Tile Quality Detection Device: Internet of Things (IoT) Demonstration

Prototype

Bernhard Heiden

1,3 a

, Danijel Pa

ˇ

cnik

1

, Jessica Pregl

1

, Maximilian M

¨

uller

1

, Simone Leitner

1

,

Volodymyr Alieksieiev

2 b

and Bianca Tonino-Heiden

3 c

1

Industrial Engineering and Management Studiengang, University of Applied Sciences,

Europastrasse 4, 9524 Villach, Austria

2

Institute of Production Management and Technology, Hamburg University of Technology,

Denickestrasse 17, 21073 Hamburg, Germany

3

Institute of Philosophy, University of Graz, Heinrichstrasse 26/V, 8010 Graz, Austria

Keywords:

Tile Quality Check, IoT-Prototype, Matlab, Arduino UNO, Microcontroller, Pattern Detection.

Abstract:

In this paper we present the development of a quality tile detection device for the Internet of Things (IoT)

demonstration in a prototype for educational purposes. For this an Arduino UNO microcontroller is used, and

the prototype is chosen after an initial design process, together with suitable tile parts, that imitate possible real

tiles in a production line in the downscaled prototype. The Artificial Intelligence (AI) task of pattern detection

is performed by a Matlab script. Finally, the Arduino, that controls the conveyor belt and the switch of the

tile quality detection device is linked to the Matlab Script, that controls the picture detection and AI-script

evaluation on the PC and its backcoupling to the Arduino, yielding a semi-automatic tile quality checking

procedure with a human in the loop.

1 INTRODUCTION

A typical application in tile production industry is to

test the quality of tiles, as in the production process

imperfections can occur (see, e.g. (Frei, 2017)), and

have then to be detected in a mass production pro-

cess. A case, with regard to ceramics industry, which

is comparable to our case, is given in (Zhang et al.,

2022), showing its relevance and state of the art prob-

lem in the industry. This hence can be regarded as

an industrial application case where Artificial Intelli-

gence (AI) techniques can be applied, as well as Inter-

net of Things (IoT) applications that implement these

tasks in a prototype that merges the cybernetic tasks

with the necessary AI for detection.

(Dong et al., 2022) have developed an indus-

trial solution prototype for mosaic tiles as a complete

workflow. The system installed on a conveyor belt,

has a detection unit, and a sorting unit by means of a

spray mechanism.

There exist a lot of AI algorithms that are used for

a

https://orcid.org/0000-0001-8324-6505

b

https://orcid.org/0000-0003-0792-3740

c

https://orcid.org/0000-0001-7648-2833

tile quality detection. E.g., that of (Wan et al., 2022)

is based on deep learning.

IoT applications range from a narrow field of ba-

sic implementations, to a wide field of broad and even

global applications, where the focus is then to typ-

ical challenges like how to merge these IoT devices

to reach one goal (e.g. (Lemoine et al., 2020) and

(Choo et al., 2018)), to reach cybersecurity (see, e.g.

(Corallo et al., 2022) and (Lindstr

¨

om et al., 2018)),

and many others. This means that the tasks, which

are performed by IoT-devices, are tremendously in-

creasing with the uprise of more and more miniatur-

ised devices in all industries. The overarching devel-

opment is triggered by the high amount of micropro-

cessor driven processes world-wide, and the ongoing

trend to make those automatisations cheaper and of

higher applicability due to the development towards

a higher functional performance, e.g. in the mobility

and energy savings sector.

For the IoT applications one widely used micro-

controller board is the Arduino UNO. It is widely

applied for IoT prototyping applications according

to its low costs among many other microcontrollers.

A good reference for the Arduino UNO is given in

(Borchers, 2013).

Heiden, B., Pa

ˇ

cnik, D., Pregl, J., Müller, M., Leitner, S., Alieksieiev, V. and Tonino-Heiden, B.

Tile Quality Detection Device: Internet of Things (IoT) Demonstration Prototype.

