A Scalable Synthetic Data Creation Pipeline for AI-Based Automated

Optical Quality Control

Christian Schorr

1,2

, Sebastian Hocke

1

, Tobias Masiak

3

and Patrick Trampert

3

1

German Research Centre Artificial Intelligence, Saarland Informatics Campus D 3 2, 66123 Saarbrücken, Germany

2

University of Applied Sciences Kaiserslautern, Amerikastraße 1, 66482 Zweibrücken, Germany

3

Artificial Intelligence Lab, ZF Friedrichshafen AG, Scheer Tower II, Uni-Campus Nord, D5 2,

66123 Saarbrücken, Germany

Keywords: Synthetic Data, Digital Reality, Digital Twin, Defect Detection, Deep Learning, Quality Control, Computer

Vision, Visual Inspection, Simulation, Rendering.

Abstract: In recent years, the industry's interest in improving its production efficiency with AI algorithms has grown

rapidly. Especially advancement in computer vision seem promising for visual quality inspection. However.

the proper classification or detection of defects in manufactured parts based on images or recordings requires

large amounts of annotated data, ideally containing every possible occurring defect of the manufactured part.

Since some defects only appear rarely in production, sufficient data collection takes a lot of time and may

lead to a waste of resources. In this work we introduce a configurable, reusable, and scalable 3D rendering

pipeline based on a digital reality concept for generating highly realistic annotated image data. We combine

various modelling concepts and rendering techniques and evaluate their use and practicability for industrial

purposes by customizing our pipeline for a real-world industrial use case. The generated synthetic data is used

in different combinations with real images to train a deep learning model for defect prediction. The results

show that using synthetic data is a promising approach for AI-based automated quality control.

1 INTRODUCTION

Recent advancements in visual computing have

revolutionized how deep learning algorithms can be

used for industrial purposes. Especially automating

tasks like quality control can drastically improve the

efficacy and speed of production (J. Li et al., 2018; S.

Li & Wang, 2022; Wang et al., 2021). However,

introducing these kinds of models into active

production environments comes with its own set of

challenges.

One of the biggest issues of deep learning for

quality inspection in industrial environments is the

availability of annotated training data. There are

many different types of defects that can occur on

machine manufactured parts that need to be classified

to ensure proper quality of the produced good. While

some of these defects will occur more regularly in the

production environment, there are many others that

will only appear on rare occasions. It is almost

impossible to gather sufficient training data for every

possible defect shape, without spending a

considerable amount of time collecting and

annotating or wasting resources by recreating known

malformations on actual production parts.

Another aspect is the extensive annotation

process that is necessary to generate training datasets

containing similar amounts of data for each defect to

ensure class balance. Overall: the creation of a good

training dataset, which produces satisfactory results

when used for training deep learning algorithms, is a

costly and time-consuming undertaking.

A promising approach to eliminate these

obstacles is the generation of synthetic image data

using a digital reality concept (Dahmen et al., 2019).

Some common methods for the creation of synthetic

image data include generative adversarial networks

(Goodfellow et al., 2014) or using 3D models and

rendering techniques. Rendered annotated synthetic

images of production parts have already been used to

improve the performance of an algorithm for the

semantic segmentation of defects on a gear fork

(Gutierrez et al., 2021).

In this paper we will further elaborate on the

process of generating 3D rendered image data and

develop a generalizable and scalable pipeline to

Schorr, C., Hocke, S., Masiak, T. and Trampert, P.

A Scalable Synthetic Data Creation Pipeline for AI-Based Automated Optical Quality Control.

DOI: 10.5220/0012717400003758

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 14th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH 2024), pages 37-46

ISBN: 978-989-758-708-5; ISSN: 2184-2841

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

37

simplify the process. This will be demonstrated by

using the specific use case of a diaphragm spring

provided by the automotive supplier ZF

Friedrichshafen AG.

2 STATE OF THE ART

The automatization of quality inspection tasks during

the manufacturing process is typically done by

analysing images of the product using computer

vision and deep learning algorithms (Bhatt et al.,

2021). Common techniques include classification or

localisation of defects on images from the production

environment. This can be achieved, among other

methods, by training Convolutional Neural Networks

for object detection like YOLO (Redmon et al., 2016)

or R-CNN (Ren et al., 2017) but also segmentation

approaches such as U-NET (Ronneberger et al., 2015)

or Mask-R-CNN (He et al., 2020). However, deep

learning algorithms also face some major problems,

such as lack of sufficient and diverse data and

adaption to new and unseen environments, affecting

the generalization performance of the model

(Mazzetto et al., 2020). Due to the low probability of

occurrence for some anomalies, generating a

balanced dataset containing vast amounts of image

data for each defect is nearly impossible (Jain et al.,

2022).

To address these issues simulated data has been

studied for the use of pedestrian detection (Fabbri et

al., 2021), general object detection (Tremblay et al.,

2018), pose estimation (Chen et al., 2016) and many

other use cases, see (Schraml, 2019) and (Mumuni et

al., 2024) for further examples. Synthesizing image

data with 3D modelling tools enables the creation of

precisely controlled datasets with automatically

generated error-free annotations (de Melo et al.,

2022). The use of photorealistic synthetic images to

train semantic segmentation algorithms has also been

successfully applied to the visual inspection of

production parts (Gutierrez et al., 2021). Increased

realism of the synthetic training images has been

shown to have a significant impact on the

performance of Convolutional Neural Networks,

especially in combination with domain

randomization.

