Data Quality Assessment for the Textile and Clothing Value-Chain

Digital Product Passport

A. M. Rosado da Cruz

1,2 a

, Pedro Silva

1

, S

´

ergio Serra

1

, Rodrigo Rodrigues

1

, Pedro Pinto

1 b

and

Estrela F. Cruz

1,2 c

1

ADiT-LAB, Instituto Polit

´

ecnico de Viana do Castelo, 4900-348 Viana do Castelo, Portugal

2

ALGORITMI Research Lab, Universidade do Minho, Guimar

˜

aes, Portugal

Keywords:

Quality Assessment, Data Quality Validation, Sustainability Indicators, Textile and Clothing Value Chain.

Abstract:

The Textile and Clothing (T&C) industrial sector is transforming to become more sustainable and in line

with the directives of the European Union. Therefore, to become more transparent and gain consumer trust,

some projects present proposals to implement the traceability of T&C products. However, this sector has a

very large and diverse value chain that involves many types of industries that are typically spread throughout

the world. Furthermore, a previously developed project to implement traceability on the value chain reveals

that the involved companies have different levels of digital maturity and, among those with the same level of

maturity, different digital platforms are used. Consequently, some values submitted for a T&C traceability

platform may be collected automatically, while others have to be manually inserted. This makes it necessary

to create a tool for validating the data values submitted to the traceability platform, which can be integrated

into the different organizational tools so that the data can be validated homogeneously. After summarizing

the relevant and contextualizing facts about the T&C value chain, and reviewing the data quality assurance

mechanisms, this paper proposes a software service for validating data values of metrics being traced across

the T&C value chain, that integrates the Digital Product Passport of T&C items. Associated with the validation

service, an admin platform for configuring the service for each metric is also proposed.

1 INTRODUCTION

Textile & Clothing (T&C) is one of the industries

that has grown the most in the last decades and one

of those that has the greatest environmental impact.

This impact comes not only from the fact that it con-

sumes a lot of natural resources but also because it

contributes to greenhouse gases and water pollution.

Furthermore, and because the population is consum-

ing more and more, this industrial sector produces a

lot of waste that has to be treated and preferably re-

cycled to be used as new raw material (Alves et al.,

2022a).

One of the ways to encourage companies to pro-

duce more sustainably falls on the end consumer, who

can buy the most environmentally friendly item of

clothing over others. However, to do this, consumers

must trust in the labels and know what they are buy-

ing. To achieve this, it is necessary to implement

traceability in the T&C industry value chain. The

a

https://orcid.org/0000-0003-3883-1160

b

https://orcid.org/0000-0003-1856-6101

c

https://orcid.org/0000-0001-6426-9939

authors in (Alves et al., 2024) propose a blockchain-

based traceability platform that implements traceabil-

ity in this sector. The traceability platform registers

relevant data items that are used to compute a sustain-

ability index, which classifies garments into different

levels of sustainability, based on indicators collected

throughout the value chain as proposed in (Alves

et al., 2022b; Williams et al., 2023). The sustainabil-

ity index label must be easy to understand by all con-

sumers and must contain summary information on the

social and environmental impact of clothing produc-

tion (Williams et al., 2023). The traceability platform

registers a set of metrics from the industrial and lo-

gistics activities along the value chain, for each pro-

duced lot of intermediate or final product. From the

collected values for each type of metric, it calculates

and registers, for each produced lot, an environmen-

tal sustainability indicator or score. In addition, some

socially relevant company-level metrics are collected

and registered. And, from those metrics, a company

social sustainability score is calculated (Alves et al.,

2024). These sustainability scores empower end-

consumers with information that allows them to select

the most sustainable clothing. However, this requires

288

Rosado da Cruz, A., Silva, P., Serra, S., Rodrigues, R., Pinto, P. and Cruz, E.

Data Quality Assessment for the Textile and Clothing Value-Chain Digital Product Passport.

DOI: 10.5220/0012732900003690

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 26th International Conference on Enterprise Information Systems (ICEIS 2024) - Volume 2, pages 288-295

ISBN: 978-989-758-692-7; ISSN: 2184-4992

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

that the values collected to calculate the sustainabil-

ity scores are reliable. During the implementation of

the reported project, the authors concluded that not all

companies were at the same level of digital develop-

ment (Alves et al., 2024). Some companies were able

to automatically collect information on sustainability

indicators, through Internet Of Things (IoT) devices,

while others did not (Alves et al., 2022b). To allow

all companies to be included in the project and im-

plement traceability on their products, a platform was

developed to manually collect this information (Dias

et al., 2023). Through this platform, companies enter

the indicator values manually into the system. In con-

tinuation of this work, it became necessary to create

a data validation tool, in particular, to validate values

that are manually entered into the system, not only

using the platform presented in (Dias et al., 2023),

but that can be used by all different platforms that are

integrated with the traceability platform Application

Programming Interface (API)(Alves et al., 2024).