DOI: 10.5220/0012634000003705

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 9th International Conference on Internet of Things, Big Data and Security (IoTBDS 2024), pages 209-215

ISBN: 978-989-758-699-6; ISSN: 2184-4976

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

209

The computer algebra and programming software

Matlab is frequently used in science and industry for

solving engineering tasks, and especially it can serve

practically to implement AI applications for at least

three reasons. Firstly (1) there exists a broad inter-

national industrial user community, especially in the

area of academia, where a lot of AI-algorithms are

developed with this language, (2) secondly there is a

good support possible, which is important for indus-

trial applications, and thirdly (3) there exists a wide

range of tutorials and ready to use libraries that al-

lows to implement AI-algorithms from the scratch to

the complete set-up. E.g., in (Hanzaei et al., 2017)

a pattern detection problem is also implemented with

Matlab, as in our case for the tile quality detection.

An overview of Computer Numerical Controlled

(CNC) machines is given in (Kief, 2015). These are

used in mechanical workshops, and are often to be

found in prototyping labs or Fablabs (see, e.g. (Ger-

shenfeld, 2006)). To produce a prototype there or in

similarly structured workshops, the rapid prototyping

approach is state of the art, which means that a series

of CNC devices is used to fabricate the prototype, be-

ginning with form construction and ending with ma-

chining, e.g. with CNC-milling or 3D-printing (see,

e.g. (Gibson et al., 2015)).

One reviewer asked to answer the question <What

is new in the paper?>. This paper deals with a new

prototype used for education to learn new and ac-

tual technologies used in industry and production.

(Mesch, 1985) has pointed out that in education new

measurement technologies lead also to a new kind of

education. (1) New material, (2) new or until now

not utilized physical effects, and (3) new applications

are, according to Mesch, elements of newness, that

induce possible different approaches in teaching as a

consequence. Applied to our case, the newness is con-

stituted by the here presented student’s project, that

has conceptualised the problem of tile quality detec-

tion in integrating all the aspects of the state of the

art industrial technologies: CNC-production, IoT pro-

totyping and algorithmic or in general AI-open IoT-

implementation.

The prototype can now additionally be used for

applying industrial concepts in a classroom environ-

ment, and it is available as an open source application

(Heiden et al., 2024) for the IoT community.

Goal of the Work. The goal of the work is to de-

velop, build and demonstrate an IoT-prototype for an

educational classroom setting of a realistic tile pro-

ducing ceramics industry exercise and as an educa-

tional task to combine mechanical engineering tasks

with the design of an IoT device, and providing an AI

method of pattern detection, by an integrated proto-

type.

Research Questions. The main research question

of the work is: <How can a downscaled prototype of

an IoT-device for educational demonstration purposes

be built for the quality detection of tiles by applying

AI-algorithms in ceramics industry?>.

Content. In this paper we first give in Section 2 an

overview over the design of the IoT model tile quality

detection device. In Section 3 we discuss the results

of this work. In Section 4 we then give the conclu-

sions and outlook of the work.

Methods Used. The method of this work is to

design, construct, build and test an IoT model pro-

totype, which incorporates essential elements of an

automatised tile quality detection. For the construc-

tion a mechanical workshop is used, as well as CNC

milling. For the quality detection AI algorithms are

implemented in Matlab. The Arduino UNO is used

as basis IoT-backbone for the prototype. A half-

automatised communication between the Arduino and

the Matlab computer application is then used to im-

plement the pattern detection, by means of a human-

machine interaction.

