An Adaptive Learning Environment for Industry 4.0 Competencies

Based on a Learning Factory and Its Immersive Digital Twin

Polina H

¨

afner

1 a

, Viktoria Bergmann

2

, Victor H

¨

afner

1 b

, Felix Longge Michels

1 c

,

Michael Grethler

1

and Abhijit Karande

3 d

1

Institute for Nuclear Waste Disposal, Karlsruhe Institute of Technology,

Hermann-von-Helmholtz-Platz 1, 76344 Eggenstein-Leopoldshafen, Germany

2

Institute of Vocational and General Education, Karlsruhe Institute of Technology, Hertzstraße 16, Karlsruhe, Germany

3

EES Beratungsgesellschaft mbH, Adalbert Stifter Str. 8, Ettlingen, Germany

Keywords:

Extended Reality, Immersive Digital Twin, Virtual Twin, Learning Environment, Learning Factory,

Industry 4.0, Engineering Education.

Abstract:

Technological advancements and the interdisciplinary nature of modern engineering projects are driving forces

behind the evolution of engineering skills today. Educational institutions are responding to the demand for new

skills through various initiatives, one notable example being the implementation of learning factories. These

facilities serve as invaluable resources for hands-on, practice-oriented learning, particularly in the context of

Industry 4.0. This publication outlines an innovative teaching concept and the implementation of an adap-

tive and immersive learning environment tailored for Industry 4.0 education. Central to this environment is

a cost-effective learning factory model complemented by its immersive digital twin, accessible on desktop

PCs or immersive hardware. The virtual learning environment comprises diverse teaching modules cover-

ing advanced engineering topics such as agile production, industrial Internet of Things, automation, machine

learning and autonomous guided vehicles. The integration of a physical learning factory with its immersive

digital counterpart allows for the playful exploration of additional relevant topics such as digital twins, virtual

commissioning and extended reality. The adaptability of this hybrid learning environment enables educa-

tors to customize teaching scenarios and adjust content and difficulty levels to suit various learner groups.

Furthermore, it accommodates a wide range of teaching methods and classroom setups, offering a versatile

educational experience.

1 INTRODUCTION

As technology advancements revolutionize traditional

production methods and reshape the operational land-

scape for businesses, they present a myriad of op-

portunities and challenges. Navigating this transfor-

mation in future factories inevitably alters the com-

petencies and skill sets required of engineering pro-

fessionals. Many educational institutions are revising

their curriculum to incorporate emerging technologies

and skills relevant to the future job market. There is

a growing recognition of the importance of lifelong

learning in staying competitive within the workforce.

Many organizations are offering continuous learning

a

https://orcid.org/0000-0003-4534-351X

b

https://orcid.org/0000-0001-8682-1122

c

https://orcid.org/0000-0001-6533-4886

d

https://orcid.org/0009-0001-3554-285X

opportunities for their employees. In addition to tech-

nical skills, there is a growing emphasis on the im-

portance of soft skills such as communication, critical

thinking, creativity, and adaptability. Furthermore,

advances in learning technologies, such as virtual re-

ality, gamification, and adaptive learning platforms,

are being leveraged to create engaging and effective

training programs. These technologies enhance the

learning experience and make education more acces-

sible to diverse learners.

Learning factories are an important educational

resource, particularly in the field of engineering ed-

ucation. Tangible learning factories are designed to

represent industrial environments as realistically as

possible. In recent years, they have been increas-

ingly used to illustrate the changes associated with

Industry 4.0 and to specifically promote the learning

of the necessary skills. In learning factories, inter-

720

Häfner, P., Bergmann, V., Häfner, V., Michels, F., Grethler, M. and Karande, A.

An Adaptive Learning Environment for Industry 4.0 Competencies Based on a Learning Factory and Its Immersive Digital Twin.

DOI: 10.5220/0012757000003693

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 16th International Conference on Computer Supported Education (CSEDU 2024) - Volume 1, pages 720-731

ISBN: 978-989-758-697-2; ISSN: 2184-5026

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

linked workplace and machine chains are available

for various phases of the production process. Learn-

ers can gain practical experience with modern plant

modules and even with product development meth-

ods (Abele et al., 2017). Learning factories integrate

teaching, training, and research within a realistic pro-

duction environment, employing didactic models for

the conveyance and reflection of learning content. De-

fined in a narrower sense, a learning factory is an ed-

ucational setting characterised by authentic processes

that include multiple stations and cover both techni-

cal and organisational aspects. This adaptable envi-

ronment mirrors a real value chain where a physical

product is manufactured. The pedagogical concept

behind a learning factory encompasses formal, infor-

mal, and non-formal learning, facilitated through the

direct actions of trainees in an on-site learning ap-

proach (Abele et al., 2019).

One way of making the most of the learning fac-

tory concept is to offer digital or virtual learning en-

vironments. Digital and virtual learning factories ex-

ist at various educational institutions, including uni-

versities, companies and, in some cases, vocational

schools. They are used for training in similar ar-

eas to physical learning factories. At the same time,

they function independently of location and do not in-

volve the large financial outlay of a physical learn-

ing factory. They are therefore considered an impor-

tant strategic tool for implementing education in the

field of manufacturing (Abele et al., 2017). Learn-

ing in virtual environments is being used more and

more frequently in various scientific disciplines due

its benefits (H

¨

afner, 2020). In engineering, particu-

larly, the integration of virtual learning environments

as a didactic tool is now widely recognized (H

¨

afner,

2021). A virtual learning factory promotes the learn-

ing of advanced manufacturing concepts by combin-

ing virtual objects with hands-on activities and pro-

viding learners with a motivating learning experience

(Aqlan et al., 2021). Learners can experience a col-

laborative and immersive learning environment in a

realistic simulation. Moreover, diverse learning sce-

narios can be effectively addressed by adjusting and

incorporating additional objects as needed.

A review by Reining and Kauffeld (2022) sum-

marised the empirical evidence on learning outcomes

and skills development in learning factories (Rein-

ing and Kauffeld, 2022). A total of 22 studies were

included, 16 of which were conducted in physical

learning factories and three in virtual learning fac-

tories. Three further studies combined physical and

virtual learning factories. The interventions evaluated

included continuing education, higher education pro-

grammes and vocational training courses, mostly on

topics such as lean, agility, Industry 4.0 and prod-

uct or software development. All 22 studies re-

ported an increase in participants’ knowledge or skills

following the learning factory interventions. Self-

assessment questionnaires showed that between 47

and 100 percent of participants felt that their knowl-

edge or understanding had increased significantly fol-

lowing the interventions. Knowledge tests, practi-

cal applications, interviews, and observations also

showed increases in knowledge and skills. Skills,

including technical, methodological, social and per-

sonal skills, were reported to have improved as a re-

sult of the learning factory experience. Looking at the

three purely virtual and the three hybrid learning fac-

tories in terms of learning outcomes, they appear to

be just as effective as the physical learning factories

in terms of learning outcomes.

