A New Digital Twin Paradigm: Definition, Framework, and Proposed

Architecture

Jhonathan Mauricio Vargas Barbosa, Omar Danilo Castrillón Gómez

and Jaime Alberto Giraldo García

Universidad Nacional de Colombia, Facultad de Ingeniería y Arquitectura, Departamento de Ingeniería Industrial,

Campus La Nubia Bloque Q piso 2, Manizales, Colombia

Keywords: Digital Twins, Architecture, Framework.

Abstract: In this paper, the concept of Digital Twins is addressed in the context of Industry 4.0, highlighting its

definition, functional components, scope of application, proposed framework, and architecture. A definition

is proposed that emphasizes the precise replication of physical reality and the ability to adapt to changes and

incoming data. The proposed framework and architecture provide guidance for the effective implementation

of Digital Twins, emphasizing the importance of data management and versatile infrastructure. In summary,

Digital Twins represent a transformative technology with the potential to improve operational efficiency,

drive innovation, and realize the vision of Industry 4.0. Their evolution will continue to require additional

research and practical applications to unlock their full potential across various industrial and commercial

sectors.

1 INTRODUCTION

The advent of Industry 4.0 implies a marked

inclination towards the full automation of

manufacturing processes. This trend is supported by

the integration of cyber-physical systems, driven by

cloud computing and connectivity provided by the

Internet of Things (IoT) (Joyanes Aguilar, 2019). The

term Digital Twin is closely linked to Industry 4.0.

These digital twins create an accurate virtual

representation of a physical entity, where its behavior

is simulated using data. They are characterized by

their real-time synchronization capability, faithful

reproduction, and high fidelity through feedback

mechanisms between the real and virtual worlds, data

fusion analysis, and optimization of iterative

decision-making. Their purpose is to foster

interaction and integration between the physical

world and the world of information, as well as to

expand the capabilities of the physical entity (Li, Lei,

& Mao, 2022). The Digital Twin provides a digital

representation of the physical product. The digital

representation is constructed based on the

information gathered from various sources (C. S.

Durão, Zancul, & Schützer, 2024).

Although the concept of "digital twin" originated

in the 1970s, its current popularization is attributed to

a presentation by Michael Grieves in 2002. In this

presentation, Grieves addressed how the creation of a

virtual model of a product could have a significant

impact on the management of the product lifecycle

(Li, Lei, & Mao, 2022). The application of digital

twin technology has expanded into the architectural,

engineering, and construction (AEC) field, and

numerous studies have been actively conducted over

the past decade. However, existing studies are more

focused on establishing the framework and

possibilities of digital twins, and on proposing

specific architectures for certain use cases, making

these approaches difficult to generalize (Wook Kang

& Mo, 2024).

Various methodologies are employed in the

development of a Digital Twin, and each phase of its

creation presents different levels of complexity.

According to Hyre et al. (Hyre, y otros, 2022), the

complexity and capability of the Digital Twin vary

depending on the established objectives, categorizing

them into four categories, each one more complex

than the previous: the representation of the real

system, the replication of the real system, the realistic

representation of the physical object, and the ability

192

Barbosa, J., Gómez, O. and García, J.

A New Digital Twin Paradigm: Definition, Framework, and Proposed Architecture.

DOI: 10.5220/0012711600003758

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 14th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH 2024), pages 192-198

ISBN: 978-989-758-708-5; ISSN: 2184-2841

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

to make decisions by integrating elements of artificial

intelligence.

In this work, we propose a new definition of

Digital Twin that encompasses not only the precise

replication of physical reality but also the ability to

adapt and evolve as circumstances and available data

change. Our approach focuses on flexibility and

interoperability, aiming to provide a robust framework

that can be applied across a variety of contexts and

sectors.

In addition to presenting our definition of Digital

Twin, we also outline a proposed framework for its

effective implementation. This framework is based on

principles of modularity, scalability, and

collaboration, with the goal of facilitating the creation

and management of complex Digital Twins in

dynamic and evolving environments.

