Ontology to Define Sizing Screw Joints for Mechanical Engineering

Applications

Henrique Priebe

1 a

, Gustavo Roberto Ramos

2 b

and Vinícius Maran

1 c

1

Laboratory of Ubiquitous, Mobile and Applied Computing (LUMAC), Polytechnic School,

Federal University of Santa Maria, Av. Roraima, 1000, Santa Maria, Brazil

2

Group on Mechanics of Materials and Structures (GMEC), Federal University of Santa Maria, Rodovia Taufik Germano,

3013, Cachoeira do Sul, Brazil

Keywords:

Machine Elements, Ontology, Bolts, Bolted Joints.

Abstract:

The sizing of bolted joints is crucial for mechanical projects that will experience working loads. This requires

careful analysis during the design specification phase, where materials, manufacturing processes, components,

and layout are determined. This analysis is time-consuming since most of it is done manually using analytical

calculations, as there are limited computational tools available. Developing such tools requires a formal repre-

sentation of knowledge that algorithms can process. The purpose of this work is to create a conceptual model,

using ontologies, to represent the information found in specialized literature about bolts and bolted joints.

By doing so, it becomes possible to automate calculations for bolt stiffness and stiffness of joint elements.

The ontology was built following the UPON methodology, which involves extracting domain terms to guide

knowledge modeling. The resulting ontology provides a formal and explicit representation of statically loaded

bolted joints in an axial direction. It also has the capability to answer predetermined competence questions,

indicating that it can be used by software applications to process information efficiently.

1 INTRODUCTION

Since the Industrial Revolution, the time needed to

develop new technologies and products has been

shorter and shorter. From the mechanization of previ-

ously artisanal processes, new methods and philoso-

phies were developed to increase the production

speed, improve the quality of the products and reduce

the costs involved (Silveira, 1998).

The common point of the different recent de-

sign methodologies are the stages that compose them.

These can be generalized as follows: an initial phase

of identifying needs, a phase of collecting informa-

tion and defining the problem, a phase of specifying

the project and sizing components, a phase of build-

ing the prototype and, finally, product validation to

start production (Silveira, 1998). During the speci-

fication of a mechanical project, screws and fasten-

ers are recurrent and of great importance components,

available in a numerous variety for the most diverse

applications. Likewise, there are abundant types of

a

https://orcid.org/0000-0001-9678-9613

b

https://orcid.org/0000-0002-3914-1826

c

https://orcid.org/0000-0003-1916-8893

bolted joints available, due to the constant evolution

of this area (Budynas and Nisbett, 2007). The cor-

rect sizing and selection of bolts in a bolted joint is of

paramount importance to avoid failures in a project,

especially when it is subject to significant loads and

stresses (Norton, 2010). There are few tools for anal-

ysis or aid in the design of bolted joints that use an-

alytical methods. For the development of computa-

tional tools in this context, it is of great importance

the adequate modeling of the information, as well as

the modular expansion of the database (Kogalovsky

and Kalinichenko, 2009). This modeling may aim

at building ontologies, formal and explicit represen-

tations of knowledge in a given domain, so that it is

understood and processed by software (Antoniou and

Harmelen, 2009). Thus, the present work aimed to

conceptually model, through a representation using

ontologies, the information found in specialized lit-

erature (Budynas and Nisbett, 2007) (Collins et al.,

2009), referring to screws and bolted joints statically

loaded under tension, so that it is possible to automate

the calculation processes for their analysis.

The paper is structured as follows: Section 2

presents a bibliographical review referring to bolts

Priebe, H., Ramos, G. and Maran, V.

Ontology to Define Sizing Screw Joints for Mechanical Engineering Applications.

DOI: 10.5220/0012675600003690

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 26th International Conference on Enterprise Information Systems (ICEIS 2024) - Volume 2, pages 53-64

ISBN: 978-989-758-692-7; ISSN: 2184-4992

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

53

and bolted joints, as well as conceptual modeling

and information systems, and some work related to

machine elements and ontologies. In Section 3, the

methodology used for the development of the work is

presented, as well as partial results obtained through

its application. In Section 4, the results regarding on-

tology tests are described and discussed. Finally, Sec-

tion 5 presents conclusions and possibilities for ex-

pansion of this work.

2 DOMAIN BACKGROUND

The product design methodology is defined, accord-

ing to (Albuquerque et al., 2020), as the study of

methods applicable to designs. It is a set of sys-

tematic and methodological procedures, adaptable to

problems in general, which aim to obtain a suitable

product to meet certain needs. These procedures

are grouped into phases, which vary among the var-

ious authors who address the topic, but in general

maintain the meaning (Silveira, 1998). According to

(Nicholas and Steyn, 2020) the phases of a project

consist of: requirements, problem statement, solu-

tion generation, evaluation and testing. Similarly,

(Omelyanenko et al., 2021) presents the phases of the

project life cycle such as conception, planning, execu-

tion, monitoring and control, closing. (Collins et al.,

2009) subdivides the design activity into four stages:

preliminary design, intermediate design, detail design

and development, and field service. It is important for

designers to have technical knowledge regarding the

machine elements necessary for a correct sizing and

selection of these (Norton, 2010). Thus, the analysis

of the components of a mechanical project must be

carried out individually and, as these are usually con-

nected, it is also necessary to evaluate the influence

of each component on the system as a whole (Budy-

nas and Nisbett, 2007). Likewise, the connections be-

tween components must be studied in order to choose

an appropriate joining method, so that problems of

geometric discontinuities and points of stress concen-

tration are avoided or reduced (Collins et al., 2009).

Consequently, there are several analytical and com-

putational methods available for the analysis of joints,

among them, screw joints (Bruzzone et al., 2019).

2.1 Screws and Screwed Joints in

Mechanical Engineering

Screws can be divided into two types according to

their application: power screws and fixing screws.

Those of the first group, also called linear actuators,

are used to convert angular movement into linear,

while those of the second group are mainly used in

non-permanent joints (Collins et al., 2009). However,

due to the defined objectives, the approach of this

work is directed to fastener-type screws. According to

(Norton, 2010), there are different ways of classifying

fasteners: according to the intended use (bolts, ma-

chine screws or studs); by the type of thread (screws,

cutters, self-drilling); according to the type of head

(hexagonal, slotted, Phillips) and according to resis-

tance (due to materials and manufacturing processes).

The distinction between bolts and machine screws is

semantic only, as the same fastener can be used in

conjunction with a nut or threaded into a hole. Stud,

on the other hand, are characterized by the absence of

a head, having threads at both ends (Norton, 2010).

Threaded fasteners have certain terminologies and

definitions in common, used to characterize them and

help in the calculation of their properties. The first

of these is the pitch (p), defined as the axial distance

between corresponding points on adjacent threads,

or the number of threads per inch, in English units

(Collins et al., 2009). Then we have major diameter

(d) as the largest diameter of the thread, minor diam-

eter (d

r

) as the smallest diameter (root) and primitive

diameter (d

p

) being a theoretical diameter between

the largest and smallest (Budynas and Nisbett, 2007).

Another definition is the lead (l), corresponding to

the axial displacement of a nut after one revolution.

This is equal to one pitch for single threads, equiv-

alent to twice the pitch for double threads, or three

times the pitch for triple threads (multi-entry threads)

(Norton, 2010). By default, threads are made clock-

wise (unless otherwise specified), so the bolt advances

through the nut when turned in this direction and re-

tracts when turned in the opposite direction (Budynas

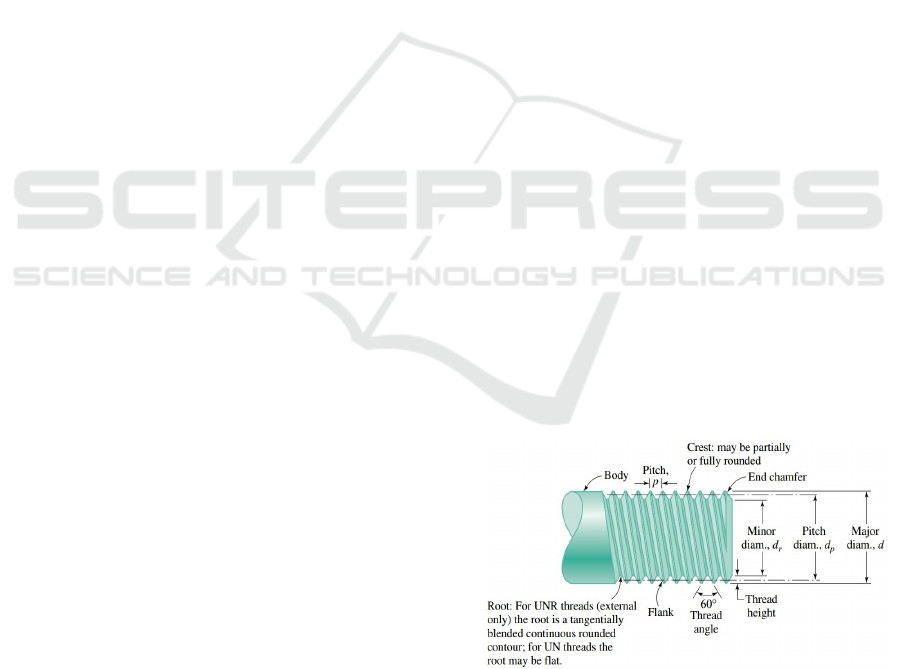

and Nisbett, 2007). Figure 1 illustrates some of these

definitions for a single-thread screw.

