Industry 4.0: Wearable IoT Device Applied to Warehouse Management

Lucas Samaniego Vicente

a

, Saul Delabrida

b

, Mateus Coelho Silva

c

,

Adrielle de Carvalho Santana

d

and Ricardo Augusto Rabelo Oliveira

e

Programa de P

´

os-Graduac¸

˜

ao em Instrumentac¸

˜

ao, Controle e Automac¸

˜

ao de Processos de Minerac¸

˜

ao, Universidade

Federal de Ouro Preto e Instituto Tecnol

´

ogico Vale, Ouro Preto, Minas Gerais, Brazil

Keywords:

Warehouse, Raspberry Pi, IoT, Node-Red, Wearable, RFID.

Abstract:

Companies in the retail sector need proper control of their stock to avoid financial waste and guarantee the

effectiveness of their operations. A more detailed analysis of this problem reveals the complexity of imple-

menting a management methodology that enables optimal control of all stock, since human errors occur during

operations and various scenarios depend on different variables. Therefore, to solve the problem of efficient

warehouse stock management and the resulting inefficiency of operations, this study proposes the implemen-

tation of a wearable, developed using a Raspberry Pi 4B with IoT and Node-Red, in conjunction with a mobile

device, which assists operators during the processes of stocking, searching for and removing material from

the warehouse more efficiently. As a result, the proposed system can identify, by reading an RFID tag with

a mobile device, the characteristics of the equipment in question, showing all this information on an OLED

display, as well as directing what will be done with this equipment via an app. Among the metrics that demon-

strate the effectiveness of the proposed system is the time taken to stock and remove the material, since all the

procedures are managed in real-time on the app and updated in its inventory control.

1 INTRODUCTION

The purpose of having a stock in a company is based

on the notion that certain products or materials are

expected to be used later, to meet market demand

or internal demand. Among its many functions, the

following can be mentioned: Increased scale in the

retail and transport sectors, protection against price

increases, as well as safeguarding the organization

against uncertainties in demand and replenishment

times. In a nutshell, stockpiling provides a better bal-

ance in terms of the organization’s operations, mak-

ing it possible to reduce labor costs and maximize

installed capacity. (Bertaglia, 2012) To have access

to these functionalities, it is often necessary to spend

a lot of money, but stocks guarantee safety levels in

complex and uncertain environments. (Gonc¸alves,

2013)

In this context, efficient stock management is es-

a

https://orcid.org/0009-0004-3526-2454

b

https://orcid.org/0000-0002-8961-5313

c

https://orcid.org/0000-0003-3717-1906

d

https://orcid.org/0000-0003-1457-8930

e

https://orcid.org/0000-0001-5167-1523

sential, and there are alternatives to help this complex

process. Among them, the use of technology, lever-

aged by the advent of Industry 4.0, has become in-

creasingly attractive. This is justified by its potential

to be used on a large scale, at an increasingly afford-

able cost, and because it incorporates challenges that

are on the frontier of human knowledge, with the po-

tential to revolutionize sectors in the field of logistics.

