Multi-Method Approaches for Simulation Modelling of Warehouse

Processes

Pietro De Vito

a

, Umberto Battista

b

, Anna Bolognesi

c

and Stefano Sanfilippo

d

STAM S.r.l., Engineering Solutions, Via Lorenzo Pareto 8 Rosso A, Genoa, Italy

Keywords: Warehouse Optimization, Multi-Method Simulation, Agent-based Modelling, Discrete Event Simulation,

Resource Allocation, Intralogistics Optimization.

Abstract: Efficient warehouse management is essential for business-to-business (B2B) operations, ensuring timely

delivery, cost minimization, and operational efficiency. To meet these challenges, advanced modelling and

simulation techniques are increasingly adopted. This paper shows the application of multi-method simulation

approaches, specifically agent-based and discrete event simulation, applied to optimize warehouse processes

and resource allocation for a leading sport brand retailer in the B2B sector. By combining these approaches,

we aimed to capture the complexity of warehouse operations and identify opportunities for improvement. The

simulation model developed using AnyLogic software, integrated agent-based modelling to represent entities

such as packages, articles, orders, warehousemen, and trucks, along with discrete event simulation to model

key events like order arrival and truck departure. The developed model has been used to optimize the resource

allocation ensuring order fulfilment. Scenario analyses revealed varying resource requirements across

different demand scenarios, highlighting the challenges posed by increasing demanded volumes. The study

underscores the importance of strategic resource planning and proactive measures to address capacity

limitations and ensure warehouse efficiency in meeting future demand. Our findings contribute to informed

decision-making in warehouse management, guiding strategies for optimization and adaptation to evolving

market demands.

1 INTRODUCTION

1.1 Context

In modern commerce, two primary transactional

models prevail: Business-to-Consumer (B2C) and

Business-to-Business (B2B), representing distinct

paradigms for goods and services exchange. B2C

transactions involve direct interactions with

individual consumers, focusing on personalized

experiences and brand loyalty. On the other hand,

B2B transactions occur within corporate ecosystems,

involving complex networks and multiple

stakeholders to meet supply chain needs. Efficient

warehouse management is crucial for B2B

operations, ensuring timely delivery, cost reduction,

and operational efficiency. To address these

a

https://orcid.org/0000-0002-7353-2011

b

https://orcid.org/0000-0001-5479-684X

c

https://orcid.org/0009-0009-2762-3703

d

https://orcid.org/0009-0001-0547-6222

challenges, businesses increasingly employ advanced

modelling and simulation techniques to optimize

warehouse processes.

This paper discusses the use of multi-method

simulation approaches, including agent-based and

discrete event simulation, for modelling and

optimizing B2B warehouse processes for a leading

sport brand retailer. Through a detailed case study, we

demonstrate the efficacy of simulation models in

analysing and optimizing key processes, such as order

fulfilment and inventory management, to improve

overall efficiency in serving B2B clientele.

The main objective of this study was to create a

simulation model to understand the warehouse's

capacity to manage predicted volumes and identify

opportunities for productivity enhancement and so to

provide strategic decision-making support for

De Vito, P., Battista, U., Bolognesi, A. and Sanfilippo, S.

Multi-Method Approaches for Simulation Modelling of Warehouse Processes.

DOI: 10.5220/0012771700003758

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 14th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH 2024), pages 305-312

ISBN: 978-989-758-708-5; ISSN: 2184-2841

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

305

resource allocation, workflow optimization, and

infrastructure investments in the warehouse

environment. The study conducted scenario analyses

to identify potential capacity constraints and

opportunities for process improvement, providing

actionable recommendations for mitigating risks and

enhancing resilience.

Ultimately, this study aimed to empower

stakeholders with the tools and information needed to

make informed decisions aligning with the

organization's strategic goals, while laying the

foundation for future-proofing the operation and

positioning for long-term success and growth.

2 LITERATURE REVIEW

Warehouse optimization is a topic of significant

interest in both academia and industry, with

numerous studies exploring various approaches to

enhance the efficiency and effectiveness of

warehouse operations. In this section, we review the

existing literature on simulation modelling in

warehouse optimization, with a particular focus on

multi-method approaches and their application in the

context of B2B operations. Simulation modelling has

emerged as a powerful tool for analysing, predicting,

and optimizing warehouse operations. By replicating

the behaviour of a real-world system within a model,

simulation enables researchers and practitioners to

experiment with different scenarios, test alternative

strategies, and evaluate the performance of various

configurations without disrupting actual operations.