Figure 1: Screw thread terminology. Adapted from (Collins

et al., 2009).

After the Second World War, there was a need to

standardize the shapes of the threads, and the series

UNS (Unified National Standard) emerged through

the countries England, Canada and the United States

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

54

of America, as well as the European standard through

ISO (International Organization for Standardization)

(Norton, 2010). UNS series threads have inch dimen-

sions and are designated by “UN”, while ISO stan-

dard threads use the metric system and are designated

by “M”. These designations receive, respectively, the

letters “R” and “S” at the end, when you want to

specify a rounded root (Collins et al., 2009).

2.2 Shigley’s Method for Analysis of

Bolted Joints

The main function of a screw is to keep two or more

elements together, for this purpose it is pulled through

the application of torque to the nut, producing a reten-

tion force called preload, which guarantees the union

of the elements as long as the external force does not

cause their separation (Budynas and Nisbett, 2007).

According to (Norton, 2010), in static assemblies a

preload of 90% of the proof load can be imposed on

the bolt, while in joints subject to dynamic loads the

preload can exceed 75%. According to (Budynas and

Nisbett, 2007), in permanent connections a preload of

90% is recommended and, in non-permanent joints in

which the fasteners will be reused, a preload of 75%.

The importance of preload is related to the elastic be-

havior of the bolted joint, whose components can be

modeled as linear springs (Collins et al., 2009). For

springs in series, the total spring constant can be cal-

culated by:

1

k

=

1

k

1

+

1

k

2

+

1

k

3

+ ...+

1

k

n

, (1)

where n is the number of springs. Thus, according

to (Norton, 2010), for a screw of diameter d with a

length of the threaded portion of the grip l

t

, used in

a joint with a clamped zone of length l, the elastic

constant is given by:

k

b

=

A

t

A

b

A

b

l

t

+ A

t

l

s

E

b

, (2)

where l

s

= l − l

t

is the length of the unthreaded part

of the bolt, A

t

is the tensile stress area of the fas-

tener, A

b

is the total cross-sectional area, and E

b

is the

Young’s modulus of the bolt. To obtain the stiffness

of the elements (which are being compressed) there

are different analytical methods that are distinguished

mainly by the format attributed to the stress distribu-

tion along the elements. According to (Budynas and

Nisbett, 2007), one of the best known and widely used

is the method proposed by Shigley, which considers

the stress distributed in the form of a truncated cone

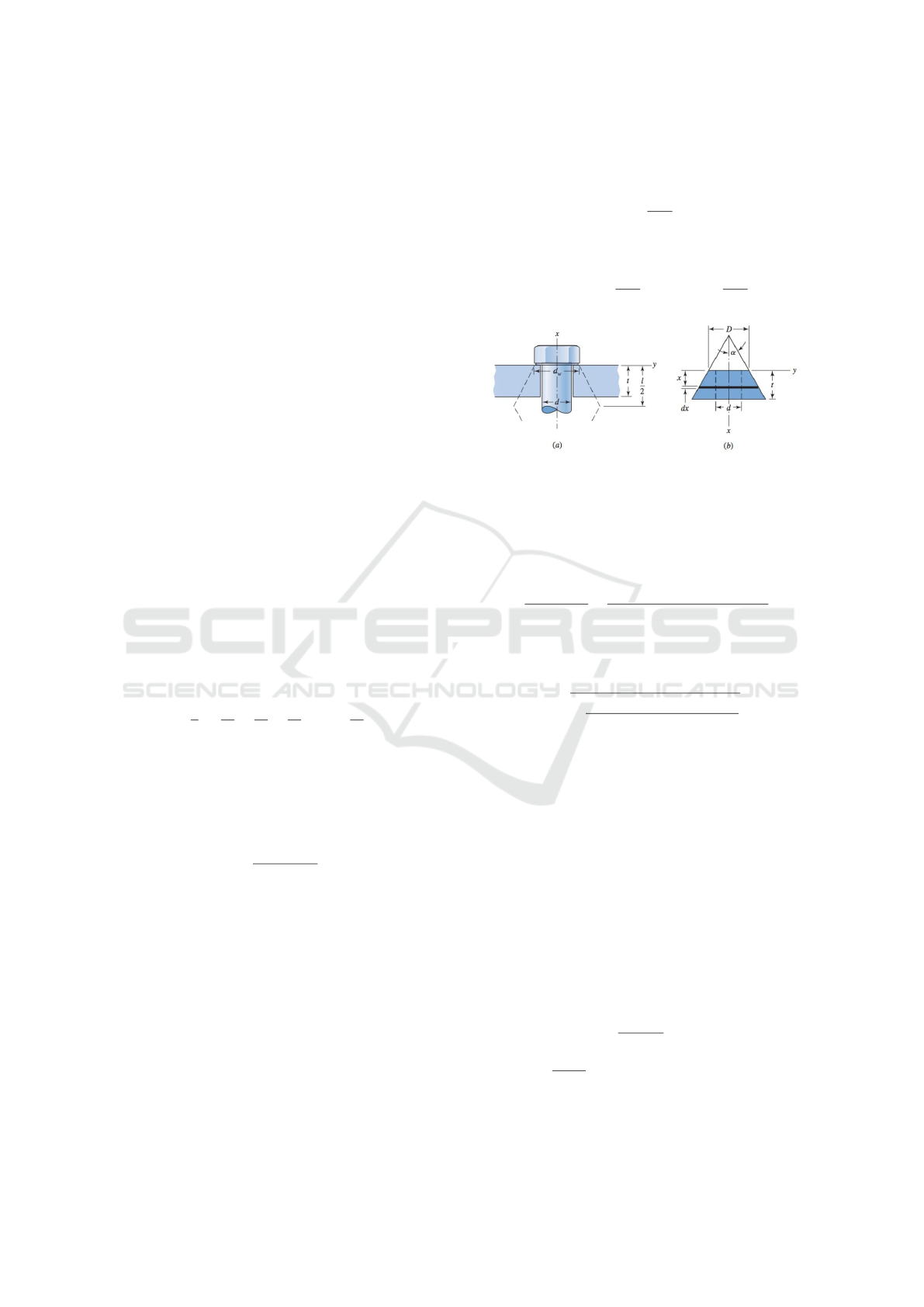

with angle α = 30º, as shown in Figure 2. When sub-

jected to a compressive force P, a certain element of

thickness dx of the cone (Figure 2(b)) suffers a con-

traction given by:

dδ =

Pdx

EA

, (3)

where E is the material’s Young’s modulus and A is

the area of the element, given by:

A = π

x tan α +

D+d

2

x tan α +

D−d

2

. (4)

Figure 2: Representation of the stress distribution by a trun-

cated hollow cone. Adapted from (Budynas and Nisbett,

2007).

Thus, the total contraction of the element is ob-

tained by substituting the result of the area in the

Equation 3 and integrating, which results in:

δ =

P

πEd tan α

ln

(2t tan α + D − d)(D + d)

(2t tan α + D + d)(D − d)

. (5)

Therefore, as the stiffness of the cone is given by

k = P/δ, substituting α = 30° this will be:

k =

0.5774πEd

ln

(1.155t + D − d)(D + d)

(1.155t + D + d)(D − d)

. (6)