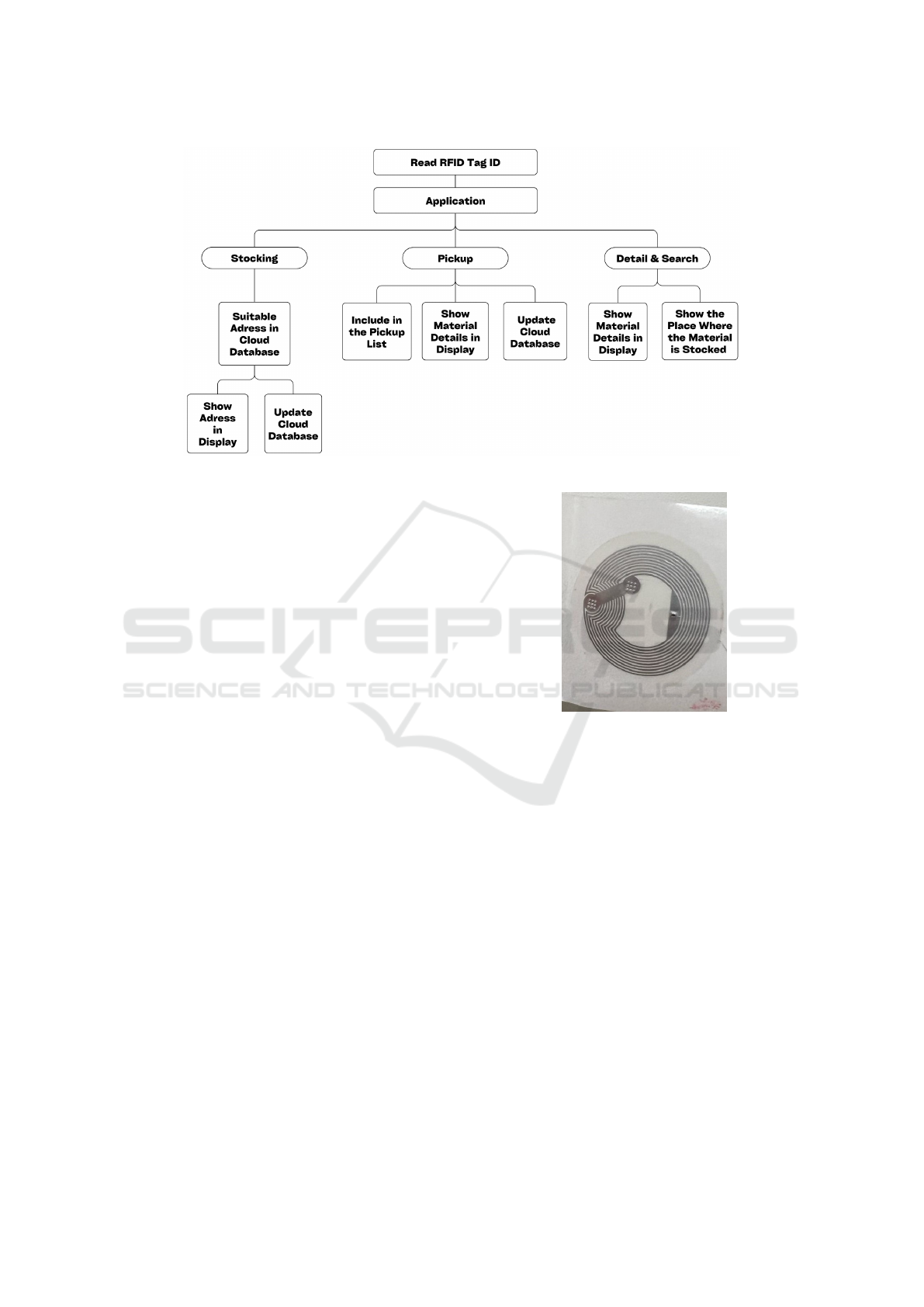

Figure 1: Schematic diagram of the proposal architecture.

The fourth industrial revolution, or industry 4.0,

seeks to increasingly integrate various productive sec-

tors, with machinery and devices connected, forming

a complex and robust system. In this context, this in-

532

Vicente, L., Delabrida, S., Silva, M., Santana, A. and Oliveira, R.

Industry 4.0: Wearable IoT Device Applied to Warehouse Management.

DOI: 10.5220/0012736300003690

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 26th International Conference on Enterprise Information Systems (ICEIS 2024) - Volume 2, pages 532-539

ISBN: 978-989-758-692-7; ISSN: 2184-4992

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

dustry has six important attributes in terms of project

management: The Internet of Things, cyber-physical

systems, Big Data, automation, artificial intelligence,

and cloud computing. (Borges et al., 2022)

From the current market reality, one case worth

highlighting concerns order picking, since it is seen

as a laborious, arduous, time-limited, repetitive, error-

prone, and expensive process in warehouses. These

characteristics put a significant strain on the human

worker, creating fatigue and feelings of monotony,

as well as dissatisfaction, generally leading to poor

performance and employee demotivation.(Ponis et al.,

2020) (Rejeb et al., 2020)

Because of this reality, one of the most promi-

nent technologies in Industry 4.0 has begun to be used

when it comes to manufacturing and logistics opera-

tions, which is Augmented Reality. It uses computer-

generated displays, sound, text, and effects to en-

hance the user experience in the real world and sup-

port workers in their daily tasks, such as assembly,

order picking, and maintenance. (Plakas et al., 2020)

This article aims to present a proposal for a sys-

tem that uses an IoT wearable device to optimize op-

erations within a warehouse, using a low-coast system

to read RFID tags within an smartphone, and provide

essential data to the wearable. To this end, this arti-

cle is divided into related works, the state of the art

in wearables in Industry 4.0, an overview of the pro-

posed system, the methodology used, and, finally, the

respective results and discussions.

2 RELATED WORKS

This section presents the related works in the litera-

ture, providing an overview of how Industry 4.0 tech-

nologies can be applied in a warehouse scenario.

