Using Soft Computing and Computer Vision to Create and Control an

Integrated Autonomous Robotic Manipulator Process

Jo

˜

ao Ant

ˆ

onio Toledo Rodrigues

1 a

, Samuel Dos Anjos

1 b

, Mateus Coelho Silva

1,2 c

,

Ricardo C. C

ˆ

amara de M. Santos

1 d

and Ricardo Augusto Rabelo Oliveira

1 e

1

Departmento de Computac¸

˜

ao - DECOM, Universidade Federal de Ouro Preto - UFOP, Ouro Preto, Brazil

2

Instituto Tecnol

´

ogico Vale, Universidade Federal de Ouro Preto - UFOP, Ouro Preto, Brazil

Keywords:

Soft Computing, Robotic Manipulator, Object Detection, Evolutionary Algorithm, Inverse Kinematics.

Abstract:

The development and control of an integrated autonomous robotic manipulation process requires a focus on the

convergence of technologies such as soft computing, object detection, robotic arm engineering, and direct and

inverse kinematics. For instance, the inverse kinematics issue can be targeted using soft computing instead

of challenging mathematical applications. This paper explores using soft computing systems, an algorithm

that produces approximate solutions to complex problems and phenomena. Thus, the use of soft computing

proved valid, given the accuracy and speed of the claw. The soft computing technology is based on an evo-

lutionary algorithm that allows us to create several points on a cartesian plane and mix them to implement

inverse kinematics. Our results showed that using soft computing, which is different from the traditional way,

leads to solid and functional results. The implementation involves integrating Arduino, Raspberry Pi 4.0, a

PWM model PCA9685, a camera, and six servo motors to create a robotic arm. The system employs video

streaming to transmit data to a local network, where the Raspberry Pi processes RGB to HSV images for

object identification. The present work in this paper has experiments for the accuracy and speed of the claw to

take a determinate object from the center and the side of the checkered board.

1 INTRODUCTION

Automation and robotics have been playing an in-

creasing role in our society, simplifying complex

tasks and performing essential functions in various

industries, as Royakkers et al. say in (Royakkers

and van Est, 2015). In this context, the value of

autonomous robot systems increases daily, and the

need to integrate them into our daily lives becomes

more apparent. From the manufacturing industry and

medicine facilities to the indoors of our houses, au-

tonomous robots are reshaping how we live and work.

In other roles, automation technology dominates

daily tasks, with self-driving cars, trucks, drones, ma-

chines for modern medical operations, and robot fa-

cilities in the industry. In this way, the prospect of a

future with technology for cleaning our house, mak-

a

https://orcid.org/0009-0005-3905-3163

b

https://orcid.org/0009-0001-0347-5461

c

https://orcid.org/0000-0003-3717-1906

d

https://orcid.org/0000-0002-2058-6163

e

https://orcid.org/0000-0001-5167-1523

ing up our beds, storing clothes and utensils is getting

closer. In this way, those new kinds of facilities will

become crucial for the sake of an easy life. According

to Raja et al. (Raja and Nagasubramani, 2018), tech-

nology significantly influences how students learn and

teachers teach. The introduction of technology into

the educational environment has made the teaching-

learning process more interactive, efficient, and glob-

alized.

The article also emphasizes using soft computing

techniques that are valuable for their ability to han-

dle uncertainty, imprecision and partial truth. In this

way, soft computing can achieve and improve chal-

lenges and issues in modern agriculture, such as re-

source management, labor, technology advancements

in other industries, product quality, modernization, or-

ganic farming and sustainable practices. The article

(Yardimci, 2007) by Yardimci et al. reviews the appli-

cations of fuzzy logic-neural networks methodology

utilized in the clinical science of medicine. Further-

more, the article showed an interest in applying soft

computing methodologies in genetics, physiology, ra-

diology, cardiology, and neurology.

820

Rodrigues, J., Anjos, S., Silva, M., Santos, R. and Oliveira, R.

Using Soft Computing and Computer Vision to Create and Control an Integrated Autonomous Robotic Manipulator Process.

DOI: 10.5220/0012705600003690

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 26th International Conference on Enterprise Information Systems (ICEIS 2024) - Volume 1, pages 820-827

