Towards a Goal-Oriented Approach for Engineering Digital Twins of

Robotic Systems

Jeshwitha Jesus Raja

a

, Meenakshi Manjunath

b

and Marian Daun

c

Center of Robotics, Technical University of Applied Sciences W

¨

urzburg-Schweinfurt, Schweinfurt, Germany

Keywords:

Requirements Engineering, Goal Modeling, Digital Twin, Industry Automation, Robotic Systems.

Abstract:

In many smart manufacturing scenarios of Industry 4.0, robots play a vital role. Robotic systems allow for au-

tomatization and semi-automatization of individual work tasks using standard hardware. Thus, production and

assembly processes can be flexibly redefined during operation. In addition, human workers can be supported

for complex and specific work tasks where full automation by industrial production systems is not possible

or not cost-efficient. To monitor current process execution, to predict process outcome, and to ensure safe

behavior of the robots at runtime, digital twins are seen as a vital part of future smart manufacturing. How-

ever, current industrial approaches typically define the digital twin on the go, i.e. when the factory has been

build and equipped with robotic systems. Thus, the absence of systematic planning of the digital twin leads to

unused potential for more complex analysis, monitoring, and prediction tasks of digital twins commonly sug-

gested in research. This is partly due to the absence of structured software and systems engineering approaches

for the development of robotic systems. In this paper, we explore the use of goal modeling to systematically

define the robotic system, its monitoring system, and the digital twin. Application to case examples shows that

this lightweight approach aligns with industry preferences to focus on technical challenges rather than invest

too much effort in a thorough yet cost intensive engineering approach, while at the same time allowing for the

proper definition of robots and their digital twins.

1 INTRODUCTION

Robotic systems involve mechanisms that interact

with their surroundings, including humans, utilizing

an array of sensors, actuators, and interfaces to of-

fer intelligent services and information (Demir and

Turan, 2021). Robot systems must work to achieve

tasks while monitoring and reacting to unexpected sit-

uations (Kortenkamp et al., 2016). Digital twins are

virtual representations of physical systems (Koulamas

and Kalogeras, 2018). Within smart manufacturing,

incorporating robotic systems for production, digi-

tal twins are used to monitor and analyze the status

of their physical counterparts. Consequently, digital

twins aid in planning real-time adaptations by detect-

ing unexpected events or errors during process execu-

tion.

Among others, the huge potential of digital twins

is seen in supporting safety assurance at runtime, ex-

ploring problem spaces to find optimal or near opti-

a

https://orcid.org/0009-0008-7886-7081

b

https://orcid.org/0009-0005-6421-1450

c

https://orcid.org/0000-0002-9156-9731

mal solutions (Liu et al., 2020), foster prediction of

runtime properties (Tao et al., 2019), foster more sus-

tainable manufacturing (Xu et al., 2022), or improve

cybersecurity (B

´

ecue et al., 2022). Thus, the basic

idea is that the twin can be used to simulate the exe-

cution of a task in a safe environment, and, as a conse-

quence, the actual robot will only execute this task if

determined safe by the digital twin (Kor et al., 2023).

This also allows a better instrumentation for moni-

toring system execution and determining the current

state of the system (Tao et al., 2019).

1.1 Current Challenges in the Definition

of Digital Twins for Robotic Systems

The utilization of digital twins in the field of robotic

systems is relatively new and presents several chal-

lenges. Some of the most common ones include com-

patibility issues, high development costs, uncertainty

in development and real-time feedback, as well as low

accuracy and precision. This necessitates the acquisi-

tion of new sensory devices that are more compati-

ble, consequently leading to an increase in the overall

466

Jesus Raja, J., Manjunath, M. and Daun, M.

Towards a Goal-Oriented Approach for Engineering Digital Twins of Robotic Systems.

DOI: 10.5220/0012681500003687

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 19th International Conference on Evaluation of Novel Approaches to Software Engineering (ENASE 2024), pages 466-473

ISBN: 978-989-758-696-5; ISSN: 2184-4895

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

cost (Ramasubramanian et al., 2022). Notably, the

flexibility of human-robot collaborations expands the

range of conceivable states in the digital twin. Fur-

thermore, in cyber-physical systems, challenges re-

lated to connectivity, computational power, and var-

ious other factors significantly impact the creation of

a highly reliable digital twin (Ding et al., 2019).

Albeit the existence of these technical challenges,

there exists a need for structured development ap-

proaches, systematically designing the digital twins in

combination with their physical counterparts. There

particularly exist a need for approaches support-

ing early development phases (Sandkuhl and Stirna,

2020). A promising approach to overcome this lack of

systematic engineering approaches is seen in model-

based development, which is popular in the context of

industry 4.0 (Wortmann et al., 2020).

1.2 Contribution

Goal modeling is an established lightweight model-

ing approach for early development phases (Van Lam-

sweerde, 2001; Horkoff et al., 2019). In this pa-

per, we explore the use of goal modeling with the

goal oriented requirement language (GRL, (ITU Int.