Finally, we explore a proposed architecture to

support the implementation of Digital Twins across

various domains. This architecture is based on a

combination of emerging technologies, such as the

Internet of Things (IoT), machine learning, and cloud

computing, and is designed to provide the necessary

infrastructure for collecting, storing, and analyzing

data in real-time, as well as for visualizing and

simulating virtual environments accurately.

2 APPLICATION SCOPE

The Digital Twins, although emerging, represent a

promising innovation in today's technological

landscape. While the concept can be traced back to

the 1970s, their widespread adoption and practical

application in various fields are relatively recent. The

rapid evolution of technology in areas such as cloud

computing, the Internet of Things (IoT), and artificial

intelligence has propelled the development and

expansion of Digital Twins, making them an

increasingly relevant and powerful tool for enhancing

efficiency, productivity, and decision-making across

a wide range of industries and sectors.

So far, a formal or widely accepted definition, as

well as a unified process for the creation and

implementation of the Digital Twin, have not been

achieved. Different industries and application fields

present diverse perspectives and approaches. A

thorough review reveals that the Digital Twin is

progressively leaving its initial phase and moving

towards a stage of rapid development, where

researchers are beginning to explore real industry

practices and technologies. Although the original

vision of fully understanding and reflecting every

aspect of the physical twin is still far from being fully

realized, the application fields of the Digital Twin

demonstrate great vitality (Liu, Fang, Dong, & Xu,

2021).

This article is part of the doctoral thesis titled

"Methodological Proposal for Improving Production

and Service Systems in the Waste Industry through

the Use of a Digital Twin. Application in High-

Population Density Areas. In this study, an updated

definition of Digital Twins is presented, which

encompasses not only the precise replication of

physical reality but also the ability to adapt and

evolve dynamically in response to changes in the

environment. Furthermore, a proposed conceptual

framework and architecture are described to support

its effective implementation, with emphasis on

modularity, scalability, and integration with

emerging technologies such as the Internet of Things

(IoT) and cloud computing. These functional

components lay the necessary groundwork for fully

understanding and harnessing the potential of Digital

Twins in improving production and service systems.

3 FUNCTIONAL COMPONENTS

OF DIGITAL TWINS

In the Functional Components section of Digital

Twins, we will delve into a proposed definition of

these innovative systems, as well as the conceptual

framework and architecture designed to support their

effective implementation. Firstly, we will introduce

an definition of Digital Twins, which encompasses

not only the precise replication of physical entities in

virtual environments but also their ability to adapt and

evolve dynamically in response to changes in the

environment. Subsequently, we will examine the

proposed framework, which provides a structured

guide for the design and implementation of Digital

Twins in various industrial and service contexts.

Finally, we will explore in detail the architecture

designed to support the functionality and operability

of Digital Twins, emphasizing their modularity,

scalability, and integration capabilities with emerging

technologies such as the Internet of Things (IoT) and

cloud computing. These functional components

provide the necessary foundation for fully

understanding and harnessing the potential of Digital

Twins in improving production and service systems.

3.1 Proposed Definition

In the realm of Digital Twins, they have been

proposed as a practical option for real-time

A New Digital Twin Paradigm: Definition, Framework, and Proposed Architecture

193

interaction. Based on this, some general

characteristics have been established (Ogunsakin,

Mehandjiev, & Marin, 2023).

• Digital Twins must accurately represent both

the structure and the state of their physical

system, and data transfer must occur in real-

time with said physical system (Ogunsakin,

Mehandjiev, & Marin, 2023).

• Digital Twins should enhance designs and

processes of the physical system even when the

physical system undergoes changes (online or

in real-time) (Ogunsakin, Mehandjiev, &

Marin, 2023).

• Since physical systems are dynamic and

changing over time, the Digital Twins

representing them must also be able to change

their states in real-time (Singh, y otros, 2021).

• A Digital Twin evolves alongside its physical

counterpart throughout its lifecycle. Any

changes in either twin, whether physical or

digital, are reflected in the other, creating a

closed feedback loop. A Digital Twin must be

self-adaptive and self-optimizing with the help

of data collected by its physical twin in real-

time, thus maturing along with its physical

counterpart throughout its entire lifespan

(Singh, y otros, 2021).