Recent works in the literature include (Hamdy

et al., 2022), which aimed to propose a system that

uses the Node-Red platform to apply the Internet of

Things in a warehouse scenario. Based on a database,

it was possible to manage inventory and forecast stock

demand, using both quantitative and qualitative meth-

ods. In this context, the system could not be tested in

a real warehouse, nor did it implement a user interface

with a dashboard linked to Node-Red for real-time vi-

sualization of all inventory, which the author suggests

as an opportunity for application in future work.

For the entire warehouse to communicate with the

internet, it is necessary to have middleware that is

also capable of receiving information from the ma-

terials and interacting with the user. Among the var-

ious devices that have this potential, the Raspberry

Pi 4 Model B was an option used in the (Silapunt

et al., 2022) study. Using this middleware, an in-

telligent manual pallet truck was created, whose in-

stalled Raspberry Pi processed and uploaded the data

received on the server via the local Wi-Fi network

and, with the web application developed, analyzed

this data and carried out specific warehouse activities.

Based on (Peri

ˇ

sa et al., 2018), it can be seen

that wearable devices are applicable to warehouse

management. Through this study, a smart wearable

bracelet was created, which had RFID tag readers,

NFC, and a Bluetooth connection. When wearing the

smart wristband, the user receives all the relevant in-

formation collected from the smart warehouse envi-

ronment and can read barcode information from prod-

ucts and pallets. In addition, the user obtains the in-

formation needed to determine the location of specific

pallets of products.

3 STATE OF THE ART IN

WEARABLES FOR INDUSTRY

4.0

3.1 Augmented Reality in Warehouses

A use case is presented in a study on the possibili-

ties of augmented reality in warehouse management.

In this study, the global supply chain of the logis-

tics company DHL is evaluated, which is one of the

first companies to introduce augmented reality tech-

nology. The entire system runs on a platform, where

a worker uses a smart glasses, like Vuzix, and a ring

scanner to collect goods.

These devices provide the operator with various

functions and information, starting with the operator’s

login, and visual aids displayed graphically through

the glasses, where the user will see on the graphi-

cal tool the exact location of the goods, the quantity

they should select and the next item. This information

guides the worker precisely, quickly, and efficiently to

a particular order item.

Therefore, this method of picking goods is much

more efficient than the classic form of paper picking.

Finally, about worker training and integration into the

work process, it can be said that this technology is

not difficult to use and can be quickly learned by the

worker.(Hus

´

ar and Knap

ˇ

c

´

ıkov

´

a, 2021)

3.2 Wearable Devices in Inventory

Management

The use of digital resources has proven to be a facilita-

tor inefficient inventory management, which enables

Industry 4.0: Wearable IoT Device Applied to Warehouse Management

533

it to even be a crucial requirement in the market, since

dealing with large-scale data is not a simple task, and

through its use, new insights can be investigated for

improvements in the supply chain process, as noted

by (Anusha et al., 2022).

In this context, in a world of scarce resources, the

use of information converted into knowledge is essen-

tial not only today but also for the future of human-

ity. Thus, this creation and utilization of knowledge

is a basic condition in the supply chain, and inventory

management must be supported by intelligent algo-

rithms and modern heuristics that use this knowledge

to avoid overstocking while combating stock short-

ages or losses (Cimen et al., 2021) (Manuel Vera,

2021).

3.3 Communication Between Hardware

and RFID Sensors

Well-known logistics companies such as Amazon use

sensors to optimize processes in which it is necessary

to identify several items simultaneously, which would

be too slow and error-prone without this implementa-

tion. Its application can extend even to the food indus-

try since there are studies in which RFID tags are in-

tegrated with chip-free sensors to measure humidity,

temperature, gas concentration, and pH. (Fathi et al.,

2020)

The way it is applied varies according to need

since this technology can be molded for different

types of use. Analyzing the behavior and monitor-

ing the movement of a visitor in a museum, for ex-

ample, can be done using a set of mobile antennas

and passive RFID tags. The embedded system was

made up of an RFID reader, a 10-axis inertial man-

agement unit, and a logger that allows internal local-

ization based on the detection of multiple tags located

in known positions along the visitor’s route. This ap-

proach was tested in simulation and in real museum

practice.(Vena et al., 2021)

However, the biggest challenge that discourages

the implementation and full benefits of Industry 4.0

technologies are the costs involved with the technol-

ogy. In the supply chain, the implementation of RFID

technology is hampered by the cost of RFID tags and

adoption problems. The costs involved with the use-

ful life of the systems tend to make organizations re-

luctant to implement these Industry 4.0 technologies

and, in the case of organizations that have already im-

plemented the technology, they tend to fall behind in

maintaining these systems due to the costs and the

inaccuracies of the system, since the lack of main-

tenance makes the systems unreliable.(Tikwayo and

Mathaba, 2023)

3.4 Wearable Device Apple Vision Pro

The Apple Vision Pro is a wearable device with sig-

nificant potential to transform human interaction with

the digital world. This device can provide real-time

access to information and detailed guidance for the

execution of complex tasks, enhancing operational ef-

ficiency across various contexts.

