Regression Equations for Preliminary Dimensioning of Axial

Compressor Discs

O. V. Baturin

a

, E. D. Gataullina

b

, E. S. Goryachkin

c

, S. A. Melnikov

d

and Liu Xin

e

Department of Aircraft Engine Theory, Samara National Research University, 34 Moskovskoe Highway,

Samara, Russian Federation

Keywords: Axial Compressor, Compressor Discs, Dimensions, Statistical Analysis, Conceptual Design.

Abstract: In compressor design today, the process of obtaining disc parameters at the first steps is poorly formalised.

This process is often determined by the experience of the designer and is not very predictable. As a result, it

is possible to estimate compressor efficiency during design calculation, but determination of compressor

mass and strength factors is often difficult or is performed using approximate formulas. The authors of the

paper proposed to use regression formulae derived from statistical processing of a database of dimensionless

parameters of more than 20 different gas turbine engines from different countries. Relying on the obtained

regularities, it is possible to get a sketch of the disc in the meridional plane and to estimate its mass and

strength using a semi ring model by means of the design gas-dynamic calculation model. As a result, even at

the first steps of compressor design the engineer has an opportunity to screen out obviously unacceptable

variants and choose the best option not only by efficiency criteria. The selected option will require fewer

refinements in the future, which will reduce the number of iterations in the design process and minimise

design time and costs.

a

https://orcid.org/0000-0002-7674-6496

b

https://orcid.org/0009-0008-0431-6471

c

https://orcid.org/0000-0002-3877-9764

d

https://orcid.org/0000-0002-0170-3846

e

https://orcid.org/0000-0002-3137-8247

1 INTRODUCTION

In all methods for designing axial compressors of

gas turbine engines (GTE) known to the authors the

criterion for optimizing the design at the 1D

calculation stage is their gas-dynamic efficiency

(efficiency). [Belousov A. (2006), Cumpsty A.

(2004), Falck N. (2008), Gallimore S. J. (1999)]

However, as is known, when designing compressors,

they are subject to not only efficiency requirements,

but also weight, strength, design, manufacturability,

etc. [Inozemtsev A. (2022), Mattingly, J. D. (2002)].

Existing 1D compressor design methods take into

account other criteria, usually at the level of size

limitations and statistical dependencies, which is not

enough for a reliable assessment of these criteria.

For this reason, a proposal was made to generate

sketches of the discs in the first (rough)

approximation for the compressor flow path variants

obtained in the design calculation. The known shape

of discs will allow not only to estimate their mass

more accurately, but also to carry out a simplified

assessment of strength criteria using a semi ring

model. Thus, during the initial design steps, the

designer will receive not only the gas-dynamic

properties of the compressor together with the flow

path shape, but will also be able to estimate their

masses and strength factors quite accurately (more

accurately than existing regression dependencies).

As a result, it is possible to perform multi-criteria

optimisation of compressors at the design step and to

screen out high mass and low reliability (high stress)

options at an early step. This will result in a high

quality variant that will be an excellent starting point

for further 3D calculations, reducing the number of

necessary calculations performed with high-level

models that require a large amount of computation

time and computational resources.

Baturin, O., Gataullina, E., Goryachkin, E., Melnikov, S. and Xin, L.

Regression Equations for Preliminary Dimensioning of Axial Compressor Discs.

DOI: 10.5220/0012718800003758

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 14th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH 2024), pages 237-241

ISBN: 978-989-758-708-5; ISSN: 2184-2841

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

237

2 A DATABASE OF EXISTING

COMPRESSOR DISCS

Information search in available technical

publications did not reveal any formal

recommendations on forming the compressor disc

geometry in the first approximation. For this reason,

it was decided, relying on the existing designs of

high-pressure compressors of gas turbine engine, to

obtain regression dependences, with the help of

which it is possible to obtain the expected shape of

the disc in the first approximation. In the following

steps, this shape will be refined to reduce mass and

stresses. However, even the first approximation

discs (based on statistical data) will help to screen

out obviously unacceptable compressor designs.