This paper proposes a software service and asso-

ciated API for validating the values introduced for the

metrics used for calculating the sustainability indica-

tors of a textile company and its product lots. This

data validation service may be integrated with the dif-

ferent software applications that feed the traceability

platform.

The rest of this paper is structured as follows: the

next section covers the research methodology used

in this project. Section 3 presents an example T&C

value-chain business process for the production of a

T-shirt, and details the different steps, which require

the reporting of indicator values to the traceability

platform. In section 4, the mechanisms for data qual-

ity assurance and reliability are reviewed. Then, sec-

tion 5 covers our proposed solution for a data vali-

dation software service. Finally, section 6 presents

conclusions and draws some lines for future work.

2 RESEARCH METHODOLOGY

To conduct this study, we use the Design Science Re-

search (DSR) methodology. This research method-

ology seeks to produce actionable knowledge to cre-

ate artifacts that address specific organizational chal-

lenges (Cruz and da Cruz, 2020). DSR is intended

to solve problems never solved before, in a unique

and innovative way, or to solve problems previously

solved, but more efficiently and effectively than the

existing approaches.

DSR is a process composed of the following main

research activities (Cruz and da Cruz, 2020; Hevner

et al., 2004):

• Problem identification and motivation - for fi-

nal consumers, it is important to have trans-

parency in how the products in the T&C value

chain have reached them, that is, which activities

have been developed in order to produce and sell

any given garment, and what social and environ-

mental impact they had. For companies, it is im-

portant to know their suppliers, and how they im-

pact environment and society.

• Definition of the objectives for the solution -

having previously developed a traceability plat-

form for the T&C value chain, the goal is now to

ensure quality in the data that is submitted to the

traceability platform.

• Design and implementation - a prototype solu-

tion has been implemented, and this is presented

in this paper.

• Demonstration - In a more advanced state, we

will prove that the artifacts are capable of solving

the mentioned problems, putting them to work in

a T&C traceability system.

• Evaluation - The developed data quality assess-

ment service will undergo different tests (e.g., per-

formance, usability) and, at a later stage, collected

data will be assessed for completeness and consis-

tency.

• Communication - When the project passes all ap-

proval tests, the results are to be published and

discussed at a conference.

3 THE TEXTILE AND CLOTHING

VALUE CHAIN

This section summarizes the main activities that can

be involved in manufacturing garments. Many differ-

ent types of industries can be involved in the creation

of a garment, starting with the production of raw ma-

terials. There is a huge variety of raw materials with

different origins, such as natural fibers, which come

from agriculture and livestock farming, like cotton,

silk, or wool; cellulose fibers such as viscose, etc. ex-

tracted from plants and wood; synthetic fibers, chem-

ically produced from materials, such as petroleum,

like polyester, acrylic, or nylon (Alves et al., 2024).

Nowadays, some industries already use recycled ma-

terials as raw materials. These materials are produced

from textile waste, plastic bottles, etc.

As a simple and concrete example of the process

of creating a garment, is represented in Figure 1. It

presents a business process for producing a 100% cot-

ton T-shirt. This is one of the simplest processes be-

Data Quality Assessment for the Textile and Clothing Value-Chain Digital Product Passport

289

Figure 1: Example business process for producing a cotton T-shirt.

cause it involves only one type of raw material (cot-

ton); however, in the vast majority of cases, textile

and clothing items are made from several types of raw

materials with different origins.

As can be seen in Figure 1, to produce a T-shirt,

the following production activities are necessary:

• Raw Material production, represented in Figure 1

by the activity Growing Cotton, is the first activity

in the value chain.

• Spinning, where the raw material is transformed

into yarn. In the case shown in Figure 1, it trans-

forms the cotton bales into cotton yarn.

• Weaving, transforms yarn into fabric. The same

fabric can be made up of several types of yarn, for

instance, 50% cotton and 50% polyester.

• Printing is about coloring the fabric with simple

colors, patterns, etc.

• Manufacturing that involves cutting, sewing, and

assembling the piece of textile or clothing.

• Finishing may involve some final finishing.

