Enhancing Hydroponic Farming Productivity Through IoT-Based

Multi-Sensor Monitoring System

Khadijah Febriana R.

a

, Rahul Thakur

b

and Sudip Roy

c

Department of Computer Science & Engineering, Indian Institute of Technology Roorkee, India

Keywords:

Hydroponic, IoT, Automation, LoRaWAN, Sensors.

Abstract:

Hydroponic farming has gained prominence in modern agriculture owing to its inherent advantages in resource

efficiency and crop yield. This research explores the integration of Internet of Things (IoT) technologies

to further optimize hydroponic systems by monitoring and controlling crucial solution and environmental

parameters. A novel IoT-based hydroponic monitoring system has been developed, featuring a comprehensive

array of sensors including solution’s temperature, acidity (pH), total dissolved solids (TDS) and electrical

conductivity (EC), ambient temperature and humidity, and light intensity. This system leverages both WiFi

and LoRaWAN technologies to enhance connectivity, ensuring reliable communication over extended ranges.

This integration of communication protocols facilitates seamless data transmission and real-time control of

hydroponic conditions. The proposed IoT-based system aims to provide growers with a comprehensive and

user-friendly platform to monitor and adjust key parameters critical for plant growth, thereby maximizing the

productivity and yield in hydroponic farming. The results of this study contribute valuable insights into the

potential of IoT technologies to revolutionize precision agriculture and sustainable food production.

1 INTRODUCTION

The agricultural sector plays a crucial role in nu-

merous global economies, with traditional land-based

farming remaining the primary source of food produc-

tion. However, traditional agriculture confronts vari-

ous challenges, including climate change, cultivation

difficulties, and rising transportation costs. Essential

elements like fertilizers, pesticides, and irrigation sys-

tems are pivotal for enhancing the quality of agricul-

tural products. Yet their prices continue to escalate

alongside operational expenses such as irrigation and

machinery. Moreover, challenges persist due to exten-

sive distances between markets and agricultural sites,

inadequate transportation infrastructure, and volatile

fuel prices. These hurdles serve as catalysts for in-

novation and creativity to address present agricultural

dilemmas, particularly impacting small-scale farmers

with limited financial means and capabilities. Escalat-

ing cultivation and transportation expenses threaten to

erode profits and to burden farmers with debt, poten-

tially discouraging them from continuing their farm-

a

https://orcid.org/0009-0009-6046-6826

b

https://orcid.org/0000-0002-1371-8404

c

https://orcid.org/0000-0001-7873-3069

ing practices. To optimize resource utilization and to

mitigate the environmental impacts, soil-less farming

techniques like hydroponics have gained considerable

traction.

Hydroponic systems offer several advantages over

the conventional farming methods, including resource

efficiency, controlled environmental conditions, and

reduced ecological footprint. By cultivating plants in

nutrient-rich water solutions, hydroponics eliminates

the need for soil, promoting faster growth with in-

creased yields. Furthermore, technological advance-

ments, such as LoRaWAN (long range wide area net-

work) technology, facilitate remote monitoring for en-

hanced efficiency and effectiveness. LoRaWAN, rec-

ognized for its reliability and energy efficiency in

long-distance wireless communication, enables real-

time monitoring of various agricultural parameters

like temperature, humidity, soil pH, and nutrient lev-

els. This can empower farmers to make informed de-

cisions promptly, adapting to evolving environmental

conditions with greater precision and efficacy.

Recent years have witnessed a significant integra-

tion of sensors and actuators into hydroponic farm-

ing systems, enabling precise control and measure-

ment of crucial environmental parameters for optimal

plant growth. This integration has been emphasized

R., K., Thakur, R. and Roy, S.

Enhancing Hydroponic Farming Productivity Through IoT-Based Multi-Sensor Monitoring System.

DOI: 10.5220/0012741300003705

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 9th International Conference on Internet of Things, Big Data and Security (IoTBDS 2024), pages 351-357

ISBN: 978-989-758-699-6; ISSN: 2184-4976

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

351

by Niu et al. (Niu and Masabni, 2022), highlighting

the importance of proper nutrition, conducive tem-

peratures, and appropriate growing solutions for suc-

cessful hydroponic farming. Several studies have fo-

cused on the synergy between IoT technology and hy-

droponic agriculture. For example, Fang et al. (Fang

et al., 2014) developed a comprehensive system com-

bining IoT technology with other monitoring tools

to track environmental changes, whereas Bakhtar et

al. (Bakhtar et al., 2018) engineered a hydroponic

setup with sensors and remote control mechanisms to

optimize spinach cultivation by monitoring humidity,

temperature, and water levels. Their systems conduct

real-time data analysis, triggering notifications for de-

viations from predefined parameters. Additionally,

they explored IoT challenges and opportunities within

hydroponic contexts, including sensor accuracy, data

security, and operational costs.

