A Data-Driven Approach for Predictive Maintenance of Impellers in

Flexible Impeller Pumps Using Prophet

Efe Can Demir

a

and Sencer Sultano

˘

glu

b

Eliar Electronics Corp., Istanbul, Turkey

Keywords:

Predictive Maintenance, Flexible Impeller Pumps, Prophet Algorithm, Data-Driven Approach, Textile

Industry, Fabric Dyeing Efficiency, Machine Learning.

Abstract:

This article presents a data-driven approach aimed at improving the efficiency of fabric dyeing operations in

the textile industry. It specifically focuses on the predictive maintenance of flexible impeller pumps (FIP) and

the application of the Prophet algorithm. The study extensively explores the potential of machine learning

and data analytics to increase operational efficiency and enable early failure detection. By using the Facebook

Prophet model and time series data for early detection of wear and tear, it offers an approach to maintain pump

efficiency without installing new hardware, relying solely on data.

1 INTRODUCTION

The textile industry is a broad sector encompassing

complex physical and chemical processes involved

in the production stages of textile products. At the

heart of these processes is the fabric dyeing opera-

tion, where dyes and chemicals are applied to en-

sure color and durability. Fabric dyeing, as a batch

process, is conducted in fabric dyeing machines and

requires careful control of various variables such as

temperature, chemical ratio, dye quantity, conductiv-

ity, pH, and duration. This control is a critical ele-

ment determining the success of the dyeing process

and the correct chemical application is a crucial step

in achieving the fabric’s color absorption capacity and

desired color. (Sarkar et al., 2023).

In the textile dyeing process, liquid chemicals are

weighed in order of the steps of the dyeing process

and transferred to the chemical dosing tanks in real-

time without human intervention. This process, en-

hancing the repeatability of the dyeing process, is car-

ried out by mechatronic systems shown in Figure 1.

These systems robotically weigh chemicals according

to the given recipe and send them to the main tanks of

the fabric dyeing machines for dosing. For instance,

in a factory with 40 fabric dyeing machines, a liq-

uid chemical weighing system performs about 1000

weighings daily for approximately 30 different chem-

a

https://orcid.org/0009-0000-5251-9101

b

https://orcid.org/0009-0000-1521-8596

Figure 1: Liquid Chemical Weighing and Dispensing Sys-

tem.

icals.

In the liquid chemical weighing process, chem-

icals taken from chemical silos are weighed using

pumps and flow meters. The impeller in the FIP

(Flexible Impeller Pump), a significant rotating me-

chanical part containing blades in the middle between

two faces, is often referred to as a closed impeller.

Due to mechanical wear, the impeller requires care-

ful monitoring. This wear can lead to serious dam-

age in the pump and significantly reduce both the life

span of the pumps and overall efficiency. In weighing

and dispensing systems using FIP, the wear of the im-

peller over time is inevitable. Predicting this wear is

vital for ensuring accurate weighing within tolerance

limits and the uninterrupted continuation of produc-

tion. Recently, there has been an increase in the use

Demir, E. and Sultano

ˇ

glu, S.

A Data-Driven Approach for Predictive Maintenance of Impellers in Flexible Impeller Pumps Using Prophet.

DOI: 10.5220/0012710100003756

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 13th International Conference on Data Science, Technology and Applications (DATA 2024), pages 245-252

ISBN: 978-989-758-707-8; ISSN: 2184-285X

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

245

of machine learning-based methods for anomaly and

damage detection in textile dyeing processes (G

¨

org

¨

ul

et al., 2023), (Wang and Li, 2022). Studies related

to the detection of impeller wear in FIP have been

conducted experimentally or using additional sensors

(Qu et al., 2009), (Daraz et al., 2019). Our proposed

approach focuses on effectively solving the impeller

wear issue in FIP without additional hardware, us-

ing a data-driven approach and the Facebook Prophet

method (Taylor and Letham, 2017). The necessary

methodology for this approach has been determined

and its effectiveness has been demonstrated through

implementation. This study addresses the wear is-

sue of FIP not merely as the deterioration of a ma-

chine part but also as a strategic matter in terms of the

efficiency and sustainability of the entire production

chain.

The rest of the paper is organized as follows. In

Section 2, related works on predictive maintenance of

pumps are given Section 3 defines the problem in de-

tail. In Section 4, the proposed methodology is pre-

sented. Section 5 gives details of application in the

pilot textile factory. Finally, concluding remarks are

provided in Section 6.

2 RELATED WORKS

Recent studies in the literature mainly focus on pre-

dictive maintenance and performance prediction of

FIP , with emphasis on various approaches including

artificial intelligence models and real-time data anal-

ysis, especially in the textile industry. This area of

research integrates various approaches, including ad-

vanced computational models and real-time data anal-

ysis, to improve the operational efficiency and relia-

bility of FIP in industrial environments.

(Demirkiran et al., 2022) conducted a study on the

application of the Prophet method for time series fore-

casting in AI models and the real-time data analysis

of industrial equipment. This research highlights the

effective utilization of the Prophet method with opti-

mized parameters.