Telecommunication Union, 2018)) for systematically

defining the robotic system, its monitoring system,

and the digital twin. Application to an industry ex-

ample shows that this lightweight approach aligns

with industry preferences to focus on technical chal-

lenges rather than invest too much effort in a thorough

yet cost intensive engineering approach, while at the

same time allowing for the proper definition of robots

and their digital twins. Additionally, the utilization of

runtime analysis through goal reasoning unveils more

benefits in understanding the system and its digital

twin.

1.3 Outline

The paper is outlined as follows. Section 2 gives

an overview of the related work. Section 3 presents

the goal-oriented engineering approach for develop-

ing robotic systems and their digital twins, being used

to explore the use of goal modeling in the engineering

of these systems. Based on this approach, Section 4

evaluates the applicability and usefulness of this ap-

proach using an industry case example from the in-

dustry automation domain. Finally, Section 5 con-

cludes the paper and discusses the next steps in future

work.

2 RELATED WORK

Goal modeling is an established approach in require-

ments engineering (Van Lamsweerde, 2001; Horkoff

et al., 2019). The concept of goal models has

been advocated to express stakeholder objectives and

to capture and choose among requirement alterna-

tives (Horkoff and Yu, 2016). Goal models have

proven useful for eliciting, documenting, and validat-

ing stakeholder intentions (Van Lamsweerde, 2001).

They are commonly used in early phase requirements

engineering to document the basic high-level require-

ments and to already reason over fundamental design

decisions and to identify crucial conflicts in the very

early stages of development (Grubb and Chechik,

2021).

The most common goal modeling approaches are

KAOS (Dardenne et al., 1993; Van Lamsweerde,

2009) and iStar (Yu, 1997; Dalpiaz et al., 2016).

The iStar (originally i*) framework defines a con-

ceptual modeling language for capturing and analyz-

ing properties of complex systems in terms of ac-

tors, their intentions, and their relationships (Amyot

et al., 2009). The Goal-oriented Requirement Lan-

guage (GRL) is a lightweight standardized version of

iStar, it is regulated by the International Telecommu-

nication Union (ITU) in its recommendation Z.151

(ITU Int. Telecommunication Union, 2018). The

GRL documents goals in graph-based structures. Ac-

tors are used to define the belonging of goals to dif-

ferent stakeholders or, as in the case of this paper, to

systems. In addition to goals, the GRL defines fur-

ther intentional elements that allow separating differ-

ent concepts like qualities and tasks. Intentional ele-

ments can be decomposed, and they can contribute to

each other, or even depend on each other.

Analyses (i.e. goal satisfaction analysis or rea-

soning) of goal models allow for early detection of

defects (Giorgini et al., 2003; Brings et al., 2019).

Thereby, the benefit of goal models is often seen in

early discovery and definition of relations (e.g., con-

tributions, dependencies, conflicts) between different

requirements (Kavakli, 2004), as goal reasoning can

also be used to allow complex analyzes in the early

development phases (Pardillo and Trujillo, 2008).

3 APPROACH

3.1 Overview and Process Steps

The major idea of the approach is to use a goal model

for runtime analysis, as has also been suggested by

(Cheng et al., 2014). It suggests that goals can pro-

Towards a Goal-Oriented Approach for Engineering Digital Twins of Robotic Systems

467

vide assurance at runtime as they adapt to changes in

their execution environment. Goal modeling enables

assurance techniques, and modification of the model

to adapt to the change of the application.