In the context of warehouse optimization, simulation

models can highlight the intricate interactions

between different processes, resources, and

constraints.

Discrete Event Simulation (DES), System

Dynamics, and Agent-Based Modelling (ABM) are

three simulation methods commonly used in

warehouse-oriented environments. DES (Rana, D. S.,

2018, Gagliardi, J.-P., Renaud, J., & Ruiz, A. 2007,

Saderova, J., Rosova, A., Behunova, A., Behun, M.,

Sofranko, M., & Khouri, S. 2022) allows for the

modelling of discrete events, such as order entry,

order processing, transport, and delivery, providing

detailed insight into warehouse dynamics. System

Dynamics (Ramirez-Malule, D., Jaén-Posada, J. S., &

Villegas, J. G. 2021) analyses the interdependencies

and feedback loops within a warehouse system,

helping to understand its behaviour over time. Agent-

based (Maka, A., Cupek, R., & Wierzchanowski, M.

2011) modelling is a methodology that focuses on

modelling the behaviour of individual agents within a

warehouse. This enables the analysis of emergent

properties and the optimisation of warehouse

operations. These methodologies are essential tools

for improving efficiency, optimising resource

utilisation, and addressing warehouse management

challenges.

DES has several advantages in warehouse-

oriented environments. Firstly, it helps to analyse

system behaviour, identify bottlenecks, evaluate

trade-offs, and optimize processes in logistics and

supply chain management. Moreover, DES enables

decision-makers to test multiple tactics in a virtual

system without disrupting operations, thereby

optimizing inventory management, transportation

routing, and warehouse operations. However, while

DES models can be useful, they often rely on

simplified assumptions that may not fully capture the

dynamics of real-world systems.

In contrast, System Dynamics offers valuable

insights into complex warehouse systems by

capturing the interactions between various actors and

processes. Decision-makers can use System

Dynamics to assess the impact of different variables

on system performance and optimize procedures for

increased efficiency. However, accurately modelling

all variables in System Dynamics models can be

challenging due to their complex interrelationships,

which poses a limitation.

ABM provides a more realistic representation of

how agents interact within the warehouse

environment and adapt dynamically to changing

conditions. This approach assists decision-makers in

comprehending emergent behaviours, optimising

resource allocation, and enhancing overall efficiency

in warehouse operations. However, creating precise

agent-based models can be a challenging and time-

consuming task due to the requirement for detailed

data and behavioural rules for individual agents.

2.1 Multi-Method Approaches in

Simulation Modelling

Multi-method simulation approaches have gained

popularity for their ability to provide a

comprehensive understanding of complex systems.

While traditional simulation methods like DES focus

on system-level behaviours and resource utilization

(Law and Kelton, 2018; Rossetti et al., 2019), they

may overlook nuanced interactions among individual

entities within warehouses. To overcome this

limitation, researchers integrate multiple simulation

methods, such as ABM and DES, to better understand

warehouse dynamics (Macal and North, 2010). ABM

models individual entities and their interactions,

SIMULTECH 2024 - 14th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

306

allowing for detailed analysis of decision-making

processes (Bonabeau, 2002), while DES excels in

representing system-level processes and events,

facilitating the analysis of resource utilization

(National Aeronautics and Space Administration,

1995). Integrating ABM and DES enables researchers

to capture the complexity of warehouse operations,

providing insights into system-level behaviours and

individual agent interactions (Klügl and Bazzan,

2019). Studies have demonstrated the effectiveness of

multi-method simulation approaches in optimizing

warehouse processes (Heath et al., 2012).

In warehouse optimization, traditional simulation

approaches like DES are widely used for modelling

system-level behaviours (Law and Kelton, 2018).

However, in complex warehouse systems, DES alone

may not provide a complete understanding of

dynamics due to pivotal interactions between

individual entities (Rossetti et al., 2019; Meredith et

al. 2023). To address this limitation, researchers

integrate multiple simulation methods, such as ABM

and DES, enhancing modelling capabilities. ABM

focuses on modelling individual entities and their

interactions within a system, allowing for a granular

analysis of the system's complexity. This integration

enables researchers to capture both macroscopic

system-level behaviours and microscopic agent-level

interactions, providing a comprehensive

understanding of complex warehouse systems.

