system of vehicle diagnostic

technology. This literature review seeks to

consolidate all available research on this topic and

identify the central outcomes and patterns that can be

employed in practical settings. This review article

examines advancements in this area, highlighting the

significant developments and techniques used to

create vehicle damage detection and classification

systems.

Studies showcased in this review are

predominantly sourced from academic publications

such as scholarly journals and conference

proceedings, concentrating on advanced diagnostics,

expert systems, computer vision, and artificial

intelligence. Moreover, the review also considers

commercial materials produced by experts within the

automotive sector and third-party manufacturers of

vehicle diagnostic tools.

IoTBDS 2024 - 9th International Conference on Internet of Things, Big Data and Security

200

In this literature review, recent progress in the field

of vehicle damage detection and classification has

been presented. Different imaging technologies like

3D scanning, infrared imaging, and stereo vision have

been employed to accurately assess the extent of

damage resulting from an accident. Furthermore,

several studies have revealed the potential of machine

learning approaches, including convolutional neural

networks and deep learning-based object detectors, for

precisely identifying and categorizing vehicle

damage.

The primary objective of this literature review is

to pinpoint two essential elements, firstly, examine

the efficacy of current automated systems for

detecting damage and analyzing the outcomes of their

precision. Secondly, it will reveal the current

tendencies within vehicle damage classification by

scrutinizing established damage classifications'

dependability, credibility, and consistency.

2.1 Vehicle Damage Detection

Before the advent of automated systems, damage

detection was frequently conducted through visual

inspections and manual measurements. Despite

being helpful, this technique has shortcomings and is

susceptible to inaccuracies and unreliability.

Consequently, researchers have endeavored to create

a more practical approach to damage detection. For

example, Liu et al. (2020) highlight that by utilizing

sophisticated data-gathering methods like stereo

vision, it is feasible to detect and precisely measure

physical deformations in an object. Hong-Jie Zhang

et al. (2022) also examined the potential implications

of model-based object detection within the

diagnostic domain. The study postulates that a three-

dimensional vehicle model can be established

through the fusion of shape-based segmentation and

stereo-vision, leading to a more precise and detailed

depiction of the inflicted damages. Zhao et al. (2018)

provided further evidence of the advantages of

automated inspection techniques. The study

investigated the long-term benefits of automated

damage detection systems, suggesting that the risk of

human error can be eliminated, resulting in more

precise estimates of vehicle damage reports. This

improvement in accuracy has been reported in

several studies (Jeon et al., 2020).

Zhao et al. (2018) concluded that automated

vehicle damage recognition systems could save

dozens of person-hours, significantly reducing the

time required to diagnose vehicle problems.

Image processing techniques, which include 3D

scanning, infrared imaging, active imaging, and

stereo vision, have gained significant popularity in

detecting and categorizing vehicle damage. 3D

scanning creates high-quality images of the damaged

car's surface, which can be utilized to determine the

damage's extent and classify the damage type.

Zhang et al. (2022) conducted a study in which an

infrared camera was utilized to capture images of a

damaged vehicle. These images were then processed

to measure and categorize the damage precisely. The

research demonstrated that the infrared imaging

system could identify various types of damage,

including dents and scratches, more accurately than a

conventional visual inspection system.

2.2 Algorithms for Vehicle Damage

Classification

The process of damage classification involves sorting

damages into various types. This is typically achieved

by utilizing image recognition software, which is

capable of distinguishing various types of

abnormalities within an object. Recent research has

extensively utilized machine learning techniques to

enhance the accuracy of vehicle damage detection

and classification systems. For example, In a study by

Jiang et al. (2021), a deep learning-based object

detection model was used to detect and classify

vehicle damage utilizing a dataset of damaged car

images. The model accurately detected and classified

vehicle damage with a high degree of accuracy.

According to White et al. (2006), initial efforts at

damage classification were rudimentary, utilizing a

small number of rule-based algorithms to categorize

surface damage through a method known as

"hierarchical damage categorization." This was

subsequently improved upon by Jiang et al. (2007),

who introduced the concept of "context-aware

damage detection" to move closer to automated

damage detection by implementing a knowledge-

based framework.

3 METHODOLOGY

3.1 Dataset Description

A secondary dataset containing 1631 images of

vehicles taken in various settings and lighting

conditions was collected from Kaggle

(https://www.kaggle.com/datasets/prajwalbhamere/c

ar-damage-severity-dataset). This dataset contain

images of vehicles captured in various settings and

lighting conditions.

