Greener Information Systems for Product Configuration

Management: Towards Adaptation to Sustainability Requirements

Anders Jakobsen

a

, Torben Tambo

b

and Maja Kadenic

c

Department of Business Development and Technology, Aarhus University, Birk Centerpark 15, Herning, Denmark

Keywords: Sustainability, Product Configuration, Product Life-Cycle Management, Information Systems, Mechanical

Engineering, ISO14020.

Abstract: The purpose of this paper is to shed light on the need to reconceptualize the dimension of product life-cycle

management systems related to product configuration to embrace data of the specific sustainability impact of

the configuration choices. While this is very much related to physical products, the information systems

dimension is fundamental to include to model, decide, document, trace and review sustainability of products.

This paper is based on a longitudinal case study along with a comprehensive literature review. Key findings

related to the isolation of product configuration systems as key determinants for specific sustainability in a

governed and traceable form. These systems do largely not cover sustainability as of today: A redesign is

needed. A research agenda is outlined combining sustainability-thinking with socio-technical design. A

proposal for the design is presented using a multi-level, multi-tier approach to Product Configuration Systems.

The process has major implications around in the industry as legislators are mandating extensive

documentation for specific choices and documentation of the sustainability impact of physical products.

1 INTRODUCTION

In the current context, there is a growing emphasis on

sustainability, leading to an increased demand for

environmentally conscious products. This is raising a

strong issue within design of information systems.

Organizations are compelled to adopt more

sustainable practices throughout the product life cycle

(Hassan et al., 2017; Huang & Badurdeen, 2018).

This shift is driven by concerns over non-renewable

resource use, the obligation of strong regulations, and

increased consumer awareness. During this evolving

landscape, the product configuration system (PCS)

emerges as a key enabler, facilitating cost-effective,

customer-centric product development through

tailored customization (Hassan et al., 2017; Zheng et

al., 2017; Huang & Badurdeen, 2018). The

importance of environmental protection and rigorous

application of environmental regulations, the request

of sustainable product design has become more

prevalent (Badurdeen et al., 2018). This intensifies

the increased tendency of mass customization and

a

https://orcid.org/0009-0006-4196-9469

b

https://orcid.org/0000-0001-8491-7286

c

https://orcid.org/0000-0002-5197-1179

specialized customer-centric products to satisfy

individual customer requirements (Zheng et al., 2017;

Kristjansdottir et al., 2018). Sustainable products can

be defined as manufactured products that follows

sustainable principles and are sustainability

compliant during their absolute product life cycle

(Zheng et al., 2017). PCS consists of predefined

attributes with restrictions and information related to

product features, product structure, production

processes, costs, and prices for customers to select

(Zheng et al., 2017; Shafiee et al., 2018; Haug et al.,

2019). In such a way, PCS have been defined as a

socio-technical system, consisting of technical

components and an organizational element involving

individuals, procedures, processes etc. (Forza &

Salvador, 2006). This challenges organizational

sustainable design of engineered products and

systems as it requires addressing both technical and

organizational dimensions (Forza & Salvador, 2006;

Skerlos, 2015). Although the literature related to

sustainability is rich, and academia has made efforts

to the conceptualization and materialization of long-

100

Jakobsen, A., Tambo, T. and Kadenic, M.

Greener Information Systems for Product Configuration Management: Towards Adaptation to Sustainability Requirements.

DOI: 10.5220/0012737200003690

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 26th International Conference on Enterprise Information Systems (ICEIS 2024) - Volume 2, pages 100-109

ISBN: 978-989-758-692-7; ISSN: 2184-4992

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

term stakeholder value of its three pillars of

sustainability: economic, environmental, and social

sustainability (Huang & Badurdeen, 2018;

Ghobakhloo, 2020); this supports the driving

mechanism of innovation and long-term product

success (Huang & Badurdeen, 2018). The major

impact of sustainability impacts is normally taking

place outside of the company, therefore systems and

architectures must look across organisational

boundaries (Tambo, 2017). The dilemma can be

stated as: How can sustainable practices support PCS

in engineering of highly complex industrial products?

Manufacturers today are confronted with a range of

diverse challenges as many configuration projects

fails, as literature doesn't elaborate on strategic nor

sustainable alternatives in a comprehensive way;

instead, it offers broad suggestions for individual

strategies with no holistic perspectives (Haug et al.,

2019). Crafting a PCS demands complex

technicalities or business expertise, which domain

specialists may find challenging to effectively convey

to configuration professionals (Shafiee et al., 2018).

The challenge of representing the necessary technical

or business expertise may be characterised by detailed

quantification of the benefits, costs, and ROI from

using PCS in the literature (Kristjansdottir et al.,

2018). PCS activities focus on quotation or

production processes rather than multiple business

processes (Bredahl Rasmussen et al., 2021). These

critiques of PCS call for a refinement for a holistic

approach for an establishment of sustainable practices

in manufacturing companies (Huang & Badurdeen,

2018).

Therefore, this paper focuses on identifying the

PCS landscape related to the novelty of sustainability

gains, excluding the product configurator is not

limited to sales phases (Myrodia et al., 2019).

Including the life cycle phases of a configurable

product and connecting it across all business

processes is considered a challenging task (Myrodia

et al., 2019). Extensive literature and industrial use

cases emphasize the difficulties in data acquisition

and verification, valid product modelling, and

accurate product documentation (Kristjansdottir et

al., 2018; Myrodia et al., 2019). Interconnected

information systems and digital connective

information development and sharing may can

challenge the triple bottom line (economic,

environmental, and social) sustainability

(Ghobakhloo, 2020). This paper further investigates

functions for sustainability implications related to

PCS. In doing so, this paper initiates a state-of-the-art

content-driven review and analysis of existing

literature to identify the critical elements of

sustainability functions respective to PCS and its

nuanced perspectives. Finally, this paper discusses

the findings and justifies the fundamental design

principles and sustainability trends favourably in

support of PCS.