Several studies have demonstrated the effectiveness

of multi-method simulation approaches in warehouse

optimization, highlighting the importance of

considering both macroscopic and microscopic

factors for achieving operational efficiency (Macal

and North, 2010, Hafezalkotob et al., 2016).

2.2 Challenges and Opportunities

Multi-method simulation approaches offer promise in

addressing the complexities of warehouse

optimization, yet they present challenges and

opportunities that require careful consideration.

Integrating ABM and DES introduces complexity,

requiring meticulous attention to model assumptions,

data capture, and computational resources. Scaling

the model amplifies these challenges in development

and implementation. Parameter estimation in multi-

method simulations demands sophisticated

techniques, necessitating a deep understanding of

system dynamics and iterative refinement for

accuracy.

Validation of multi-method simulation models is

inherently complex due to the stochastic nature of

warehouse operations and the interplay between

macroscopic and microscopic dynamics. Extensive

validation against empirical data is essential to ensure

accurate representation and reliable results, often

involving comparisons with operational metrics and

sensitivity analyses.

Despite challenges, multi-method simulation

offers significant opportunities for advancing

warehouse optimization by providing a

comprehensive understanding of B2B operations.

This holistic perspective uncovers inefficiencies,

identifies optimization opportunities, and evaluates

strategic interventions. Multi-method simulation

facilitates scenario analysis and decision support,

enabling stakeholders to explore alternative

strategies, assess outcomes, and make informed

decisions.

In conclusion, while multi-method simulation

presents challenges in model complexity, parameter

estimation, and validation, its benefits in capturing

the intricacies of B2B warehouse operations justify

further research and exploration. Leveraging the

strengths of agent-based and discrete event

simulation, multi-method approaches offer a

powerful toolset for optimizing warehouse operations

and enhancing efficiency in B2B supply chains.

3 SIMULATION MODEL

DEVELOPMENT

Figure 1: Warehouse environment.

The aim of developing the model was to simulate the

flow of items through packaging, storage, picking,

and delivery to trucks after preparation by warehouse

staff. The process depends on the arrival of customer

orders and the departure of trucks. When a customer

order is received, the storekeeper prepares it for

delivery by lorry. The preparation of orders involves

organizing items into package, each containing a

specific set of articles. The shop aims to maintain a

stock of the majority of articles in the warehouse to

Multi-Method Approaches for Simulation Modelling of Warehouse Processes

307

ensure prompt fulfilment of most orders. All of these

aspects must be managed accurately within the

operation to ensure effective matching of demand and

supply. The development has been done in the

AnyLogic commercial software.

3.1 Overview of Anylogic

AnyLogic is a versatile simulation software that

offers support for various modelling paradigms,

including agent-based (Agent-Based Modelling),

discrete event (Event-Based ), and system dynamics.

Its graphical interface and Java-based modelling

language provide flexibility and ease of use, making

it well-suited for complex simulation projects such as

warehouse optimization. AnyLogic was chosen for its

capabilities, which allowed us to craft a thorough

multi-method simulation model proficient in

capturing the complexities of both individual entities

within the warehouse environment and overall

warehouse operations. Our approach utilizes ABM to

represent various elements within the warehouse

environment, including packages, articles, orders,

warehousemen involved in different processes, and

trucks. Additionally, we incorporate discrete event

simulation to model events that occur at different

moments during the simulation, such as the arrival of

orders and the departure of trucks.

3.2 Agent-Based Modelling

ABM forms the cornerstone of our simulation

approach, allowing us to represent individual entities

(agents) within the warehouse environment with high

granularity. Each agent is endowed with specific

properties, behaviours, and decision-making

capabilities to accurately simulate their interactions

within the warehouse ecosystem. The implemented

agents include:

Packages and Articles, packages represent the

containers in which articles are stored and

transported within the warehouse. Each package

agent is characterized by properties such as size,

weight, destination, and contents. Articles, on the

other hand, represent the individual items

stocked in the warehouse and objects of the

orders.

Orders represent the requests placed by

customers for specific articles. Each order agent

contains information such as customer details,

order quantity, truck and the related warehouse

bay. Orders may consist of multiple articles and

packages, depending on the customer's

requirements.

Trucks represent the vehicles used for

transporting goods to and from the warehouse.

Each truck agent is characterized by properties

such as capacity and destination. Trucks are

responsible for transporting packages and orders

between the warehouse and customer locations.