Other researchers, such as Dutta et al. (Dutta et al.,

2021) and Nguyen et al. (Nguyen et al., 2022), have

investigated leveraging IoT for indoor plant cultiva-

tion and automated monitoring of lettuce plants, re-

spectively. Furthermore, studies like those by Chang-

mai et al. (Changmai et al., 2018) have applied IoT

for efficient watering of lettuce plants while monitor-

ing vital parameters. The technological advancements

have reshaped agriculture significantly with data ex-

change playing a pivotal role in enabling IoT func-

tionalities. Various communication technologies in-

cluding Bluetooth, ZigBee, WiFi, GPRS, and LoRa

have facilitated the establishment of robust sensor net-

works. Researchers like Muangprathub et al. (Muang-

prathub et al., 2019) and Deokar et al. (Deokar et al.,

2021) have demonstrated the collection and transmis-

sion of crop and water data via wireless sensor net-

works, enabling comprehensive monitoring of crops

through smartphones or web applications. More-

over, other studies, such as those by Benyezza et

al. (Benyezza et al., 2021) and Dasgupta et al. (Das-

gupta et al., 2020), have explored IoT applications

in optimizing water and energy consumption in ir-

rigation and predicting plant growth using AI, re-

spectively. Additionally, researchers like Rajkumar

et al. (Rajkumar et al., 2018) and Komal et al. (Ko-

mal and Bhardwaj, 2014) have developed IoT sys-

tems for enhancing energy efficiency and introduc-

ing robotic applications in agriculture. Similarly,

Mishra et al. (Mishra and Jain, 2015) and Codeluppi

et al. (Codeluppi et al., 2020) have utilized IoT tech-

nologies for automating nutrient delivery to plants

and managing livestock efficiently. Furthermore,

Wang et al. (Wang et al., 2021) have expedited re-

cycling processes in factories using LoRaWAN tech-

nology.

The objective of this research paper is to present a

novel IoT-based hydroponic monitoring system. This

system is equipped with an extensive array of sen-

sors, including those for solution temperature, acidity

(pH), ambient temperature, humidity, Total Dissolved

Solids (TDS), Electrical Conductivity (EC), and light

intensity. Leveraging both WiFi and LoRaWAN tech-

nologies, it aims to enhance connectivity, ensuring re-

liable communication over extended ranges. Through

seamless integration of communication protocols, the

system enables real-time data transmission and fa-

cilitates immediate adjustments to hydroponic condi-

tions. The primary goal of this IoT-driven solution is

to provide growers with a user-friendly platform for

monitoring and adjusting key parameters critical for

plant growth, ultimately maximizing productivity and

yield in hydroponic farming operations.

1.1 Measured Parameters and Related

Sensors

• Total Dissolved Solids (TDS). TDS level in a hy-

droponic solution serves as a crucial indicator of

nutrient concentration. TDS represents the total

quantity of dissolved minerals, salts, and nutrients

in the water. A higher TDS generally corresponds

to a greater nutrient concentration in the solu-

tion. Monitoring TDS is essential for ensuring

that plants receive an adequate and balanced sup-

ply of nutrients, promoting healthy growth. De-

viations from the optimal TDS range can lead to

nutrient imbalances, affecting plant development.

Consequently, maintaining the right TDS level is

integral to achieving precise control over nutrient

concentrations in hydroponic systems, fostering

optimal conditions for plant nutrient uptake and

overall growth.

• Solution Acidity (pH). The pH level in hydro-

ponic nutrient solutions profoundly shapes plant

growth by influencing nutrient availability and up-

take. Maintaining the optimal pH range of 5.5

to 6.5 is crucial, ensuring nutrients are in a sol-

uble form accessible to plants. Deviations lead

to issues like deficiencies, toxicities, and compro-

mised enzyme activity. pH impacts microbial ac-

tivity, influencing nutrient cycling, and directly

affects root health. Efficient nutrient uptake, en-

zyme functionality, and microbial support are all

contingent on maintaining the right pH. Regular

monitoring and adjustment of pH levels are im-

perative, fostering an environment conducive to

balanced nutrient availability, optimal uptake ef-

ficiency, and overall robust plant development in

hydroponic systems.