• The Digital Twin, being a virtual replica of its

physical counterpart, needs to incorporate the

properties of the latter across multiple scales or

levels. This means that the virtual model of the

Digital Twin is based on both the macroscopic

and microscopic geometric properties of the

physical twin, as well as its physical properties

such as structural dynamics models,

thermodynamics, stress analysis, fatigue

damage, and material properties, including

stiffness, strength, hardness, and fatigue

resistance, among others. Therefore, the Digital

Twin is multi-physical, as it considers both the

geometric and physical properties of the

physical twin (Singh, y otros, 2021).

• Industry 4.0 encompasses various areas of

knowledge, and the Digital Twin is essential for

its operation as it integrates disciplines such as

computer science, information technology,

communications, mechanical engineering,

electrical engineering, electronics,

mechatronics, automation, industrial

engineering, and systems integration physics,

among others (Singh, y otros, 2021).

Given the characteristics of Digital Twins, we

propose a conceptualization that encompasses their

ability to dynamically and in real-time represent

physical systems, integrating multidisciplinary data

and models to accurately reflect both the structure and

behavior of their physical counterparts. This approach

would allow for the synchronous evolution of Digital

Twins with their associated physical systems,

facilitating continuous adaptation and optimization in

response to changes and events in the real

environment. Furthermore, Digital Twins would

provide a platform for simulation, analysis, and

prediction of operational scenarios, significantly

contributing to improving efficiency, productivity,

and quality across a wide range of industrial and

commercial applications.

A Digital Twin is an active representation

technique of a real system with continuous feedback,

which, using tools such as autonomous learning, Data

Mining, and sensors among other integrated tools in

Industry 4.0, generates active and predictive

information of systems in the virtual space.

Depending on the level of implementation and the

objectives set in its creation, the Digital Twin can be

used as a tool for short, medium, and long-term

decision-making, as an evaluation and training tool,

or as a key tool for improving production systems.

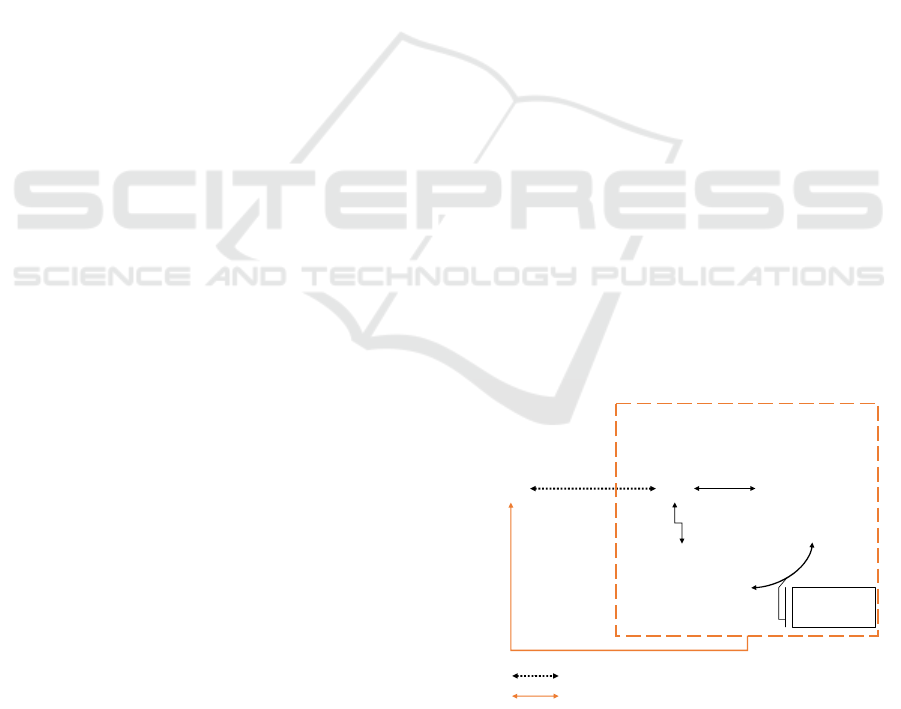

Figure 1 shows a proposed schematic definition of

Digital Twins.

