Development of a Ship Mooring Inspection Winch Tool with Extended

Reality

Wagner Aparecido de Oliveira

1 a

, Saul Emanuel Delabrida Silva

2 b

and Adrielle de Carvalho Santana

3 c

1

Graduate Program in Instrumentation, Control and Automation of Mining Processes (PROFICAM),

Federal University of Ouro Preto (UFOP), Vale Institute of Technology (ITV) and Vale S.A, Ouro Preto, Brazil

2

Department of Computing (DECOM), Federal University of Ouro Preto (UFOP), Ouro Preto, Brazil

3

Control and Automation Engineering Department (DECAT), Federal University of Ouro Preto (UFOP), Ouro Preto, Brazil

Keywords:

Ship Mooring Winches, Ship Mooring System, Extended Reality, Training, Maintenance.

Abstract:

Over the years, the interactivity between the real world and the virtual world has been increasing, making it

attractive for engineers to increasingly seek new tools for application in industrial areas Practices that recon-

cile the safety of people and assets, adds strength to investments. The focus here is a solution for working with

winches for ship mooring systems. The mooring system used to moor ships at a pier is made up of methods

characterized using combinations of hooks, bollards, and winches. Through the instrumentation on board this

equipment, information is obtained to analyze the stabilization of the mooring. The main parts of the winch

system consist of the sensing and measuring system, cable tension measurement system, electrical and the

mechanical system. This work proposes the development of an extended reality application for training main-

tenance teams. The application will enable the trained team to interact with the equipment’s functionalities

and information in a virtual and safe way, thus ensuring they have access to the operation, fault diagnosis with

simulations of problem solutions in a virtual reality environment. Is still expected to be added, in future devel-

opments, a of virtual interfaces for remote equipment operations increasing the speed of fault identification.

1 INTRODUCTION

The mooring system is complex, made up of equip-

ment that guarantees the stability of the ship during

its mooring period. These in turn consist entirely of

winches and land hooks, responsible for the safety

of mooring ships. At TMPM (Terminal Mar

´

ıtimo da

Ponta da Madeira) in Vale S

˜

ao Lu

´

ıs, Brazil, there is

four piers where ships are moored.

The piers I and II are protected from tidal varia-

tions due to their physical characteristics. However,

pier IV, due to its characteristics and location in the

open sea is directly affected by variations in sea cur-

rents and tide.

The complexity of pier IV is driven by the respon-

sibility of the shore winch. In turn, the analysis and

operability of this functionality is the responsibility

of the ground operations team, which analyzes the

a

https://orcid.org/0009-0006-3500-2972

b

https://orcid.org/0000-0002-8961-5313

c

https://orcid.org/0000-0003-1457-8930

data received throughout the loading and tide varia-

tion process and directs the operator to interact with

the equipment, whether local or remote interaction, to

apply the appropriate safety operational tension to the

ship’s mooring cable.

The load cell is the main monitoring instrument

of the mooring system, responsible for ensuring ac-

curate information to the operator about the mooring

tension. However, the cable tension of the monitor-

ing system is not the only functionality that must be

taken into consideration. It must be considered that

the winch depends on its entire operability so that

when requested, it can act effectively to tension or

loosen the cable.

The winch is exposed to marine weather and sub-

jected to impacts during its operation, which tends to

cause defects. Thus, it is subjected to regular main-

tenance stops which, in turn, can impact operational

losses and even affect ship loading and security. Prob-

lems can occur whether the winches are at rest or

when in operation. In this situation, the maintenance

team is called and has to intervene in the maintenance

Aparecido de Oliveira, W., Silva, S. and Santana, A.

Development of a Ship Mooring Inspection Winch Tool with Extended Reality.

DOI: 10.5220/0012703000003690

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 26th International Conference on Enterprise Information Systems (ICEIS 2024) - Volume 2, pages 247-255

ISBN: 978-989-758-692-7; ISSN: 2184-4992

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

247

of the equipment.

Currently, the maintenance team, when called, di-

rects a technician to go to the location and diag-

nose the problem. This treats the problem by act-

ing directly on the equipment, however, failure sit-

uations can occur between the electrical /mechani-

cal/ hydraulic areas and the professional is not trained

in all disciplines. When it comes to mooring ships,

faulty equipment can even cause a catastrophe.