(Chhabria et al., 2022) focused on the develop-

ment of a system architecture for the early detec-

tion of failures in industrial water pumps using ma-

chine learning techniques. Utilizing the Random For-

est method, this approach enables the early detection

of potential failures.

(Emir

ˇ

Zuni

´

c, 2020) presents a retail sales fore-

casting framework using Prophet algorithm, focusing

on real-world data from a major retail company. It

aims to enhance inventory and production planning

through accurate forecasts and product classification.

(Khoie et al., 2015) developed a novel magnetic

sensor to measure wear in centrifugal pumps. This

sensor provides real-time measurements of wear, cru-

cial for maintaining the efficiency of pumps and min-

imizing downtime.

(Sugiyama et al., 2009) examined the prediction

of wear depth distribution caused by slurry in alu-

minum pump impellers. The study successfully pre-

dicts wear distribution, showcasing its usefulness in

maintenance and material selection.

(Almazrouei et al., 2023) conducted a comprehen-

sive review of AI models used in the predictive main-

tenance of water injection pumps. This review un-

derscores the effectiveness and challenges of various

AI techniques including machine learning and deep

learning.

(Sanayha and Vateekul, 2017) developed a two-

stage model for fault detection in circulating water

pumps. The model focuses on forecasting sensor

trends using the ARIMA method and classifying fail-

ure modes based on these predictions.

(Chen et al., 2022) designed an IoT system archi-

tecture with smart sensors for monitoring and predic-

tive maintenance of centrifugal pumps. This design

emphasizes the effectiveness of both wired and wire-

less sensors in real-time fault detection and diagnosis.

This research area integrates varied approaches,

including advanced computational models and real-

time data analysis, to enhance the operational effi-

ciency and reliability of FIP in industrial environ-

ments.

3 PROBLEM DEFINITION

A FIP shown in Figure 2 is a pump style featuring

a rubber impeller that is circular in shape, equipped

with numerous pliable rubber vanes. This impeller is

set within a housing or casing (Hooton, 2019).

The liquid chemical weighing and dispensing sys-

tem shown in in Figure 3, significant wear and tear oc-

cur over time on the impeller within the FIP, as shown

in Figure 4. These harsh working conditions can lead

to incorrect amounts of liquid chemical weighing or

Figure 2: Flexible impeller pump and impeller.

DATA 2024 - 13th International Conference on Data Science, Technology and Applications

246

Figure 3: Pump position of liquid chemical weighting and

dispensing system.

prolonged weighing durations. This may result in un-

desirable dyeing quality and can disrupt the dyeing

process if the pump fails.

Figure 4: Impeller wear out.

FIP, particularly in precise operations like fabric

dyeing, are critical for the accurate and timely trans-

mission of fluids. As one of the most crucial com-

ponents of these pumps, the impeller, being in con-

stant motion, wears down depending on the physical

and operational stress, the chemicals weighed, and the

number of weightings. This wear jeopardizes the effi-

ciency of the pumps over time and thus the integrity of

the entire production process. Detailed observations

and process analyses have revealed that these pumps

typically show significant signs of wear after a usage

period of 4 to 6 months. During this time, the wear

of the impeller leads to a noticeable decrease in the

amount of fluid pumped per unit time.This reduction

is observed to adversely affect not just the efficiency

of the operation.

However, the real magnitude of the problem man-

ifests in the quality of the final product. Due to the

wear of this critical component, the pump becomes

dysfunctional, which may lead to the machine operat-

ing at reduced efficiency for weeks, thereby causing

serious disruptions in production processes. These

disruptions lead not only to financial losses but also

to negative impacts on production continuity and cus-

tomer satisfaction.