2 METHOD

This paper is based on a qualitative research approach

for an in-depth case study combined with an

extensive literature review and a singular case study

(Dubois & Gadde, 2002; Yin, 2009). The literature

review is based on the bibliometric approach

(Carvalho et al., 2013). The case study is from a major

European electromechanical manufacturer. The case

study is longitudinal applying qualitative approach

with company interviews. The case study is employed

to evaluate the practical implications of the current

PCS, which relates to empirical data based on the

longitudinal approach of a two-year employment

within the case company. The case study constructs

the foundational agenda discussion based on

information system within the case company

(Shakirov et al., 2019).

Relevant literature and its content were based on

the bibliometric approach (Carvalho et al., 2013),

which primarily focus on identification of patterns

within the literature based on; analysis of citations.

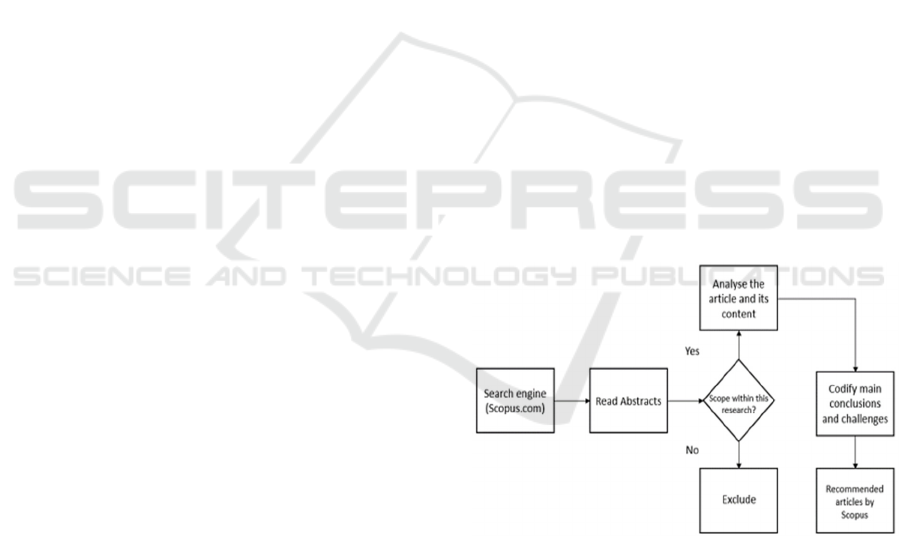

Figure 1: Literature review process.

The bibliometric study for this paper includes a

content analysis, which is based on the researchers to

allow the identification of the most important topics,

approaches, and methods, thereby the most important

definitions for this paper (Carvalho et al., 2013). To

acquire a sample a database was chosen and was

searched with no restrictions but by the use of

keywords, such as “Product Configuration System”,

“Product Configuration”, “Product Information

Management”, “Product Lifecycle Management”,

Greener Information Systems for Product Configuration Management: Towards Adaptation to Sustainability Requirements

101

“Data Management Systems”, “Sustainability”,

“Sustainable Systems”, and “Sustainability

Evaluation”. To create transparency the workflow of

the literature review is shown below in Fig 1.

3 THEORETICAL

BACKGROUND

3.1 Product Configuration

Architecture

The definition of product architecture yields the

configuration process logically possible, without

involving technical expertise (Forza & Salvador,

2006). Although, it is necessary to define system

instruments to support configuration to reduce

computing complexity as salesmen, engineers, and

customers are within the conditions to operate

autonomously in a defined configuration process

(Forza & Salvador, 2006; Zheng et al., 2017).

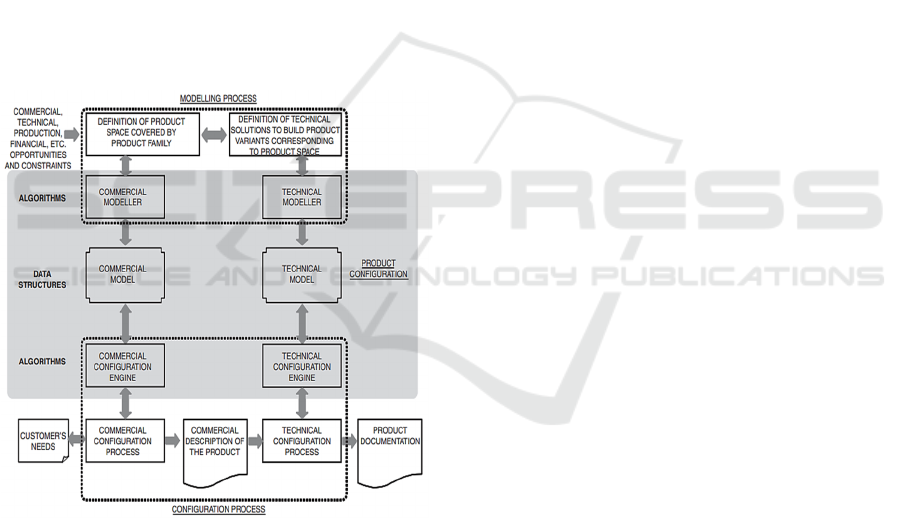

Figure 2: Logical Architecture of a PCS (Forza & Salvador,

2006).

This emphasize that the PCS and its architecture

operates between function and physical domain,

excluding the customer domain. Thereby, the CTO

refers to product configurability, which relates to the

product family architecture, where the organization

has pre-defined all possible variants of components

and established rules governing their determination

within a product family (Forza & Salvador, 2006;

Zheng et al., 2017). Product functions and purposes,

along with their characteristics, are linked to

individual component variants or their combinations.

Although the PCS can be perceived as a computing

tool that interacts with the personnel and is linked to

processes: the configuration process and the

modelling process (Forza & Salvador, 2006; Zheng et

al., 2017). This means two uniquely interfaces related

to a configuration engine and a modelling engine.

3.2 Sustainable Product Development

Skerlos, (2015) emphasize that organizations must

establish their sustainability dimensions and targets

based on the three pillars of sustainability (economic,

environmental, and social sustainability) (Huang &

Badurdeen, 2018; Ghobakhloo, 2020). These driving

pillars of sustainability enforce the internal

innovation mechanism for long-term product success

(Ahmad et al., 2018; Huang & Badurdeen, 2018).

