From Plant to Lab: Industrial Emulation Tools for

Real-World Security Testing in Industrial Control Systems

Argiro Anagnostopoulou

1a

, Thomas Papaloukas

2

, George Stergiopoulos

2b

and Dimitris Gritzalis

1c

1

Dept. of Informatics, Athens University of Economics and Business, 76 Patision Ave, Athens, Greece

2

Dept. of Information and Communication Systems Engineering, University of the Aegean, GR-83200 Samos, Greece

Keywords: Industrial Control System, Industrial Process, Emulation Software, Comparative Analysis.

Abstract: The industry and research communities have introduced a variety of approaches and algorithms that require

evaluation of their security and safety in industrial settings. However, conducting such assessments is chal-

lenging, given the need to maintain operational availability of these infrastructures. Consequently, scientists

often capture datasets from authentic industrial environments, but assess attacks on such data in emulated or

simulated environments. To replicate proper industrial conditions within controlled and simulated environ-

ments, testbeds need to be able to assess the effectiveness of implemented attacks and provide results usable

to real-world systems. In this study, we present and compare such tools that aim to emulate or simulate in-

dustrial control systems by establishing eight criteria. The objective of our work is to address concerns sur-

rounding the selection of an appropriate emulation tool based on specific needs.

1 INTRODUCTION

Industrial Control System (ICS) is a term used to de-

scribe industrial automation systems that are usually

responsible for visualization and control of industrial

processes and data acquisition. These systems are

mainly used in industrial sectors or critical infrastruc-

tures (Mattioli and Moulinos, 2015). Indicative exam-

ples of ICS are the Supervisory Control and Data Ac-

quisition (SCADA), the Programmable Logic Con-

trollers (PLC), the Distributed Control Systems

(DCS), and the Industrial Automation Systems (IAS).

These systems are employed in environments where

automation and monitoring are required, such as pow-

erplants, water facilities, nuclear plants etc. (Stouffer

and Falco, 2006), (Drias et al., 2015).

There is an increased interest of both research

community and industries to reduce the attack surface

on industrial environments. Researchers are constant-

ly proposing algorithms and models to secure the in-

dustrial sector. However, these approaches cannot be

evaluated on real-time industrial environments since

a

https://orcid.org/ 0000-0003-4199-6257

b

https://orcid.org/ 0000-0002-5336-6765

c

https://orcid.org/ 0000-0002-7793-6128

such infrastructures must be always up and running.

For this reason, there are alternatives that may assist

in the testing of the approaches. The first option is to

develop, physically or virtually, a testbed in order to

emulate the business processes of such infrastructu-

res. However, in this alternative there is a dilemma:

whether someone chooses an emulation software in-

stead of physically designs a testbed on a research lab.

The answer is not clear and depends on the purposes

that the testbed need to be designed. Additional fac-

tors to consider may be the cost of equipment, the

scale of the testbed, the downtime, or the risk of fai-

lure. A great advantage of preferring the emulation

tools is that they are able at a great extend to emulate

the conditions and setup of industrial sector at a low

or even zero cost.

Another option is to find a publicly available data-

set, and evaluate an approach using these data. This is

a difficult task, since information regarding the busi-

ness processes and transmitted values are quite pro-

tected. Sources that drive to real-wolrd datasets are

limited, because such information describe the opera-

tion of a critical infrastructure. Moreover, using a da-

Anagnostopoulou, A., Papaloukas, T., Stergiopoulos, G. and Gritzalis, D.

From Plant to Lab: Industrial Emulation Tools for Real-World Security Testing in Industrial Control Systems.

DOI: 10.5220/0012710700003767

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 21st International Conference on Security and Cryptography (SECRYPT 2024), pages 13-25

ISBN: 978-989-758-709-2; ISSN: 2184-7711

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

13

taset limits the researcher's capabilities, since it would

not be able to launch an attack scenario.

In this work, we present nine available tools that

emulate industrial environments. We compare these

tools regarding specific factors, such as complexity,

pricing, accessibility of documentation, ease of confi-

guration, and scalability.

1.1 Motivation and Contribution

There is a plethora of software available for emulat-

ing a SCADA system. The question is why a resear-

cher chooses to use an emulation software instead of

physically design and implement a testbed. There are

multiple factors that we should consider before we

decide, including pricing, downtime, flexibility, or

risk of failure (Queiroz et al., 2011).

The primary obstacle for physically developing a

testbed is its cost. An industrial environment is a quite

complex infrastructure with various types of equip-

ment. For example, SCADA is composed of multiple

distributed devices. Each device may be included to a

different type. Regarding the aim and the type of the

device, there is a different cost and effort for its con-

figuration. Thus, when we decide which device will

be included in our testbed, for instance PLC or RTU,

we should bare in mind the cost and the expertise

needed (Queiroz et al., 2011).

In case that someone wants to launch attacks on

the infrastructure, it is crucial such action not to hap-

pen in productive environment. Attacks like distrib-

uted denial of service (DDoS) cause downtime issues,

because attackers overwhelm the resources of the in-

fected system which is not designed to handle such

amount of traffic. Such activities can either increase

the response time, or even shutdown the whole servi-

ce. Impacting the provided services for testing purpo-

ses, especially in SCADA systems, is not tolerable

(Queiroz et al., 2011). Moreover, testing malevolent

scenarios in real-time systems raises a great risk since

the tested attacks aim to bypass any security measures

that are in place. This may have a great impact on the

business processes of the critical infrastructure (Quei-

roz et al., 2011).

In order to tackle such issues, the option of devel-

oping a testbed using an emulation software is quite

appealing. Despite the fact that some emulation tools

may be an expensive choice, on average we can re-

duce the implementation cost. Moreover, we can be

more flexible since we are able to load saved projects,

revert a virtual machine to a previous state, or elimi-

nate the risk factor of causing impact on the operation

of a real-world critical infrastructure. Our work aims

to help research community to pinpoint which of the

available emulation tools can be suitable for corres-

ponding purposes, budget and we attempt to address

any concerns researchers may have.

1.2 Structure of the Work

The remainder of the paper is structured as follows.

In Section 2 we outline the methodology used to carry

out this work. In Section 3 we provide an overview of

the industrial control systems, protocols and stand-

ards. In Section 4 we present nine tools used for the

emulation of an ICS, while in Section 5 we thorough-

ly compare these tools. Finally, the paper ends with a

few concluding remarks.

2 RESEARCH METHODOLOGY

For conducting a transparent and reproducible over-

view of the scientific literature regarding emulation

tools for industrial environments, we utilize certain

features of the PRISMA statement (Page et al., 2021).

PRISMA approach is consisted of four steps: (a) de-

fine the work protocol, (b) identify studies based on

targeted searches, (c) evaluate the selected studies,

and (d) extract data, synthesize the main findings, and

report the results.

2.1 Research Objectives and Strategy

As mentioned earlier, during the first phase of our

study we defined our research questions, that helped

us find publicly available information about emula-

tion tools for industrial environments. Based upon our

properly formulated research questions (see Table 1),

Table 1: Research questions and objectives of the work.

Research Question Objectives

RQ1: What are the

reasons to support

the use of emulati-

on software tools?

The objective here is to better

understand the problem and

identify why it will be helpful

for research community to use

emulation software tools.

RQ2: What are the

available software

tools that emulate

ICS systems?

The aim is to identify the emula-

tion software that focus on ICS

systems.

RQ3: What are the

emulation tools that

can be used for re-

search

p

ur

p

oses?

The objective is to identify and

present this software that can be

used by research community.

SECRYPT 2024 - 21st International Conference on Security and Cryptography

14

we conducted a systematic literature review from Jan-

uary 2023 to August 2023. To retrieve relevant scien-

tific literature, we used widely known academic

search systems, including Google Scholar, Scopus,

and Web of Science. Moreover, Google's search en-

gine was used to extract relevant standards and best

practices (grey literature). Table 2 shows the queries

we used at all search systems.