Domain randomization (Tobin et al., 2017) is a

technique that randomizes specific conditions inside

the simulation by randomizing the parameters, such

as colour, texture, position, and orientation, during

the data generation process. Borrego et al achieved

significant performance improvements applying this

technique by finetuning a model with synthetic image

data for multi-category object detection (Borrego et

al., 2018).

By exposing the model to a wide variation of data

and scenarios we aim to improve the domain adaption

of the deep learning model and prepare it for

unexpected situations in the manufacturing

environment.

The goal of domain adaption (Lee et al., 2020) is

to reduce the gap between real and synthetic data.

This is especially important when using different

domains for creating the model, such as using a

synthetic dataset for the training process and

generalizing the model on a real dataset. The

generation of a highly realistic synthetic dataset can

be achieved with 3D modelling software or rendering

solutions using physically accurate and GPU-

accelerated rendering solutions, such as Maxwell

Render 5, which is built on the Nvidia CUDA

computing platform (Maxwell Documentation, 2024).

The generation of the synthetic data itself follows

the concept of generative partial modelling, a

technique that simplifies the analysis of complex

systems by focusing on a specific set of features from

the real world. In our case this set of features consists

of the shape of the manufactured part, its location and

rotation in the production environment, the textures

including potential defects, as well as environmental

properties that affect the object, like lighting or the

camera setup.

3 MATERIALS AND METHODS

3.1 Digital Reality Concept

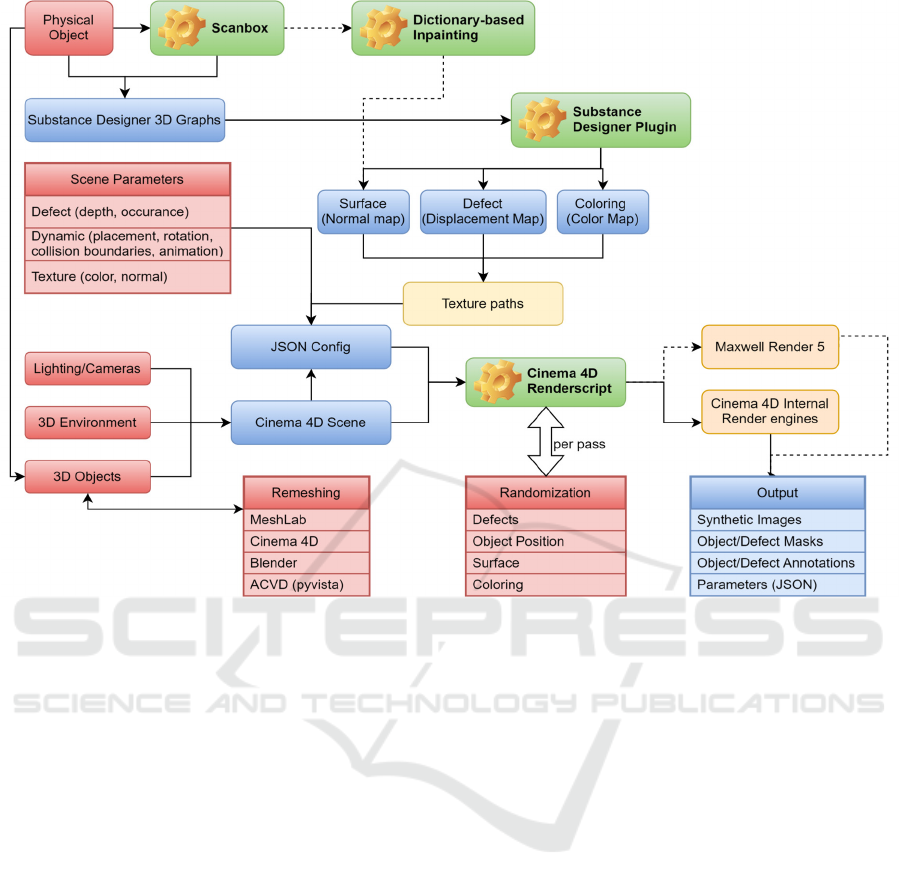

We base our simulation pipeline on the digital reality

concept (Dahmen et al., 2019). The idea behind this

concept is to build parametrizable partial models

governing geometry, textures, lighting, camera

settings and defects among others, which can be

combined in a modular way into a generative scenario

describing all aspects of the object and its

environment we want to simulate (figure 1). This

scenario model acts as a digital twin that can be

sampled using different parametrizations of the

partial models to obtain an arbitrary amount of

rendered training images with the desired properties

for subsequent AI model training. Partial models we

want to describe in greater detail in this section are

the geometric model of the object's shape (section

3.2), its surface texture model (section 3.3) and the

defect model of possible manufacturing faults

(section 3.4).

SIMULTECH 2024 - 14th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

38

Figure 1: Digital reality concept diaphragm spring.

For the digital twin we use techniques like texture

and geometry parameterisation, procedural texture

synthesis, parametric damage modelling and

characterization, as well as deep learning for defect

detection to evaluate the quality of the synthesised

dataset. The following sections describe the

development and implementation of these techniques

based on creating a digital twin of a diaphragm spring

provided by ZF Friedrichshafen AG. With the help of

this production part, we design our synthetic data

creation pipeline to be scalable and usable for

different real-world production scenarios.

3.2 Geometry Modelling

The 3D model of the digital twin of the production

environment is realized in Maxon Cinema 4D R21.