The total elastic constant of the elements re-

quested in the union (k

m

) is obtained by solving Equa-

tion 6 separately for each frustum of cone and sub-

stituting the results in Equation 1, to which the in-

dex m is added in this case. If the joint has back-to-

back symmetrical frusta and elements with the same

value for E, the total elastic constant will be given by

k

m

= k/2 (Budynas and Nisbett, 2007). Considering

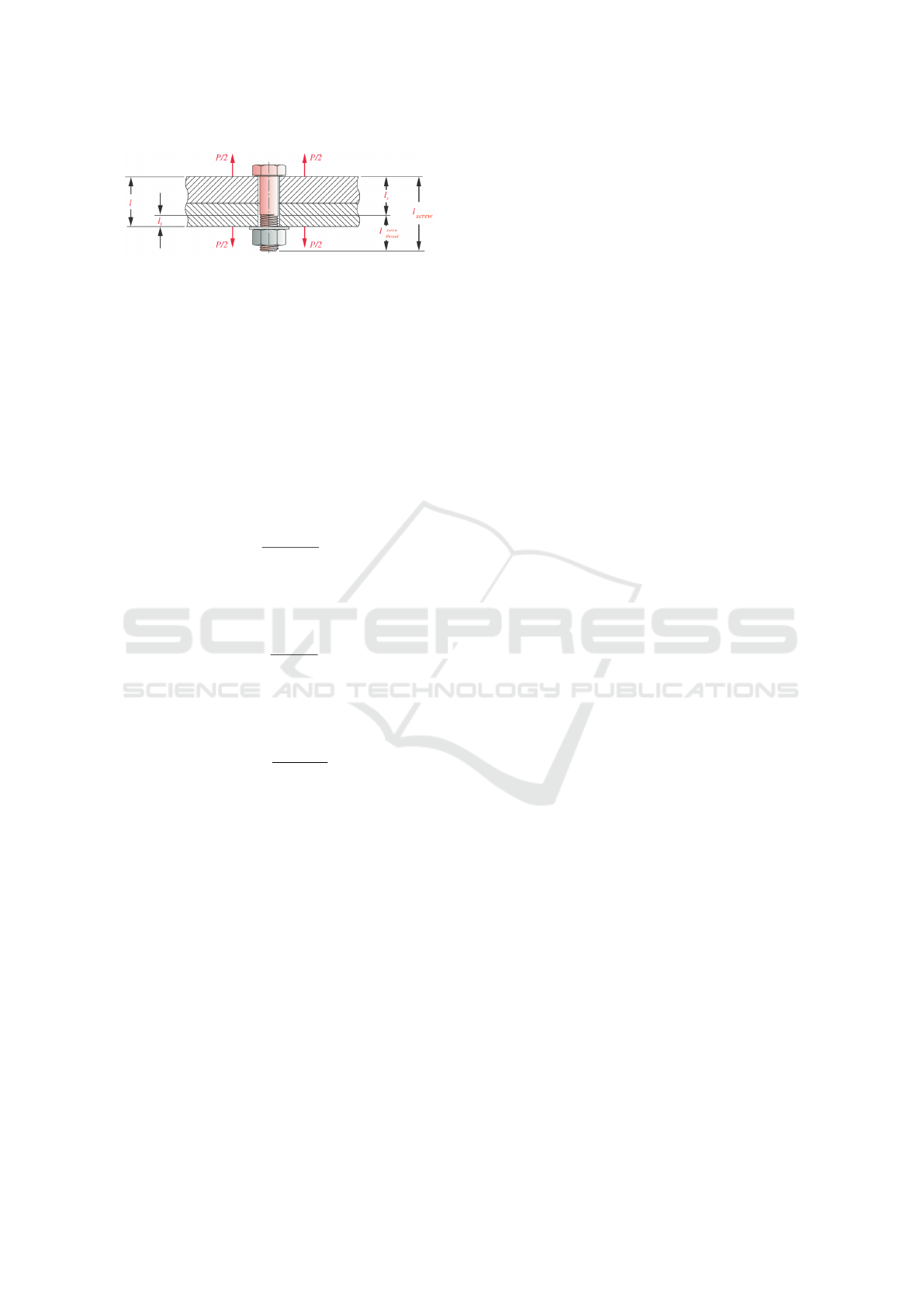

an external tensile load P (Figure 3), a portion P

b

of

this will act on the screw and the remaining P

m

on

the elements being compressed. As shown in Figure

3, each side of the junction receives half the load P,

resulting in P/2.

It can be shown that the portion P

b

of the external

load applied to the joint is given by:

P

b

=

k

b

P

k

b

+ k

m

= CP, (7)

where C =

kb

kb+km

is defined as the joint stiffness con-

stant. Therefore, the portion P

m

is:

P

m

= (1 − C)P. (8)

Ontology to Define Sizing Screw Joints for Mechanical Engineering Applications

55

Figure 3: Bolted joint under external tensile load. Adapted

from (Norton, 2010).

Thus, the resulting load on the bolt is obtained

through:

F

b

= P

b

+ F

i

, (9)

where F

i

is the preload. Analogously, the resulting

load on the elements is obtained from

F

m

= P

m

− F

i

, F

m

< 0. (10)

With this, (Budynas and Nisbett, 2007) establish a

load factor n, which guarantees that the stress on the

bolt is less than its proof strength as long as n > 1.

This factor is given by

n =

S

p

A

t

− F

i

CP

, (11)

where S

p

is the bolt proof strength. Analogously, the

authors established a safety factor against screw yield-

ing (n

p

), obtained through

n

p

=

S

p

A

t

CP + F

i

. (12)

According to (Norton, 2010), it is also possible to

find a safety factor against failure by separation N

sep

.

This is given by

N

sep

=

F

i

P(1 − C)

. (13)

From the presented equations, the point of in-

terest is centered on the determination of the stiff-

ness of the elements requested in the union (k

m

),

using the Shigley method. According to (Brown

et al., 2008), despite the particularities, Shigley’s ap-

proach considering a truncated cone for stress distri-

bution along compressed elements has been success-

fully used since 1960 for the design and analysis of

bolted joints with axisymmetric geometry.

2.3 Ontology Methodologies

For the construction of ontologies, several method-

ologies were developed. Among the first publications

in this context are those by (Guarino, 1997) and (Noy

and McGuinness, 2001), in which sequential and sys-

tematic actions were proposed to obtain ontologies

with good representativeness of modeled knowledge.

Afterwards, other methods were also developed, in-

cluding UPON (Unified Process for ONtology) by

(De Nicola et al., 2009) and SABiO (Systematic Ap-

proach for Building Ontologies) by (Falbo, 2014),

seeking solutions for problems of previous methods

or aiming to meet more specific needs. According

to (Maran et al., 2018), there is not a single suitable

methodology for all situations, as all of them present

formalisms to be followed, with the choice depend-

ing on the objectives and the domain to be repre-

sented. Thus, the UPON developed by (De Nicola

et al., 2009) was chosen, due to the clarity of the steps

elucidated with examples, the possibility of evaluat-

ing the partial results during the construction and rel-

evance of the work. This methodology was based on

the Unified Software Development Process, or Uni-

fied Process (UP), a consolidated standard due to its

wide use in software engineering (De Nicola et al.,

2009). Thus, it consists of five general workflows: (a)

Requirements workflow, (b) Analysis workflow, (c)

Design workflow, (d) Implementation workflow and

(e) Test workflow.

2.4 Related Work

As already mentioned, there are few works report-

ing the development of tools for analysis of bolted

joints that use analytical calculation techniques. The

closest found was from (Godden, 2015), in which a

computer program called FORTRESS (Fastener Op-

timization Research Technologies Rapid Efficient Se-

lection Software) was developed to identify and se-

lect the most efficient threaded fasteners for the joint

selected by the user, based on the information pro-

vided by the user. (Sanli, 2017) developed analy-

sis methods through the creation of Artificial Neural

Networks. In these cases, as the field of application

of the tools was Aeronautics, several analyzes were

needed in a short period of time, aiming at the max-

imum reduction of mass of the joints. In both, the

conceptual modeling of the information resulted in

a large database, which mainly kept results of previ-

ous analyzes, which were used for training the devel-

oped Artificial Neural Networks. However, despite an

extensive literature search, no papers were found re-

porting the use of ontologies to represent knowledge

related to bolts and bolted joints. However, ontolo-

gies are already used in related areas, as, for exam-

ple, in the work of (Chang et al., 2017), in which

an ontology was proposed to assist in the planning

of a cold forging process of flanged nuts. More gen-

erally, (Gupta and Gurumoorthy, 2021) developed an

ontology that allows the continuous exchange of in-

formation at the semantic level, during all stages of

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

56

the life cycle of an industrial product. In the area of

systems design, (Liang and Paredis, 2004) developed

an ontology to formally represent concepts of interac-

tion ports between a component and the surrounding

environment. These ports are component interfaces

through which iterations such as signal, energy, or

material exchanges must take place. Thus, expanding

the ontology to include LEGO components, the au-

thors demonstrated that it is possible, among others,

to refine the design and verify compatibility.

Also in the area of designs, but aiming at col-

laborative development, (Tran and Lobov, 2020) de-

veloped an ontology to represent geometric shapes

and functionalities of CAD (Computer Aided Design)

software, aiming at the automated generation of 3D

geometries. Thus, from instructions in Python to gen-

erate a shape, the knowledge base (ontology) is con-

sulted, with the information returned about the shape

and the resources to create it transmitted to the soft-

ware Siemens NX and Knowledge Fusion, responsi-

ble for generating it. Thus, a manual water pump was

created to demonstrate the potential of the developed

system.