Warehousemen represent the workers

responsible for performing various tasks within

the warehouse, such as inbound receiving,

stocking shelves, picking items for orders, and

loading/unloading trucks. Each warehouseman

agent is associated with properties related to their

productivity capacity, such as articles processed

per hour. By modelling warehousemen with

different productivity capacities, we can

accurately simulate the impact of workforce

variability on overall warehouse performance.

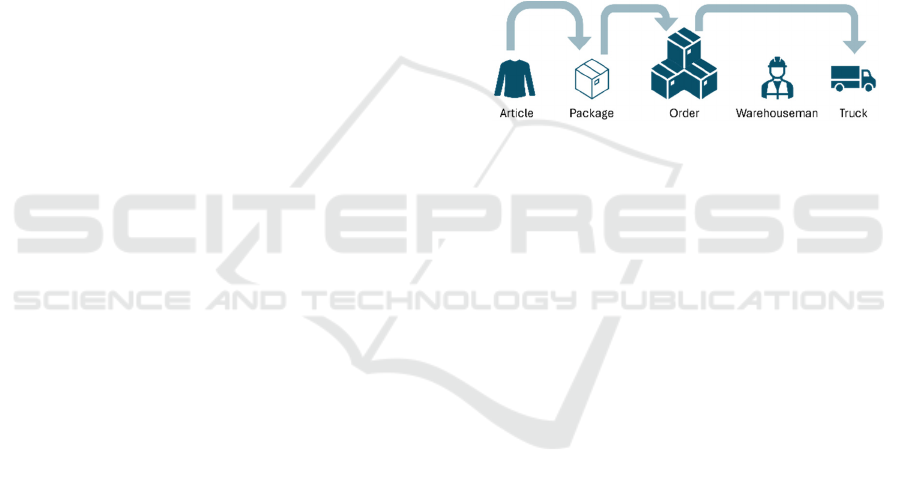

Figure 2: Agents of the model.

3.3 Event-Based Modelling

In integration and support to the ABM approach, our

simulation model incorporates event-based

simulation to capture key events that occur at

different moment of the simulation. ABM enables the

simulation of the behaviours and interactions of

individual entities within the warehouse environment.

Event-based simulation, in contrast, allows the

modelling of the occurrence of specific events and the

subsequent impact on workflow dynamics.

Order Arrival: one of the key events we model in

our simulation is the arrival of orders from

customers. Orders arrive at the warehouse

according to predefined arrival patterns or

distribution functions. The timing, quantity, and

characteristics of incoming orders influence

warehouse workload, resource utilization, and

order fulfilment processes. By simulating order

arrival events, we can replicate the dynamic

nature of customer demand and evaluate the

warehouse's ability to meet service level

agreements and customer expectations.

Truck Departure: another key event we capture

in our simulation is the departure of trucks

transporting goods to delivery destinations. Once

orders are picked and packaged, trucks are

dispatched from the warehouse to deliver the

goods to customer locations. By simulating truck

SIMULTECH 2024 - 14th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

308

departure events, we can assess the efficiency of

delivery operations, optimize routing decisions,

and minimize transportation costs. Additionally,

truck departure events may trigger subsequent

events within the simulation, such as updating

inventory levels and initiating replenishment

processes.

Therefore, by integrating event-based simulation

with agent-based modelling, we create a dynamic

simulation environment that accurately reflects the

real-world dynamics of warehouse operations. Events

drive changes in system state, trigger agent

behaviours, and influence decision-making

processes, resulting in emergent behaviours and

system-wide effects. This integrated approach allows

us to capture the complexity and uncertainty inherent

in warehouse operations and provides valuable

insights into system performance under various

conditions.

4 WAREHOUSE PROCESSES

SIMULATION

4.1 Warehouse Processes

The warehouse chain can be divided into 4 main

phases: inbound, stocking, picking, and outbound.

Inbound operations include receiving, sorting, and

storing incoming goods at a warehouse or distribution

centre. Stocking involves arranging and organizing

items within the warehouse for easy accessibility

during subsequent picking. Picking involves

retrieving individual items or specific orders from

warehouse shelves in preparation for shipment or

delivery. Outbound encompasses all operations

related to shipping the stocked items from the

warehouse to customers, stores, or other final

destinations. These processes are essential for

ensuring efficient inventory management and timely

delivery of goods.