The proposed adaptive Virtual Learning Platform

(VLP) in this publication leverages the Agile Produc-

tion Simulation, a small-scale learning factory offered

by the fischertechnik company. It incorporates an im-

mersive digital twin, expanding upon it to offer ad-

ditional educational content, resulting in a compre-

hensive, flexible, and expandable learning environ-

ment. The VLP can be deployed on different immer-

sive hardware such as VR headset or CAVE, facilitat-

ing its utilization in a hybrid fashion. In the following

sections, the authors describe current developments

in the area of digital learning factories (section 2), the

teaching concept (section 3), as well as its implemen-

tation (refer to section 4). Furthermore, a comprehen-

sive evaluation concept is proposed in section 5.

2 RELATED WORKS

Various examples of training approaches using digi-

tal twins and virtual production environments can be

identified in the literature.

The digital twin learning factory, as presented by

Algeddawy et al. (2020), comprises a 1:1 scaled envi-

ronment featuring various material handling modules,

including an automatic storage and retrieval system, a

robotic handling with vision module, a robotic pick-

and-place and rotating storage module, and a robotic

assembly module with a SCARA robot. Constructed

using a combination of open-source and low-cost dig-

ital components, this digital twin utilizes tools such as

RoboDK for 3D simulation, CODESYS for automa-

tion control programming, and Modbus and OPC UA

for communication, along with Python for scripting.

The model for creating the digital twin progresses

through three stages, focusing on the connection to

the physical twin and data processing methodologies

An Adaptive Learning Environment for Industry 4.0 Competencies Based on a Learning Factory and Its Immersive Digital Twin

721

(Al-Geddawy, 2020).

A similar approach combining real learning fac-

tory, and its digital twin is followed by (Rasovska

et al., 2022), but is advanced by a virtual reality (VR)

factory model. It features two reconfigurable pro-

duction lines, each comprising five assembly stations.

The learning factory is equipped with MES software

developed in-house, as well as ERP systems. Ad-

ditionally, it utilizes flow simulation software, along

with a metrology laboratory. Six ergonomics equip-

ment, including various types of exoskeletons, and

logistics equipment and line-side supermarkets are

also incorporated. The developed system facilitates

comprehensive practical training in industrial engi-

neering and Lean manufacturing. Practical training is

provided within Bachelor’s and Master’s degree pro-

grams, available in both initial and continuing educa-

tion formats (Rasovska et al., 2022).

Aqlan et al, (2021) discuss the development of a

virtual learning factory that represents manual and au-

tomated processes such as welding and 3D printing,

including a multiplayer VR environment for toy car

assembly and a car manufacturing simulation with an

interactive avatar (Aqlan et al., 2021).

Sibanda and colleagues (2023) developed a VR

application for lathe training, consisting of a digital

content module and a game engine to teach lathe op-

eration in a realistic way (Sibanda et al., 2023). An-

other concept for learning factory, based on a CNC

lathe machine and its virtual representation was de-

veloped by Mourtzis et al. (2021), centered on the

teaching and implementation of a Teaching Factory

Network (Mourtzis et al., 2021).

A further paper explores the digitalization and in-

corporation of Industry 4.0 technologies within pro-

duction and logistics systems, focusing on their ap-

plication in contemporary teaching and learning en-

vironments utilizing the fischertechnik Learning Fac-

tory 4.0 (Behrendt et al., 2022).

As seen in the examples above, many publications

promote manufacturing education using learning

factories through immersive experiences (Rasovska

et al., 2022; Behrendt et al., 2022; Aqlan et al., 2021;

Sibanda et al., 2023; Mourtzis et al., 2021). Many

of these learning factories replicate 1:1 scale ma-

chines found in production facilities, boasting high

costs and complexity, and are primarily utilized for

higher education purposes. While much of the lit-

erature focuses on the implementation of digital or

virtual twins, there is a notable gap in discussions

regarding teaching methods, didactic approaches, or

comprehensive evaluation, except for the evaluation

conducted by (Rasovska et al., 2022).

The novelty of our work lies in utilizing a small-

scale, cost-effective factory model that offers excep-

tional flexibility and expandability while demonstrat-

ing agile production simulations. The primary con-

tribution is the development of an adaptive teaching

concept, manifested as a virtual learning platform,

consisting of both digital and virtual twins. In addi-

tion, our didactic model accommodates highly diverse

target groups and provides educators with a flexible

toolset to adapt their courses to various teaching se-

tups.

3 TEACHING CONCEPT

In this chapter, we delve into the innovative teaching

concept designed to harness the synergies between

physical and digital learning environments and to en-

able an immersive educational experience. To em-

power educators in utilizing this hybrid learning fac-

tory, a virtual learning platform was developed. It

builds upon the immersive digital twin of the ”Agile

Production Simulation,” providing guidance through

Industry 4.0 topics and enabling educators to greatly

benefit from its adaptive approach. It enables teachers

to work more efficiently, granting them the flexibility

to adjust learning content and teaching scenarios as

needed for specific target groups. Learners have the

opportunity to independently explore theoretical fun-

damentals in an engaging manner, and subsequently

tackle more complex tasks with the guidance of the

teacher. This approach enables the use of modern

teaching methods such as the flipped classroom and

blended learning. Educators gain time and flexibil-

ity to focus their attention more on the individual

needs of the students and optimally support the learn-

ing process. This changes the teacher’s role from pure

knowledge provider to expert moderator, who flexibly

guides the learning process. The virtual learning envi-

ronment offers additional benefits, as learners can ex-

periment in the digital realm without concerns about

damaging real-world equipment. In a traditional vo-

cational learning setting, students gain practical expe-

rience directly on machines in the shop floor. How-

ever, this often requires halting production, resulting

in idle workers and potential downtime for machines

and factories. Immersive digital twins provide an ef-

fective alternative.