Raw material production is the first activity in the

value chain. After the raw material is produced, a

large number of different types of industries can be

involved. Some industries carry out all activities from

receiving the raw materials to creating the final gar-

ment. Other industries carry out some of the activities

involved, for example spinning and weaving. How-

ever, some industries specialize in a single activity,

e.g. spinning. This means that, from the production

of the raw material to the creation of the final gar-

ment, intermediate products can travel several kilo-

meters, and it is very common for these products to

be transported between different countries on differ-

ent continents, using different types of transportation

(boat, train, truck, etc.) This is represented in Figure

1 by the BPMN gateways and the optional activities

“transport to other facilities”, meaning that, between

each production activity, it may be necessary to trans-

port the (intermediate) product from one facility to

another. The transport itself can be more or less envi-

ronmentally friendly.

For the DPP, in each of these production activities,

it is necessary to collect and store, in the traceability

platform, the information about the activity as well as

the values on the various indicators that can affect the

environment, such as water consumed, toxicity pro-

duced, energy consumed, waste, etc.

4 RELATED WORK ON DATA

QUALITY ASSESSMENT

Data is some value that characterizes a real-world ob-

ject or event. Data quality assurance mechanisms are

essential and crucial for any system that relies on data.

Data quality plays an important role in any sector and

has a significant impact on organizational and value

chain operations. Data quality may be characterized

and measured through different attributes or dimen-

sions. These attributes indicate the overall quality

level of data. Different Data Quality Frameworks

identify different relevant quality attributes (Cichy

and Rass, 2019).

The most common and consensual quality at-

tributes or dimensions, from different frameworks,

are, according to (Cichy and Rass, 2019; Wang and

Strong, 1996):

• Completeness: The degree to which the data pos-

sesses adequate breadth, depth, and scope for the

given task.

• Accuracy or Validity: The degree to which data

are valid, reliable, and certified.

• Timeliness: The degree to which the age of the

data is appropriate for the given task.

• Consistency: The degree to which data present a

standard format and are compatible with previous

data.

• Accessibility: The degree to which data is avail-

able, or easily and quickly retrievable.

The level or degree of data quality refers to the

extent to which the data meets the expectations and

requirements of its intended purposes (Sebastian-

Coleman, 2012). This data quality degree is a func-

tion of the level of adherence of data to each stated

dimension.

