Diagnosis Automation Using Similarity Analysis:

Application to Industrial Systems

Ivan Orefice

1

, Wissam Mallouli

1

, Ana R. Cavalli

1

, Filip Sebek

2

and Alberto Lizarduy

3

1

Montimage EURL, Paris, France

2

R&D ABB Marine and Ports, V

¨

aster

˚

as, Sweden

2

FAGOR Arrasate S.Coop, Spain

fi

Keywords:

Incident Diagnosis, Root Cause Analysis, Automation, Load Position System, Manufacturing Machinery,

Security.

Abstract:

The paper introduces the MMT-RCA framework, an automated incident diagnosis system crucial for main-

taining security and reliability in complex systems such as ABB’s Load Position Sensor (LPS) and FAGOR’s

remote manufacturing machinery access. Traditional incident response methods often involve time-consuming

and error-prone manual analysis, hindered by limited human expertise. MMT-RCA addresses this challenge

by leveraging similarity analysis techniques. It utilizes historical incident data to create a comprehensive

repository, capturing characteristics and outcomes of past incidents. By employing sophisticated algorithms,

the MMT-RCA framework identifies patterns and correlations among incidents, facilitating the swift identifi-

cation of similar problems and their root causes. To validate its efficacy, the framework underwent real-world

experiments with industrial data from both companies. The results demonstrate the framework’s ability to

accurately diagnose incidents and identify root causes.

1 INTRODUCTION

Ensuring the security and safety of critical industrial

system (Kalam, 2021) is essential to prevent incidents

that can result in significant damage, financial losses,

and potential harm to human lives. In fact, these

systems face various security and safety challenges

that can lead to incidents, making incident diagno-

sis a crucial aspect of their overall protection (Hem-

sley and Fisher, 2018). One of the key challenges is

the complex and evolving nature of threats. Attack-

ers are continuously developing new techniques to ex-

ploit vulnerabilities in industrial systems (Kallel et al.,

2021), necessitating proactive monitoring, threat in-

telligence, and robust incident detection capabilities

(Salazar et al., 2022). Effective incident diagnosis en-

ables the identification of security breaches and helps

determine the root causes of these incidents, allowing

organizations to implement appropriate countermea-

sures and strengthen their security posture.

Another challenge is the detection and diagnosis

of safety incidents within critical industrial systems

(He et al., 2022). Safety incidents can arise from

equipment failures, human errors, procedural viola-

tions, or environmental factors. Identifying the root

causes of safety incidents is crucial to prevent their

recurrence and improve overall safety measures.

Furthermore, the integration of security and

safety incident diagnosis is essential for a compre-

hensive approach to protect critical industrial sys-

tems(Kirkpatrick, 2019). Security and safety inci-

dents are often intertwined and can have cascading

effects on each other. For example, a cyber attack tar-

geting an industrial control system can lead to safety

hazards if critical safety controls are compromised.

Conversely, a safety incident, such as an equipment

malfunction, can create vulnerabilities that can be ex-

ploited by malicious actors. By integrating security

and safety incident diagnosis, organizations can gain

a holistic understanding of incidents, their interde-

pendencies, and the underlying causes, enabling them

to implement appropriate measures (Lanotte et al.,

2023) to address both security and safety concerns ef-

fectively.

In this paper, we propose an automated diagnosis

framework called MMT-RCA a new feature of Mon-

timage Monitoring Tool

1

that aims to leverage sim-

ilarity analysis techniques to enhance the identifica-

1

https://www.montimage.com/products

Orefice, I., Mallouli, W., Cavalli, A., Sebek, F. and Lizarduy, A.

Diagnosis Automation Using Similarity Analysis: Application to Industrial Systems.

DOI: 10.5220/0012719200003753

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 19th International Conference on Software Technologies (ICSOFT 2024), pages 331-338

ISBN: 978-989-758-706-1; ISSN: 2184-2833

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

331

tion of the root causes of incidents within critical in-

dustrial systems. Traditional manual incident analy-

sis processes can be time-consuming and subjective,

relying heavily on the expertise and experience of hu-

man operators. By incorporating similarity analysis

techniques (Black et al., 2019) , the framework aims

to expedite the incident diagnosis process by identify-

ing patterns and correlations among incidents.

Similarity analysis involves comparing the char-

acteristics and outcomes of incidents to identify sim-

ilarities and associations that can help determine the

underlying root causes. This can be achieved through

clustering algorithms that group similar incidents to-

gether based on shared or close metric values. By uti-

lizing historical incident data and real-time monitor-

ing data, the framework can continuously learn and

improve its diagnosis capabilities.

The integration of similarity analysis techniques

in the automated diagnosis framework offers sev-

eral advantages. Firstly, it can significantly reduce

the time required for incident diagnosis, enabling

prompt response and mitigation actions. Secondly,

it helps minimize the subjectivity and biases associ-

ated with manual analysis, providing more objective

and data-driven results. Moreover, by identifying the

root causes of incidents, organizations can implement

targeted remediation strategies, enhance system re-

silience, and proactively address potential vulnerabil-

ities.