Specialized tools are required at the product design

level to evaluate the expected environmental impact

of different design options (Skerlos, 2015). The

importance of such tools is central as product

development engineers may be challenged by

conducting impact assessments for each design

option without dedicated assistance (Skerlos, 2015;

Ahmad et al., 2018). Literature for sustainable design

serve distinct purposes, including: 1) presenting

awareness about potential environmental impacts and

suggesting mitigating design strategies (e.g.,

checklists, guidelines, and case studies), 2) enabling

the ranking or scoring of a product's environmental

performance concerning specific environmental

aspects (e.g., toolboxes or advisory software tools),

and 3) facilitating life cycle assessments (LCA)

(Skerlos, 2015; Ahmad et al., 2018; Huang &

Badurdeen, 2018). Skerlos, (2015) highlights that

such guidelines in typical checklists conflicts with

themselves or with other product attributes of the

design. To address this conflict between sustainable

design guidelines and to foster innovation, several

application-specific software tools have emerged

(Skerlos, 2015; Ahmad et al., 2018). Application-

specific software tools requires less information than

a full LCA, allowing ranking of design options and

justification for specific decisions aimed at reducing

environmental impact, they may lack the

transparency of full LCAs. In addition, these tools do

not capture the environmental characteristics of the

supply chain and are less likely to comprehensively

account for situational factors in production, use, and

disposal (Skerlos, 2015). Moreover, it was found that

80% of sustainability impacts are defined within the

initial stages of the product development design stage

(Ahmad et al., 2018). To address this challenge in the

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

102

manufacturing sector, the development and

production of sustainable products have been defined

as a crucial strategy to achieve sustainability (Ahmad

et al., 2018). Myrodia et al. (2019) argues that

Configuration Lifecycle Management (CLM) is

relevant for manufacturing organizations of

configurable products as the significance of CLM

aims to establish a singular source for configuration

data and models shared across various business units

within an organization. Although, CLM refers to the

management of all configuration models and

correlated data across all phases of a product's

lifecycle, Product Lifecycle Management (PLM)

focuses on keeping track related to existing product

information processes and information systems

(Myrodia et al. 2019). However, CLM focuses on

maintaining the PCS for generating new

specifications from the PCS. Product configurator is

set to model complex configurable products, where

engineering rules are provided as inputs for the

configurator from the PLM system. Myrodia et al.

(2019) highlights the challenge of integrating product

configurators with other IT systems to facilitate data

exchange, as input and/or output of each

configuration step. This complexity comes to IT

systems utilized by multiple departments. Beyond the

technical complexities of connecting, aligning, and

integrating IT systems with product configurators, the

operational perspective holds a significant

importance and should not be discarded (Myrodia et

al., 2019). The operational perspective involves

factors such as process standardization, resource

allocation, knowledge sharing, and supportive

methods for cross-department collaboration, are

crucially interconnected with the success of relevant

data (Myrodia et al., 2019).

3.3 Product Configuration – Digital

Solutions

Product configuration systems (PCS) are systems

designed to facilitate product customization for

customers (Hvam et al., 2008; Hvam et al., 2013;

Kristjansdottir et al., 2018; Piroozfar et al., 2019).

Such system specifies pre-defined product entities,

whether these are physical or non-physical, along

with their properties, fixed or variable (Li et al., 2015;

Kristjansdottir et al., 2018; Piroozfar et al., 2019).

The reliability and complexity of a configuration

systems is reflected of the organizational product

portfolio (Kristjansdottir et al., 2018). A PCS can

support organizational activities of specifying

product features, product performance, product costs

etc. for customers during sales and engineering

phases of a product (Li et al., 2015; Kristjansdottir et

al., 2018; Piroozfar et al., 2019). These activities can

be defined as the specification process, which

involves customer needs, design, and specification of

a product variant to full-satisfy customer

requirements and specification of e.g., product

manufacturing, supply-chain management, service

delivery, product life cycle properties (Hvam et al.,

2008; Hvam et al., 2013; Kristjansdottir et al., 2018).

The facilitation of a PCS requires robust product

information, as this is increasingly prevalent in

multiple life cycles (Piroozfar et al., 2019). Activities

respective to the specification process are within pre-

defined attributes and well-defined complex product

solutions, contradictory the goal of the customer is to

find an optimal solution according to the needs,

quality of specifications, lead time etc. within defined

information modelled in the PCS (Hvam et al., 2008;

Piroozfar et al., 2019). The configuration of the

product is based on the defined solution space relative

to the information modelled within the PCS. This can

be referred to as customers configure-to-order (CTO),

as customers defines a product within the solution

space found in the configuration system (Hvam &

Ladeby, 2007). Additionally, this brings substantial

benefits related to generating quotations, capabilities

to meet customer needs, and on-time delivery (Hvam

et al., 2008; Hvam et al., 2013; Kristjansdottir et al.,

2018; Piroozfar et al., 2019).