3.1 Competences

The learning platform comprises diverse teaching

modules covering advanced engineering topics such

as agile production, industrial Internet of Things, au-

tomation, machine learning, autonomous guided ve-

ERSeGEL 2024 - Workshop on Extended Reality and Serious Games for Education and Learning

722

hicles, robotics and more. The integration of a phys-

ical learning factory with its immersive digital coun-

terpart allows for the playful exploration of additional

relevant topics such as digital twins, virtual commis-

sioning, extended reality, as well as digital skills (as

depicted in figure 1). With the help of production

process modelling and analysis tools, students gain

an overview of the relationships and interactions be-

tween different elements and processes in the fac-

tory environment, which increases understanding of

the totality of processes and procedures. The learn-

ing environment is divided in learning modules. Each

learning module includes a theoretical section, prac-

tical tasks, reflective questions, and multiple-choice

assessments. The practical tasks in this learning mod-

ules are categorized based on whether they can be

completed solely in the virtual or physical environ-

ment, as well as those that benefit from a hybrid ap-

proach, combining elements of both. By integrat-

ing the adaptive learning environment with appropri-

ate teaching methods, it becomes possible to cultivate

not only technological and industry-specific skills but

also essential digital and cross-disciplinary competen-

cies.

At the beginning of the VLP development, three

competence levels were defined for the learners: Un-

derstand, Apply and Improve. It is important to em-

phasize that these three levels have different charac-

teristics, which should not be interpreted in terms of

Bloom’s taxonomy of learning objectives (Forehand,

2010). Rather, the target perspectives - and thus learn-

ing levels - identified by Windelband et al. (2023)

specifically in the context of vocational learning fac-

tories are used as a rough guidance for the orientation

of the individual learning levels of the VLP (Windel-

band et al., 2023). For each of the three levels, these

describe specific problem-oriented questions in the

context of vocational learning factories.

Level 1 - Understand. This target perspective fo-

cuses on providing an initial overview of knowledge

and skills relating to Industry 4.0 and artificial intel-

ligence (AI). Learners are enabled to understand and

comprehend facts, circumstances and contexts.

Level 2 - Apply. This perspective serves to deepen

the competencies for the use and selection of suitable

methods and professional actions. Professional skills

are taught that are necessary to be able to act com-

petently in the operational environment in the field of

Industry 4.0. Learners are enabled to transfer and ap-

ply what they have learned to other situations.

Level 3 - Improve. At this level, an expert under-

standing of the specific professional challenges, nec-

essary for tasks such as optimizing and maintaining

systems within the realm of Industry 4.0, is provided.

Figure 1: Expansion of the acquired skills through digital

twins and Virtual Reality (left).

This level is therefore aimed at learners who have al-

ready reached level 2 and should now be able to act

at higher levels and provide concrete assistance. This

includes making comprehensive generalizations and

finding new solutions, as well as weighing up these al-

ternatives, evaluating them according to self-imposed

criteria and making competent decisions.

All three target perspectives and learning levels

differ from one another in terms of their objectives,

target group and didactic implementation. Neverthe-

less, the boundaries between them can be fluid.

3.2 Target Group

The teaching concept caters to a diverse target audi-

ence characterized by significant heterogeneity, inter-

disciplinary specialization, varying age ranges, and

diverse cultural backgrounds. Furthermore, it encom-

passes a range of educational institutions such as high

schools, vocational schools, universities, as well as

intercompany training and further vocational qualifi-

cation.

One of the parameters used to adjust the learning

environment is the learning level. The three learning

levels outlined in section 3.1 target various aspects of

vocational training (Windelband et al., 2023). ”Un-

derstanding” serves as a fundamental stage, particu-

larly beneficial for learners with limited prior knowl-

edge, such as trainees in the metal and electrical in-

dustry. In this context, the VLP acts as a valuable in-

troductory tool during vocational school lessons, of-

fering an initial grasp of individual system compo-

nents and their interplay within the broader system.

This foundational module also holds potential as a

primer for university students pursuing technical de-

grees (e.g., engineering programs). Additionally, it

could cater to employees in production and logistics

sectors, providing non-technical personnel (e.g., from

commercial or human resources backgrounds) with

an overview of Industry 4.0’s technical processes.

An Adaptive Learning Environment for Industry 4.0 Competencies Based on a Learning Factory and Its Immersive Digital Twin

723

The ”Apply” level, the second stage, is designed

for proficient learners with prior training in metal and

electrical professions. At this stage, the objective is to

enhance skills, allowing learners to utilize their exist-

ing knowledge in new situations. For example, tasks

previously focused on professional applications may

evolve into tasks within the context of Industry 4.0,

like repair and maintenance activities.

The third level, ”Improving,” primarily targets

academic professionals such as engineers. Within In-

dustry 4.0 systems, their roles involve process analy-

sis, evaluation, and optimization. For this group, the

VLP functions as an intermediate training tool, aid-

ing in the comprehension and practical application of

essential aspects of their professional responsibilities.

As a result, the VLP is versatile and can be used

for a wide range of target groups and prior knowledge

across the entire spectrum of vocational training.

3.3 Teaching Methods and Setups

The developed Virtual Learning Platform can be uti-

lized with a wide array of teaching methods. Here, we

will illustrate only some examples. The main goal of

this platform is to reduce frontal teaching or augment

it by active learning approaches such as practical exer-

cises, group work or project-based learning, as well as

novel teaching methods such as flipped classroom or

blended learning. The use of the learning factory dig-

ital twin and VR learning environment opens up fur-

ther possibilities for simulation as a teaching method.

Learners could run through complex production pro-

cesses in a virtual environment, simulate scenarios

with different variables and analyze the results in real

time. They could also specifically investigate errors

or problems in a safe environment and develop so-

lutions. Simulations as a teaching method promote

critical thinking, problem-solving skills and an ex-

perimental approach among learners. They empower

learners to apply theoretical concepts in practical sce-

narios and understand the consequences of their deci-

sions. The VLP also allows an explorative approach,

promoting self-directed learning. Learners can freely

explore the virtual factory and discover different as-

pects of Industry 4.0 technologies and processes. This

encourages curiosity and supports independent learn-

ing, as learners can explore different scenarios and ap-

plication areas at their own pace.

Regardless of the teaching methods employed, the

Virtual Learning Platform can be utilized in various

teaching setups. Depending on the number of stu-

dents and available facilities, instructors can conduct

classes in traditional classrooms, computer pools,

or laboratories equipped with virtual reality technol-

ogy where the tangible learning factory is located.

The software architecture and VR engine support the

use of different immersive hardware devices such as

CAVE, Powerwall, or VR headsets. Additionally, ed-

ucators can leverage immersive collaboration mode

for teaching. They have the flexibility to switch be-

tween the physical and virtual learning factories, par-

ticularly for topics like virtual commissioning, where

processes are configured in the virtual environment

and observed both virtually and in the real world.