Table 2: Keywords used during the search phase.

Scientific literature Grey literature

("ICS" OR "SCADA") AND ("emu-

lation software" OR "emulation

tool") AND ("free of charge" OR

"free" OR "open source") AND

("SCADA" OR "PLC" OR "RTU")

SCADA emulation,

ICS emulation, in-

dustrial environment

emulation

After evaluating the initial 200 results obtained

from Google, we identified the available grey litera-

ture. We limited the inclusion to this number because,

beyond this threshold:

a) the Google query produced numerous irrelevant

and low-quality results with minimal impact, as out-

lined in our exclusion criteria;

b) not all actual results were accessible due to bro-

ken or inactive hyperlinks.

Google searches served as a supplementary search

strategy, while Scopus was our main source. The quan-

tity of documents retrieved from Google was relatively

small compared to the bibliography obtained from Sco-

pus. In order to effectively handle the vast volume of

relevant literature and ensure that our review is thor-

ough and conforms to the high standards of academic

integrity, we created a list of inclusion and exclusion

criteria which are applied at several sta-ges.

The inclusion criteria on the first stage referred to

whether the title is aligned with the research focus,

while on the second stage we focused on how useful

and relevant each study was regarding on both the ab-

stract and the introduction. At the final stage we con-

sidered how applicable each publication was after

comprehensive full-text reading.

The exclusion criteria on the first stage referred to

research papers, book chapters and scientific articles

that lacked peer review, publications not written in

English, and studies lacking abstracts or introducti-

ons. On the second stage we eliminated articles that

seemed relevant but were out-of-scope upon closer

review, reports from organizations lacking recogniz-

ed national or international status, and publications by

authors not affiliated with reputable scientific com-

munities or lacking citations and references.

Papers from repositories like arXiv are not exclu-

ded, because even though they may not meet all pub-

lication standards, some studies are considered credi-

ble (Xarhoulacos, 2021).

2.2 Selection of Studies and Analysis

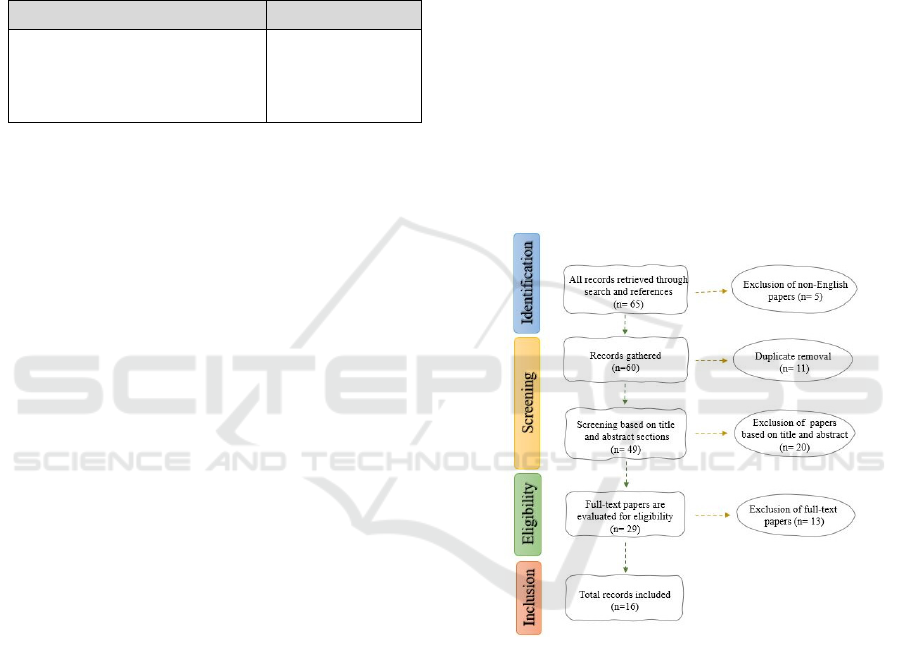

According to PRISMA statement (Page et al., 2021),

the four stages for the selection of literature are: (a)

identification, (b) screening, (c) eligibility, and (d) in-

clusion. In Figure 1 we present the number of docu-

ments we retained on each stage. On the identification

stage, we gathered 65 documents in the academic

field. However, we excluded 13 of them since those

were written in languages we could not parse. During

the screening stage, we removed duplicates, and af-

terwards we evaluated the rest documents. A total of

20 papers were removed based on their title and ab-

stract. Finally, on the eligibility stage 13 papers were

rejected after reading the complete text body.

Figure 1: Flowchart of the search strategy.

Overall, in the main body of our literature review

we included 16 papers. We also used additional liter-

ature for peripheral information presented in the man-

uscript, but they were not considered on the total

number of included files as they did not address our

research questions. The predominant challenge we

faced was that the majority of the Google search re-

sults directed us to the websites of companies which

sell emulation software.

From Plant to Lab: Industrial Emulation Tools for Real-World Security Testing in Industrial Control Systems

15

3 INDUSTRIAL CONTROL

PROTOCOLS & STANDARDS

We provide an overview of the ICS, along with the

available communication protocols and standards that

such systems utilize.

3.1 ICS Overview

ICS is mostly used for the mechanism of data gather-

ing from various endpoint devices, in order to parti-

ally or fully automate the production process. Indica-

tive types of ICS include the Process Control Systems

(PCS), DCS, and SCADA (Macaulay and Singer,

2011). SCADA systems are mainly found in critical

infrastructures and industrial sectors, such as water

distribution systems, waste-water collection systems,

or oil and gas pipelines (Macaulay and Singer, 2011).

SCADA collects data from remote devices and con-

trollers and send this information to a centralized sys-

tem (Control Center), where an authorized user can

connect, physically or remotely, in order to monitor

and control the values in real-time.

The main components of SCADA are the control

center, the distributed devices (e.g. PLC, RTU, etc.),

the Human-Machine Interface (HMI), and the Master

Terminal Unit (MTU). In details, HMI is located in

the Control Center, along with the Data Historian, and

MTU. HMI provides user with an environment that

displays the monitored values, and the available ac-

tions for the configuration and control of the remote

devices. MTU is the server that processes and stores

the acquired data from the RTUs and PLC. The Data

Historian provides a centralized database located in

the control system, that supports analytics based on

statistical process control techniques. Finally, Remo-

te Terminal Unit (RTU) and Programmable Logic

Controller (PLC) collect data, monitor and control

sensors and actuators (Macaulay and Singer, 2011).

3.2 Communication Protocols

3.2.1 RS-485

RS-485 bus standard is used in the physical layer. It

transfers small blocks of data over long distances (up

to 1219m) at high speeds (≤10Mbps) (Marais, 2008)

(Axelson, 1999). The main advantage of this standard

is the ability for communication in electrically noisy

environments, and the support of multiple devices on

the same bus (CUI Devices, 2020). The protocol was

designed years before the development of Ethernet,

and thus the security aspect was not a priority.

3.2.2 Modbus

Modbus is a publicly available protocol. A central

master sequentially requests status information from

each connected device (Modbus Organization, 2006),

(OPS Telecom, 2023). Modbus is implemented in ap-

plication layer, used for real-time communication and

monitoring. Modbus was designed for serial commu-

nication and was later extended to run over TCP

(Drias et al., 2015). Modbus provides two types of

communication: (1) query/response between a master

and a slave, and (2) broadcast communication, where

the master sends a command to its slaves (Fovino et

al., 2009). Its main advantage is that it can be included

in a wide range of device types from any equipment

vendor (OPS Telecom, 2023). The drawback of Mod-

bus is the lack of security features, as it was originally

developed without considering security aspects

(Stouffer, 2006).