IoTBDS 2024 - 9th International Conference on Internet of Things, Big Data and Security

352

• Electrical Conductivity (EC). EC level in hy-

droponic solutions plays a pivotal role in influ-

encing plant growth by serving as a reliable in-

dicator of nutrient concentration. An optimal EC

range is vital for ensuring plants receive an ap-

propriate nutrient supply, fostering robust growth.

Inadequate EC levels may lead to nutrient de-

ficiencies, while excessively high levels can re-

sult in nutrient toxicity, both adversely affecting

plant development. Maintaining a balanced EC

is crucial to achieving optimal nutrient uptake

and preventing nutrient imbalances. Addition-

ally, there exists a dynamic relationship between

EC and pH levels. Alterations in one parame-

ter can impact the other, underscoring the impor-

tance of coordinated adjustments. Properly syn-

chronized EC and pH levels are essential for cre-

ating a harmonious nutrient environment, promot-

ing healthy plant growth, and mitigating poten-

tial nutrient-related challenges within hydroponic

systems. Regular monitoring and precise manage-

ment of both factors contribute to achieving opti-

mal plant performance in hydroponic cultivation.

• Solution Temperature. The temperature of a hy-

droponic solution is pivotal for plant growth and

performance. Optimal water temperature ensures

efficient nutrient uptake, metabolic processes, and

enzymatic activity. Maintaining the right temper-

ature is particularly crucial to prevent issues such

as oxygen depletion, root rot, and moss accumula-

tion. Cold water may impede nutrient absorption

and encourage moss growth, while excessively

warm water can lead to reduced oxygen levels,

promoting conditions conducive to root rot. Care-

ful temperature regulation is essential for prevent-

ing these challenges, ensuring a well-balanced hy-

droponic environment that fosters nutrient absorp-

tion and discourages detrimental factors like root

rot and moss accumulation, ultimately promoting

robust plant growth.

• Environment Temperature and Humidity. The

meticulous control of air temperature and humid-

ity in hydroponic farms is indispensable for creat-

ing optimal growing conditions, particularly in the

context of nutrient absorption and disease preven-

tion. Precise humidity regulation holds immense

significance, as it directly influences transpiration

rates—the pivotal process through which plants

absorb nutrients. Fluctuations in humidity levels

can lead to irregular water uptake, potentially re-

sulting in nutrient imbalances and hindered plant

growth. Furthermore, the control of air temper-

ature and humidity plays a vital role in disease

prevention. Elevated humidity levels provide an

ideal breeding ground for pathogens, increasing

the susceptibility of plants to fungal diseases and

other ailments. By diligently managing these en-

vironmental factors, hydroponic farmers can not

only mitigate the risk of diseases but also opti-

mize nutrient absorption. This strategic control

contributes to the creation of an ideal environment

that fosters vigorous plant growth, ensuring the

maximization of crop yields in hydroponic culti-

vation.

• Light Intensity. Control over environmental

light, or luminosity, is paramount in hydroponic

farms to ensure optimal growing conditions for

plants. Light is a primary factor driving photo-

synthesis, the process through which plants con-

vert light energy into chemical energy, crucial

for growth and development. Precise control of

light intensity, duration, and spectrum enables

growers to tailor conditions to the specific needs

of different crops. Inconsistent or inadequate

light can result in uneven growth, reduced yield,

and poor quality crops. By carefully manag-

ing light levels, hydroponic farmers can optimize

plant metabolism, nutrient absorption, and over-

all energy conversion. Additionally, controlling

light exposure is essential for preventing issues

like photo-inhibition, where excess light can harm

plant tissues and hinder growth. Moreover, main-

taining a consistent light schedule is crucial for

regulating plant circadian rhythms, influencing

processes such as flowering and fruiting. By fine-

tuning luminosity, hydroponic growers can cre-

ate an ideal environment that fosters robust plant

growth, maximizes yield, and enhances the over-

all quality of crops in hydroponic systems.

In order to measure the above mentioned param-

eters, we have explored sensors from different man-

ufacturers based on their cost, reliability, availability,

and measurement range. Table 1 shows the list of the

sensors used to developed our proposed monitoring

system.

2 HARDWARE AND

COMMUNICATION

PROTOCOLS/INTERFACES

2.1 Sensors

The sensors used for our proposed system can be dig-

ital or analog. These simple sensors are connected

to digital/analog pins of microcontoller to send and

Enhancing Hydroponic Farming Productivity Through IoT-Based Multi-Sensor Monitoring System

353

Table 1: Detailed Specifications of Sensors.

