Product-Line Engineering for Smart Manufacturing:

A Systematic Mapping Study on Security Concepts

Richard May, Alen John Alex, Rakky Suresh and Thomas Leich

Harz University of Applied Sciences, Wernigerode, Germany

Keywords:

Security, Configurable Systems, Product-Line Engineering, Smart Manufacturing, Systematic Mapping Study.

Abstract:

The growing configurability of smart-manufacturing software systems (SMSS) introduces a variety of security

concerns. Although there is an ever-increasing risk for exploiting configuring-caused issues, there is currently

no overview of research on security within SMSS, especially those based on product-line engineering (PLE).

To address this gap, we employed a systematic mapping study of 43 publications (2014–2023) related to the

intersection of security, SMSS, and PLE. Besides an overview of what properties have been researched, we

identified nine literature gaps to guide future research. Overall, there is a need for more research on PLE

security concepts in SMSS. Current approaches often address security as a separate requirement rather than

integrating it into the PLE framework or mapping it to the unique properties of SMSS. Concrete security

concerns are typically hardly described, which may have fatal consequences in safety-critical systems.

1 INTRODUCTION

In the past few years, smart manufacturing (SM)

has emerged as a novel approach that embraces the

convergence of advanced technologies, e.g., based

on machine-learning-driven data analytics (Kusiak,

2018). This paradigm shift transcends traditional

manufacturing methods, transforming factories into

adaptive ecosystems that seamlessly integrate auto-

mated, data-driven production processes (Qu et al.,

2019). SM supports the increase of functions and

their configurations, making smart-manufacturing

software systems (SMSS) variant-rich and highly

complex (Fischer et al., 2023). Product-line engi-

neering (PLE) is an established approach for develop-

ing and maintaining such configurable software sys-

tems (Uysal and Mergen, 2021). Specifically, PLE

enables the creation of product families (i.e., variants)

with shared functionalities (i.e., features), optimiz-

ing development efficiency and reducing costs (Apel

et al., 2013). Configurability is becoming increas-

ingly important for SMSS, which often require con-

figuration to accommodate different production lines

or product variants (Uysal and Mergen, 2021). How-

ever, the growing variability of SMSS presents sev-

eral unique challenges, particularly in terms of sys-

tem security (Kenner et al., 2021). Precisely, the more

configurable systems are, the greater the risk of po-

tential (mis)configurations or (unintended) feature in-

teractions, leading to vulnerable bugs or even system

failure (May et al., 2024).

PLE in the context of SM has already been ad-

dressed by research, e.g., Heikkil

¨

a et al. (2016) ana-

lyzed how to deal with configurability in robot sys-

tems and Fischer et al. (2021) investigated cyber-

physical systems configuration testing. However, we

miss a systematic overview of existing research – es-

pecially how they handle security. We aim to address

this gap by employing a systematic mapping study to

analyze existing literature (2014–2023) and investi-

gate: (1) to what extent the properties of configurabil-

ity and security are covered by research and (2) which

properties are underexplored and thus need more re-

search. In this context, our contributions are:

• An overview understanding of current research re-

garding security in the context of PLE and SMSS.

• A discussion of which properties have been ade-

quately covered or need more research.

• An open-access replication package.

1

2 BACKGROUND

Next, we address preliminary knowledge on config-

urable systems, SM, and security.

1

https://doi.org/10.5281/zenodo.10653363

May, R., Alex, A., Suresh, R. and Leich, T.

Product-Line Engineering for Smart Manufacturing: A Systematic Mapping Study on Security Concepts.

DOI: 10.5220/0012715400003753

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 19th International Conference on Software Technologies (ICSOFT 2024), pages 323-330

ISBN: 978-989-758-706-1; ISSN: 2184-2833

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

323

Configurable Systems. A configurable system is a

software platform containing sets of reusable features

that can be enabled, disabled, or adjusted to config-

ure platform variants (Apel et al., 2013). PLE is an

established approach for managing configurable soft-

ware, incorporating concepts such as feature model-

ing (Meinicke et al., 2017) to facilitate maintenance

or flexibility (van der Linden et al., 2007). There

are three common verification strategies: product-

based (i.e., code or abstraction analysis on each con-

figuration), feature-based (i.e., analysis of each fea-

ture), and family-based (i.e., analysis of a meta sys-

tem) (Th

¨

um et al., 2014). Configurable systems

usually rely on the classification by their projection

space, including problem space (i.e., domain abstrac-

tion to identify requirements), solution space (i.e., im-

plementation and product derivation), and their con-

nection through a mapping in which appropriate fea-

tures are derived (Meinicke et al., 2017).

Smart Manufacturing. SM aims to be highly inte-

grated within software and hardware, giving a high

degree of productivity, flexibility, and configurabil-

ity (Kusiak, 2018). It points towards intelligent, inter-

acting systems, primarily based on data-driven tech-

nologies and the Internet-of-Things (IoT) which is a

bridge between the cyber and physical worlds (Zheng

et al., 2018). SM technologies are an essential part

of Industry 4.0, aiming to transform traditional man-

ufacturing into smart, network-driven, and nearly au-

tonomous manufacturing (Tuptuk and Hailes, 2018).