In daily life, the Apple Vision Pro can have a sub-

stantial impact on user health and well-being. The

device can monitor user health, providing alerts when

rest is needed or if a position could cause injury. Fur-

thermore, real-time feedback allows users to quickly

correct errors and learn new skills more efficiently.

In industry, the Apple Vision Pro has the poten-

tial to improve both operational efficiency and prod-

uct quality. Workers can use the device to inspect

products on a production line, identifying defects that

may be difficult to detect with the naked eye.

4 OVERVIEW OF THE

PROPOSED SYSTEM AND

VALIDATION TESTS

This section presents the architecture of the proposed

system. Figure 1 shows a schematic diagram of the

desired architecture and its functionalities.

Generally speaking, the proposed system includes

RFID tags, whose identifications will be read by a

mobile application, which interacts with the tag via its

NFC sensor, and publishes the tag’s identification ID

via MQTT communication, according to the task to

be performed. The tasks are divided into three forms:

1. Stocking: Once the material has been identified,

you want to store it in a suitable place in the ware-

house. Thus, according to the item’s ID, Rasp-

berry Pi 4B will process this data, and, depend-

ing on the material’s characteristics, the cloud

database will indicate the appropriate storage ad-

dress on the display.

2. Pickup: Once a material is to be withdrawn, it

can be updated in the database system by reading

the relevant tag and clicking on the ”withdraw”

button in the application.

3. Detail and Search: Within the mobile applica-

tion, the user will enter the material they want

to search for or have its detailed information

and, according to the information contained in the

database, the display will be informed of the ad-

dress where the item is located and its respective

characteristics. Among the information returned

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

534

Figure 2: System Flowchart.

is material location data, name, part number, se-

rial number, and status, among others. As a result,

the operator can see all the desired information

about a particular item in an up-to-date display.

In more detail, the system can be divided as shown

in Figure 2.

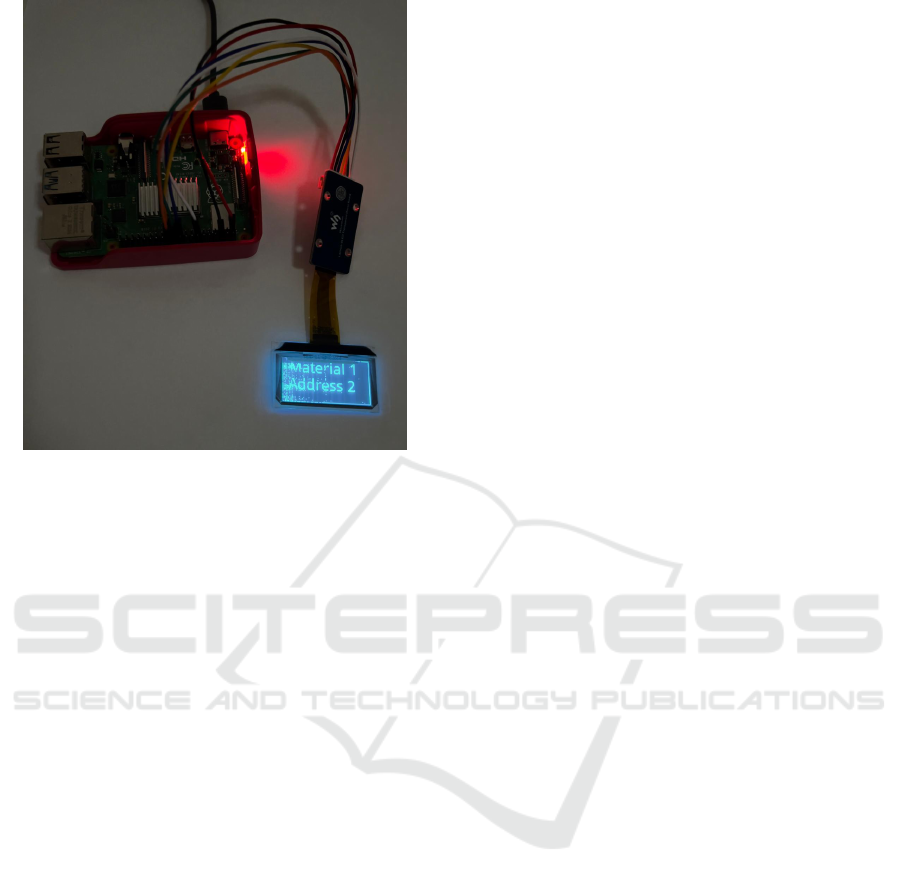

4.1 RFID Tags

Passive RFID tags, which store unique identifications

(IDs), function as passive antennas that receive radio

frequency signals and can be attached using labels to

materials that require stricter control.