3.2.3 DNP3

Distributed Network Protocol (DNP3) is another pro-

tocol implemented in application layer. It is primarily

designed to simplify the communication across vari-

ous types of data acquisition and control systems.

Three types of communications are defined in DNP3

protocol: i) unicast transaction, ii) broadcast transac-

tion, and iii) unrequested responses from remote de-

vices (East et al., 2009). In unicast transaction, the

master can make a request to a targeted destination

slave, and the slave device responds back with a mes-

sage. In broadcast transaction, the master broadcasts

a request towards all its slaves within the network,

and in this instance, the slaves do not reply. The last

type of communication is typically periodic, unreque-

sted (by the master) updates or alerts are sent from the

remote devices to the master (East et al., 2009).

3.2.4 HART

Highway Addressable Remote Transducer (HART)

protocol is mostly applied to transmitters located in

hazardous environments (petrochemical, pharmaceu-

tical, chemical industries). Some of the published pro-

ducts provide a Bluetooth HART modem for the

transmitters to connect, in order to remotely configure

the transmitters while being in a dangerous environ-

ment, without the need of physical access to configure

them (Yu et al., 2018). HART is a combination of an-

alog and digital industrial automation protocol.

WirelessHART was later released to enhance wi-

reless capabilities to HART technology while main-

taining compatibility with pre-existing HART devi-

SECRYPT 2024 - 21st International Conference on Security and Cryptography

16

ces. WirelessHART is designed to use mesh network-

ing technology. In a mesh network, each device can

serve as a router for messages coming from other de-

vices. Thus, a device can forward a message to the

next closest one instead of communicating directly

with a gateway. This extends the range of the network

and provides redundant communication routes to in-

crease reliability (Song et al., 2008).

3.2.5 ICCP/TASE 2.0

Inter-control Center Communications Protocol, also

referred as Tele-control Application Service Element

(TASE 2.0), is a protocol that allows communication

and data exchange between different control centers

over Local Area Networks and Wide Area Networks

(Cunha et al., 2004), (Ilgner et al., 2021). TASE 2.0

relies on Manufacturing Message Specifications in

order to transfer data and monitor network nodes.

TASE 2.0 does not support authentication or encryp-

tion; instead, it implements an ingrained security suite

of underlying TCP/IP stack (Ilgner et al., 2021).

3.2.6 CIP

Common Industrial Protocol (CIP) is an object-ori-

ented protocol that transfers data between communi-

cation objects. An object is consisted of attributes,

services, connections, and behaviors. The protocol

also includes an extensive library that supports (a)

typical automation functions (e.g. analog and digital

input/output devices, HMI, motion control and posi-

tion feedback etc.), (b) general purpose network com-

munications, and (c) network services (e.g. file trans-

fer etc.) (Weehuizen et al., 2007), (ODVA, 2006).

3.2.7 BACnet

Building Automation & Control Network (BACnet)

is a protocol that was initially designed for heating,

ventilation, and air conditioning (HVAC) systems,

and was later extended to support further functionali-

ties (Esquivel-Vargas et al., 2017). BACnet solves in-

teroperability issues among devices from different

vendors, by modelling exchanged information with

object-oriented representations (Tang et al., 2020).

An object in BACnet is defined as a collection of

information related with the functionality of a BAC-

net device (Newman, 2013). Although BACnet was

not primarily designed with security in mind, there

are a-vailable options to secure BACnet, such as

through IP security solutions, IPsec, etc. (Peacock et

al., 2017), (Peacock, 2019).

3.3 Communication Standards

We introduce the standards encountered during the

communication of different components within an In-

dustrial Control System (ICS).

3.3.1 IEC 60870-5-104 (IEC 104)

IEC 104 was developed on top of the serial commu-

nication standard IEC 60870-5-101 (IEC 101).

Standard IEC was originally developed to enable

ba-sic tele-control messages between a control station

and outstations, over a communication link between

them (e.g. telephone network, modem circuit) (Mai et

al., 2019). IEC 104 is implemented in application lay-

er and is based on TCP/IP. However, this makes it

prone to attacks since it carries all the security issues

of TPC /IP. Moreover, the lack of encryption on the

transmitted data in the application layer is another se-

curity concern, making it vulnerable to Man-in-the-

Middle (MITM) attacks (Radoglou, et al., 2019).

3.3.2 IEC 61850

IEC 61850 is an international standard that defines a

comprehensive framework for communication bet-

ween devices and systems used in substations (e.g.,

control systems). One of its goals is to improve the

interoperability and integration of devices and sys-

tems in substation automation systems. It can support

both Ethernet and serial communication protocols,

and thus it provides an easier integration between var-

ious devices across different vendors. It is commonly

implemented in electric power industries (Mackie-

wicz, 2006). An important aspect of IEC 61850 is the

security guidelines that are included and focus on: i)

authentication and access control, ii) data integrity

and confidentiality, iii) network security, and iv) risk

assessment and management (Hussain et al., 2019).

On the other hand, IEC 61850 proposed SNTP proto-

col that has less accuracy, while in time-critical appli-

cations (such as in industrial sector) there is need for

accurate protocols to be applied (Sidhu et al., 2008).

3.3.3 ISO 15745

ISO 15745 proposes a framework for the develop-

ment of communication profiles for industrial auto-

mation systems. The standard outlines the conditions

for the creation and application of communication

profiles, which are used in industrial automation envi-

ronments to guarantee interoperability between devi-

ces and systems. A communication profile is a set of

rules and protocols in order to describe how devices

communicate in a system (Kosanke, 2006). Although

From Plant to Lab: Industrial Emulation Tools for Real-World Security Testing in Industrial Control Systems

17

this standard provides rules and profiles as a frame-

work for the development of communication proto-

cols (which could be designed to meet security re-

quirements), it does not explicitly deal with security

requirements of industrial automation systems.

3.3.4 EN 62443

EN 62443 is a set of industrial cybersecurity stand-

ards developed by the International Electro-technical

Commission (IEC) and the International Society of

Automation (ISA). EN 62443 was designed to provi-

de a comprehensive framework for securing indust-

rial automation and control systems against cyber

threats. The standard includes criteria for cybersecu-

rity management systems, risk assessment, and inci-

dent response plans, along with a list of recommen-

dations and best practices for safeguarding the net-

work and devices of industrial automation and control

systems. Due to restrictions on cost and resources, it

is difficult to effectively address all security issues as

required by IEC 62443 (Maidl et al., 2018).

4 EMULATION SOFTWARE

In this section we make an analysis of nine software

tools that can be used to realistically emulate complex

industrial processes or entire plants.

4.1 IEC Server & QTester104

IEC Server is a software, written in Java, that emu-

lates field devices (such as an RTU) and SCADA, im-

plementing a telecontrol message protocol specified

in the IEC 60870-5 (Parcharidis, 2018). The software

is free of charge, and it is simple to operate. The tool

comes as a portable executable and does not need to

be installed, reducing the configuration time compar-

ed to the other emulation tools. A drawback of this

software is that the documentation is not publicly

available because it is hosted on a website that is cur-

rently unavailable. Despite the lack of a manual, the

tool includes several interesting actions, such as add

IEC a 60870-5-104 command from a short list, pause

or resume the emulation, start or stop the server that

listens to a specified port, or even save a preset of a

given configuration.

QTester104 is a software designed to receive data

from a field device, based on the IEC 60870-5-104

communication protocol, in a SCADA system (Par-

charidis, 2018). This software is also free of charge and

can be compiled on Linux and Windows platforms.

There is adequate documentation that explains both the

tool functionalities and the user interface.