In general, the goal of SM is to meet the changing

requirements and conditions in the factory, the sup-

ply network, and customer needs through real-time

responses (Kang et al., 2016). In this way, the manu-

facturing industry aims to address the ever-increasing

demands for individualization, quality improvement,

and shorter time-to-market (Zheng et al., 2018).

Security. As more manufacturers are transitioning

to SM, the physical and cyber worlds are merging,

leading to increasing system complexities and greater

attack surfaces (Alani and Alloghani, 2019). So,

achieving robust security oriented towards customer

demands, policies, and legal regulations is crucial to

mitigate threats (ISO/IEC 27000, 2018). Threats are

adverse incidents that may have a negative impact on

a system, e.g., vulnerability exploits. The likelihood

and impact of these incidents is called a risk (ISO/IEC

27005, 2022). Typically, countermeasures (e.g., au-

thentication) are implemented in the context of a de-

fined strategy (i.e., pattern) to provide an appropriate

security level. Such countermeasures are usually ori-

ented towards the fulfillment of six essential security

goals, including confidentiality, integrity, and avail-

ability (i.e., CIA triad), as well as accountability, au-

thorization, and non-repudiation (i.e., goals of infor-

mation security) (ISO/IEC 27000, 2018).

3 METHODOLOGY

To address our research objectives, we carried out a

systematic mapping study (Petersen et al., 2015). The

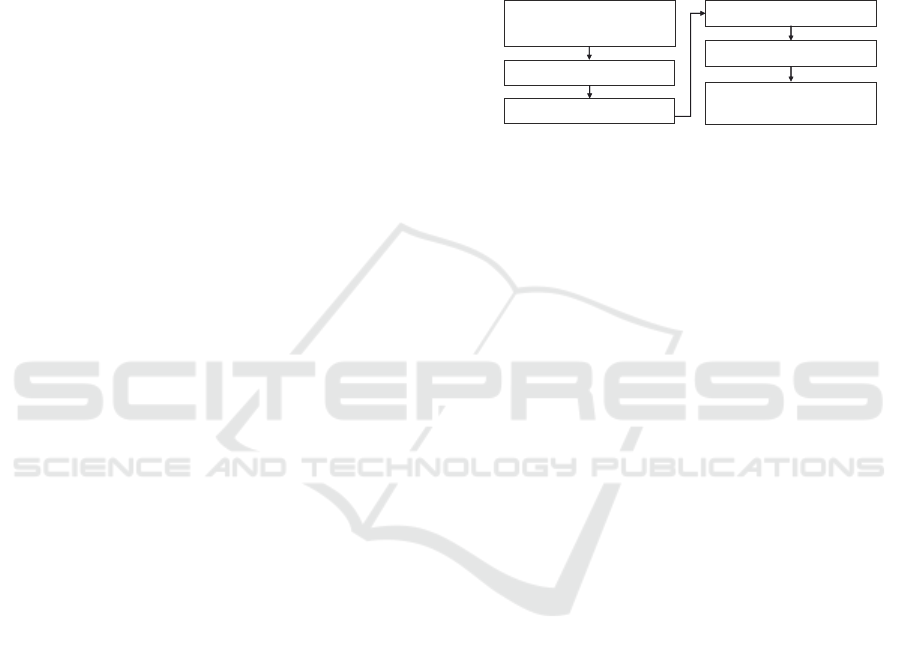

methodological steps are illustrated in Figure 1.

IEEE Scopus

ACM

abstract selection

snowballing selection

title/

data extraction/analysis

research gaps

523

69

full-text selection

38

43

discussion &

literature databases

Figure 1: Overview of methodological research steps with

numbers indicating the amount of selected publications.

3.1 Study Design

Databases and Search String. We relied on three

databases: SCOPUS, IEEE XPLORE, and ACM DIG-

ITAL LIBRARY and used the following search string:

(“product*line*”) AND (“famil*” OR “config*” OR

“variab*” OR “variant*” OR “feature” OR “model*”)

AND (“secur*” OR “protect”) AND (“industry” OR “in-

dustrial” OR “manufactur*” OR “production” OR “cy-

ber*physical”)

Inclusion Criteria. We applied the following inclu-

sion criteria (IC) to select relevant publications:

IC

1

. The publication must have been published in the

past decade (2014–2023), ensuring the topics

included are fairly recent.

IC

2

. The publication must be longer than three

pages, ensuring that the literature included pro-

vides sufficient details.

IC

3

. The publication must be a peer-reviewed book

chapter, journal article, or conference paper to

achieve a minimum quality of the publications

included in our selection. We intentionally ex-

cluded review and/or overview studies.

IC

4

. The publication must cover PLE approaches in

the context SM as well as security concepts.

Data Extraction Criteria. To extract data valuable

enough to achieve our research objectives, we created

the following data extraction categories:

Publication including four criteria:

• Publication year of the contribution.

• Contribution type, i.e., a publication classifica-

tion, including open items, method, model, met-

ric, or tool (Engstr

¨

om and Runeson, 2011).