Data quality is important because it can affect the

conclusions drawn from it. Poor data quality can lead

to wasted resources and missed opportunities, while

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

290

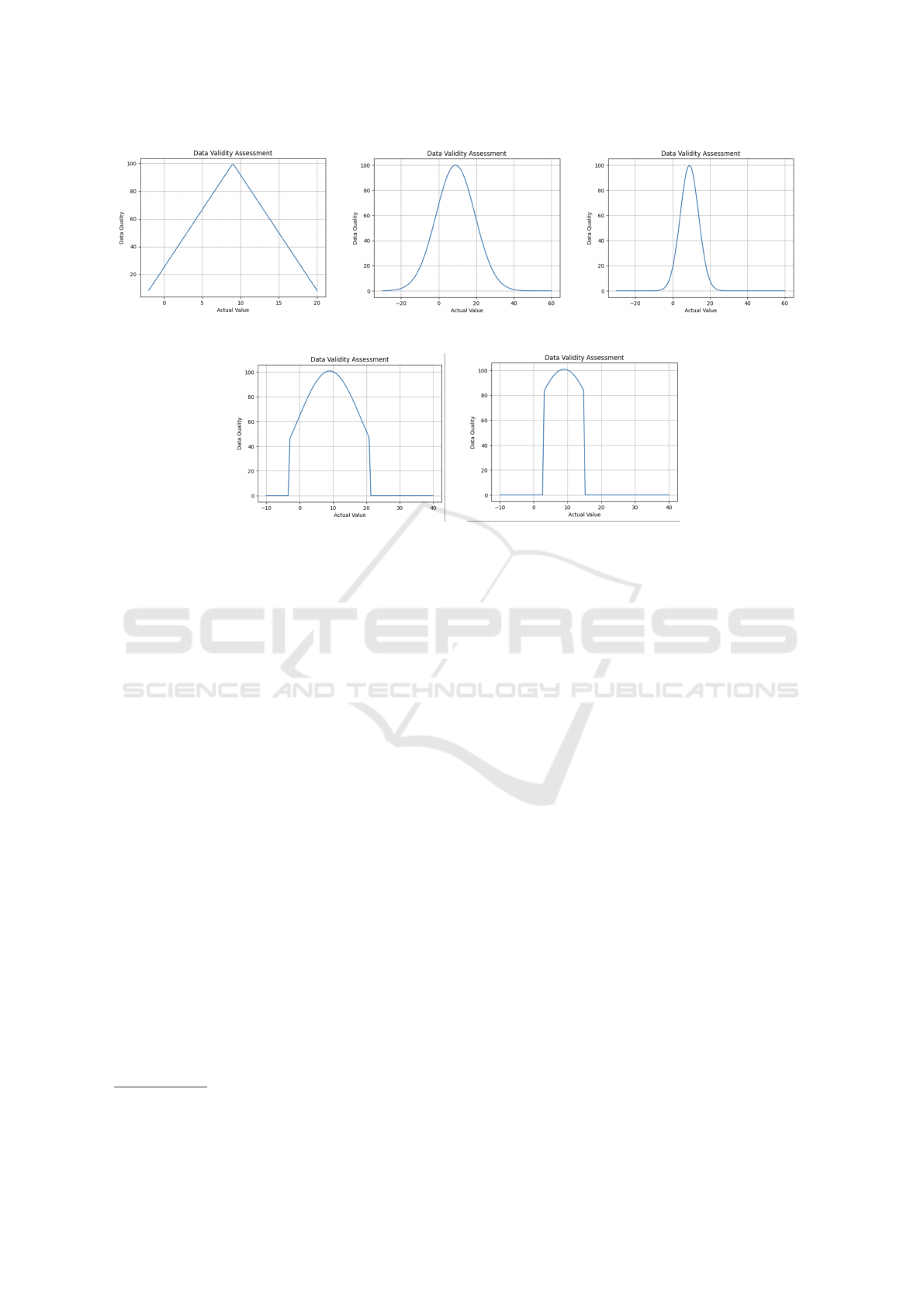

f (x) = 100 × ·

|x−Mean|

Allowed Range

(a) Assessing data validity, with linear

decay of validity score

f (x) = 100 × e

−k·

|x−Mean|

Allowed Range

2

(b) Assessing data validity, with

exponential decay of validity score,

where k represents the rate of decay.

f (x) =

100 × e

−k·

|x−Mean|

Allowed Range

2

+ BI ,

if x inside range

0 , otherwise

(c) Assessing data validity, with

exponential decay of validity score, if

the actual value is inside the range,

where k represents the rate of decay,

and the allowed range is (max − min).

f (x) =

100 × e

−k·

|x−Mean|

Allowed Range

2

+ BI ,

if x > min

V

x 6 max

V

x inside range

0 , otherwise

(d) Assessing data validity, with

exponential decay of validity score, if

the actual value is between min and

max and is inside the allowed range

around the mean, where k represents

the rate of decay, and the allowed range

is (max − min).

Figure 2: Proposed formulas for assessing data quality - validity (x is the actual value being validated).

high-quality data can enhance the effectiveness and

efficiency of data-driven solutions.

Any data-dependent activity or solution needs to

have confidence in the data that is being received

and used. This data quality assessment can measure

both subjective and objective quality characteristics

of data. Subjective characteristics measure the per-

ceptions of people involved with the data, and objec-

tive characteristics measure states of the data (Pipino

et al., 2002).

The assessment of data quality by stakeholders,

including data collectors and consumers, is subjective

and influenced by their needs and experiences. If the

quality of the data is perceived as low, it will affect the

behavior of stakeholders (Pipino et al., 2002). Objec-

tive assessments may be independent of the task or

dependent on the task. Metrics for data quality task-

independent assessments have no contextual knowl-

edge of the application domain and can be applied re-

gardless of the tasks at hand. While, task-dependent

metrics must have the organization’s business rules,

regulations, and other contextual information into ac-

count (Pipino et al., 2002).

Metrics for objective assessment need to be devel-

oped according to a set of defined principles, so that

they are tailored to specific requirements. Three func-

tional forms are typically used (Pipino et al., 2002):

simple ratio, minimum or maximum operation, and

weighted average. These functional forms can incor-

porate sensitivity parameters for further customiza-

tion.

Existing data quality metrics are mainly de-

rived without any contextual information (Even and

Shankaranarayanan, 2007). For improving data qual-

ity for specific needs, it is needed to incorporate and

better reflect contextual information in the assessment

formulas. In the next section, a set of quality assess-

ment formulas is proposed to assess numeric data val-

ues for specific ends in the context of the T&C value

chain. The proposed formulas are customizable in or-

der to be adaptable to different ends. The specific

formula to be used for validating values for each de-

fined metric or indicator within each specific produc-

tion activity, together with its associated customizable

parameters, may be selected and “tuned” through an

admin backoffice application.