The MMT-RCA framework has been applied to

both LPS provided by ABB company

2

and remote

access to manufacturing machinery, a system used

inside FAGOR company

3

, and has yielded interest-

ing results. By leveraging historical incident data and

real-time monitoring data from the LPS and the man-

ufacturing system, the framework successfully iden-

tified patterns and correlations among incidents, en-

abling the prompt identification of root causes. The

application of the framework to both datasets signifi-

cantly reduced the time required for incident diagno-

sis, improving incident response efficiency and over-

all system uptime. These interesting results demon-

strate the effectiveness of the framework in automat-

ing the root cause analysis of incidents within these

two industrial complex contexts.

The paper is organised as follows. Section 2

presents related work to root cause analysis of in-

cident in industrial systems. Section 3 presents the

proposed framework architecture and implementation

details. Furthermore, Section 4 presents its applica-

tion results to LPS system and FAGOR use case. Sec-

tion 5 concludes the paper and present future work.

2

https://global.abb/group/en

3

https://fagorarrasate.com

2 RELATED WORK

There is a significant body of scientific work related

to protecting critical industrial systems (Salazar et al.,

2022) (Kalam, 2021) (Hemsley and Fisher, 2018)

and some of them focused on incidents diagnosis and

root cause analysis. The basic concepts and termi-

nologies related to Root Cause Analysis (RCA) are

defined in the literature.

The authors of (Kiermeier and Feld, 2018) dis-

cuss the challenges of performing root cause analysis

in self-organizing industrial systems (SOIS). These

systems adapt their behaviour dynamically, making

it difficult to establish explicit connections and iden-

tify root causes. The authors present a taxonomy of

possible root causes in SOIS, with a focus on error

sources arising from the online decision-making pro-

cess. They propose backtracking approaches, distin-

guishing between automatable and non-automatable

procedures. For cases where automatable evaluation

is not feasible due to the state space explosion, a vi-

sual analytics solution is proposed. The paper also

includes a proof of concept for an expert-based as-

sessment, demonstrating the necessary functions for

tracing back anomalies in SOIS.

Besides, (Wang et al., 2021) introduces Groot, an

event-graph-based approach for root cause analysis

in large-scale distributed systems. Groot addresses

the challenges posed by microservice architecture, in-

cluding operational complexities, system scale, and

monitoring. It constructs a real-time causality graph

based on events, incorporating various metrics, logs,

and activities for analysis. Groot can be customized

with user-defined events and domain-specific rules,

allowing integration of domain knowledge from site

reliability engineering (SRE) engineers. The paper

demonstrates the usability and effectiveness of Groot

in industrial settings, highlighting its practical appli-

cation and lessons learned. However, the Groot tool

presents some limitations associated with its scalabil-

ity, adaptability to different system architectures, or

potential challenges in integrating real-time data from

distributed environments.

These scientific works contribute to the under-

standing and development of root cause analysis

methodologies in industrial systems, providing valu-

able insights and practical guidance for incident in-

vestigation, prevention, and overall system improve-

ment. In our paper, we propose a generic root cause

analysis solution called MMT-RCA that can extended

to different sectors and can easily be integrated in op-

erational environments due to its modularity.