ISBN: 978-989-758-692-7; ISSN: 2184-4992

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

With that in mind, our work describes the imple-

mentation and use of a modern system of a robot arm

that performs the catch of an object inside the field of

vision of the camera. The image stream comes from a

Raspberry Pi working with a Pi Camera. The arm of

the robot is made of six servos motors, an Arduino, a

Raspberry Pi 4.0, a camera, and a PWM controller, as

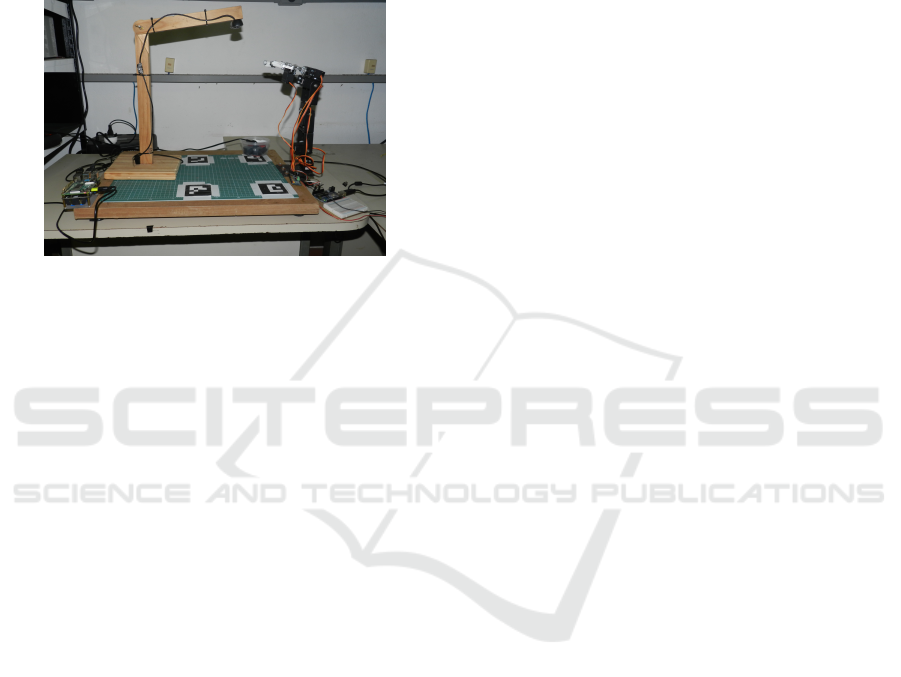

we can see in Figure 1.

Figure 1: Experimental apparatus used in this work.

In this way, it is possible to create an arm that can

perform tasks that are interesting to practitioners of

technology or even industrial uses. Thus, the main

goal of this work is:

• The employment of soft computing and computer

vision techniques to create an autonomous robotic

manipulator process.

In the remainder of this work, Section 2 presents

the theoretical baseline of this work. Section 3 dis-

cusses how this work relates to the literature. Section

4 presents the methodology employed to create the

solution, and Section 5 displays the results of the val-

idation experiments. Finally, Section 6 displays the

conclusions obtained from this work.

2 THEORETICAL REFERENCES

This section introduces some background that sus-

tains the work. We explored the concepts of soft com-

puting, robotic manipulators, the integration of au-

tonomous robots, and kinematics.

2.1 Soft Computing

Soft computing is system that offers a versatile and

adaptable approach to problem-solving, rendering it

a valuable asset in tackling intricate, ambiguous, and

uncertain challenges across diverse fields such as:

• Decision-Making.

• Optimization in Manufacturing.

• Predictive Maintenance.

• Supply Chain Management.

• Energy Management.

• Quality Control.

• Human-Machine Interaction.

• Smart Infrastructure and Cities.

• Healthcare Diagnostics.

• Financial Forecasting.

The article (Aguado and Cantanhede, 2010) by

Aguado et al. talks about fuzzy logic. The logi-

cal system introduced by fuzzy logic extends beyond

Boolean reasoning, moving beyond the binary notion

of merely present or not. Rather than settling for a

binary perspective, the aim is to discern the extent

to which an element is present or absent. For this,

sideways glance fuzzy logic is a mathematical ap-

proach that handles uncertainty by allowing for de-

grees of truth, practical in situations where informa-

tion is imprecise or ambiguous. In our work, the evo-

lutionary algorithm decides by itself. The evolution-

ary algorithms are another pillar that sustains the area,

as Bartz-Beielstein et al. says in (Bartz-Beielstein

et al., 2014). These algorithms refer to a category of

population-based stochastic direct search techniques

that, in a certain way, imitate the processes of natural

evolution. Another cornerstone is the neural networks

that M

¨

uller et al. say in (M

¨

uller et al., 1995). The

human brain’s architecture inspires these techniques.

The computational models are designed for machine

learning and artificial intelligence. The artificial neu-

rons, organized in layers, can learn complex patterns

and relationships from data.

2.2 Manipulator Process

The manipulation process is deliberately manipulat-

ing objects or substances using a robotic manipulator.

This specialized mechanical device is intricately de-

signed to execute an array of tasks, encompassing but

not limited to handling, lifting, positioning, and mov-

ing objects with meticulous precision and control.

Within industrial operations, the manipulator pro-

cess extends its functionality to tasks such as as-

sembly, packaging, sorting, inspection, and welding.

These activities necessitate a high degree of accuracy

in controlling the movements of the robotic manipu-

lator. In essence, as Raibert et al. discuss in (Raibert,

1978), the manipulator process signifies the strategic

application of a robotic manipulator within specific

production or operational contexts, where its dexter-

ity and automated capabilities play a pivotal role in

enhancing efficiency and precision.

Using Soft Computing and Computer Vision to Create and Control an Integrated Autonomous Robotic Manipulator Process

821

In this way, the Manipulator process stands as

a cornerstone in modern industrial operations, rep-

resenting a sophisticated approach to the controlled

manipulation of materials through robotic manipula-

tors. Mass production shows the highest level of au-

tomation in the industry is paramount, as displayed

by Krasilnikyants et at. in (Krasilnikyants et al.,

2013). In this context, the manipulator process is criti-

cal in achieving and maintaining this crucial element.

Robotic manipulators, equipped with advanced sen-

sors, actuators, and control systems, contribute to a

level of precision unattainable through manual labor

alone. However, using computational elements like

Raspberry Pi makes it possible to create a whole new

world of possibilities.