For example, a stray ship can collide with other

moored ships or even with other piers, even so, there

is no way to measure the losses of an accident of this

magnitude because it involves large machines.

Electrical inspection of the winch in the field has

some disadvantages such as: the exposure to risk re-

lated to SS&MA (Health and safety & Environment);

exposure to the operational area, mainly in circum-

stances where the system may be operational; and

travel time from the workshop to the pier area (1400m

from the workshop to the bridge entrance plus 1800m

from the bridge to the pier entrance plus 1000m to the

Pier itself).

Therefore, the development of an inspection tool

with extended reality becomes interesting. Through

this tool, the maintenance team will be able to train

virtually with the aim of an intervention focused on

the likely point of equipment defect, increasing the

effectiveness in solving the problem. It can also be

highlighted that the use of a tool with extended re-

ality will bring greater security to the professional’s

training, which can be carried out in a safe environ-

ment, not needing to be carried out directly on the

equipment.

The main motivation for using this tool is that

the user will be trained to inspect the equipment and,

when there is a real need for a defect in the real equip-

ment, they will gain agility in solving the problem. If

the developed tool enables online connection with the

equipment, the gains would be extraordinary, as the

user could identify the defect remotely and go to the

location with the defined solution significantly reduc-

ing the ship’s mooring risks.

In summary, the application will allow the trained

team to interact with the functionalities and informa-

tion of the equipment in a virtual and safe way, thus

ensuring access to the operation, diagnosis of failures

with simulations of problem solutions in a virtual re-

ality environment.

2 THEORETICAL AND

SCIENTIFIC FRAMEWORK

2.1 Ship Mooring

The Mooring System is carried out as follows: when

the ship is positioned on the pier by the tugs, the on-

board cables begin to be launched, which in turn are

hooked to the land hooks. This process takes approxi-

mately 1h30. Once completed, the laying of the earth

cables begins. These, in turn, are the cables for the

earth winches, the object of this project. The operator

begins the process of releasing the cable to be hitched

to the ship. Depending on the ship, the hitch may be

on bollards or even ship hooks. Figure 1 depicts the

land and ship equipment.

Figure 1: Ship at berth. Source: VALE (2018).

2.2 Mooring Winches Automation

System

The mooring winch system is integrated into a ro-

bust automation system, comprising control associ-

ated with PLCs (Programmable Logic Controllers)

for equipment operation; remote monitoring and ac-

tivation system through the system supervisory; and

the PIMs system for operational and monitoring data,

and statistics.

The supervisory system, well known as the

human-machine interface, makes it possible for the

operator to remotely interact with the equipment, hav-

ing visual and operational control of the equipment.