Revolutionizing Vehicle Damage Inspection: A Deep Learning Approach for Automated Detection and Classification

201

3.2 Data Preparation

The first step in training a CNN is to prepare the data.

This includes acquiring a large dataset of labeled

images for training, validation, and testing. The data

would be cleaned, normalized, and augmented to

ensure diversity in the images trained by the model

(Amrutha, 2020).

This dataset provides a diverse range of examples

for training and testing vehicle damage detection

models. Each image is annotated with bounding

boxes around areas of damage, including dents,

scratches, and other types of wear and tear.

The dataset includes vehicles of different makes

and models, ranging from sedans and SUVs to trucks

and motorcycles. This variety ensures that models

trained on this dataset can detect damage on various

vehicles.

The dataset was classified into 3 categories as

shown in table 1:

Table 1: Description of data set for damage classification.

Category Image Number

Minor

534

Moderate

583

Severe 595

In addition to the image annotations, the dataset

also includes information on the type and severity of

the damage.

With this dataset, the possibilities for machine

learning and computer vision applications are

endless. This dataset is a valuable resource for any

project that improves vehicle safety and efficiency,

from advanced driver assistance systems to insurance

claim processing.

3.2.1 Data Pre-Processing

Once the dataset was collected, it was pre-processed

to remove any unwanted data or artifacts that may

interfere with the analysis, Image pre-processing is a

critical aspect of preparing data for computer vision

tasks. It involves manipulating images to eliminate

distortions, improve quality and standardize their

characteristics. This study employed fundamental

techniques used in image pre-processing such as

image cropping, resizing, and normalization.

By standardizing the image size, resizing can help

to reduce the computational burden on the model

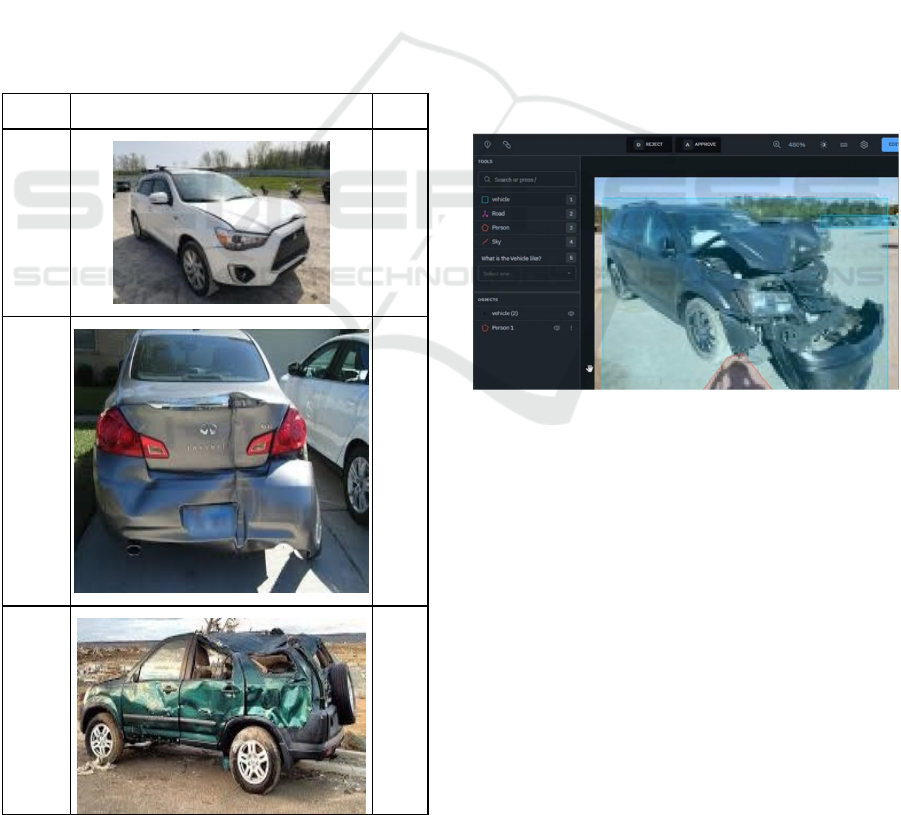

during training as shown in fig 1:

Figure 1: Image Resizing.