The development of a Digital Twin must be

planned following some key concepts and practices

of project management. Just like in discrete event

simulation, Digital Twins should not be applied

indiscriminately, but rather a decision should be made

based on considerations about the system under study

and the relevance of the problem to be solved with

this tool.

Figure 1: Proposed Definition of Digital Twin.

Given the preceding discussion, it becomes

apparent that every real-world system has the

potential to be mirrored in the virtual realm,

Real

System

Virtual

System

Bidirectional

information transfer

- Virtual Model

- Virtual Model with

data generation

- Virtual Mosdel with

Autonomous decision

making"

- Short-term, medium-

term, and long-term

decision-making

- Evaluation and

training

- Improvement of

production and

service systems

Characteristics

Generated

services

Digital Twins

Implementation

Level

Modification of the

Real System

Data transfer

Performance of the virtual system in the real system

SIMULTECH 2024 - 14th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

194

facilitated by unidirectional data transfer in its

primary stage or bidirectional communication in its

more sophisticated form. In this context, the virtual

counterpart, or Digital Twin, encompasses a spectrum

of characteristics and functionalities tailored to the

level of implementation, ranging from a rudimentary

virtual replica to an intelligent decision-making entity

driven by the constant generation and acquisition of

data. The depth of implementation is intricately tied

to the predefined objectives established during the

methodological deployment of the Digital Twin.

In broad terms, the primary objectives of

implementing a Digital Twin could be to obtain a

resource that facilitates: (1) enhanced real-time

remote control, maintenance, and optimization; (2)

heightened safety concerning both material and

human factors; (3) enhanced understanding and

awareness of dynamic processes (Føre, y otros,

2024).

At an advanced stage of Digital Twin evolution, it

gains the capability to actively influence and adapt

the behavior of the real-world system, thus fostering

a feedback loop of predictive analytics and

continuous enhancement for the systems under study.

The extent to which this influence is exerted, and the

effectiveness of the feedback loop are contingent

upon both the level of implementation and the

specific objectives delineated for the Digital Twin's

development.

3.2 Proposed Architecture

Arise during the interaction between the physical twin

and its virtual counterpart, it is imperative to establish

a series of mechanisms that facilitate the efficient

management of this data. The inherent complexity of

this interaction demands a robust and versatile

architecture capable of encompassing a wide variety

of tools, processes, models, and mechanisms. In this

regard, the proposed architecture stands as a dynamic

and adaptable framework responsible for

orchestrating all these elements to effectively carry

out the task of data management. Its comprehensive

design aims not only to optimize the collection,

storage, and processing of information but also to

ensure its integrity, security, and availability always.

This holistic approach to data management within the

framework of digital twins is essential to ensure their

effective operation and their ability to support

informed decision-making processes in various

industrial and commercial contexts.

The proposed architecture consists of three

fundamental layers: one dedicated to the physical

environment, another to the virtual environment, and

a third layer for communication and data transfer.

Both the layer of the physical environment and the

layer of the virtual environment have structural and

functional elements that describe the process, collect

data, and act based on the data processed and

collected by the communication layer. These

elements can be defined as follows:

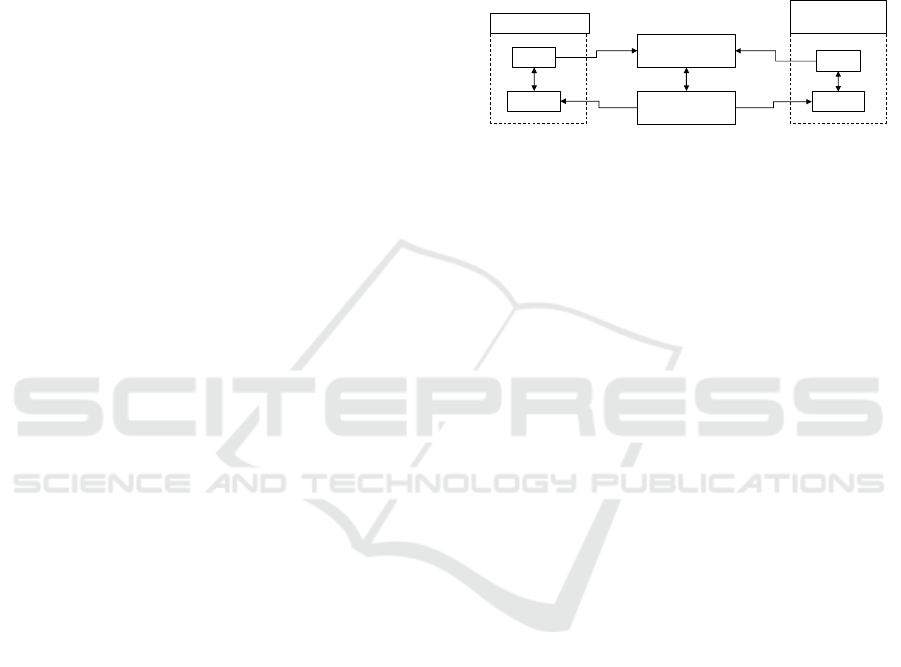

Figure 2: Proposed Architecture

3.2.1 The Physical Environment

In the context of the Digital Twin, the functional

process refers to the system under study that will have

its digital counterpart, with clearly defined

boundaries. This process should incorporate sensors

and actuators according to the desired level of

application and automation, with these aspects

established in the implementation objectives. Sensors

are information-capturing devices that detect changes

in the system and generate data related to these

changes. On the other hand, actuators are devices

responsible for executing predefined actions in a

process in response to the information captured by the

sensors.

3.2.2 Cloud Services/Offline Services

Data management encompasses the collection,

maintenance, and secure, efficient, and cost-effective

use of data. Authors such as Munappy define data

management as a process that includes data

collection, analysis, validation, protection, and

monitoring to ensure data consistency, accuracy, and

reliability (Munappy, Bosch, Olsson, Arpteg, &

Brinne, 2022). On the other hand, data processing and

analysis refer to the transformation of data into

knowledge (value), aiming for these processes to

occur within a reasonable timeframe. This can be

achieved through batch processing, where data is

collected over a specified time interval and

transformations are executed as scheduled, or through

real-time processing, which involves executing

transformations as data is collected.

Physical Environment

Virtual Environment

Cloud Services /

Offline Services

Sensor

Actuator

Functional Process

Data

Administration

Data

Processing

Sensor

Actuator

Functional

Virtual Model

A New Digital Twin Paradigm: Definition, Framework, and Proposed Architecture

195

3.2.3 The Virtual Environment

In the context of Digital Twins, the virtual

environment consists of several key components.

Firstly, the functional virtual model, analogous to the

functional process described in the physical

environment, possesses identical functional and

operational characteristics but exists within the

virtual space. Additionally, virtual sensors, mirroring

their counterparts in the physical space, perform the

same function of data capture but within the virtual

environment. Similarly, virtual actuators, akin to

physical actuators, operate within virtual

environments, executing actions based on the data

received. These components collectively form an

essential part of the digital replication process,

enabling real-time monitoring, analysis, and

simulation in virtual settings.

3.3 Proposed Framework

This text presents a framework designed to address a

specific issue in the application of Digital Twins. This

conceptual framework is based on a combination of

existing theories and practices, highlighting specific

needs in the implementation of digital twins for

improving production and service systems. The aim

of this framework is to provide a solid and coherent

structure for understanding and solving the problem

effectively and sustainably. Throughout this text, the

key components of the framework are described,

along with how they interact to achieve its goal.

Figure 3 illustrates the framework, which is described

below.

Figure 3: Proposed framework.

The proposed framework is based on the

architecture described earlier, which addresses three

layers: the physical environment layer, the cloud

services layer based on information technologies, and

the virtual environment layer. These layers and their

elements are described below.