2 TILE QUALITY DETECTION

DEVICE

In Figure 1 we see the prototype of the tile quality

detection device. It consists of downscaled round tile-

models, the slide, the conveyor belt the photoelectric

and the tile detection sensor and a switch for choosing

the right tile, powered by a stepper motor. The flow

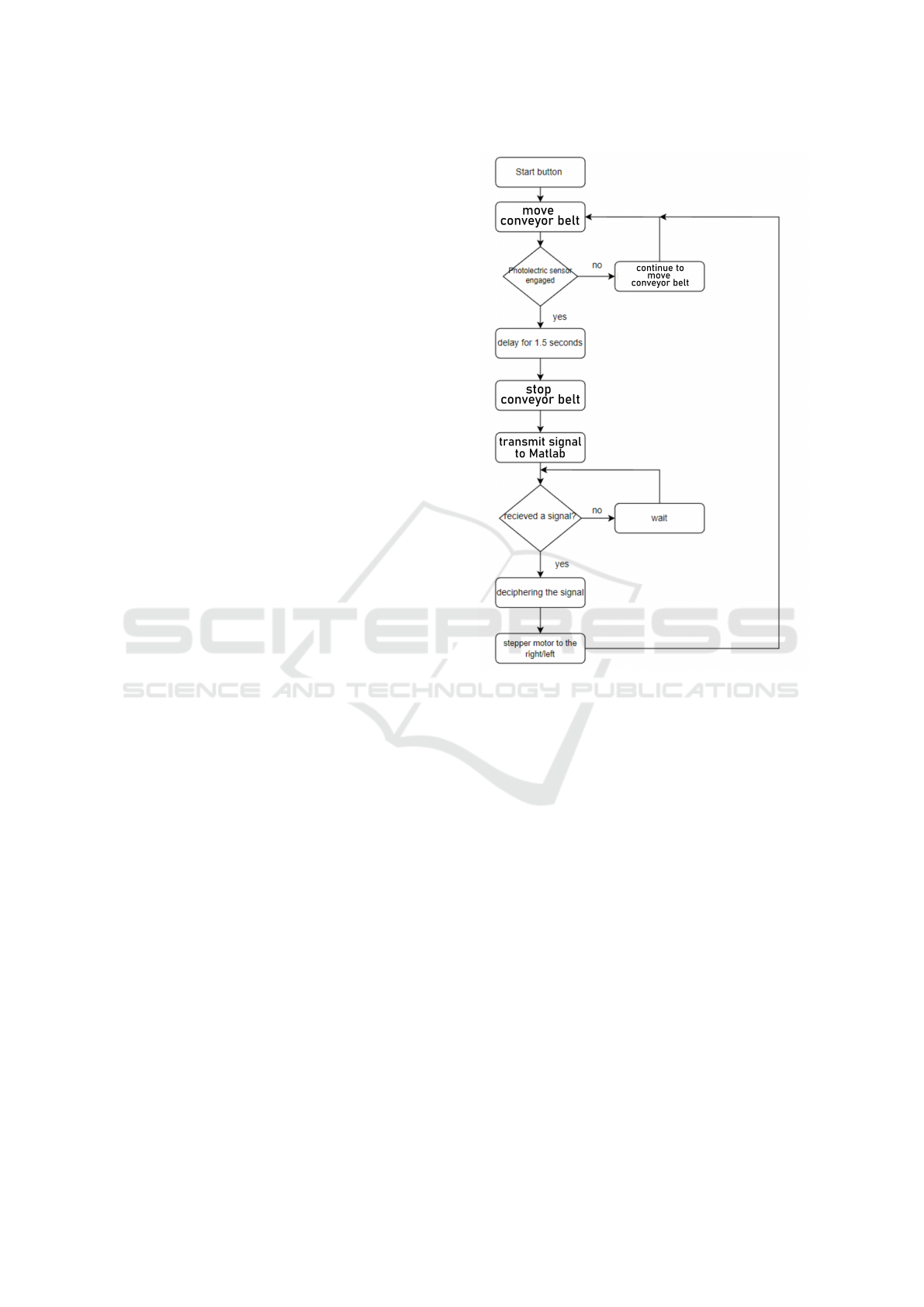

diagram can be seen in Figure 3.