No. Name of Sensor Type Input Manufacturer Parameter Range Cost

1 DS18B20 Probe Analog 3 − 5.5V Dallas Semiconductor Solution Temperature −55

◦

C − 125

◦

C USD 0.8

2 pH Sensor Analog 3.3 − 5.5V DFRobot Acidity or Alkalinity 5.5 − 7.5 USD 40

3 TDS Sensor Analog 3.3 − 5V SeeedStudio Dissolved Solids/Nutrient 0 − 1000 ppm USD 14

4 BH1750 Sensor Digital 2.4 − 3.6V ROHM Semiconductors Light Intensity 0 − 65K lux USD 2

5

AHT10 Sensor

Analog 3.3 − 5V Bosch

Temperature Temp: −40

◦

C−80

◦

C

USD 3

and Humidity Humidity: 0 − 99%

6 EC Sensor Analog 3 − 5V DFRobot Solution’s Electrical Conductivity 0.07 − 50,000 µS/cm USD 70

receive data. In order to facilitate connection of com-

plex sensors, various hardware communication pro-

tocols (or Interfaces) can be used. For example, we

have used AHT10 (high precision digital tempera-

ture and humidity) and BH1750 (light luminosity)

sensors, which use I2C communication protocol for

sending the data to the microcontoller. I2C stands

for Inter-Integrated Circuit (I

2

C), is the most versa-

tile communication standard for connecting hundreds

for sensors using a shared bus. There are other com-

munication interfaces such as Serial Peripheral In-

terface (SPI) or Universal Asynchronous Receiver-

Transmitter (UART), which can be used to connect

the sensors. However, I2C provide clear advantage

over other two considering the following:

• I2C does not require analog-to-digital conversion

(ADC) to interface with the digital world. This

digital communication simplifies the wiring and

reduces the susceptibility to noise and interfer-

ence, resulting in more accurate and reliable data

transmission.

• I2C sensors use a simplified two-wire interface

(SDA - Serial Data Line, and SCL - Serial Clock

Line) for communication. I2C allows multiple

sensors to be connected to the same bus, which

means you can interface with several sensors us-

ing just a few pins of the microcontroller. Each

sensor has a unique address, allowing the micro-

controller to address and communicate with spe-

cific devices individually.

• I2C is a widely adopted standardized communi-

cation protocol with defined specifications, mak-

ing it easier to integrate I2C sensors from various

manufacturers into your projects without worry-

ing about compatibility issues.

Even though I2C protocol emerges as the optimal

choice for sensor connectivity, it’s worth noting that

the market offers a limited number of sensors with

native I2C support. To overcome this limitation, we

have developed an innovative I2C adapter prototype

capable of converting any digital or analog sensor into

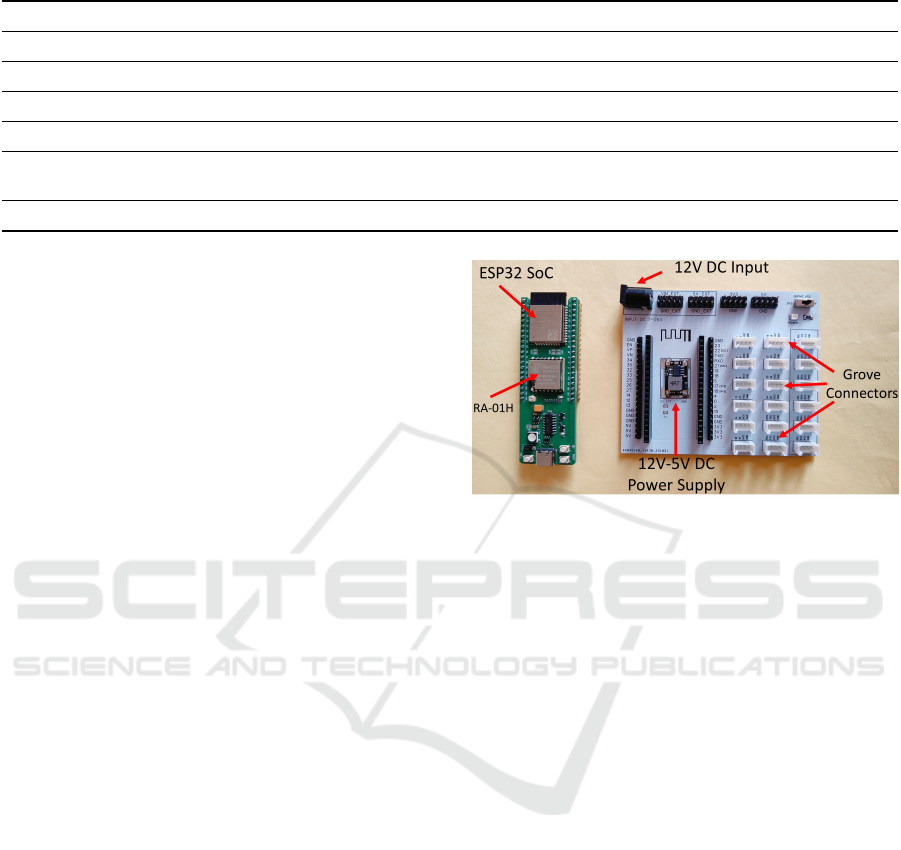

Figure 1: Microcontroller and Expansion Board.