3 THE DEVELOPMENT

PROCESS

3.1 The Requirements Workflow

The domain of interest was defined as "Bolts and

bolted joints", with the scope restricted to joints with

axisymmetric geometry, statically loaded under ten-

sion. Furthermore, for reasons of simplification, all

elements of the bolted joint were considered to be

composed of the same material, including any wash-

ers used. As a business objective or motivating sce-

nario, the main reasons for creating the ontology

should be listed. At the time of this work these were:

(i) Formally represent the knowledge of the domain

of interest, enabling queries and inferences; (ii) En-

able the automation of bolted joints analysis calcula-

tions by applications that may use the ontology. The

writing of one or more storyboards aims to describe

a sequence of actions or activities that may occur in

a particular scenario, involving the constructed ontol-

ogy (De Nicola et al., 2009). Thus, considering that

the ontology was hypothetically integrated into an ap-

plication, two situations were described:

• “The user, through an application, makes a re-

quest for analysis of a junction to the server. The

server processes the request by querying the on-

tology, and returns the types of bolted joints avail-

able for analysis.”;

• “The user selects a type of joint, assigns values

to the variables (external load, element thickness,

number of bolts, bolt length, diameter, among oth-

ers) necessary for the calculations and requests

the server for the analysis. The server, through

pre-defined algorithms and queries to the ontol-

ogy, performs the calculations and returns the re-

sults of the analysis to the user”.

The Application Lexicon (AL) consists of a set of

terms extracted from specific application documents,

using the storyboards as a reference to prioritize the

terms to be extracted. The elaborated AL was con-

cluded with a total of 80 terms, mainly extracted from

the specialized literature referenced in Section 2.1.

The competency questions must be answered by the

ontology during the Test Workflow, to assess its cov-

erage in relation to the domain and its depth in rela-

tion to the (De Nicola et al., 2009) concepts. Thus, the

following questions were listed, which refer mainly

to the relationships that the components of a bolted

joint have with each other: CQ.1 What are the main

components of a bolted joint? CQ2. What types of

threads can a screw have? CQ3. What type of screw

should be used when one of the joint elements has a

threaded hole? At the end of this workflow, the LA

and the competence questions are validated, verify-

ing whether the collected terms represent the domain

and whether the competence questions are appropri-

ate. Therefore, for the present work, some iterations

were necessary, aiming to reassess the domain of in-

terest and scope, as well as to include new terms in

the LA and adapt the competence issues to the capa-

bilities of the intended ontology.

3.2 Analysis Workflow

According to (De Nicola et al., 2009), the first stage

of this workflow is the creation of a Domain Lexi-

con (DL), through the collection of terms in docu-

mented resources related to the considered scope (ar-

ticles, technical reports, manuals or other ontologies).

As this task can be aided by text mining tools, a script

in Python was developed again to collect and manage

these terms. In order to collect terms directly from

documents, the library PDFMiner

1

was used in the

script to extract only the text from files in PDF, and

the library Yake

2

to collect keywords from extracted

text. At the end of the extraction, 27 versions of the

.txt file were created by the script in Python, with the

last version containing a total of 288 terms, extracted

1

Available at: https://pypi.org/project/pdfminer/

2

Available at: https://github.com/LIAAD/yake

Ontology to Define Sizing Screw Joints for Mechanical Engineering Applications

57

mainly from scientific articles and books related to the

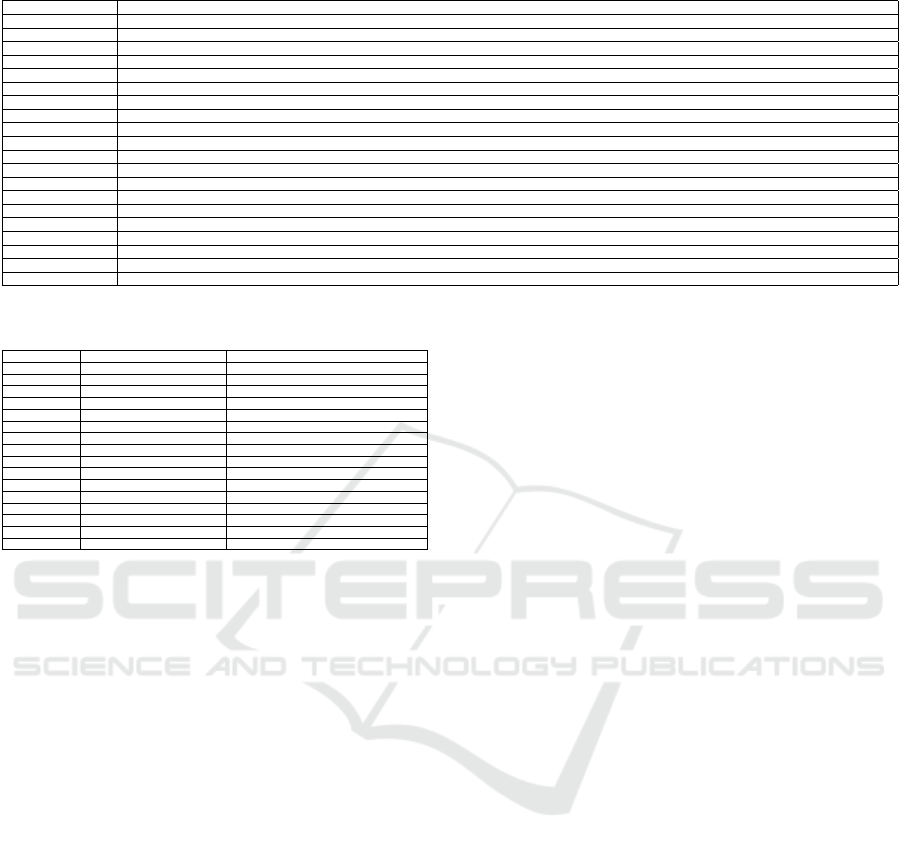

considered domain. The Table 1 shows part of these

terms that make up the Domain Lexicon.

Table 1: Part of the terms that make up the Domain Lexi-

con.

Axial external force Factor of safety Member stiffness Stress

Bolt Fasteners Nut Tapped thread joint

Bolt tension Fine pitch thread Plain washer Thread

Bolted joint Geometry Regular nut Threaded connection

Clamped member Hexagonal nut Results Tool

Coarse pitch thread ISO thread SAE specifications UNC thread

Connection system Joint Screw UNF thread

Design Loads Simplified method UNS thread

Disassembly Material Size Variables

Element Mechanical properties Software Washers

The next step in this workflow consists of creating

the Reference Lexicon (LR), through the intersection

between the LA and the LD (terms common to both

lexicons). In addition, unique terms can be added to

each of the lexicons, which are considered important

by the Domain Expert (De Nicola et al., 2009). To

help with the task of identifying terms common to LA

and LD, another script was created in Python, with

the options to compare the two lexicons, as well as to

allow manual entry of terms. With the intersection of

the LA and LD terms, as well as adding some terms

manually, the LR was completed after creating seven

versions in .txt format and with a total of 58 terms.

The creation and intersection of lexicons aims to

identify the most important concepts of the consid-

ered domain, which will serve as a basis for building

the ontology, mainly in the form of classes and prop-

erties. Therefore, it is important that these terms are

formally defined, associating definitions from several

sources for each (De Nicola et al., 2009) term. Thus,

the next stage of this workflow dealt with the elabora-

tion of a Reference Glossary (GR), where a definition

was associated with each term. Table 2 shows a frac-

tion set of the GR. This workflow ends with the vali-

dation of the GR by verifying the scope of the defined

terms. Thus, there was a need to perform some iter-

ations, returning to LA and LD to find and add new

terms, as well as manually adding important terms to

LR, present in only one of the predecessor lexicons.

3.3 The Project Workflow

According to (De Nicola et al., 2009), this workflow

starts with the modeling of concepts, in which they

are organized into three primary categories and some

complementary categories. The primary categories

are: business actor (business actor), business object

(business object) and business process (business pro-

cess). In the business actor category, elements capa-

ble of activating, executing or monitoring a process

are identified. Entities in which a process operates are

allocated in a business object. As a business process,

activities or operations that aim to achieve a defined

objective (De Nicola et al., 2009) are classified. For

this work, the concepts present in the Table 3 were

listed for the primary categories, mainly coming from

the GR. As a business actor, a user of a possible appli-

cation that uses the knowledge modeled in the ontol-

ogy was identified. In a business object, entities were

listed that an application would use to request infor-

mation from the ontology or perform calculations. Fi-

nally, in the business process category, activities car-

ried out by the possible application were separated. In

addition to the primary categories, there are comple-

mentary categories, necessary for a rich ontological

representation of the considered domain.

The next step in this workflow deals with mod-

eling concept hierarchies, where formal relationships

begin to be adopted and a hierarchical approach must

be chosen. According to (De Nicola et al., 2009),

there are three usual approaches: from top to bottom,

starting from more general terms towards more spe-

cific ones; from bottom to top, starting with specifics

towards general; and center out, an approach that

combines the previous ones. The last (combined) ap-

proach is considered to be the most efficient because

it starts with the most relevant and informative con-

cepts located in the central area of the domain, creat-

ing generalizations and specifications from these (De

Nicola et al., 2009). With that, a semantic network of

concepts begins to be built, represented by a class dia-

gram to which object properties are also added, which

relate individuals belonging to a class to individuals

of another class (Antoniou and Harmelen, 2009).