ICSOFT 2024 - 19th International Conference on Software Technologies

332

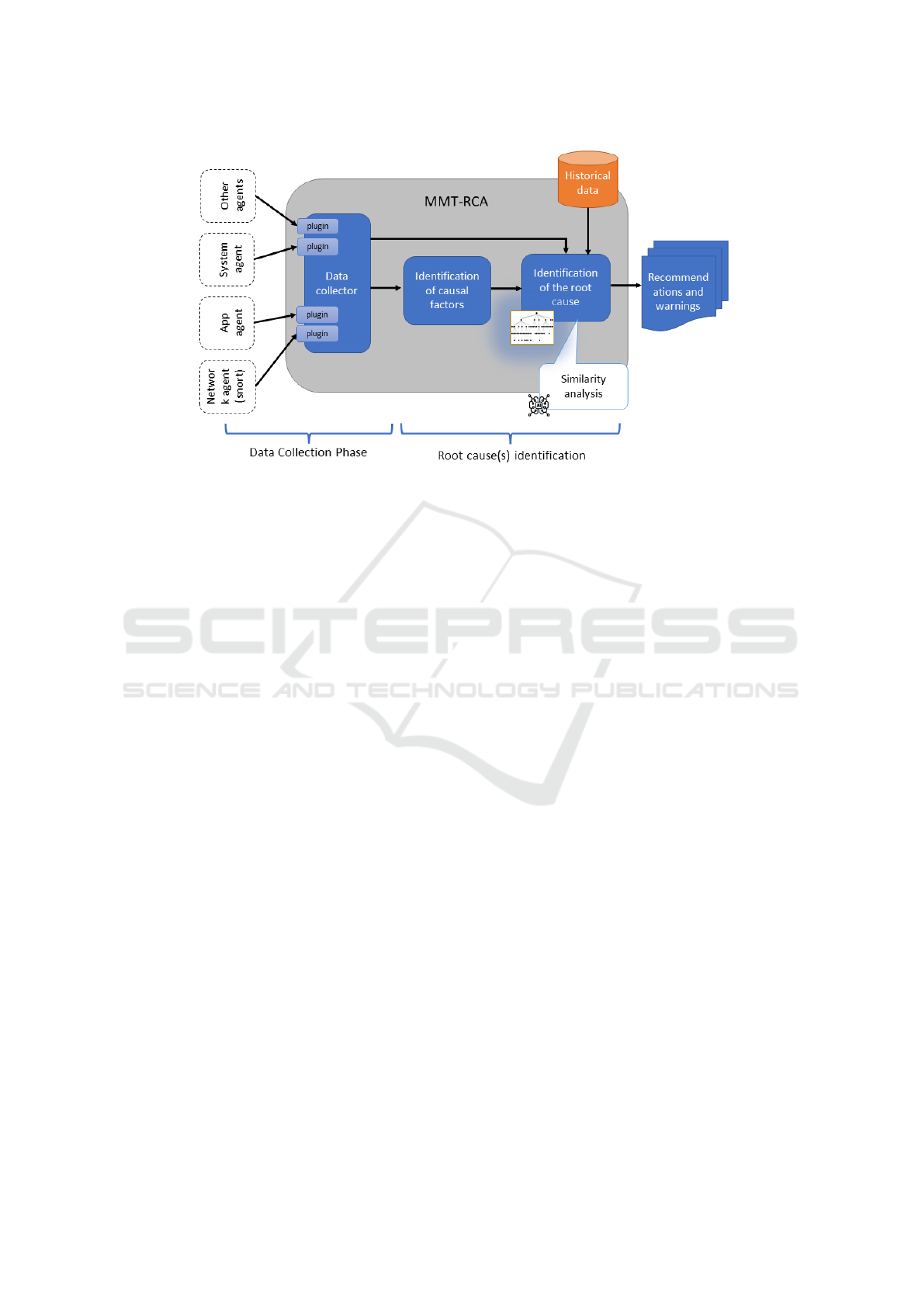

Figure 1: The automated diagnosis framework architecture.

3 THE AUTOMATED DIAGNOSIS

FRAMEWORK: MMT-RCA

In this section the complete framework of MMT-RCA

will be explained and showed in details.

3.1 The Automated Diagnosis

Framework

Figure 1 illustrates the high-level architecture of the

automated diagnosis framework. The tool utilizes

a data collector that gathers information from vari-

ous sources within the industrial critical system, such

as network, application, system and hardware, using

dedicated monitoring agents. The data collector em-

ploys a plugin architecture to support the extraction of

attribute values relevant for identifying the origin of

incidents. Machine learning algorithms are applied to

select the most significant attributes called causal fac-

tors, enhancing analysis accuracy and reducing com-

putational resource requirements.

The data collector can be either provided by the

system itself or deployed as an agent, captures net-

work traffic and reads and extracts logs in different

formats like JSON, CSV or even binary. Relevant

metrics are selected, considering performance indica-

tors and specific case studies.

Historical data consisting of labeled events and

their associated attribute values is used for learning

purposes. By using similarity learning, particularly

Ranking Similarity Learning, the tool compares new

system states with known undesirable states to rec-

ognize root causes. The tool recommends relevant

countermeasures based on known mitigation strate-

gies.

The RCA tool operates in two phases: knowl-

edge acquisition, also called learning phase, and mon-

itoring phase. The learning phase involves building

a historical database of known problems and inci-

dents, while the monitoring phase continuously an-

alyzes real-time system data, queries the historical

database, and suggests potential root causes. Root

cause identification relies on similarity analysis, treat-

ing system states as vectors in a multidimensional

space.

Recommendations and visualization of similarity

scores, known incidents, and root causes assist sys-

tem administrators in anticipating system evolution,

detecting faults, and taking appropriate mitigation ac-

tions.

3.2 Implementation Details

As described in the previous section, the RCA is

based on two phases: knowledge acquisition and

monitoring stage. Both of them require to define a set

of metrics or features describing the system status and

its related incidents. This set of features are obtained

thanks to the use of 4 in-house modules of MMT tool,

their combination constitute the MMT-RCA solution:

• MMT-Extract: this module allows parsing the in-

put traces of the MMT-RCA. These inputs can

have different formats and sources. That’s why

MMT-Extract has a plugin architecture to deal

with heterogeneous inputs. Today MMT-Extract

has more than 650 plugins and can deal with pre-

Diagnosis Automation Using Similarity Analysis: Application to Industrial Systems