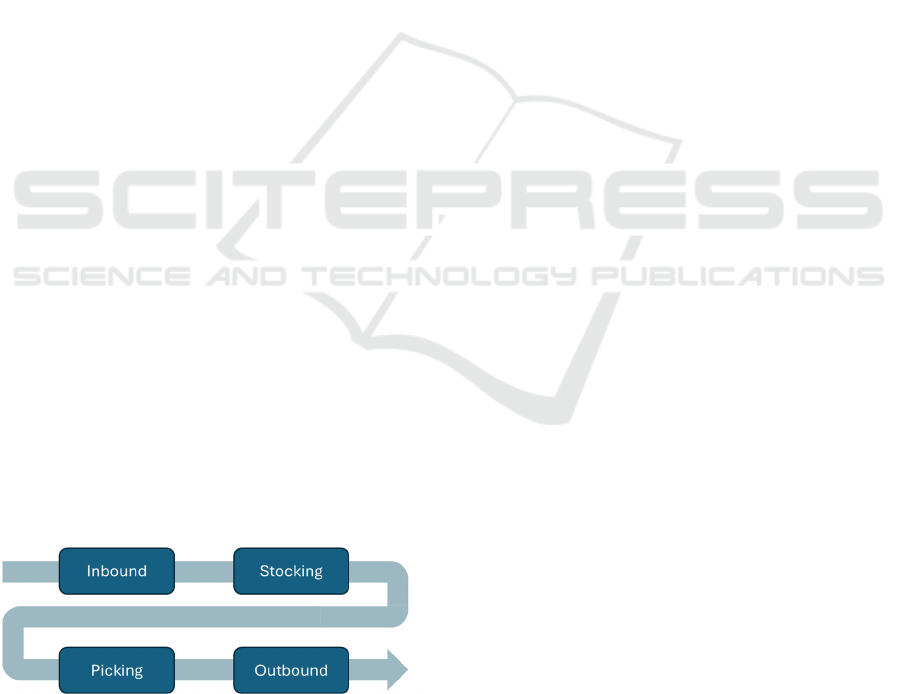

Figure 3: Warehouse intralogistics processes.

This section provides an overview of the

simulation model developed to replicate the key

processes within the warehouse environment. The

model aims to replicate the real-world workflows and

interactions observed in the warehouses of the sport

brand retailer.

The inbound process begins with the arrival of

trucks carrying packages containing goods destined

for the warehouse. Upon arrival, packages are

unloaded, and goods with standard-sized packages

are directed to an intricate conveyor system for

distribution to the shelves. Warehousemen stationed

at this destination sector receive these packages and

proceed to stock them on the shelves, recording their

positions in the Warehouse Management System

(WMS). This process ensures accurate inventory

management and facilitates efficient retrieval during

order fulfilment.

In the stocking process, warehousemen retrieve

packages from the conveyor system and place them

on designated shelves according to product categories.

The WMS guides warehousemen to the appropriate

shelf locations, ensuring optimal storage organization

and minimizing retrieval times during picking

operations. Warehousemen record the stocking of

packages in the WMS, updating inventory levels and

ensuring real-time visibility of available stock.

The picking process starts when an order is

received on the WMS. The warehousemen in charge

of order processing go through the shelves to pick the

individual items needed to fulfil the order. In contrast

to traditional bulk picking, in which entire parcels are

dispatched, in this area, packages filled with a few

units of heterogeneous items are prepared (generally

the contents correspond to about 20 items). Then the

warehousemen systematically retrieve the articles

and place them in the new packages until the order is

completed.

Finally, in the outbound process, completed

orders are conveyed to the outbound area where

packages are collected and palletized for loading onto

trucks. Warehousemen ensure that packages are

correctly labelled, sealed, and prepared for shipment.

Once palletized, packages are loaded onto trucks for

transportation to customer destinations.

4.2 Integration of Processes

The simulation model integrates these warehouse

processes to replicate the dynamic flow of goods and

activities within the warehouse environment. We

adopted a high-level approach to modelling each

process for standard packages, encompassing

inbound, stocking, picking, and outbound operations.

To ensure accuracy, we created a 2D model based on

the warehouse plans and the structure of conveyors.

This enabled us to account for distances and the time

Multi-Method Approaches for Simulation Modelling of Warehouse Processes

309

required to move packages between different areas of

the warehouse.

In addition, we developed a detailed microscopic

model for the picking area to analyse operations in

relation to the number of warehousemen present. This

microscopic analysis was crucial for identifying

inefficiencies and understanding the impact of

workforce allocation on overall performance, a topic

that will be explored further in the Results chapter.