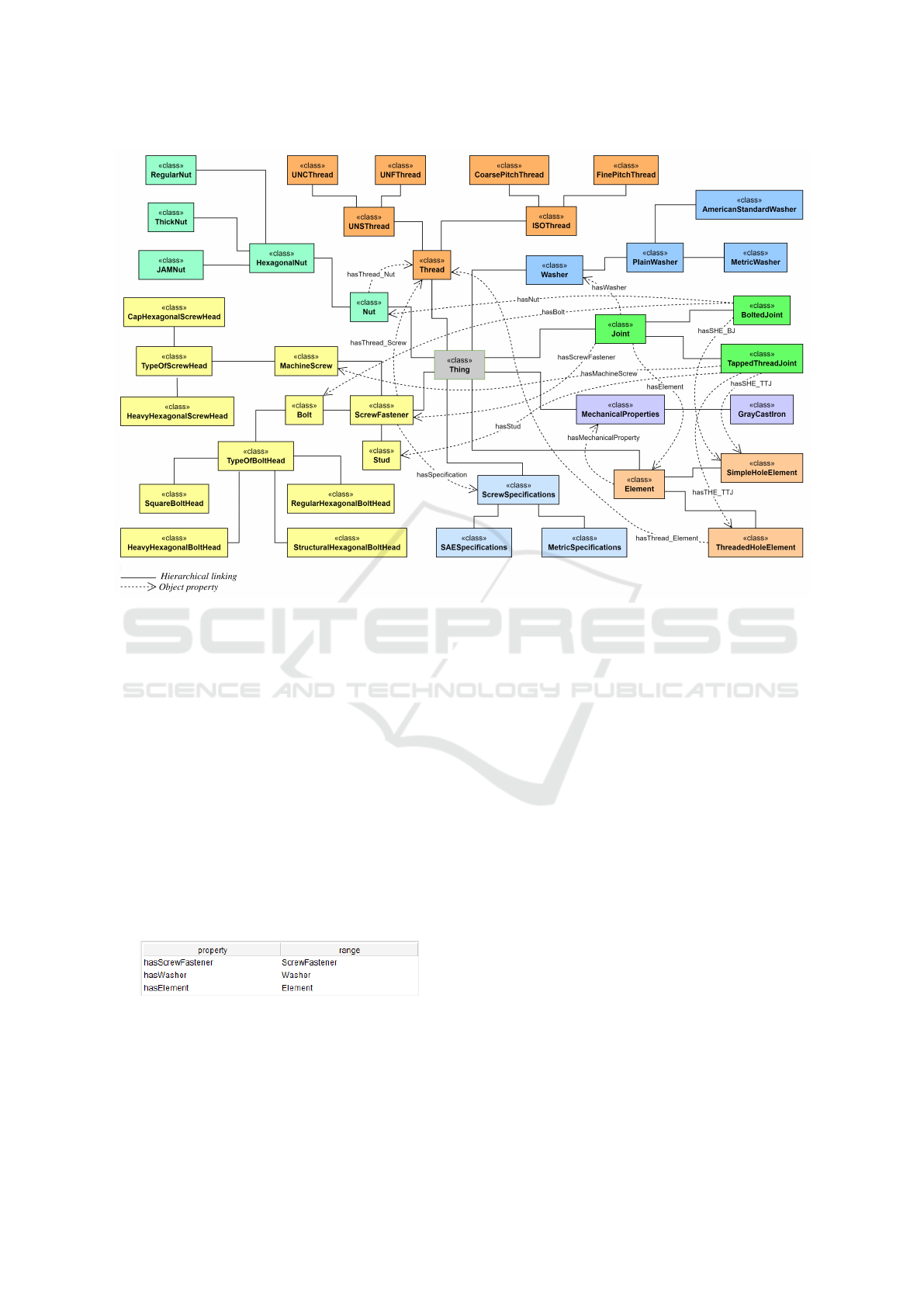

Using the combined approach, the hierarchy of

concepts for the present work was initiated by a class

Joint and the respective subclasses TappedThread-

Joint and BoltedJoint, representing the categories of

joints with threaded hole and bolted joints. In ad-

dition, a joint must be composed of elements and

bolts, as well as nuts and washers, making it neces-

sary to use the object properties hasElement, hasS-

crewFastener and hasWasher, relating the class Joint

to the respective classes of these components. Sub-

classes of a superclass can also have object proper-

ties, so TappedThreadJoint has the properties has-

THE_TTJ

3

and hasSHE_TTJ

4

, whereas BoltedJoint

has hasSHE_BJ

5

, so that it is possible to distinguish

which elements each type of joint can contain (with

simple or threaded hole). A property like hasWasher

does not appear in subclasses of Joint as both can have

the same washers. On the other hand, hasNut is a

3

hasThreadedHoleElement_TappedThreadJoint.

4

hasSimpleHoleElement_TappedThreadJoint.

5

hasSimpleHoleElement_BoltedJoint.

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

58

Table 2: Part of the Reference Glossary terms and their definitions.

Term Description

Bolt Is a type of fastener made from metal, that comprises a head at one end, a chamfer at the other, and a shank characterized by an external helical ridge known as a thread.

Bolted joint Demountable joint, made up of screws, nuts and compressed elements, capable of withstanding external loads.

Clamped member Element fixed by bolts in a bolted connection.

Coarse pitch thread Coarse pitch series metric thread.

Elastic modulus It is the quantity that measures the resistance of an object to elastic deformation when a stress is applied.

Element Component of a mechanical system subject to loads and stresses.

Fine pitch thread Fine pitch series metric thread.

Hexagonal nut Nut that has a hexagonal cross-sectional area.

ISO thread Thread with diameters and areas according to the International Organization for Standardization.

Joint Union of two or more elements, held by bolts.

Mechanical properties Properties that influence the material’s reaction to applied loads.

Nut Fastening device consisting of a square or hexagonal block of metal, with a hole in the center, and internal threads that fit the external threads of a screw.

SAE specifications Bolt specifications for SAE grades.

Screw fastener Screws used in non-permanent joints.

Tapped thread joint Demountable joint, made up of screws and compressed elements, in which one of the elements has threaded holes.

Thread A continuous helical ridge formed on the inside or outside of a cylinder.

UNC thread UNS thread of coarse series.

UNF thread UNS thread of fine series.

Washer Small metal, rubber or plastic ring used under a nut or bolt head to distribute pressure when tightened or between two mating surfaces as a spacer or seal.

Young’s modulus Property of the material that inform how easily it can stretch and deform, defined as the ratio of tensile stress to tensile strain.

Table 3: Concepts listed for primary modeling categories.

Business Actors Business Object documents Business Processes

User Available joints Calculation of joint stiffness

Available bolts Calculation of safety factor against bolt yielding

Bolted joint analysis Calculation of safety factor against separation

Joint data Calculation of the bolt stiffness

Safety factor against bolt yielding Calculation of the joint stiffness constant

Safety factor against separation Calculation of the load on the bolt

Screw data Calculation of the load on the elements

Process joint data

Process screw data

Request available bolts

Request available joints

Request bolted joint analysis

Return available bolts

Return available joints

Send joint data

Send screw data

unique property of BoltedJoint because only this type

of joint should contain nut.

To represent the components of a joint, we started

by creating a class Element and subclasses Simple-

HoleElement and ThreadedHoleElement. The Ele-

ment class has the object property hasMechanical-

Property and is related to the Joint class through

the hasElement property. Furthermore, the sub-

class ThreadedHoleElement still has the property

hasThread_Element. Then, the fastening screws were

represented through the ScrewFastener class and its

subclasses Bolt, MachineScrew and Stud, following

the classification according to the intended use (bolt,

machine screw or stud), as discussed by (Norton,

2010). With the exception of the Stud subclass,

the class hierarchy continues after the ScrewFastener

subclasses, aiming to classify the screws also accord-

ing to the head shape. As object properties, the class

ScrewFastener has hasThread_Screw linking it with

the class that represents the threads, and hasSpecifi-

cation which connects it with the class where tech-

nical specifications of screws are hierarchical. Fur-

thermore, ScrewFastener and its subclasses are linked

to Joint and its hierarchy through the properties has-

ScrewFastener, hasMachineScrew, hasBolt and has-

Stud.