333

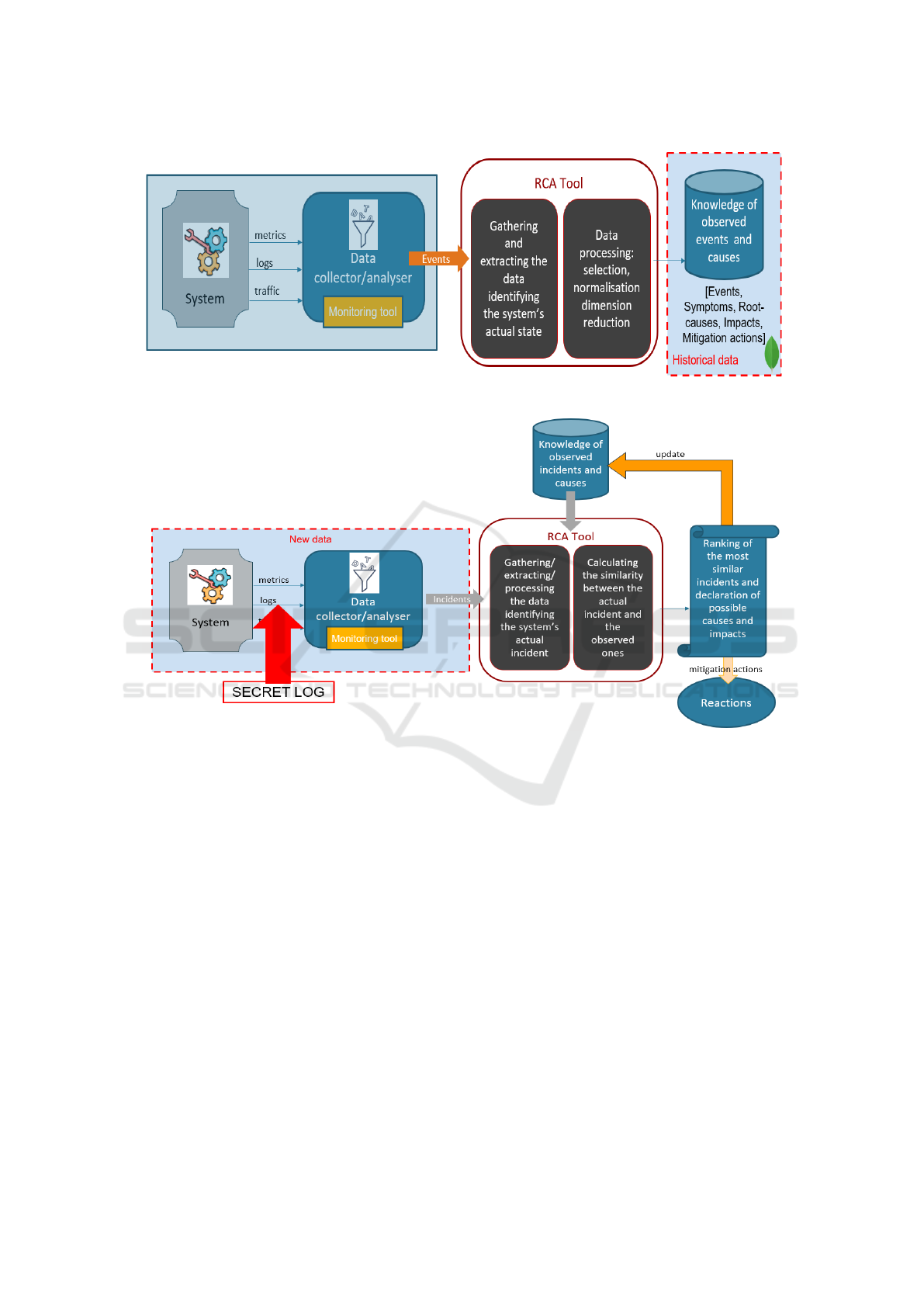

Figure 2: The Knowledge acquisition phase.

Figure 3: The monitoring and diagnosis phase.

captured logs/datasets or live streaming logs. The

data extracted can be coming from the raw data

(a specific attribute in the log) or computed data

by correlating several events. Example: comput-

ing packet loss rate in a session, or speed from 2

positions of a vehicle etc.

• MMT-Security: this module allows to perform

Complex Event Processing (CEP) to detect secu-

rity incidents and attacks. To do so, it aggregates

and applies a logic to the extracted variables.

• MMT-Similarity: Based on the historical data (i.e,

list known metrics values denoting each security

incident), a distance is computed for newly moni-

tored datasets. This allows to compute the similar-

ity of events and identify the root causes of prob-

lem with a specific accuracy. This identification

is based on similarity analysis algorithms that can

be chosen in the configuration file.

• MMT-Operator: allows the display of the results

of analysis and classify the possible causes and

provide recommendations and warnings.

The learning phase is depicted in Figure 2. During

this phase, labelled incidents need to be used. They

can be either old detected incidents or simulated ones.

The monitoring phase illustrated in Figure 3 relies

on precaptured logs or can be done at runtime where

incidents are detected and an automatic diagnosis is

performed. The MMT-RCA software solution is im-

plemented as open source solution in C, Python and

Javascript and its modules are available at

https://github.com/Montimage.

ICSOFT 2024 - 19th International Conference on Software Technologies

334

4 APPLICATION TO IT SYSTEMS

4.1 ABB Case Study

ABB Load Position Sensor (LPS) is a camera-based

tracking system that determines a hanging crane load

position with help of attached LED markers on the

load. As can be seen in Figure 4, the system consists

of a camera on top of a crane that keeps tracks of LED

markers on a load that is in motion. In addition, there

is single Programmable Logic Controller (PLC) that

analyses the camera images. The sensor acts as feed-

back to the automatic control of the crane.

However, it has happened that noise detected by

the camera is tagged as markers by the PLC. This sit-

uation might lead to incorrect movements of the crane

and compromise the safety of the system.

Figure 4: The Load Position Sensor (Salazar et al., 2022).

4.1.1 Potential Causes of Incidents

In this experiment, we focus only on 3 types of chal-

lenges that could cause an incident:

• Problem 1. Internal bugs in camera firmware that

could cause faulty output;

• Problem 2. Markers are split by a hanging cable

between the camera and the marker;

• Problem 3. Random noises from the environment

in the collected data.

Three datasets of each problem have been gathered by

ABB. Secret logs (without labelling) has been gener-

ated for testing purposes.