3.4 Product Configurator Development

Process

The application development of configurators is a

subtype of the software-based systems applicable to

formalize a e.g., CTO of product specifications (Haug

et al., 2012). The organizational task of developing

the configurator can be complex and time-consuming,

whereas Haug et al. (2012) argues that it is crucial to

apply an appropriate strategy. In addition, literature

lacks an in-depth exploration of various strategic

alternatives; it merely offers broad suggestions for

individual strategies (Haug et al., 2012). Therefore,

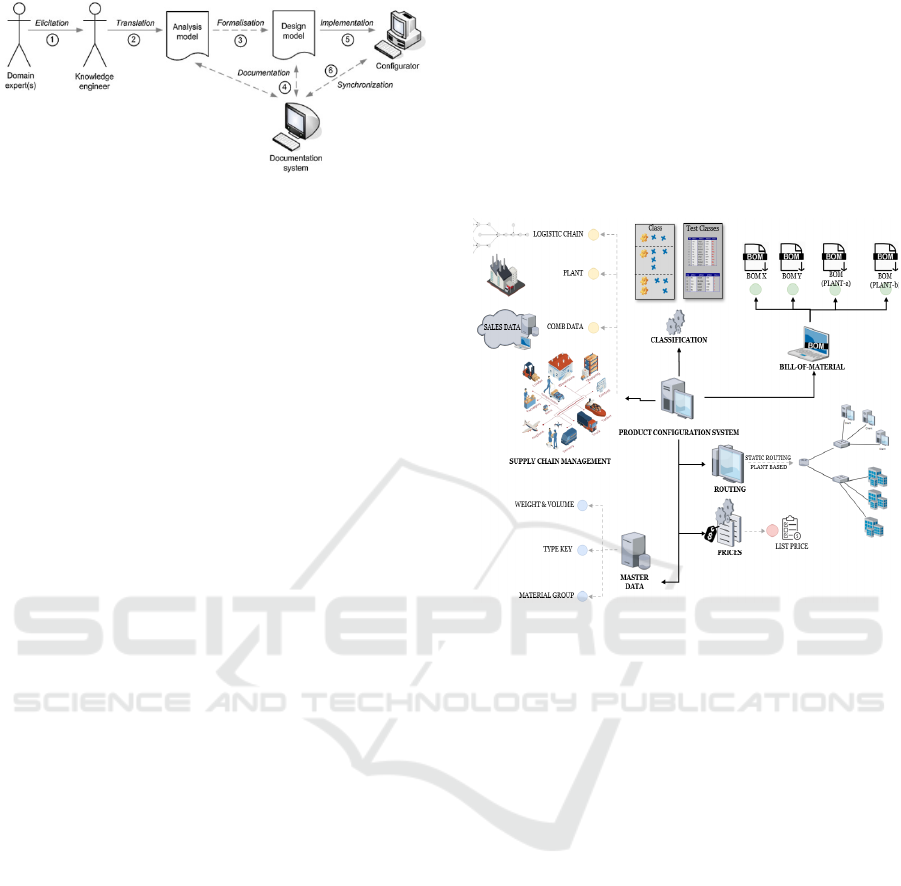

fig. 3 is an overview related to the process of the

development and maintenance a product configurator

involving six phases (Haug et al., 2012). The dotted

lines are not necessarily explicitly defined as e.g., the

distinction between analysis module and design is not

formulated with real-world practices as this involves

variation in organizational practices.

Greener Information Systems for Product Configuration Management: Towards Adaptation to Sustainability Requirements

103

Figure 3: The Process of Creating Product Configurators

(Haug et al., 2012).

3.5 Sustainable Product Configuration

System

Literature represents sustainable PCS based on real-

world applications for environmental accountability

and product traceability within the supply chain level

solutions (Helo et al., 2024). This relates to

quantifying environmental impact within the PCS

correlated to the organizational supply chain and its

potential impact respective to their suppliers and the

transportation operations. In other words, the PCS is

based on emission calculations for each product

variant (Helo et al., 2024). In addition, Helo et al.

(2024) proposes that PCS, bill-of-materials (BOM),

operations routing information, supplier locations,

and environmental inventory database must be

consolidated into one practical application built on

industrial standards. This involves PCS, enterprise

resource planning (ERP), and computer aided design

automation systems merged with LCA. Borsato,

(2014) highlights that PLM strategies must embrace

sustainability respective to multi-disciplinary efforts

by bridging product and process data beyond the

organizational information system e.g., ERP, but

throughout their entire supply chain. In addition,

Borsato, (2014) emphasize that PLM information

flows in various organizational business channels and

patterns, whereas these must be linked to the current

IT infrastructure and technology capabilities to

exchange information and explore sustainable

practices. The PLM information is relevant for

sustainability purposes as the decision-making

relevant for environmental issues early in the product

development stage can yield more significant results,

as reactive measures may prove to be less effective

than proactive ones (Borsato, 2014).

4 CASE STUDY

The case company was selected based on assessment

of complete access to information, data, and internal

documents, as well as the availability of the existing

configurator that supports multiple stages. The

extension of multiple configurator processes and

stages from the existing configurator, this case is

reduced to industrial offerings for generalizability

(Bredahl Rasmussen et al., 2021). This single-case

study design can be mitigated to other case companies

as an initial mapping of current PCS within the case

company support several business processes and IT

systems.

Figure 4: Product Configuration System, Case Company.

The review of the existing configuration system is

applicable to investigate the conditions required for

the beneficial application of understanding the

sustainability perspective related to PCS (Bredahl

Rasmussen et al., 2021). Fig. 4 outlines the

investigated application and its conditions based on

the case study of an CTO company, which provides

empirical evidence of the potentiality of sustainability

and the feasibility within the existing PCS. This case

varies in scale of complexity as the PCS are

characterized as a multistage configurator for

electromechanical industrial product offerings. The

formulation of a multistage configuration provides

reductions at additional stages to increase the sales

performance respective to improved customer

communication and product quality (Bredahl

Rasmussen et al., 2021). In other words, a multistage

configuration includes several stages of the order-

fulfilment process (e.g., quotation, product design,

detailed design, manufacturing, sales areas, delivery

or installation processes). The evaluation of this PCS

based on a multistage configuration contributes

valuable application insights into the complexities

and potentialities of sustainability in diverse system

excellence.

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

104

5 FINDINGS

The case company operates in various differentiated

markets, where customization is highly necessary to

satisfy requirements from customers, local

regulations, compliance, and local authorities. The

range of industrial product offerings are to

accommodate specific needs to fit within existing

production or process lines. The company handles the

process of designing and configuring the product

based on compliance from a manufacturing

perspective, obtaining approval from e.g., authorities.

Initially, the PCS have a broad range of standardized

product family. This is as one product group for one

singular standardized product offering has 10950

unique hits. In addition to this product group for PCS

the product is within the range of the classification of

CTO category. The number of 10950 unique hits

specifying the complexity and the number of

attributes that could be mixed and matched based on

the large variety of product offerings. The number of

attributes and constraints can be classified as a PCS

with high complexity (Shafiee et al., 2020).