ICSOFT 2024 - 19th International Conference on Software Technologies

324

• Perspective, i.e., a decision whether the publi-

cation is focused on a security concept devel-

oped on PLE techniques or (static) security of

an PLE-based system.

• Fields, e.g., robotics, manufacturing.

Configurable System including five criteria:

• System focus, i.e., a specification of what is ac-

tually configurable, including software, hard-

ware, or both.

• Evolution, i.e., a description of evolutionary

processes and issues, e.g., related to updates.

• Verification strategy, i.e., a method that is ad-

dressed in the publication, including feature-,

product-, or family-based verification.

• Projection space, i.e., a classification into prob-

lem space, solution space, or mapping.

• Tool, i.e., if the publication mentioned any spe-

cific tool support for configuration.

Security including six criteria:

• Standard, e.g., ISO/IEC 27000 series.

• Goals, including confidentiality, integrity, avail-

ability (CIA triad), authorization, accountabil-

ity, non-repudiation (information security), and

other goals (e.g., authenticity).

• Threats and risks, i.e., threat- or risk-related se-

curity issues of configurable systems.

• Vulnerabilities, i.e., exploitable weaknesses.

• Patterns, i.e., concrete strategies to ensure sys-

tem security.

• Countermeasures, i.e., mitigation techniques

addressing threats, vulnerabilities, or risks to

ensure security.

3.2 Study Conduct

The search was performed by the first author on

November 15

th

, 2023 and resulted in 523 publica-

tions after applying the selection criteria (489 after

removing duplicates). By reading the titles and ab-

stracts, a total of 69 publications was found. Then,

the number of selected publications was reduced to

38 publications based on the full-texts, followed by a

single pass of forward/backward snowballing, yield-

ing five more publications (i.e., 43 publications in to-

tal). Next, the first author analyzed all selected lit-

erature. In this context, open-coding (i.e., labeling

of data) and open-card-sorting methods (i.e., classi-

fication of recurring data into common themes) were

applied. The second and the third author took ran-

dom samples (five papers each) to verify the results.

All analyzed data and interpretations were discussed

until consensus was reached between all authors. In

Figure 1, all methodological steps are illustrated.

4 RESULTS

In the following subsections, we describe the results

classified according to our categories (cf. Table 1).

4.1 Publication

Publication Years. Starting in 2014 with two publi-

cations, the number remains constant between 2015

and 2018 (4.5 publications per year on average).

There is a peak in 2019 with eight publications, fol-

lowed by six publications per year in 2020 and 2021.

Surprisingly, we found only two publications in 2022

and one publication in 2023.

Contribution Type. Most publications focus on open

items (e.g., challenges). Methods and models are each

described by 12 publications. In six cases, a concrete

tool (e.g., framework) is proposed.

Perspective. We identified that the majority (37) is

related to quite static security as part of the PLE while

only in six publications configurable security mecha-

nisms are described.

Fields. The application fields comprise diverse work-

ing areas and SM sub-fields. However, most publi-

cations (17) are focused on cyber-physical production

systems. Ten publications are related to general man-

ufacturing without further specifications. We identi-

fied seven more fields with less publications, includ-

ing, e.g., robotics (4) and cloud manufacturing (3).

4.2 Configurable System

System Focus. Most publications (24) focus on soft-

ware without considering any hardware components.

19 publications are related to software and hardware

(e.g., cyber-physical production systems).

Evolution. About half of the publications (21) con-

sidered quite diverse evolutionary processes, e.g., fea-

ture interaction evolution. However, these are typi-

cally described in a rather superficial way.

Verification Strategy. 24 publications present infor-

mation on verification, including feature-based (13),

product-based (7), and both feature- and product-

based (4). Interestingly, there was no information on

family-based verification of any SMSS.

Projection space. We found that 17 publications

relied on a mapping of the problem and the solu-

tion space. Furthermore, 15 publications covered the

problem space and 11 publications the solution space.

Tool. Only 13 tools for supporting PLE or secu-

rity management are applied, including FeatureIDE

(3), HyperFlex Toolchain (2), and others (8) such as

pure::variants. We highlight that there are current

frameworks focusing on the field of cyber-physical

Product-Line Engineering for Smart Manufacturing: A Systematic Mapping Study on Security Concepts

325

Table 1: Overview of the extracted data regarding publication, security, and configurable system.