an I2C enabled sensor, broadening the range of sen-

sors that can utilize I2C protocol for communication.

Readers can find more details about the prototype in

the Section 5. In this work, we focus our attention on

connecting the sensors using traditional digital/analog

pins only. The integration of I2C adapter for each sen-

sor will be explored in our future work.

2.2 Microcontroller and Expansion

Board

In response to the limited availability of LoRaWAN

microcontrollers in our region, we innovatively en-

gineered a bespoke ESP32 + LoRaWAN-based mi-

crocontroller board. This board features additional

5V and ground pins, enabling seamless connection

of multiple sensors simultaneously. Moreover, to

streamline experimentation and mitigate the risk of

loose connections, we devised an expansion board

equipped with standard Grove connectors. Notably,

this expansion board is designed with future-proofing

in mind, capable of accommodating additional sen-

sors through its expandable Grove connectors. Fur-

thermore, for scenarios requiring enhanced power

supply to the sensors, the expansion board includes

12V barrel connectors. Figure 1 illustrates both

the developed microcontroller and expansion boards,

showcasing their integrated design and versatility.

IoTBDS 2024 - 9th International Conference on Internet of Things, Big Data and Security

354

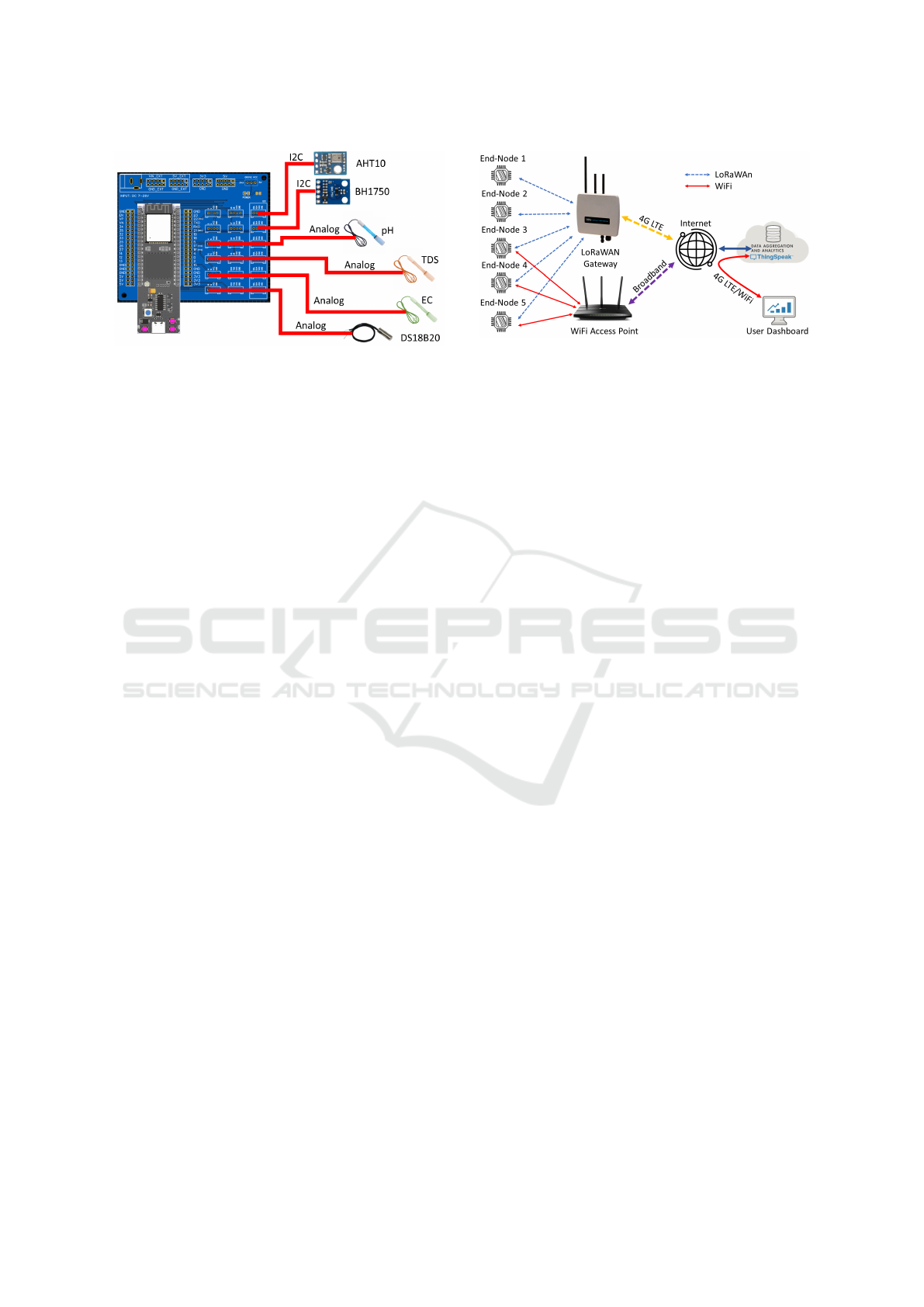

Figure 2: Peripheral Connection Diagram of an End-node.

2.3 Peripheral Connection Diagram

Figure 2 illustrates the comprehensive sensor-to-

microcontroller board connections facilitated by the

expansion board. Once the firmware is uploaded to

the microcontroller board, the USB connection is dis-

connected, and power is subsequently provided via a

12V-5V DC power supply.

3 LOCAL AND WIDE AREA

NETWORKING

The custom-designed microcontroller board incorpo-

rates ESP32-WROOM-32 (Espressif, 2024) and RA-

01H (Ai-Thinker, 2024) SoCs, capable of support-

ing WiFi, Bluetooth, and LoRaWAN wireless tech-

nologies. Our project focuses on WiFi 802.11 (2.4

GHz Band) and LoRaWAN (868 MHz Band) in line

with regional specifications. WiFi serves as a lo-

cal area networking technology, enabling high-speed

data transfer over short distances (approximately 100

meters). Conversely, LoRaWAN emerges as a long-

range, low-power wireless solution tailored to meet