5.1 Exploring the PCS

This paper explores the novelty of sustainability in

PCS within the case company. The exploration seeks

to identify critical PCS elements of sustainability

related to semantic interoperability. Considering the

future sustainable industry expectations, the

exploration are centralized in identifying critical

aspects and potential areas in PCS layouts, this

research addresses the inadequacy in academic

investigations as literature related to PCS does not

involve sustainability. The PCS process used by the

case company consisted of six major phases: (1)

Master Data, (2) Classification, (3) BOM, (4)

Routing, (5) Supply Chain management, and (6)

Prices. Fig. 4 illustrates the original configuration

system, where the PCS is based on a multistage

configurator, where product specifications are

provided based on commercialized data structures

related to a commercial configuration engine,

corresponding to data structures related to a technical

configuration engine. These computing algorithm

engines are not documented nor investigated related

to other IT systems.

5.2 Sustainability-Thinking in the PCS

PCS is encountered by complex real-world

applications related to regulations, compliance,

environmental impact evaluation. Literature link PCS

and sustainability respectively for environmental

accountability and product traceability within the

supply chain level solutions (Helo et al., 2024). This

is emphasized by the multistage configurator

employing (5) Supply Chain management within the

case companies PCS related to e.g., potential impact

respective to suppliers, sales offices, and

transportation operations. However, the technicality

and subsystem with interfaces are not defined within

the existing PCS. Optional sizing parameters for life

cycle cost calculations is a subsystem within PCS

uniquely defined product specification profile related

to: operating time, energy prices, anticipated

increasement in energy prices, CO2 emission

intensity, maintenance cost based on a Life-Cycle-

Cost (LCC) analysis. The subsystems of BOM,

operation routing information, supplier locations, and

sales office/areas are consolidated into the PCS

design, which correlates with literature for

sustainable PCS each product variant (Helo et al.,

2024). However, literature emphasize the need for the

consolidation for one practical application based on

industrial standards. This involves the PCS to be

merged with an environmental LCA database.

Computing and consolidating such practical

application are critically overlooked. Despite the

multistage configurator involving sustainable

mechanisms and resources the interface is yet to be

discovered considering the investigated research

literature and case results. PLM strategies are not

sufficient as these case results highlights the tendency

of not including multi-disciplinary efforts to bridge

product and process data beyond the organizational

information system.

In addition, Borsato, (2014) emphasize that PLM

information flows in various organizational business

channels and patterns, whereas these must be linked

to the current IT infrastructure and technology

capabilities to exchange information and explore

sustainable practices. The PLM information is

relevant for sustainability purposes as the decision-

making relevant for environmental issues early in the

product development stage can yield more significant

results, as reactive measures may prove to be less

effective than proactive ones (Borsato, 2014).

5.3 Sustainable Socio-Technical System

Analysis

Sustainable Socio-Technical System (Forza &

Salvador, 2006; Skerlos, 2015) challenges

organizational sustainable design of engineered

products and systems as it requires addressing both

technical and organizational dimensions. The

Greener Information Systems for Product Configuration Management: Towards Adaptation to Sustainability Requirements

105

adoption of sustainable practices related to PLM

(Hassan et al., 2017; Huang & Badurdeen, 2018)

concerns the obligation of severe regulations and

environmental product declarations (EPD) as

manufacturers must report comparable and third-

party verified data like environmental performance

of their respective products (Environmental Product

Declarations, 2024). The formulation of a multistage

configuration (Bredahl Rasmussen et al., 2021) is set

to increase sales performance relative to product

quality, where EPD the environmental performance

of each configured product must be described based

on LCA of each configured product in the PCS based

on ISO 14020 (Environmental Product Declarations,

2024). The implementation of LCA relates to

information compiled in a EPD reporting format and

ISO 14020 conjunctions, which leads to customer-

centric product development through tailored

customization based on sustainability-thinking.

Predefined PCS attributes and information related to

product features, product structure, production

processes, costs, and prices for customers to select

shall be verified by developing a EPD subsystem that

corresponds to PLM activities, PCS functionalities,

and with other standards in the ISO 14020 family.

The case company focuses on operational excellence

based on LCC analysis that relates to operational

sizing parameters in the PCS, relying on investment-

risk of a product beyond its initial acquisition

expenses. This paper supports a holistic approach to

integrating sustainability-thinking leading to a

sustainable PLM generation, emphasizing the

implementation of ISO 14020 and EPD reporting

elements with a renewed PLM and PCS focus on

representing sustainability-thinking based on real-

world applications for environmental accountability

and product traceability. The emphasis correlates to

quantifying environmental impacts on understanding

the considering facilitation of ISO 14020 and the

information system driving products through

standardized declaration methods.

5.4 Bridging Sustainability-Thinking

with PCS

The theoretical background of the process of

developing product configurators introduces the

concept of CTO product specifications (Hvam et al.,

2008; Haug et al., 2012).