It is worth noting that for it to be operable, a remote

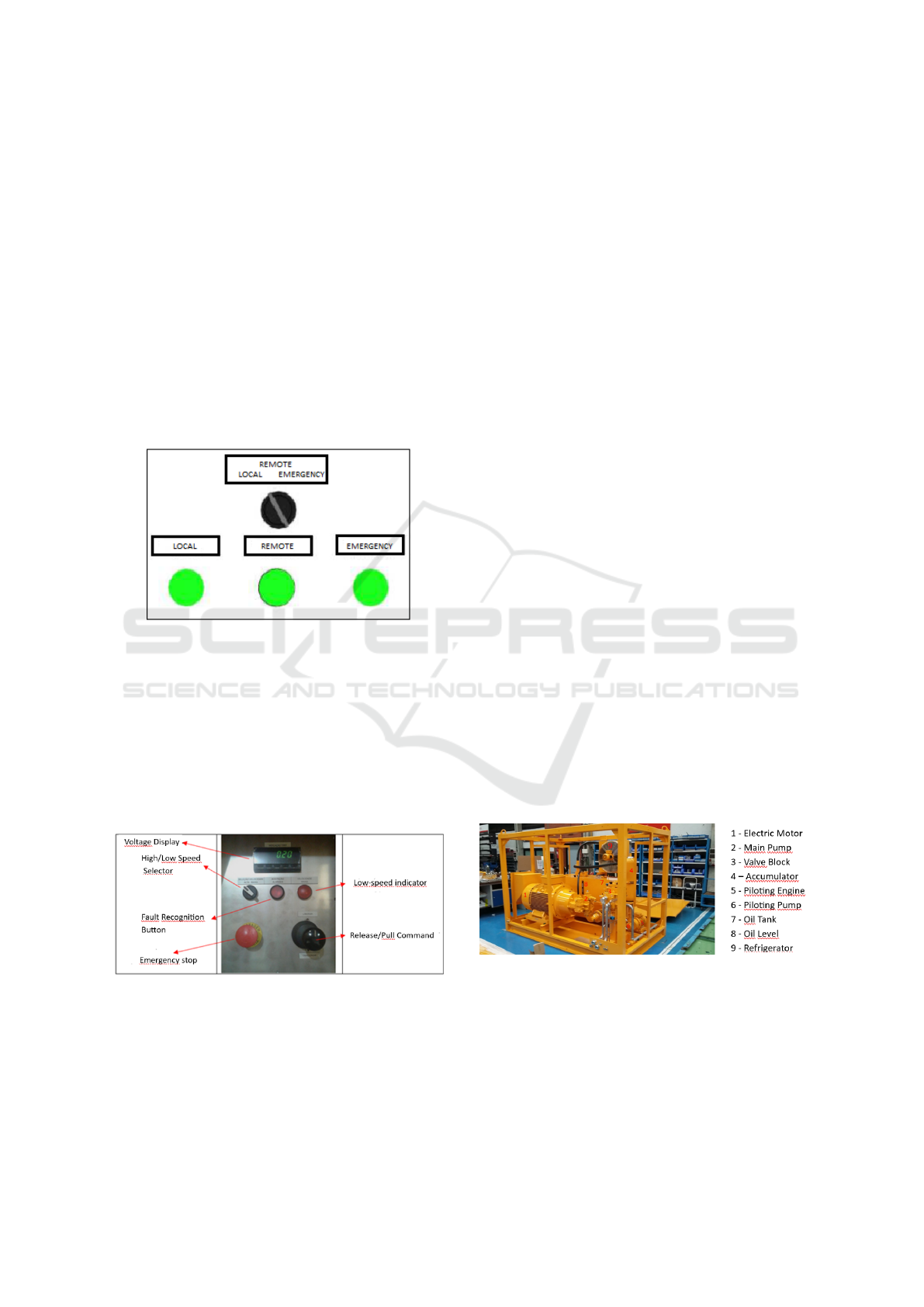

release must be done on the equipment. Figure 2 il-

lustrates the print taken from the winch supervisory

system screen.

The equipment’s automation control system is

developed through a PLC application using spe-

cific software. The one used in the equipment was

RSLogix, specifically for use in Rockwell PLCs.

The equipment’s electrical panel has several con-

trol and drive components. This, in turn, is specific to

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

248

Figure 2: Winch supervisory system screen.

the operational electrical control of the equipment. In

Figure 3, it is possible to check the winch electrical

panel.

Figure 3: Power and Control Panel.

There is also the Rockwell distributed I/O panel,

which is the connection point for all instrumentation

on board the winch. Figure 4 illustrates this panel.

2.3 Extended Reality

This section highlights the evolution of augmented re-

ality today and how it can be used in educational or

training processes, including ship mooring training.

2.3.1 Virtual Reality Breaking Paradigms

It appears that technology has been accompanying the

industry for around 50 years. This evolution is grow-

ing day by day. For some time now, technology added

to the increasing reality has been applied in various

segments, such as: training, maintenance support, op-

erations (Engineering 4.0), among other segments. In

the literature there are reports of the benefits related to

maintenance in augmented reality, aiming to reduce

Figure 4: Distributed I/O Panel.

risk exposure and bringing benefits to users’ health,

as in the work of Justimiano et al. (2021).

A notable advance can be seen in the graphic qual-

ity of many digital games in recent times, without los-

ing sight of the ease of use of consoles with much

more exposed quality, displaying high-performance

computing capacity, compared to the CAD programs

known on virtual platforms (de Oliveira et al., 2017).

In a simplified way, virtual reality (VR) is an

advanced interface technique between the user and

the computer, which simulates a real environment

in a virtual way, allowing the interaction, visualiza-

tion and manipulation of three-dimensional synthetic

environments generated by computers using certain

types of multisensory channels. VR enables the user

to have a high-performance experience of reality.