Normalization was done to adjust the pixel values of

the images to ensure that they have similar ranges and

distributions. This technique enhances the image's

contrast and makes it simpler for the model to identify

and learn relevant features.

3.2.2 Data Annotation

The next step of annotation, which is a crucial step in

preparing a dataset for machine learning applications,

was performed. vehicle images were manually

labeled with the corresponding metadata or labels to

create a labeled dataset that can be used to train

machine learning models. This helps the model

understand the relevant features and patterns in the

data. This process involved labeling images with the

corresponding damage type and severity in the

IoTBDS 2024 - 9th International Conference on Internet of Things, Big Data and Security

202

context of an image-based predictive maintenance

application.

Annotated datasets are a critical component of

deep learning models. They are used to train the

model to recognize and classify objects in images or

videos. The annotations provide the model with the

information it needs to identify specific features or

patterns that correspond to different classes or labels.

In the instance of this study, the annotations would

help the model recognize diverse types of damage and

their severity levels.

Automated annotation can be much faster and

more efficient than manual annotation, but it may not

always provide the same level of accuracy and detail.

Figure 1 shows the manual annotation process

performed on a vehicle image in other to attain

highest quality form the datasets.

In the context of image-based predictive

maintenance, the annotation process would typically

involve identifying and labeling the different types

of damage that are relevant to the application. The

annotations would also include information about the

severity of the damage, such as a minor scratch or a

significant structural defect. Hence, this data image

will be labelled into three classes: Minor damage,

Medium Damage, and Severe Damage as shown in

figure 2.

Figure 2: Data classification.

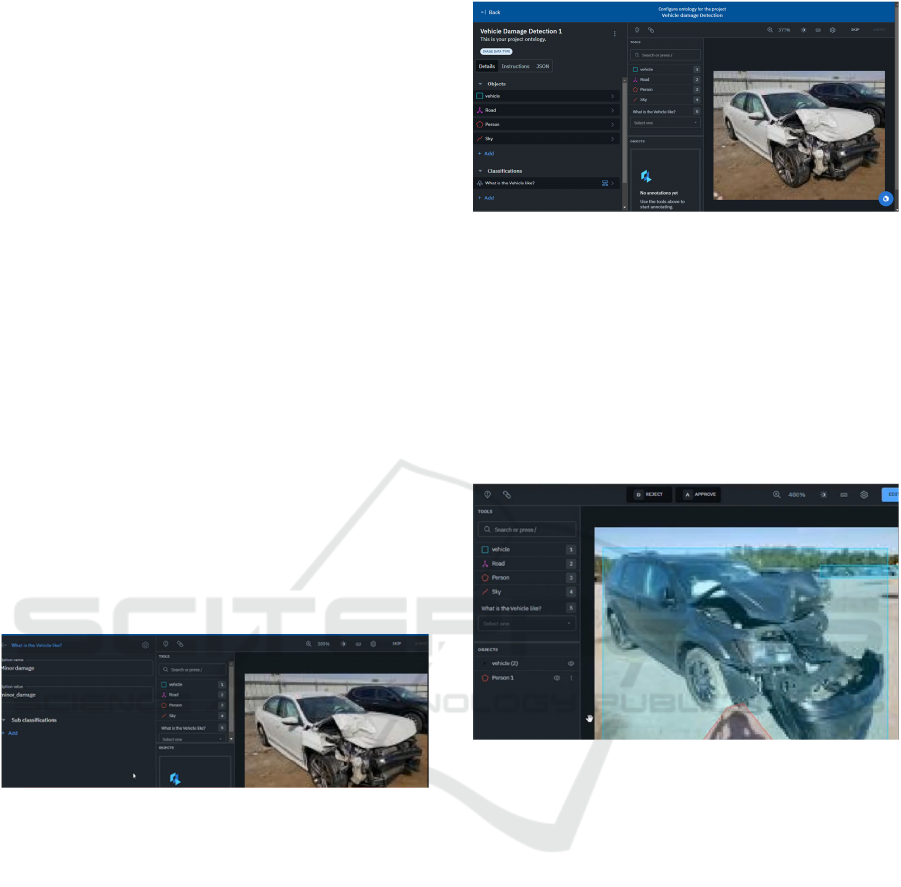

The annotation process was broken down into several

steps. Step 1 was to determine the types of damage

that need to be labeled. This involves identifying the

specific use case and the types of damage that are

relevant to that use case. Step 2 was to create a

labeling schema (Ontology) that defines the different

types of damage and their severity levels as shown in

figure 3. This schema (Ontology) provides a

standardized set of labels that can be used

consistently across the dataset.