By simulating the intricate details of the picking

process, such as the movement of warehousemen, the

retrieval of individual items, and the organization of

packages, we were able to capture the complexities of

real-world operations and assess the effectiveness of

different staffing levels and strategies.

To implement the logic of the models, we utilized

flowcharts made available by the logical blocks

present in AnyLogic libraries. These blocks were

customized to incorporate functions capable of

replicating the algorithms and logic adopted by the

WMS.

Through the integration of these processes, our

simulation model provides valuable insights into

system performance, resource utilization, and

operational efficiency, facilitating informed decision-

making and strategic planning for warehouse

management. The comprehensive nature of our model

allows to explore various scenarios, experiment with

different strategies, and identify opportunities for

improvement. By leveraging simulation technology,

businesses can optimize warehouse operations,

improve customer service, and adapt to changing

market demands with confidence and agility.

4.3 Model Validation

The validation phase played a crucial phase of our

work and involved a thorough comparison of

simulation results with real-world and well-known

situations occurred in the past. The validation

procedure involved gathering real-world data and

outlining reference scenarios that encompassed

various operational conditions and challenges

typically encountered. The available real-world data

was leveraged to input the parameters into the model

to generate output data comparable with the reference

scenarios. This process was iterative in order to

recalibrate the model and minimize the error degree.

These scenarios provided valuable insights into

the complexities of warehouse operations, allowing to

validate the performance of the simulation model

under various conditions.

We specifically focused on historical data

representing both off-peak and peak conditions in the

sport brand retailer's warehouse, respectively the

scenarios n. 0a and 0b reported in Table 1. Executing

the simulation involved closely mimicking real-world

parameters and configurations. This included

replicating staffing levels, equipment capacities,

order volumes, and workflow processes to accurately

simulate the operational dynamics.

Comparing simulation results to real-world

observations involved a meticulous analysis of key

performance metrics such as throughput, order

fulfilment rates, inventory levels, and resource

utilization.

Through this validation process, we were able to

estimate the magnitude of model error and identify

specific components or processes within the model

that contributed to inaccuracies. This iterative

refinement process allowed to adjust parameters,

refine algorithms, and incorporate additional details

or complexities into the model to minimize

discrepancies and improve alignment with real-world

observations. The validation campaign performed on

the latest version of the model returned the results

shown in the table below. The model's error shows

high reliability overall. On the peak scenario in

particular, the model has a lower average error (2,8%)

than the off-peak scenario (5,6 %). With the use case,

it was determined that the error obtained is still

acceptable. In fact, there are several factors, external

and psychological, which the model does not take into

account and which play a non-negligible role on

resource efficiency. For example, when the workload

is not particularly high, people tend to work not to

their full capacity, which slows down operations. In

addition, there may be unexpected events that often

slow down the smooth running of warehouse

operations, which means that at such times there is a

surplus of resources to make up for lost time.

Table 1: Comparison of simulation results with real

implementation.

Scen.

n.

Volumes

[packages/

day]

Total number

of resources

(real)

Total Number

of Resources

(simulated)

Error

0a 5.828 28 26,5 5,6%

0b 7.576 35 34 2,8%

Therefore, the validation process provided

valuable insights into the accuracy and reliability of

our simulation model. By ensuring that simulation

results were comparable to real-world situations and

configurations encountered in the sport brand

retailer's warehouses, we enhanced the reliability of

the model and gained confidence in its predictive

capabilities.

SIMULTECH 2024 - 14th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

310

5 RESULTS

Following the rigorous validation process aligning

the simulation model with real-world warehouse

performances, the study delved into various scenario

analyses to assess the warehouse's capacity to handle

forecasted volumes over the coming years, as

outlined in Section 1. The primary focus was on

optimizing the allocation of resources to effectively

meet the increasing demand while maintaining

operational efficiency.