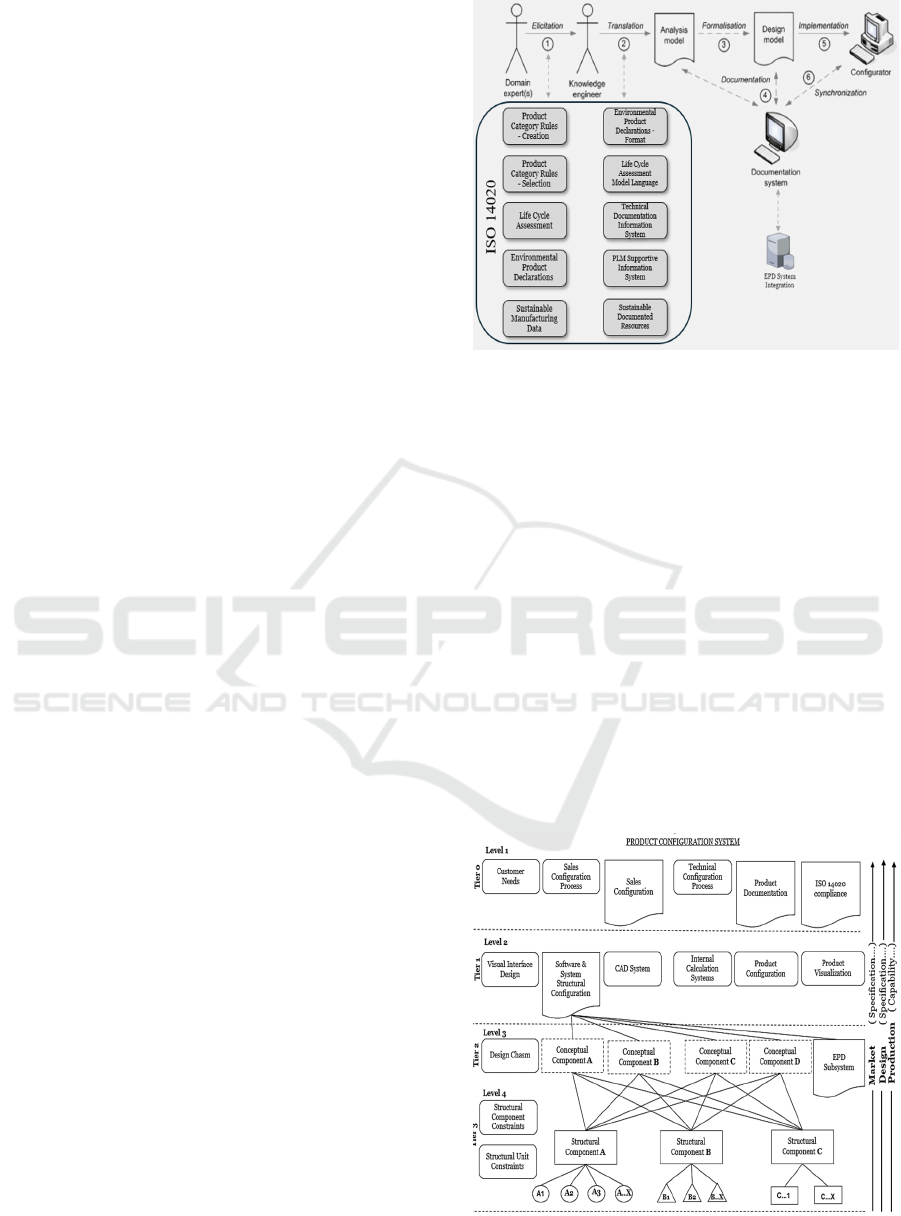

The complexity of integrating sustainability-

thinking lacks an in-depth exploration based on PLM

strategic alternatives. Therefore, Fig.5 follows the

process of the development and maintenance of a

product configurator (Haug et al., 2012), which

Figure 5: ISO 14020 Configuration System Integration.

considers the importance of sustainability-thinking

respective to EPD systems and ISO 14020

compliance. The real-world application of Fig.5 does

not account for schematic foundational algorithms

programming of optimized sustainable practices. The

growing importance of sustainability concerns the

attention of introducing sustainable PLM to support

processes related to the practicality and credible

modelling of

optimized sustainable footprints by changing

sustainable documented resources.

5.5 Information Architecture Proposal

The proposed information architecture is based on

Forza & Salvador, (2006) and Haug et al., (2012) for

a sustainable socio-technical architectural informa-

tion system of a PCS

.

Figure 6: Proposed IS Architecture.

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

106

The sustainable socio-technical architectural

information system is modularized according to

patterns of hierarchy, defining the basic concept for

how to bridge sustainability-thinking with PCS. The

proposal establishes the layout and integration

relationships of structural components and units for

the software PCS items. In addition, the architecture

is comprised into several structural units, which is

connected and integrated into structural components.

Structural components and units are product elements

that can be managed through e.g., LCA. Structural

components are combined into multiple conceptual

components, which enables the software of the PCS

to be utilized. The information for a sustainable socio-

technical system requires the adoption of PLM

practices related to obligations of strict regulations of

EPD. This information is a dynamic interaction

between the company and the customer as this

interaction is fundamentally important as

manufacturers must report product compliance and

environmental performance. The product

specifications and characteristics are defined by the

customer, explored in the customer interface. Fig. 6

considers the importance of sustainability-thinking

regarding product specifications to satisfy customer

needs through configuration activities respectively if

the product variety offered is compliant with ISO

14020 based on the information system connected to

the EPD subsystem. Additionally, the proposed

information architecture improves the transparency

and efficiency of front-end communication as

sustainability opportunities becomes transparent for

customers to decides.