RFID tags, employing Radio-Frequency Identi-

fication technology, have emerged as indispensable

tools for optimizing and automating processes across

various domains. Equipped with microchips and an-

tennas, these tags facilitate data transmission through

radiofrequency, enabling efficient identification and

tracking of objects, animals, or even individuals. This

technology represents an evolution compared to con-

ventional barcodes, offering the capability of remote

reading, resulting in faster and more precise data col-

lection in diverse environments.

The distinctive advantage of RFID tags lies in

their ability to store and transmit unique informa-

tion associated with each label. This feature not only

streamlines logistical operations but also contributes

to product authentication and ensures the integrity of

the supply chain.

4.2 Smartphone Application

To read RFID tags and then enable the user to per-

form tasks based on the ID of the tag read, a smart-

Figure 3: RFID Tag.

phone application was developed that has an interface

for interaction with the user, as well as a backend that

directs the application’s MQTT communications with

the broker.

In the Figure 4, it’s show that the smart phone ap-

plication is able to help the operator to search any

good, pick up the item, update the database and stock,

using the NFC reader in the smart phone for identify

the ID number of the RFID tag.

Among the ways to use the functionalities of the

mobile application is the possibility of turning on or

off the device’s NFC sensor, using a button. When

a RIFD tag is identified, its respective ID number is

shown on the smart phone screen. Based on this iden-

tification, the operator specifies what he wants to do

with that material.

We will assume that the indoor location is associ-

ated with the Smartphone Application and the Cloud

Server communication.

Industry 4.0: Wearable IoT Device Applied to Warehouse Management

535

Figure 4: Smartphone application layout.

4.3 Wearable Device

A Raspberry Pi 4B, with a Linux-based operating

system, will be responsible for running code which,

when connected to the internet via Wi-Fi, will be able

to receive specific information from the requested

sensors and send it to a server in the cloud. Once this

data has been processed, the microprocessor receives

it and uses it to help the operator through augmented

reality visualization on the OLED display.

The Figure 5 illustrates how the wearable device

is used. The OLED display is supported by a sup-

port made by 3D printing, which was developed to

be viable as a wearable device and be suitable for the

display fittings and their respective connections to the

Raspberry Pi.

Figure 5: Wearable Device with display.

4.4 Cloud Server

A server hosted in the cloud can have a variety of

resources to meet the demands of software or stor-

age services. Working as a complement to the mi-

croprocessor, which has limited resources due to its

structure, the server is capable of storing, processing,

and managing a large amount of data, and can inte-

grate applications such as MySQL, i.e. a structured

database that helps control data and can be presented

in the form of a dashboard.

In practice, the server receives the RFID tag iden-

tifications checks its database for the information re-

lating to these requested identifications, and sends an

action back to the microprocessor. Also it is responsi-

ble for managing the client’s physical location in the

indoor environment. This feedback provides the nec-

essary information for the Raspberry Pi to transmit

the data requested by the operator to an OLED display

so that the operator can interact with the environment

and this information can be linked to the material in

the form of augmented reality. This form of interac-

tion constitutes an Internet of Things mechanism and

helps make the system lean.

4.5 OLED Display

The component in which the operator can interact

with the environment, with augmented reality, to

identify relevant information about a material, be it its

location, part number, serial number, material status,

and status of said item.

The transparent OLED display has the capability

to allow the wearer to see the surrounding environ-

ment, even if information is being shown on the dis-

play.