To obtain regression dependencies for disc shape

calculation, a database of GTEs of different

generations, design firms, types and purposes was

formed. The database was created by measuring

quality drawings - meridional cross-sections of

GTEs, obtained from reliable sources (usually

directly from partner engine-building enterprises,

reference books and operational literature), the

quality of which is not questionable. A total of 27

gas turbine engines from various countries designed

over the last 40 years were reviewed (including

recent models such as PW1100, Leap GE NX, etc.).

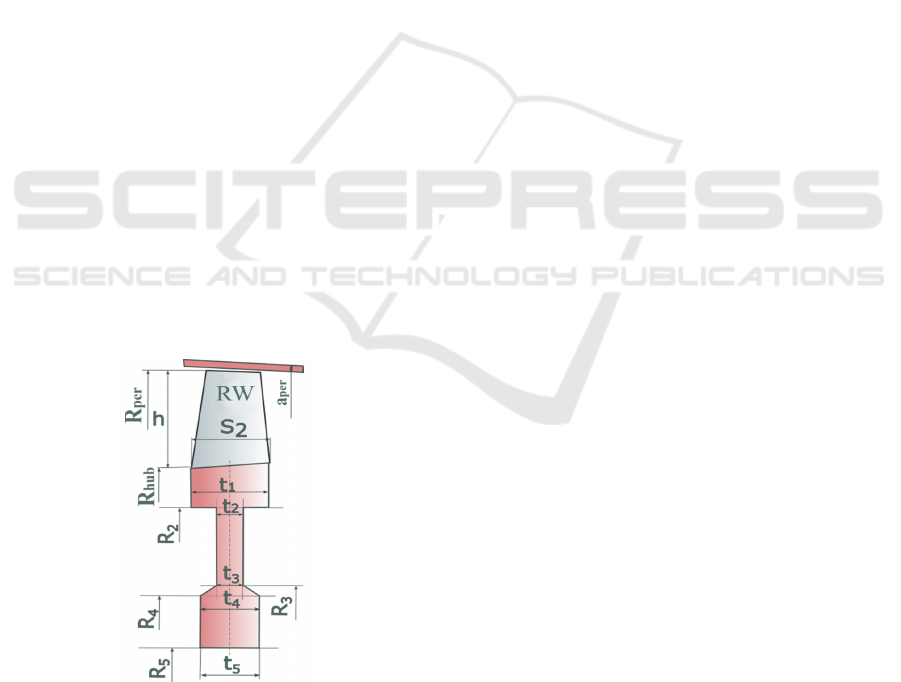

Based on the analysis of available GTE

compressor drawings, a generalized disc shape was

determined (Figure 1) and the dimensions whose

statistical information was to be collected were

outlined.

Figure 1: Principal generalized diagram of an axial

compressor disc with main dimensions.

The disc dimensions shown in Figure 1 were

measured and then disproportioned. The axial and

diametral dimensions of the discs were related to the

axial chord of the RW blades (S

2

), characteristic

diameters (hub diameter R

hub

, middle R

mid,

peripheral

diameter

R

per

) and blade heights h. (a total of 11

dimensional and 20 dimensionless parameters).

In the future it is planned to expand this database

and to refine the obtained regression equations.

3 DISC SHAPE DEPENDENCIES

The regression dependencies for determining the

main dimensions of discs (indicated in Figure 1)

were searched in the following sequence:

1. All parameters (mostly dimensionless) that can

influence the value of the size of interest were

collected in a single table. This included both

universal parameters that are likely to influence

any size (stage number, relative hub diameter

(R

hub

/R

к

) etc.) and size-specific parameters

(e.g., dimensions of neighboring elements) in

all possible combinations.

This creates a table of possible dimensionless

parameters with probable influencing factors.

2. For the generated table the preliminary data

cleaning from the values falling out of the

general array is carried out. Their occurrence

can be caused by errors in the measurement of

the prototype, data input into the database, as

well as by the unusual design of the measured

sample. To screen out the "uncharacteristic"

values, the mathematical expectation of the

parameter (arithmetic mean) X and its standard

deviation σ, Walpole, R., Montgomery, D.

(2012), were determined for each data column

in the table formed in step 1. All points whose

values were outside the range (X±2σ) were

excluded from consideration. On average, no

more than 5% of the points in each column

were rejected. Often a point was out of the

sample range for several parameters.