4.2 OMNeT++

OMNeT++ (Objective Modular Network Testbed in

C++) is an extensible, modular, component-based

C++ simulation framework. It is primarily used for

building network simulations. OMNeT++ is an open-

source tool with extensive documentation. It can be

used for free and for non-commercial purposes, such

as for academic institutions or teaching (Ahmad and

Durad, 2019). The OMNeT++ simulation kernel is

standard C++ and runs on all platforms where C++

compiler is available. The simulation IDE requires

Windows, Linux, or macOS. A project in OMNeT++

consists primarily of three files. A NED file that con-

tains the topology of the network, an INI file that con-

tains the configuration of the simulation, and the

source code file which is written in C++ and manages

the simulation (Ahmad and Durad, 2019). The project

is compiled using the NEDC compiler, included in the

OMNeT++ (Varga, 2005).

The greatest advantage of this software is its ex-

tensive documentation, provided both by researchers

and the community. One negative point is that the

configuration needed for the creation of a new project

can be overwhelming, since there are many compo-

nents that have to be included and users must have

adequate knowledge of the C++ language.

4.3 RINSE

RINSE (Real-time Immersive Network Simulation

Environment) is used to conduct real-time emulation

for network-security purposes (Liljenstam et al.,

2005). RINSE can emulate large networks, along with

a great number of attacks and defensive measures

(Davis et al., 2006). RINSE is composed of five basic

elements: i) iSS FNet network simulator, ii) simulator

database manager, iii) database, iv) data server, and

v) client-side network viewers. The iSSFNet is a net-

work simulator that runs over the Scalable Simulation

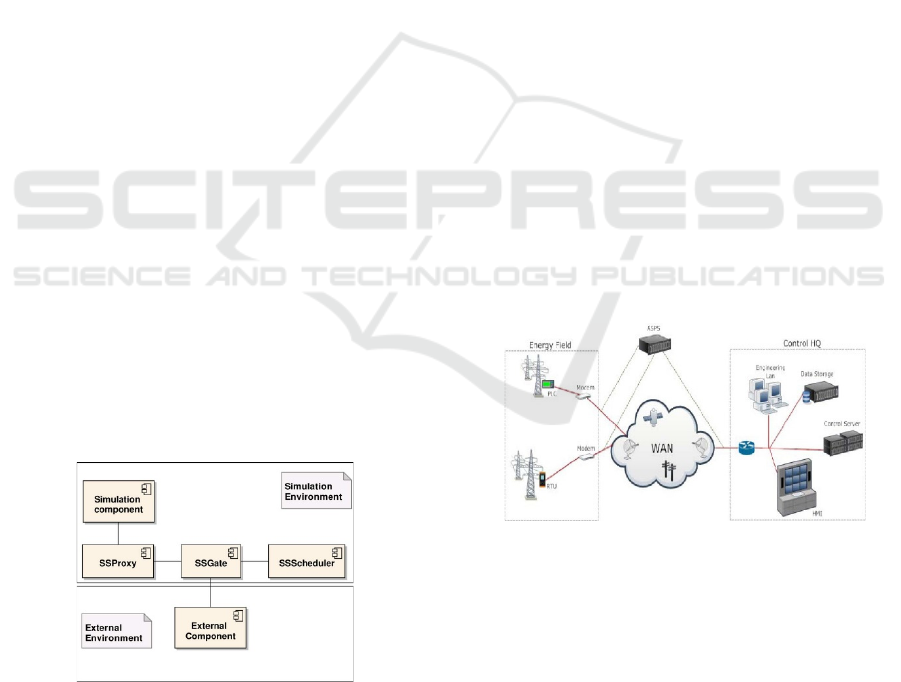

Figure 2: RINSE architecture.

SECRYPT 2024 - 21st International Conference on Security and Cryptography

18

Framework (iSSF), an Application Programming

Interface (API) which is responsible for the synchro-

nization and the functionality support. The iSSFNet

is running on parallel machines and supports the sim-

ulation of large-scaled networks. The simulator data-

base manager is responsible for supervising the data

gathering from the simulation nodes, in order to store

them in the database. These data are later delivered to

the simulator. The data server allows users to monitor

and control the simulated network. Finally, the net-

work viewers are running on the clients, allowing us-

ers to gain a local view of the network (Liljenstam et

al., 2005). RINSE architecture is depicted in Figure 2.

Through the network view clients, the users can

execute basic commands that modify the simulation.

Such commands can be categorized, based on their

functionality:

Attack: Commands used for launching attacks

(such as DDoS, worms).

Defense: Commands used for applying counter-

mea-sures (such as packet filters).

Diagnostic networking tools: Commands for basic

networking communication.

Device control: Commands for the control of the

devices (such as restart, reboot).

Simulator data: Commands sent to the simulator

in order to modify the output.

Although RINSE appears to be a promising simu-

lation software tool (highly scalable, with multiple

functionalities etc.), it has limited options to the com-

mands that can be used for attacks. Most of the attack

commands revolve around denial of service.

4.4 GRFICS

GRFICS (Graphical Realism Framework for Indus-

trial Control Simulations) is a simulation tool de-

signed specifically for ICS. It can be customized to

meet user needs. GRFICS helps users understand ICS

protocols through virtual network environments. This

accessibility aims to improve community knowledge

in ICS security. Users can simulate and observe cy-

bersecurity attacks like command injection, man-in-

the-middle attacks, and buffer overflows through 3D

visualizations. Finally, the tool offers the chance of

practicing defensive strategies by deploying proper

firewall and intrusion detection rules within the vir-

tual network. (Slatman H).

GRFICS allows users to swap components (such

as PLCs, HMI and any I/O module) with real ICS de-

vices. In order to emulate its physical processes, the

software utilizes: i) the emulation backend, ii) the e-

mulation API, iii) the 3D visualization, and iv) the I/O

modules (Formby et al., 2018). In regard to the visu-

alization of the PLC, developers used a modified ver-

sion of the OpenPLC. OpenPLC is an open-source

software for virtualizing controllers, which supports

multiple communication protocols (e.g., IEC 61131-

3, Modbus/TCP or DNP3). For the HMI’s visualiza-

tion, developers implemented Advanced HMI, an

open-source software allowing HMI virtualization.

Figure 3: SCADAVT architecture.

Overall, GRFICS is a great framework that com-

bines all the essential components: a virtualized net-

work of PLC, HMI, router, and a workstation.

It is an ideal tool for researchers that want to con-

duct basic security attacks and defensive counter-

measures at no cost. GRFICS can be downloaded

from the GRFICS Git-Hub repository. Also, there is

available an adequ-ate documentation, as well as

video tutorials on how to configure the virtual ma-

chines.

4.5 SCADAVT

SCADAVT is a security framework that is targeted to

security experts of SCADA systems (Almalawi et al.,

2013). It was developed on top of the CORE emulator

(Ahrenholz, 2010). CORE is a network emulator, si-

milar to OMNET++, OPNET, QualNet, NetSim, SSF

Net, NS2 (NetWork Simulator 2) and NS3 (Network

Simulator 3) (Ahmad and Durad, 2019), (Pan and

Jain, 2008). Since the CORE emulator does not sup-

port the commonly used SCADA protocols, the crea-

tors of the testbed developed three essential compo-

nents, which were integrated as services within the

CORE emulator. These components are:

Modbus/TCP Simulators of Master/Slave: Uti-

lizes the master-slave architecture essential for

SCADA systems. SCADAVT supports the Mod-

bus protocol, and the modes of master-slave are

integrated into the CORE emulator, using the

Modbus library and python scripts.

Modbus/TCP Simulator of HMI Server: Acts as

the communication medium between the HMI cli-

ent and MTU, facilitating a two-way communica-

tion for command exchanges.