5 PROPOSED SOLUTION

As explained before, the application scenario for the

proposed data validation service is a traceability plat-

form for environmental, social, and economic sustain-

ability information across the T&C value chain. The

goal is to assess data quality once, before registering

the data on the traceability platform. In this scenario,

the focus is on the accuracy or validity of data, as it

has been previously defined. Besides, all data being

registered are numeric data, but still can have differ-

ent validation criteria. The data quality validation ser-

vice, proposed in this paper, offers, to the applications

integrated with the traceability platform, a unique val-

idation tool for all stakeholders. And, because differ-

ent data may need different validity criteria, the pro-

posed solution may be tuned to use different valida-

tion methods for different sustainability metrics being

Data Quality Assessment for the Textile and Clothing Value-Chain Digital Product Passport

291

(a) Linear Function (b) Non-linear exponential function (k

= 0.67)

(c) Non-linear exponential function (k

= 3)

(d) Non-linear exponential function

with exclusion of values not in the

allowed range around the mean.

(e) Non-linear exponential function

with exclusion of values not between

the minimum and maximum values.

Figure 3: Assessing Data Validity (min=3, max=15, mean=9).

recorded.

In the next subsection, we propose four formulas

that can be used to validate each sustainability metric

value. Then, we explain the different aspects of our

proposed solution for creating a validation service, in-

cluding its architecture and entity classes model.

5.1 Assessing Data Quality - Validity

Four formulas for validating the sustainability met-

rics’ values are analyzed in this subsection (refer to

Figure 2).

All formulas are based on checking the value to

be evaluated as to whether it belongs to a range of

values, between a minimum (min) and a maximum

(max), and its proximity to a mean value. This mean

value intends to identify the central tendency of the

set of values of that sustainability metric. Central ten-

dency has three important measures that are the arith-

metic mean, median, and mode. The arithmetic mean

of a set of numbers is the average of those numbers.

The median of a set of numbers is the middle number

in that set, having the numbers ordered. The mode or

modal of a set of numbers is the most repeated num-

ber in the set, i.e. is the number with the highest fre-

quency in that set

1

.

1

https://statistics.laerd.com/statistical-

guides/measures-central-tendency-mean-mode-median.php

Values closest to the mean, or central tendency

value, have the greatest validity degree. A value far

from the mean will have a lower validity degree. The

decay of the validity of the value, as it moves away

from the mean, may be different from one metric to

another. Furthermore, in case a value crosses the ex-

tremes of the range (minimum or maximum), step-

ping out of the defined range, its degree of validity

may be zero or may still be an acceptable value, de-

pending on the metric in question. The first formula

(Figure 2a) may be used to assess values for metrics

where the validity degree of a value decays linearly,

as it moves away from the mean. This can be seen

graphically in Figure 3a.

Plots in Figure 3 show examples of applying the

four validation functions from Figure 2 for assessing

the validity of a value x. The goal is to validate that x

is inside the interval from 3 to 15, with a mean value

of 9.

In the second formula (Figure 2b), the validity de-

cays exponentially, depending on a defined rate of de-

cay. Figure 3b shows the plot for k = 0, 67, and Figure

3c shows the plot for k = 3.0. In that formula (Figure

2b):

• e is the Napier’s constant, or Euler’s number (ap-

proximately 2.71828).

• k is a positive constant that determines the rate of

decay. k may be adjusted to control how quickly

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

292

(a) Non-linear exponential function (k

= 0.8)

(b) Non-linear exponential function

with exclusion of values not in the

allowed range around the mean.

(c) Non-linear exponential function

with exclusion of values not between

the minimum and maximum values.

Figure 4: Assessing Data Validity (min=3, max=15, mean=5).

the data quality decreases as the actual value de-

viates from the mean.

In formula (c) (Figure 2c) the validity degree also

decays exponentially, but, if the value being assessed

is outside of the defined range around the mean, it

rapidly decays to zero (see graphic in Figure 3d). In

formula (c), a bonus value (BI) may be defined to be

added to values inside the defined range.

In formula (d) (Figure 2d), if the value being as-

sessed is below the minimum or above the maximum

values, it immediately decays to zero (see graphic in

Figure 3e). In formula (d), a bonus value (BI) may be

defined to be added to values inside the defined range

around the mean and between the min and max values.

Plots in Figure 4 illustrate formulas (b), (c) and (d)

for min = 3, max = 15 and mean = 5. And, plots in

Figure 5, illustrate the same formulas for min = 150,

max = 500 and mean = 300.