3.4 Evaluation and Assessment Criteria

The virtual learning platform utilizes dedicated

multiple-choice questions for each learning module,

tailored to its specific topic. Additionally, the plat-

form suggests questions following each task, en-

abling teachers to initiate discussions, foster reflec-

tion, or facilitate the transfer of learning from the sim-

ulated factory environment to real-world production

settings. Furthermore, the assessment of performance

and achievements within the framework of this teach-

ing concept can be further enhanced through estab-

lished evaluation criteria. One assessment method can

be project-oriented work. In this case, both the in-

dividual performance standards and the expected re-

sults are taken into account in order to ensure fair

assessment. The tasks and assessment criteria may

vary depending on the target group and may require

minor adjustments. For example, in dual study pro-

grams, the focus may be on direct applications of the

technologies learned in a corporate context. For vo-

cational schools, precise descriptions of fictitious use

cases (detailed presentation of the solution space), the

problems to be solved, and the solution approaches

are of greater importance.

3.5 Enhancement with Gamification

Elements

The virtual learning platform can be enhanced

through gamification, immersing students in situa-

tional learning scenarios where they, for instance, in-

herit a factory. The objective is to transition it from

conventional production methods to modern, flexible

practices. Players must manage order fulfillment, de-

ciding which orders to accept or decline based on

profitability and current circumstances. Profits earned

from executing orders can be reinvested to optimize

the factory, purchasing additional machines or ex-

panding operations, such as acquiring more AGVs.

Players also tackle troubleshooting and maintenance

tasks as they arise. Challenges are presented within

specific time frames.

ERSeGEL 2024 - Workshop on Extended Reality and Serious Games for Education and Learning

724

3.6 Adaptability

Our concept embodies adaptability and flexibility due

to its versatile design and comprehensive approach to

education. By integrating both physical and digital

learning environments, we provide educators with a

range of options to tailor their teaching methods to

diverse student needs and preferences. The open char-

acter of the tools allows for the incorporation of new

tasks related to specific topics, fostering a dynamic

and evolving learning experience. Learners can select

between using the available resources - physical mod-

els, digital twins only, the combination of the two, or

the VR mode - based on their learning preferences and

objectives.

As previously discussed, the VLP accommodates

learners with varying levels of prior knowledge, sig-

nified by the learning levels integrated into the envi-

ronment. These levels denote the extent of complexity

or abstraction in reflection and action that participants

should aim to attain within a subject area. A partic-

ular strength of the concept lies in the flexible orga-

nization of time. Learners can choose from different

subject areas and levels to adapt the lessons to their

individual needs and learning progress. Additionally,

the teaching concept allows the teacher the flexibility

to adjust the time allocated to the virtual environment

and the practical work with physical models.

The division of the course into learning phases

with different focal points based on features in the

virtual learning environment, such as introduction

through exploration and application through the task

area, is intended to promote understanding and appli-

cation of the content. The teacher should regularly in-

corporate feedback from participants regarding time

management and course structure to enable continu-

ous improvement. This requires periodic reflections

from the learners on the progress to date.

4 IMPLEMENTATION

The implementation of the learning environment is

based on the virtual engineering software PolyVR.

This software provides simulation and emulation

modules for virtual twins of machines and production

facilities, as well as data and dynamic protocol-based

interfaces (H

¨

afner, 2019) . It also provides some de-

gree of platform independent deployment, Linux and

Windows, and visualisation capabilities on most VR

platforms such as CAVEs, Powerwalls and VR head-

sets.

4.1 Tangible Learning Factory

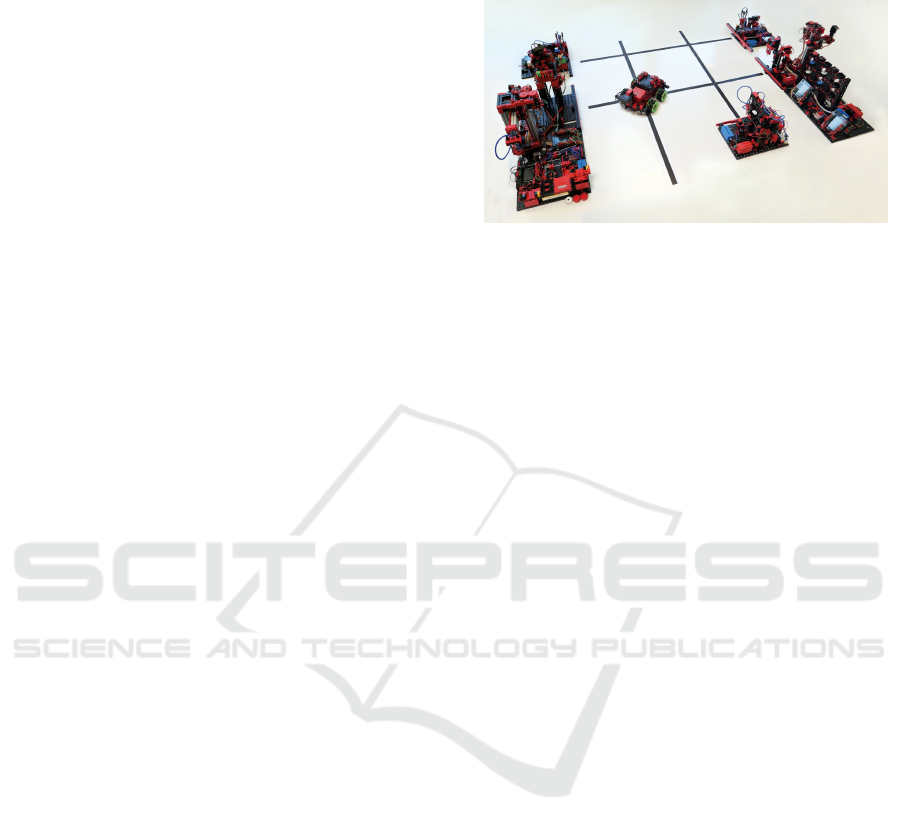

Figure 2: Agile Production Simulation 24V learning fac-

tory, a product by fischertechnik company.

With the Agile Production Simulation (APS), fis-

chertechnik has introduced an innovative model of a

learning factory that is intended to reflect the flexibil-

ity and modularity of modern factories, while offering

an easily accessible and user-friendly experience (see

figure 2). The Agile Production Simulation system

includes various modules like incoming and outgoing

goods, high-bay warehouse, milling station, drilling

station and a quality assurance with AI on an area of

129 x 184 cm (fischertechnik, 2024).