From Plant to Lab: Industrial Emulation Tools for Real-World Security Testing in Industrial Control Systems

19

I/O modules Simulator: Acts as a server, and is

charge of receiving input data, from the external

environment, and sending it to the requesting

nodes.

In order to utilize the SCADAVT framework, the

user should install the following components: i) the

CORE emulator, ii) a third party publicly accessible

Modbus library, iii) a Python interpreter, iv) a securi-

ty tool (such as hping3), and v) the integration Python

scripts, developed by the creators (Ahrenholz, 2010).

The architecture of SCADAVT is shown in Figure 3.

Because the CORE emulator is a GUI-friendly solu-

tion that does not require code to configure a network

topology, the absence of the python scripts used to

implement the required SCADA components into the

emulator shifts the burden of developing new python

scripts to end-users.

4.6 TASSCS

TASSCS (Testbed for Analyzing Security of SCADA

Control Systems) is a testbed developed at the NSF

Center for Autonomic Computing at the University of

Arizona, aiming to help the security research, by pro-

viding innovative protection techniques for SCADA

systems (Mallouhi et al., 2011). TASSCS uses three

tools: (i) OPNET, a long-used by the industry com-

mercial network simulator (Pan and Jain, 2008), (ii)

PowerWorld that simulates the operations of the elec-

trical power grid, and (iii) Autonomic Software Pro-

tection System (ASPS) whose role is to protect SCA-

DA system and its network from the tested attacks

(Mallouhi et al., 2011). Modbus RSim is a tool that

helps users emulate PLC devices (Modbus server).

The Modbus server is combined with the Power-

World server and OPNET in order to listen incoming

requests (Mallouhi et al., 2011). In Figure 4 we depict

how the components of TASSCS are connected.

Figure 4: TASSCS architecture.

The TASSCS architecture has three components:

(i) Control HQ, (ii) WAN, and (iii) Energy Field.

Through the Control HQ, users can control all the

available resources within the emulated environment,

along with the provided services. This component al-

lows the presentation and storage of the collected data

(e.g. historical data from the devices and sensors).

Moreover, through Control HQ the end-users can ma-

nage the grid’s resources. The WAN component con-

sists of multiple emulated sensors, such as PLC, RTU

etc. These devices provide SCADA with the required

data and execute the requested commands from the

control center through the HMI. Finally, the Energy

Field serves as the electrical grid controlled by the

SCADA system. Through this component, develop-

ers would showcase the effectiveness of the ASPS, as

it prevents the launched attacks, and minimizes the

impact on the operations of the grid.

TASSCS has a great potential as it allows users to

test various attack scenarios and has defensive capa-

bilities which permit users to study the detection and

prevention aspect, through the ASPS.

4.7 SCADASim

SCADASim is a framework used for emulating SCA-

DA systems, developed at the Royal Melbourne Insti-

tute of Technology in Australia. SCADASim is an all-

in-one, plug and go emulator, that utilizes the OM-

NET++ discrete event simulation engine (Qassim et

al., 2017). SCADASim was developed with three key

requirements (Queiroz et al., 2011): (a) no need for

programming skills, (b) connectivity to multiple ex-

ternal devices (both hardware and software), and (c)

support of multiple industry standard protocols (e.g.

Modbus/TPC, DNP3).

Figure 5: SCADASim architecture.

As depicted in Figure 5, SCADASim’s architec-

ture consists of three essential components: i) SSS-

cheduler, ii) SSGate, and the iii) SSProxy. The SSS-

cheduler is a real-time scheduler, that allows users to

add new schedulers to the OMNET++ simulator. Us-

ers can control and synchronize the messages that re-

ceive from the external environment. SSScheduler

manages the SSGate instances, which are responsible

to send and receive messages from the external envi-

ronment. SSGate is the communication link to the ex-

SECRYPT 2024 - 21st International Conference on Security and Cryptography

20

ternal environment, where external SCADA compo-

nents are allowed to connect, through a supported

communication protocol.

Currently SCADA Sim supports three types of

gates: ModbusGate, DNP3Gate, and HTTPGate. SS-

Proxy is a representation of a real device or an exter-

nal application with-in the emulated environment,

and it communicates with the emulated objects (e.g.

PLC, RTU, MTU) through the SSGate which routes

their messages (Queiroz et al., 2011). SCADASim al-

lows many attacks to be launched on the emulated en-

vironment, such as: Denial of Service, Man in the

Middle, Spoofing, and Eavesdropping etc. Overall,

SCADA Sim has an easy configuration, with adequ-

ate documentation provided.

Figure 6: ICSSIM reference architecture.

4.8 ModbusPal & Rodbus

ModbusPal is a free, open-source emulation software

written in Java, which supports both natively TCP/IP

communication and serial communication as well.

The user can include up to 247 slaves, and each slave

can hold both registers and coils. ModbusPal can dy-

namically generates missing resources (slaves, regis-

ters and coils) as it receives requests from the master.

ModbusPal supports automations, where an automa-

tion is defined as a generator that creates the values

(through Linear, Random, and Sine generators) with

a predefined step, and these values can be bound with

a register or a coil. ModbusPal by default listens on

port 502, which can be easily changed through the

user interface. A slave can have its own IP address in

order to be identified in the network. Finally, a project

can be saved in an XMPP format so that the user can

load it again on the emulator.

Rodbus (Rust and Modbus) is a Rust implementa-

tion of the Modbus protocol. It is a command-line tool

written in Rust and can be easily installed using Car-

go. Rodbus provides in simple syntax all the essen-

tials commands that could be used by the master, such

as reading coils and registers, writing both single and

multiple coils or registers, etc.

4.9 ICSSIM

ICSSIM is a python-based emulation testbed, created

for security-research purposes. Several components

of the emulation are created as Docker containers that

may either share resources (such as a shared SQLite

database for “hardwired” communication) or commu-

nicate across the network using configurable, private

IP addresses. It supports Modbus TCP and includes

classes that might be extended to support new proto-

cols. The ICSSIM is capable of supporting both hard-

ware and emulated ICS components, such as a PLC

(Dehlaghi-Ghadim et al., 2023). Figure 6 presents the

ICSSIM reference architecture.

The Attack Generator, a key component of this

testbed, enables for the emulation of an adversary

within the environment, assuming that the attacker al-

ready has a foothold. Because this Attack Generator

is a Docker running Kali Linux, attackers can launch

a variety of attacks. This emulation software does not

require highly technical skills to operate, but basic

containerization understanding is required. Finally,

programming skills would help end-users to increase

the emulation capabilities of the tool.