For the digital twin, we want to foster re-use of

design time models. As has been shown by Daun et

al. (Daun et al., 2019), GRL goal models are a good

approach to define requirements and analyze early de-

sign decisions for cyber-physical systems, particular

in the domain of industry automation. Therefore, we

aim at re-using design time models for the smart fac-

tory, especially for the runtime analysis. In particu-

lar, we build upon a iStar-compliant GRL extension

(Daun et al., 2021), which we have shown to be ap-

plicable to robotic production systems (Daun et al.,

2023). In previous work, we have shown that goal

models can be used to specify the digital twin (Je-

sus Raja et al., 2023), in this paper we focus on the

systematic development of the digital twin goal model

based on the goal model of the robotic system. Figure

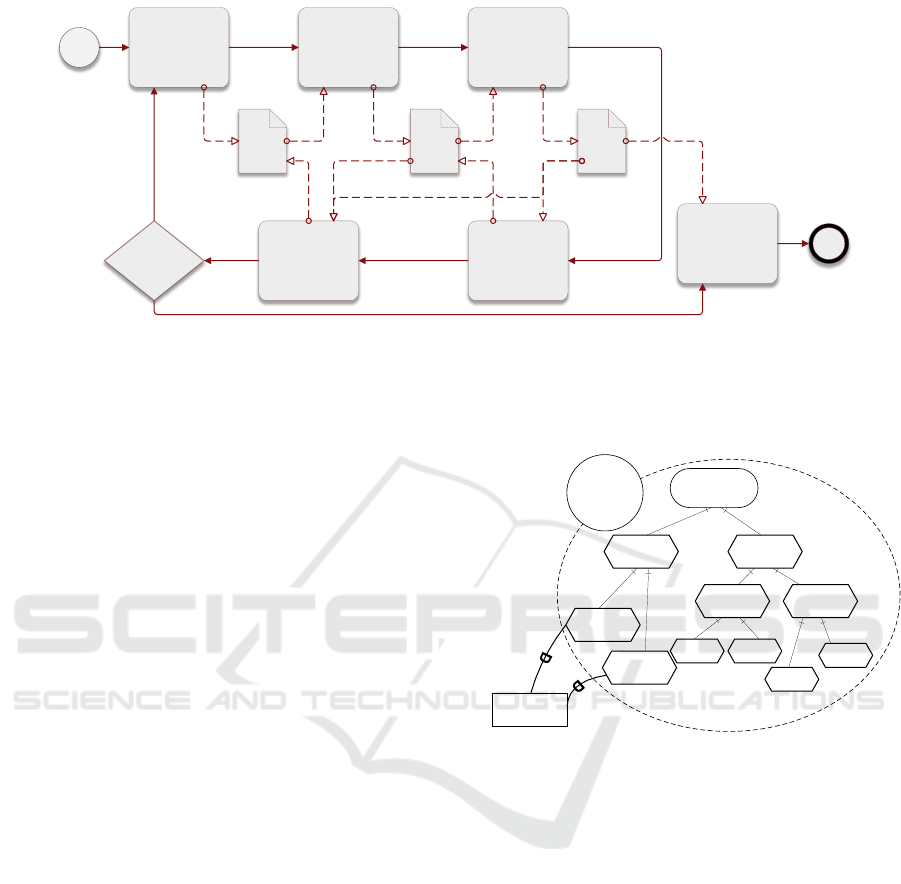

1 shows the overall idea.

First, the smart factory and the individual cyber-

physical production and transport systems of the

smart factory are defined using a GRL goal model.

Based on the goal model, the digital twin is defined.

The production system is completely automated and

therefore only requires humans as a backup monitor-

ing system. Therefore, the initial goal model is ex-

tended with monitoring tasks reflecting the runtime

objectives of the digital twin itself. Finally, the digital

twin goal model is linked to the factory and, based on

monitoring data, the system is updated to reflect the

current status of the factory. We then use, goal rea-

soning techniques to identify problematic situations

and propose runtime adaptations.

In summary – and as outlined in Figure 1, we

propose the goal-oriented specification of the physi-

cal and the digital twin with four consecutive process

steps.

• Step 1: Specify the Physical Twin (i.e. the Sys-

tem) in a Goal Model. First, a goal model is cre-

ated defining the physical twin. This goal model

focuses on the goals to be achieved by each robot

to be part of the overall robotic system. For these

goals, tasks are defined to specify the basic func-

tionality needed for each robot.

• Step 2: Specify the Monitoring System by Ex-

tending the System Goal Model. Robotic sys-

tems heavily rely on a wide range of monitor-

ing devices. These can be, for instance, cameras

needed to identify certain poses of work pieces

or the robot itself, or even safety shutdown mats

monitoring whether a human worker is in a cer-

tain area coming too close to the robot. In addi-

tion, monitoring devices need to be specified for

each task from Step 1. This allows representing

the current state of the robot (and its goal fulfill-

ment) in the digital twin.

• Step 3: Specify the digital twin and Combine

the Goal Models of the Different Systems and

their Monitoring Systems. In this step, the goal

model of the digital twin is defined. In addition, to

the simple monitoring tasks, the digital twin shall

typically provide some additional business value.

For instance, the digital twin shall predict whether

a potential safety hazard might occur in the direct

future (i.e. if a worker is likely to step into the

path of the robot), whether the current assembly

process might fail due to insufficient adherence to

the specified process execution, or the tool needs

replacement due to wearing. In addition, often

a robotic system – specifically in manufacturing

and assembly processes – consists of multiple in-

dividual robots. In this case, the digital twin needs

to aggregate the data collected from the different

monitoring systems and the different goal models

of each robot need to be combined.

• Step 4: Specify Goal Fulfillment Criteria for

Runtime Analysis. Finally, the goal model shall

be used as a runtime model to highlight the cur-

rent state of goal fulfillment for the robot and the

monitoring system (e.g., to detect system failures)

and to foster the prediction of the outcome of the

current production step. Therefore, goal fulfill-

ment criteria need to be defined for each task of

the system and the monitoring system.

Furthermore, Figure 1 shows some needed itera-

tions. In our case, we follow a bottom-up approach

as it best fits the thought process of current indus-

trial engineers (i.e. define first the robot you want to

build and later think about the digital twin). How-

ever, in this process, it is not ensured that all tasks

needed for functionality of the digital twin has al-

ready been defined. Therefore, the definition of the

digital twin model will often lead to the need to re-

vise the monitoring system model, or even the system

model. When defining the monitoring system in the

first place, emphasis is often given to a) the defini-

tion of monitoring devices needed for proper system

execution (e.g., pose recognition), b) the definition of

monitoring devices for safety concerns (e.g., detect

human workers in a certain area), or c) the imple-

mentation of quality assurance measures (e.g., check

that the work product has been assembled correctly).