4 PROPOSED METHODOLOGY

4.1 Data Acquisition and Cleaning

In factories, impeller pumps used are prone to wear

and tear and fragmentation depending on the intensity

and conditions of use, leading to the halt of chemical

weighing operations in the factory and disruptions in

production.This study aims to detect the wear condi-

tion of the pump early by using data collected from

the devices, and to provide a solution by informing

the operation before a problem occurs. The analysis

of the data obtained from the devices plays a critical

role in determining the wear condition of the pump

over time and making predictions for the pump’s per-

formance based on the amount of wear. This method-

ology aims to reduce the need for regular maintenance

in businesses and prevent disruptions in production

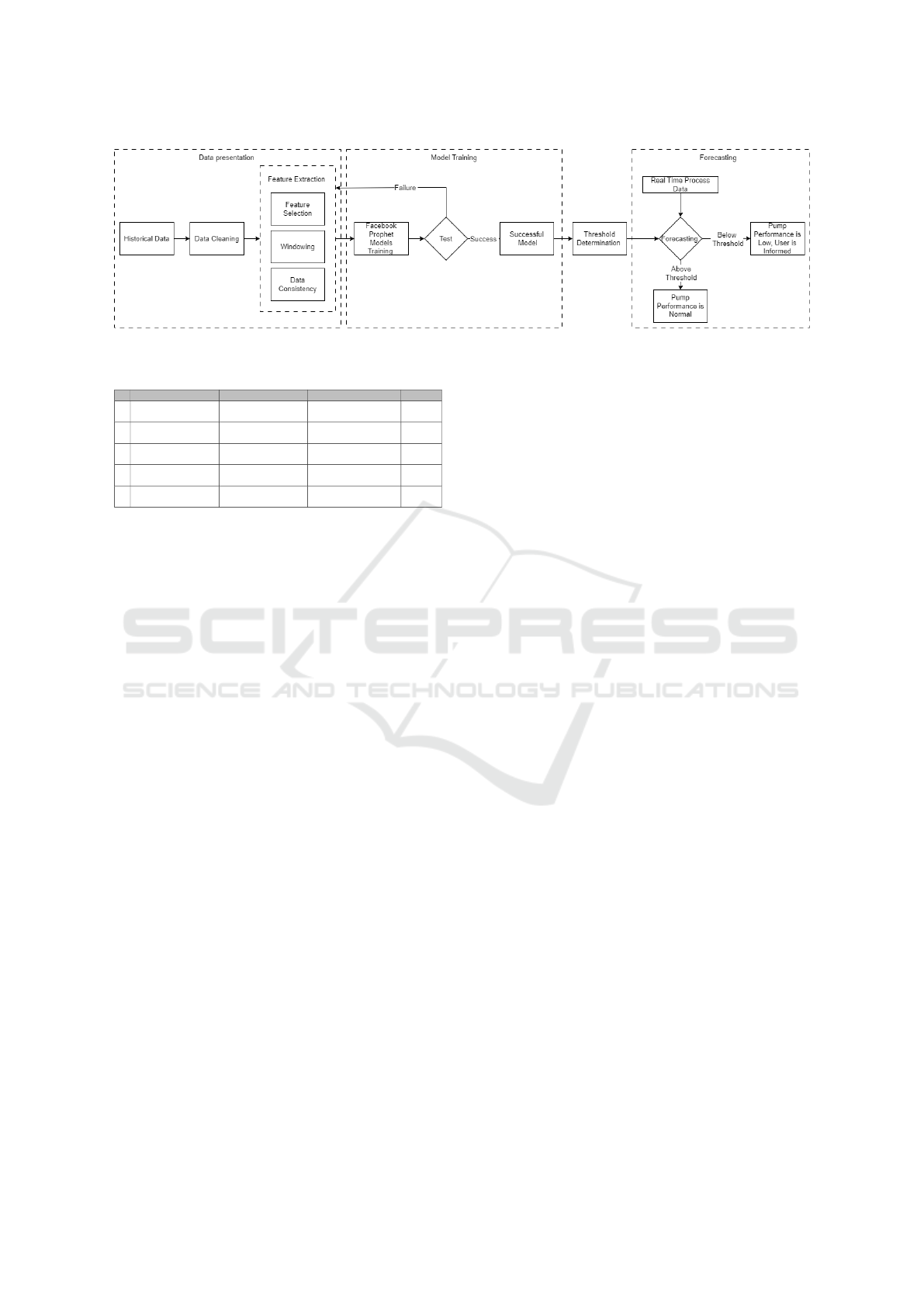

processes. The flowchart of the methodology is given

in Figure 5.

Our database reflects daily data records show-

ing the operational performance of the pump sys-

tem. The data are obtained through daily ETL (Ex-

tract, Transform, Load) data collection cycles. Our

ETL module deployed on a cloud server and connect

the databases of dispensing systems through VPN.

These records include process values such as Weight-

ing time, Weighted amount (g), Weighting duration

(s) and g/s. Our sample dataset can be examined in

Table 1. Below are the descriptions of the dataset

columns:

• Name / Type: Weighting time / Timestamp

Description: The operation start time with pre-

cise timestamps.

• Name / Type: Weighted amount (g) / Float

Description: The amount of substance used.

• Name / Type: Weighting duration (s) / Integer

Description: The total operation duration in sec-

onds.

• Name / Type: g/s / Float

Description: The rate of substance pumped per

second.

This dataset is not limited only to the compilation of

process data but also includes these data in a simpli-

fied and transformed form.

During the data collection process, the accuracy

of each weighing in liquid chemical weighing and

distribution systems is of critical importance. Out-

lier detection identifies data points that deviate from

the expected or indicate possible errors. For exam-

ple, interruptions in the weighing process, deviations

from expected values, or sensor errors, as well as

A Data-Driven Approach for Predictive Maintenance of Impellers in Flexible Impeller Pumps Using Prophet

247

Figure 5: Flowchart of the methodology.

Table 1: Sample dataset.

# Weighting time Weighted amount (g) Weighting duration (s) g/s

1

2024-01-23

15:49:43.160

168.166 59 2.850

2

2024-01-23

15:48:38.152

497.0 5 99.4

3

2024-01-23

15:48:21.447

239.087 50 4.781

4

2024-01-23

15:47:41.000

4790.0 27 177.407

5

2024-01-23

15:47:40.263

144.0 3 48.0

certain inconsistencies in daily weighing speeds, can

be observed. These inconsistencies may stem from

the operational status of the business; for instance,

days when the business is closed due to bans, reduced

working hours, or holidays, can affect the integrity

of our dataset. Such data are carefully filtered out

from the dataset. In the data cleaning phase, canceled

weightings, failed operations, and other anomalies

are identified using statistical filters and algorithms.