5.2 Validation Service and Associated

Admin Platform

For the scenario previously described, two different

actors of the data quality assessment platform have

been identified. These are depicted in the platform’s

use case model in Figure 6. The ”User via API” rep-

resents the value chain operator using the assessment

service’s API to validate the value of a sustainabil-

ity indicator, while using its organizational ERP or

MRP application, or the integration portal described

in (Dias et al., 2023). The Admin user type defines the

indicators metadata, whose values will be validated

through the platform. The admin uses a backoffice

Admin platform.

The proposed platform domain model, repre-

sented in Figure 7, is composed of three main enti-

ties: Metric, Productive Activity, and ProductiveAc-

tivityMetric. Each entity has its unique identifier (ID)

and employs soft-delete functionality for elimination.

Metric is the entity that represents the information

about the sustainability indicators, such as water or

CO2 footprint, among others. Here, only the Metric’s

name and a brief description are considered.

Productive Activity represents the existing activi-

ties that a piece of clothing needs to go through un-

til it reaches the stores, like spinning, weaving, and

many others. The Productive Activity may be charac-

terized by its name and its reference, which is used to

uniquely identify each productive activity. Because

a productive activity can have many metrics associ-

ated with it, and vice-versa, and a given metric may

have different validation requirements depending on

the productive activity it is being associated with, en-

tity ProductiveActivityMetric unfolds the relationship

between a metric and a productive activity, and de-

fines the formula and other parameters used to vali-

date the record values. These parameters include the

minimum (min), maximum (max), mean (mean), and

the rate of decay (k). These parameters are essential

for validating whether the values inserted by the user

are correct or not and assessing their validity, by using

the formula specified in the ProductiveActivityMetric.

Additionally, the Record entity represents the data

entered by users on the platform through the service’s

API, which undergoes validation. The validated val-

ues are stored, together with their validity degree to

create a dataset that will be used in the future to train

a machine learning model for enhancing this valida-

tion service.

5.3 Architecture

The architecture of the proposed validation service

and platform comprises a backend service for quality

assessment of value metrics, which includes a Post-

greSQL

2

database, a services’ API built on FastAPI

3

2

https://www.postgresql.org

3

https://fastapi.tiangolo.com

Data Quality Assessment for the Textile and Clothing Value-Chain Digital Product Passport