Publication Security Configurable system

Reference

Perspective

Field

Standard

Confidentiality

Integrity

Availability

Authorization

Accountability

Non-repudiation

Threats and risks

Vulnerabilities

Patterns

Countermeasures

System focus

Projection space

Verification

Evolution

Eichelberger et al. (2014) S → PLE GM S S –

Gherardi et al. (2014) S → PLE R S M –

Smiley et al. (2015) S → PLE IA S M F

Vogel-Heuser et al. (2015) S → PLE GM S/H P F

Garc

´

ıa et al. (2015) S → PLE ERP S M –

Galindo et al. (2015) S → PLE GM S P –

Arrieta et al. (2015) S → PLE CPPS S M –

Kokaly et al. (2016) S → PLE GM S/H P F

Etigowni et al. (2016) PLE → S CPPS S M –

Heikkil

¨

a et al. (2016) S → PLE R S/H S –

Feldmann and Vogel-Heuser (2017) S → PLE GM S P –

Larrucea et al. (2017) S → PLE IN S/H M P

Young et al. (2017) S → PLE A

1

S P F

Seidl et al. (2017) S → PLE GM S P –

McGee et al. (2017) S → PLE IA S P F

Jalil and Bakar (2017) S → PLE ERP S M P

Krieter et al. (2018) PLE → S CM S P P

Brugali and Hochgeschwender (2018) S → PLE R S/H S –

Zhang et al. (2018) S → PLE CM S/H S F/P

Islam and Azim (2018) S → PLE CPPS S/H S F

Shaaban et al. (2019) PLE → S CPPS S S P

Hajri et al. (2018) S → PLE A

1

S/H M F/P

de Oliveira et al. (2019) S → PLE A

2

S/H M P

Ca

˜

nete (2019) S → PLE CM S/H S F

Bennaceur et al. (2019) PLE → S CPPS S/H M P

Ebnauf et al. (2019) S → PLE CPPS S S –

Meixner et al. (2019) S → PLE CPPS S/H P –

Daun et al. (2019) S → PLE GM S M –

Garc

´

ıa et al. (2020) S → PLE R S/H P –

Pett et al. (2020) S → PLE A

1

S/H M F/P

Meixner (2020) S → PLE CPPS S P –

Ca

˜

nete et al. (2020) S → PLE CPPS S/H M –

Varela-Vaca et al. (2020) PLE → S CPPS S M P

Bandyszak et al. (2020) S → PLE CPPS S M F

Xiao and Li (2021) S → PLE CPPS S S F/P

Varela-Vaca et al. (2021) PLE → S CPPS S S F

Uysal and Mergen (2021) S → PLE GM S S F

Fischer et al. (2021) S → PLE CPPS S/H P –

Bressan et al. (2021) S → PLE GM S/H M –

Capilla et al. (2021) S → PLE GM S M F

Feichtinger et al. (2022) S → PLE CPPS S P F

Vogel-Heuser et al. (2022) S → PLE CPPS S/H P –

Fischer et al. (2023) S → PLE CPPS S/H P F

General: Fulfilled Not fulfilled Perspective: S → PLE: static security concept besides PLE, PLE → S: security concept based on PLE

Field: A

1

: Automotive, A

2

: Avionics, CM: Cloud manufacturing, CPPS: Cyber-physical production systems, ERP: Enterprise-resource planning

GM: General manufacturing, IA: Industrial analytics, IN: Industrial networks, R: Robotics

System focus: S: Software, H: Hardware; Projection space: P: Problem space, M: Mapping, S: Solution space; Verification: F: Feature-based, P: Product-based

production systems and security-configuration verifi-

cation, namely CyberSPL (Varela-Vaca et al., 2020)

and CARMEN (Varela-Vaca et al., 2021).

4.3 Security

Standard. There were four publications referenc-

ing standards, precisely NIST cyber-physical-systems

program (2), IEC 62443 (1), and IEEE 1686 (1).

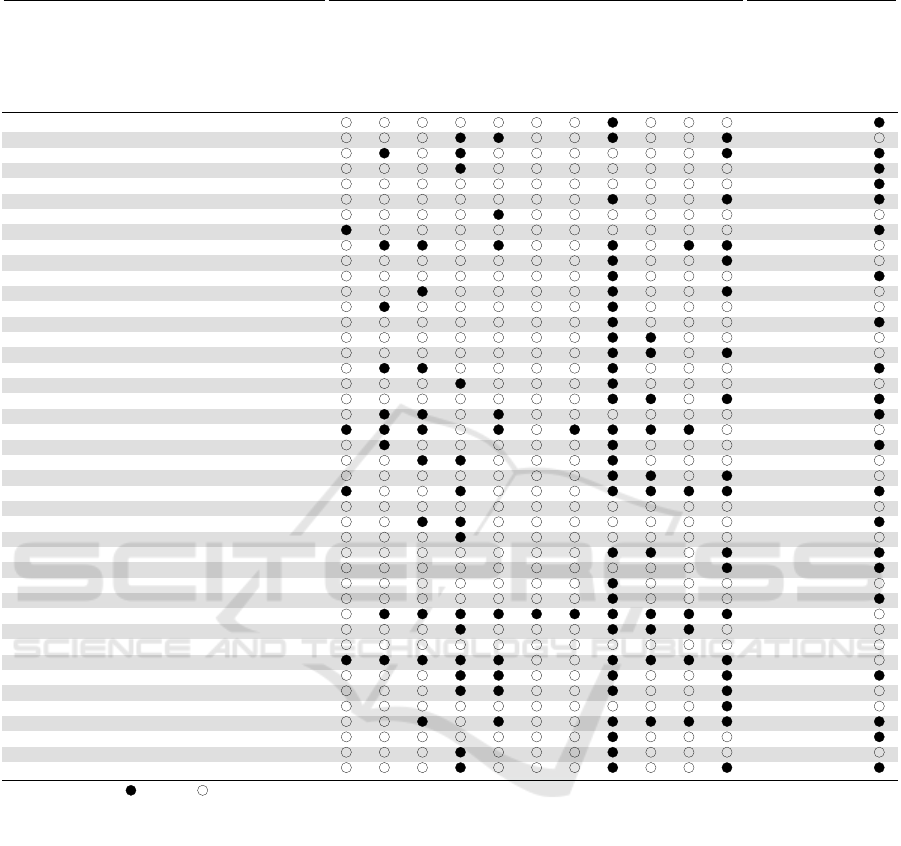

Goals. In the context of the CIA triad, confidentiality

(9), integrity (9), and availability (16) are mentioned.