the demands of IoT sensors and systems (Jouhari

et al., 2023). With LoRaWAN capable of support-

ing thousands of end-nodes per gateway and offering

coverage of up to 20 kilometers, it becomes an ideal

choice for rural or remote agricultural IoT deploy-

ments where cellular or satellite connectivity may be

impractical or unavailable.

Our system capitalizes on both WiFi and Lo-

RaWAN technologies, enhancing reliability by en-

abling data transmission through either medium. Fig-

ure 3 illustrates the connectivity and data flow from

end-nodes to the cloud server via WiFi access points

and/or LoRaWAN gateways. In cases where end-

nodes, such as End-Node 1 and 2, encounter limita-

tions in data transmission via WiFi due to coverage

issues, they seamlessly transition to LoRaWAN for

Figure 3: Network Connection for the IoT Setup.

dependable data transfer (Jouhari et al., 2023).

For cloud services, we selected ThingSpeak as the

provider due to its cost-effectiveness and provision of

an integrated dashboard for real-time data collection

and analytics (thingSpeak, 2024). This dashboard is

accessible to end-users via a web browser or mobile

application, facilitating remote monitoring and man-

agement from anywhere in the world.

4 DATA REPRESENTATION AND

ANALYTICS

In this hydroponic system there are many nodes and

these nodes can be equipped with LoRa transceivers.

The node includes sensors to measure pH, tempera-

ture, humidity, light intensity, and gas concentration

levels. Each node can also have a microcontroller

to process data collected by sensors and then send

it for wireless communication. In mesh communi-

cation, each node can be a sender and receiver of

data. Each node is interconnected and forms its rout-

ing, where data can be delivered through intermedi-

ate nodes in the network.Figure 2 shows that in the

hydroponic system that we built, with mesh commu-

nication, nodes can send their sensor data to the net-

work server and send data to their neighboring nodes.

These adjacent nodes, in turn, will convey further data

until it reaches a node connected directly to gateways.

With this relay mechanism, even nodes far from the

gateway can communicate effectively. In addition,

with mesh communication, if a node experiences an

interruption, the network can reroute the data to an al-

ternative path so that the information reaches the des-

tination.