From the virtual environment with new versions of

interaction, using increasingly dynamic keyboards or

controls, VR enables innovative experiences that lead

to an increasingly detailed understanding of projects

or activities of their implementation in a physical en-

vironment (de Oliveira et al., 2017).

VR allows navigation in the digital world us-

ing computer graphics, giving the user a three-

dimensional view of the real world, which requires

a hardware and software structure capable of rec-

ognizing six types of movements: front/back, up

/down, left/right, right/left angle, up/down tilt, and

clockwise/counterclockwise rotation. This dynamic

of movements allows a simulation to the point of giv-

ing the user the sensation of touching objects, causing

a change with the movements established in real-time

(Valerio Netto et al., 2002).

Development of a Ship Mooring Inspection Winch Tool with Extended Reality

249

2.3.2 Augmented Reality with Technological

Advancement

Augmented reality differs from virtual reality due to

its ability to generate new multimodal interfaces with

high ease of manipulating objects in a given space,

in which the user can use their hands to interact with

a real environment. To make everything happen, the

use of augmented reality techniques can place real el-

ements, using optical tracking so that the scene has

maximum realism, without the technological appara-

tus of much connectivity. Therefore, it is possible to

create detailed and immersive environments, with in-

teractive elements to allow several innovative applica-

tions, as they allow the reliable reproduction of real-

life environments such as a house, bank, university,

or even a city, guaranteeing the user interaction with

each part of the environment and its proper purpose

(Kirner and Tori, 2006).

For Kirner and Tori (2006), augmented reality can

be defined as “the enrichment of real environment

with virtual objects, using some technological device,

working in real time”. The mechanisms for making

this combination between these realities stand out due

to the user’s sense of presence and the quality of the

images, leaving them free in the environment without

the application of as much technological equipment as

happens in virtual reality. With augmented reality, the

feeling of coexisting with the real world in the same

space can combine and align real and virtual objects

in real time.

2.3.3 Learning Methods

In recent years there has been a significant increase in

the application of mobile devices in the field of educa-

tion. The educational or training process constitutes

a purposeful interaction with technology mediated by

learning content between teachers and students where

teaching materials seek to solve educational tasks in

a systematized and updated way for the development

of students. In this sense, the learning environment is

virtually guided by information and communication

technologies combined with traditional teaching tech-

nologies providing greater understanding with virtual

environment tools (Zinonos et al., 2018).

With recent technological advances in the areas

of cyber-physical systems, actuators and sensors, the

flexibility of areas along value chains have demon-

strated increasing digitalization in both society and

industry. In this context, an ambitious technological

trend is “Augmented Reality” (AR). Its use facilitates

employees’ work by providing data in specific situa-

tions, in real time and with targeted information. As

a result, connecting data to machines results in work

without the need for a fixed work environment. How-

ever, the inclusion of new technologies also implies a

change in the way people work, leading to the restruc-

turing of work processes, particularly in the manufac-

turing industry (Sorko and Brunnhofer, 2019).

Due to this factor, augmented reality offers sev-

eral potentials for the industry, allowing, for example,

digitize process, in real time, for parallel processes.

In this regard, two types of processes can be men-

tioned: learning processes and industrial processes.

If the focus is on industrial processes, it is possible

to check which stage can be improved, the reduction

of delivery times, and activities to be carried out, ob-

serving the step by step of a work process (Sorko and

Brunnhofer, 2019).

Therefore, some industries already apply aug-

mented reality in their processes, developing environ-

ment projects and activities inherent to the develop-

ment of employees in the learning process. In the

view of authors Makransky and Klingenberg, virtual

reality improves safety training in industrial processes

(Makransky and Klingenberg, 2022). The use of these

resources can positively affect the results of safety

training, since engaging training is three times more

effective in promoting knowledge and skill acquisi-

tion, compared to non-engaging training.

AR-based simulations are more immersive as they

promote high levels of psychological presence, offer-

ing the sensation of being at the scene of the activ-

ity, which are often difficult, expensive or dangerous

to produce in real life (Makransky and Klingenberg,

2022).