A bolted joint can also contain washers with dif-

ferent functionalities, however, for this work only flat

washers were represented, as they have a more ho-

mogeneous geometry and can be considered part of

the joint elements for analytical purposes, when made

of the same material of these (Norton, 2010). The

representation of these washers occurred through the

Washer class, its subclass PlainWasher and the rest

of the hierarchy. The Washer class is linked to the

Joint class via the hasWasher object property. An-

other component that may be included in a bolted

joint is the nut, with the function of ensuring the union

together with the bolt when none of the elements has

a threaded hole. This component was represented us-

ing the Nut class, its subclass HexagonalNut and the

rest of the hierarchy. The Nut class has the prop-

erty hasThread_Nut linking it to the class that rep-

resents the threads, and is connected to the Bolted-

Joint class through the hasNut property. Although

there are several types of nuts, we chose to represent

only the hexagonal ones. In addition to the classes

already mentioned, concepts responsible for specifi-

cations, properties and particularities of the bolted

joint elements were also represented, with emphasis

on the Thread class and its subclasses UNSThread and

ISOThread, which characterize the two thread form

standards adopted since the end of World War II (Nor-

ton, 2010). Thus, the complete hierarchy of all classes

and their respective object properties are presented in

the diagram of Figure 4, where the generic class Thing

appears in the center, uniting all classes to the same

primary root. The validation of the semantic network

required at the end of this workflow was carried out

by analyzing the first versions of the diagram in Fig-

ure 4 regarding the scope of the considered domain.

In these analyses, it was noticed the need to include

classes to represent individuals from tabulated infor-

mation in the literature, mainly from (Budynas and

Nisbett, 2007) and (Norton, 2010). Thus, some itera-

tions were necessary, going back from writing story-

boards, passing through LA and LD, resulting in new

Ontology to Define Sizing Screw Joints for Mechanical Engineering Applications

59

terms in GR, which would become new classes in the

diagram. Examples are UNCThread, SAESpecifica-

tions, MetricWasher, among others.

3.4 The Implementation Workflow

This workflow consists of coding the ontology in a

formal language, with good expressiveness and ac-

ceptance by the community, also considering the as-

sociated computational complexity (De Nicola et al.,

2009). Thus, for this work, the OWL-DL language

was chosen, capable of supporting adequate expres-

siveness and even evolving to OWL Full depending

on the complexity of the representations used (Hit-

zler, 2021). To create the ontology, the Protégé (Noy

et al., 2003) tool was used, a free software with an

open architecture, which allows the development of

new functionalities by the users themselves. In this,

the ontology is encoded and converted into an output

file with the extension .owl, which can be consulted

and manipulated by algorithms and libraries of differ-

ent languages.

3.5 The Test Workflow

According to (De Nicola et al., 2009), in this work-

flow the ontology is evaluated in terms of four dif-

ferent aspects: syntactic, semantic, pragmatic and so-

cial quality. The first three can be measured during

and soon after the construction of the ontology, while

the last one can only be estimated after a certain time

from its publication. Thus, the consequences of this

workflow are shown in the Evaluation Section of this

work.

4 EVALUATION

The UPON methodology implementation workflow,

applied to this work, ended up resulting in an ontol-

ogy with the following metrics: 40 classes, 19 object

properties, 44 data type properties and 379 individu-

als. In addition to the metrics, an ontology needs to be

evaluated for the aspects already highlighted earlier

(Section 3.5). Therefore, the syntactic quality mea-

sures the formality and the way the ontology is cre-

ated, which according to (De Nicola et al., 2009), is

already verified in the implementation workflow. In

the case of the present work, as the creation was car-

ried out using specific software (Protégé), the syntac-

tic quality can be considered sufficient to validate this

aspect. The semantic quality is assessed by check-

ing the consistency of the ontology, verifying the cor-

rect modeling of the concepts, so that there are no (De

Nicola et al., 2009) contradictions. This activity can

be aided by an inference engine (IE), or Reasoner,

which in addition to checking consistency, can also

reclassify the ontology, changing the hierarchy of el-

ements if necessary (Horridge et al., 2004).

Protégé, in its version 5.5.0 brings the IE HermiT

in version 1.4.3.456. Thus, during the construction of

the present ontology, the first executions of the IE re-

sulted in the detection of some errors, mainly arising

from the non-disjunction between the classes. How-

ever, after correcting these, no other problems were

identified. The pragmatic quality is related to the

evaluation of three characteristics of the ontology: fi-

delity, relevance and completeness. The first can be

validated by checking the references used to create the

lexicons and define the terms in the reference glos-

sary. Relevance and completeness can be evaluated

together, verifying the correct application of the on-

tology and meeting the objectives listed in the first

workflow (De Nicola et al., 2009). As for fidelity,

both the terms in LA, LD and LR, and the definitions

shown in the GR, were extracted from scientific arti-

cles cited in the Bibliographic Review of this work, as

well as from the textbooks (Collins et al., 2009), (Bu-

dynas and Nisbett, 2007) and (Norton, 2010), mainly.

In addition, efforts were made during development

to prioritize terms and definitions identified as com-

mon to more than one reference, ensuring greater fi-

delity in the representation of the considered domain.

The relevance and completeness characteristics can

be evaluated by checking coverage and by answering

the competence questions, using the ontology con-

tent (De Nicola et al., 2009). As for the coverage (or

range) of this ontology, analyzing the diagram in Fig-

ure 4, it is possible to see that most of the concepts

related to bolts and bolted joints were represented.

In addition, the classes TypeOfBoltHead and TypeOf-

ScrewHead, for example, which specify together with

their subclasses types of head of bolts and machine

screws, cover concepts that are rarely used in analysis

of bolted joints. However, they were included in the

ontology to extend the scope, bringing tabulated data

related to these particularities.

4.1 Analysis Related to Competence

Questions

The competence questions listed in the requirements

workflow must be answered by consulting the on-

tology, using, for example, the language SPARQL

6

,

adopted for this work. These queries can be exe-

cuted in the SPARQL Query tab of Protégé together

6

Available at: https://www.w3.org/TR/rdf -sparql-

query/

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

60

Figure 4: Hierarchy of all ontology object classes and properties.

with standard prefixes, receiving the name of a refer-

ence class and possibly some parameter to filter the

results. Thus, for the first competence question that

says: “What are the main components of a bolted

joint”, the query shown in Figure 1 was elaborated.

This can be read as: “Select distinctly property and

scope when property is of type object property and

has as domain the element Joint, also returning the re-

spective classes of the scope of each property.”. This

results in the table shown in Figure 5.

1 SELECT DISTINCT ? p r o p e r t y ? r an g e

2 WHERE {

3 { ? p r o p e r t y r d f : t y p e owl : O b j e c t P r o p e r t y }

4 ? p r o p e r t y r d f s : domain b d j t : J o i n t .

5 ? p r o p e r t y r d f s : r a n g e ? r a n g e .

6 }

Listing 1: Consultation for the first question of competence.

Figure 5: Query results for the first competency question.

The results of Figure 5 show the object proper-

ties of the class Joint and the respective classes in

the scope of each property, which answers the first

competence question saying that screws, washers and

elements are the main components of a bolted joint.