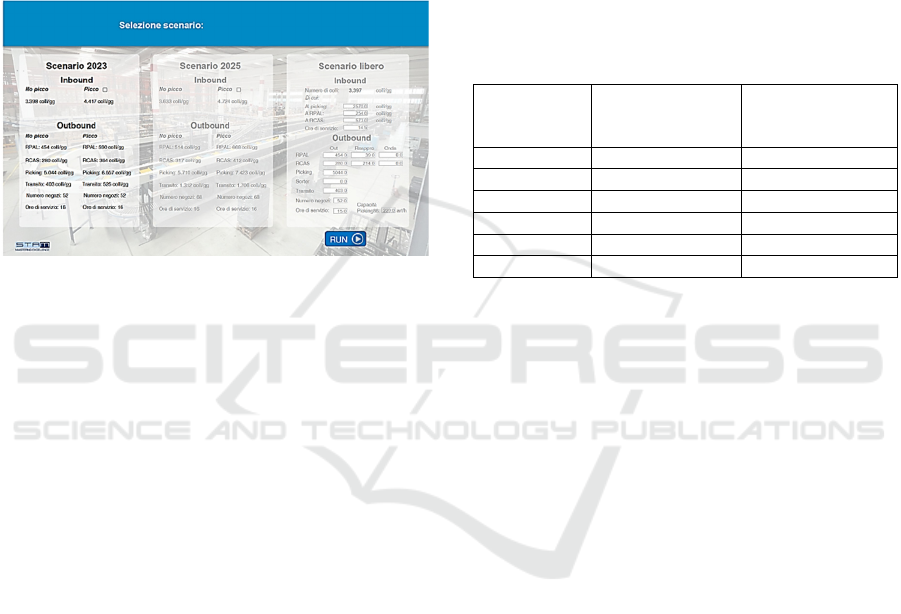

Figure 4: Model UI for scenario setting.

The simulation model was subjected to multiple

scenario tests based on different demand projections

and operational conditions. These scenarios were

categorized into optimistic and pessimistic scenarios,

each with variations in peak and off-peak demand

conditions. The aim was to evaluate how the

warehouse performed under various demand

scenarios and to identify resource requirements for

each scenario.

The simulation model analysed the number of

warehousemen and machines needed in different

sectors to handle the projected volumes effectively.

This optimization process involved fine-tuning

resource allocation to ensure efficient workflow

management while meeting customer demands. By

identifying the optimal number of resources required

in each scenario, the model provided valuable

insights for strategic resource planning and

allocation.

Results from the scenario analyses revealed

varying resource requirements across different

demand scenarios. In the optimistic off-peak scenario

(1a), which corresponds to the average demand for

the year, volumes increased by 6% compared to the

baseline (0a). The resource requirement in this case

has already increased significantly compared to the

current operating set-up (+66%).

In the peak optimistic scenario (1b), where

demand surged during peak periods, the model

indicated a notable increase in resource requirements,

particularly in manpower compared to 0b (+176%).

The challenges intensified in scenarios 2a and 2b,

the pessimistic off-peak and peak scenarios,

respectively. In these scenarios, characterised by

significantly higher demand than at present, the

simulation model predicted a significant increase in

resources. In particular, the most drastic increase was

in the number of warehousemen.

The Table 2 shows the key results on which the

assessments were made, i.e. for each scenario, the

volumes and the corresponding required resources are

indicated.

Table 2: Simulation campaign results.

Scenario n. Volumes

[packages/day]

Total Number of

Resources

(simulated)

0a 5.828 26.5

0b 7.576 34

1a 6.181 44

1b 11.434 94

2a 7.853 54

2b 15.495 128

Our study emphasizes the critical role of strategic

resource planning and allocation in warehouse

management. While our simulation model provided

valuable insights into resource requirements under

varying demand scenarios, it also highlighted the

imperative for proactive measures to overcome

capacity limitations and ensure the warehouse's

resilience in meeting future demand effectively.

Integrating simulation results with practical

considerations and strategic decision-making enables

the sport retailer to devise robust strategies for

optimizing warehouse operations and navigating

evolving market demands adeptly.

However, discussions with sport retailer

management revealed a crucial consideration

regarding the feasibility of implementing the

recommended resources. The projected volumes

could potentially strain the warehouse, particularly in

the picking process, due to space constraints and

congestion issues. The warehouse's physical

limitations, including limited space and

infrastructure, pose challenges to scaling up resources

beyond a certain threshold.

In response, it is essential to explore additional

measures beyond resource allocation to mitigate

potential crises in warehouse operations. Strategies

such as layout optimization, process redesign,

automation implementation, and facility expansion

offer promising avenues to enhance the warehouse's

capacity to handle increasing volumes while

Multi-Method Approaches for Simulation Modelling of Warehouse Processes

311

sustaining operational efficiency. These proactive

measures are essential for ensuring the warehouse's

adaptability and competitiveness in an ever-evolving

business landscape.