In this area, It is noteworthy that the ISO

organization (International Standard Organization,

2021) formulates the document ISO 23247-2:2021,

which establishes a reference framework for the use

of digital twins in the field of manufacturing. This

framework provides reference models from a domain

and entity perspective, as well as a functional view of

digital twins in manufacturing.

3.3.1 The Physical Environment

The physical environment of the system under study

is divided into three interconnected layers to facilitate

the flow of information: the physical environment

layer, the networks and connections layer, and the

control and execution sublayer. The physical

environment layer, the first one, houses the system

under study and relevant physical resources, as well

as the computational systems necessary for data

analysis and storage. The networks and connections

sublayer includes sensors for data capture, such as

temperature, pressure, and light sensors, converting

these measurements into electrical or digital signals.

Additionally, it encompasses data transfer

connections, both wired and wireless. The control and

execution sublayer are responsible for acting upon the

information processed by the Digital Twin, using

mechanical actuators and operators. The mechanical

actuators automatically perform actions based on the

received information, while operators act according

to an operation plan generated by the Digital Twin.

3.3.2 Cloud Services/Offline Services

This layer hosts intelligent data storage and

processing services, serving as the direct

communication interface between the physical

environment and the virtual environment. It houses

data obtained from the physical model, as well as data

from the virtual model resulting from information

analysis and processing. This layer acts as the direct

link, and a well-structured one ensures fast

bidirectional transfer of information.

3.3.3 The Virtual Environment

The virtual layer is fundamental in the development

and implementation of Digital Twins, as it hosts the

virtual replica of the real physical system, known as

Physical Environment Cloud Services/

Offline Services

Virtual

Envirnoment

Physical

Environment

Studied

system

Computational

Resource

Storage

Control and

Implementation

Networks and

Connections

Sensor Interconections Worker

Actuator

Data

Storage

Data

Processing

-

Iterative

Optimization

-

Control

Instructions

Service Layer

Functional

Virtual Model

Virtual

System

Generated

Data

- Production test

- Operational Process

Improvement

-ProcessDesign

-DesignofOperationalPlans

Including but not limited to

SIMULTECH 2024 - 14th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

196

the functional virtual model. Here, the services that

the Digital Twin can provide are designed and

executed, ranging from production tests to process

design and improvement, as well as operational

planning. This layer is formed through the continuous

collection and analysis of real-world data, which are

used to build a virtual model that emulates the

behavior and characteristics of the corresponding

physical system. Additionally, it allows the

simulation of various scenarios and conditions to

evaluate the performance and efficiency of the system

in different situations, as well as to test new design

strategies and techniques before implementing them

in the real world.

This virtual layer is dynamic and constantly

updated with the latest real-world data, allowing the

Digital Twin to accurately reflect changes in the

physical system in real time. The services offered by

the Digital Twin are diverse and range from data

analysis and simulation to assess process

performance and efficiency, to predictive

maintenance to anticipate failures and avoid

downtime. They also include performance

optimization to improve resource utilization and

energy efficiency, as well as personnel training to

enhance their skills and knowledge. Additionally, the

integration of systems into a single platform allows

for better coordination and control of production

processes, improving efficiency and reducing errors.

In summary, the virtual layer is essential for the

effective operation of Digital Twins, facilitating

constant interaction between the physical and virtual

environments and enabling an iterative optimization

process based on control instructions from the virtual

system to the real system.

4 CONCLUSIONS

In this paper, we have explored the concept of Digital

Twins within the context of Industry 4.0, providing

insights into their definition, functional components,

application scope, proposed framework, and

architecture. Drawing upon existing literature and

theoretical frameworks, we have proposed a

comprehensive understanding of Digital Twins as

dynamic and adaptable entities that bridge the

physical and virtual realms, offering real-time

representation, analysis, and optimization of complex

systems.

Our proposed definition of Digital Twins

emphasizes not only the accurate replication of

physical reality but also their capacity to adapt and

evolve in response to changing circumstances and

data inputs. We have outlined key characteristics that

define Digital Twins, including real-time

synchronization, continuous feedback mechanisms,

multidisciplinary integration, and self-adaptation

throughout the lifecycle.