The simulation environment is created based on

images and information about the size and position of

the object it contains. The position of the lighting and

other influences that affect the component to be

simulated are particularly important to be able to

recreate a representation as physically accurate as

possible. The object itself is then placed in this digital

twin of the production environment and is properly

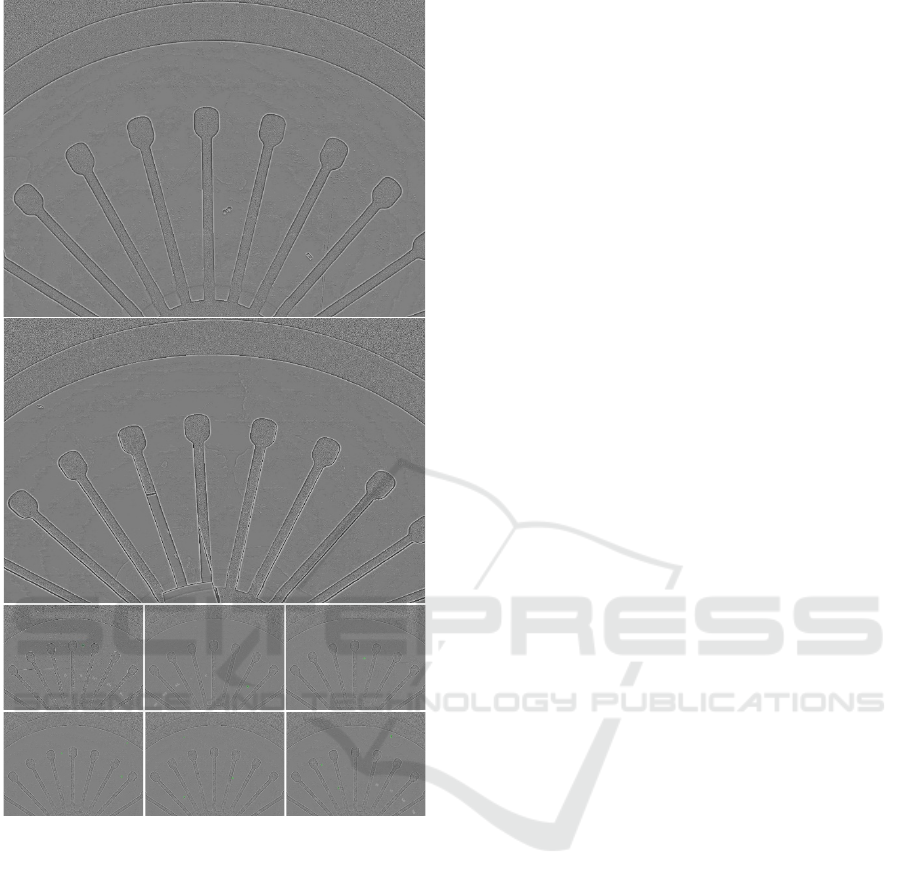

Figure 2: Cinema 4D scene and viewport rendering.

aligned based on real images. Figure 2 shows an

exemplary placement and rendering of the diaphragm

spring inside the Cinema 4D viewport.

We use the Cinema 4D dynamic simulation

feature for the correct positioning of the object to

avoid polygon overlapping. For the simulation and

modelling of realistic surfaces for the diaphragm

spring, we use various texture mapping techniques as

part of the automation process to represent complex

and customisable materials in the synthetic

environment. To compute these textures in a

reproducible and automatable process, we use tools

and algorithms available in the software Substance

Designer 3D from Adobe.

3.3 Defect Modelling

The creation of realistic surface defects requires a

precise characterisation of all damage types that could

occur in the production. Ideally, a material scientific

model for the defect formation and shape is available.

In real life, this is almost never the case, so we must

manage with images of real defects only, which again

are often only available in a very limited quantity. For

our use case, we use a defect catalogue provided from

ZF Friedrichshafen AG, containing images of real

defects from the production line, as well as several

physical diaphragm springs to gain an understanding

of the different defect forms. These can range from

scratches and small indents to material inclusions or

broken-out material. To simulate the defects on the

surface of the virtual object, we use the displacement

mapping technique (Cook, 1984).

Geometry

- Polygon model

- Placement

- Quantity

Camera

- Parameters

- Orientation

- Placement

Lighting

- Angle

- Intensity

-Temperature

Defects

- Form

-Depth

- Positioning

Textures

- Parameters

- Surface depth

- Generation

Dynamic

simulation

- Animation

- Collision

- Movement

A Scalable Synthetic Data Creation Pipeline for AI-Based Automated Optical Quality Control