At incoming and outgoing goods the inbound and

outbound logistics occur. Here the workpieces are

fed into the real factory and delivered after process-

ing an order. This is where the material flow of a

workpiece begins and ends. The raw material is de-

livered at the goods receipt, positioned on the color

sensor for quality control using the 6-axis robot with

vacuum gripper, and then encoded on the NFC reader.

The robot then places the workpiece on the AGV for

further transport. The module also contains the cen-

tral control unit (Raspberry Pi) and the environmen-

tal sensor, which measures the different environmen-

tal conditions in the factory. The integrated, movable

camera can be swiveled in two axes and provides an

insight into the entire factory via the fischertechnik

cloud dashboard. At the end of a cycle, a finished

workpiece is delivered at the goods dispatch by the

AGV.

The next stop for a workpiece after goods receipt

is usually the high-bay warehouse. It contains nine

slots for workpieces, a stacker crane, and a vacuum

gripper that picks up the workpiece from the AGV at

the docking station and hands it over to the stacker

crane for storage. The workpiece is placed in a work-

piece carrier for storage. Retrieval is done according

to the First In First Out (FIFO) principle.

The drilling station consists of a docking station

for the AGV, a vacuum gripper that places the work-

piece onto a conveyor belt, from where it is trans-

An Adaptive Learning Environment for Industry 4.0 Competencies Based on a Learning Factory and Its Immersive Digital Twin

725

ported under the drilling head. After the simulated

drilling process, the workpiece is transported back to

the gripper on the conveyor belt. The gripper then

places it back onto the AGV. The milling station is

constructed in exactly the same way as the drilling

machine, simulating the milling of pockets.

In the quality assurance module, a vacuum grip-

per places the workpiece on a conveyor belt. It is

transported underneath the camera and scanned there.

The workpieces, which come in three different col-

ors (white, red, blue), with three machining features

(drilling, milling, drilling and milling), as well as var-

ious fault patterns, are classified using the trained AI.

Depending on the color, feature and fault pattern, the

workpieces are then either placed back onto the AGV

or sent to the reject container.

A driverless transport system, automated guided

vehicle (AGV) transports the workpieces from one

module to another. It is a track-bound vehicle that fol-

lows the printed black tracks. It uses ultrasonic sen-

sors to detect obstacles. The vehicle has omniwheels,

which allow it to move in all directions. Two buttons

and a phototransistor help the vehicle dock to individ-

ual factory modules. The factory’s expandable design

allows for the addition of components like kilns, ex-

tra machining stations, and supplementary driverless

transport systems (fischertechnik, 2024).

The factory is also seamlessly linked to the fis-

chertechnik cloud via a WLAN router, providing ac-

cess to a web interface which also serves as a dash-

board offering several functionalities like real-time

monitoring of orders, customizing the task on differ-

ent colored workpieces, ordering workpieces, factory

status visualization, performance metrics analysis etc.

Individual factory modules are interconnected physi-

cally using a tongue and groove mechanism, forming

a cohesive baseplate. New modules can be seamlessly

integrated into the existing structure, offering config-

urability and scalability facilitated through the dash-

board interface.

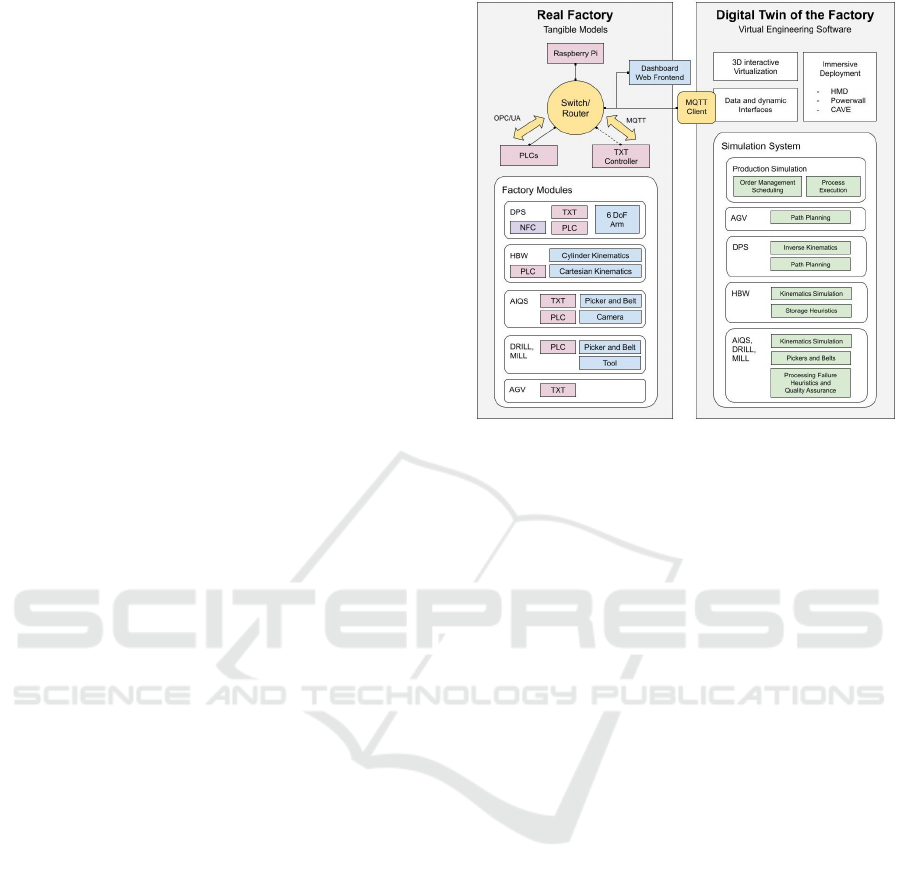

4.2 Virtualization Process

The virtual twin of the Agile Production Simulation

accurately mirrors the tangible factory model and its

modules. The immersive digital twin incorporates

3D models of each module into a virtual environ-

ment, merging them with dynamic-kinematic data,

controller programming, and production simulation.