In this hydroponic system, data will be collected

by sensors, packaged into LoRa packets, and sent to

the LoRa gateway to be forwarded to The Things Net-

work (TTN). TTN is a cloud-based LoRaWAN plat-

form that manages and collects sensor data, ensuring

its integrity and authenticity. TTN also offers an API

Enhancing Hydroponic Farming Productivity Through IoT-Based Multi-Sensor Monitoring System

355

to access stored data for further analysis. In this hy-

droponic system, sensor data sent via LoRa is dis-

played on the Node-RED dashboard. The dashboard

connects to the TTN API to capture real-time sensor

data and present it via graphs, charts, or visual repre-

sentations so users can access this information on the

web and mobile devices.

One of the big challenges in a hydroponic system

is nutrient balance, therefore it is necessary to under-

stand nutrient mixing. According to (Son et al., 2020)

mixing nutrients can be done periodically as shown in

Eqn. 1:

C

T

EC

T

= C

c

EC

c

+ bUU =

C

t

EC

t

−C

c

EC

c

b

(1)

for EC calculating by Eqn. 2:

EC

22

=

EC

t

1 + αC(t − 22)

(2)

where C

t

is the maximum capacity that can be

achieved by the solution in the tank, EC

t

is the target

electrical conductivity value dSm

−1

to be achieved,

C

c

and EC

c

are the current volume of nutrient-rich

solution from the nutrient tank, U are the nutrients ab-

sorbed by the plant in the tank. b are empirical coeffi-

cients for EC conversion and salt concentration. Ac-

cording to (Jung et al., 2019), the b coefficient value

that is suitable for hydroponics is b = 9.819, while the

EC

t

value that is considered suitable is in the range of

0.8 − 4.0 dSm

−1

.

In order for the hydroponic system to operate ef-

ficiently some of the sensors we use in this system

need to be calibrated beforehand in order to obtain

accurate and reliable measurements, maintain sensor

performance and to ensure the quality of the results.

For the TDS grove sensor used in this system, we first

convert the analog reading into voltage using Eqn 3:

Voltage = sensorValue ×

5.0

1024.0

(3)

where Voltage is a variable that will store the volt-

age value calculated from sensor readings and sensor-

Value is a variable that stores the analog reading ob-

tained from the Grove TDS sensor. For TDS sensor,

we need to calibrate first using Eqn. 4.

tdsValue =(133.42/Voltage

3

− 255.86 ×Voltage

2

+ 857.39 ×Voltage) ×0.5

(4)

and for pH, we need to calculate using Eqn. 5.

ph act = −5.70 ×volt + calibration value (5)

Figure 4: I2C Adapter.

5 FUTURE RESEARCH

DIRECTIONS

To expedite programming and simplify sensor re-

placements, we embarked on developing an I2C

adapter board facilitating communication between

any digital/analog sensor and the primary microcon-

troller via the I2C protocol. For N sensors, N I2C

adapters are employed, each endowed with a unique,

programmable I2C address for communication. Es-

sentially, the I2C adapter board operates as a low-

power microcontroller, gathering digital/analog data

from a sensor and transmitting it to the primary mi-

crocontroller via the I2C protocol. Figure 4 show-

cases the prototype of our I2C adapter board, employ-

ing an inexpensive ($1) ATTINY85 microcontroller.

In future iterations, our goal is to minimize the size

and power consumption of this adapter board to seam-

lessly integrate it with hydroponic sensors.

Apart from developing I2C adapter, we plan to uti-

lize the Bluetooth connectivity option available in the

ESP32 SoC to create a multi-hop mesh network. This

will allow end-nodes which are not in range of both

WiFi router and LoRaWAN gateway to relay data via

neighboring end-nodes. This will further increase the

coverage range for the end-nodes.

6 CONCLUSIONS

The surge in interest towards hydroponics and aero-

ponics, driven by limited fertile soil availability, un-

derscores the need for precise monitoring of envi-

ronmental conditions. To address this, we introduce

an IoT-based multi-sensor monitoring system tailored

for hydroponic agriculture. Distinguished from ex-

isting solutions, our system boasts a broader parame-

ter measurement range and combines LoRaWAN and

WiFi technologies for extended data transmission in

WiFi/cellular challenged areas. Additionally, our in-

novative I2C sensor adapter simplifies sensor commu-

IoTBDS 2024 - 9th International Conference on Internet of Things, Big Data and Security

356

nication and replacement, enhancing system flexibil-

ity. Future developments will focus on refining the

I2C sensor adapter design and integrating Bluetooth

mesh networking for further system optimization.

ACKNOWLEDGMENTS

This work was partially supported by the Doctoral fel-

lowship in India (DIA) programme of the Ministry of

Education, Government of India.

REFERENCES

Ai-Thinker (2024). Ai-Thinker SX1276 SoC Chip 868Mhz

Ultra Long Distance Wireless Spread Spectrum LoRa

Module Ra-01H.