3 RELATED WORKS

The implementation of the robotic gripper is directly

related to an embedded system. In this sense, it is nec-

essary to understand how the elements interact with

each other.

3.1 Soft Computing in Robotics

The Use of Evolutionary Algorithms article mentions

the use of evolutionary algorithms, specifically for the

robotic claw’s movement based on the four spots of

the checkered board. This soft computing system,

named evolutionary algorithms, contributes to the dy-

namic movement of the robotic arm.

The article (Lopez-Franco et al., 2018) by Lopez

et al. shows that inverse kinematics is a crucial fac-

tor in allowing a robotic arm to achieve its objec-

tive, defining the angle settings applied to each ac-

tuator to make this possible. With that here, the fol-

lowing article addresses a possible solution to the in-

verse kinematics problem using soft computing meth-

ods. The article proposes using a CMA-ES algorithm,

which presents superior performance among other al-

gorithms evaluated through statistical tests. The re-

sults defend an approach used as a promising tech-

nique for solving inverse kinematics problems in the

movement of robotic arms. The use of the algorithm

called CMA-ES makes non-linear and non-convex

optimization.

The article (Kumar et al., 2017) by Kumar et

al. uses a mathematical way with soft computing to

solve inverse kinematics. In this sense, they explored

mathematical equations that relate the spatial coordi-

nates of the desired endpoint with the angles of the

robot’s joints. These equations are derived based on

the geometry and kinematic structure of the robot.

Then, they apply soft computing techniques to opti-

mize fuzzy logic controllers. In developing this work,

the way to apply inverse kinematics with soft comput-

ing did not use complex math manipulation and fuzzy

logic.

The article (Chin et al., 2020) by Chin et al. dis-

cusses the combination of parameterized analytical

models, the Gaussian models, and neural networks

(NN). In this way, they apply this technique to im-

prove the control and sensing of soft robotic systems.

The innovation is also present in applying soft com-

puting to deal with soft systems’ stochastic and non-

linear dynamics. Besides that, they used soft com-

puting techniques about control and sensing, using a

model that can learn and understand the terrain that is

to, but it needs help in modeling and training the sys-

tem. This way, our work has a different aspect when

using the HSV system of vision and soft computing.

The facilities to implement and make the code valid

in different situations.

3.2 Robotic Manipulator Control

The article (Hock and Sedo, 2018) by Hock et al.

presents two main techniques for solving the inverse

kinematics problem: analytical and numerical meth-

ods. The joint variables are solved analytically in the

analytical method according to the given configura-

tion data. In the numerical method, the joint variables

are obtained based on numerical techniques. The pa-

per focuses on the analytical solution of the manipu-

lators rather than the numerical solution. On the other

hand, our article uses direct kinematics to lead us to

a universal solution for the coordinates. As such, as

the experiment presents, there is no real difference be-

tween the places that the arm is leading to, taking us

to a faster response to the arm and keeping the preci-

sion.

The article (Chandana et al., 2015) by Chandana

et at. proposes a smart surveillance system for home

and office security. The system uses Raspberry Pi, a

gyroscopic sensor, and a Raspberry Pi camera to de-

tect movement, capture images, and send email alerts

to the user. In our article, the data transmission within

the system is facilitated through video streaming to a

local network, and the Raspberry Pi processes RGB

to HSV images. This innovative approach allows for

real-time data transmission and processing, contribut-

ing to the efficiency of the integrated autonomous

robotic manipulator process.

The article (Niloy et al., 2021) by Niloy et al. re-

views the main challenges in the design and control of

autonomous robots for application in indoor and out-

door environments. The choice of robot components

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

822

and models is considered to alleviate some problems

related to the movement and perception of robots con-

cerning the environment in which they are located. It

also relates to mapping and location, which are essen-

tial for the equipment to function correctly. In addi-

tion, neural network training techniques used to en-

sure improvements in robot control and autonomy are

mentioned. In this idea, our work uses the system of

HSV to perform arm manipulation better and create a

model to work in different places.

The article (Deepak et al., 2012) by Deepak et

al. uses Denavit Hartenberg parameters to create a

mobile arm manipulator. This way, the article uses

direct kinematics for the manipulator process based

on mathematical formulation. In this way, our article

proposes a different approach with inverse kinemat-

ics to solve the problem. In this way, we reach the

angles of the servo’s motor by the final point and not

the final point by the angles of the servo’s motor. This

difference is because this process only requires a little

mathematical formulation, as it uses an evolutionary

algorithm.

The article by Xu et at. (Xu et al., 2005) used a

mathematical formulation similar to the article above

but to solve inverse kinematics. In this way, they use

a matrix model with Denavit Hartenberg parameters

to obtain orientation and the end position of angles.

With the matrix to solve, they get the position of joint

angles. Our article came with a different approach. It

does not require a direct solution for the joint angles

and, with the evolutionary algorithm, creates an easier

way to get the desired angles for the robotic arm.

4 METHODOLOGY

This work presents soft computing techniques to cre-

ate an integrated autonomous arm manipulator. The

implementation of the project used an Arduino, a

Raspberry Pi 4.0, a camera, six servo motors, a check-

ered plane, and software to receive the information

and process it. The idea is to create a robotic arm

to recognize targetable objects according to the hue,

saturation, and value (HSV) color system. The data

is transmitted through video streaming to a local net-

work by installing the Raspberry Pi Cam Web Inter-

face software on the Raspberry Pi. This software is

responsible for enabling the transmission and access

of camera data over the Wi-Fi network.