Although on certain occasions it is possible to con-

sider the washers as part of the element for analysis

purposes, they can be present in any type of joint, in-

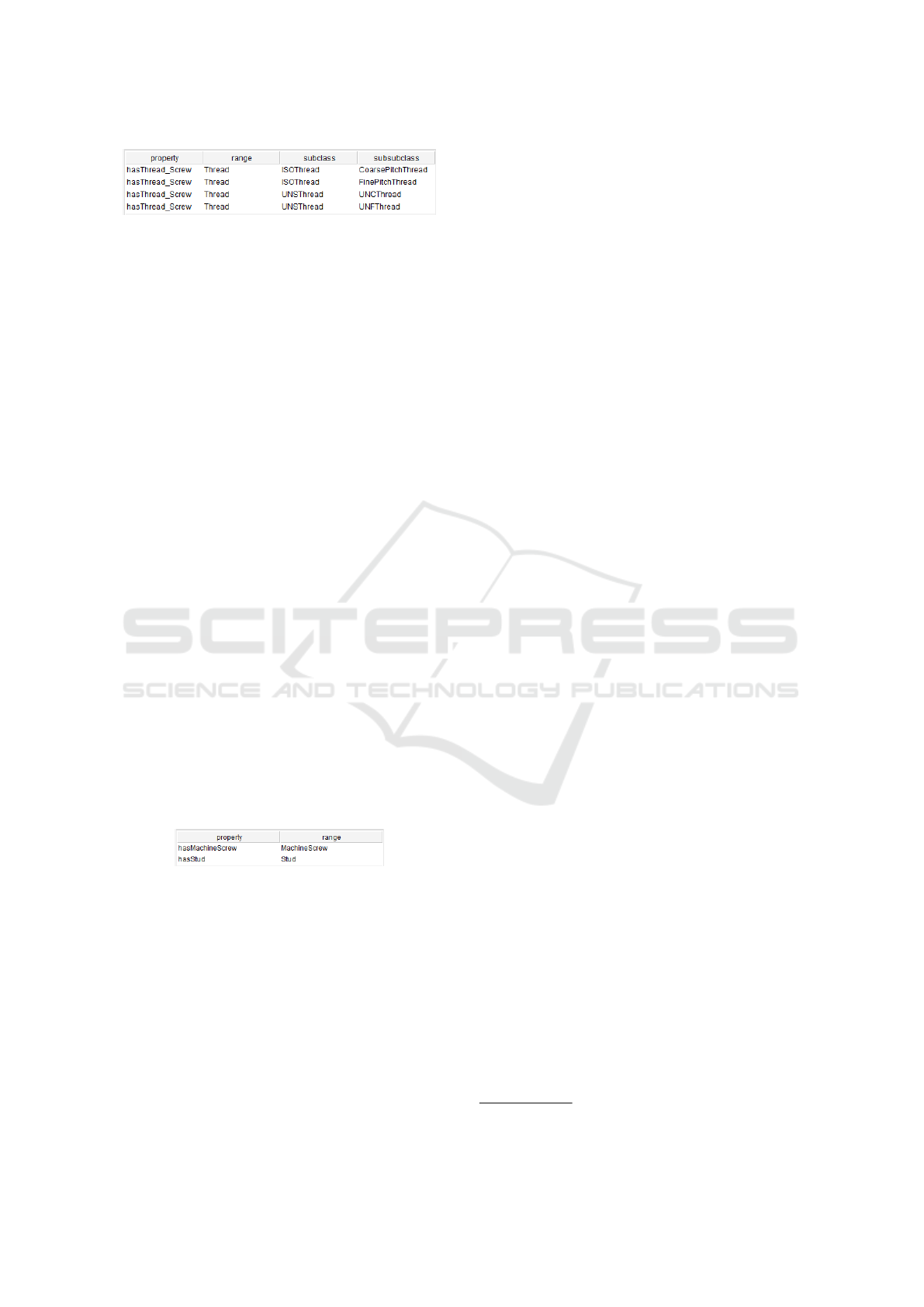

dicating their importance. For the second competency

question: "What types of threads can a screw have?",

the Figure query 2 was developed, which reads as:

“Select distinctly property, scope, subclass and “sub-

subclasse” when the property is of the object property

type and has the ScrewFastener element as domain,

also returning the respective classes of the scope of

each property, filtering the properties that have the

term “thread”. Also return the subclasses of each

class in the domain and the subclasses of each sub-

class.”. Thus, this results in the table in Figure 6.

1 SELECT DISTINCT ? p r o p e r t y ? r an g e

2 ? s u b c l a s s ? s u b s u b c l a s s

3 WHERE {

4 { ? p r o p e r t y r d f : t y p e owl : O b j e c t P r o p e r t y }

5 ? p r o p e r t y r d f s : domain b d j t : S c r e w F a s t e n e r .

6 ? p r o p e r t y r d f s : r a n g e ? r a n g e .

7 FILTER REGEX( s t r ( ? p r o p e r t y ) , " t h r e a d " , " i " )

8 {

9 ? s u b c l a s s r d f s : s u b Cl a s s O f ? ra n g e

10 FILTER ( ? s u b c l a s s != ? ra n ge )

11 }

12 {

13 ? s u b s u b c l a s s r d f s : s u b C l a ss O f ? s u b c l a s s

14 FILTER ( ? s u b s u b c l a s s ! = ? s u b c l a s s )

15 }

Listing 2: Consultation for the second question of

competence.

Ontology to Define Sizing Screw Joints for Mechanical Engineering Applications

61

Figure 6: Query results for the second competency ques-

tion.

The table in Figure 6 displays the object prop-

erty (hasThread_Screw) of the class ScrewFastener,

as well as the class (Thread) in the scope of this prop-

erty and their hierarchy in the “subclass” and “sub-

subclass” columns. Thus, it shows that the types of

thread that a screw can have, according to the ontol-

ogy, are: coarse-pitch and fine-pitch ISO, as well as

coarse-pitch UNS (UNC) and fine-pitch (UNF), an-

swering the second question of competence. Finally,

the third competency question asks: “What type of

screw should be used when one of the joint elements

has a threaded hole?”. For this, the query in Figure

3 was elaborated, read as: “Select distinctly property

and scope when property is of type object property

and has as domain the element TappedThreadJoint,

returning also the respective classes of the scope of

each property, requesting the superclasses of each

class of the scope, filtering the classes whose super-

classes have the term “screw”. The result of this is

shown in Figure 7.

1 SELECT DISTINCT ? p r o p e r t y ? r a n g e

2 WHERE {

3 { ? p r o p e r t y r d f : t y p e owl : O b j e c t P r o p e r t y

}

4 ? p r o p e r t y r d f s : domain b d j t :

T a p p e d T h r e a d J o i n t .

5 ? p r o p e r t y r d f s : r a n g e ? r a n g e .

6 ? r a n g e r d f s : s u b C l a s s O f ? s u b c l a s s o f .

7 FILTER REGEX( s t r ( ? s u b c l a s s o f ) , " s c r e w " ,

" i " )

8 }

Listing 3: Consultation for the third question of

competence.

Figure 7: Query results for the third competency question.

The results of Figure 7 present the object proper-

ties of the class TappedThreadJoint and the respective

classes in the scope of each property that belong to the

superclass ScrewFastener, as the interest is centered

only on the screws. Thus, the third competency ques-

tion is answered showing that machine screws and

studs should be used when the joint has a threaded

hole element.

4.2 Evaluation in a Sample Application

To assist in the evaluation of relevance and complete-

ness, as well as to verify the possibility of automating

the calculations for the analysis of bolted joints, an

application was developed in Python capable of al-

lowing some tests to be carried out. This is composed

of three files: app.py responsible for carrying out

the interaction with the user (reading and presenting

data), bolted_joint.py which contains functions to per-

form bolted joint analysis calculations (lengths, stiff-

ness, preload, among others), and query_executor.py

where the interaction with the ontology takes place

through requests in the SPARQL language. The user’s

interaction with the application takes place via the ter-

minal, with the available calculation options shown at

the beginning of the program’s execution. For interac-

tion with the ontology, the file query_executor.py uses

the library RDFLib

7

and contains functions in that a

generic query in SPARQL is concatenated with vari-

ables and property names of data type, according to

the data required for each calculation.

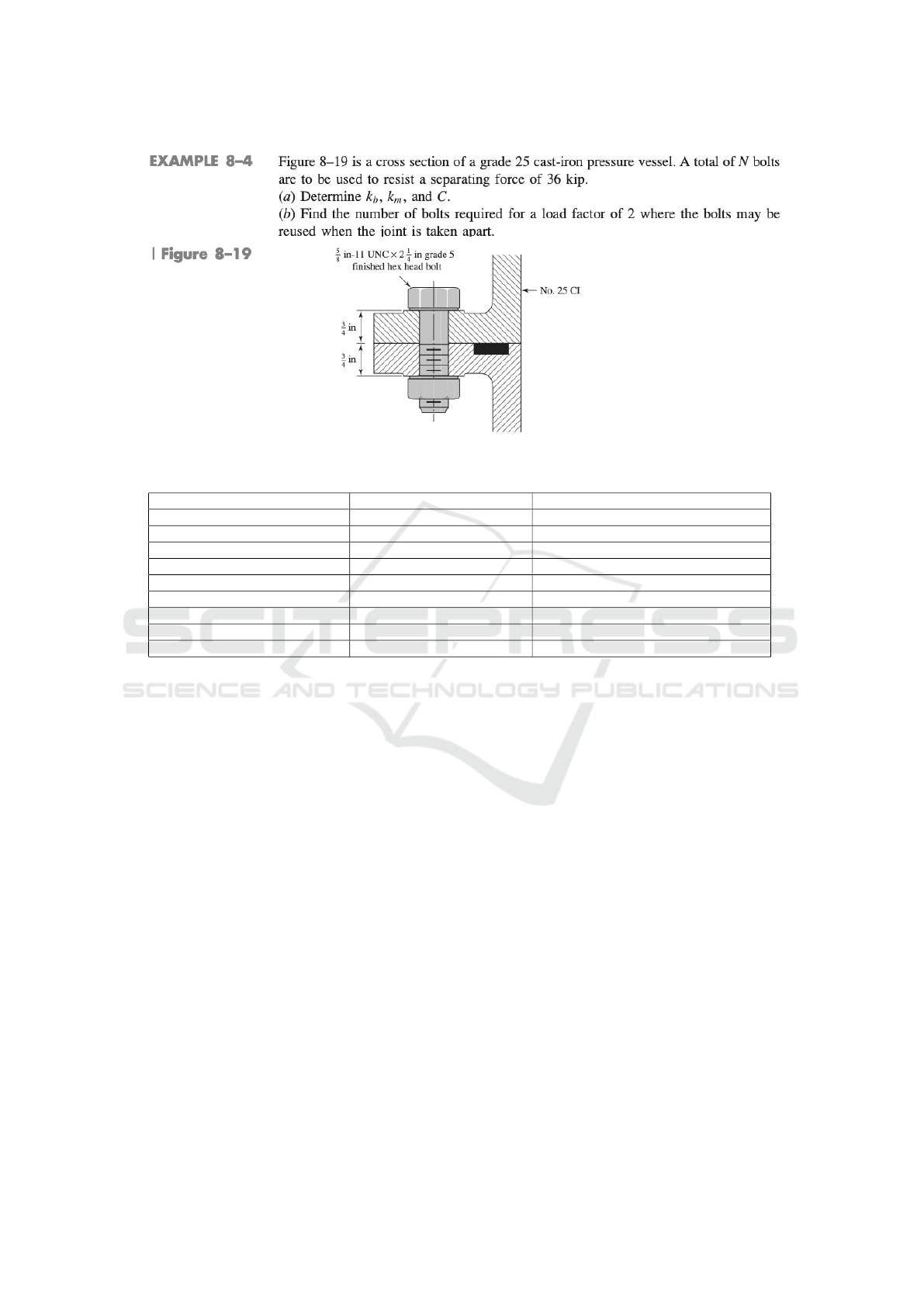

4.3 Study Case and Discussion

To validate the developed application and, conse-

quently, part of the knowledge modeled in the on-

tology, the resolution of Example 8-4 from (Budynas

and Nisbett, 2007) is shown below. Table 4 shows the

comparison of the application results with the exam-

ple results.