2.3.4 Augmented Reality in Ship Mooring

Training

Currently, some companies are already using aug-

mented reality to carry out safety training. This is

the case of OMS-VR, a Ukrainian company, which

carries out various maritime safety training in VR in

the same location, where it is developing its own soft-

ware and hardware solution. In this case, VR training

allows obtaining results on the professional’s physical

and psychological state in various stressful situations,

without exposing them to the risks of such activities,

including equipment for cargo handling, pump room

for the fire detection and firefighting system on the

Ship’s deck and ship mooring winches, all on board.

What is desired in this current research project is

the implementation and analysis of a methodology ap-

plicable to land winch mooring systems, where the

principles for training are like those observed in a

real world training, seeking acceptable principles for

a better condition of safety levels for maintainers.

In navigation mooring cable protection training,

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

250

the modules provide practical instructions signaling

dangers and other associated risks, as well as identi-

fying the return zone in compliance with the require-

ments of the STCW convention, Regulation 1/12.

2.4 Virtual Reality Development

Feature

This section presents the tools used to develop the

augmented reality application proposed in this work.

2.4.1 Software Unity

Unity is a set of diverse 3D modeling tools for cre-

ating interactive media optimized in simple geome-

tries, enabling detailed editing and UV unfolding, as

it has rapid prototyping. Unity is a widely used tool,

as it guarantees support for independent developers,

allowing the development of games and simulations

in a more accessible way (Haas, 2014). This software

is compatible with different platforms (PC, consoles,

mobile, VR and AR) using a visual editor and pro-

gramming through and scripting, offering users pro-

fessional tools capable of meeting the requirements

of any game.

The main idea is to bring the reality of the winch

to a virtualized reality environment integrated with

the real functionality of the equipment, providing the

user with an interface with the equipment in a graphic

image, making it possible to train the inspection.

Unity offers developers three ways to program

applications attached to the IDE: Unity JavaScript

(Commonly known as UnityScript), C#, and Boo. Re-

gardless of the choice of which language to use, they

all allow developers to implement the same content

regardless of the established language (Haas, 2014).

2.4.2 UnityScript

UnityScript is a language that resembles Javascript,

and is the best choice for beginners. Generally used

by most developers, it is easier to obtain assistance

in the IRQ forum or the Unity forum. This language

is simple to learn and quick to type. Javascript is a

prototypical language, while UnityScript is a classical

language, which grants it certain benefits. However,

even though UnityScript has dynamic typing support,

in certain cases it will be less efficient than the C# lan-

guage, as the compiler must recognize that the object

type can change (Haas, 2014).

2.4.3 Boo

The Boo language has a syntax similar to Python, and

its structure is similar to UnityScript. However, it is

little used by users, which makes it difficult to seek

assistance (Haas, 2014).

2.4.4 Virtual Reality Glasses

Virtual reality glasses is a equipment that allows you

to view images in a stereoscopic 3D effect. This can

be connected to a PC and even smartphones. This

allows the user to immerse themselves in a virtual

3D environment to practice inspecting the equipment.

Since 2012, with the creation of the so-called Rift

glasses, many possibilities have emerged with simu-

lations of real environments, being designed with a

degree closer to reality, in which high-performance

projects are presented with a level of immersion in dy-

namic visualization spaces in their direct interaction

with projects implemented based on the technologi-

cal advancement of virtual reality (de Oliveira et al.,

2017).

2.5 Use of Virtual Reality in Training

Nowadays, when it comes to economic issues, the

job market and technological advances, organizations

must adapt and look for effective and efficient ways

to develop training programs, in order to educate, in-

spire and awaken knowledge in their employees, at

the same time as they face the challenge of main-

taining employee engagement and motivation in their

training. Thus, while companies are challenged to

maintain this engagement, comes the task of provid-

ing standardized training in a variety of geographic

locations, with different groups of employees, which

can result in high financial and energy costs, and ex-

pose the employee to various risks throughout the pro-

cess (Makransky and Klingenberg, 2022).

Therefore, it was necessary to search for a way to

overcome these challenges, creating flexible learning

environments and incorporating technology to com-

plement learning, and develop trained professionals

in an effective and safe way. To verify such learning

effectiveness in augmented reality training, a study

was carried out by the Department of Psychology in

Copenhagen, involving a training program at a mar-

itime industry, on the islands of Kiribat, to investigate

whether carrying out training based on augmented re-

ality is more effective than standard safety training. It

is detailed in the work of Makransky and Klingenberg

(2022).