Step 3 was to select the images that need to be

annotated. This can be done manually or using

automated tools. The selection process should ensure

that the images are representative of the different

types of damage and severity levels. The fourth step

is to annotate the images with the corresponding

labels or metadata. This can be done manually or

using automated tools, as discussed earlier.

Figure 3: Data Annotation (ontology).

During the annotation process, it is essential to

maintain a high level of accuracy and consistency

across the dataset. This means that the annotators

need to be trained on the labeling schema and given

clear instructions on how to apply the labels to the

images. It also means that the annotations need to be

reviewed and validated to ensure that they are correct

and consistent as shown in the labelling schema in

figure 4.

Figure 4: Labelling schema.

In addition to the labeling schema (ontology), it is

also essential to maintain a record of the annotations

and their corresponding images. This record should

include information about the annotator, the date and

time of the annotation, and any notes or comments

related to the annotation. This record can be used to

track the progress of the annotation process and to

identify any errors or inconsistencies that need to be

corrected.

The quality of the annotated dataset is critical to

the performance of the deep learning model. A high-

quality dataset is one that is accurate, consistent, and

representative of the use case. To ensure the quality

of the dataset, it is essential to perform regular quality

checks and validation on the annotations. This can be

done using manual reviews or using automated tools

that compare the annotations to ground truth labels or

other sources of truth.

Revolutionizing Vehicle Damage Inspection: A Deep Learning Approach for Automated Detection and Classification

203

3.2.3 Data Augmentation

To improve the dataset's quality, data augmentation

techniques such as flipping, rotation, and scaling was

used to increase the diversity of the dataset.

3.2.4 Data Splitting

Data splitting is essential to prevent overfitting,

which can occur when a model is too closely tailored

to the training data. The model needs to be trained to

recognize and classify the different types of damage

accurately, such as dents, scratches, and cracks, and

to differentiate between different levels of severity.

This is a complex task that requires a large and

diverse dataset, which must be split into appropriate

subsets for training, validation, and testing.

The training subset is the largest of the three

subsets. It is used to train the model to recognize

patterns and features in the data that correspond to

different types and levels of damage.

The validation subset was used to tune the model's

hyperparameters, such as the learning rate, batch size,

and number of epochs. Hyperparameters are

important as they control how the model learns from

the training data, and they can significantly impact the

model's performance. The validation set is used to

fine-tune the hyperparameters, allowing the model to

generalize better to new data.

The testing subset was used to evaluate the final

model's performance. It is kept separate from the

training and validation sets and is used to simulate

how the model will perform on new, unseen data. The

performance on the testing set provides an unbiased

estimate of how well the model will perform in the

real world.

The dataset comprises 1631 images of vehicle

damage with corresponding labels indicating the type

of damage (e.g., scratches, dents, cracks, etc.). This

dataset is randomly divided into training, validation,

and testing subsets with a 70-15-15 split. 70% of the

dataset used for training, 15% for validation, and 15%

for testing.

The table 2 below illustrates the process:

Table 2: Training and testing results.

DATASET NUMBER OF IMAGES PERCENTAGE

Training Set 1141 70%

Validation Set 245 15%

Testing Set 245 15%

After splitting the dataset, the training set was used to

train the model and adjust the model's hyper

parameters using the validation set. Once the model's

performance is optimized, the testing set evaluates its

accuracy.

3.2.5 Data Encoding

Data encoding is necessary to transform the catego-

rical labels of vehicle damage types into numerical

values that machine learning algorithms can

understand.

The dataset of images of damaged vehicles with

corresponding labels indicating the type of damage.

The labels include categories such as "Scratch,"

"Dent," "Crack,", "Tear", "Chip”, “Glass Damage",

"Spider Crack", "Large range glass damage",

"Miscellaneous damage" and "Broken Windows." To

use this data for machine learning algorithms, there is

a need to encode these categorical labels into

numerical values.

One standard data encoding method used is one-

hot encoding, where each category is assigned a

unique numerical value, represented as a binary

vector.

The datasets consist of 1631 images of damaged

vehicles, with corresponding labels indicating the

type of damage. Table 3 shows a sample of the dataset

and the corresponding encoded labels using one-hot

encoding:

Table 3: Sample of the dataset and the corresponding

encoded labels using one-hot encoding.