Given the above, it can be seen that some re-

sults differ only in terms of the number of decimal

places used, showing that the automation of bolted

joints analysis calculations became possible with the

adopted methodology. Furthermore, the accuracy

achieved by the application indicates that the litera-

ture data were properly modeled and inserted into the

ontology, as well as retrieved correctly. However, as

it was developed with a view to carrying out simple

tests, the application can be greatly expanded, includ-

ing calculation algorithms for more complex configu-

rations of bolted joints.

5 CONCLUSION

This work presents the construction of an ontology

to represent information related to bolted joints, us-

ing most of the steps of the UPON methodology and

developing a simple application to demonstrate the

possibility of automating some calculation processes.

7

Available at: https://rdflib.readthedocs.io/en/stable/

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

62

Figure 8: Example used to validate the application in Python (Budynas and Nisbett, 2007).

Table 4: Comparison of results for Example 8-4 of (Budynas and Nisbett, 2007).

Calculation (Budynas and Nisbett, 2007) Python application using the ontology

Screw length (L

T

) 1,50 in 1,50 in

Length of unthreaded portion (l

d

) 0,75 in 0,75 in

Threaded length (l

t

) 0,75 in 0,75 in

Screw stiffness (k

b

) 5,21 Mlbf/in 5,21 Mlbf/in

Stiffness of the elements (k

m

) 8,95 Mlbf/in 8,95 Mlbf/in

Stiffness constant (C) 0,368 0,368

Recommended preload (F

i

) 14,4 kip 14,4 kip

Quantity of screws (N) 6 6

Load factor (n

L

) 2,18 2,18

Thus, analyzing the general objective, it is clear that

this was achieved through the fulfillment of the spe-

cific objectives and their respective consequences.

Methods of analysis of axisymmetric bolted

joints, statically loaded under tension, were identified,

as well as forms of knowledge representation through

ontologies. With that, the information of the men-

tioned joints were hierarchized in classes and con-

verted into an ontology through the UPON method-

ology. This ontology was evaluated in relation to

the aspects foreseen in the methodology and, in ad-

dition, through an application in Python that used

the modeled knowledge to perform some calculations

and present results. The ontology developed, despite

showing to be adequate for the defined objective, con-

tains information about a fraction of the knowledge

referring to bolted joints. However, it can be easily

expanded, including information regarding the analy-

sis of joints loaded under shear and subject to variable

loading, for example. Other types of components may

also be included (socket head bolts, wing nuts, lock

washers, among others.), as well as tabulated data on

various materials used in their manufacture.

This expansion of the ontology could be started by

changing the domain and scope, aiming to cover new

areas of knowledge. As a consequence, the LA would

be added with new terms through the expansion of

the Bibliographic Review of the present work, as well

as the LD with the search for terms in documents of

these new areas. Thus, new terms would be included

in the LR, defined in the GR and incorporated into

the ontology. As with the ontology, the Python ap-

plication developed can be greatly expanded through

the inclusion of new features. For example, queries

to the ontology for knowledge of available compo-

nents and new analysis methods beyond the Shigley

method. Furthermore, it could receive an interface

elaborated through libraries in Python or be integrated

with other technologies, giving rise to countless pos-

sibilities.

ACKNOWLEDGEMENTS

This research is supported by CNPq/MCTI/FNDCT

n. 18/2021 - UNIVERSAL grant n. 405973/2021-

7. The research by Vinícius Maran is supported by

CNPq grant 306356/2020-1 (DT-2).

Ontology to Define Sizing Screw Joints for Mechanical Engineering Applications

63

REFERENCES

Albuquerque, F., Torres, A. S., and Berssaneti, F. T. (2020).

Lean product development and agile project manage-

ment in the construction industry. Revista de Gestão.

Antoniou, G. and Harmelen, F. v. (2009). Web ontology

language: Owl. Handbook on ontologies.

Brown, K. H., Morrow, C. W., Durbin, S., and Baca, A.

(2008). Guideline for bolted joint design and analysis.

Technical report, Sandia National Laboratories.

Bruzzone, F., Delprete, C., and Rosso, C. (2019). A pro-

posal of a unique formula for computing compliance

in bolted joints. Procedia Structural Integrity.

Budynas, R. G. and Nisbett, J. K. (2007). Mechanical En-

gineern Design.

Chang, C. W., Lee, R. S., and Chang, T. W. (2017). De-

velopment of knowledge-expandable ontology-based

expert system for process planning in cold forging of

flange nuts. Procedia engineering, 207:502–507.

Collins, J. A., Busby, H. R., and Staab, G. H. (2009). Me-

chanical design of machine elements and machines: a

failure prevention perspective. John Wiley & Sons.

De Nicola, A., Missikoff, M., and Navigli, R. (2009). A

software engineering approach to ontology building.

Information Systems, 34(2):258–275.

Falbo, R. d. A. (2014). Sabio: Systematic approach for

building ontologies. In ONTO. COM/ODISE@ FOIS.

Godden, N. (2015). Develop an algorithm able to select a

bolted fastener capable to perform at known environ-

mental conditions. Master’s thesis, FDMM.

Guarino, N. (1997). Understanding, building and using on-

tologies. International journal of human-computer

studies, 46(2-3):293–310.

Gupta, R. K. and Gurumoorthy, B. (2021). Feature-based

ontological framework for semantic interoperability in

product development. Adv. Engineering Informatics.

Hitzler, P. (2021). A review of the semantic web field. Com-

munications of the ACM, 64(2):76–83.

Horridge, M., Knublauch, H., Rector, A., Stevens, R., and

Wroe, C. (2004). A practical guide to building owl on-

tologies using the protégé-owl plugin and co-ode tools

edition 1.0. University of Manchester.

Kogalovsky, M. R. and Kalinichenko, L. A. (2009). Con-

ceptual and ontological modeling in information sys-

tems. Programming and Computer Software.

Liang, V.-C. and Paredis, C. J. (2004). A port ontology

for conceptual design of systems. J. Comput. Inf. Sci.

Eng., 4(3):206–217.

Maran, V., Machado, A., Machado, G. M., Augustin, I., and

de Oliveira, J. P. M. (2018). Domain content querying

using ontology-based context-awareness in informa-

tion systems. Data & Knowledge Engineering.

Nicholas, J. M. and Steyn, H. (2020). Project management

for engineering, business and technology. Routledge.

Norton, R. L. (2010). Machine design. Prentice Hall.

Noy, N. F., Crubézy, M., Fergerson, R. W., Knublauch, H.,

Tu, S. W., Vendetti, J., and Musen, M. A. (2003).

Protégé-2000: an open-source ontology-development

and knowledge-acquisition environment. In AMIA.

Annual Symposium proceedings. AMIA Symposium.

Noy, N. F. and McGuinness, D. L. (2001). Ontology devel-

opment 101: A guide to creating your first ontology.

Omelyanenko, V., Braslavska, O., Biloshkurska, N.,

Biloshkurskyi, M., Kliasen, N., and Omelyanenko,

O. (2021). C-engineering based industry 4.0 innova-

tion networks sustainable development. International

Journal of Computer Science and Network Security.

Sanli, T. V. (2017). Development of Artificial Neural Net-

work Based Design Tool for Aircraft Engine Bolted

Flange Connection Subject to Combined Axial and

Moment Load. PhD thesis, MIDDLE E. Tech. Univ.

Silveira, Z. d. C. (1998). Development of a manager sys-

tem for calculation of machine elements for mechani-

cal projects. In Teses.Usp.Br.

Tran, T. A. and Lobov, A. (2020). Ontology-based model

generation to support customizable kbe frameworks.

Procedia Manufacturing, 51:1021–1026.

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

64