39

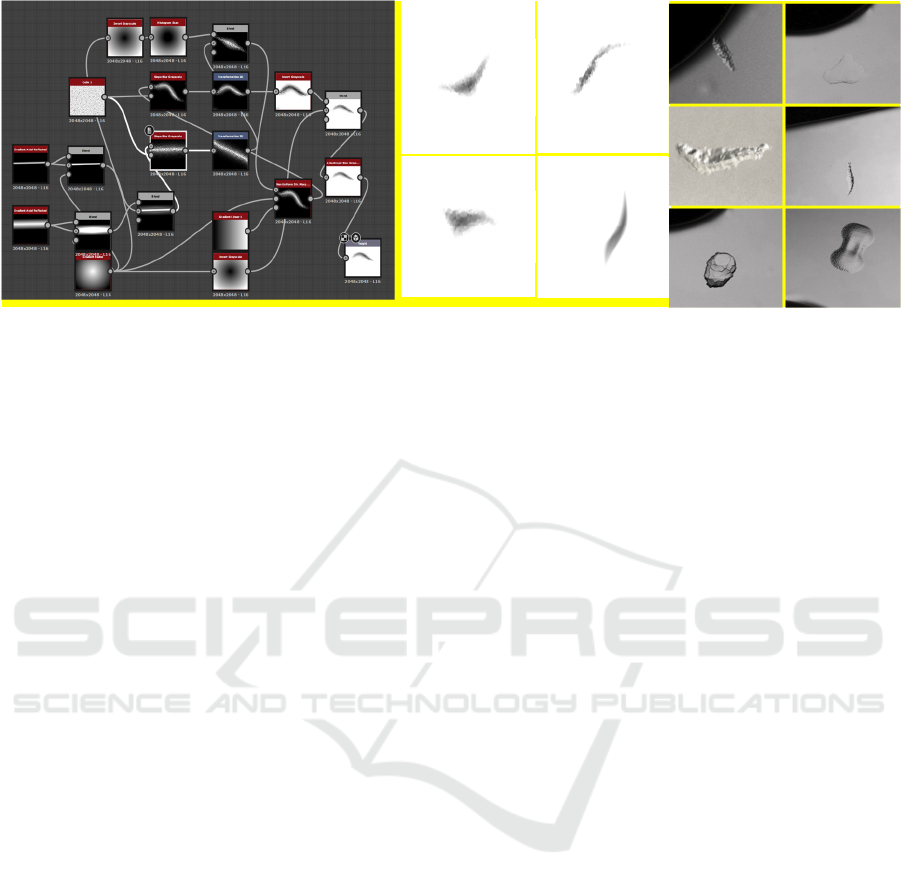

Figure 3: Structure of the Substance Designer 3D defect creation workflow, resulting defect textures and rendered examples.

In our case, this approach starts with the defect-

free surface of a three-dimensional object and

modifies it to add defects. An 8-bit RGB texture

called a displacement map or height map is used for

this purpose, which contains information about the

displacement of the polygon mesh at every point in

the form of a grey value in each pixel. As the actual

polygon mesh of the object is changed during

displacement mapping, the number of polygons may

have to be greatly increased to create a realistic and

detailed surface.

This technique improves reflection effects and

ensure that the surface deviation of defects is always

visible, even if they are viewed from a steep angle.

For the generation of the displacement maps we

utilize the software Substance Designer 3D from

Adobe, which allows us to procedurally generate

complex surfaces and materials through a node-based

workflow (figure 3). The individual nodes consist of

various mathematical image operations, which are

connected in series to model the corresponding defect

from a basic geometric shape. The nodes were

selected in such a way that a change of individual

values within the image processing operation has

comprehensible effects on the displacement maps

created to obtain an estimate of the extent to which

these can be changed so that as many different

realistic variants of the modelled defect as possible

can be created. This automation technique is based

entirely on the procedural modification of individual

values within the nodes.

To simplify the automation process, a Python

plugin for Substance Designer was developed, which

offers simple customisation options for adapting the

generation process to new defects or other Substance

Designer graphs. The plugin is configured via a JSON

file that contains information or IDs of the individual

mathematical operations, the corresponding

variables, and a list of possible values. Within the

automatic process, each node configured in the JSON

file is iterated over and the graph is recalculated for

each value used, thus generating an arbitrary number

of output textures. The advantage of this procedural

process is that the resulting displacement maps are

precisely defined by a suitably selected graph,

duplicates can be avoided, and the result is

correspondingly predictable.

The resulting displacement maps for the defects

must now be applied to the texture corresponding to

the correct location on the diaphragm spring. This

requires mapping the 3D mesh of the object to a 2D

texture, which we realized within Cinema 4D´s UV

editor.

For the placement of the defect, we developed a

comprehensible python workflow, executable in

Jupyter notebooks. For this, we first need to mark all

polygons of the 3D object, where a defect can occur.

The script can then be used to export this selection

into a mask and automatically scale and place the

defect texture within the exported mask on the final

displacement texture for the object.

3.4 Texture Modelling

Besides the damage modelling, we also need textures

to control the reflections and colouring of the

simulated object and environment, to achieve a

realistic result. For this reason, we expanded the

functionality of our defect generation Python plugin

to be able to automate all kinds of texture graphs.

Substance Designer's extensive library makes it easy

to find suitable textures, manipulate and randomize

them in a targeted manner.

In case of the simulation of the diaphragm spring,

which is made of slightly reflective steel with some

production induced discolorations, we need two

SIMULTECH 2024 - 14th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

40

components - a colour map and a normal map. The

colour map will be used to simulate blemishes on the

surface that do not indent the diaphragm spring itself

in a significant way. The normal map will simulate

deeper indents and impurities that affect the depth of

the surface but still are not classified as defect.

Normal mapping is a texturing technique that

simulates the appearance of dents and bumps without

changing the actual polygon mesh (Cignoni et al.,

1998). It uses a normal map to change the way the

surface reflects light by storing the alignment of the

surface normal in each pixel as a RGB value that

corresponds directly to the x, y, and z coordinates of

the 3D environment.

Realistic normal maps play a key role for the

variety of the synthetic dataset, since we use them to

simulate imperfections on the surface which are not

classified as a defect and should not be identified as

such by our deep learning model. A multitude of

different normal maps should therefore reduce the

number of false positives detected by the model. For

the basis of the normal map, we characterized the

surface of numerous real diaphragm springs, as well

as the images from the real dataset from the

production line. This resulted in multiple different

Substance Designer 3D graphs, each highlighting

distinct aspects of the surface for more individual

control. For example, small scratches that can occur

during machining were simulated by generating

random splines on the surface, specks of dirt by

overlaying randomly generated grunge maps, or the

surface composition itself by choosing different

combinations of noise generators.