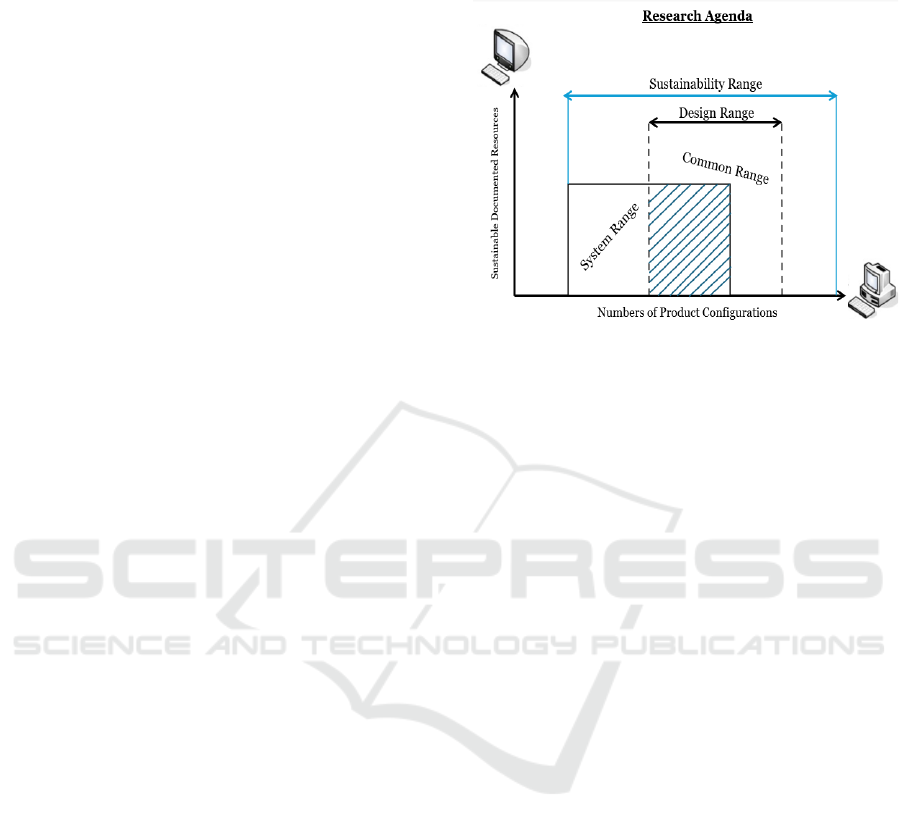

5.6 Research Agenda

The findings in this paper it is expected that ISO

14020 provides a foundation for environmental

declarations, and product categories rules (PCR)

development can be combined with detailed and

specific rules for PCS and PLM strategy dimensions.

Moreover, to ensure organizational consistencies and

reliability in environmental information systems.

Properties of sustainability-thinking broadens the

vocabulary of promoting sustainability and

information systems respective to environmental

impact of products in the context of PCS and PLM.

The properties of this case study revealed a

differentiated understanding between what existing

literature defines as sustainable PCS and what is

expected to be uniformed and compliant with

distinctive sustainability-thinking for PCS. Through

research Fig.6 summarizes a proposed research

agenda to share experience based on real-world

applications into the sustainability-thinking domain.

Figure 7: Proposed Research Agenda.

6 CONCLUSIONS

This paper acknowledges that sustainability in

Product Lifecycle Management (PLM) is an ongoing

discourse rather than a concluded enterprise system,

and the information system respective to engaging a

meaningful conversation is yet to be explored (Forza

& Salvador, 2006; Hvam et al., 2008). The primary

emphasis relates on the aspect of modelling and

fostering alternative mindsets of sustainability-

thinking that goes beyond sustainable manufacturing

and sustainable product development (Hassan et al.,

2017; Huang & Badurdeen, 2018). The case study

results emphasize that that the most significant risk

associated with sustainability is reducing it to a mere

reporting tool as the system complexity increases

(Bredahl Rasmussen et al., 2021). There are

undefined tolerances of facilitation where sustainable

PLM goes beyond reporting, aiming instead for

practical and credible modelling of optimized

sustainable footprints through the adaptation and

utilization of well-documented sustainable resources

(Hvam et al., 2008; Hvam et al., 2013). The research

agenda emphasizes that constraining sustainability

initiatives to a superficial undertaking solely aimed at

generating reports is cautioned against. This intricate

research necessitates continuous dialogue and

collaboration to effectively implement sustainability

initiatives in practice.

Greener Information Systems for Product Configuration Management: Towards Adaptation to Sustainability Requirements

107

REFERENCES

Ahmad, S., Wong, K. Y., Tseng, M. L., & Wong, W. P.

(2018). Sustainable product design and development: A

review of tools, applications and research prospects.

Resources, Conservation and Recycling, 132, 49–61.

https://doi.org/10.1016/j.resconrec.2018.01.020

Andersen, R., Brunoe, T. D., & Nielsen, K. (2022). Module

Drivers in Product Development: A Comprehensive

Review and Synthesis. Procedia CIRP, 107, 1503–

1508. https://doi.org/10.1016/j.procir.2022.05.182

Badurdeen, F., Aydin, R., & Brown, A. (2018). A multiple

lifecycle-based approach to sustainable product

configuration design. Journal of Cleaner Production,

200, 756–769. https://doi.org/10.1016/j.jclepro.2018.

07.317

Blazek, P., Partl, M., & Streichsbier, C. (2020).

Configurator Database Report 2017/2018. Lulu.com.

Borsato, M. (2014). Bridging the gap between product

lifecycle management and sustainability in

manufacturing through ontology building. Computers

in Industry, 65(2), Article 2. https://doi.org/10.1016/

j.compind.2013.11.003

Bredahl Rasmussen, J., Haug, A., Shafiee, S., Hvam, L.,

Henrik Mortensen, N., & Myrodia, A. (2021). The costs

and benefits of multistage configuration: A framework

and case study. Computers & Industrial Engineering,

153, 107095. https://doi.org/10.1016/j.cie.2020.107095

Carvalho, M. M., Fleury, A., & Lopes, A. P. (2013). An

overview of the literature on technology roadmapping

(TRM): Contributions and trends. Technological

Forecasting and Social Change, 80(7), Article 7.

https://doi.org/10.1016/j.techfore.2012.11.008

Dubois, A., & Gadde, L.-E. (2002). Systematic combining:

An abductive approach to case research. Journal of

Business Research, 55(7), Article 7.

https://doi.org/10.1016/S0148-2963(00)00195-8

Environmental Product Declarations. (2024).

Environmental Product Declarations – Construction

Products Europe. https://www.construction-products.

eu/publications/environmental-product-declarations/

Forza, C., & Salvador, F. (2006a). Configurational

Approach: Aligning Product, Processes and

Organization Systems. In C. Forza & F. Salvador

(Eds.), Product Information Management for Mass

Customization: Connecting Customer, Front-office and

Back-office for Fast and Efficient Customization (pp.

194–206). Palgrave Macmillan UK.

https://doi.org/10.1057/9780230800922_12

Forza, C., & Salvador, F. (2006b). Product Information

Management for Mass Customization: Connecting

Customer, Front-office and Back-office for Fast and

Efficient Customization. Springer.

Ghobakhloo, M. (2020). Industry 4.0, digitization, and

opportunities for sustainability. Journal of Cleaner

Production, 252, 119869. https://doi.org/10.1016/

j.jclepro.2019.119869

Hassan, M. F., Mahmood, S., Saman, M., Sharif, S., &

Sapuan, syarfa zahirah. (2017). Application of product

sustainability evaluation tool (ProSET) on car seat

design configurations. International Journal of

Mechanical and Mechatronics Engineering, 17, 88–97.