From there, the data collected by the camera will

be available for access through an IP address provided

by the software. The data will then be received on the

primary device, which captures the RGB images pro-

vided by the camera and makes a transformation to

HSV. These images are then processed by software

responsible for converting the data into a checkered

plane, which the object identification system will use.

After the identification system has read the data, the

necessary coordinates for the robotic arm to reach its

objective are sent to the Raspberry Pi 4.0 using a USB

cable, which will transmit the data to the Arduino. In

sequence, the Arduino will act, ensuring the move-

ment of the arms towards the given coordinates.

The arm movement is performed by applying the

concepts of direct and inverse kinematics, from which

the necessary information for the arm movement is

provided, such as the current position of the arm and

the possible combinations of angles required at each

actuator for the system to reach the desired point. The

locomotion of the part is made out by applying the

concepts of direct kinematics, which calculates the

current position of the arm based on the recorded po-

sitions in its joints, and inverse kinematics, which cal-

culates the possible combinations of angles required

at each actuator for the system to reach the desired

point.

Based on the calculations performed by these two

methods, it is possible to precisely control the arm

movement, from its departure from the initial point to

contact with the target and return to the original po-

sition. Is this way, direct kinematics deals with com-

puting the position and orientation of the tool refer-

ence system in relation to the base system. On the

contrary, inverse kinematics involves unraveling the

enigma: starting with the desired position and ori-

entation of the end travel, it’s about discovering the

myriad ways joint angles can join forces to bring that

vision to life.

The conversion from RGB to HSV occurs math-

ematically, and some functions help in the process.

The RGB parameters from 0 to 255 are sent to a

function that saturates the colors so that the differ-

ence between the minimum and maximum values is

highlighted. Thus, another function calculates the ho-

mography transformation, which leads to finding the

angles of the desired figure and highlighting it. In

this way, the process ends with highlighting points in

the figure to correct and parameterize the object’s per-

spectives.

We start a serial communication with the Rasp-

berry Pi and receive the image from the cameras that

are received in the code. Then, the system uses func-

tions to calculate the distance between points and or-

der them. Afterward, with the ArUco tags, the four

points are detected. Once the points are located, a

perspective transformation is performed on an image

based on the tags’ reference points.

After defining the points in the gridded space, the

Using Soft Computing and Computer Vision to Create and Control an Integrated Autonomous Robotic Manipulator Process

823

image is segmented to locate objects of interest us-

ing RGB and then, for better operation, transformed

to HSV. In this sense, the contours of the objects of

interest are obtained, and their centers are calculated,

which is reread by the system in an infinite loop. Af-

terward, the actual position of the objectives is calcu-

lated based on the ArUco tags.

After pressing the command key, the code sends

the pulse to the Arduino, which receives it and passes

it to the PWM controller that controls the servo mo-

tors so that they mimic an arm picking up an object,

which, shortly after, deposits the objective in a prede-

fined space in the code.