This integration yields a fully operational and interac-

tive model of the APS, accurately replicating the au-

thentic behavior of every module. It offers a compre-

hensive simulation of the execution of all processes

within the factory, including those involving kine-

Figure 3: Software Architecture.

matic, mechanical, electrical, and pneumatic systems,

with meticulous detail. The digital twin utilizes exist-

ing planning data, such as CAD and controller (PLC)

programming, to analyze and integrate them, ensur-

ing precise replication of the real factory’s behavior

within a virtual environment across diverse simula-

tions. For example: a logistics simulation was set

up for the Automated Guided Vehicle system. Here

paths on which AGV drives are defined and then with

the help of a path planner the shortest path to the des-

tination is planned and executed in order to optimise

the transport routes for the AGV. Various indicators

and factors like transport and processing times, de-

fect rates and throughput are computed and compiled

for the user. This allows him to compare alternative

processes or optimize a process regarding those indi-

cators.

The digital twin can be used in two modes:

Software-in-loop and Hardware-in-loop. In the

software-in-loop mode, the virtual simulation is not

connected to the physical learning factory (APS). The

digital twin operates independently, facilitating teach-

ing and factory operations solely within the virtual

environment. Conversely, in the hardware-in-loop

mode, the real factory connects to the digital twin

through MQTT, enabling synchronization between

the virtual and physical systems as well as control-

ling factory processes from the virtual environment.

When synchronizing, the state of the real factory is

replicated in real-time in the virtual environment. An

ideal level of synchronisation would be on sensor and

actuator level, but in the case of the APS these sig-

nals are not present on the bus for efficiency reasons.

This means that the synchronisation is limited to the

ERSeGEL 2024 - Workshop on Extended Reality and Serious Games for Education and Learning

726

Figure 4: Immersive digital twin of the Agile Production Simulation learning factory.

process control level. This approach provides a more

authentic representation of real-world factory oper-

ations within the digital twin. Automatic synchro-

nization mechanisms continuously update the status

of both the physical and virtual factories, guarantee-

ing coherence between the two environments in real-

time. Bidirectional communication capabilities em-

power users to not only monitor, but also actively

control the real factory through interactions with the

virtual model. This integration facilitates a dynamic

feedback loop, where adjustments made in the virtual

space directly impact the physical production pro-

cesses.

The creation of the factory simulation can be de-

scribed in the following steps. The mechanical com-

ponents have been segmented and simulated using the

geometry analysis and mechanical simulation mod-

ules of the virtual engineering software. Many opti-

mizations of the scene-graph were necessary to create

motion groups and kinematic chains. The 6 Degrees

of Freedom (DoF) robotic arm was also simulated us-

ing the inverse kinematic solver included in the virtual

engineering software. The wiring was not provided as

dataset, thus the actuators and sensors had to be man-

ually mapped to IDs in the PLC programming. Those

programs have been studied to get a complete under-

standing of the module behaviors. This was necessary

to validate the parsing and execution of the programs

in the virtual environment and develop missing com-

ponents to fully process the programming data. Fi-

nally, a process planning, scheduling and execution

system was implemented, tailored to the capabilities

of the APS.

4.3 Adaptive Virtual Learning Platform

The virtual learning environment comprises a user in-

terface designed to offer distinct modes tailored to dif-

ferent learning needs. The introduction of the VLP to

the user is realized with a start screen, describing the

three main areas:

• Introduction APS. The user can explore the Ag-

ile Production Simulation factory digital twin by

examining the production modules, or clicking on

individual components for detailed explanations.

• Learning Environment. The user can choose a

learning module from the topics provided in the

learning environment.

• Simulation Environment. Enables the user to

plan, simulate, and analyze production processes

using the planner and analysis tools, or simply

start a demo simulation process.

Additionally, the start screens offer the option to

change the language and provide explanation to input

device controls, as well as a video introduction to the

main tools.

An Adaptive Learning Environment for Industry 4.0 Competencies Based on a Learning Factory and Its Immersive Digital Twin

727

Figure 5: Introduction of the milling module with camera

flight and meta data.

In the introduction area, the VLP features anima-

tions demonstrating the assembly of baseplates and

modules, along with a menu allowing users to select

either a process module or a technical component (see

figure 5). Selecting a technical component from the

list will highlight it while making all other geome-

tries transparent (see figure 6). Users have the free-

dom to explore the virtual factory without limitations,

becoming acquainted with its layout and technical el-

ements. Clicking on 3D objects triggers a widget dis-

playing an image and explanation of their function.

This exploratory approach fosters curiosity and self-

directed learning, empowering individuals to navigate

the factory at their own pace.

In the learning environment mode, users access

educational material organized in learning modules

and designed to educate them about various aspects of

factory operations. Here, learners tackle specific tasks

across different categories within the realm of Indus-

try 4.0. The ability to identify various components

in the virtual twin performing specific tasks adds a

hands-on dimension to the learning process, allowing

users to apply their knowledge and problem-solving

skills in a realistic environment. Moreover, the op-

tion for learners to select one category at a time en-

hances the convenience and user-friendliness of this

mode. The VLP has tasks in different levels of diffi-

culty (as described in section 3). For instance, the first

level tasks are called ”find and click tasks”, which

should recall the function and the place of a tech-

nical component in a factory. An example of such

task in the learning module ”Industrial Internet of

Things” is as follows: ”A typical communication pro-

tocol in the IIoT area is MQTT. This requires a bro-

ker. Which component of the fischertechnik APS pro-

vides the broker functionality?” Figure 7 illustrates

the task list widget associated with the selected learn-

ing module, specifically the module ”Agile Produc-

tion.” This module encompasses various tasks, includ-

Figure 6: Highlighting the sensors in the virtual factory.

ing those related to agile warehousing, analysis of

product throughput, optimization of layout, and par-

allelization of processes for two workpieces.