Regarding information security, most publications re-

fer to authorization (10). Only three publications con-

sider non-repudiation (2) or accountability (1). Five

other non-standardized goals are described, including

reliability (6), authenticity (3), dependability (2), per-

formance (2), and robustness (1).

Threats and Risks. We found that threats and risks

are usually not described in detail. In general, issues

that threaten the security of the SMSS are typically

related to six categories: safety (13), communication

(7), configurability (7), access (6), privacy (4), and

trust (2). Note that publications may refer to more

than one category. 12 publications do not mention

any concrete threats or risks.

Vulnerabilities. The majority of the publications (32)

do not consider vulnerabilities. However, in 11 cases,

vulnerabilities that are closely related to threats and

ICSOFT 2024 - 19th International Conference on Software Technologies

326

risks are mentioned, e.g., misconfigurations.

Patterns. There are eight publications that propose

patterns that, however, vary greatly, e.g., due to dif-

ferent fields and use cases, including misuse cases (1)

or access control patterns (1).

Countermeasures. We identified various mitigation

techniques in 20 publications which we classified into

four categories: access control (8), system or data iso-

lation (6), general security analyses (3), and encryp-

tion mechanisms (2). Other countermeasures (5) in-

clude decentralization (1) or modularization (1).

5 DISCUSSION

In the following, we discuss our study results and

derive nine literature gaps (LG) to be addressed in

future research. We are aware that there are cur-

rently numerous approaches to dealing with security

in SMSS that have little or no context to PLE – and

thus usually also to configuring. Here, it should be

investigated to what extent such approaches can be

transferred to PLE. However, this would exceed the

scope of our study.

5.1 Configurable Smart-Manufacturing

Software Systems

Referring to the publications years, our results show

that there is an awareness of SMSS security in the

PLE community. However, this trend is decreas-

ing since 2021. Interestingly, a significant num-

ber of open items as contribution types (e.g., chal-

lenges) were described until 2017, while more meth-

ods and models were published between 2018 and

2020. Since 2021, the focus has been much more

on open items again. Specifically, current challenges

arise mainly in the handling of complexities (e.g.,

time, configuration), variability (e.g., variant man-

agement), knowledge management and artificial in-

telligence, and (testing) agile requirements. Thus,

(LG1) there is a need for novel solutions (i.e., meth-

ods, models, tools that address the solution space)

considering recent challenges of PLE-based SMSS

during their development life cycle.

While verification feature- and product-based ver-

ification strategies seem common for SMSS. So,

(LG2) there is a lack of family-based verification

techniques that could be used to assess secure func-

tionalities across the entire product portfolio and

identify potential vulnerabilities that may arise from

evolving configurations. Note that despite its bene-

fits, family-based verification faces challenges such

as modeling the interactions between features and

configurations, handling feature interactions, and ef-

ficiently verifying large product portfolios.

SMSS are constantly evolving, including chang-

ing requirements, features, and interactions, with in-

creasingly automated evolutionary processes (Capilla

et al., 2021). Although evolution is addressed in

about half of the publications, more and deeper anal-

yses are needed, especially since evolution is mostly

described in a rather superficial way and handling

configuration throughout updates is still highly chal-

lenging. Consequently, (LG3) there is a need for

concrete methodologies that can handle evolving con-

figurations, feature interactions, and dependencies –

without introducing new vulnerabilities (e.g., due to

faulty system configurations).

5.2 Security

Compliance with security standards can provide

a baseline level of protection for SMSS. However,

the consideration of general (e.g., ISO/IEC 27000

series) and domain-specific security standards (e.g.,

IEC 62443) is typically neglected in the PLE commu-

nity, impairing the successful transfer of SMSS ap-

proaches into practice. We argue that (LG4) there is

a need for mapping security standards to the security

engineering of the PLE framework. We are aware that

standard diversity means that it will hardly be possi-

ble to harmonize them in one single framework. Thus,

we assume that either dynamic frameworks or several

domain-dependent frameworks are required.

Surprisingly, the publications typically do not ad-

dress vulnerabilities, although their management is

an increasingly important field – especially in SMSS,

where vulnerability exploits may have fatal conse-

quences (e.g., system failure, reduced safety) (Yadav

et al., 2022). Consequently, (LG5) research is needed

that focuses on detecting and managing vulnerabili-

ties, especially in the context of the PLE framework.

Specialized variability and security modeling

tools are usually not mentioned by the publications.