These data are labeled and stored in the database, so

that when analysis queries are performed, work is car-

ried out on a meaningful and clean dataset.

One of the biggest challenges encountered in the

data analysis process is the accurate interpretation of

the unique characteristics displayed in the weighing

operations of each chemical. Especially frequently

used chemicals like hydrogen peroxide, liquid caus-

tic, and acetic acid, when examined individually, can

give misleading results due to the complexity of the

weighing process. This is because the weighing

speed, amount of weight, type of chemical, environ-

mental factors (such as seasonal temperature, humid-

ity), and machine parameters depend on numerous

variables.

Therefore, to analyze the daily operations of the

business and enhance efficiency, it is need to exam-

ine the average values of all chemicals and weighings.

This approach aids in understanding the relationship

between the quantities of chemicals used daily and

the overall performance of the business. For instance,

it has been observed that there is a significant corre-

lation between the daily usage amounts of frequently

used chemicals (’SERAZ ZYME CKXE’, ’LAUCOL

SRD CONC’, ’EXAPON BHL-PLUS’) and the over-

all performance of the business. These correlations

have been determined to be 89.87%, 84.77%, and

84.54% respectively, which has proven to be a mean-

ingful method of measuring daily performance and

consistency.

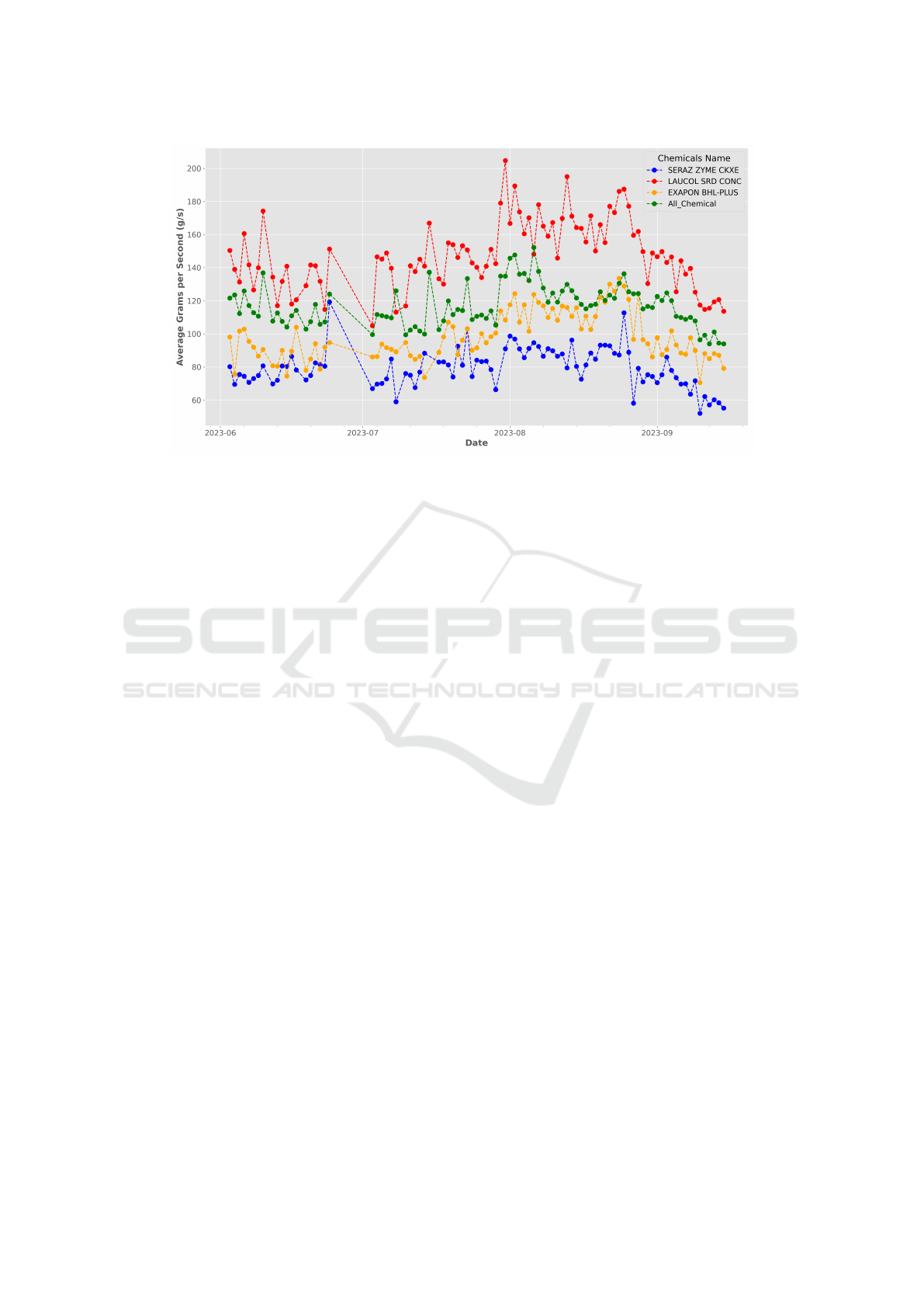

Figure 6 provides a detailed representation of the

chemical weighings performed by the liquid chem-

ical weighing and distribution system. Our graph

shows the average flow rate in grams per second of

different chemicals based on date. The axes represent

time (Date) and flow rate (Average Grams/Second),

with different chemicals distinguished by color codes.