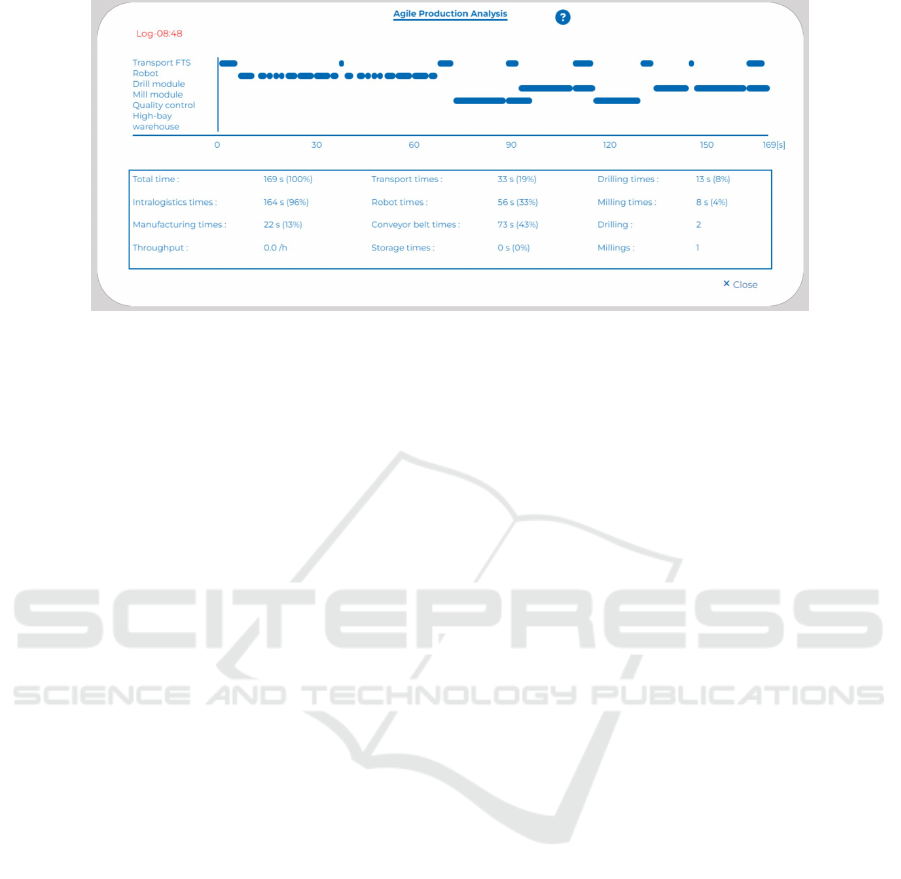

To configure a process, the Agile Production Plan-

ner tool was developed (refer to figure 8). Once the

process is configured, users can initiate the simulation

and observe it within the virtual environment. Subse-

quently, statistics for the simulated process, such as

throughput, can be analyzed using the analysis tool

Figure 7: VLP Tasks List for learning module ”Agile Pro-

duction”.

ERSeGEL 2024 - Workshop on Extended Reality and Serious Games for Education and Learning

728

Figure 8: Agile Production Planner.

(refer to figure 10). The simulated process can also be

sent to the real factory and executed there, which en-

ables the teaching of virtual commissioning process.

Meanwhile, simulation environment presents in-

teractive simulations that allow users to apply their

knowledge in practical scenarios, thereby enhancing

their understanding and skills. Here, educators can

propose additional tasks for simulation, or learners

can experiment freely.

4.4 Usability

The implementation of the virtual learning plat-

form prioritizes usability for learners, particularly for

CAVE and VR headset deployment, where several us-

ability features were considered. These include the

use of audio output for text, such as theory descrip-

tions and tasks, to alleviate the challenge of reading

extensive text, especially on older VR headsets. Ad-

ditionally, the user interface employs large buttons de-

signed for easy interaction in the virtual environment

using ray casting.

Introduction to the tool is facilitated by video ex-

planations of key tools and tooltips for buttons, while

navigation follows a common thread, ensuring users

can easily locate needed functionality. Tasks to be

solved in the 3D environment, whether on desktop or

immersive hardware, are planned to utilize controllers

without the need for text input or parameters via key-

board, focusing heavily on interaction with the im-

mersive twin.

The VLP adopts a task start and stop paradigm,

allowing users to validate their input or cancel tasks

as needed. Upon entering a solution, visual and au-

dio feedback indicates success or failure with the

task. Furthermore, extensive metadata visualization

Figure 9: Deployment on CAVE System.

enhances understanding of the factory environment,

such as the depiction of active actuators or sensors

via pictograms.

In virtual reality mode, scaling factors such as

1:10 replicate real factory dimensions to immerse the

user effectively (as depicted on figure 9).

5 EVALUATION CONCEPT

Given that the Virtual Learning Platform and the APS

factory have only very recent been introduced and in-

tegrated into the educational framework, this section

outlines a proposed strategy for designing an effective

evaluation and assessment process.

The VLP has been developed to support learners

in training within Industry 4.0, with the aim of equip-

ping them with essential specialist knowledge, en-

hancing existing skills and fostering an understanding

of the connections between workflows and business

processes. This comprehensive educational approach

emphasises both formative/accompanying and sum-

mative/final evaluations, facilitating continuous adap-

tation and optimisation of the teaching approach. By

using an integrated evaluation model that combines

the strengths of the CIPP (Context, Input, Process,

Product)(Stufflebeam, 1971) and Kirkpatrick models

(Kirkpatrick, 1959), the effectiveness and efficiency

of VLP can be comprehensively assessed. The CIPP

model provides a comprehensive framework focusing

on context, input, process and product for programme

evaluation, while the Kirkpatrick model specifically

assesses training effectiveness at four levels: reaction,

learning, behaviour and results, with an emphasis on

learning outcomes and organisational impact. These

models, when integrated, provide a robust evaluation

framework that not only measures immediate learning

outcomes, but also promotes a deep understanding of

effective learning processes. This integrated approach

ensures that VLP remains responsive to the evolving

needs of learners and Industry 4.0.

An Adaptive Learning Environment for Industry 4.0 Competencies Based on a Learning Factory and Its Immersive Digital Twin

729

Figure 10: Agile Production Analysis Tool.

Data collection to evaluate the VLP is carried out

by measuring the outcomes and impact of the teach-

ing approach on learners, including the acquisition

of knowledge, skills and competences related to In-

dustry 4.0. The evaluation will be carried out using

a variety of tools, such as surveys to identify learn-

ers’ needs, stakeholder interviews, expert evaluation

of teaching materials and methods, teacher and stu-

dent feedback, observations, performance tests and

competency assessments. According to Kirkpatrick,

the reaction, learning, behaviour and outcomes of the

VLP are recorded to assess learning, using similar

tools to those used in the CIPP model. In this way

it is possible to compare the results of different teach-

ing approaches.

A comparative study is recommended in order to

evaluate the results of the new approach. It is rec-

ommended to carry out a study with three groups of

learners at each of the three learning levels (see sec-

tion 3. ”Teaching approach”). In this way the results

at the different levels can be compared and the suit-

ability of the VLP approach for different VET (vo-

cational education and training) target groups can be

analysed. In this design, three groups of test sub-

jects would be randomly assigned for each learning

level: a first group whose training would use only

the physical learning factory, a second group whose

training would use only the VLP virtual learning en-

vironment, and a third group whose training would

use both the physical and VLP virtual learning envi-

ronments. For each group, the same instructor would

teach exactly the same content with the same learning

objectives. For meaningful results without confound-

ing factors, it would be crucial that all three groups

contained subjects with the same or at least very sim-

ilar prior knowledge. In addition, the learning tasks

used in the training programmes should have exactly

the same indicative, coarse and fine learning objec-

tives, as well as the same Bloom’s levels within the

taxonomies (cognitive, affective, psychomotor).