IMAGE LABEL ENCODED LABEL

Image 1 Scratch [1, 0, 0, 0, 0, 0, 0, 0, 0,0]

Image 2 Dent [0, 1, 0, 0, 0, 0, 0, 0, 0,0]

Image 3 Crack [0, 0, 1, 0, 0, 0, 0, 0, 0,0]

Image 4 Broken Window [0, 0, 0, 1, 0, 0, 0, 0, 0,0]

Image 5 Tear [0, 0, 0, 0, 1, 0, 0, 0, 0,0]

Image 6 Chip [0, 0, 0, 0, 0, 1, 0, 0, 0,0]

Image 7 Spider Crack [0, 0, 0, 0, 0, 0, 1, 0, 0,0]

Image 8 Miscellaneous Damage [0, 0, 0, 0, 0, 0, 0, 1, 0,0]

Image 9 Large Range Glass

Damage

[0, 0, 0, 0, 0, 0, 0, 0, 1,0]

Image 10 Metal Damage [0, 0, 0, 0, 0, 0, 0, 0, 0,1]

… … …

Image 1627 Scratch [1, 0, 0, 0, 0, 0, 0, 0, 0,0]

Image 1628 Scratch [0, 1, 0, 0, 0, 0, 0, 0, 0,0]

Image 1629 Crack [0, 0, 1, 0, 0, 0, 0, 0, 0,0]

Image 1630 Broken Window [0, 0, 0, 1, 0, 0, 0, 0, 0,0]

Image 1631 Scratch [0, 0, 0, 0, 1, 0, 0, 0, 0,0]

IoTBDS 2024 - 9th International Conference on Internet of Things, Big Data and Security

204

In table 3, the one-hot encoding assigns a unique

binary vector to each category, where the value 1

indicates the presence of the category in the label, and

0 indicates its absence. This encoded data can now be

used as input for machine learning algorithms to train

models for vehicle damage detection and

classification.

GANs are a type of neural network that can

generate new images similar to the input images

(Amrutha, 2020). GANs are used to generate

synthetic images of damaged vehicles, which can be

used to augment the training data and improve the

performance of other deep-learning algorithms, while

DNNs have a more general architecture with fully

connected layers that can learn from any type of data.

3.2.6 Creating Model to Train, Validate and

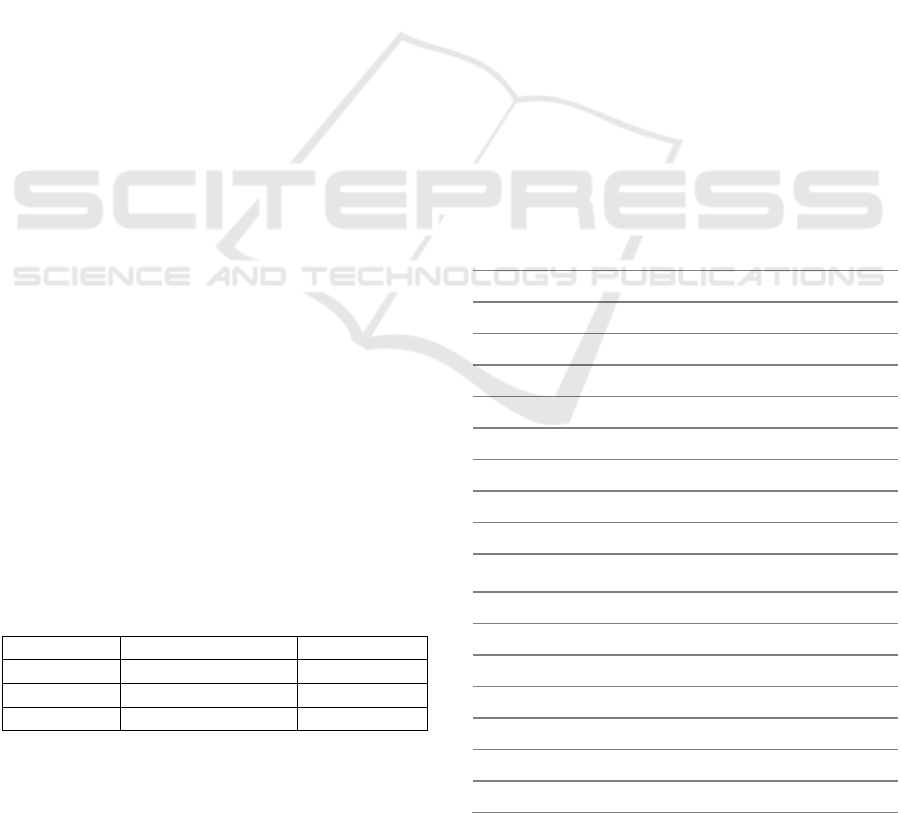

Test

For the first model a pre-trained mobile net

architecture was used without the top layer, this can

be used as a feature extractor for transfer learning.