These data are collected for the purpose of continuous

monitoring and improvement of our devices’ perfor-

mance.

In the outlier detection process, the quantile

method, a statistical approach, has been used to iden-

tify outliers in the dataset. The primary purpose of

this method is to determine values representing a cer-

tain percentage of the dataset. In this context, the

0.1 quantile value has been chosen to detect outliers.

This choice implies that 10% of the observations in

the dataset will be considered outliers. Determining

this ratio is critical to measure and calibrate how well

the algorithm can detect outliers.

To express this in formulaic terms, let Q(p) be a

quantile function, then for p=0.1 the value Q(0,1) rep-

resents the top and bottom 10% of the observations in

the data set, and all other than this value observations

are considered anomalies. This outlier detection has

been fine-tuned to discern real issues and significant

patterns within the dataset.

4.2 Data Analysis and Machine

Learning

After outlier detection and cleaning processes on the

dataset, the data were prepared for machine learning

and advanced analysis techniques. At this stage, var-

ious algorithms for time series analysis were exam-

ined and tested. The Prophet algorithm developed

DATA 2024 - 13th International Conference on Data Science, Technology and Applications

248

Figure 6: Daily average chemical usage of some chemicals.

by Facebook was selected for use. During time se-

ries analyses, it was observed that data points in the

dataset that spanned periods longer than six months

responded slowly to future predictions. Therefore, the

necessity of using more dynamic and current data for

analyses emerged. In order to capture trends and sea-

sonal effects more quickly, it was decided to use data

less than six months old in the analysis.

4.2.1 Enhancing Predictive Maintenance with

the Prophet Algorithm

The Prophet algorithm offers unique advantages when

working with datasets that include seasonal patterns,

holidays, and other periodic effects in time series

data. This algorithm contains flexible components de-

signed to adapt to the characteristics of time series

data. These components enable Prophet to explain

complexities in the dataset and make accurate future

predictions.

The prominent features of Prophet are:

• Adaptive Seasonality: It models complex season-

alities using Fourier series, adjusting to various

frequencies and magnitudes.

• Holiday Effects: Prophet effectively captures hol-

idays and events, a common shortcoming in tradi-

tional models.

• Robust Anomaly Detection: Prophet robustly

manages outliers and missing data, reducing their

adverse effects on prediction accuracy.

• Ease of Implementation and Adjustability: The

model’s hyperparameters are easily tunable, en-

suring flexibility and ease of use across various

datasets.

The basic mathematical model of Prophet is as fol-

lows:

y(t) = g(t) +s(t) + h(t)+ ε

t

(1)

• y(t): Time-dependent target variable.

• g(t): The trend component is usually modeled

with linear or logistic growth functions.

• s(t): The seasonal component is modeled using a

Fourier series

• h(t): The holiday effects component represents

the impacts of holidays or special days.

• ε

t

: The error term represents random effects not

explained by other factors.

The daily chemical weighing data obtained from the

database are analyzed using this model, and the poten-

tial failure times of the impeller pump are predicted.

Based on the learned data characteristics, our appli-

cation of the Prophet algorithm can predict potential

pump failures up to two weeks in advance and convey

this information to businesses. This predictive capa-

bility provides a significant contribution to factories

and businesses in maintaining uninterrupted produc-

tion processes and allows for the implementation of

an effective predictive maintenance program.

5 APPLICATION

This section details the pilot applications of the deter-

mined modeling and fault detection methodology in

various textile factories.

A Data-Driven Approach for Predictive Maintenance of Impellers in Flexible Impeller Pumps Using Prophet

249

5.1 Input and Data Collection

In the first step, historical data obtained from ma-

chines performing daily chemical weighing opera-

tions were collected to begin data preparation. The

machines used for data selection are those employed

as liquid chemical weighing and distribution systems

in factories. In total, 5400 manipulated and 1048000

raw data points were used per machine.

5.2 Outlier Detection, Setting Threshold

Values, Data Analysis, and

Performance Evaluation

After the dataset was formatted appropriately, two

new threshold values were calculated: Pump Main-

tanance Date (PMD), representing the average weigh-

ing amount at the last repair period of the pump,

reflecting the machine’s optimum performance; and

Predictive Maintanence Alarm Limit (PMAL), a

value used to detect the presence of any problem.

When calculating PMAL, the average of the dataset

from the last repair point PMD and the smallest value

in the dataset are determined. Then, 5% of the av-

erage value is calculated. This step performs a type

of fine-tuning by setting aside a ’safety margin’ from

the average value for determining the threshold value.