To summarise, the VLP offers an innovative ap-

proach to Industry 4.0 education, but the implementa-

tion of the proposed comparative study poses signif-

icant practical challenges. Coordinating three differ-

ent learning environments to subject groups of three

different learning levels illustrates the complexity of

effectively evaluating educational technologies. De-

spite these difficulties, such research is essential for

the improvement of the VLP and must be tackled in

the future - perhaps not even comprehensively, but at

least selectively.

6 CONCLUSION AND FUTURE

WORKS

The developed learning environment shows how a

combination of practical application, digital technolo-

gies and innovative teaching methods can help to op-

timally prepare future specialists for the requirements

of Industry 4.0. The use of fischertechnik agile fac-

tory and its digital twin creates a unique learning ex-

perience in a hybrid manner, which can be adapted

to several heterogeneous user groups and teaching

setups. The implemented features in the VLP of-

fer a comprehensive and immersive learning experi-

ence, ensuring users can seamlessly explore and com-

prehend the factory environment. It also provides

users with an overview of Industry 4.0 applications

within the virtual or physical factory. Through pro-

cess modelling and analysis tools, users gain insight

into the relationships and interactions among various

elements and processes in the factory environment,

leading to a holistic understanding of procedures. Fu-

ture work will focus on the development of further

learning modules such as robotics and maintenance.

ERSeGEL 2024 - Workshop on Extended Reality and Serious Games for Education and Learning

730

We are planning a long-term evaluation based on the

proposed concept, but also strongly limited by the po-

tential users and available funding.

ACKNOWLEDGEMENTS

This work was supported by fischertechnik company

and partially by the project KolabBW, funded by

the Ministry for the Environment, Climate and En-

ergy Management of the German province Baden-

W

¨

urttemberg. Additionally, we would like to express

our thanks to Mr. Horst Maywald for his valuable

consultations in the field of Industry 4.0 education.

REFERENCES

Abele, E., Chryssolouris, G., Sihn, W., Metternich, J., El-

Maraghy, H., Seliger, G., Sivard, G., ElMaraghy, W.,

Hummel, V., Tisch, M., et al. (2017). Learning facto-

ries for future oriented research and education in man-

ufacturing. CIRP annals, 66(2):803–826.

Abele, E., Metternich, J., Tisch, M., Abele, E., Metter-

nich, J., and Tisch, M. (2019). Best practice exam-

ples. Learning Factories: Concepts, Guidelines, Best-

Practice Examples, pages 335–459.

Al-Geddawy, T. (2020). A digital twin creation method for

an opensource low-cost changeable learning factory.

Procedia Manufacturing, 51:1799–1805. 30th Inter-

national Conference on Flexible Automation and In-

telligent Manufacturing (FAIM2021).

Aqlan, F., Zhao, R., Yang, H., and Ramakrishnan, S. (2021).

A virtual learning factory for advanced manufactur-

ing. In Proceedings of the Winter Simulation Confer-

ence.

Behrendt, F., Lehner, O., Rettmann, A., Schmidtke, N., and

Wollert, T. (2022). Process analysis of a teaching and

learning factory environment to demonstrate industry

4.0 solutions by using the smart logistics zone ap-

proach. In 2022 IEEE 6th International Conference

on Logistics Operations Management (GOL), pages

1–10. IEEE.

fischertechnik (2024). Agile Production Simulation 24V.

https://www.fischertechnik.de/en/products/industry-a

nd-universities/training-models/569289-agile-produ

ction-simulation-24v. Accessed: 2024-02-27.

Forehand, M. (2010). Bloom’s taxonomy. Emerging

perspectives on learning, teaching, and technology,

41(4):47–56.

H

¨

afner, P. (2020). Categorisation of the benefits and lim-

itations of immersive technologies for education. In

19th International Conference on Modeling & Ap-

plied Simulation, pages 154–159.

H

¨

afner, P. (2021). Holistic approach for authoring im-

mersive and smart environments for the integration in

engineering education. PhD thesis, Karlsruhe, Karl-

sruher Institut f

¨

ur Technologie (KIT), 2021.

H

¨

afner, V. (2019). PolyVR-a virtual reality authoring

framework for engineering applications. PhD thesis,

Karlsruhe, Karlsruher Institut f

¨

ur Technologie (KIT),

2019.

Kirkpatrick, D. L. (1959). Techniques for evaluating train-

ing programs. Journal of the American Society of

Training Directors, 13:3–9.

Mourtzis, D., Angelopoulos, J., and Panopoulos, N. (2021).

Development of a teaching factory framework fusing

a virtual simulated machine shop with the physical

counterpart for upscaling human machine interface. In

Proceedings of the Conference on Learning Factories

(CLF).

Rasovska, I., Deniaud, I., Marmier, F., and Michalak, J.-L.

(2022). Learning factory flextory: Interactive loops

between real and virtual factory through digital twin.

IFAC-PapersOnLine, 55(10):1938–1943. 10th IFAC

Conference on Manufacturing Modelling, Manage-

ment and Control MIM 2022.

Reining, N. and Kauffeld, S. (2022). Empirical findings

on learning success and competence development at

learning factories: A scoping review. Education Sci-

ences, 12(11):769.

Sibanda, V., Kanganga, M., and Sibanda, N. (2023).

Bridging the gap between industry and academia-the

essence of virtual reality in skills development and

learning factories. Available at SSRN 4470489.

Stufflebeam, D. L. (1971). The relevance of the cipp evalu-

ation model for educational accountability.

Windelband, L., Bergmann, V., Reifschneider, O.,

Reimann, D., and Schwarz, M. (2023). Ab-

schlussbericht des projekts wb@lernfabriken.

handlungsempfehlungen zur inhaltlichen umsetzung

von lernfabriken f

¨

ur die berufliche weiterbildung

wb@lernfabriken. Technical report, Karlsruher

Institut f

¨

ur Technologie (KIT), Karlsruhe.

An Adaptive Learning Environment for Industry 4.0 Competencies Based on a Learning Factory and Its Immersive Digital Twin

731