293

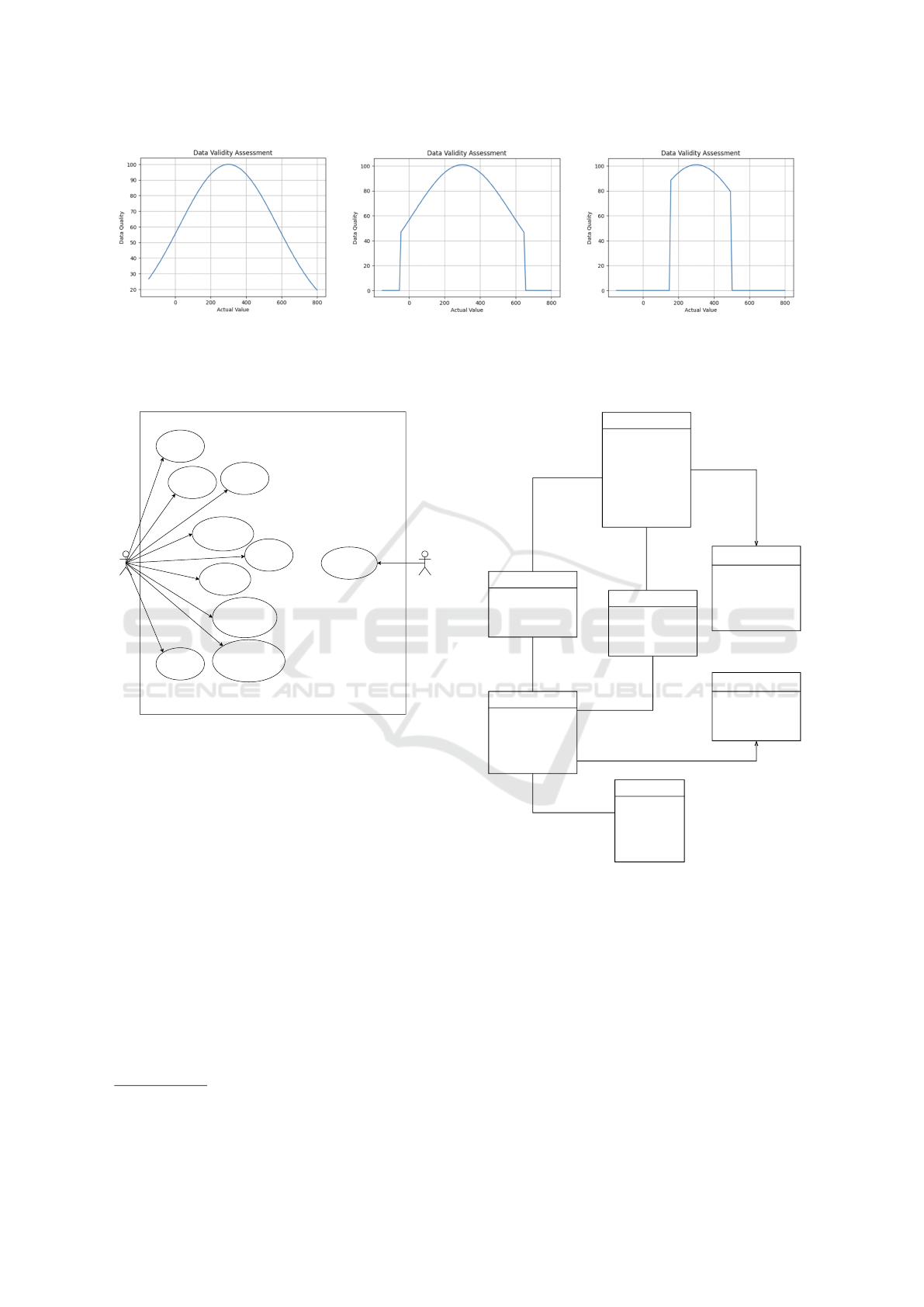

(a) Non-linear exponential function (k

= 0.8)

(b) Non-linear exponential function

with exclusion of values not in the

allowed range around the mean.

(c) Non-linear exponential function

with exclusion of values not between

the minimum and maximum values.

Figure 5: Assessing Data Validity (min=150, max=500, mean=300).

Create new

productive activities

Delete productive

activities

Validation

Platform

Validate metric

value

Alter productive

activities

Create new

records

Create new

metrics

Alter metrics

Delete metrics

Associate metrics with

productive activities

Disassociate metrics with

productive activities

Admin User via API

Figure 6: Use Case Model for the T&C Traceability Plat-

form.

framework, and Keycloak

4

for user authentication

and authorization; and, a frontend web application for

the Admin user profile, built with Next.js

5

.

The flow begins with admin users accessing the

Next.js frontend, which interacts with the FastAPI

backend. Upon initiating requests, authentication is

managed through Keycloak, ensuring secure access.

The backend, in turn, retrieves and stores data in the

PostgreSQL database, facilitating the Quality Assess-

ment service. This architecture enables a seamless

and secure workflow for value metrics assessment and

enables the collection of value metrics for building a

dataset for future work toward an ML-based assess-

ment service.

The user will authenticate from the frontend of the

developed back office. After the authentication is suc-

cessful, the Keycloak server will return a token. Then,

4

https://www.keycloak.org

5

https://nextjs.org

ProductionActivityMetric

+ min

+ max

+ mean

+ k

+ minDegValid

+ minDegSuspect

Metric

+ name

+ description

+ unit

ProductionActivity

+ name

+ reference

+ field: type

ValueRecord

+ value

+ datetime

+ validity_degree

+ lot_reference

1

*

1

*

1

*

1

*

ValidationFormula

<<enum>>

+ linear

+ exponential

+ exp_strict_range

+ exp_strict_MinMax

-formula1

-activity

-metric

-activity

-metric

-values

-values

-customParsByMetric

-customParsByActivity

Validity Category

<<enum>>

+ Valid = 1

+ Suspect = 0

+ Invalid = -1

+ validity_category 1

Organization

+ name

+ orgCode

+ eac

+ country

1

*

-organization

Figure 7: Domain Model for the T&C validation Platform.

this token will be passed to the backend, where it will

ensure that the token is valid, to ensure maximum se-

curity possible. In a case the user is accessing the val-

idation service via API, the explained flow remains

the same but, instead of the authentication being done

through the back office, it is done through a Keycloak

endpoint specifically for this purpose.

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

294

6 CONCLUSION AND FUTURE

WORK

Economic globalization has meant that business part-

ners (or companies) based in various parts of the

world can participate in the global product’s value

chains. As a result, products often travel many kilo-

meters around the world, involving different trans-

port companies. This phenomenon amplifies the

complexity of regulatory frameworks and legal juris-

dictions governing product manufacturing. Conse-

quently, within a product’s value chain, there may be

highly automated companies using IoT devices and

Artificial intelligence (AI), and also companies with-

out any form of digitalization.