Thus, when defining the desired functionality of the

digital twin, it will often be detected that more moni-

toring devices are needed to support predictions. This

can also be monitoring devices not directly attached

ENASE 2024 - 19th International Conference on Evaluation of Novel Approaches to Software Engineering

468

Step 1: Model

the robotic

system

Step 2: Model

the monitoring

system

Step 3: Model

the digital twin

Step 4: Define

goal fulfillment

criteria

System Model Monitoring Model Digital Twin Model

Refine the

Monitoring

System

Refine the

System

yes

Revisions

needed

Final?

Figure 1: Overview.

to the physical twin. For instance, it might be neces-

sary to monitor the production rate of a certain work

piece produced by another machine in the factory to

estimate whether the current assembly process might

be disturbed.

3.2 Modeling the System

We use our goal modeling extension for collaborative

cyber-physical systems to model the physical twin. In

addition, we restrict the way the goal model is cre-

ated to foster the later development of the digital twin.

Therefore, we need to ensure that the goal model can

be properly connected to the real world. This means

that the elements of the goal model must be moni-

tored. This allows updating goal fulfillment of the

model according to the current state of the system and

use reasoning techniques to analyze the system.

Important for linking the goal model to the real

world are tasks. As our primary focus lies in mon-

itoring our data, ’tasks’ serve as a means of moni-

toring as they articulate the system’s behavior. Tasks

represent abstract instructions executed by a system

to attain a goal (ITU Int. Telecommunication Union,

2018). For a more comprehensive understanding of

functionality, tasks can be further broken down into

finer-grained tasks. In production processes, task ful-

fillment is determined by monitoring the outcomes of

the tasks. This modeling approach is in-line with ex-

isting ideas to foster a more structured approach to

modeling GRL and iStar goal models (Keller et al.,

2018).

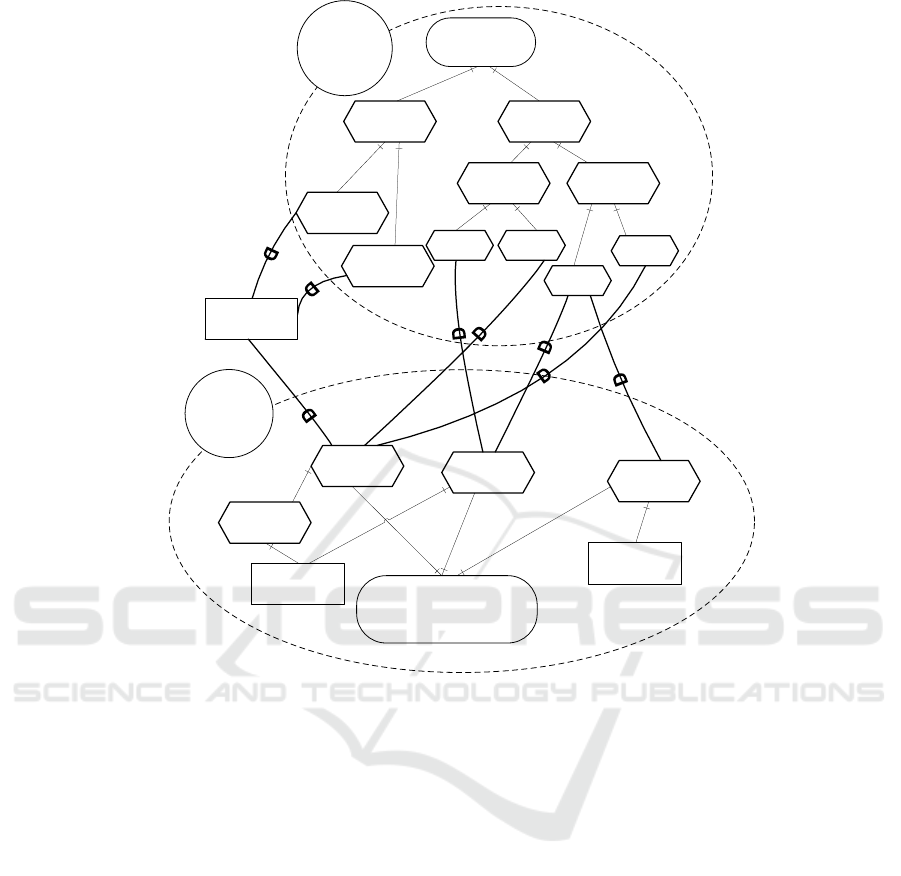

Figure 2 shows this goal modeling approach for

a collaborative robot (cobot) used in a manufacturing

production line for welding a car’s doors to its chas-

sis. The cobot shown is responsible for executing a

simple pick and place operation. This is an operation

commonly needed in robotic automation as the work

pieces needed, must be identified, selected, and posi-

tioned properly, so that subsequent robots (and partly

human workers) can use them.