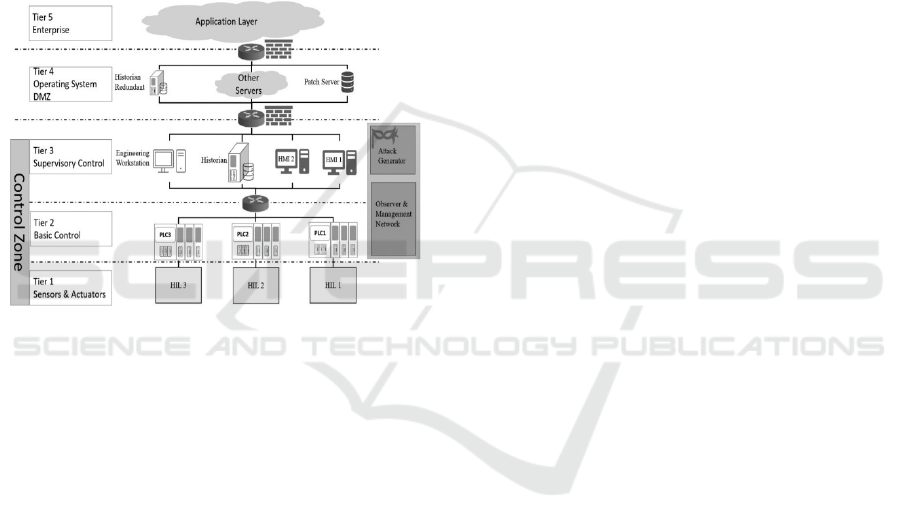

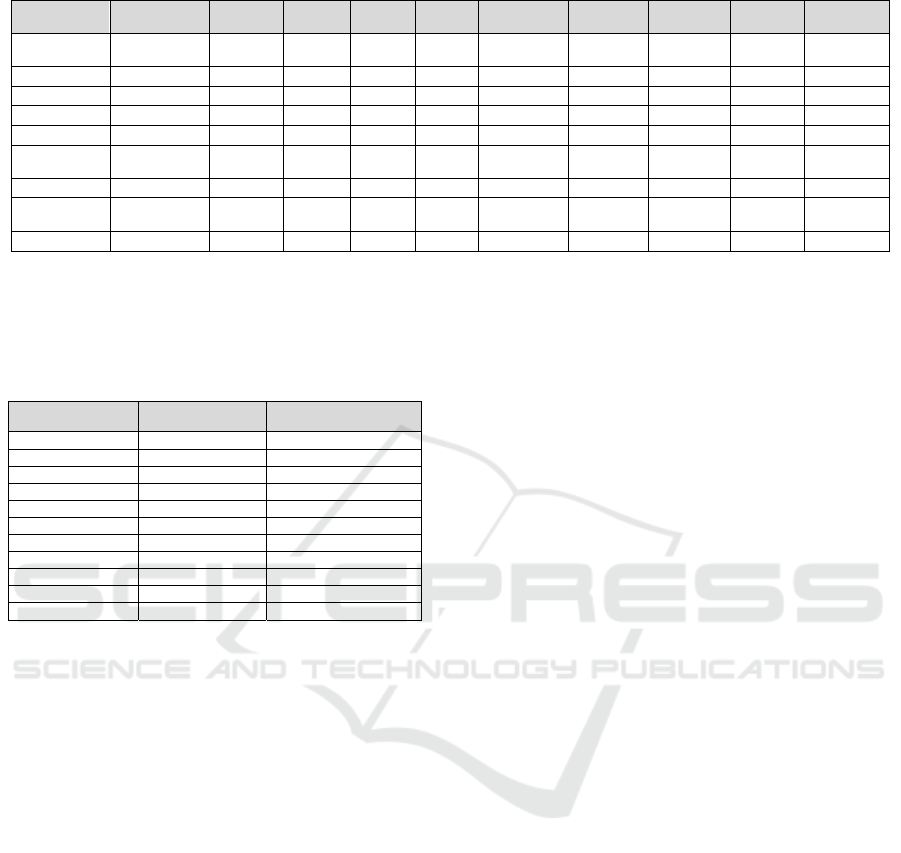

5 EMULATION SOFTWARE

COMPARISON

In this section, we undertake a comparison of the

emulation tools based on the criteria outlined in Table

3. Due to the software's modularity, most emulation

tools can model any protocol as needed by research-

ers. The term "modularity" here refers to a software

design approach that divides the program's function-

ality into independent, interchangeable modules. As

indicated in Table 4, half of the tools have the capa-

bility to simulate any protocol requested by the user.

Specifically, SCADAVT, TASSCS, ModbusPal

& Rodbus, and ICSsim are dedicated to the Mod-

bus/TCP protocol, with TASSCS also incorporating

DNP3. On the other hand, IEC Server & QTester104

exclusively support the IEC 60870-5 protocol.

From Plant to Lab: Industrial Emulation Tools for Real-World Security Testing in Industrial Control Systems

21

Table 3: Description of comparison criteria.

Criterion Description

Modularity

Modularity of the software defines whether an emu-

lation software could model any protocol that a re-

searcher desires.

Sector The sectors that an emulation tool is focused.

Attack vari-

et

y

How flexible is to emulate several attacks or is spec-

ified to a sin

g

le attack.

Open source

The capability of a tool and its source code to be

used, altered, or distributed to anyone and for any

p

ur

p

ose.

Free of

char

g

e

Whether a researcher should purchase the emulation

tool.

Complexity

Whether the use of an emulation tool requires higher

technical knowledge (e.g. programming skills) from

users.

Scalability

Factors that indicate scalability of a tool: number of

emulated devices, whether Firewalls, Intrusion De-

tection Systems etc., could be used in the emulation.

Easy to con-

fi

g

ure

How easy is for a researcher, may not be familiar in

a

g

reat extend with

p

ro

g

rammin

g

and en

g

ineerin

g

Flexibility

The degree of flexibility is determined by how con-

figurable the environment is, the variety of attacks

that can be launched.

Documenta-

tion

A tool offers a good experience if the user can easily

find the details of how to confi

g

ure and use it.

Pricing and accessibility of software are crucial

aspects in comparison. Some tools are proprietary and

intended for use by specific organizations. Fortunate-

ly, a significant number of tools are freely available

and open-source. As shown in Table 4, IEC Server &

QTester104, OMNeT++, GRFICS, SCADASim,

ModbusPal & Rodbus, and ICSsim are all examples

of tools that are both free of charge and open-source.

Additionally, we considered specific sectors applic-

able by these tools. According to Table 4, most tools

are not sector-specific. Only two tools have a con-

centrated focus on specific areas. GRFICS targets the

chemical sector, while TASSCS is designed for use

in the chemical and energy sectors.

A feature that is beneficial to users is the presence

of adequate documentation. Unfortunately, only four

tools have accessible documentation, which are OM-

NeT++, RINSE, ModbusPal & Rodbus, and ICSsim.

Furthermore, it is important the tools to be kept up to

date. This is because when the tools integrate updates,

then enhance existing features, fix bug issues, or im-

prove their performance. Based on Table 5, the most

up-to-date tools are the IEC Server, the OMNeT++,

the Rodbus, and the ICSsim. The GRFICS, SCA-

DAVT, and TASSCS are no longer available.

Researchers aim to emulate environments not on-

ly for testing but also for launching attacks and draw-

ing conclusions without impacting real-world infrast-

ructures. Therefore, we evaluate the presented soft-

ware based on the criterion of attack variety. Most of

the tools meet this criterion, except IEC Server &

QTester104, RINSE, and SCADAVT. In terms of fle-

xibility and scalability, as indicated in Table 4, IEC

Server & QTester104, SCADAVT, and ModbusPal &

Rodbus are identified as less scalable tools. Specifi-

cally, IEC Server & QTester104 and SCADAVT are

noted as the least flexible among the tools.