Each of these workflows is then automated with

the help of our Substance Designer plugin, for which

we specify the values that can occur within individual

nodes in a configuration file for each graph.

For the stamped part number on the diaphragm

spring, we utilized Cinema 4D´s bump mapping

feature, which uses a technique similar to normal

mapping, but is configured via grayscale values

instead of RGB information and is available inside a

different material channel. The bump maps were

generated by placing random numbers along a spline

corresponding to the location, where the stamp can

occur on the diaphragm spring´s texture.

Afterwards we selected some generated textures

from each automated texture graph and inserted them

into the Cinema 4D material for the diaphragm

spring, to ensure that they achieve the desired effect.

1

Maxon Cinema 4D R23 Handbook: Material Editor:

Reflectance

Figure 4: Rendered image/defect mask/object mask.

This also helps finding the right configuration for

the material settings, so we can finetune different

materials for specific visual effects for later

automation purposes. For the reflection layer of the

material, the GGX reflection model is used together

with the metal absorption presetting. This model is

particularly suitable for simulating metallic surfaces

1

.

3.5 Rendering Pipeline

Finally, the components created from the previously

developed methods are combined and assembled in

an automatic pipeline to generate the desired

synthetic image data of the diaphragm spring.

We developed two approaches to automate this

process with either Cinema 4D´s internal render

solutions or Maxwell Render 5´s engine. Although

these two methods overlap in their basic

functionality, they offer different advantages and

disadvantages when customised more precisely for

different production parts or processes.

Our first approach utilizes the Python API of

Maxwell Render 5 in combination with the digital

twin exported from Cinema4D. It is parametrized via

a configuration file, from where all elementary

functions of the Python automation script can be

accessed. We chose this variable configuration

concept for better scalability, so that new functions or

scenarios can be implemented into our automation

script with little effort. Furthermore, this concept

allows us to easily run the automation script on a

separate rendering server and profit from the GPU

Render Engine from Maxwell Render to minimize the

required runtime.

The current configuration file can be divided into

the following broad parent categories for configuring

and randomising the simulation. It contains the paths

to all the folder and files necessary for the simulation,

such as texture and output directories, settings to

configure which textures should be randomized and

the range within the texture parameters can be

changed, dynamic simulation parameters that affect

the physical environment, such as object rotation and

placement, configuration options for automatically

A Scalable Synthetic Data Creation Pipeline for AI-Based Automated Optical Quality Control

41

Figure 5: Flowchart of the rendering pipeline.

generated annotations, including options for multiple

object and defects and settings that affect the

rendering process, such as number of renderings,

render quality settings and additional command line

arguments for the render engine.

To improve the physical accuracy of the rendered

images, the basis for a simple simulation of the

physical properties of the environment was created.

This means that basic rules for placing the objects in

the scene can be defined in the configuration file in

such a way that overlapping polygon meshes of the

objects can be minimised or completely excluded.

This also makes it possible to create simulations with

multiple objects in which the objects can be randomly

distributed in the scene.

For each object and defect in the scene, a mask

with the respective segmented defect or object is

output for each rendered image (figure 4), as well as

a text file containing information about the

corresponding bounding box in YOLO PyTorch TXT

format.

The second automation approach we created

relies purely on Cinema 4D and its internal render

solutions. This development was initiated in order to

have more direct customizations of the Cinema 4D

scene or simulation itself available, as the Python

interface of Cinema 4D offers a few more

configuration options than that of the Maxwell

Render engine.

In addition, one of the Cinema 4D internal render

engines can be used for certain components, which

reduces the required runtime of the automatic

rendering process in some cases. The use of the

dynamic simulation engine opens further possibilities

for the physically accurate placement of objects

within a scene and can also be used in conjunction

with the Maxwell render script, for more realistic

lighting conditions in the final rendering. Cinema 4D

offers far more configuration options for materials,

making it possible to customise the finer details of the

materials and surfaces and add specific markings or

effects to the rendered industrial component. It is also

possible to use other functions of Cinema 4D, such as

the creation of animation videos or the use of various

generators for modelling objects/scenes during the

rendering process. The basic concept of the Cinema

4D automation script is still very similar to the

Maxwell script and offers, among other things, the

same functions. The configuration is carried out via a

config file, the Cinema 4D scene itself and the

textures required for randomisation.