Placeparts

together

AND

Movepart

Position

calculator

Checkposition

ofpart

Calibratecobot

position

Pickobject Placeobject

AND

AND

Cobot

Camera1

Camera2a

Double‐check

Position

MonitorCobot

Position

MonitorPick

andPlace

Ensuresuccessful

completionofPickingand

placingpart

Checkplacedpart

Monitoring

System

AND

Holdpart

Moveto

location

Droppart

inlocation

Moveback

toorigin

AND

AND

Camera2b

Placeparts

together

AND

Movepart

Position

calculator

Checkposition

ofpart

Calibratecobot

position

Pickobject Placeobject

AND

AND

Cobot

Camera1

Holdpart

Moveto

location

Droppart

inlocation

Moveback

toorigin

AND

AND

Figure 2: Goal model of the physical twin.

The goal model illustrates all the tasks the cobot

must execute to pick and place the parts necessary

for welding a car. The cobot initiates the process by

calculating and calibrating the positions of the parts

required for picking. These procedures depend on a

camera, which is considered an external resource in

our goal model as it does not belong to the cobot but

to the factory itself. Subsequently, the cobot proceeds

to move the picked parts to their designated positions.

The essential sub-tasks, ’pick object’ and ’place ob-

ject,’ play a pivotal role in accomplishing the over-

arching task of ’Move part.’ Both of these sub-tasks

have their own respective sub-tasks that need comple-

tion for the entire process to succeed. All tasks and

sub-tasks are interconnected through an ’AND’ con-

nection, signifying that the successful completion of

the process hinges on each individual task and sub-

task being completed without any errors.

Towards a Goal-Oriented Approach for Engineering Digital Twins of Robotic Systems

469

3.3 Modeling the Monitoring System

Subsequently, we define the goal model for the digi-

tal twin by extending the existing goal model of the

cobot (Figure 2) to incorporate essential elements of

the monitoring system that are later used by the dig-

ital twin. The resulting goal model for the monitor-

ing system is depicted in Figure 3. Notably, we have

introduced monitoring tasks dedicated to overseeing

system execution. These are represented as distinct

goals connected based on dependencies.

To ensure system monitoring during operation,

multiple sensors and cameras are strategically po-

sitioned. Various potential system malfunctions —

such as sensor errors, human errors, part misalign-

ment, interference from other equipment, or environ-

mental factors — are anticipated. These refined mon-

itoring tasks are intricately tied to the cobot’s process

tasks, enabling clear associations between monitor-

ing and the specific processes like pick and place in

our case. Additionally, we’re able to introduce sup-

plementary monitoring tasks unrelated to the primary

process tasks. For instance, one task involves evaluat-

ing the work product after completing its task of cal-

culating the product’s position, while another focuses

on precisely picking and placing the product. This lat-

ter task aims to verify whether the calibration aligns

with the digital twin’s predictions. Notably, a second

camera is utilized for this monitoring task, distinct

from the task that checks the part’s position. Here, the

objective isn’t solely to monitor task accuracy; rather,

it’s to confirm whether the calibration aligns with the

predicted results.

3.4 Modeling the Digital Twin

In the next step, the digital twin can be defined for

each robotic system or for the system-of-systems (i.e.

for all robotic systems together). Therefore, we again

use GRL goal modeling and integrate a new actor for

the digital twin into the goal model. Thereby, we can

differentiate between the physical system, the mon-

itoring of the system, and the analysis procedures of

the digital twin. The goals and tasks of the digital twin

are then connected to the monitoring tasks. Thereby,

it is ensured that all analysis procedures are suffi-

ciently grounded in the available data gathered by the

monitoring system during runtime. In this phase, it is

likely that data is identified that is needed for the dig-

ital twin but has not yet been monitored. Therefore,

the goal model of the monitoring system will need re-

vision and integrate these new monitoring tasks. An-

other likely effect is the introduction of the function-

ality in the system due to the outcome of predictions.

As the results of the calculation conducted by the dig-

ital twin shall impact the physical twin (e.g., to op-

timize process execution, to stop unsafe execution),

functionality is needed in the system that allows re-

acting to the outputs of the digital twin.

3.5 Goal Reasoning for Runtime

Analysis

Using goal modeling to model the system and the dig-

ital twin, might allow us to reason over the goal model

to identify goal fulfillment or the lack of goal fulfill-

ment during runtime. Therefore, we investigate dif-

ferent application scenarios for existing goal satisfac-

tion analysis approaches to support runtime analysis

and adaptation planning of the digital twin.

For the monitoring, forward reasoning (Amyot

et al., 2010) can be applied, thereby, we need to

ensure that all leaves of the goal graph are moni-

tored. As discussed above, the goals of the cobot

have been decomposed until reaching a level of fine-

grained tasks that can be monitored. Subsequently,

the monitoring data is used to estimate whether a task

is fulfilled or not. Based on these measurements, the

goal fulfillment is propagated up to the higher level

goals. Thus, can be determined if the cobot is cur-

rently performing its duties as intended or whether an

intervention is needed.