2.1 Material for Virtual Tile Detection

Since dealing with normal tiles is quite unwieldy,

‘sample tiles’ are designed and made. Therefore, the

patterns are milled from a phenolic resin coated ply-

wood in different variants. The coating is brown, fur-

ther the coating is glossy and therefore simulates a

regular tile surface. The plate thickness is 10 mm.

In addition, the tiles have a diameter of 70 mm. The

round shape is chosen for the sake of simplicity be-

cause we are implementing a model production sys-

tem. The following samples were produced:

• Model 1: Error-Free

IoTBDS 2024 - 9th International Conference on Internet of Things, Big Data and Security

210

tile-detection camera

stepper motor

for switch underneath

conveyor belt

photoelectric

sensor

bad tiles

lane

good tiles

lane

power line 12V

tile-

models

slide

start

button

Figure 1: Tile Quality Detection Device IoT-Demonstration Prototype. More details can be found in the complete project

documentation (in German) of the prototype in (Heiden et al., 2024).

• Model 2: Error 1

• Model 3: Error 2

• Model 4: Special motive 1 ‘Platypus’

• Model 5: Special motive 2 ‘Koi’

These five Models were chosen to be programmed at

the image processing (pattern recognition) in the fur-

ther course. Model 1 should be recognized without er-

rors, Models 2 and 3 should be recognized with errors

and the accuracy of the system should also be tested.

The special motives koi and platypus must be recog-

nized as mistakes in Model 4 and 5 (see also Figure

2).

First, the five design Models were each individu-

ally converted into 3D drawings/3D models in the

program Fusion 360 and the associated G code (see,

e.g. (Kief, 2015)) was created. The G code, also

called DIN code, is the machine language with which

the user controls the CNC machine and with which

the CNC machine moves to the desired position or

depth and mills or engraves. Secondly, the program

Estlcam V11 processes the G code and controls the

CNC machine used. Thirdly, the coordinate system of

the CNC machine must be determined, and the work-

piece must be clamped. Finally, the desired motive is

milled.

The used tools were (1) the engraving graver with

a 30° tip and an end mill. For safety reasons, the

samples were milled beginning with a bar, so that

they are not loose in the machine. For this reason, all

samples were reworked with a (2) jigsaw, (3) a belt

sander with fine-grain sandpaper and (4) an air com-

pressor.

A total of 24 pieces were made: 10x Model 1

error-free, 4x Models error error 1 and error 2 each,

1x special motive platypus and koi, or Models 4 and

5, and 4 samples without the brown coating (wood

look).

2.2 Artificial Intelligence (AI) Tile

Detection

In the project, image processing is carried out using

Matlab. A webcam of the company CamPark of the

type PC02 is used (see also Figure 1), and document-

ation in (Heiden et al., 2024).

The program workflow is shown in Figure 3. (1)

First a function is created by the user to get inputs and

outputs and, as in this case, these are reused in another

file. With ‘Bildverarbeitung002.m’ (see the program

code in (Heiden et al., 2024)), a single image is cap-

tured with the camera. The captured image is always

an RGB image. This program uses the standard resol-

ution of the camera. Image corrections are then made.

A structuring element is a binary-valued neighbour-

hood, either 2-D or multi-dimensional, in which the

true pixels are included in the morphological calcu-

lation and the false pixels are not. The central pixel

Tile Quality Detection Device: Internet of Things (IoT) Demonstration Prototype

211

(a)

(b)

Model 1

Model 2

Model 3

Model 4

Model 5

Figure 2: Tile Quality Test Parts - Constructed and Real

Implementation.

Figure 3: Program Workflow.

of the structuring element, called the origin, identifies

the pixel in the image to be processed. In this case,

‘strel(“disk”,r)’ creates a disk-shaped structuring ele-

ment, where r indicates the radius, here 15. Then,

using this structuring element, ‘imdilate’ expands the

image.