4.1 Direct Kinematics

The inverse kinematics problem is built on the

problem of how you could calculate angles of

(θ

0

,θ

1

,θ

2

,θ

3

) to reach a certain (x,y,z) spot and

make the system efficient. In this sense, it is possible

to solve the problem with a vector sum and Euclidean

distance approach. That is, the vector sum provides,

together with the Euclidean distance that the robotic

arm system can go from a three-dimensional system

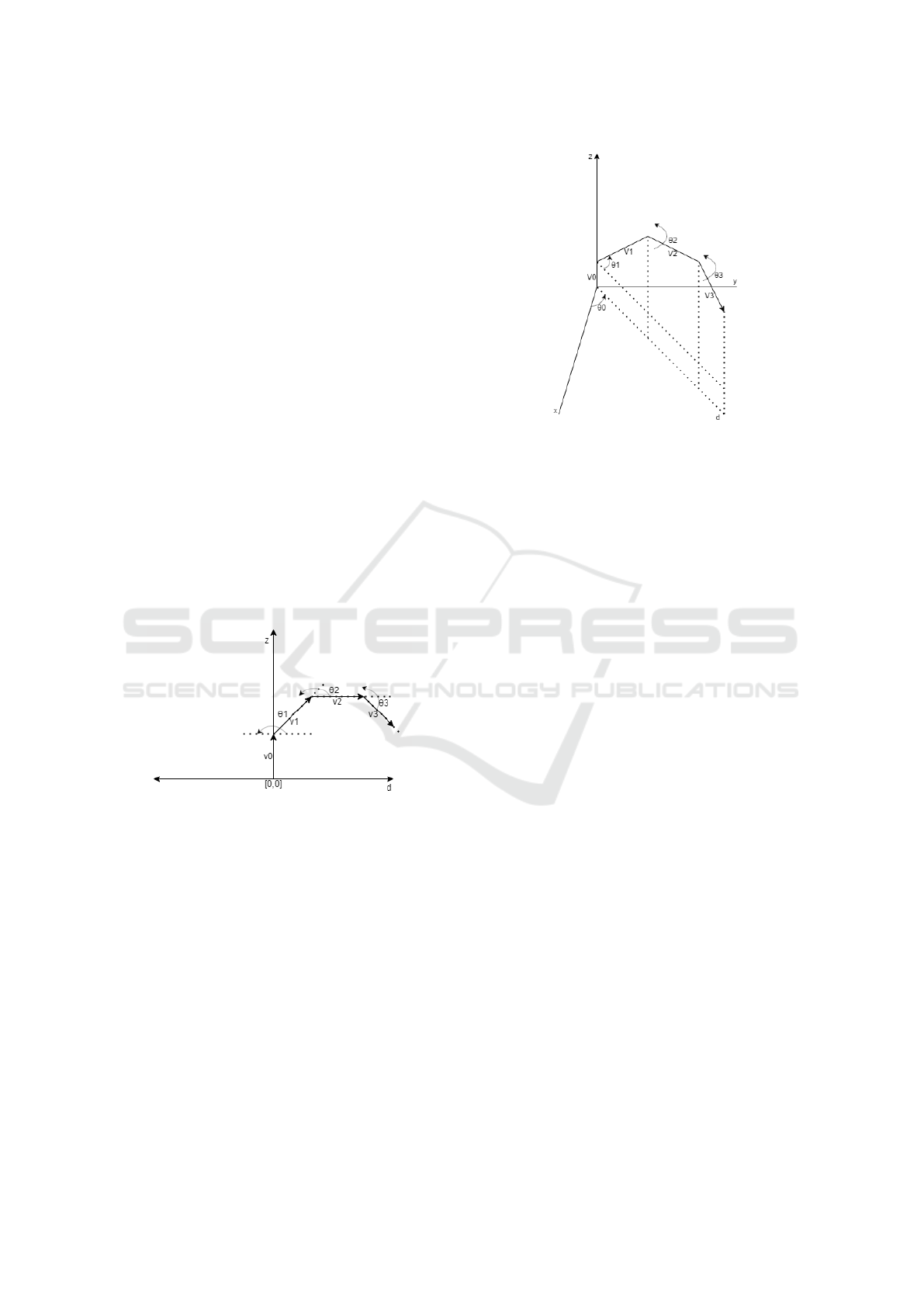

to a two-dimensional system. As is evident in the fig-

ures Figure 2 and Figure 3.

Figure 2: Two-Dimensional Vector Representation of Arm

Configuration.

Direct kinematics is the relation of which angles

the servo motors need to be at to the control to have

precision. The formulation that describes this model-

ing is presented in Equations 2 and 1.

y = v

0

· sin(θ

1

)

+ v

1

· sin(θ

1

+ θ

2

)

+ v

2

· sin(θ

1

+ θ

2

+ θ

3

)

+ v

3

· sin(θ

1

+ θ

2

+ θ

3

+ θ

4

)

(1)

x = v

0

· cos(θ

1

)

+ v

1

· cos(θ

1

+ θ

2

)

+ v

2

· cos(θ

1

+ θ

2

+ θ

3

)

+ v

3

· cos(θ

1

+ θ

2

+ θ

3

+ θ

4

)

(2)

Figure 3: Three-Dimensional Vector Representation of Arm

Configuration.

To determine the best functioning of the claw, the

following parameters were used to write this article:

• x = 0 + 104 ×cos((pi/2+t1) + 75×cos((pi/2)+

t1+t2) + 35 × cos((pi/2)+t1 +t2 +t3) + 165 ×

cos(t1 + t2 +t3)

• y = 65 + 104×sin((pi/2+t1) + 75×sin((pi/2)+

t1 +t2) + 35 × sin((pi/2)+t1 + t2 +t3) + 165 ×

sin(t1 +t2 +t3)

4.2 Inverse Kinematics

Inverse kinematics combines the concept of plan di-

mensions and soft computing to have a method that

uses the target coordinates to process and find an an-

swer to position the manipulator tool in this mark.

This way, we explored the concepts of evolutionary

algorithms to complete the proposal, considering the

following steps:

• Population Initialization.

• Aptitude Assessment.

• Selection.

• Crossing over.

• Mutation.

• Replacement.

• Stopping Criterion and Optimal Solution.