The main issue highlighted is that the combina-

tion of augmented reality associated with a generative

learning strategy can allow students to reflect on the

topics covered even after class, which increases learn-

ing results. Most training carried out in a standard

Development of a Ship Mooring Inspection Winch Tool with Extended Reality

251

way generally uses a single method to pass on con-

tent, without evaluating the needs of each student, or

providing the opportunity for professionals to expe-

rience the relevance of their activity, without expos-

ing themselves to risks (Makransky and Klingenberg,

2022).

In the study in question, a sample was used con-

sisting of 86 students, both men and women, between

16 and 40 years old, all of them from the maritime ed-

ucation center in Denmark, Svendborg International

Maritime Academy. The experiment was carried out

as part of safety training on the topic of “Safety Dur-

ing a Mooring Operation” (Makransky and Klingen-

berg, 2022).

To obtain a comparative study on security training

based on virtual reality, and standard training, the stu-

dents in question were exposed to two different types

of methodologies, one with a trainer and the other

with VR, where the results were obtained. following

results.

The results of this research demonstrate that the

group included in the training with augmented real-

ity significantly accepted and appreciated this train-

ing, obtaining significantly greater intrinsic motiva-

tions and changes in behavior. It was then discovered

that professionals obtained higher levels of pleasure,

motivation and learning, but the result in self-efficacy

did not maintain many changes.

Therefore, the study in question points to several

pieces of evidence suggesting that training with im-

mersive simulations in augmented reality leads to sig-

nificantly greater pleasure in learning, highlighting

the potential that immersive technologies have with

a wide range of users in the future.

3 MATERIALS AND METHODS

Pier 4 North was the largest project implemented at

Vale, approved in 2008 by the board and it is located

in S

˜

ao Lu

´

ıs do Maranh

˜

ao at the Ponta da Madeira

Maritime Terminal (TMPM). This project had as

its fundamental principle the capacity for 130MTPA

(Million tons per year), that is, an additional 30MTPA

more than the 100MTPA (Million tons per year) that

already had operational capacity. The project did not

only involve increasing the port’s unloading, storage

and boarding capacity; it also generated many job and

income opportunities for the entire region.

Ore shipment includes a long journey for the iron

ore to be shipped. This process begins in Caraj

´

as-

PA where the ore is extracted. After the entire pro-

cess at the Caraj

´

as mine, it is transported by the Ra-

mal Ferrovi

´

ario Sudoeste do Par

´

a to the TMPM-SL

in Maranh

˜

ao. In Figure 5, there is an aerial view of

Pier IV South and North, where the ship moored can

be seen in the North Berth, in its first test with cargo,

and in Figure 6 it is possible to see the location of Pier

IV on the map.

Figure 5: Offshore Project - First test with Pier IV North

Load. Source: VALE (2018).

Figure 6: Geographic Location – TMPM. Source:

GOOGLE MAPS, obtained in 2023.

The boarding area at Pier IV consists of 2 load-

ing berths (South and North). The mooring system

is carried out as follows: first, the onboard cables are

launched, which will be fixed to the land hooks, af-

ter the onboard mooring is completed, the ground ca-

bles are launched, which, in turn, originate from the

winches. of land. The effectiveness of earth winches

is guaranteed through scheduled inspections to verify

the state of integrity and functionality of the equip-

ment. Based on these inspections, decisions are made

regarding the actions of the areas responsible for pre-

ventive and corrective maintenance of the equipment.

In Figure 7 it is possible to see a calibration procedure

for the winch load cell.

3.1 Data

Equipment inspection is currently carried out visu-

ally through operational testing and must be carried

out in person. All equipment history data is obtained

through PIMs. With this record, reports of failures

that occur during equipment operations can be ob-

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

252

Figure 7: Winch Calibration.

tained and statistics and trends can be generated for

preventive maintenance and plans of reviews. In a

graphical view, the process does not present any in-

teraction with the equipment, just a database in which

spreadsheets of registered events in the operational or

idle state of the winch are processed.

All information is collected from the winch PLC

via the ETH/IP communication network. The model

developed in Unity will be used to link real and on-

line data from the PLC application and supervisory

system with the developed 3D model. This collected

data will refer to status information in the actual oper-

ating situation of the equipment. It is expected to have

inspection training in the model, which will provide a

link between the real scenario and virtual reality.