Although there are tools, e.g., in the context of veri-

fying security configurations, (LG6) there still seems

to be a lack of appropriate tools for, as well as a lack

of awareness in the community since existing tools

are not or only rarely applied. So, there is a need

for accepted tool support that considers variable se-

curity concerns in the context of PLE activities that

are relevant to security and the unique requirements

of SMSS. Developing such tools may help automate

security tasks, such as avoiding typical threats and

risks in the context of system access or communica-

tion (cf. Figure 2). Such tools may also include the

application of appropriate security patterns as con-

Product-Line Engineering for Smart Manufacturing: A Systematic Mapping Study on Security Concepts

327

0

5

10

15

20

25

Occurences

Threats and risks

Non-repudiation

Accountability

Authorization

Availability

Integrity

Confidentiality

Figure 2: Distribution of security goals according to threats

and risks (multiple goals or threats and risks per paper).

crete security strategies for configurable systems.

5.3 Security and Configurable

Smart-Manufacturing Systems

Interestingly, most publications (88%) refer to SM

fields which are highly dependent on hardware and

software (e.g., cyber-physical production systems).

However, most research (65%) focuses solely on soft-

ware security although hardware security is equally

important in SM, especially in the context of safety-

critical systems. Thus, (LG7) specifically intercon-

nected hardware and software components with com-

plex cross-dependencies in particular, require secu-

rity mechanisms in comprehensive security manage-

ment throughout domain engineering, security engi-

neering, and application engineering.

We identified that (LG8) security in SMSS is typ-

ically addressed as a separate concern, rather than

integrating it into the PLE framework or PLE-related

activities for SMSS. The approaches may lead to in-

flexible security countermeasures that cannot adapt

to changing SMSS requirements and configurations.

We argue, that this fact might be problematic be-

cause SMSS are constantly evolving due to new tech-

nologies, feature interactions, and changing busi-

ness needs. Thus, traditional security countermea-

sures (e.g., mechanisms such as ownership and con-

trol) are hardly adequate (Uysal and Mergen, 2021).

Continuous adaptive risk-based assessment and real-

time decision-making enable appropriate adaptive re-

sponses at production level (i.e., cyber-physical pro-

cesses) and business level (i.e., business processes).

The results show that availability and authoriza-

tion are the most common security goals. This is not

surprising, as both are essential for ensuring and con-

trolling access to resources in SMSS. However, most

goals are often overlooked in PLE-based SMSS ap-

proaches, despite their critical role in achieving a reli-

able security level by addressing common threats and

risks (cf. Figure 2). To address this gap, (LG9) the lit-

erature needs more compliant approaches to achieve

standardized security levels in the context of the PLE-

based system life cycles.

5.4 Threats to Validity

There is an inconsistent level of detail as well as vary-

ing understandings of terms and concepts presented

within the set of publications (e.g., system availabil-

ity vs. security availability). Furthermore, some pub-

lications fulfill the extraction criteria from different

perspectives and to varying extents, leading to poten-

tial risks for misinterpretations. The search string we

created might not contain all the literature available

which addresses security in SMSS, possibly affecting

the external validity. To tackle the risk of misinter-

pretation, multiple researchers systematically investi-

gated the publications and discussed the result until

consensus on a decision was achieved. Moreover, be-

sides relying on three well-known databases, we addi-

tionally performed a snowballing process. In this way,

we were able to increase the first number of publica-

tions (38), making the extracted results more reliable

and valuable.

6 RELATED WORK

We found related research within the field of PLE

which (partly) covers several aspects regarding secu-

rity or SMSS. Montagud et al. (2012) did a literature

review (1996–2011) on quality attributes (i.e., includ-

ing security) and measures for general PLE. Mahdavi-

Hezavehi et al. (2013) presented a literature review

(2000–2011) regarding variability in service-based

software systems and considered security in a broad

quality-related term. Geraldi et al. (2020) investigated

publications related to the IoT and PLE (2006–2018),

considering security as a non-functional requirement

and manufacturing as an IoT application field. There

is a systematic literature review by Uysal and Mergen

(2021) (no restricted time frame) focusing on SM and

the integration of PLE enterprise architectures. Se-

curity is described in the context of the (adaptive) risk

and trust trend. In a mapping study conducted by May

et al. (2022) security concepts for PLE-related data

storages (2013–2022) are analyzed. They identified

the manufacturing domain as one important domain

when considering PLE and data storages.

We consider two studies as close to our work.

Kenner et al. (2021) did a mapping study on PLE

safety and security (2011–2020) and May et al. (2023)

ICSOFT 2024 - 19th International Conference on Software Technologies

328

focused on security in PLE-based safety-critical sys-

tems (2008–2022). Both publications share an ap-

proach similar to that of our work, which is why

they served as a general orientation for our method-

ology. There are partly content-related similarities to

our study (e.g., cyber-physical production systems),

however, none of the publications is specifically fo-

cused on SM, distinguishing their insights from ours.

We argue that our findings are of high value to the

research community as we highlight unique insights

based on a different body of knowledge.