4.1.2 Data Extraction and Knowledge

Acquisition

A first attempt of using raw features in the datasets

has been ineffective as the information inside the

log was not enough to describe each of the prob-

lems. Therefore, new features were derived by us-

ing MMT-Extract applying computations and aggre-

gation of many rows of the log. These features are

listed in Table 1. A core step in the workflow of the

tool is the attributes selection. In order to do so, Re-

cursive Feature Elimination (RFE) (Choi et al., 2011)

and clusterization (Ezugwu et al., 2022) were applied

to the feature set and was computed a correlation ma-

trix, whereby it was selected a subset of metrics that

are more relevant to the incidents and enable higher

performance: metrics ids (1), (2), (3), (4), (5), (6),

(18), (20).

4.1.3 Learning Phase

During the learning phase, the tool takes in input the

subset of selected features for each labelled dataset.

From here on, normalisation is implemented: it per-

mits to have all the feature in the range [0,1] but also

to ease the comparison among the states of the inci-

dents. After the normalisation, parameters of Gaus-

sian distribution per problem are computed (mean,

standard deviation, min and max).

4.1.4 Evaluation Results

MMT-RCA recognised correctly most of the exam-

ples (with a similarity score above 80%) while the

tool had little trouble recognising the log without any

faults, but these examples still had a acceptable simi-

larity score (above 70%). The overall accuracy of the

tool was 95.1% while the amount of examples that

had not been correctly recognised was only 14 on a to-

tal of 292 examples. Finally, also the results obtained

with the secret log used as input of MMT-RCA are

satisfying; the log was composed of a scarce number

of examples of normal behaviour and a large amount

of examples related to the first problem. RCA clas-

sified successfully the examples to the first problem

while the ones not containing an issue were associ-

ated to problem 0 (normal behaviour). It is important

to underline that to obtain these results only one ex-

ample of each incident log was enough to learn and

build the knowledge database. This makes the MMT-

RCA unique and interesting for the industrial context.

4.2 Fagor use case

To use their manufacturing equipment, Fagor pro-

vides a Remote Desktop Protocol (RDP) connection

to remote users.Despite the robust RDP framework,

challenges may arise, leading to potential disruptions

in reaching the destination host. Monitoring is crucial

to identify and address these challenges promptly.

Diagnosis Automation Using Similarity Analysis: Application to Industrial Systems