3.2 Methodology

The development of the extended reality application

takes place during the development of the project. In

this phase, an extended reality tool is used so that the

user, with the 3D equipment, has the ability to interact

with the equipment virtually.

The entire project is developed with real informa-

tion from the equipment, so that the user can, in a

virtual system, obtain data that is as close to reality as

possible.

The feasibility of obtaining virtualized images of

the winch with an interface with reality will be stud-

ied. For the development of the tool, the Unity

software is used and the Virtua VR Oculus Real-

ity Glasses are used for visualization. In the test-

ing phase, the application will be submitted to users.

After completing the training, feedback will be re-

quested through a questionnaire on the experience of

carrying out the inspection using the tool. The main

topic will be focused on results in terms of expecta-

tions with equipment.

3.2.1 Analysis Procedure

The suggested procedure is to take the tool to users

(professionals involved in winch maintenance) so that

they can give a feedback on the developed product

and, through the results of their training on the tool,

generate a spreadsheet and a technical report with in-

formation about their experience. A statistical anal-

ysis will be done on the quantitative and qualitative

data collected.

3.2.2 Requirements for Winch Inspection

In this step, the necessary requirements are presented

for the winch inspection to occur safely in a hydraulic

mooring system, and which will be taken into account

when preparing the proposed tool. Some procedures

are adopted to control machinery and mechanical

equipment. An interesting part to note is the hydraulic

power unit that is attached to the base structure of the

mooring winch. This unit has two power sources to

ensure the necessary flow for the proper functioning

of the winch. It consists of a 132kW power supply

unit and another of unit of 4.8kW, which can all be

delivered as a compact unit.

Another frequently used piece of equipment is the

L46 pump, which is a fixed flow gear pilot pump that

is used to activate the cylinder brake or change the en-

gine displacement, with a composition of directional

control valves of various shapes that are accompanied

of solenoid valves and pressure filters to prevent ex-

cessive pressure from occurring.

The pilot pump operates in a controlled manner

via the PLC in accordance with the signal from the

pressure switch installed in the pilot line, and it is rec-

ommended to keep the selector in automatic mode.

The pilot pump has a “Manual/Automatic” selector.

The selector must always be in the“Automatic” posi-

tion. The PLC controls the start/stop of the pilot pump

via a pressure switch. With “Manual Selection”, the

pilot pump starts when pressing the green ”Start pilot

pump” button. Once the pump is running, the button

remains lit. To stop the pump, press the red “Switch

off pilot pump” button. With ”Automatic Selection”,

the pilot pump is controlled via the PLC and pressure

switch PS1.

The mooring winch is assembled with the hy-

draulic unit on the same base, where hydraulic and

electrical power is supplied. This unit only needs

power supply connection and communication connec-

tion with the remote-control room.

Development of a Ship Mooring Inspection Winch Tool with Extended Reality

253

The mooring winch is operated from the control

panel, so the site will always communicate with the

remote-control room in “Local Run” mode. In this

sense, the recommendation is to constantly provide

information about alarms, pressure, load indication.

It is worth noting that the winch cannot be con-

trolled remotely if this mode is selected. In “Oper-

ation in remote mode”, the mooring winch can be

controlled from the remote-control room based on

the hauling information. On the other hand, when

it comes to emergency operation, the mooring winch

is operated by the local control panel, noting that

in this case, the system does not communicate with

the remote-control room. Figure 8 represents the

panel and the light indications on the winch selection

modes.

Figure 8: Winch Selection Modes. Source: VALE (2018).

For winch operation, the system must have the

flow and pressure necessary to allow the hydraulic

motor to operate. The hydraulic pump in operation

enables smooth starting after 10 seconds of system

operation via joystick control. It is not recommended

to operate in joystick mode until startup is complete.

The system is signaled by the green light on the con-

trol table. Figure 9 represent the control panel, joy-

stick.

Figure 9: Hydraulic Pump Control Panel.

In this context, for the winch to function correctly,

it is necessary that all controls and equipment com-

ply with the characteristics presented above. Its op-

eration must occur in “Local Control” mode, and its

power lamp must be on, indicating that voltage is

available. The pilot pump must be activated (being

controlled through the PLC), together with the main

pump, which provides the flow and pressure of the

hydraulic motor, for the correct winch mooring. Its

control, as previously mentioned, is carried out using

the joystick, and the speed and rotation of the winch

can be controlled. To perform the operation from the

control room in remote operation, it is necessary to

activate the “Remote” selection mode.