7 CONCLUSION

We presented a systematic mapping study on the ex-

tent of security research in PLE-based SMSS. Specifi-

cally, we analyzed 43 publications and presented nine

relevant literature gaps. We argue that there is high

potential for research in terms of security within con-

figurable SMSS. Publications often address security

as a necessary but quite static feature that refers to

the quality of SM systems. However, threats, risks,

or vulnerabilities that may arise in configurable sys-

tems as well as related PLE activities are typically not

further specified. We highlight that security in PLE-

based SMSS seems underexplored, although there is a

lot of literature related to security exclusively for SM

(without any focus on PLE). There is great research

potential regarding the investigation of software and

hardware security as well as their cross-dependencies

throughout configurations, harmonized mappings of

security standards, and tools for managing threats,

risks, and vulnerabilities in PLE-based SMSS.

REFERENCES

Alani, M. M. and Alloghani, M. (2019). Security challenges

in the Industry 4.0 era. Industry 4.0 and Engineering

for a Sustainable Future.

Apel, S. et al. (2013). Feature-oriented software product

lines. Springer.

Arrieta, A. et al. (2015). Cyber-physical systems product

lines: Variability analysis and challenges. Jornadas

de Computaci

´

on Empotrada.

Bandyszak, T. et al. (2020). Orthogonal uncertainty mod-

eling in the engineering of cyber-physical systems.

Transactions on Automation Science and Engineer-

ing, 17(3).

Bennaceur, A. et al. (2019). Modelling and analysing re-

silient cyber-physical systems. In SEAMS. IEEE.

Bressan, L. et al. (2021). A variability modeling and trans-

formation approach for safety-critical systems. In Va-

MoS. ACM.

Brugali, D. and Hochgeschwender, N. (2018). Software

product line engineering for robotic perception sys-

tems. International Journal of Semantic Computing,

12(01).

Ca

˜

nete, A. (2019). Energy efficient assignment and deploy-

ment of tasks in structurally variable infrastructures.

In SPLC. ACM.

Ca

˜

nete, A. et al. (2020). Supporting the evolution of appli-

cations deployed on edge-based infrastructures using

multi-layer feature models. In SPLC. ACM.

Capilla, R. et al. (2021). On autonomous dynamic software

ecosystems. IEEE Transactions on Engineering Man-

agement, 69(6).

Daun, M. et al. (2019). Using view-based architecture de-

scriptions to aid in automated runtime planning for a

smart factory. In ICSA-C. IEEE.

de Oliveira, A. L. et al. (2019). Variability management in

safety-critical systems design and dependability anal-

ysis. Journal of Software: Evolution and Process,

31(8).

Ebnauf, M. et al. (2019). State-driven architecture design

for safety-critical software product lines. In ICOM.

IEEE.

Eichelberger, H. et al. (2014). EASy-producer: Product line

development for variant-rich ecosystems. In SPLC.

ACM.

Engstr

¨

om, E. and Runeson, P. (2011). Software product line

testing–a systematic mapping study. Information and

Software Technology, 53(1).

Etigowni, S. et al. (2016). CPAC: Securing critical infras-

tructure with cyber-physical access control. In AC-

SAC. ACM.

Feichtinger, K. et al. (2022). Industry voices on software

engineering challenges in cyber-physical production

systems engineering. In ETFA. IEEE.

Feldmann, S. and Vogel-Heuser, B. (2017). Interdisci-

plinary product lines to support the engineering in the

machine manufacturing domain. International Jour-

nal of Production Research, 55(13).

Fischer, S. et al. (2021). Testing of highly configurable

cyber-physical systems–A multiple case study. In Va-

MoS. ACM.

Fischer, S. et al. (2023). Testing of highly configurable

cyber–physical systems—-Results from a two-phase

multiple case study. Journal of Systems and Software,

199.

Galindo, J. A. et al. (2015). Supporting distributed product

configuration by integrating heterogeneous variability

modeling approaches. 62.

Garc

´

ıa, C. et al. (2015). A software process line for service-

oriented applications. In SAC. ACM.

Garc

´

ıa, S. et al. (2020). Robotics software engineering: A

perspective from the service robotics domain. In ES-

EC/FSE. ACM.

Geraldi, R. T. et al. (2020). Software product line applied to

the internet of things: A systematic literature review.

Information and Software Technology, 124.

Gherardi, L. et al. (2014). A software product line ap-

proach for configuring cloud robotics applications. In

CLOUD. IEEE.

Product-Line Engineering for Smart Manufacturing: A Systematic Mapping Study on Security Concepts

329

Hajri, I. et al. (2018). Change impact analysis for evolving

configuration decisions in product line use case mod-

els. Journal of Systems and Software, 139.

Heikkil

¨

a, T. et al. (2016). Dealing with configurability in

robot systems. In MESA. IEEE.

Islam, N. and Azim, A. (2018). Assuring the runtime be-

havior of self-adaptive cyber-physical systems using

feature modeling. In CASCON. ACM.

ISO/IEC 27000 (2018). Information technology – Security

techniques – Information security management sys-

tems. Standard, ISO.

ISO/IEC 27005 (2022). Information security, cybersecurity

and privacy protection – Guidance on managing infor-

mation security risks. Standard, ISO.

Jalil, D. and Bakar, M. S. A. (2017). Adapting software

factory approach into cloud ERP production model.