335

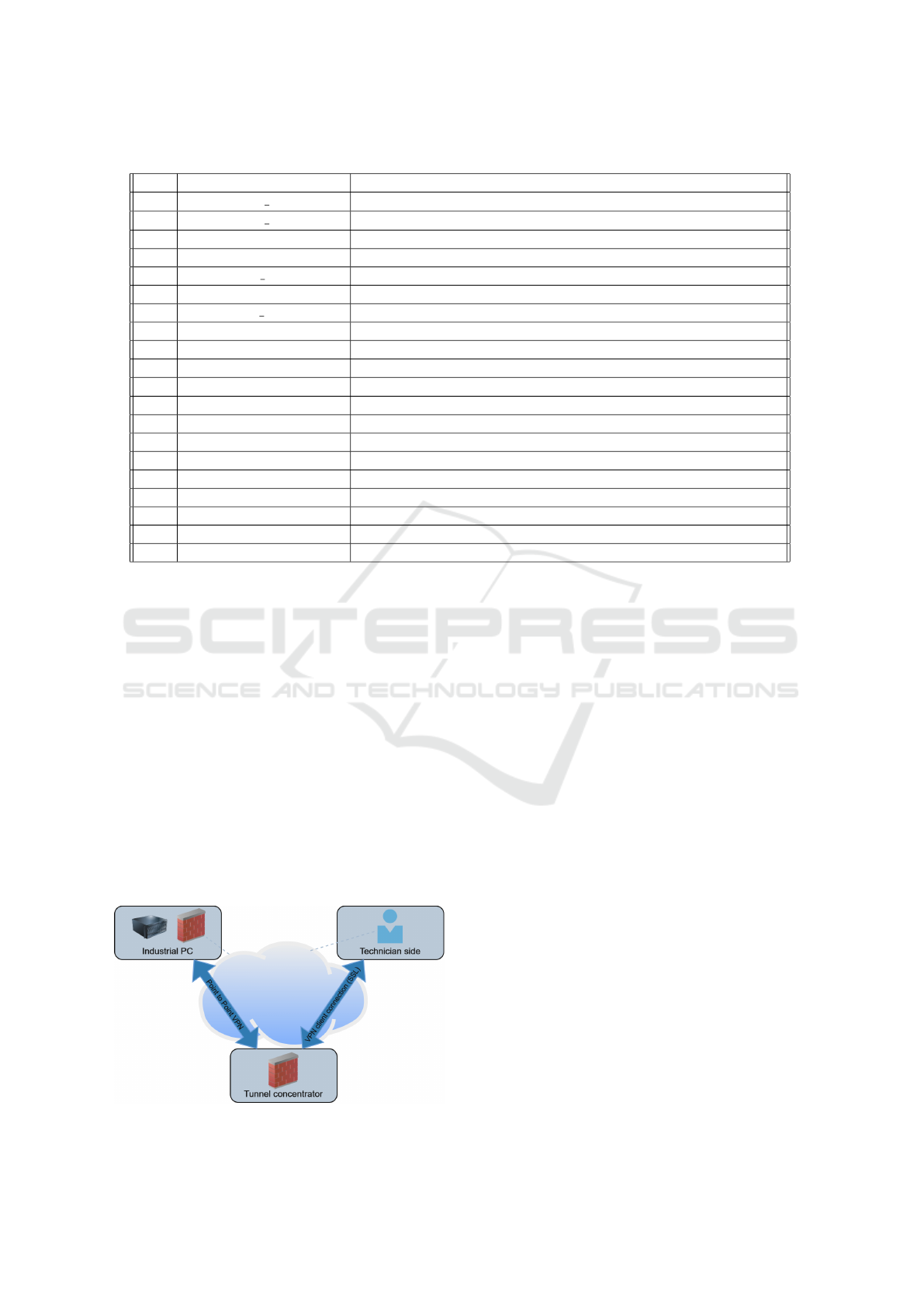

Table 1: List of attributes extracted with MMT-Extract for ABB use case.

Ref Attribute Description

(1) NSE M

i

th

Number of entries markers were frozen in the same position (x,y)

(2) NST M

i

th

Number of times markers were frozen in the same position (x,y)

(3) MDAM Minimum distance between all the entries for same marker

(4) ADAM Average distance between all the entries for same marker

(5) ADT TNM Average ∆ T the trolley was not moving with speed >0.5

(6) TTNM Number of times the the trolley was not moving with speed >0.5

(7) ADT HNM Average ∆ T the hoist was not moving with speed >0.5

(8) THNM Number of times the the hoist was not moving with speed >0.5

(9) AvgTrolleyPos Average position of the trolley in the log (x,y)

(10) AvgHoistPos Average position of the hoist in the log (x,y)

(11) AvgMarker

i

th

Average coordinates x and y per each marker

(12) AvgMhSpeed Average speed of Main Hoist

(13) AvgGaSpeed Average speed of Gantry

(14) AvgTrSpeed Average speed of Trolley

(15) AvgMhAcceleration Average acceleration of Main Hoist

(16) AvgGaAcceleration Average acceleration of Gantry

(17) AvgTrAcceleration Average acceleration of Trolley

(18) TotalDistanceMarker Total euclidean distance per marker in a window of time

(19) AvgNumberOfMarkers Average number of markers considered valid by PLC

(20) NotAligned Number of times the markers were not aligned (angle °<170)

Additionally, a VPN tunnel is used to transmit net-

work traffic between the Industrial PC and the Tele-

service host. In order to manage the traffic and guar-

antee the security and privacy of the operations, the

point-to-point VPN has a remote firewall that may

block traffic between the Industrial PC and the end-

point. Figure 5 illustrates the described architecture

and three different incident scenarios has been simu-

lated and pcap files provided for the learning phase.

• a trace describing the situation in which the Indus-

trial PC running, but RDP protocol was not acti-

vated (Problem 1);

• a problem known as Problem 2 where communi-

cation with the industrial PC was blocked by the

firewall;

• a pcap in which the firewall could not be contacted

(Problem 3).

Figure 5: FAGOR system topology.

4.2.1 Data Extraction and Knowledge

Acquisition

Several network features have been computed for this

analysis and are listed in Table 2. The feature selec-

tion process was still required despite the small num-

ber of metrics that were recovered. Features (1) and

(2) were finally discarded.

4.2.2 Learning Phase

Similar to how it was done for the ABB use case,

RCA was given the datasets as input so that it could

learn the states of every problem. After normalis-

ing the values, the states were stored in a MongoDB

collection, while the Gaussian distribution parameters

were kept in a separate collection. At the end of this

step there were four states in the historical data, one

for each scenario.

4.2.3 Evaluation Results

The majority of issues were acknowledged by the

tool as problems (with a similarity score in this case

above 75%, which was considered as a good thresh-

old). Only a few instances were mistakenly classified

as belonging to a separate problem, demonstrating the

tool’s reliability: in fact, the tool’s overall accuracy

was 91.42%, with only 35 out of a total of 408 sam-

ples failing to acquire the correct identification. Fi-

nally, the results from injecting unlabeled trace data

ICSOFT 2024 - 19th International Conference on Software Technologies

336

Table 2: List of attributes extracted and sent to RCA for FAGOR use case.

Ref Attribute Description

(1) RDP Percentage of RDP packets in the entire trace

(2) TPKT Percentage of TPKT packets in the entire trace

(3) ICMP Percentage of ICMP packets in the entire trace

(4) ARP Percentage of ARP packets in the entire trace

(5) MDNS Percentage of MDNS packets in the entire trace

(6) LENGTH Length of the trace (number of packets)

(7) NO-RDP-TPKT Absence of both RDP and TPKT packets in the

entire trace

(8) NO-RDP-TPKT-ICMP Absence of both RDP and TPKT and ICMP pack-

ets in the entire trace

into MMT-RCA are encouraging; the tool was able to

classify each trace to the appropriate incident with a

similarity score of ≈ 75%, with the exception of the

normal incident, which has a lower similarity rate but

is still correctly identified.