Bakhtar, N., Chhabria, V., Chougle, I., Vidhrani, H., and

Hande, R. (2018). Iot based hydroponic farm. In

2018 International Conference on Smart Systems and

Inventive Technology (ICSSIT), pages 205–209.

Benyezza, H., Bouhedda, M., and Rebouh, S. (2021). Zon-

ing irrigation smart system based on fuzzy control

technology and iot for water and energy saving. Jour-

nal of Cleaner Production, 302:127001.

Changmai, T., Gertphol, S., and Chulak, P. (2018). Smart

hydroponic lettuce farm using internet of things. In

2018 10th international conference on knowledge and

smart technology (KST), pages 231–236. IEEE.

Codeluppi, G., Cilfone, A., Davoli, L., and Ferrari, G.

(2020). Lorafarm: A lorawan-based smart farming

modular iot architecture. Sensors, 20(7):2028.

Dasgupta, I., Saha, J., Venkatasubbu, P., and Ramasubrama-

nian, P. (2020). Ai crop predictor and weed detector

using wireless technologies: a smart application for

farmers. Arabian Journal for Science and Engineer-

ing, 45:11115–11127.

Deokar, M., Iyer, V., Badgujar, S., Yadav, H., and Venkat,

J. (2021). Iot based automated hydroponic system.

International Research Journal of Engineering and

Technology (IRJET), 8.

Dutta, A., Nag, I., Basu, S., Seal, D., and Gayen, R. K.

(2021). Iot based indoor hydroponics system. In 2021

5th International Conference on Electronics, Mate-

rials Engineering & Nano-Technology (IEMENTech),

pages 1–8. IEEE.

Espressif (2024). ESP32 WROOM 32E, ESP32 WROOM

32UE Datasheet.

Fang, S., Da Xu, L., Zhu, Y., Ahati, J., Pei, H., Yan, J.,

and Liu, Z. (2014). An integrated system for regional

environmental monitoring and management based on

internet of things. IEEE Transactions on Industrial

Informatics, 10(2).

Jouhari, M., Saeed, N., Alouini, M.-S., and Amhoud, E. M.

(2023). A survey on scalable lorawan for massive iot:

Recent advances, potentials, and challenges. IEEE

Communications Surveys and Tutorials, 25(3):1841–

1876.

Jung, D.-H., Kim, H.-J., Cho, W.-J., Park, S. H., and Yang,

S.-H. (2019). Validation testing of an ion-specific

sensing and control system for precision hydroponic

macronutrient management. Computers and electron-

ics in agriculture, 156:660–668.

Komal, M. and Bhardwaj, K. (2014). Implementation of

controlled hydroponics in urban infrastructure. IOSR

Journal of Mechanical and Civil Engineering, 11.

Mishra, R. L. and Jain, P. (2015). Design and implementa-

tion of automatic hydroponics system using arm pro-

cessor. International journal of advanced research in

electrical, electronics and Instrumentation Engineer-

ing, 4.

Muangprathub, J., Boonnam, N., Kajornkasirat, S., Lek-

bangpong, N., Wanichsombat, A., and Nillaor, P.

(2019). Iot and agriculture data analysis for smart

farm. Computers and electronics in agriculture,

156:467–474.

Nguyen, H. C., Thi, B. T. V., and Ngo, Q. H. (2022). Auto-

matic monitoring system for hydroponic farming: Iot-

based design and development. Asian Journal of Agri-

culture and Rural Development, 12(3):210–219.

Niu, G. and Masabni, J. (2022). Chapter 9 - hydroponics.

In Plant Factory Basics, Applications and Advances,

pages 439–449. Elsevier.

Rajkumar, R., Dharmaraj, R., and Scholar, P. (2018). A

novel approach for smart hydroponic farming using

iot. International Journal of Engineering Research in

Computer Science and Engineering (IJERCSE), 5.

Son, J. E., Kim, H. J., and Ahn, T. I. (2020). Chapter 20-

hydroponic systems.

thingSpeak (2024). Learn More About ThingSpeak.

Wang, C.-Y., Tsai, C.-H., Wang, S.-C., Wen, C.-Y., Chang,

R. C.-H., and Fan, C.-P. (2021). Design and im-

plementation of lora-based wireless sensor network

with embedded system for smart agricultural recy-

cling rapid processing factory. IEICE Transactions on

Information and Systems, 104(5):563–574.

Enhancing Hydroponic Farming Productivity Through IoT-Based Multi-Sensor Monitoring System

357