International Journal of Computer Science and Infor-

mation Security, 15(1).

Kang, H. S. et al. (2016). Smart manufacturing: Past re-

search, present findings, and future directions. In-

ternational Journal of Precision Engineering and

Manufacturing-Green Technology, 3.

Kenner, A. et al. (2021). Safety, security, and configurable

software systems: A systematic mapping study. In

SPLC. ACM.

Kokaly, S. et al. (2016). Model management for regulatory

compliance: A position paper. In VaMoS. ACM.

Krieter, S. et al. (2018). Towards secure dynamic product

lines in the cloud. In ICSE. ACM.

Kusiak, A. (2018). Smart manufacturing. International

Journal of Production Research, 56.

Larrucea, A. et al. (2017). Modular development and cer-

tification of dependable mixed-criticality systems. In

DSD. IEEE.

Mahdavi-Hezavehi, S. et al. (2013). Variability in quality

attributes of service-based software systems: A sys-

tematic literature review. Information and Software

Technology, 55(2).

May, R. et al. (2022). A systematic mapping study of secu-

rity concepts for configurable data storages. In SPLC.

ACM.

May, R. et al. (2023). A systematic mapping study on se-

curity in configurable safety-critical systems based on

product-line concepts. In ICSOFT. SciTePress.

May, R. et al. (2024). Vulnerably (mis)configured? Explor-

ing 10 years of developers’ Q&As on Stack Overflow.

In VaMoS. ACM.

McGee, E. T. et al. (2017). Designing for reuse in an in-

dustrial internet of things monitoring application. In

WASCHES. ACM.

Meinicke, J. et al. (2017). Mastering software variability

with FeatureIDE. Springer.

Meixner, K. (2020). Integrating variability modeling of

products, processes, and resources in cyber-physical

production systems engineering. In SPLC. ACM.

Meixner, K. et al. (2019). Towards modeling variability

of products, processes and resources in cyber-physical

production systems engineering. In SPLC. ACM.

Montagud, S. et al. (2012). A systematic review of qual-

ity attributes and measures for software product lines.

Software Quality Journal, 20.

Petersen, K. et al. (2015). Guidelines for conducting sys-

tematic mapping studies in software engineering: An

update. Information and Software Technology, 64.

Pett, T. et al. (2020). Risk-based compatibility analysis in

automotive systems engineering. In MODELS. ACM.

Qu, Y. J. et al. (2019). Smart manufacturing systems: State

of the art and future trends. The International Journal

of Advanced Manufacturing Technology, 103.

Seidl, C. et al. (2017). Challenges and solutions for opening

small and medium-scale industrial software platforms.

In SPLC. ACM.

Shaaban, A. M. et al. (2019). Ontology-based security tool

for critical cyber-physical systems. In Systems and

Software Product Line Conference. ACM.

Smiley, K. et al. (2015). Evolving an industrial analytics

product line architecture. In SPLC. ACM.

Th

¨

um, T. et al. (2014). A classification and survey of anal-

ysis strategies for software product lines. Computing

Surveys, 47(1).

Tuptuk, N. and Hailes, S. (2018). Security of smart manu-

facturing systems. Journal of Manufacturing Systems,

47.

Uysal, M. P. and Mergen, A. E. (2021). Smart manufac-

turing in intelligent digital mesh: Integration of enter-

prise architecture and software product line engineer-

ing. Journal of Industrial Information Integration, 22.

van der Linden, F. J. et al. (2007). Software product lines in

action. Springer.

Varela-Vaca,

´

A. J. et al. (2020). Definition and verification

of security configurations of cyber-physical systems.

In ESORICS. Springer.

Varela-Vaca,

´

A. J. et al. (2021). CARMEN: A framework

for the verification and diagnosis of the specification

of security requirements in cyber-physical systems.

Computers in Industry, 132.

Vogel-Heuser, B. et al. (2015). Evolution of software in au-

tomated production systems: Challenges and research

directions. Journal of Systems and Software, 110.

Vogel-Heuser, B. et al. (2022). Automation software ar-

chitecture in cpps-definition, challenges and research

potentials. In ICPS. IEEE.

Xiao, B. and Li, F. (2021). Knowledge-based formal mod-

eling for CPPS in personalized intelligent manufactur-

ing. In DASC. IEEE.

Yadav, G. et al. (2022). Vulnerability management in IIoT-

based systems: What, why and how. In Secure and

Trusted Cyber Physical Systems: Recent Approaches

and Future Directions. Springer.

Young, B. et al. (2017). Product line engineering meets

model based engineering in the defense and automo-

tive industries. In SPLC. ACM.

Zhang, Z. et al. (2018). CMfgIA: A cloud manufacturing

application mode for industry alliance. The Interna-

tional Journal of Advanced Manufacturing Technol-

ogy, 98.

Zheng, P. et al. (2018). Smart manufacturing systems for in-

dustry 4.0: Conceptual framework, scenarios, and fu-

ture perspectives. Frontiers of Mechanical Engineer-

ing, 13.

ICSOFT 2024 - 19th International Conference on Software Technologies

330