SIMULTECH 2024 - 14th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

42

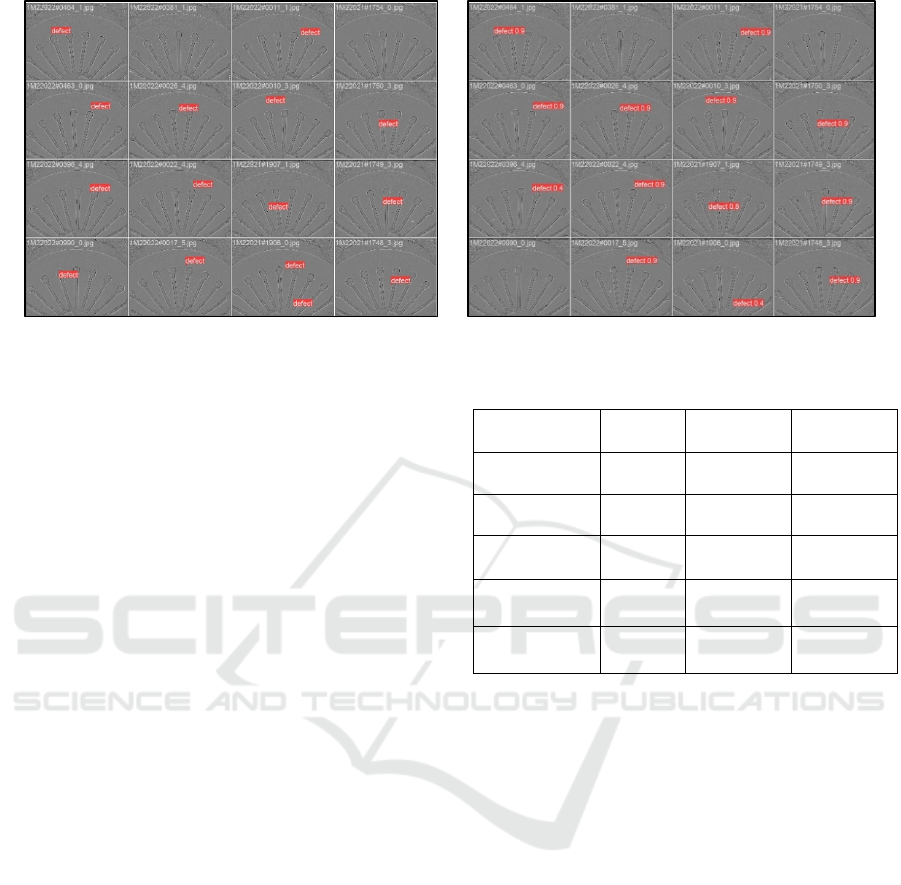

Figure 6: Synthetic images with different defects and

normal maps generated by the rendering pipeline.

As output, we receive the rendered image, a

binary mask for each object and defect in the scene

and a JSON file for each image. The mask(s) for the

defect(s) are created by automatically going through

an additional rendering pass, where all textures,

except for the displacement map are removed, leading

to a rendering where only the defects are illuminated.

The mask(s) for the object(s) are generated by using

Cinema 4D´s own multiple-render-pass function,

which will create a mask for each specified object.

The JSON file, contains information about rendering

parameters, including textures used, strength of

normal map and bump mapping, as well as the

strength of the defect.

For the synthetic dataset, which is used for

supplementing the real dataset, we generated images

with the same configuration, but a different lighting

environment and processed them with the help of

another script to simulate the image process that is

already used in the real production. Figure 6

showcases some rendered image examples of the

diaphragm spring with different automatically

generated defects and normal maps from the resulting

synthetic dataset.

3.6 Automated Defect Detection

There are many deep learning architectures suitable

for detecting defects. Due to the precise information

on the position of the defects, which is simulated and

annotated with the help of the synthetic data, it was

decided to localise the defects to simplify subsequent

manual quality checks of the predictions.

Object detection algorithms such as YOLO (Redmon

et al., 2016) or R-CNN (Ren et al., 2017), but also

segmentation approaches such as U-NET

(Ronneberger et al., 2015) or Mask-R-CNN (He et al.,

2020) are suitable for such purposes.

With respect to the fact that the synthetic data can

later be used to supplement real data from the

production, the creation of the model for the pipeline

was based on the conditions of the production

environment and existing real image data from this

environment. For this purpose, we were provided a

real image data set with images from the current

production as well as a defect catalogue containing

information on which surface anomalies have already

been classified as defects on the diaphragm springs.

The real images were manually annotated using

the defect catalogues by marking each defect with a

bounding box, so that the resulting real dataset can be

used to train deep learning models for object

detection. This dataset is used to train a baseline

model, which was exclusively trained with real data

from the production, as well as to evaluate the models

that were trained with the synthetic dataset and to

create a supplemented dataset containing real-world

and synthetic data.

To conduct initial tests, the deep learning model

"YOLOv8" from Ultralytics (Jocher et al., 2023) was

used. We chose this model for its low hardware

resource consumption for inference, its fast inference

rate and easy-to-use configuration options. We expect

that Mask-R-CNN or U-NET models will perform

comparably on the data set. Note that the focus of this

paper is the simulation pipeline and not an optimized

defect detection model, therefore we show only first

results on the impact of adding synthetic data.

A Scalable Synthetic Data Creation Pipeline for AI-Based Automated Optical Quality Control

43

Figure 7: Defect detection Real + Synthetic V2: Ground Truth (left) / Prediction with Confidence (right).

The real image dataset from production used for

training consisted of a total of 231 images, 105 of

which were used for validation. A total of 300 images

were generated for the basic synthetic dataset, of

which 100 were without defects, 75 with multiple

defects and 125 with single defects. The second

version of the synthetic dataset was further

supplemented with 100 more single defect images

and 100 more images with multiple defects.

To assess the quality of the synthetic data in

comparison to the real-world data, the models were

trained with different datasets, and each evaluated

with the same validation data set consisting of 105

real-world images. The first model "Real" was trained

exclusively with real images from production,

"Synthetic v2" only with synthetic image data and for

the model "Real + Synthetic v1" and "Real +

Synthetic v2" these two training data sets were

combined.

All models were trained for 200 epochs, with an

image size of 1408x1408 pixels, a batch size of 32

and the SGD Optimiser (learning rate initial: 0.1,

learning rate final: 0.01). Since the defects were quite

small on the real production images, it was necessary

to use such a high image resolution for the training

process. For the evaluation of the resulting models,

we used the metrics Mean Average Precision at an

Intersection of Union threshold of 0.5, Precision and

Recall.