The PMAL is calculated by subtracting 5% of the av-

erage from the obtained minimum value. This process

not only ensures that the threshold value is more pro-

tective than just the minimum value but also takes into

account the overall data distribution. Thus, it shifts

the lower boundary of the dataset to a point that is

lower than the lowest value. Such an adjustment helps

prevent the model from overreacting while still offer-

ing a sensitive enough threshold to detect potential

problems. Especially, it reduces the impact of anoma-

lies such as noise or sudden changes in the dataset,

ensuring that the model is more stable and reliable.

Figure 7: Three-day windows.

After the process, the dataset was reversed in time

and divided into three-day windows, starting from the

most recent date. The average weighing amounts

and counts for the created three-day windows (for

example Figure 7, January 22, 21, and 20) were

found, summed up, and then divided by the number of

days. Thus, the average weighing amount and count

for each three-day window were calculated. Subse-

quently, for performance analysis, a comparison was

made with the next day (in our example Figure 7,

January 19), and two main control mechanisms were

used to determine whether the pump performance was

at an acceptable level:

1. Fixed Threshold Value (Pump Maintenance

Date Threshold): As a predetermined fixed

threshold value has been used a comparison point

in evaluating whether the pump performance is

sufficient. This threshold value represents the

lower limit of performance that is considered nor-

mal for the pump.

2. Data Set Time Range: When conducting perfor-

mance evaluations, it is important that the dataset

covers a minimum period of 14 days. We esti-

mate a 14-day period because studies conducted

on datasets shorter than our estimated period may

not yield accurate results.

When the established checks are met, the selected

date (for our example Figure 7, January 19) is con-

sidered as the last repair date of the pump, and the

average weighing from this date onwards is evaluated

as an indicator of the pump’s optimum performance.

Since variables such as the environmental conditions

of the machines in each factory, the usage styles of

the operators, and their changing work habits over

time are taken into account, the average weighing and

quantity obtained since the last repair, rather than a

general average, are used as a more meaningful per-

formance indicator. This method has been found to

provide a more consistent performance measurement

by reducing the impact of daily and environmental

variability.

5.3 Modeling and Forecasting

From the identified date, the dataset was reorga-

nized, and training was conducted with customized

hyperparameters for each machine using the Face-

book Prophet algorithm. The used hyperparameters

are as follows:

1. Changepoint Range (changepoint range): This

parameter specifies the portion of the dataset used

to detect trend changes. A value between 0 and 1

is set, where 1 means using the entire dataset. For

instance, a value of 0.95 indicates the model uses

95% of the data for detecting trend shifts, mak-

ing it sensitive to even minor changes, essential in

monitoring pump performance over time.

2. Changepoint Prior (changepoint

prior scale):

This controls how rapidly the model responds to

trend changes. A higher value means quicker

adaptation to trends, crucial for promptly identi-

fying potential issues in the dataset.

DATA 2024 - 13th International Conference on Data Science, Technology and Applications

250

3. Seasonality Mode (seasonality mode): Prophet

offers two modes: ’additive’, where seasonal ef-

fects are a fixed amount added to the forecast,

and ’multiplicative’, where seasonal effects vary

in proportion to the forecasted value. The ’mul-

tiplicative’ mode is chosen when seasonal varia-

tions are proportional to the time series level, as

seen in datasets where weighings increase on busy

days.

4. Additional Seasonalities (add seasonality): Be-

sides standard annual, weekly, and daily seasonal-

ity, extra patterns like monthly or quarterly can be

added. For instance, ’daily’ seasonality is added

with three sub-parameters:

• Name: Specifies the seasonality type, e.g.,

’daily’.

• Period: Defines the duration of the seasonality,

e.g., ’1’ for daily.

• Fourier Order: Determines the complexity of

the seasonal component, with higher values

capturing more complex patterns.