Using a pre-trained model as a base, the knowledge

learned by the MobileNetV2 model can be leveraged

on a large dataset and adapted to a new task with a

smaller dataset.

model_final = Model(inputs=model_base.input,

outputs=model_head)

Figure 5: Pre-training models.

Figure 5 shows the process of pre-training the models

enabling the model to capture the features and

knowledge from the dataset ensuring it generalizes

well to new data.

4 EXPERIMENTS AND RESULTS

A comprehensive analysis of the performance and

features of various models is necessary when

assessing them for vehicle damage detection. The

primary goal center's on the accurate detection and

categorization of various kinds of damage. Among

these metrics, accuracy is particularly important as a

key indicator of how well a model can identify and

categorize car damage. A high accuracy score

indicates not only how well the model performs in

precisely identifying damages, but also how far the

field has come as we navigate the most recent

improvements in automotive damage identification.

(Gidaris and Komodakis, 2014).

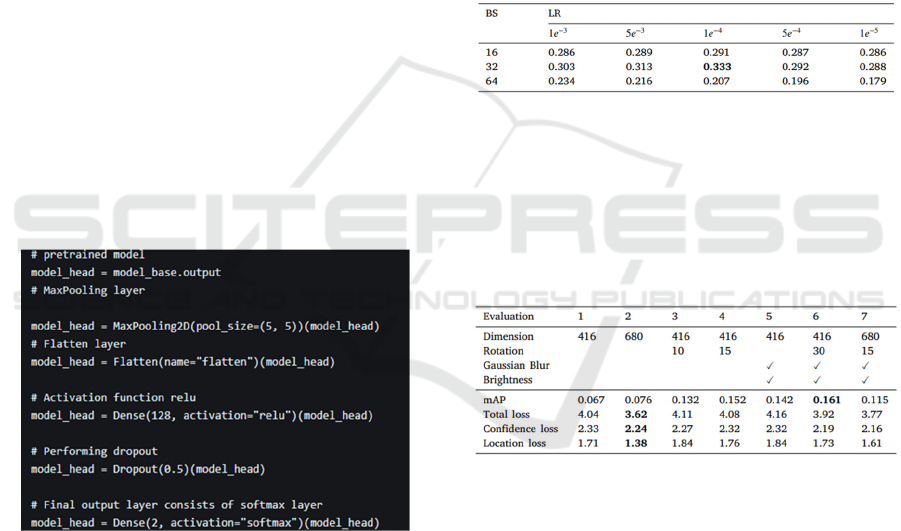

Table 4 shows results for the experiments for

Batch size and learning rate optimization. Using 𝛼

𝑐𝑟𝑜𝑝 = 0.3 and 𝛼 𝑝𝑎𝑑 = 1.7, 50 epochs, dataset mean

scaling, and ignoring the aspect ratio. Results are

reported in terms of the mAP.

Table 4: Batch size and learning rate optimization.

The effect of augmentation on scratch detection is

shown in table 5. using a subset of images which

contains at least one scratch. Using hyperparameters:

𝛼 𝑐𝑟𝑜𝑝 = 0.3, 𝛼 𝑝𝑎𝑑 = 1.7, horizontal flipping(𝑝 =

0.5), resize while ignoring the aspect ratio, 𝐿𝑅 = 1𝑒

−4, and 𝐵𝑆 = 32.

Table 5: Augumentation of scratch detection.

Preserving the aspect ratio has not shown any

notable enhancement compared to disregarding it.

However, when considering individual classes,

maintaining the aspect ratio leads to a higher mean

Average Precision (mAP) for the "Missing" class.

Conversely, ignoring the aspect ratio appears to

improve the mAP for the "Hail" and "Scratch"

classes.