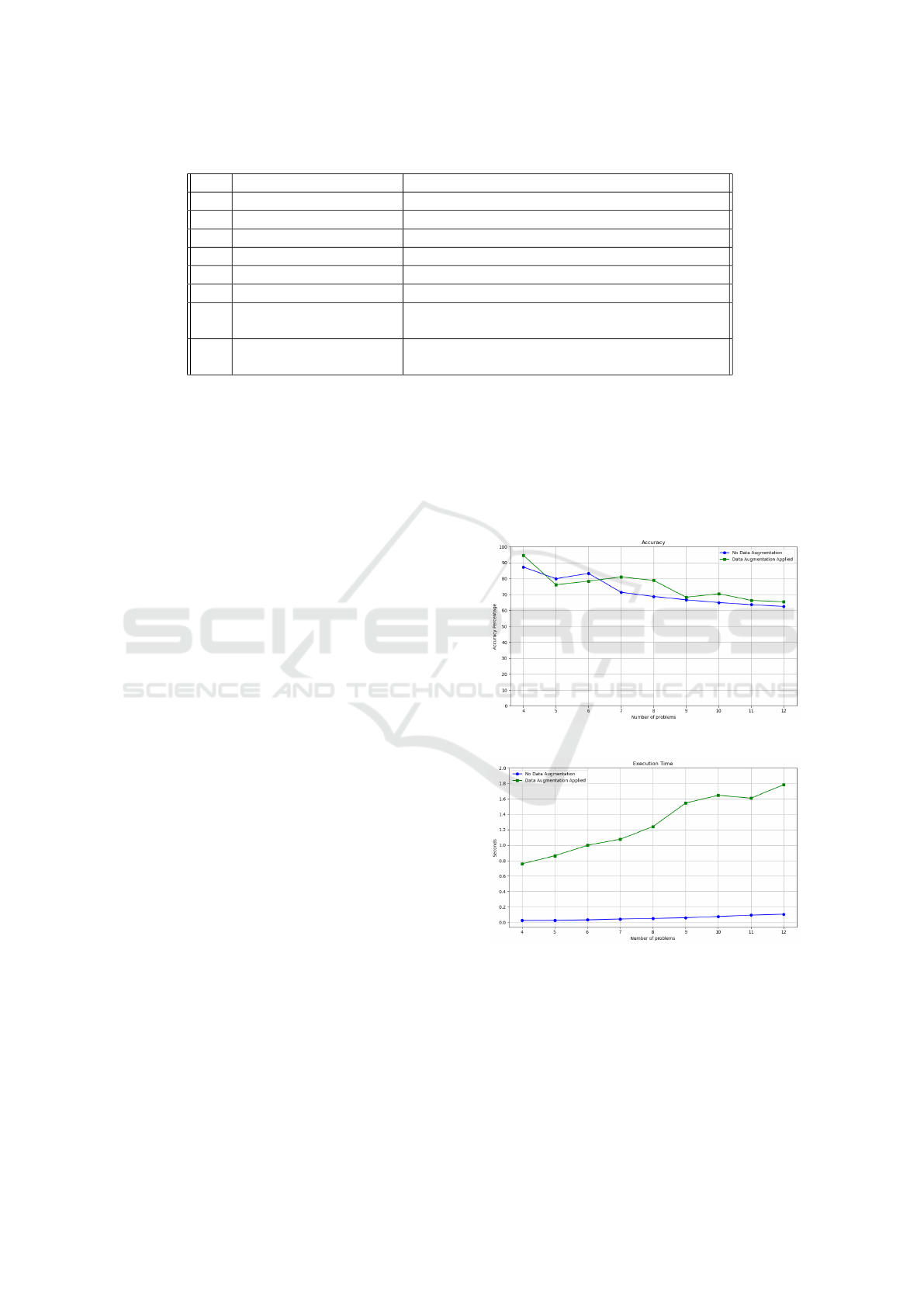

4.3 Performance Evaluation

To assess the performance of MMT-RCA, multiple

experiments were carried out regarding scalabilty and

execution time. The amount of root cause scenarios

was increased up to 12 which represent a high num-

ber of potential causes in a realistic case study. Each

different scenario was created taking into account a

likely possible scenario by applying a perturbation

to a subset of the features. For each case, the tool

has been applied to the examples and were collected

quantitative metrics such as the accuracy and execu-

tion time.

The experiments conducted can be divided into

two main groups:

• the first group is related to those experiments

which did not include data augmentation and had

a number of examples used during the learning

phase equal to 2 · |root − causes| according to the

number of problems used in that case;

• in the experiments of the second group instead

was used data augmentation, so that the number

of examples for every case was ≈ 400.

This division allowed to understand how MMT-RCA

performed with a small or a large amount of exam-

ples used during the learning phase. For all the ex-

periments of both groups it has been applied feature

selection, so as to get the highest possible value of

accuracy: the number of features ranges from 7 to 9.

Firstly, the experiments done to evaluate MMT-

RCA showed it can reach high levels of accuracy,

whether many examples are present with which to

learn the states of incidents or not. As anybody would

expect, the higher is the number of examples during

the learning phase, the more precise and definite is the

state, therefore the more accurate is the tool; on the

other hand, MMT-RCA still reaches high values of

accuracy when it encounters only few examples, that

is the formidable outcome of the instrument: just few

examples are needed (in our experiments each prob-

lem was described by only two instances) to create a

state which is in any case reliable.

Figure 6: Accuracy of MMT-RCA.

Figure 7: Execution Time of MMT-RCA.