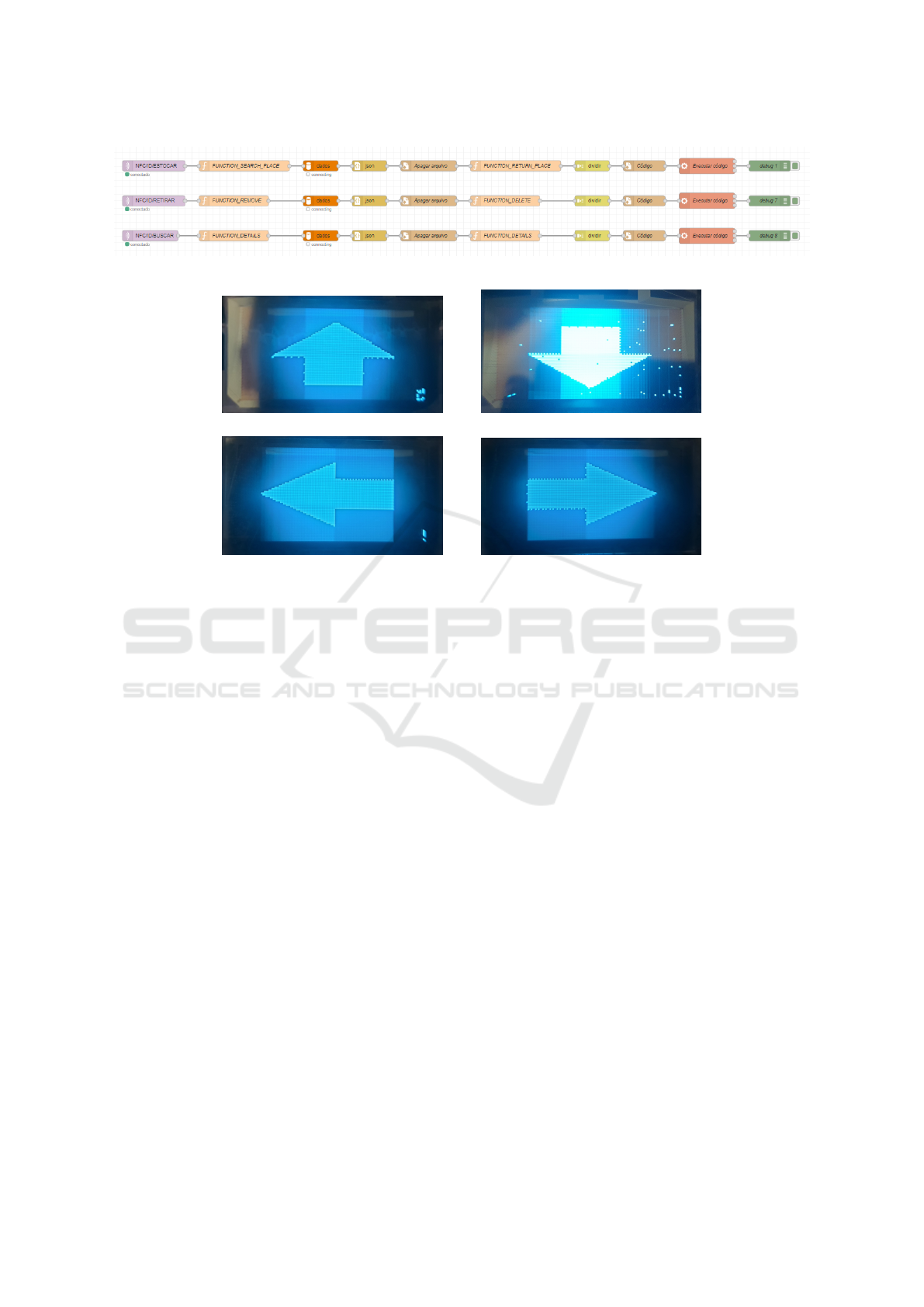

4.6 Validation Tests

Validation tests for a wearable device in a warehouse

environment should indeed focus on critical aspects

such as accurate identification of materials. The de-

vice must be capable of accurately recognizing and

differentiating between various materials and prod-

ucts in the warehouse.

In addition, the device’s ability to provide clear

guidance to the operator is crucial. For instance, the

device could use arrows or other visual indicators to

guide the operator to the exact location of the ma-

terial. This must involve testing the accuracy of the

device’s navigation system and its ability to integrate

with the warehouse’s inventory management system.

These tests help ensure that the device not only

improves the efficiency of warehouse operations but

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

536

Figure 6: Raspberry Pi with OLED display.

also minimizes errors, thereby enhancing the accu-

racy and reliability of the material handling process.

5 METHODOLOGY

5.1 Internet of Things

The Internet of Things is becoming one of the main

foundations of Industry 4.0, helping companies and

organizations to strengthen their level of competitive-

ness in the market. In this context, linked to the pop-

ularization of embedded systems with Wi-Fi connec-

tivity, wireless communication and exchange of infor-

mation between devices has proved to be an alterna-

tive for guaranteeing the security of this information

and its scalability.