The next step is to count the black pixels, this

is done to determine if the sample is a good or bad

pattern. First, the greyscale image is binarised by

thresholding, replacing all values above a globally

defined threshold with ones and setting all other val-

ues to zeros. Since the image has now been divided

into zeros and ones, the black pixels must be counted,

i.e. all ones, since the zeros represent the white pixels.

(2) The file ‘createMask1.m’ (see the program

code in (Heiden et al., 2024)) is used to differentiate

those colour areas that occur on the pattern pane. The

Color Thresholder app is used for this. It automat-

ically generates a code. The Color Thresholder app

can be used to segment colour images by threshold

values for the colour channels based on different col-

our spaces. With this app, one can create a bin-

ary segmentation mask for a colour image. Color

Thresholder supports segmentation in four colour

spaces. In each colour space, the application displays

the image, the three colour channels and the colour

value of all pixels as points in a 3D colour space dia-

gram. One can select the colours contained in the

mask by displaying the colour channel values in a

window or by drawing Regions of Interest (ROI) in

the image or in the 3D colour space diagram. In the

following we show how to segment an image and cre-

ate a mask image using the Color Thresholder app.

With the pattern slice, the pattern (triangle) is seg-

mented from the background (slice and conveyor belt)

based on colour values. The image can be segmen-

ted in several of the colour spaces supported by the

app, as one colour space can isolate a particular col-

our better than another. In the project, the RGB col-

our space is chosen because it gave the best result. In

each of the supported colour spaces, one can first per-

form an automatic segmentation by selecting an area

in the foreground or background. Then one can refine

the segmentation using the colour component controls

provided by the application. Once the segmentation is

complete, the results are saved, a mask image is cre-

ated and the Matlab code used by the app to perform

the segmentation is retrieved.

(3) Finally, the communication between Matlab

and Arduino is implented. This is done by the pro-

gram ‘KommunikationMaltabArduino002.m’ (see the

program code in (Heiden et al., 2024)).

2.3 Construction of the IoT Device

Demonstration Prototype

To demonstrate and evaluate the process of tile qual-

ity detection an IoT device is needed. Therefore,

a prototype was produced by common manufactur-

ing processes. In other words, a conveyor belt has

been built, driven by a 12 VDC gear-motor to gen-

erate enough torque for the application. All needed

work steps were achieved by in house manufactur-

ing. These include some of the following manufac-

turing processes: several joining and cutting meth-

ods containing CNC cutting, 3D-Modelling, weld-

IoTBDS 2024 - 9th International Conference on Internet of Things, Big Data and Security

212

ing, soldering and other commonly known proced-

ures. Moreover, all the electrical requirements needed

to be addressed as well, whereas the implementation

belongs to and has a huge impact on the proper func-

tionality. To address this necessity up to date methods

were used, like prototype circuit board cutting with

an application related CNC cutting machine (details

can be found in the project documentation in (Heiden

et al., 2024)). Moreover, the choice of all the elec-

trical components were chosen to allow for an inter-

action between all the used sensors and actuators. The

prototype-like circuit board construction is needed,

because the whole IoT-device is powered by an ex-

ternal 12VDC energy source, but some of the com-

ponents need an individual DC potential to operate.

An Arduino UNO was used to process all the sensor

signals and operate the actuators, requiring a custom

Arduino shield.

2.4 Control System of Prototype

The control system of the application is based upon

the Arduino UNO microcontroller, thus the coding

was ensued in the Arduino development environ-

ment. The inspection process can be portrayed and

explained via the flow chart diagram in Figure 3 and

4.

It starts with a press of a physical button (there is

an option to start the process through serial monitor

as well). As a result, the DC motor powers on and

puts the conveyor belt in motion. If the photoelec-

tric sensor picks up a signal the belt is stopped in 1.5

seconds. This allows for the object to align directly

under the camera, which is responsible for creating

an image of the inspected object. While it is posi-

tioned under the camera, the Arduino transmits a sig-

nal via serial communication to the connected laptop

that runs the Matlab software, where the image pro-

cessing takes place. While the Matlab process takes

place, the state of the device stays the same. After-

wards a signal is sent back, which consists either of a

zero (‘0’) or one (‘1’). The Arduino therefore needs

to decipher the signal and acts then according to the

outcome. A ‘1’ signal causes to move the stepper mo-

tor to the left, where the qualified objects are sorted

and the ‘0’ to the right. Finally, the conveyor belt

starts moving again to successfully sort the inspected

object.