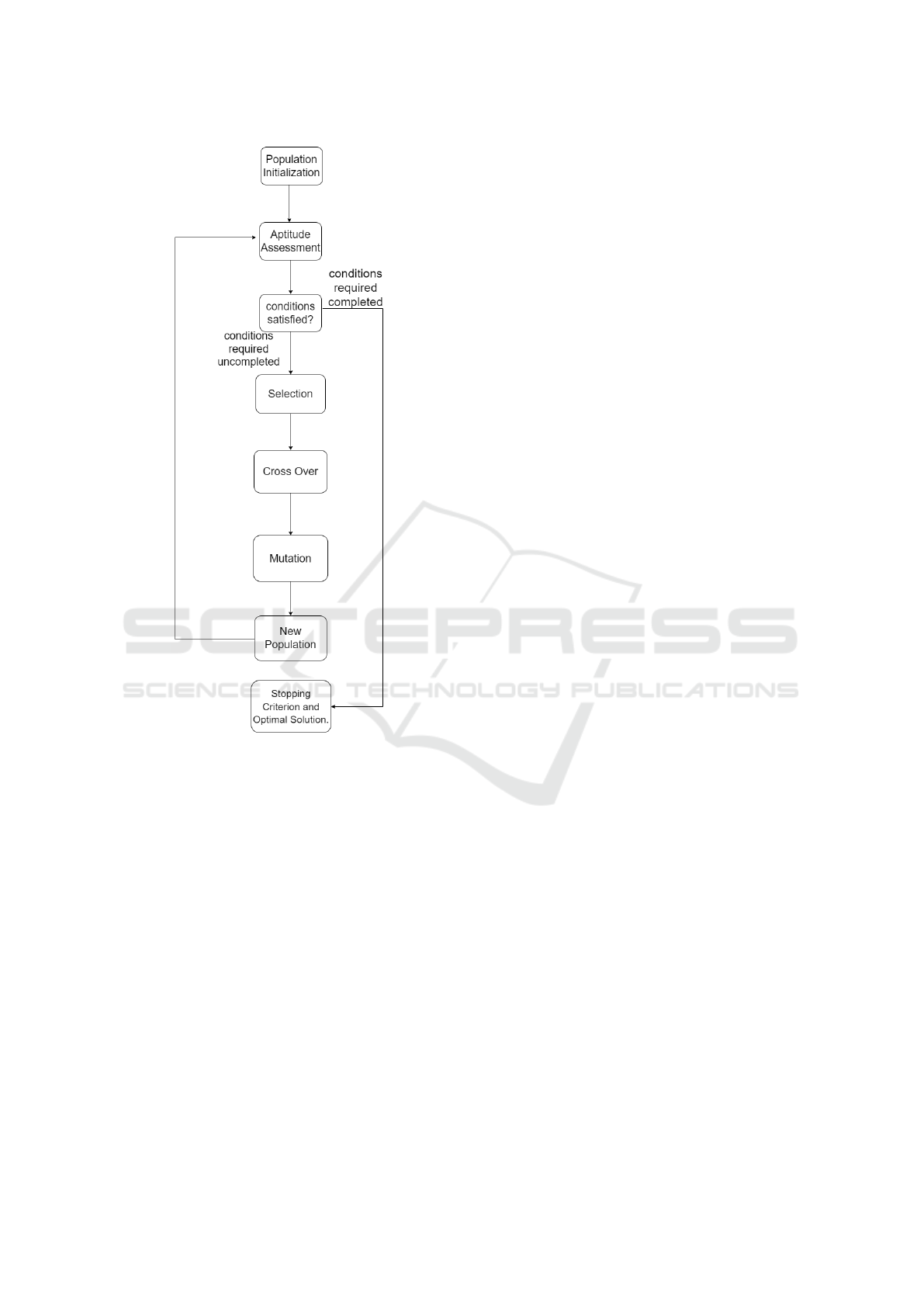

To explain further we can see the Figure 4, the next

few’s paragraphs relate to the upper items.

We find the standard deviation of the range of ag-

gregated data in the repeated expression or field in

the chart dimensions. When the standard deviation

of fitness is less than 0.01, the population has con-

verged. Another stoppage criterion happens if the fit-

ness standard deviation is less than 0.1, but the system

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

824

Figure 4: Flowchart of evolutionary algorithm.

has found a solution whose result is sufficiently satis-

factory. If this solution is found and the desired point

is less than 0.1cm, the solution is good enough. The

stages that compose the evolutionary algorithm are:

• Population Initialization: Initial generation of

random sets of gripper angles. The evolutionary

algorithm starts with a population of individuals,

each representing a potential solution to the prob-

lem. The individual is a set of angles of the robotic

arm.

• Aptitude Assessment: Inverse kinematics is used

to calculate the position of the end-effect with the

current joint angles, and the fitness function eval-

uates how close it is to the desired position. It

evaluates how good a solution is in relation to the

objective of the problem. The fitness function can

measure how close the angles are to the desired

position of the robotic arm.

• Selection: Individuals are selected proportion-

ally to their fitness (proximity). Individuals with

greater fitness are more likely to be selected for re-

production. In the algorithm, this selection mim-

ics the evolutionary process in nature. In this

case, the fittest individuals contain the values that

best adjust the arm’s position relative to the target

point.

• Crossover and Mutation: Pairs of individuals

are combined (crossover), and some individuals

mutate. The selected individuals are combined to

create offspring. This step involves combining the

joint angles of three parents to generate new sets

of angles.

• Replacement: The descendants and part of the

individuals from the previous generation form the

next population. That is, the new descendants re-

place part of the previous population. This stage

is a mimicry to select and maintain the best indi-

viduals from the previous generation.

• Stopping Criterion: The process is repeated un-

til a stopping criterion is reached, be it 0.1 cm or

population conversion.

4.3 Validation Experiments

The experiment carried out in this article involved the

use of computer vision and soft computing. To this

end, two parameters were used for the experiment.

One involves the number of hits of the claw to grab

the object, and the other is the time required by infer-

ence for the claw.

The experiments were carried out with 150 arm

tests using soft computing to solve the inverse kine-

matics at more than one point on the checkerboard.