5.2 Node-Red Development

Environment

The Node-Red programming tool has been widely

used in the context of research and industry when it

comes to developing programs for automation, mak-

ing it possible to connect devices, APIs, and online

services. (Node-Red Site, 2023)

Unlike other types of development environments,

Node-Red is a browser-based editor, built in Node.js,

which is capable of connecting flows via nodes. Be-

cause it has vast libraries of nodes, Node-Red can per-

form various functions, such as communicating be-

tween devices using the MQTT protocol, connecting

a system to a database hosted in the cloud, performing

logical-mathematical operations, and executing code

locally.

5.3 Interaction Between Devices via

MQTT Protocol

The operator needs to perform actions that indicate to

the device its need for information. To do this, the

operator can interact with the device using buttons

which, when pressed, help to select the correct item

to be evaluated.

Once the desired item has been selected, commu-

nication takes place between the smartphone applica-

tion and the display, and for this, we chose to build

communication via the MQTT (Message Queuing

Telemetry Transport) protocol. This protocol is based

on the transport of messages in a client/server format,

enabling communication between (MQTT Site, 2023)

machines, which, in the case of this work, is the com-

munication between the Raspberry Pi and the OLED

Display integrated with augmented reality.

As an alternative to setting up MQTT communica-

tion, we chose to implement a code in the Node-Red

development environment. Through this code, the mi-

croprocessor can send requests arising from the oper-

ator’s handling of the wearable device, which, in re-

turn, receives information relevant to warehouse man-

agement. Once the item data is returned to the device,

the operator can see the exact location of the material

or its particular characteristics.

6 RESULTS

As a result of implementing the system, it was pos-

sible to demonstrate its operation and functionality.

Figure 4 illustrates the layout of the mobile applica-

tion.

The layout of the app shows the connection status

of the smartphone’s NFC sensor and the connection

between the app and the MQTT broker. In addition,

the app has buttons that act sending the ID of the iden-

tified item. Although all the buttons send the ID, they

send it via a specific topic, which tells the wearable

device what kind of information it should pass to the

display.

As a result of processing the tag ID read, the dis-

play was able to show the following results for each

task:

As a way of measuring the impact of this device

on a real warehouse application, a qualitative compar-

ison was made of the average time taken to update the

system and the database of a warehouse that does not

Industry 4.0: Wearable IoT Device Applied to Warehouse Management

537

Figure 7: Raspberry Pi Flow in Node Red.

(a) Go ahead (b) Go back

(c) Turn left (d) Turn right

Figure 8: Illustration of arrows for operator direction.

have this type of infrastructure. In this context, for

the user to write off materials that have been stored

and removed from the system, it is necessary to fill

in a lot of information and, the more materials that

need to be processed, the longer it takes to complete

all the write-offs, especially if the warehouse has few

employees available to carry out the write-offs. In

the case of the proposed system, the material write-

off is carried out automatically by the system in the

database, making the user’s routine more productive

and with less manual work.

In the Figure 8, it’s shown an illustration of arrows

for operator direction when it’s needed to find some

materials. Like a GPS guide, the display guide the

operator to the correct position of an especific good.

The position of the good is saved in the cloud database

and track the position of the operator by the GPS in-

side the smartphone e show how to go to the item.

In addition, the proposed system offers greater se-

curity in the process of identifying material for stor-

age and withdrawal, since each item has a unique

identification, which reduces the chance of human er-

ror when carrying out the collection.

7 CONCLUSIONS AND FUTURE

WORK

In this work, a wireless communication system was

developed and implemented between an embedded

device, i.e. a Raspberry Pi 4B, and a smartphone ap-

plication, using the MQTT protocol. The system aims

to provide information about items in a warehouse to

an operator via a transparent OLED display connected

to the Raspberry Pi, generating a user experience with

the environment. In addition, the system has been

integrated with RFID tags and a smartphone’s NFC

reader, which allow items in the warehouse to be iden-

tified, facilitating stock control and monitoring and

providing low-cost identification of rfid tags using a

smartphone..

The system can be tested in a real scenario, with

different types and quantities of items. The pro-

posed system is applicable in various contexts involv-

ing inventory management, warehousing, and logis-

tics, helping to improve the efficiency and safety of

processes. In future work, we suggest integrating the

system with other technologies, such as cameras and

robots, to expand the functionalities and possibilities

for operator interaction with the environment.

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

538

ACKNOWLEDGEMENTS

The authors would like to thank FAPEMIG, CAPES,

CNPq, Instituto Tecnol

´

ogico Vale, and the Federal

University of Ouro Preto for supporting this work.