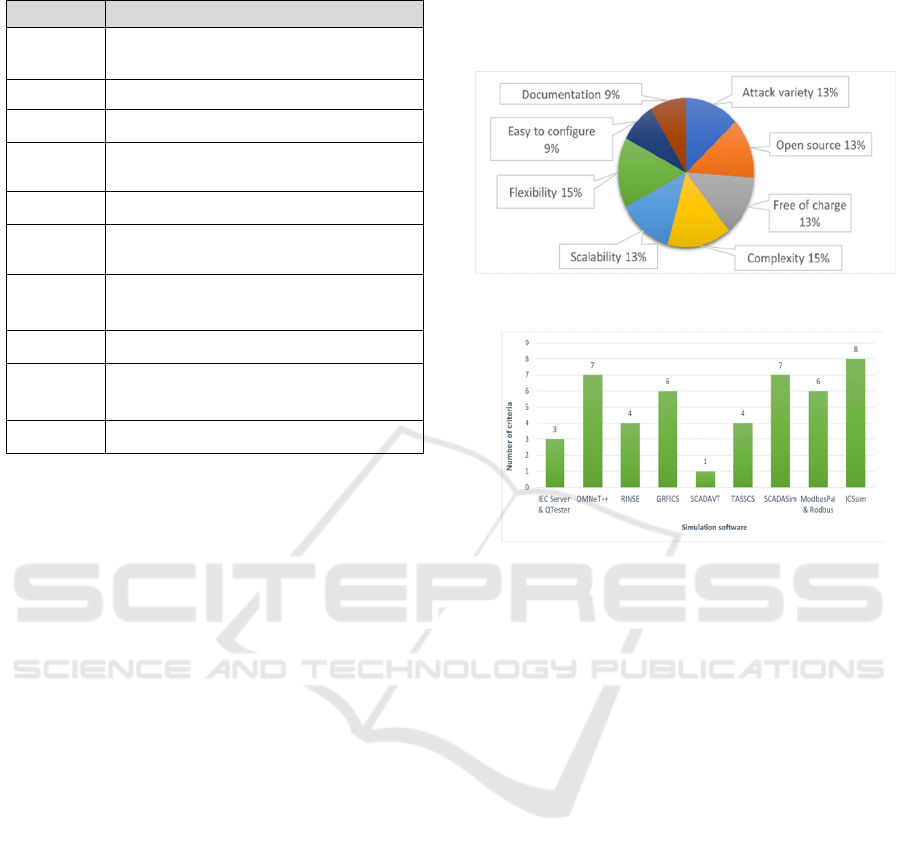

Figure 7: Number of criteria per emulation software.

Figure 8: % of tools that incorporate each criterion.

Figure 7 indicates how many emulation tools in-

corporate a particular criterion. We notice that the lar-

ger percentage is attributed to complexity and flexibi-

lity. Conversely, the lowest percentage suggests that

developers are not concerned with the ease of config-

uration and the documentation provision. Based on

the above observations, we can assume that software

developers focus enough on adding new features, but

they sacrifice the ease of configuring the tool. Have

in mind that the user, in our case a researcher, may

not be familiar to a great extend with programming

and engineering and customization adds complexity

to execution.

Figure 8 depicts the number of criteria that each

of the presented tools incorporates. We notice that on-

ly the ICSsim meets all the requirements. The second

place, with 7 out of 8 incorporated criteria, belongs to

the OMNeT++ and the SCADASim. The tool that sat-

isfies only one requirement is SCADAVT.

Researchers are flexible to choose emulation soft-

ware based on their expertise, specific emulation

needs, and budget constraints. This analysis suggests

ICSsim as a recommended choice that meets all speci-

fied criteria. Alternatively, researchers may consider

either OMNeT++ or SCADASim, both satisfying 7 out

of 8 criteria. The choice between these two tools de-

pends on individual needs. OMNeT++ offers extensive

SECRYPT 2024 - 21st International Conference on Security and Cryptography

22

Table 4: Emulation Software Comparison.

Emulation

software

Modularity Sector

Attack

variet

y

Open

source

Free of

char

g

e

Complexity Scalability Flexibility

Easy to

confi

g

ure

Documen-

tation

IEC Server &

QTester104

IEC 60870-5 Generic -

✓

✓

- - -

✓

-

OMNeT++ Any protocol Generic

✓

✓

✓

✓

✓

✓

-

✓

RINSE Any protocol Generic - - -

✓

✓

✓

-

✓

GRFICS Any protocol Chemical

✓

✓

✓

✓

✓

✓

- -

SCADAVT Modbus/TCP Generic - - -

✓

- - - -

TASSCS

Modbus/TCP,

DNP3

Energy,

Chemical

✓

- -

✓

✓

✓

- -

SCADASim Any protocol Generic

✓

✓

✓

✓

✓

✓

✓

-

ModbusPal

& Rodbus

Modbus/TCP Generic

✓

✓

✓

- -

✓

✓

✓

ICSsim Modbus/TCP Generic

✓

✓

✓

✓

✓

✓

✓

✓

documentation despite being challenging in configura-

tion, while SCADASim is easy to configure but lacks

accompanying documentation.

Table 5: Software Latest Updates.

Emulation software Release date Latest update

IEC Serve

r

February, 2018 June 27, 2023

QTeste

r

A

p

ril, 2016 Novembe

r

10, 2022

OMNeT+

+

Decembe

r

2018 Jul

y

5, 2023

GRFICS N/

A

N/

A

RINSE Ma

y

, 2018 Decembe

r

14, 2020

SCADAVT N/

A

N/

A

TASSCS N/

A

N/

A

SCADASi

m

December, 2018 Novembe

r

9, 2020

ModbusPal March, 2009 Februar

y

20, 2018

Rodbus Au

g

ust, 2019 A

p

ril 27, 2023

ICSsi

m

A

p

ril, 2022 Februar

y

2, 2023

6 CONCLUSIONS

Our work aimed to identify and present tools that can

be used for the emulation of complex ICS infrastruc-

tures and systems, such as SCADA. We made a thor-

ough analysis and comparison among these tools bas-

ed on a number of criteria regarding the accessibility

to the tool, flexibility in terms of the emulation com-

ponents, configuration complexity, latest updates of

the software, pricing, scalability, as well as the acces-

sibility to documentation and manuals.

For an effective tool selection, a user should first

define requirements per use-case and specific needs

of the facility that requires the emulation tool. This

includes understanding the type of ICS in use (e.g.,

SCADA, PLC, DCS), critical processes and compo-

nents that must be emulated, along with the overall

objectives of using the tool (e.g., training, vulnerabil-

ity testing, system analysis).

At a minimum, plant users should choose based

on (i) protocol support regarding the communication

protocols used in the existing ICS (e.g., Modbus, IEC

61850), (ii) actuator and sensor emulation support to

simulate the types of equipment used in the system,

and (iii) material mapping capabilities to be relevant

to the processes (e.g., chemical properties in a pro-

cessing plant).

Some of the simulation software provide high fle-

xibility regarding the simulation components. This

may cost the ease of using and configuring the soft-

ware and leads to an increased level of complexity,

requiring higher technical knowledge (e.g. program-

ming skills) from users. For example, OMNeT++, of-

fers simulation of any desired component within an

industrial control system, supporting any communi-

cation protocol, due to its modularity. However, it re-

quires considerably higher technical skills, compared

to other simulation solutions. The pricing is another

concern that we have in mind. Most of the emulation

software is free of charge, where others are either not

publicly available, or require a license.

Finally, we aimed at addressing the challenging

dilemma of whether someone chooses an emulation

software instead of physically designs a testbed on a

research lab. The objective of our analysis is to help

research community identify which of the existing

emulation tools can be suitable for corresponding pur-

poses and budget.

REFERENCES

Ahmad, Z., Durad, M. (2019). Development of SCADA

simulator using omnet++. In 2019 16

th

International

Bhurban Conference on Applied Sciences and Tech-

nology, pg. 676–680. IEEE.

Ahrenholz, J. (2010). Comparison of core network emula-

tion platforms. In 2010 Military Communications Con-

ference, pg. 166–171. IEEE.

Almalawi, A., Tari, Z., Khalil, I., Fahad, A. (2013). Sca-

davt-a framework for scada security testbed based on

virtualization technology. In 38

th

Annual IEEE Confer-

ence on Local Computer Networks, pg. 639–646.

Axelson, J. (1999). Designing rs-485 circuits. Circuit Cel-

lar, 107:20–24.

From Plant to Lab: Industrial Emulation Tools for Real-World Security Testing in Industrial Control Systems

23

Coffey, K., Smith, R., Maglaras, L., Janicke, H. (2018).

Vulnerability analysis of network scanning on SCADA

systems. Security and Communication Networks, 2018.

CUI Devices (2020). RS-485 serial interface explained.