From this perspective, we could observe, note, and

detail the algorithm’s response time and accuracy. For

this matter, the observed variables are:

• Capture success ratio in the central position con-

sidering 100 measurements;

• Capture success ratio in the lateral position con-

sidering 50 measurements;

• Inference time in central position versus lateral

position;

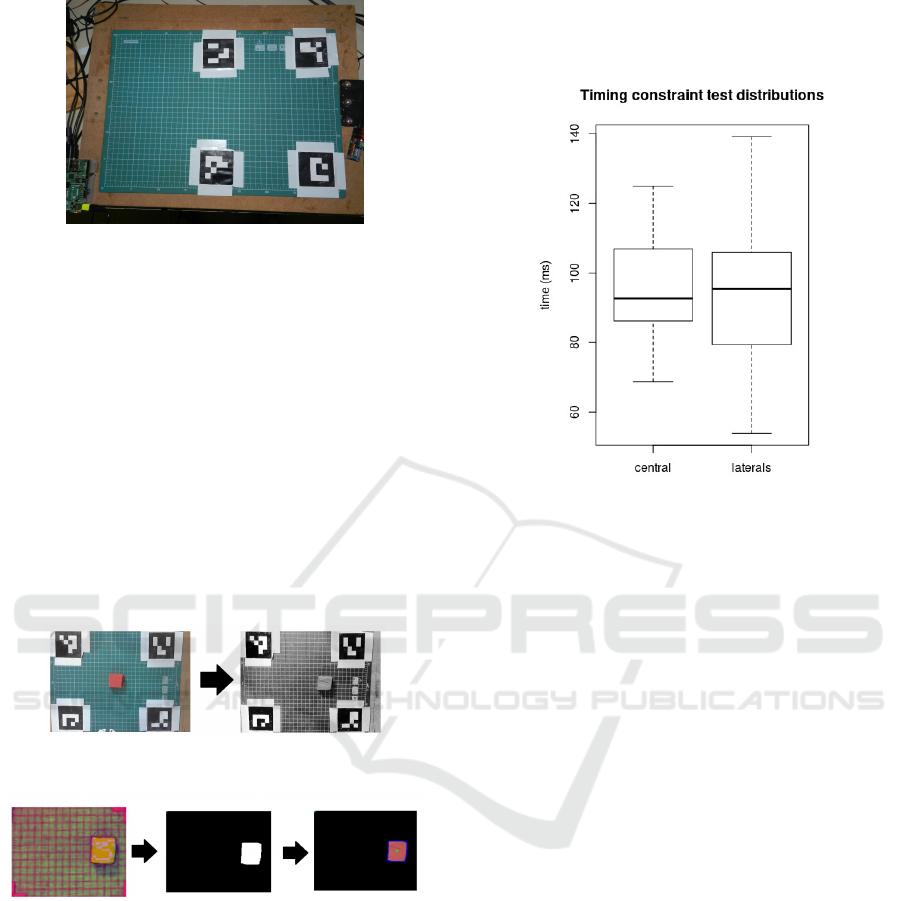

5 RESULTS

This section presents the experiments made in the lab-

oratory to test if the inverse kinematics have different

times of responses according to the local that the piece

is positioned on the checkered board Figure 5.

Using Soft Computing and Computer Vision to Create and Control an Integrated Autonomous Robotic Manipulator Process

825

Figure 5: Checkered board.

We separated a red cube to set a condition for the

claw to have a better chance to hold it, and we can

evaluate the results based on the speed and accuracy

of the claw. Initially, it is important to learn that the

way the claw moves is based on a soft computing sys-

tem named evolutionary algorithms that, based on the

four spots of the checkered board, makes operations

to achieve that coordinate.

With the direct kinematics doing the servo motor

angle adjustments, what is needed is the image to use

inverse kinematics for the claw to go to the desired

point. In this way, the dynamic way that the algorithm

transforms the image to the read of RGB is shown in

Figure 6. Moreover, the continuous read is shown in

Figure 7.

Figure 6: Location of the ArUco tags to separate the work-

ing area on the checkerboard.

Figure 7: Continuous camera reading to find the target ob-

ject.

With that all settled, the red cube is positioned in

two ways. In the first and left one, it is positioned

right in the center, and in the second and right one, it

is on the spot next to the center but distant enough to

make a difference.

For the experiments, we took 100 rounds of the

claw, taking the red cube in the center, leading us to

the result of 92% of catches and 100 measurements of

how fast the claw went to take right in the center of the

checkered board. For the side positioning, we took 50

rounds of experiments, and we came to the result of

80% of catches and 50 measurements of how fast the

claw went to catch the red cube in a position next to

the center. Figure 8 depicts the boxplots containing

the results for both stages.

Figure 8: Timing distribution for both tests in a boxplot.

In this way, we evaluate and investigate the hy-

pothesis of the existence of differences between cen-

tral and lateral positioning concerning the time it takes

the algorithm to infer inverse kinematics. We per-

formed statistical tests to compare the two results we

had in the experiments.

The variance test evidenced that the two data sets’

value of 0.01 indicates no significant difference in

variances, suggesting that the variances are equal. Af-

ter that, we performed the t-test, demonstrating no

significant difference between the means of the two

groups. The averages are listed as 97ms and 99ms.

The conclusion is that the object location makes no

significant difference in the average inference time.