The whole CNC system consists of the following

components:

• DC Motor – for powering the conveyor belt

• Stepper motor – Stepper is attached with a

custom-made sorter to angle the objects

Figure 4: Flow Sheet Program of the Tile Quality Check

Prototype.

• Photoelectric sensor – to sense the objects, which

pass by

• Limit switch – mounted to the left and right of the

stepper motor to limit its movement

• Start key – to power on the device

The Arduino code consists of switch cases, which

allow the device to move from case to case accord-

ingly in a loop. Moreover, multiple time variables

are used, in order to keep track of the process and

to control its movements as well as the integrated Ar-

duino functions such as millis() for the time measure-

ments and isAlpha() and isAlphanumeric() for deci-

phering the received signals. A thing to keep in mind,

while using serial communication as indicators for the

switch sequences, is to regularly clear the contents out

of the serial monitor, due to the possibility of reading

the older or wrong input.

Tile Quality Detection Device: Internet of Things (IoT) Demonstration Prototype

213

3 DISCUSSION

The first test

1

has shown, that there is a huge depend-

ency of the light condition on the effective detection.

The sensitivity to this problem is also reported in in-

dustry in (Coskun et al., 2022), and counter measures

have been taken by, e.g. illumination equipment. Al-

though the general overall problem has been simpli-

fied by the round geometry of the tiles, there remain

problems of pattern detection, although the mechan-

ical handling works fine.

Another point is that in such experiments then the

statistical results are automatically and not manually

generated. By this different algorithms could be ana-

lysed systematically in an empirical fashion, which is

now limited to a lot of manual interaction.

Concerning real world applications, this prototype

is usable in classroom settings, as it is small, mobile

and easy to transport. For a scale-up of this proto-

type to industrial applications, the Matlab automation

can easily be used and adapted for industrial environ-

ments. The before mentioned problems with scanning

quality, has additionally to be addressed.

The overall process is not fully automated, as there

has to be an interaction of the operation with the tiles

and the user who runs the Matlab program. For an

industrial application procedure it would be necessary

that the process works autonomously and reliable.

An automated testing extension for test data gen-

eration and to make automated testing and its statist-

ical data evaluation of the quality of the testing would

improve the current prototype system significantly,

which would then be in the upscaled version a kind

of auto-calibration function in the field.

4 CONCLUSION AND OUTLOOK

An IoT prototype for detection patterns in tiles, that

are related to quality issues in production is investig-

ated in this paper. For this an IoT device has been

designed, built, and tested. The result is the IoT-

prototype shown in Figure 1. The AI is implemen-

ted with a Matlab program. The communication is

triggered by Matlab and the main control of the device

on the other side is done by an Arduino UNO pro-

gram, powering the hardware of the given IoT device.

The future outlook of the work is to improve the

light sensitivity of the device, the robustness, of the

detections algorithms with regard to different tiles and

the implementation of more sophisticated AI models

like, e.g. deep learning. Another point is to further

1

See project documentation in (Heiden et al., 2024).

generalise (a) the prototype, so that it can be used

for the detection of more complex patterns, and (b)

patterns that are derived from real examples from in-

dustry. In those cases also the velocity is important,

which then means that a different than purely Matlab

and Arduino based method for this application could

possibly be taken into consideration for improving the

effective productivity, reliability, reproducibility, ef-

fective detection efficiency, etc.