Based on the results in Table 1 it can be observed

that supplementing the real data set with the synthetic

image data in the "Real + Synthetic v1" model

improves the precision, while in "Real + Synthetic

v2" all of the three evaluation metrics improved

compared to the "Real" model. This improvement is

important when it comes to real production use of

such a model.

Table 1: Evaluation metrics of the training.

Dataset mAP Precision Recall

Real 0.672 0.703 0.655

Synthetic v1 0.207 0.268 0.306

Synthetic v2 0.343 0.428 0.575

Real +

S

y

nthetic v1

0.751 0.885 0.616

Real +

S

y

nthetic v2

0.785 0.911 0.658

To properly implement the model in an active

environment, we will still need to evaluate on more

real-world data and generate suitable and especially

more synthetic image data. Although the mAP of the

“Synthetic v2” model which was exclusively trained

on synthetic data is significantly lower, when

compared to the “Real” model, it also shows that the

synthetic data is quite close to the real data, since the

model can detect defects on the real data to some

degree. This also indicates that we can use synthetic

data to train a model to recognize defects it has never

seen before on real data. Note that these tests were

performed with the goal of assessing the impact of

using synthetic data and not of fine-tuning the model

for peak performance. Additional hyperparameter

optimization is expected to improve the metrics

further. Increasing the amount of synthetic data

further will also bring additional improvements.

4 CONCLUSION & OUTLOOK

In this work we presented a digital reality pipeline to

create synthetic image data that can be applied to

SIMULTECH 2024 - 14th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

44

visual quality inspection. We demonstrated that our

approach can be used to train deep learning models

and improve the performance of models when used in

combination with real data.

The digital reality pipeline is designed for low

manual configuration effort allowing for a quick,

affordable, and thus broad use in industry. We have

analysed numerous processes and previous

developments in this area, adapted and improved

them, and combined these methods in a toolbox to

enable easy implementation for different production

parts. The main advantage of our approach compared

to other simulation tools lies in the implementation of

the modular digital reality concept. The next step is to

conduct a comprehensive study with different types

of objects and more synthetic data in combination

with fine-tuning the object detection models to

elaborate on the preliminary results described in

section 3.6. Furthermore, the processes for synthetic

data generation and defect detection described in the

previous sections are suitable for integration as an

automated visual quality control system into an active

production environment. This requires a continuous

process to allow the defect detection model to be

improved or enriched with new data. An example of

this would be training with a new defect type that only

occurred on the object after the model has been

deployed. The digital reality concept of using partial

models reduces the workload of integrating this new

defect type to parameterising the defect model

accordingly and finetuning the deep learning model

with the newly generated data. In the future, we aim

to further evaluate the pipeline with additional use

cases and an integration study in a real production

environment.

ACKNOWLEDGEMENTS

Part of this research has been funded by the Ministry

of Economics, Innovation, Digitalisation and Energy

of Saarland under grant number D/2-ML-

SYNTHOM-7/2022.

REFERENCES

Bhatt, P. M., Malhan, R. K., Rajendran, P., Shah, B. C.,

Thakar, S., Yoon, Y. J., & Gupta, S. K. (2021). Image-

Based Surface Defect Detection Using Deep Learning:

A Review. Journal of Computing and Information

Science in Engineering, 21(4). https://doi.org/

10.1115/1.4049535

Borrego, J., Dehban, A., Figueiredo, R., Moreno, P.,

Bernardino, A., & Santos-Victor, J. (2018). Applying

Domain Randomization to Synthetic Data for Object

Category Detection. http://arxiv.org/abs/1807.09834

Chen, W., Wang, H., Li, Y., Su, H., Wang, Z., Tu, C.,

Lischinski, D., Cohen-Or, D., & Chen, B. (2016).

Synthesizing Training Images for Boosting Human 3D

Pose Estimation. 2016 Fourth International

Conference on 3D Vision (3DV), 479–488.

https://doi.org/10.1109/3DV.2016.58

Cignoni, P., Montani, C., Rocchini, C., & Scopigno, R.

(1998). A general method for preserving attribute

values on simplified meshes. Proceedings Visualization

’98 (Cat. No.98CB36276), 59–66. https://doi.org/

10.1109/VISUAL.1998.745285

Cook, R. L. (1984). Shade Trees. Computer Graphics

(ACM), 18(3), 223–231. https://doi.org/10.1145/

964965.808602

Dahmen, T., Trampert, P., Boughorbel, F., Sprenger, J.,

Klusch, M., Fischer, K., Kübel, C., & Slusallek, P.

(2019). Damen et al. (2019). Digital reality. A model-

based approach to supervised learning from synthetic

data.pdf. 1–12.

de Melo, C. M., Torralba, A., Guibas, L., DiCarlo, J.,

Chellappa, R., & Hodgins, J. (2022). Next-generation

deep learning based on simulators and synthetic data.

Trends in Cognitive Sciences, 26(2), 174–187.

https://doi.org/10.1016/j.tics.2021.11.008

Fabbri, M., Brasó, G., Maugeri, G., Cetintas, O., Gasparini,

R., Ošep, A., Calderara, S., Leal-Taixé, L., &

Cucchiara, R. (2021). MOTSynth: How Can Synthetic

Data Help Pedestrian Detection and Tracking? 2021

IEEE/CVF International Conference on Computer

Vision (ICCV), 10829–10839. https://doi.org/

10.1109/ICCV48922.2021.01067

Goodfellow, I., Pouget-Abadie, J., Mirza, M., Xu, B.,

Warde-Farley, D., Ozair, S., Courville, A., & Bengio,

Y. (2014). Generative Adversarial Nets. In Z.

Ghahramani, M. Welling, C. Cortes, N. Lawrence, & K.