Cunha, C., Rein, O., Jardini, J., Magrini, L. (2004). Electri-

cal utilities control center data exchange with iccp and

cim/xml. In 2004 IEEE Transmission and Distribution

Conference & Exposition, pg. 260–265. IEEE.

Davis, C., Tate, J., Okhravi, H., Grier, C., Overbye, T.,

Nicol, D. (2006). SCADA cyber security testbed devel-

opment. In 2006 38

th

North American Power Sympo-

sium, pg. 483–488. IEEE.

Dehlaghi-Ghadim, A., Balador, A., Moghadam, M., Hans-

son, H., Conti, M. (2023). Icssim - a framework for

building industrial control systems security testbeds.

Computers in Industry, 148:103906.

Drias, Z., Serhrouchni, A., Vogel, O. (2015). Taxonomy of

attacks on industrial control protocols. In 2015 Interna-

tional Conference on Protocol Engineering, pg. 1–6.

IEEE.

East, S., Butts, J., Papa, M., Shenoi, S. (2009). A taxonomy

of attacks on the dnp3 protocol. In Internatio-nal Con-

ference on Critical Infrastructure Protection, pg. 67–81.

Springer.

Esquivel-Vargas, H., Caselli, M., Peter, A. (2017). Au- to-

matic deployment of specification-based intrusion de-

tection in the bacnet protocol. In Proc. of the 2017

Workshop on Cyber-Physical Systems Secuity and Pri-

vacy, pg. 25–36.

FieldComm Group. Wirelesshart.

Formby, D., Rad, M., Beyah, R. (2018). Lowering the bar-

riers to industrial control system security with

{GRFICS}. In 2018 USENIX Workshop on Advances

in Security Education.

Fovino, I., Carcano, A., Masera, M., Trombetta, A. (2009).

Design and implementation of a secure mod- bus pro-

tocol. In International conference on critical infrastruc-

ture protection, pg. 83–96. Springer.

Hussain, S., Ustun, T., Kalam, A. (2019). A review of iec

62351 security mechanisms for iec 61850 message ex-

changes. IEEE Transactions on Industrial Informatics,

16(9):5643–5654.

Ilgner, P., Cika, P., Stusek, M. (2021). Scada-based mes-

sage generator for multi-vendor smart grids: Distribut-

ed integration and verification of tase. 2. Sensors,

21(20):6793.

Incorporated, A. (2005). BusWorks® 900EN Series: 10/

100M Industrial Ethernet I/O Modules w/Modbus.

Kosanke, K. (2006). Iso standards for interoperability: A

comparison. In Interoperability of enterprise software

and applications, pg. 55–64. Springer.

Liljenstam, M., Liu, J., Nicol, D., Yuan, Y., Yan, G., Grier,

C. (2005). Rinse: The real-time immersive network si-

mulation environment for network security exercises.

In Workshop on Principles of Advanced and Distribu-

ted Simulation, pg. 119–128. IEEE.

Macaulay, T., Singer, B. L. (2011). Cybersecurity for indu-

strial control systems: SCADA, DCS, PLC, HMI, and

SIS. CRC Press.

Mackiewicz, R. E. (2006). Overview of iec 61850 and ben-

efits. In 2006 IEEE Power Engineering Society General

Meeting, pg. 8–10. IEEE.

Mai, K., Qin, X., Silva, N., Cardenas, A. (2019). Iec 60870-

5-104 network characterization of a large-scale opera-

tional power grid. In 2019 IEEE Security and Privacy

Workshops, pg. 236–241. IEEE.

Maidl, M., Kroselberg, D., Christ, J., Beckers, K. (2018). A

comprehensive framework for security in engineering

projects-based on iec 62443. In 2018 IEEE Interna-

tional Symposium on Software Reliability Engineering

Workshops, pg. 42–47. IEEE.

Mallouhi, M., Al-Nashif, Y., Cox, D., Chadaga, T., Hariri,

S. (2011). A testbed for analyzing security of SCA-DA

control systems. In ISGT 2011, pg. 1–7. IEEE.

Marais, H. (2008). Rs-485/rs-422 circuit implementation

guide. AN-960 Analog Devices.

Mattioli, R., Moulinos, K. (2015). Analysis of ICS-SCADA

cyber security maturity levels in critical sec-tors.

Modbus Organization (2006). Modbus messaging on TCP/

IP Implementation Guide V1.

Journal on Wireless Communications and Networking,

2012(1):1–17.

Newman, H. (2013). Bacnet explained. ASHRAE Journal.

ODVA (2006). Common Industrial Protocol (CIP).

OPS Telecom (2023). Understanding modbus protocol - rtu

vs tcp vs ascii.

Page, M., et al. (2021). The Prisma 2020 statement: An

updated guideline for reporting systematic reviews. 88:

105906.

Pan, J., Jain, R. (2008). A survey of network simulation to-

ols: Current status and future developments. 2(4):45.

Parcharidis, M. (2018). Simulation of cyber-attacks against

scada systems.

Peacock, M. (2019). Anomaly detection in bacnet/ip

managed building automation systems.

Peacock, M., Johnstone, M., Valli, C., Camp, O., Mori, P.,

Furnell, S. (2017). Security issues with bacnet value

handling. In ICISSP, pg. 546–552.

Qassim, Q., et al., (2017). A survey of SCADA testbed imp-

lementation approaches. Indian Journal of Science and

Technology, 10(26):1–8.

Queiroz, C., Mahmood, A., Tari, Z. (2011). Scada-sim - A

framework for building scada simulations. IEEE

Transactions on Smart Grid, 2(4):589– 597.

Radoglou-Grammatikis, P., Sarigiannidis, P., Giannoula-

kis, I., Kafetzakis, E., Panaousis, E. (2019). Attacking

iec-60870-5-104 SCADA systems. In 2019 IEEE

World Congress on Services, vol. 2642, pg. 41–46.

IEEE.

Slatman H. A curated list of resources related to Industrial

Control System (ICS) security.

Sidhu, T., Kanabar, M., Parikh, P. (2008). Implementation

issues with iec 61850 based substation automation

systems. In 15

th

National Power Systems Conference,

pg. 473–478.

Song, J., Han, S., Mok, A., Chen, D., Lucas, M., Nixon, M.,

Pratt, W. (2008). Wirelesshart: Applying wireless

technology in real-time industrial process control. In

SECRYPT 2024 - 21st International Conference on Security and Cryptography

24

2008 IEEE Real-Time and Embedded Technology and

Applications Symposium, pg. 377–386. IEEE.

Stouffer, K., Falco, J. (2006). Guide to supervisory control

and data acquisition (SCADA) and industrial control

systems security. NIST.

Tang, S., Shelden, D. R., Eastman, C. M., Pishdad-Bozorgi,

P., Gao, X. (2020). Bim assisted building automation

system information exchange using bacnet and ifc. Au-

tomation in Construction, 110:103049.

Varga, A. (2005). Omnet++ discrete event simulation sys-

tem, ver. 3.2, User Manual.

Weehuizen, F., Brown, A., Sunder, C., Hummer, O. (2007).

Implementing IEC 61499 communication with the cip

protocol. In 2007 IEEE Conference on Emerging Tech-

nologies and Factory Automation, pg. 498–501. IEEE.

Xarhoulacos, C. G., Anagnostopoulou, A., Stergiopoulos,

G., & Gritzalis, D. (2021). Misinformation vs. situa-

tional awareness: The art of deception and the need for

cross-domain detection. Sensors, 21(16), 5496.

Yu, Y.-S., Chen, C.-H., Cheng, K. (2018). Design and im-

plementation of a remote hart configurator. In 2018

IEEE International Conference on Applied System In-

vention, pg. 510–512. IEEE.

From Plant to Lab: Industrial Emulation Tools for Real-World Security Testing in Industrial Control Systems

25