Finally, it has to be mentioned that the solution

of the problem of pattern detection is only one aspect

of quality issues. The other is of improving the pro-

cess, which then means that the patterns are subject

to an evolutionary change in the course of continu-

ous process improvement. This then also will open up

the question how to implement this pattern changing

situation into the pattern detection problem on the one

hand and to use AI to avoid quality issues by process

identification and process parameter improvement on

the other side before those quality issues occur, which

then also means that the ’quality type’ or the meta-

quality of detection could change in the course of this

continuous improvement process.

This, as well could then be implemented in a fu-

ture new version of an educational prototype, which

can then be understood as a downscaled educational

IoT twin of the industrial original IoT device.

REFERENCES

Borchers, J. (2013). Arduino in a Nutshell. http://hci.rwth-

aachen.de/arduino

Choo, K.-K. R., Bishop, M., Glisson, W., and Nance, K.

(2018). Internet- and cloud-of-things cybersecurity re-

search challenges and advances. 74:275–276.

Corallo, A., Lazoi, M., Lezzi, M., and Luperto, A. (2022).

Cybersecurity awareness in the context of the indus-

trial internet of things: A systematic literature review.

137:103614.

Coskun, H., Yigit, T., and

¨

Unc

¨

u, I. S. (2022). Integration of

digital quality control for intelligent manufacturing of

industrial ceramic tiles. 48(23):34210–34233.

Dong, G., Sun, S., Wu, N., Chen, X., Huang, P., and Wang,

Z. (2022). A rapid detection method for the surface

defects of mosaic ceramic tiles. 48(11):15462–15469.

Frei, F. (2017). Production optimisation based on a case

study at the company CerMed inc., original in Ger-

man: Produktionsoptimierung anhand einer Fallstudie

bei der Firma CerMed GmbH. Bachelor Thesis, Vil-

lach, Carinthia University of Applied Sciences.

Gershenfeld, N. (2006). Unleash your creativity in a fab

lab. Feb. 2006, video, length: 17’15”. https://www.

ted.com/talks/neil gershenfeld on fab labs

Gibson, I., Rosen, D., and Stucker, B. (2015). Additive

Manufacturing Technologies 3D Printing, Rapid Pro-

totyping, and Direct Digital Manufacturing. Springer.

IoTBDS 2024 - 9th International Conference on Internet of Things, Big Data and Security

214

Hanzaei, S. H., Afshar, A., and Barazandeh, F. (2017).

Automatic detection and classification of the ceramic

tiles’ surface defects. 66:174–189.

Heiden, B., Pacnik, D., Pregl, J., M

¨

uller, M., and Leit-

ner, S. (2024). Source code for the tile quality

detection device. https://github.com/BernhardHeiden/

TileQualityDetectionDevice

Kief, H. (2015). CNC-Handbuch CNC, DNC, CAD,

CAM, FFS, SPS, RPD, LAN, CNC-Maschinen, CNC-

Roboter, Antriebe, Energieeffizienz, Werkzeuge, In-

dustrie 4.0, Fertigungstechnik, Richtlinien, Normen,

Simulation, Fachwortverzeichnis. Hanser, M

¨

unchen.

Lemoine, F., Aubonnet, T., and Simoni, N. (2020). Self-

assemble-featured internet of things. 112:41–57.

Lindstr

¨

om, J., Eliasson, J., Hermansson, A., Blomstedt, F.,

and Ky

¨

osti, P. (2018). Cybersecurity level in IPS 2

: A case study of two industrial internet-based SME

offerings. 73:222–227.

Mesch, F. (1985). Impact of new technology on measure-

ment education. 3(1):44–48.

Wan, G., Fang, H., Wang, D., Yan, J., and Xie, B. (2022).

Ceramic tile surface defect detection based on deep

learning. 48(8):11085–11093.

Zhang, H., Peng, L., and Lei, G. (2022). Saliency detec-

tion for surface defects of ceramic tile. 48(21):32113–

32124.

Tile Quality Detection Device: Internet of Things (IoT) Demonstration Prototype

215