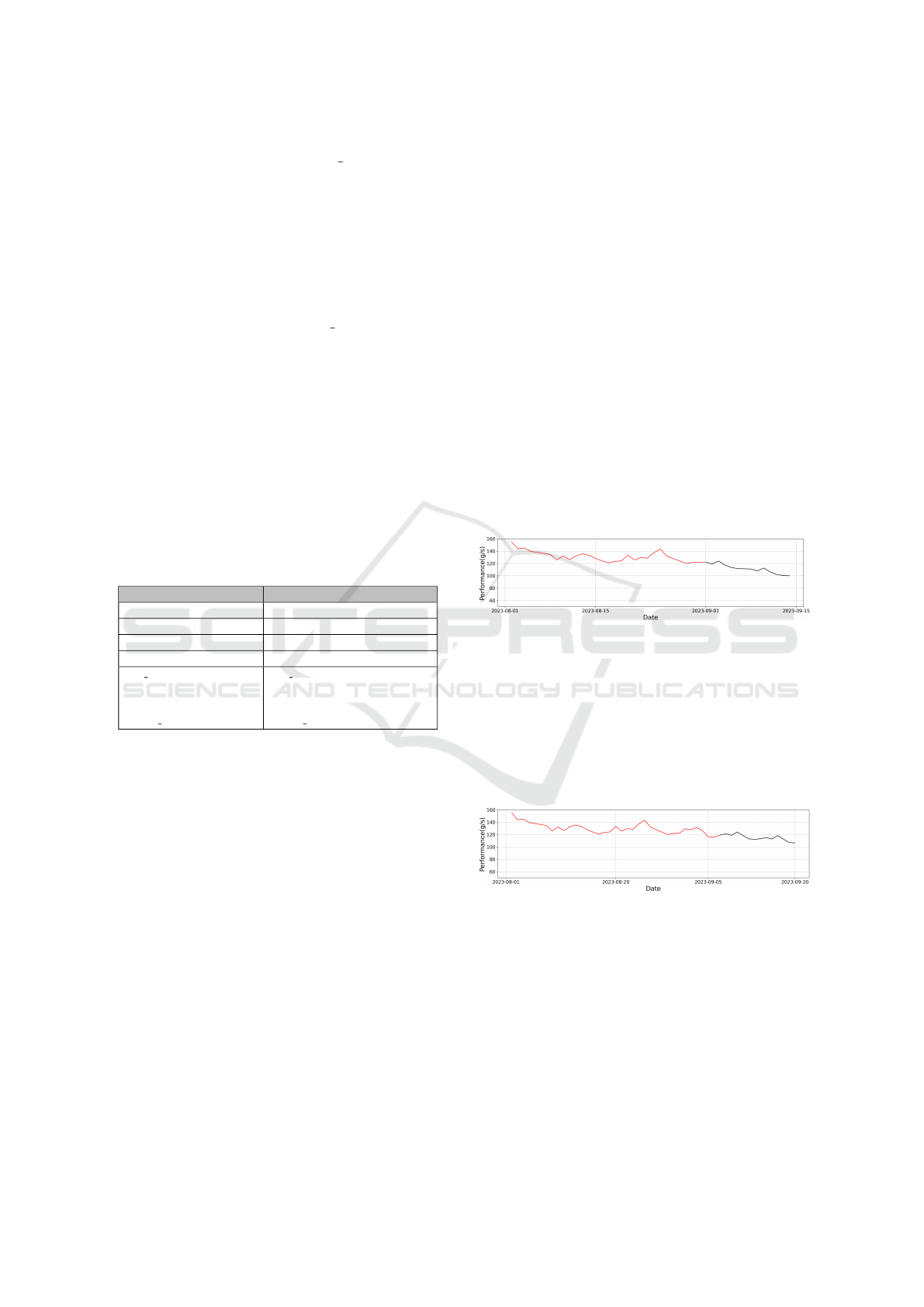

Table 2: Comparison of Default and Optimized Parameters.

Default Parameter Optimized Parameter

Changepoint Range = 0.8 Changepoint Range = 0.95,

SeasonalityMode= ’additive’ SeasonalityMode= ’Multiplicative’,

Sparse Prior = 10.0, Sparse Prior = 0.01,

Changepoint Prior = 0.05 Changepoint Prior = 0.1,

add seasonality(

name=annual,

period=365,

fourier order=5)

add seasonality(

name=’daily’,

period=1,

fourier order=15)

The model is prepared, trained, and tested in accor-

dance with the specified parameters. If the accuracy

rate of the model is found insufficient, this process is

repeated until the model makes predictions under the

desired conditions. When the model operates with the

desired level of accuracy, it is ready to make perfor-

mance predictions. Thus, the performance prediction

of the machine for the next fourteen days has been

made. If the predicted values fall below the ’PMAL’

threshold, it is concluded that the pump performance

is declining and needs to be replaced to prevent dis-

ruptions in the production process.

5.4 Reporting and Communication of

Results

The examination of the prediction Figures 8, 9 and

10 generated by our model shows that the pump per-

formance displays a decreasing trend over time. Ini-

tially, it appears that the pump functions with normal

operating performance; however, as time progresses

and issues related to the FIP arise, a decrease in per-

formance is observed. These performance declines

have been successfully predicted by our model, and

these predictions indicate the need for early measures

to prevent potential problems.

The analysis conducted on the performance de-

cline has attempted to determine the underlying

causes of the decrease in pump efficiency, considering

various factors. The examination of the graph sug-

gests that the observed fluctuations in performance

during certain time intervals could be related to fac-

tors such as the pump’s operating conditions, mainte-

nance programs, usage intensity, and wear.

In detail, the time series data in Figures 8, 9

and 10 show the frequency and severity of perfor-

mance declines on specific dates. The red line rep-

resents the observed actual performance, while the

black line represents the predicted performance. The

alignment between these two lines reflects the accu-

racy of the prediction model and its early warning ca-

pability against potential performance issues.

Figure 8: Model prediction graph start 01-08-2023 - predic-

tion time 01-09-2023.

In Figure 8, the model covering the period from

August 1st to September 1st does not forecast a sig-

nificant decline in the pump’s performance. The per-

formance indicators show that the PMAL threshold is

calculated as 111.40 and the estimated value of FIP

is determined to be 113.32. Therefore, no warning or

intervention is deemed necessary.

Figure 9: Model prediction graph start 01-08-2023 - predic-

tion time 07-09-2023.

Figure 9 encompasses an extended version of the

same date range for the pump’s operation, showing no

significant changes in its performance. PMAL thresh-

old being set at 109.16, while the estimated value of

the impeller in the FIP is at 115.15, indicates that no

problematic issues have been detected, thus negating

the need for any intervention.