Figure 8 depicts the boxplot representing the tim-

ing distribution for both tests. Although the im-

age suggests different variances for the situations,

the variance tests indicate no significant difference

(p < 0.05)

6 CONCLUSIONS

The paper describes the development of a robotic arm

manipulator solution using soft computing and com-

puter vision. With that approach, the manipulator

process became more manageable because it did not

require a complex mathematical formulation as the

other articles presented in this work. The theory is

to create a path in which, even without mathematical

modeling, we have a functional and practical inverse

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

826

kinematics that is easier to implement.

This work is based on the concept of soft com-

puting. This perspective emphasizes the development

of novel solutions without the need for hard mathe-

matical modeling to solve them. Usual tools imple-

mented in soft computing appliances are neural net-

works, fuzzy logic, and evolutionary computing. In

this work, we used the latter to integrate the manipu-

lator application.

The methodology to create and validate the the-

ory that evolutionary algorithms would work for in-

verse kinematics has reasonable evidence of success,

as seen throughout the research. The results come

with limitations due to the quality of the claw, which

is imprecise. However, as we showed in the experi-

ments, the capture error rate does not give us a real

difference, even if the location of the targeted object

to be picked up is central or lateral on the checker-

board. The limitation already mentioned above is due

to the servo motors having a system that limits them

to 180 degrees of rotation and an error, both in the

camera view and the precision of the robotic claw, re-

quiring a new investment to change the claw itself.

As shown in related works, the usual way to cre-

ate inverse kinematics was with mathematical mod-

eling, but in our paper, we used evolutionary algo-

rithms. Future works include using novel elements to

integrate a more complex environment. For instance,

further steps can integrate a moving treadmill with an-

other camera to detect objects, resulting in the tread-

mill stopping to remove the object.

ACKNOWLEDGEMENTS

The authors would like to thank FAPEMIG, CAPES,

CNPq, Instituto Tecnol

´

ogico Vale, and the Federal

University of Ouro Preto for supporting this work.

This work was partially funded by CAPES (Finance

Code 001) and CNPq (306572/2019-2).

REFERENCES

Aguado, A. G. and Cantanhede, M. A. (2010). L

´

ogica

fuzzy. Artigo sem.

Bartz-Beielstein, T., Branke, J., Mehnen, J., and Mersmann,

O. (2014). Evolutionary algorithms. Wiley Interdisci-

plinary Reviews: Data Mining and Knowledge Dis-

covery, 4(3):178–195.

Chandana, R., Jilani, S., and Hussain, S. J. (2015).

Smart surveillance system using thing speak and rasp-

berry pi. International Journal of Advanced Re-

search in Computer and Communication Engineering,

4(7):214–218.

Chin, K., Hellebrekers, T., and Majidi, C. (2020). Ma-

chine learning for soft robotic sensing and control. Ad-

vanced Intelligent Systems, 2(6):1900171.

Deepak, B., Parhi, D. R., and Amrit, A. (2012). Inverse

kinematic models for mobile manipulators. Caspian

Journal of Applied Sciences Research, 1(13):322–

151.

Hock, O. and Sedo, J. (2018). Inverse kinematics using

transposition method for robotic arm. In 2018 ELEK-

TRO, pages 1–5. IEEE.

Krasilnikyants, E. V., Varkov, A. A., and Tyutikov, V. V.

(2013). Robot manipulator control system. Automa-

tion & Remote Control, 74(9).

Kumar, S., Rani, K., and Banga, V. (2017). Robotic arm

movement optimization using soft computing. IAES

International Journal of Robotics and Automation

(IJRA), 6(1):1–14.

Lopez-Franco, C., Hernandez-Barragan, J., Alanis, A. Y.,

and Arana-Daniel, N. (2018). A soft computing

approach for inverse kinematics of robot manipula-

tors. Engineering Applications of Artificial Intelli-

gence, 74:104–120.

M

¨

uller, B., Reinhardt, J., and Strickland, M. T. (1995). Neu-

ral networks: an introduction. Springer Science &

Business Media.

Niloy, M. A., Shama, A., Chakrabortty, R. K., Ryan, M. J.,

Badal, F. R., Tasneem, Z., Ahamed, M. H., Moyeen,

S. I., Das, S. K., Ali, M. F., et al. (2021). Critical de-

sign and control issues of indoor autonomous mobile

robots: A review. IEEE Access, 9:35338–35370.

Raibert, M. (1978). Manipulator control using the config-

uration space method. Industrial Robot: An Interna-

tional Journal, 5(2):69–73.

Raja, R. and Nagasubramani, P. (2018). Impact of mod-

ern technology in education. Journal of Applied and

Advanced Research, 3(1):33–35.

Royakkers, L. and van Est, R. (2015). A literature review

on new robotics: automation from love to war. Inter-

national journal of social robotics, 7:549–570.

Xu, D., Acosta Calderon, C. A., Gan, J. Q., Hu, H., and

Tan, M. (2005). An analysis of the inverse kinemat-

ics for a 5-dof manipulator. International Journal of

Automation and Computing, 2(2):114–124.

Yardimci, A. (2007). A survey on use of soft computing

methods in medicine. In Artificial Neural Networks–

ICANN 2007: 17th International Conference, Porto,

Portugal, September 9-13, 2007, Proceedings, Part II

17, pages 69–79. Springer.

Using Soft Computing and Computer Vision to Create and Control an Integrated Autonomous Robotic Manipulator Process

827