A basic distinction commonly made for reasoning

approaches is the differentiation between qualitative

reasoning and quantitative reasoning (Amyot et al.,

2010; Giorgini et al., 2003).

• Qualitative Reasoning. The starting goals (i.e.

the leaf goals in forward reasoning and the upper

goals in backward reasoning) are assigned goal

satisfaction labels like, e.g., ‘satisfied’, ‘weakly

satisfied’, ‘weakly denied’, ‘denied’. Then dif-

ferent propagation rules are applied to determine

how these are propagated. For instance, an AND-

decomposed ‘satisfied’ and ‘weakly satisfied’ will

be composed to ‘weakly satisfied’.

• Quantitative Reasoning. Instead of goal satisfac-

tion labels, numeric values are used and propa-

gated. While different scales are possible, a com-

mon approach is using values from ‘0’ to ‘100’,

being interpreted as percentage values. Based on

mathematical formulas used as propagation rules,

these values are then added, averaged, subtracted,

etc. to propagate goal fulfillment.

We found both approaches – qualitative and quan-

titative reasoning – applicable for runtime analysis.

Both approaches can be used to support runtime mon-

itoring of system execution. The propagation of goal

ENASE 2024 - 19th International Conference on Evaluation of Novel Approaches to Software Engineering

470

Placeparts

together

AND

Movepart

Position

calculator

Checkposition

ofpart

Calibratecobot

position

Pickobject Placeobject

AND

AND

Cobot

Camera1

Camera2a

Double‐check

Position

MonitorCobot

Position

MonitorPick

andPlace

Ensuresuccessful

completionofPickingand

placingpart

Checkplacedpart

Monitoring

System

AND

Holdpart

Moveto

location

Droppart

inlocation

Moveback

toorigin

AND

AND

Camera2b

Placeparts

together

AND

Movepart

Position

calculator

Checkposition

ofpart

Calibratecobot

position

Pickobject Placeobject

AND

AND

Cobot

Camera1

Holdpart

Moveto

location

Droppart

inlocation

Moveback

toorigin

AND

AND

Figure 3: Goal model of the monitoring system.

satisfactions helps in identifying which parts of the

system function correctly or need support at run-

time. Defining thresholds for the quantitative ap-

proach poses a challenge. We need to be able to deter-

mine when we consider the system working correctly.

Due to sensor imprecision, blocked views of cameras,

etc. it is highly unlikely to reach 100% goal satis-

faction. Therefore, we need to define a threshold like,

with a goal satisfaction probability of 95% we assume

this goal to be fulfilled.

Determining goal satisfaction of the leaf tasks

pose an even more challenging situation. The ques-

tion of when do we consider a task to be satisfied

or not, is difficult to answer. Problematic is the use

of ‘weakly satisfied’ or ‘weakly denied’, which we

therefore discourage. The same obviously holds true

for quantitative reasoning. It is a challenge to deter-

mine, when can we reach 97% goal satisfaction for

the welding task or 76% goal satisfaction for a moni-

toring task. Despite this difficulty in application, this

needs to be done either way. Even traditional moni-

toring approaches work with probabilities and thresh-

olds. Thus, we see the great benefit of a goal-oriented

approach in having this discussion early during sys-

tem design. Right at the moment of the development

of the digital twin, we need to determine how we can

instantiate concrete determination of goal satisfaction

for the various values we measure.

4 EVALUATION

We evaluated the use of GRL goal models to de-

velop robotic systems and their digital twins using a

case study from the industry automation domain. We

chose an industrial production and assembly line for

this. Overall, we can state that the use of GRL goal

models is a fitting approach to model robotic systems

and support the definition of the digital twin. Partic-

ularly, they offer support for identifying the tasks to

be monitored and defining the means to do so. For

instance, in our case, each monitoring system uses an

independent camera to allow detecting camera mis-

calibrations of the primary camera used by the respec-

Towards a Goal-Oriented Approach for Engineering Digital Twins of Robotic Systems

471

tive cobot. In a next step, analysis of the model and

identifying overlaps between the different monitoring

systems can result in finding further quality checking

approaches by comparing the overlapping monitoring

output of the individual monitoring systems.

We found the following major benefits for using

GRL goal models in the development of digital twins

in industry automation:

• Re-use. Requirements goal models can be re-used

twice. First for defining the digital twin. Second,

for runtime monitoring and analysis. Therefore,

the goal models can easily be extended by mon-

itoring tasks responsible for monitoring the pro-

duction tasks of the individual cobots. Thus, it

also allows for a more continuous development of

a system, as changes in the factory outlet are in-

corporated into the goal model and thus directly

reflected in the requirements.

• Analysis. Forward and backward reasoning ap-

proaches for goal models can be easily applied

to support monitoring of the factory state (i.e., by

up-propagating runtime goal fulfillment) and cal-

culating interventions (i.e., by down-propagating

goal fulfillment to determine necessary actions).

• Simplicity for human-in-the-loop use cases.