Furthermore, our proposed framework and

architecture provide structured guidance for the

effective implementation and operation of Digital

Twins across various domains. The framework

delineates the interconnected layers of the physical

environment, cloud services, and virtual

environment, highlighting the essential components

and interactions necessary for seamless data flow and

decision-making.

Through the proposed architecture, we have

emphasized the importance of robust data

management mechanisms and versatile infrastructure

to support the functionalities of Digital Twins. By

incorporating elements such as sensors, actuators,

cloud services, and virtual models, our architecture

enables real-time monitoring, analysis, and

simulation, fostering informed decision-making and

continuous optimization of systems.

In conclusion, Digital Twins represent a

transformative technology with far-reaching

implications for diverse industries and sectors. By

leveraging real-time data integration,

multidisciplinary modelling, and adaptive algorithms,

Digital Twins have the potential to revolutionize

production processes, enhance operational efficiency,

and drive innovation in product development and

service delivery. As the field of Digital Twins

continues to evolve, further research and practical

applications will be essential to unlock their full

potential and realize the vision of Industry 4.0.

ACKNOWLEDGEMENTS

The authors would like to express their sincere

gratitude to Universidad Nacional de Colombia

campus Manizales, for their support and resources in

conducting this re-search. We also wish to thank the

Faculty of Engineering and Architecture for their

support of the doctoral program in Industrial

Engineering and Organizations.

This article is part of the doctoral thesis entitled

"Methodological Proposal for Improving Production

and Service Systems in the Waste Industry through the

Use of a Digital Twin. Application in High-Population

Density Areas" developed within the framework of the

doctoral program in the Universidad Nacional de

Colombia, and in this moment is in the final phase of

presentation. We are grateful to the Ministry of

A New Digital Twin Paradigm: Definition, Framework, and Proposed Architecture

197

Science, Technology, and Innovation for their

financial support of this research, and to all

participants and collaborators who made this study

possible.

REFERENCES

C. S. Durão, L. F., Zancul, E., & Schützer, K. (2024).

Digital Twin data architecture for Product-Service

Systems. 11th CIRP Global Web Conference (CIRPe

2023), 79-84.

Føre, M., Omholt Alver, M., Arve Alfredsen, J., Rasheed,

A., Hukkelås, T., Bjelland, H. V., . . . Norton, T. (2024).

Digital Twins in intensive aquaculture — Challenges,

opportunities and future prospects. Computers and

Electronics in Agriculture.

Hyre, A., Harris, G., Osho, J., Pantelidakis, M., Mykoniatis,

K., & Liu, J. (2022). Digital twins: Representation,

Replication, Reality, and Relational (4Rs).

Manufacturing Letters(20-23).

International Standard Organization. (2021). 23247-2

Automation systems and integration — Digital twin

framework for manufacturing.

Joyanes Aguilar, L. (2019). Industria 4.0; La Cuarta

Revolución Industrial. Bogotá: Alfaomega.

Li, L., Lei, B., & Mao, C. (2022). Digital twin in smart

manufacturing. Journal of Industrial Information

Integration.

Liu, M., Fang, S., Dong, H., & Xu, C. (2021). Review of

digital twin about concepts, technologies, and industrial

applications. Journal of Manufacturing Systems, 346-

361.

Munappy, A. R., Bosch, J., Olsson, H. H., Arpteg, A., &

Brinne, B. (2022). Data management for production

quality deep learning models: Challenges and solutions.

The Journal of Systems & Software.

Ogunsakin, R., Mehandjiev, N., & Marin, C. A. (2023).

Towards adaptive digital twins architecture. Computers

in Industry.

Singh, M., Fuenmayor, E., Hinchy, E. P., Qiao, Y., Murray,

N., & Devine, D. (2021). Digital Twin: Origin to

Future. Applied system innovation.

Wook Kang, T., & Mo, Y. (2024). A comprehensive digital

twin framework for building environment monitoring

with emphasis on real-time data connectivity and

predictability. Developments in the Built Environment.

SIMULTECH 2024 - 14th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

198