However, there is a noticeable change in Figure

10. The model predicts a critical decrease in pump

performance from September 7th onwards. Recent

A Data-Driven Approach for Predictive Maintenance of Impellers in Flexible Impeller Pumps Using Prophet

251

Figure 10: Model prediction graph start 01-08-2023 - pre-

diction time 17-09-2023.

calculations have determined the threshold for Pump

Maintenance Alert Level (PMAL) at 83.37. In light of

these findings, the estimated value of the impeller in

the FIP has been assessed at 80.02. This value, falling

below the established PMAL threshold, indicates the

necessity for maintenance intervention.

Consequently, our model’s predictions enable

maintenance and repair teams to plan effectively,

thereby increasing the efficiency and reliability of the

business. The identified situation is presented to the

relevant departments with reports containing visual

and statistical data from the trained model. This anal-

ysis process is conducted in accordance with a three-

day windowing logic. This method allows adaptation

to the dynamics of factory operations and enhances

the ability to respond quickly to changes in machine

performance.

6 CONCLUSIONS

In summary, we underscore the critical impact of

impeller wear in FIP on the textile dyeing process

and liquid chemical weighting systems through our

study. We emphasize the necessity for regular mon-

itoring and predictive maintenance of these pumps,

especially considering the wear patterns typically ob-

served within 4-6 months. Our use of the Facebook

Prophet model and time series data for early detection

of wear presents a proactive approach to maintaining

pump efficiency without installing new hardware and

high cost.

Our future research will involve applying the

Prophet model to time-series data we have already

collected from equipments in fabric dyeing machines

to develop predictive maintenance solutions.

ACKNOWLEDGEMENTS

This work is supported by The Scientific and Techno-

logical Research Council of Turkey (T

¨

UB

˙

ITAK) un-

der the project number №3200916.

REFERENCES

Almazrouei, S. M., Dweiri, F., Aydin, R., and Alnaqbi, A.

(2023). A review on the advancements and challenges

of artificial intelligence based models for predictive

maintenance of water injection pumps in the oil and

gas industry. SN Applied Sciences.

Chen, L., Wei, L., Wang, Y., Wang, J., and Li, W. (2022).

Monitoring and predictive maintenance of centrifugal

pumps based on smart sensors. Sensors, 22:2106.

Chhabria, S., Ghata, R., Mehta, V., Ghosekar, A., Araspure,

M., and Pakhide, N. (2022). Predictive maintenance

using machine learning on industrial water pumps. In-

ternational Journal of Innovations in Engineering and

Science, 7(9):76–81.

Daraz, A., Alabied, S., Gu, F., and Ball, A. D. (2019). Mod-

ulation signal bispectrum analysis of acoustic signals

for the impeller wear detection of centrifugal pumps.

In 2019 25th International Conference on Automation

and Computing (ICAC), pages 1–6.

Demirkiran, C. N.,

¨

Ust

¨

un, E., and Urhan, O. (2022).

Time series forecasting performance analysis of the

prophet method for predictive maintenance appli-

cations. ELECO 2022 Electrical-Electronics and

Biomedical Engineering Conference.

Emir

ˇ

Zuni

´

c, Kemal Korjeni

´

c, K. H., D. Ð. (2020). Ap-

plication of facebook’s probhet algorithm for success-

ful sales forecasting based on real-world data. Inter-

national Journal of Computer Science & Information

Technology (IJCSIT) Vol 12, No 2.

G

¨

org

¨

ul, A., C¸ om, M., and Sultano

˘

glu, S. (2023). Ker-

nel ridge regression based modelling and anomaly de-

tection for temperature control in textile dyeing pro-

cesses. In 27th International Conference on System

Theory, Control and Computing, pages 392–397.

Hooton, S. (2019). Flexible impeller pump

guide. https://www.northridgepumps.com/

article-141\_flexible-impeller-pump-guide.

Khoie, R., Gopaluni, B., Olson, J. A., and Stoeber, B.

(2015). A magnetic sensor to measure wear in cen-

trifugal pumps.

Qu, J., Miao, C., Hoseini, M., and Zuo, M. J. (2009).

Wear degree prognostics for slurry pumps using sup-

port vector machines. In 2009 8th International Con-

ference on Reliability, Maintainability and Safety.

Sanayha, M. and Vateekul, P. (2017). Fault detection for

circulating water pump using time series forecasting

and outlier detection.

Sarkar, A., Johnson, I., and Cohen, A. (2023). Jj piz-

zuto’s fabric science. https://books.google.com.

tr/books?id=5APXEAAAQBAJ.

Sugiyama, K., Nagasaka, H., Enomoto, T., and Hattori, S.

(2009). Prediction of wear depth distribution by slurry

on a pump impeller. International Journal of Fluid

Machinery and Systems, 2(1).

Taylor, S. J. and Letham, B. (2017). Forecasting at scale.

PeerJ Preprints.

Wang, C.-C. and Li, Y.-H. (2022). Machine-learning-based

system for the detection of entanglement in dyeing

and finishing processes. Sustainability 2022.

DATA 2024 - 13th International Conference on Data Science, Technology and Applications

252