3. Correlation analysis was performed for the pre-

cleaned data set. Using the Excel data analysis

package, pairwise calculation of statistical

correlation of all parameters of the array is

carried out, Montgomery, D. (2012).

Correlation shows to what extent one value

systematically changes when another or several

others differ. If the compared pair of

parameters is statistically interrelated, the

correlation coefficient tends to 1. If two

quantities are independent, the correlation

coefficient approaches 0.

SIMULTECH 2024 - 14th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

238

4. Using the Excel data analysis package, a

linear regression equation was found for the

parameters pre-selected in step 3:

𝑦=𝑎

+𝑏

∙𝑥

+𝑏

∙𝑥

+⋯+𝑏

∙𝑥

For some parameters we also considered non-

linear regression equations such as:

𝑦=𝑎

+𝑏

∙𝑥

+⋯+𝑏

∙𝑥

+𝑏

∙𝑥

∙𝑥

+

𝑏

∙𝑥

∙𝑥

+⋯+𝑏

∙𝑥

∙𝑥

The values of the coefficients were found using

the Excel data analysis package and the parameters

characterizing the ‘quality’ of the equation were

calculated there. Special attention was paid to the

following parameters, Montgomery, D. (2012):

R

2

- coefficient of determination, which shows to

what extent the calculated model explains the

dependence and changes of the studied parameter - Y

on the studied factors - X. If this parameter tends to 1,

then the obtained equation fully (maximally)

describes the available data array. If R

2

tends to zero,

it means that the equation poorly describes the data

set. Values above 0.6...0.7 are considered acceptable.

P-value - the probability that allows to determine

the significance of the found regression coefficient.

In cases where P>0.05, the coefficient can be

considered zero, which means that the corresponding

independent variable does not affect the dependent

variable. In other words, this parameter should be

less than 0.05 and tends to zero. This coefficient was

determined for each coefficient.

F is the observed (empirical) value of the F-

statistic, by which the hypothesis of equality of all

model coefficients to zero simultaneously is tested.

F significance is a theoretical probability that under

the hypothesis that all model coefficients are equal

to zero simultaneously, the F-statistic is greater than

the empirical value of F. This parameter should tend

to zero.

Regression coefficients and values of the above

regression parameters were found for the variables

pre-selected in step 3. If the value of parameter P

was 0.05, it was excluded from consideration. At

first, the variables with the highest P value were

excluded, then the search for coefficients and

parameters was repeated. The variables with the

largest P value were removed again and the process

was repeated until P was reduced to the required

level. At the same time, special attention was paid to

the value of R

2

. It had to be maximized. Thus, by

varying all possible combinations of Y and

influencing variables, the equations that had the

maximum value of R

2

and minimum P for all

coefficients were found. If the values of regression

coefficients with acceptable statistical parameters

were not found for the linear regression equation, the

values of coefficients of nonlinear regression

equations were searched using a similar algorithm.

Using the equations found, the values of the

parameters of interest were calculated from the

database values and the calculated values were

compared with the real database parameters. As a

result of the comparison, the mean and maximum

error values of the available data set were estimated.

These values also helped in the selection of

equations. Obviously, the calculation errors using

the equations found should be as small as possible.

4 RESULTS AND DISCUSSION

When deriving the formulae, the following

assumptions were made for simplification: t

1

=S

2

;

t

2

-=t

3

; t

4

=t

5

(Figure 1). These assumptions are made

to reduce the number of variables. It should also be

noted that such a simplification is justified due to the

fact that the article deals with the initial stages of

design, and it is important to obtain a disk shape

close to reality with a minimum number of initial

data available at this stage. The obtained regression

equations for calculating axial dimensions of axial

compressor flow path and their statistical parameters

are given in Table 1.