The Scratch dataset's performance is depicted

across seven evaluations, with the first evaluation

serving as the reference point. The model displays

greater precision in object detection for larger image

sizes, but there is only a slight increase in the mean

Average Precision (mAP). As the mAP score

considers objects with an Intersection over Union

(IoU) of at least 0.5, it implies that the larger image

Revolutionizing Vehicle Damage Inspection: A Deep Learning Approach for Automated Detection and Classification

205

Table 6: Confusion Matrix with the prediction rows and ground truth threshold.

size enhances the location accuracy of boxes that

already had an IoU of 0.5. Evaluations 3 to 6

demonstrate that the mAP benefits from Rotation,

Gaussian Blur, and Brightness adjustment. The most

outstanding mAP is attained with evaluation 6.

The confusion matrix table provides a summary

of the model's predictions and actual outcomes for

detecting the listed categories of damages ranging

from bend to no physical damage. The measure of

accuracy of detection is calculated by the proportion

of correctly classified damages divided by the total

number of damages. The proportion of true positive

predictions among all actual positive detection shows

its rate of recall and ability to detect all instances of

damage without missing any. The precision value is

determined by true-positive predictions amongst all

detection predicted as positive.

Figure 6 shows a variety of annotated vehicles in

different lighting variations and varying degrees and

types of scratches the model was trained on.

Figure 6: Effect of augmentation on scratch detection.

Figure 7: Recall values.

Figure 8: F1-score.

Figure 9: Training and validation accuracy.

Figure 10: IOU values.

Precision and Recall are additional metrics that offer

valuable insights into the model's ability to minimize

false positives and negatives. Precision measures the

proportion of correctly identified positive instances

out of all positive ones, and it reflects the model's

ability to avoid labeling non-damaged areas as

damaged. Conversely, in figure 8, the graph shows

the recall rate of the model. Recall measures the

IoTBDS 2024 - 9th International Conference on Internet of Things, Big Data and Security

206

proportion of correctly Figure 7 identified positive

instances out of all actual positive instances. It

evaluates the model's ability to detect all instances of

damage without missing any.

To assess the model's overall effectiveness, the

F1-score is often utilized as shown in figure 8. The F1

score combines precision and recalls into a single

metric that provides a balanced evaluation of the

model's performance. It considers both the ability to

avoid false positives and negatives, providing a more

comprehensive assessment of the model's capabilities

(Wang et al., 2020). Figure 9 is the graph showing a

comparison of the training and validation accuracy.

Figure 10 shows the IOU value which is another

key metric in the evaluation of object detection and

segmentation models, it measures the accuracy of the

algorithm in terms of how well it can segment objects

within an image, it is calculated by taking the ratio of

the area of overlap between the predicted region and

the ground truth region to the area of union between

these two regions. The IoU value ranges from 0 to 1,

where: 0 indicates no overlap between the predicted

and ground truth regions and 1 indicates a perfect

overlap between the predicted and ground truth

regions.

The results obtained from the experiment

provided substantial evidence to support the

superiority of the Convolutional Neural Network

(CNN) model over the Deep Neural Network (DNN)

model. The CNN model demonstrated remarkable

performance with an impressive accuracy rate of

91%. In contrast, the DNN model, though yields

acceptable results, achieved a comparatively lower

accuracy rate of 84%. Furthermore, while showing

potential, the Generative Adversarial Network

(GAN) model achieved a modest accuracy rate of

78%.

5 CONCLUSION

This study applied Image Classification and Deep

Learning Algorithms for identifying and assessing

damaged vehicles. The images were collected

manually from open-source repositories. CNN, DNN

and GAN models were trained and tested. The study

successfully obtained satisfactory results in model

performance which were measured using the models’

accuracy, precision, recall, and F1-score. When it

comes to capturing spatial characteristics and patterns

in the dataset, convolutional layers are advantageous

because of the accuracy difference between the CNN

and DNN models. CNN was able to improve its

classification and prediction accuracy by extracting

complex features from photos and other spatial data.

Because the DNN model lacks the specialised

architecture intended for spatial comprehension, it

has difficulty efficiently capturing and processing

complicated spatial data, which has a negative impact

on accuracy.

While the accuracy rate of the GAN model was

not as high as that of the CNN and DNN models, its

main application is in the generation of new data

instances, rather than classification tasks. The 78%

accuracy rate indicates that the GAN model produced

credible synthetic data instances, which might be

useful for creating new samples or augmenting

existing data.