Haug, A., Hvam, L., & Mortensen, N. H. (2012). Definition

and evaluation of product configurator development

strategies. Computers in Industry, 63(5), Article 5.

https://doi.org/10.1016/j.compind.2012.02.001

Haug, A., Shafiee, S., & Hvam, L. (2019). The causes of

product configuration project failure. Computers in

Industry, 108, 121–131. https://doi.org/10.1016/

j.compind.2019.03.002

Helo, P., Mayanti, B., Bejarano, R., & Sundman, C. (2024).

Sustainable supply chains – Managing environmental

impact data on product platforms. International Journal

of Production Economics, 109160.

https://doi.org/10.1016/j.ijpe.2024.109160

Huang, A., & Badurdeen, F. (2018). Metrics-based

approach to evaluate sustainable manufacturing

performance at the production line and plant levels.

Journal of Cleaner Production, 192, 462–476.

https://doi.org/10.1016/j.jclepro.2018.04.234

Hvam, L. (2004). A multi-perspective approach for the

design of Product Configuration Systems - an

evaluation of industry applications: International

Conference on Economic, Technical and

Organisational aspects of Product Configuration

Systems. Conference Proceedings.

Hvam, L., Haug, A., Mortensen, N. H., & Thuesen, C.

(2013). Observed benefits from product configuration

systems. The International Journal of Industrial

Engineering: Theory, Applications and Practice, 20,

329–338.

Hvam, L., & Ladeby, K. (2007). An approach for the

development of visual configuration systems.

Computers & Industrial Engineering - COMPUT IND

ENG, 53, 401–419. https://doi.org/10.1016/j.cie.20

07.05.004

Hvam, L., Mortensen, N. H., & Riis, J. (2008). Product

Customization. Springer Science & Business Media.

Kristjansdottir, K., Shafiee, S., Hvam, L., Bonev, M., &

Myrodia, A. (2018). Return on investment from the use

of product configuration systems – A case study.

Computers in Industry, 100, 57–69.

https://doi.org/10.1016/j.compind.2018.04.003

Kristjansdottir, K., Shafiee, S., Hvam, L., Forza, C., &

Mortensen, N. H. (2018). The main challenges for

manufacturing companies in implementing and

utilizing configurators. Computers in Industry, 100,

196–211. https://doi.org/10.1016/j.compind.2018.05.0

01

Li, J., Tao, F., Cheng, Y., & Zhao, L. (2015). Big Data in

product lifecycle management. The International

Journal of Advanced Manufacturing Technology,

81(1), Article 1. https://doi.org/10.1007/s00170-015-

7151-x

Myrodia, A., Randrup, T., & Hvam, L. (2019).

Configuration lifecycle management maturity model.

Computers in Industry, 106, 30–47.

https://doi.org/10.1016/j.compind.2018.12.006

Piroozfar, P., Farr, E. R. P., Hvam, L., Robinson, D., &

Shafiee, S. (2019). Configuration platform for

ICEIS 2024 - 26th International Conference on Enterprise Information Systems

108

customisation of design, manufacturing and assembly

processes of building façade systems: A building

information modelling perspective. Automation in

Construction, 106, 102914. https://doi.org/10.1016/

j.autcon.2019.102914

Shafiee, S., Haug, A., Shafiee Kristensen, S., & Hvam, L.

(2020). Application of design thinking to product-

configuration projects. Journal of Manufacturing

Technology Management, ahead-of-print.

https://doi.org/10.1108/JMTM-04-2020-0137

Shafiee, S., Hvam, L., Haug, A., Dam, M., &

Kristjansdottir, K. (2017). The documentation of

product configuration systems: A framework and an IT

solution. Advanced Engineering Informatics, 32, 163–

175. https://doi.org/10.1016/j.aei.2017.02.004

Shafiee, S., Kristjansdottir, K., Hvam, L., & Forza, C.

(2018). How to scope configuration projects and

manage the knowledge they require. Journal of

Knowledge Management, 22(5), Article 5.

https://doi.org/10.1108/JKM-01-2017-0017

Shafiee, S., Wautelet, Y., & Hvam, L. (2018). Management

Challenges in Product Configuration Projects.

Shafiee, S., Wautelet, Y., Hvam, L., Sandrin, E., & Forza,

C. (2020). Scrum versus Rational Unified Process in

facing the main challenges of product configuration

systems development. Journal of Systems and

Software, 170, 110732. https://doi.org/10.1016/j.jss.20

20.110732

Shakirov, E., Brandl, F., Bauer, H., Kattner, N., Becerril,

L., Fortin, C., Lindemann, U., Reinhart, G., &

Uzhinsky, I. (2019). Integration of Engineering and

Manufacturing Change Management: Infrastructure

and Scenarios for Teaching and Demonstration.

Procedia CIRP, 81, 535–540. https://doi.org/10.1016/

j.procir.2019.03.151

Skerlos, S. J. (2015). Promoting Effectiveness in

Sustainable Design. Procedia CIRP, 29, 13–18.

https://doi.org/10.1016/j.procir.2015.02.080

Tambo, T. (2017). Enterprise Architecture beyond the

Enterprise: Extended Enterprise Architecture Revisited.

In ICEIS 2017 - Proceedings of the 19th International

Conference on Enterprise Information Systems (Vol.

17, pp. 381-390). SCITEPRESS Digital Library.

https://doi.org/10.5220/0006277103810390

Yin, R. K. (2009). Case Study Research: Design and

Methods. SAGE.

Zheng, P., Xu, X., Yu, S., & Liu, C. (2017). Personalized

product configuration framework in an adaptable open

architecture product platform. Journal of

Manufacturing Systems, 43, 422–435. https://doi.org/

10.1016/j.jmsy.2017.03.010

Greener Information Systems for Product Configuration Management: Towards Adaptation to Sustainability Requirements

109