Q. Weinberger (Eds.), Advances in Neural Information

Processing Systems (Vol. 27). Curran Associates, Inc.

https://proceedings.neurips.cc/paper_files/paper/2014/f

ile/5ca3e9b122f61f8f06494c97b1afccf3-Paper.pdf

Gutierrez, P., Luschkova, M., Cordier, A., Shukor, M.,

Schappert, M., & Dahmen, T. (2021). Synthetic training

data generation for deep learning based quality

inspection. https://doi.org/10.1117/12.2586824

He, K., Gkioxari, G., Dollár, P., & Girshick, R. (2020).

Mask R-CNN. IEEE Transactions on Pattern Analysis

and Machine Intelligence, 42(2), 386–397.

https://doi.org/10.1109/TPAMI.2018.2844175

Jain, S., Seth, G., Paruthi, A., Soni, U., & Kumar, G. (2022).

Synthetic data augmentation for surface defect

detection and classification using deep learning.

Journal of Intelligent Manufacturing

, 33(4), 1007–

1020. https://doi.org/10.1007/s10845-020-01710-x

Jocher, G., Chaurasia, A., & Qiu, J. (2023). Ultralytics

YOLOv8. https://github.com/ultralytics/ultralytics

Lee, S., Park, E., Yi, H., & Lee, S. H. (2020). StRDAN:

Synthetic-to-real domain adaptation network for

A Scalable Synthetic Data Creation Pipeline for AI-Based Automated Optical Quality Control

45

vehicle re-identification. IEEE Computer Society

Conference on Computer Vision and Pattern

Recognition Workshops, 2020-June, 2590–2597.

https://doi.org/10.1109/CVPRW50498.2020.00312

Li, J., Su, Z., Geng, J., & Yin, Y. (2018). Real-time

Detection of Steel Strip Surface Defects Based on

Improved YOLO Detection Network. IFAC-

PapersOnLine, 51(21), 76–81. https://doi.org/10.1016/

j.ifacol.2018.09.412

Li, S., & Wang, X. (2022). YOLOv5-based Defect

Detection Model for Hot Rolled Strip Steel. Journal of

Physics: Conference Series, 2171(1), 1–7.

https://doi.org/10.1088/1742-6596/2171/1/012040

Maxwell Documentation. (2024). https://nextlimitsupport.

atlassian.net/wiki/spaces/maxwell/pages/22683383/GP

U+engine

Mazzetto, M., Teixeira, M., Rodrigues, É. O., & Casanova,

D. (2020). Deep Learning Models for Visual Inspection

on Automotive Assembling Line. International Journal

of Advanced Engineering Research and Science, 7(3),

473–494. https://doi.org/10.22161/ijaers.74.56

Mumuni, A., Mumuni, F., & Gerrar, N. K. (2024). A survey

of synthetic data augmentation methods in computer

vision. https://arxiv.org/abs/2403.10075v2

Redmon, J., Divvala, S., Girshick, R., & Farhadi, A. (2016).

You Only Look Once: Unified, Real-Time Object

Detection. 2016 IEEE Conference on Computer Vision

and Pattern Recognition (CVPR), 779–788.

https://doi.org/10.1109/CVPR.2016.91

Ren, S., He, K., Girshick, R., & Sun, J. (2017). Faster R-

CNN: Towards Real-Time Object Detection with

Region Proposal Networks. IEEE Transactions on

Pattern Analysis and Machine Intelligence, 39(6),

1137–1149. https://doi.org/10.1109/TPAMI.2016.2577

031

Ronneberger, O., Fischer, P., & Brox, T. (2015). U-net:

Convolutional networks for biomedical image

segmentation. Lecture Notes in Computer Science

(Including Subseries Lecture Notes in Artificial

Intelligence and Lecture Notes in Bioinformatics),

9351. https://doi.org/10.1007/978-3-319-24574-4_28

Schraml, D. (2019). Physically based synthetic image

generation for machine learning: a review of pertinent

literature. September 2019, 51. https://doi.org/10.1117/

12.2533485

Tobin, J., Fong, R., Ray, A., Schneider, J., Zaremba, W., &

Abbeel, P. (2017). Domain randomization for

transferring deep neural networks from simulation to

the real world. IEEE International Conference on

Intelligent Robots and Systems, 2017-Septe, 23–30.

https://doi.org/10.1109/IROS.2017.8202133

Tremblay, J., Prakash, A., Acuna, D., Brophy, M., Jampani,

V., Anil, C., To, T., Cameracci, E., Boochoon, S., &

Birchfield, S. (2018). Training Deep Networks with

Synthetic Data: Bridging the Reality Gap by Domain

Randomization. 2018 IEEE/CVF Conference on

Computer Vision and Pattern Recognition Workshops

(CVPRW), 1082–10828. https://doi.org/10.1109/CV

PRW.2018.00143

Wang, Y., Hao, Z., Zuo, F., & Pan, S. (2021). A fabric

defect detection system based improved YOLOv5

detector. Journal of Physics: Conference Series,

2010(1). https://doi.org/10.1088/1742-6596/2010/1/0

12191

SIMULTECH 2024 - 14th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

46