This study was partially funded by the Coordenac¸

˜

ao

de Aperfeic¸oamento de Pessoal de N

´

ıvel Superior

- Brasil (CAPES) - Finance Code 001, the Con-

selho Nacional de Desenvolvimento Cient

´

ıfico e Tec-

nol

´

ogico (CNPq) finance code 306101/2021-1 and

308219/2020-1, FAPEMIG - Finance Code APQ-

01331-18.

REFERENCES

Anusha, D. J., Panga, M., Fauzi, A. H., Sreeram, A., Iss-

abayev, A., and Arailym, N. (2022). Big data an-

alytics role in managing complex supplier networks

and inventory management. International Conference

on Sustainable Computing and Data Communication

Systems, ICSCDS 2022 - Proceedings, pages 533–

538.

Bertaglia, P. R. (2012). Log

´

ıstica e gerenciamento da

cadeia de abastecimento. Saraiva.

Borges, I. B., Alves, J. L., de Lima, L. K. A., and de Nadae,

J. (2022). Ind

´

ustria 4.0: impactos das novas tecnolo-

gias no gerenciamento de projetos. Exacta, 20:832–

860.

Cimen, E. B., Kurban, I., Selmanoglu, O., Sahin, M., and

Kilinc, D. (2021). A hybrid stock optimization ap-

proach for inventory management. HORA 2021 - 3rd

International Congress on Human-Computer Inter-

action, Optimization and Robotic Applications, Pro-

ceedings.

Fathi, P., Karmakar, N. C., Bhattacharya, M., and Bhat-

tacharya, S. (2020). Potential chipless rfid sensors for

food packaging applications: A review. IEEE Sensors

Journal, 20:9618–9636.

Gonc¸alves, P. S. (2013). Administrac¸

˜

ao de Materiais. Else-

vier.

Hamdy, W., Al-Awamry, A., and Mostafa, N. (2022). Ware-

housing 4.0: A proposed system of using node-red for

applying internet of things in warehousing. Sustain-

able Futures, 4:100069.

Hus

´

ar, J. and Knap

ˇ

c

´

ıkov

´

a, L. (2021). Possibilities of us-

ing augmented reality in warehouse management: A

study. Acta logistica, 8:133–139.

Manuel Vera, J. (2021). Inventory control under unobserved

losses with latent state learning. In 2021 7th Interna-

tional Conference on Computer and Communications

(ICCC), pages 1594–1599.

MQTT Site (2023). Mqtt oficial site. Available at: https:

//mqtt.org/. Accessed in September 13th, 2023.

Node-Red Site (2023). Site oficial da node-red. Acessado

em 15 de novembro de 2023.

Peri

ˇ

sa, M., Sente, R. E., Cviti

´

c, I., and Kolarovszki, P.

(2018). Application of innovative smart wearable de-

vice in industry 4.0. EAI.

Plakas, G., Ponis, S. T., Agalianos, K., Aretoulaki, E., and

Gayalis, S. P. (2020). Augmented reality in manu-

facturing and logistics: Lessons learnt from a real-

life industrial application. Procedia Manufacturing,

51:1629–1635.

Ponis, S. T., Plakas, G., Agalianos, K., Aretoulaki, E.,

Gayialis, S. P., and Andrianopoulos, A. (2020). Aug-

mented reality and gamification to increase productiv-

ity and job satisfaction in the warehouse of the future.

Procedia Manufacturing, 51:1621–1628.

Rejeb, A., Keogh, J. G., Wamba, S. F., and Treiblmaier, H.

(2020). The potentials of augmented reality in supply

chain management: a state-of-the-art review. Man-

agement Review Quarterly 2020 71:4, 71:819–856.

Silapunt, R., Panpanyatep, W., and Boonsothonsatit, G.

(2022). Design and development of the smart object

for the iot-enabled smart warehouse. In 2022 Inter-

national Electrical Engineering Congress (iEECON),

pages 1–4.

Tikwayo, L. N. and Mathaba, T. N. D. (2023). Applica-

tions of industry 4.0 technologies in warehouse man-

agement: A systematic literature review. Logistics,

7(2).

Vena, A., Illanes, I., Alidieres, L., Sorli, B., and Perea, F.

(2021). Rfid based indoor localization system to ana-

lyze visitor behavior in a museum. 2021 IEEE Inter-

national Conference on RFID Technology and Appli-

cations, RFID-TA 2021, pages 183–186.

Industry 4.0: Wearable IoT Device Applied to Warehouse Management

539