Secondly, the experiments showed a real good per-

formance of the tool in terms of speed, since increas-

ing the number of problems did not lead to an expo-

nential increase of execution time for both groups; in-

stead, the execution time grows linearly, which is a

outstanding result: increasing the number of problems

did not correspond to an interminable wait.

Diagnosis Automation Using Similarity Analysis: Application to Industrial Systems

337

5 CONCLUSIONS

In conclusion, the proposed approach of leverag-

ing historical incident data and employing similar-

ity analysis algorithms in the MMT-RCA framework

has shown promising results in incident management

and root cause identification. By building a com-

prehensive incident repository and analyzing patterns

and correlations among issues, the framework effec-

tively identifies similar incidents and their underlying

causes. The validation experiments conducted using

real-world incident data from industrial settings pro-

vided by both ABB and FAGOR have demonstrated

the framework’s accuracy in diagnosing incidents and

significantly reducing the time needed for manual

analysis. The automation of the diagnosis process not

only improves incident response time but also enables

proactive maintenance, leading to increased system

uptime and enhanced operational efficiency. Overall,

the implementation of this approach holds great po-

tential for enhancing incident management practices

and optimizing the performance of industrial systems.

ACKNOWLEDGMENT

This work is partially supported by the European

Union’s Horizon Europe research and innovation pro-

gram under grant agreements No 957212 (VERIDE-

VOPS) and No 101070455 (DYNABIC). Views and

opinions expressed are however those of the author(s)

only and do not necessarily reflect those of the Euro-

pean Union.

REFERENCES

Black, P., Gondal, I., Vamplew, P., and Lakhotia, A. (2019).

Evolved similarity techniques in malware analysis. In

18th IEEE International Conference On Trust, Secu-

rity And Privacy In Computing And Communications /

13th IEEE International Conference On Big Data Sci-

ence And Engineering, TrustCom/BigDataSE 2019,

Rotorua, New Zealand, August 5-8, 2019, pages 404–

410. IEEE.

Choi, H., Yeo, D., Kwon, S., and Kim, Y. (2011). Gene

selection and prediction for cancer classification using

support vector machines with a reject option. Comput.

Stat. Data Anal., 55(5):1897–1908.

Ezugwu, A. E., Ikotun, A. M., Oyelade, O. N., Abualigah,

L. M., Agushaka, J. O., Eke, C. I., and Akinyelu,

A. A. (2022). A comprehensive survey of cluster-

ing algorithms: State-of-the-art machine learning ap-

plications, taxonomy, challenges, and future research

prospects. Eng. Appl. Artif. Intell., 110:104743.

He, Z., Chen, P., Luo, Y., Yan, Q., Chen, H., Yu, G.,

and Li, F. (2022). Graph based incident extraction

and diagnosis in large-scale online systems. In 37th

IEEE/ACM International Conference on Automated

Software Engineering, ASE 2022, Rochester, MI, USA,

October 10-14, 2022, pages 48:1–48:13. ACM.

Hemsley, K. and Fisher, R. E. (2018). A history of cy-

ber incidents and threats involving industrial control

systems. In Staggs, J. and Shenoi, S., editors, Crit-

ical Infrastructure Protection XII - 12th IFIP WG

11.10 International Conference, ICCIP 2018, Arling-

ton, VA, USA, March 12-14, 2018, Revised Selected

Papers, volume 542 of IFIP Advances in Informa-

tion and Communication Technology, pages 215–242.

Springer.

Kalam, A. A. E. (2021). Securing SCADA and critical in-

dustrial systems: From needs to security mechanisms.

Int. J. Crit. Infrastructure Prot., 32:100394.

Kallel, S., Cuppens, F., Boulahia-Cuppens, N., Kacem,

A. H., and Othmane, L. B. (2021). Special issue on

risk and security of smart systems. J. Inf. Secur. Appl.,

61:102925.

Kiermeier, M. and Feld, S. (2018). Visual analytics for root

cause analysis in self-organizing industrial systems. In

16th IEEE International Conference on Industrial In-

formatics, INDIN 2018, Porto, Portugal, July 18-20,

2018, pages 315–320. IEEE.

Kirkpatrick, K. (2019). Protecting industrial control sys-

tems. Commun. ACM, 62(10):14–16.

Lanotte, R., Merro, M., and Munteanu, A. (2023). In-

dustrial control systems security via runtime enforce-

ment. ACM Trans. Priv. Secur., 26(1):4:1–4:41.

Salazar, Z., Cavalli, A. R., Mallouli, W., Sebek, F., Za

¨

ıdi, F.,

and Rakoczy, M. E. (2022). Monitoring approaches

for security and safety analysis: Application to a load

position system. In 15th IEEE International Confer-

ence on Software Testing, Verification and Validation

Workshops ICST Workshops 2022, Valencia, Spain,

April 4-13, 2022, pages 40–48. IEEE.

Wang, H., Wu, Z., Jiang, H., Huang, Y., Wang, J., K

¨

opr

¨

u,

S., and Xie, T. (2021). Groot: An event-graph-based

approach for root cause analysis in industrial settings.

In 36th IEEE/ACM International Conference on Auto-

mated Software Engineering, ASE 2021, Melbourne,

Australia, November 15-19, 2021, pages 419–429.

IEEE.

ICSOFT 2024 - 19th International Conference on Software Technologies

338