Smart factories are commonly monitored and run

by a factory manager. This human has the task

to ensure safe functioning of the factory and is

involved in re-scheduling and optimization tasks.

Therefore, a simple graphical model highlighting

dependencies between different tasks is benefi-

cial.

Finally, we need to briefly line out the major lim-

itations. As common for case study research, we

have only gathered insights for one case example,

thus, generalizability cannot be assumed. Further-

more, comparative experimental research is needed to

determine whether using goal satisfaction analysis at

runtime can actually contribute to digital twins in in-

dustrial production systems. Additionally, investigat-

ing the potential of using goal satisfaction analysis at

runtime needs more thorough consideration in the fu-

ture, particularly considering the definition of thresh-

olds and providing support for systematically defining

goal satisfaction labels or percentages based on mon-

itoring data.

5 CONCLUSION

In this paper, we investigated the use of GRL goal

models to develop robotic systems and their digital

twins. GRL goal models support easy specification of

high-level requirements and their interrelations. The

digital twin allows for in-depth real time analysis of

the current state of the factory and supports action

planning for new tasks or evaluating error handling

strategies for defects occurring at runtime. For the fu-

ture of manufacturing, digital twins play a vital role.

We have shown that GRL goal models are appli-

cable to model not only the cyber-physical production

systems within a factory, but also the needed mon-

itoring systems belonging to the digital twin. This

way, the digital twin can be developed closely linked

to the individual goals of the systems to be devel-

oped. In consequence, it can be ensured that every

major production step – which is defined as task con-

tributing to a major goal of a production system – is

monitorable and will be monitored by the digital twin.

The use of goal models furthermore supports the def-

inition of thresholds and decision-making about how

to define that a process step is actually executed cor-

rectly, and the corresponding task can be considered

fulfilled. Based on these definitions, goal satisfaction

analyses can be applied to estimate the overall goal

fulfillment of the factory and to calculate adaptation

scenarios to reach goal fulfillment. In addition, we

identified some modeling patterns for digital twins for

industrial manufacturing.

Future work, will have to validate these modeling

patterns in other scenarios. Furthermore, a structured

approach to estimate goal fulfillment based on moni-

toring data will help goal-based development of digi-

tal twins.

REFERENCES

Amyot, D., Ghanavati, S., Horkoff, J., Mussbacher, G., Pey-

ton, L., and Yu, E. (2010). Evaluating goal models

within the goal-oriented requirement language. Int.

Journal of Intelligent Systems, 25(8):841–877.

Amyot, D., Horkoff, J., Gross, D., and Mussbacher, G.

(2009). A lightweight grl profile for i* modeling.

In Advances in Conceptual Modeling-Challenging

Perspectives: ER 2009 Workshops, pages 254–264.

Springer.

B

´

ecue, A., Praddaude, M., Maia, E., Hogrel, N., Prac¸a, I.,

and Yaich, R. (2022). Digital twins for enhanced re-

silience: Aerospace manufacturing scenario. In Int.

Conf. on Advanced Information Systems Engineering,

pages 107–118. Springer.

Brings, J., Daun, M., Bandyszak, T., Stricker, V., Weyer,

T., Mirzaei, E., Neumann, M., and Zernickel, J. S.

(2019). Model-based documentation of dynamicity

constraints for collaborative cyber-physical system ar-

chitectures: Findings from an industrial case study.

Journal of systems architecture, 97:153–167.

Cheng, B. H., Eder, K. I., Gogolla, M., Grunske, L., Litoiu,

ENASE 2024 - 19th International Conference on Evaluation of Novel Approaches to Software Engineering

472

M., M

¨

uller, H. A., Pelliccione, P., Perini, A., Qureshi,

N. A., Rumpe, B., et al. (2014). Using models at run-

time to address assurance for self-adaptive systems.

Models@ run. time: foundations, applications, and

roadmaps, pages 101–136.

Dalpiaz, F., Franch, X., and Horkoff, J. (2016). istar 2.0

language guide. arXiv preprint arXiv:1605.07767.

Dardenne, A., Van Lamsweerde, A., and Fickas, S. (1993).

Goal-directed requirements acquisition. Science of

computer programming, 20(1-2):3–50.

Daun, M., Brings, J., Krajinski, L., Stenkova, V., and

Bandyszak, T. (2021). A grl-compliant istar exten-

sion for collaborative cyber-physical systems. Re-

quirements Engineering, 26(3):325–370.

Daun, M., Manjunath, M., and Jesus Raja, J. (2023). Safety

analysis of human robot collaborations with grl goal

models. In ER 2023: Int. Conf. on Conceptual Mod-

eling, pages 317–333. Springer.

Daun, M., Stenkova, V., Krajinski, L., Brings, J.,

Bandyszak, T., and Weyer, T. (2019). Goal model-

ing for collaborative groups of cyber-physical systems

with grl: reflections on applicability and limitations

based on two studies conducted in industry. In 34th

ACM/SIGAPP Symp. on Applied Computing, pages

1600–1609.