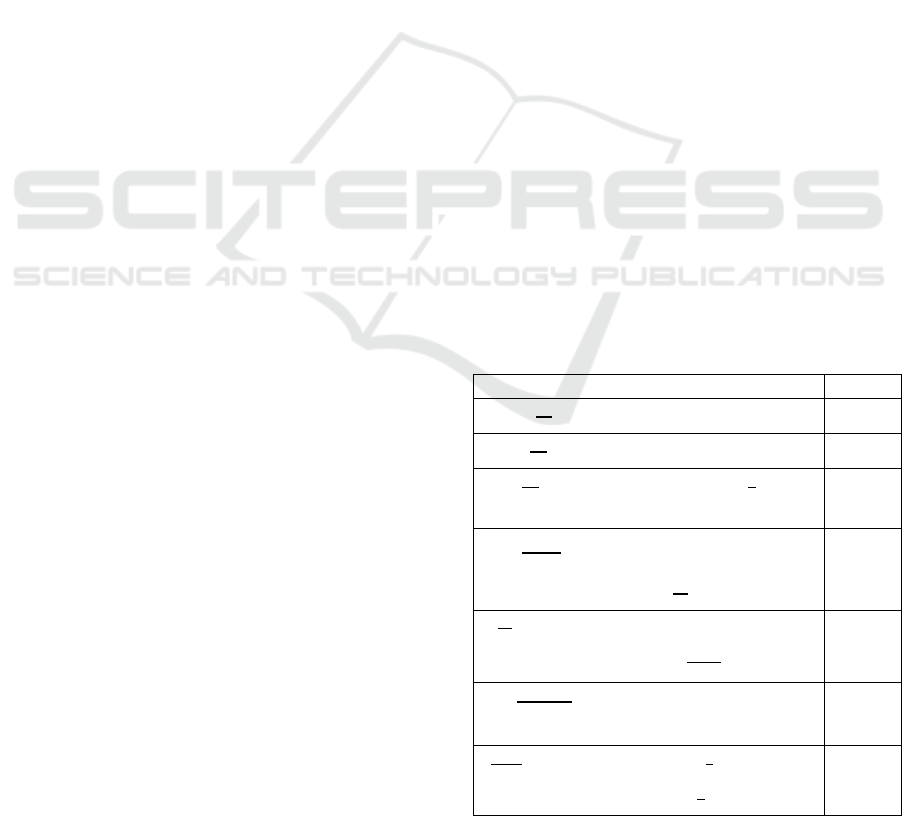

Table 1: Obtained regression formulas for calculating

axial compressor disc sizes.