6 CONCLUSIONS

Warehouse management is crucial for supply chain

operations, ensuring efficient goods movement and

order fulfilment. This study explores warehouse

optimization using advanced modelling and

simulation techniques, focusing on challenges faced

by B2B businesses. We aimed to develop a simulation

model to forecast warehouse capacity and provide

strategic insights to the sport brand retailer for

managing increasing demand. Integrating agent-

based and discrete event simulation methodologies

enabled us to capture both macroscopic and

microscopic aspects of warehouse operations.

Challenges encountered included model

development, estimation, and validation, particularly

in integrating simulation methods and parameter

estimation. Validation was rigorous but essential,

comparing simulation outputs with empirical data to

ensure accuracy. Scenario analyses identified

resource allocation strategies for different demand

scenarios, aiding strategic decision-making. Our

study highlights the significance of strategic decision-

making and proactive planning in B2B warehouse

management. Multi-method simulation approaches

offer promising opportunities for optimizing

operations and adapting to market demands.

Future work involves developing new models to

analyse the automatic systems that will be

implemented in the warehouses, enhancing the

capability to predict and optimize operations further.

This will enable businesses to stay ahead of evolving

market trends and maintain competitiveness in the

dynamic landscape of warehouse management.

REFERENCES

Law, A. M., & Kelton, W. D. (2018). Simulation Modeling

and Analysis. McGraw-Hill Education.

Rossetti, M. D., Hill, R. R., Johansson, B., Dunkin, A., &

Ingalls, R. G. (2019). Proceedings of the 2019 Winter

Simulation Conference. Winter Simulation Conference.

Macal, C. M., & North, M. J. (2010). Tutorial on agent-

based modelling and simulation. In Proceedings of the

2010 Winter Simulation Conference (pp. 2-15). IEEE.

Bonabeau, E. (2002). Agent-based modelling: Methods and

techniques for simulating human systems. Proceedings

of the National Academy of Sciences, 99 (suppl 3),

7280-7287.

Klügl, F., & Bazzan, A. L. C. (2019). Multiagent-based

simulation XIX. Springer.

National Aeronautics and Space Administration (1995),

Systems Engineering Handbook, URL: https://www.

nasa.gov/reference/systems-engineering-handbook/).

Heath, Brian & Ciarallo, Frank & Hill, Raymond. (2012).

An agent-based modelling approach to analyze the

impact of warehouse congestion on cost and

performance. The International Journal of Advanced

Manufacturing Technology. 67. 10.1007/s00170-012-

4505-5.

Meredith, E.; Papakostas, N. and Hargaden, V. (2023).

Impact of Inventory Management Policies on Supply

Chain Resilience at RiRiShun Logistics. In Proceedings

of the 13th International Conference on Simulation and

Modeling Methodologies, Technologies and

Applications - SIMULTECH; ISBN 978-989-758-668-

2; ISSN 2184-2841, SciTePress, pages 159-168. DOI:

10.5220/0012146800003546

Rana, D. S. (2018). Discrete event simulation for logistics

and supply chain management. International Journal of

Mechanical Engineering and Technology (IJMET),

9(2), 974-985.

Gagliardi, J.-P., Renaud, J., & Ruiz, A. (2007). A

simulation model to improve warehouse operations.

*Proceedings - Winter Simulation Conference*, 2012-

2018. https://doi.org/10.1145/1351542.1351899

Saderova, J., Rosova, A., Behunova, A., Behun, M.,

Sofranko, M., & Khouri, S. (2022). Case study: the

simulation modelling of selected activity in a

warehouse operation. *Wireless Networks, 28*(1),

431-440. https://doi.org/10.1007/s11276-021-02574-6

Ramirez-Malule, D., Jaén-Posada, J. S., & Villegas, J. G.

(2021). A System Dynamics Model for Warehouse

Performance Measurement with Highly Seasonal

Demand and with Long and Short Life Products. In

Proceedings of the International Conference on

Industrial Engineering and Operations Management

(pp. 1-6).

Maka, A., Cupek, R., & Wierzchanowski, M. (2011).

Agent-based Modeling for Warehouse Logistics

Systems. In “2011 UkSim 13th International

Conference on Computer Modelling and Simulation”

(pp. 151-155). Cambridge, UK. doi:

10.1109/UKSIM.2011.37.

Hafezalkotob, A., & Farahani, R. Z. (2016). An integrated

simulation-optimization framework for supply chain

network design under uncertainty. Computers &

Industrial Engineering, 100, 1-12.

SIMULTECH 2024 - 14th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

312