Demir, K. A. and Turan, B. (2021). Developing trends

in power and networking technologies for intelligent

cities. In Developing and monitoring smart environ-

ments for intelligent cities, pages 61–85. IGI Global.

Ding, K., Chan, F. T., Zhang, X., Zhou, G., and Zhang, F.

(2019). Defining a digital twin-based cyber-physical

production system for autonomous manufacturing in

smart shop floors. Int. Journal of Production Re-

search, 57(20):6315–6334.

Giorgini, P., Mylopoulos, J., Nicchiarelli, E., and Sebas-

tiani, R. (2003). Reasoning with goal models. In ER

2002: 21st Int. Conf. on Conceptual Modeling, pages

167–181. Springer.

Grubb, A. M. and Chechik, M. (2021). Formal reasoning

for analyzing goal models that evolve over time. Re-

quirements Engineering, 26(3):423–457.

Horkoff, J., Aydemir, F. B., Cardoso, E., Li, T., Mat

´

e, A.,

Paja, E., Salnitri, M., Piras, L., Mylopoulos, J., and

Giorgini, P. (2019). Goal-oriented requirements engi-

neering: an extended systematic mapping study. Re-

quirements engineering, 24:133–160.

Horkoff, J. and Yu, E. (2016). Interactive goal model analy-

sis for early requirements engineering. Requirements

Engineering, 21:29–61.

ITU Int. Telecommunication Union (2018). Recommenda-

tion itu-t z.151: User Requirements Notation (URN).

Technical report.

Jesus Raja, J., Manjunath, M., Kranz, P., Schirmer, F., and

Daun, M. (2023). Using goal modeling for defining

digital twins in industry automation. In Companion

Proceedings 42nd Int. Conf. Conceptual Modeling.

Kavakli, E. (2004). Modeling organizational goals: Anal-

ysis of current methods. In ACM Symp. on Applied

computing, pages 1339–1343.

Keller, K., Brings, J., Daun, M., and Weyer, T. (2018). A

comparative analysis of itu-msc-based requirements

specification approaches used in the automotive indus-

try. In 10th Int. Conf. System Analysis and Modeling,

pages 183–201. Springer.

Kor, M., Yitmen, I., and Alizadehsalehi, S. (2023). An in-

vestigation for integration of deep learning and digital

twins towards construction 4.0. Smart and Sustainable

Built Environment, 12(3):461–487.

Kortenkamp, D., Simmons, R., and Brugali, D. (2016).

Robotic systems architectures and programming.

Springer handbook of robotics, pages 283–306.

Koulamas, C. and Kalogeras, A. (2018). Cyber-physical

systems and digital twins in the industrial inter-

net of things [cyber-physical systems]. Computer,

51(11):95–98.

Liu, C., Jiang, P., and Jiang, W. (2020). Web-based

digital twin modeling and remote control of cyber-

physical production systems. Robotics and computer-

integrated manufacturing, 64:101956.

Pardillo, J. and Trujillo, J. (2008). Integrated model-driven

development of goal-oriented data warehouses and

data marts. In ER 2008: 27th Int. Conf. on Conceptual

Modeling, pages 426–439. Springer.

Ramasubramanian, A. K., Mathew, R., Kelly, M., Har-

gaden, V., and Papakostas, N. (2022). Digital twin for

human–robot collaboration in manufacturing: Review

and outlook. Applied Sciences, 12(10):4811.

Sandkuhl, K. and Stirna, J. (2020). Supporting early phases

of digital twin development with enterprise model-

ing and capability management: Requirements from

two industrial cases. In Enterprise, Business-Process

and Information Systems Modeling: 21st Int. Conf.

BPMDS, 25th Int. Conf. EMMSAD, pages 284–299.

Springer.

Tao, F., Qi, Q., Wang, L., and Nee, A. (2019). Digital twins

and cyber–physical systems toward smart manufactur-

ing and industry 4.0: Correlation and comparison. En-

gineering, 5(4):653–661.

Van Lamsweerde, A. (2001). Goal-oriented requirements

engineering: A guided tour. In Fifth ieee Int. Symp.

on requirements engineering, pages 249–262. IEEE.

Van Lamsweerde, A. (2009). Requirements engineering:

From system goals to UML models to software, vol-

ume 10. Chichester, UK: John Wiley & Sons.

Wortmann, A., Barais, O., Combemale, B., and Wimmer,

M. (2020). Modeling languages in industry 4.0: an ex-

tended systematic mapping study. Software and Sys-

tems Modeling, 19:67–94.

Xu, L., de Vrieze, P., Lu, X., and Wang, W. (2022). Digital

twins approach for sustainable industry. In Int. Conf.

on Advanced Information Systems Engineering, pages

126–134. Springer.

Yu, E. S. (1997). Towards modelling and reasoning sup-

port for early-phase requirements engineering. In

ISRE’97: 3rd IEEE Int. Symp. on Requirements En-

gineering, pages 226–235. IEEE.

Towards a Goal-Oriented Approach for Engineering Digital Twins of Robotic Systems

473