Formula R

2

= −4.9428 + 8.8525 ∙ 𝑑

̅

0.4873

= −7.0514 + 12.0374 · 𝑑

̅

0.6319

= −14.1513 + 4,8883 ·

+

21.1433 · 𝑑

̅

0.8732

𝑡

𝑅

= 0.0976 − 0.1089 · 𝑑

̅

+

0.027 ·

0.5346

= −2.015 + 0.0854 · 𝑖 + 2.3505 ·

𝑑

̅

+ 4.1073 ·

0.5325

= 0.5579 − 0.0141 · 𝑖 −

0.2887 · 𝑑

̅

0.4619

= 0.0308 − 0.1831 ·

− 0.0096 ·

𝑑

̅

· 𝑖 + 0.4103 ·

·𝑑

̅

0.7186

Regression Equations for Preliminary Dimensioning of Axial Compressor Discs

239

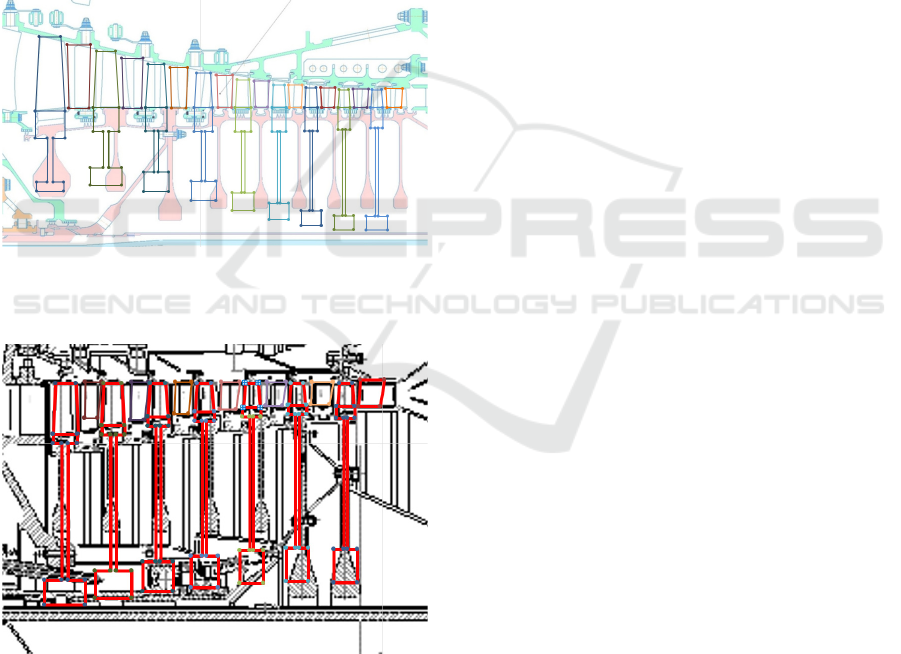

To check the adequacy of the found regression

equations, they were used to calculate the

dimensions of high-pressure compressor discs of

some engines from the database. From engine

drawings the dimensions of flow paths were taken

and then using the found formulas the disc sizes are

calculated. Comparison of original and calculated

shapes of compressor discs is shown in Figures 2-3.

As can be seen from the results shown in

Figures 2 and 3, the developed formulas allow

to determine the expected shapes of axial

compressor discs quite reliably. In the future it

is planned to supplement the database, on the

analysis results of which the equations were

obtained and to carry out thinning of regression

dependences.

Figure 2: Comparison of real dimensions of CFM-56 high-

pressure compressor discs with the results of calculation

by regression equations from Table 1.

Figure 3: Comparison of real dimensions of D-36 high-

pressure compressor discs with the results of calculation

by regression equations from Table 1.

5 CONCLUSIONS

The presented article provides a statistical

analysis of a database collected by the authors

on the sizes of 27 different multi-stage axial

high-pressure compressors of various aircraft

engines. The database contained information

about more than 200 stages. This data array was

subject to statistical analysis, because of which

empirical equations were found that allow, as a

first approximation, to obtain the shape of the

compressor disk at the initial design stages. The

resulting formulas showed good agreement with

real compressor designs. As a result, having the

results of the design calculation of the

compressor, the engineer can quickly obtain the

expected disk shape, which will allow the mass

of the compressor to be assessed and taken into

account during optimization at the early stages

and find an excellent starting point for the

compressor design and its strength analysis. In

the future it is planned to supplement the

database, on the analysis results of which the

equations were obtained and to carry out

thinning of regression dependences.

ACKNOWLEDGMENTS

The research results were obtained as part of the

state task of the Ministry of Education and Science

of Russia "Study of the patterns of working

processes of injection machines based on coupled

mathematical models" (Project FSSS-2024-0015).

REFERENCES

Belousov, A., Musatkin, N., Radko, V. and Kuzmichev, V.

(2006). Design Thermal and Gas-Dynamic

Calculation of the Basic Parameters of Aviation Blade

Machineries (in Russian). Samara: Samara State

Aerospace University Press.

Cumpsty, A. (2004). Compressor Aerodynamics. Krieger

Publishing Company.

Falck, N. (2008). Thermal Power Engineering Energy

Sources: Axial Flow Compressor Mean Line Design.

Sweden: Lund University.

Gallimore, S. J. (1999). Proc. Instn Mech Engrs Axial-

flow compressor design.

Inozemtsev, A., Nikhamkin, M. and Sandratsky, V.

(2022). Fundamentals of design of aircraft engines

SIMULTECH 2024 - 14th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

240

and power plants. Moscow: Direct-Media. Vol. 1, 2

nd

edition.

Mattingly, J. D., Heiser, W. and Pratt, D. (2002). Aircraft

Engine Design. Second ed Reston VA: American

Institute of Aeronautics and Astronautics.

Walpole, R., Myers, R., Myers, S. and Ye, K. Probability

and Statistics for Engineers and Scientists.

Montgomery, D., Peck, E., Vining, W. G. (2012).

Introduction to Linear Regression Analysis. 5

th

Ed. xvi.

Regression Equations for Preliminary Dimensioning of Axial Compressor Discs

241