Testing of CNN, DNN, and GAN models revealed

signs of overfitting, which could potentially be

attributed to the restricted number of images available

in the dataset utilized for the study. Moreover, a

limited amount of damaged car part images from the

web with some images having a low resolution may

contribute to the misclassifications. It is

recommended to have larger datasets of vehicle

damages. Combining both CNNs and DNNs can

result in highly accurate vehicle damage detection

models that aid in evaluating the severity of damage

to accidented vehicles and thus determine the

necessary repairs. This will save time and enable car

fleet managers and insurance firms and other stake

holders assess vehicle damage and agreement of

claims more efficiently.

ACKNOWLEDGEMENTS

The authors express their gratitude to the University

Centre Middlesbrough-Middlesbrough College for

their financial support and for creating an opportunity

for the researchers to carry out this study.

REFERENCES

Amrutha, M. P. (2020). Automatic vehicle damage

detection from photographs using 3D CAD models.

International Journal of Innovative Technology and

Exploring Engineering, 9(4), 487-491..

Bengio, Y., Lecun, Y., and Hinton, G. (2015). Deep

learning. Nature, 521(7553), 436-444..

Chollet, F. (2017). Deep learning with Python. Manning

Publications..

Cireşan, D. C., Meier, U., Masci, J., & Schmidhuber, J.

(2012). Multi-column deep neural networks for image

classification. In Proceedings of the IEEE Conference

on Computer Vision and Pattern Recognition (CVPR)

(pp. 3642-3649)..

Revolutionizing Vehicle Damage Inspection: A Deep Learning Approach for Automated Detection and Classification

207

Gidaris, S. and Komodakis, N. (2014). Object detection via

a multi-region & semantic segmentation-aware CNN

model.

Hong-Jie Zhang, H., Yuan, Z., & Fang, M. (2022). A

model-based object detection method for automotive

damage identification. Measurement, 184, 111099..

Jeon, S., Kim, S., Kim, S., & Seo, J. (2020). Vision-based

vehicle damage detection for mobile inspection robot.

Applied Sciences, 10(1), 90..

Jiang, J., Luo, L., & Yang, C. (2021). Deep Learning.

Journal of Management Science and Engineering, 6(2),

30-40..

Jiang, X., Lu, H., & Lin, Z. (2021). Vehicle damage

detection and classification using deep learning.

Sensors, 21(2), 402.

Jiang, Y., & Ren, H. (2007). Context-aware damage

detection on industrial equipment using knowledge-

based framework. Journal of Intelligent Manufacturing,

18(6), 689-697..

Kim, S. H., Zhang, Y., & Shin, M. J. (2013). Vehicle

damage classification using deep learning. In

Proceedings of the 2013 IEEE International Conference

on Image Processing (ICIP) (pp. 2896-2900)..

Kim, S., Kim, T., & Lee, J. (2016). Deep learning approach

to damage classification. International Journal of

Precision Engineering and Manufacturing, 17(5), 583-

590.

Kumar, S. and Bhatnagar , G. (2021). Object Detection on

Edge Devices: A Review. Journal of Ambient

Intelligence and Humanized Computing, 12, 5493–

5513. [online] Available at: https://doi.org/10.1007/

s12652-021-03220-9.

Sarkar, S., Ray, S., & Kim, T. H. (2014). Vehicle damage

classification using convolutional neural networks. In

Proceedings of the 2014 IEEE Winter Conference on

Applications of Computer Vision (WACV) (pp. 440-

447).

Wang, C., Lil, Z. and Xu, C. (2020). Efficient

Convolutional Neural Networks for Vehicle Detection.

IEEE Access, 8, 168782–168791. [online] Available at:

https://doi.org/10.1109/ACCESS.2020.3023251.

White, J. R., Yang, J., & Yu, H. (2016). Damage

classification using hierarchical algorithms. Structural

Control and Health Monitoring, 13(4), 707-722..

Zhou, J., Jin, S., Yan, Q. and Lu, J. (2021). An Overview of

Model Compression Techniques for Deep Learning.

IEEE Transactions on Neural Networks and Learning

Systems, 32(4), 1410–1424. [online] Available at:

https://doi.org/10.1109/TNNLS.2020.3016158.

IoTBDS 2024 - 9th International Conference on Internet of Things, Big Data and Security

208