3.2.3 Elements Considered for Inspection

Following is the roadmap of the research project’s in-

spection plan:

1. Basic knowledge of winching

2. Electric

• Electrical panel

• Murr I/O Board

• Local control panel

3. Hydraulic System

• Hydraulic elements

• Hydraulic plan

4. Mechanic

• Lubrication

• Reducer

• Reel

• Brake

• Load cells

5. Fairlead

6. Technical assistance

7. Spares

In Figure 10, there is an image of the winch hy-

draulic system assembly.

Figure 10: Hydraulic System.

3.2.4 Next Steps

This project is currently in the application develop-

ment stage, where we are using the information col-

lected about winch inspection, described in 3.2.2 and

3.2.3. Volunteers to participate in the experiment have

already been contacted and, with the approval of the

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

254

University’s research ethics committee, it will soon be

possible to begin testing. All from applications that

enable broader learning in handling equipment.

4 CONCLUSION

Currently, some companies are already using aug-

mented reality to carry out safety training. VR train-

ing allows obtaining results on the professional’s

physical and psychological state in various stressful

situations, without exposing them to the risks of such

activities. The contributions generated can address

engineering in more detail. With the development of

graphic images and programming, it is possible to im-

prove the interface between man and machine with

greater precision and integrate extended reality with

automation using data from PIMs and PLC database.

ACKNOWLEDGEMENTS

This study was financed in part by the Coordenac¸

˜

ao

de Aperfeic¸oamento de Pessoal de N

´

ıvel Superior

- Brasil (CAPES) - Finance Code 001, the Con-

selho Nacional de Desenvolvimento Cient

´

ıfico e Tec-

nol

´

ogico (CNPq) finance code 306101/2021-1, the

Fundac¸

˜

ao de Amparo

`

a Pesquisa do Estado de Minas

Gerais (FAPEMIG) finance code APQ-0089-30, the

Vale S.A, the Instituto Tecnol

´

ogico Vale (ITV) and

the Universidade Federal de Ouro Preto (UFOP).

REFERENCES

de Oliveira, G. M., Andal

´

o, F., and Vieira, M. L. H.

(2017). Realidade virtual e projeto arquitet

ˆ

onico:

da criac¸

˜

ao

`

a experi

ˆ

encia do usu

´

ario. TRIADES–

Transversalidades— Design— Linguagens, 6(2):1–

18.

Haas, J. K. (2014). A history of the unity game engine.

Diss. Worcester Polytechnic Institute, 483(2014):484.

Justimiano, A. C., Motta, E. S. d., and Sementille, A. C.

(2021). Sistema de realidade aumentada para o en-

sino e treinamento de pessoas quanto a execuc¸

˜

ao de

servic¸os de montagem e manutenc¸

˜

ao de equipamen-

tos. Revista Iberoamericana de Tecnolog

´

ıa en Edu-

caci

´

on y Educaci

´

on en Tecnolog

´

ıa, (28):34–40.

Kirner, C. and Tori, R. (2006). Fundamentos de realidade

aumentada. Fundamentos e tecnologia de realidade

virtual e aumentada, 1:22–38.

Makransky, G. and Klingenberg, S. (2022). Virtual real-

ity enhances safety training in the maritime indus-

try: An organizational training experiment with a non-

weird sample. Journal of Computer Assisted Learn-

ing, 38(4):1127–1140.

Sorko, S. R. and Brunnhofer, M. (2019). Potentials of aug-

mented reality in training. Procedia Manufacturing,

31:85–90.

VALE (2018). Book de Projetos Porto Norte S11D – Off-

shore/Onshore.

Valerio Netto, A., Machado, L. d. S., and Oliveira, M. C.

F. d. (2002). Realidade virtual-definic¸

˜

oes, dispositivos

e aplicac¸

˜

oes.

Zinonos, N., Vikhrova, O., and Pikilnyak, A. (2018).

Prospects of using the augmented reality for training

foreign students at the preparatory departments of uni-

versities in ukraine. Educational Dimension, 51:115–

122.

Development of a Ship Mooring Inspection Winch Tool with Extended Reality

255