Regardless of the level of digitalization of the

companies involved in the value chain, for imple-

menting the traceability of a product and store infor-

mation for calculating its sustainability index, there is

the need to collect and integrate data from all partici-

pants in the value chain, from the creation of raw ma-

terials, transport, manufacturing, etc. until it reaches

the final consumer. Before integrating the collected

data, in the moment of collecting it, the quality and

veracity of the data must be ensured. Thus, the data

must be validated in an homogeneous manner regard-

less of the level of digital maturity of the business

partner company.

This article has presented a solution for validating

the data collected by any of the business partners in-

volved in the T&C value chain, before integrating it in

a traceability platform. This article arises within the

scope of a project whose objective is to collect infor-

mation throughout the value chain of the textile and

clothing industries, in order to implement the digital

passport of products and allow the calculation of the

product’s sustainability index.

As future work, we intend to use Machine Learn-

ing algorithms, trained with the dataset being built

with the presented service, allowing for more dy-

namic and accurate data validation.

ACKNOWLEDGEMENTS

This contribution has been developed in the context

of Project ”BE@T: Bioeconomia Sustent

´

avel fileira

T

ˆ

extil e Vestu

´

ario-Medida 1”, funded by ”Plano de

Recuperac¸

˜

ao e Resili

ˆ

encia” (PRR), through mea-

sure TC-C12-i01 of the Portuguese Environmen-

tal Fund (”Fundo Ambiental”). For improving the

manuscript’s text some AI-based tools have been

used, such as Google Translator and Writefull. The

plots presented in the manuscript have been based on

a Chat-GPT suggested program in Python.

REFERENCES

Alves, L., Cruz, E. F., Lopes, S. I., Faria, P. M., and da Cruz,

A. M. R. (2022a). Towards circular economy in the

textiles and clothing value chain through blockchain

technology and iot: A review. Waste Management &

Research, 40(1):3–23. PMID: 34708680.

Alves, L., Cruz, E. F., and Rosado Da Cruz, A. M. (2022b).

Tracing sustainability indicators in the textile and

clothing value chain using blockchain technology. In

2022 17th Iberian Conference on Information Systems

and Technologies (CISTI), pages 1–7.

Alves, L., S

´

a, M., Cruz, E. F., Alves, T., Alves, M., Oliveira,

J., Santos, M., and Rosado da Cruz, A. M. (2024).

A traceability platform for monitoring environmen-

tal and social sustainability in the textile and clothing

value chain: Towards a digital passport for textiles and

clothing. Sustainability, 16(1).

Cichy, C. and Rass, S. (2019). An overview of data quality

frameworks. IEEE Access, 7:24634–24648.

Cruz, E. F. and da Cruz, A. M. R. (2020). Design science

research for is/it projects: Focus on digital transfor-

mation. In 15th Iberian Conf. on Information Systems

and Technologies (CISTI), pages 1–6.

Dias, R., Cruz, E. F., and Rosado Da Cruz, A. M. (2023).

Traceability platform for the textile and clothing value

chain. In 23 Confer

ˆ

encia da Associac¸

˜

ao Portuguesa

de Sistemas de Informac¸

˜

ao (CAPSI’2023), pages 1–7.

Even, A. and Shankaranarayanan, G. (2007). Utility-

driven assessment of data quality. SIGMIS Database,

38(2):75–93.

Hevner, A. R., March, S. T., Park, J., and Ram, S. (2004).

Design science in information systems research. MIS

Quarterly, 28(1):75–105.

Pipino, L. L., Lee, Y. W., and Wang, R. Y. (2002). Data

quality assessment. Commun. ACM, 45(4):211–218.

Sebastian-Coleman, L. (2012). Measuring Data Quality for

Ongoing Improvement: A Data Quality Assessment.

Morgan Kaufmann.

Wang, R. Y. and Strong, D. M. (1996). Beyond accuracy:

What data quality means to data consumers. J. Man-

age. Inf. Syst., 12(4):5–33.

Williams, A., Hodges, N., and Watchravesringkan, K.

(2023). An index is worth a thousand words: Con-

sidering consumer perspectives in the development of

a sustainability label. Cleaner and Responsible Con-

sumption, 11:100148.

Data Quality Assessment for the Textile and Clothing Value-Chain Digital Product Passport

295