Discretization Strategies for Improved Health State Labeling in

Multivariable Predictive Maintenance Systems

Jean-Victor Autran

1,2

, V

´

eronique Kuhn

1

, Jean-Philippe Diguet

2

, Matthias Dubois

1

and C

´

edric Buche

3

1

ArianeGroup, Issac, France

2

IRL CROSSING, CNRS, Adelaide, Australia

3

ENIB, Brest, France

Keywords:

Data Labeling, Discretization, Predictive Maintenance, Data Preprocessing.

Abstract:

In machine learning, effective data preprocessing, particularly in the context of predictive maintenance, is a

key to achieving accurate predictions. Predictive maintenance datasets commonly exhibit binary health states,

offering limited insights into transitional phases between optimal and failure states. This work introduces an

approach to label data derived from intricate electronic systems based on unsupervised discretization tech-

niques. The proposed method uses data distribution patterns and predefined failure thresholds to discern the

overall health of a system. By adopting this approach, the model achieves a nuanced classification that not only

distinguishes between healthy and failure states but also incorporates multiple transitional states. These states

act as intermediary phases in the system’s progression toward potential failure, enhancing the granularity of

predictive maintenance assessments. The primary objective of this methodology is to increase anomaly detec-

tion capabilities within electronic systems. Through the utilization of unsupervised discretization, the model

ensures a data-driven approach to system monitoring and health evaluation. The inclusion of multiple tran-

sitional states in the labeling process facilitates a more precise predictive maintenance framework, enabling

informed decision-making in maintenance strategies. This article contributes to advancing the effectiveness of

predictive maintenance applications by addressing the limitations associated with binary labeling, ultimately

encouraging a more nuanced and accurate understanding of system health.

1 INTRODUCTION

Labels in datasets are crucial in the use of super-

vised machine learning, their quality directly affects

the performance of prediction (Budach et al., 2022).

For instance, in predictive maintenance, a crucial en-

deavor is reducing failures and associated costs by

predicting issues (Mobley, 2002; Ran et al., 2019).

The quality of labels is then directly linked to the reli-

ability of whether or not failures are predicted before

they occur and deviate from optimal states.

While machine learning techniques have shown

promise in predictive maintenance (Carvalho et al.,

2019), the reliance on traditional supervised labeling

methods presents significant challenges. Manual an-

notation of data is time-consuming, often requiring

expert knowledge, and can lead to limitations in scal-

ability and efficiency. Moreover, in the context of

electronic systems, the dynamic and intricate nature

of data poses challenges for accurate labeling with

health indicators or Remaining Useful Life (RUL).

Consequently, this research aims to explore data la-

beling within complex electronic systems.

In response to the limitations of traditional label-

ing methods, the goal of this study is to propose an

approach of unsupervised labeling using discretiza-

tion techniques for electronic systems. Discretiza-

tion methods, such as Equal Width (EW) and Equal

Frequency (EF) (Catlett, 1991), provide an unsuper-

vised method for classifying parameters into cate-

gories such as health states. By incorporating failure

thresholds, a clear distinction can be established be-

tween healthy, failure, and transition states for each of

the system parameters. By combining those, a global

state of the system can be created, giving a more de-

tailed system health assessment compared to common

binary states in public datasets (Tan and Raghavan,

2010).

The proposed approach significantly enhances the

details by determining new transition states to assess

the system’s health. This detailed prediction capabil-

ity facilitates decision-making since it provides more

434

Autran, J., Kuhn, V., Diguet, J., Dubois, M. and Buche, C.

Discretization Strategies for Improved Health State Labeling in Multivariable Predictive Maintenance Systems.

DOI: 10.5220/0012788800003756

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 13th International Conference on Data Science, Technology and Applications (DATA 2024), pages 434-441

ISBN: 978-989-758-707-8; ISSN: 2184-285X

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

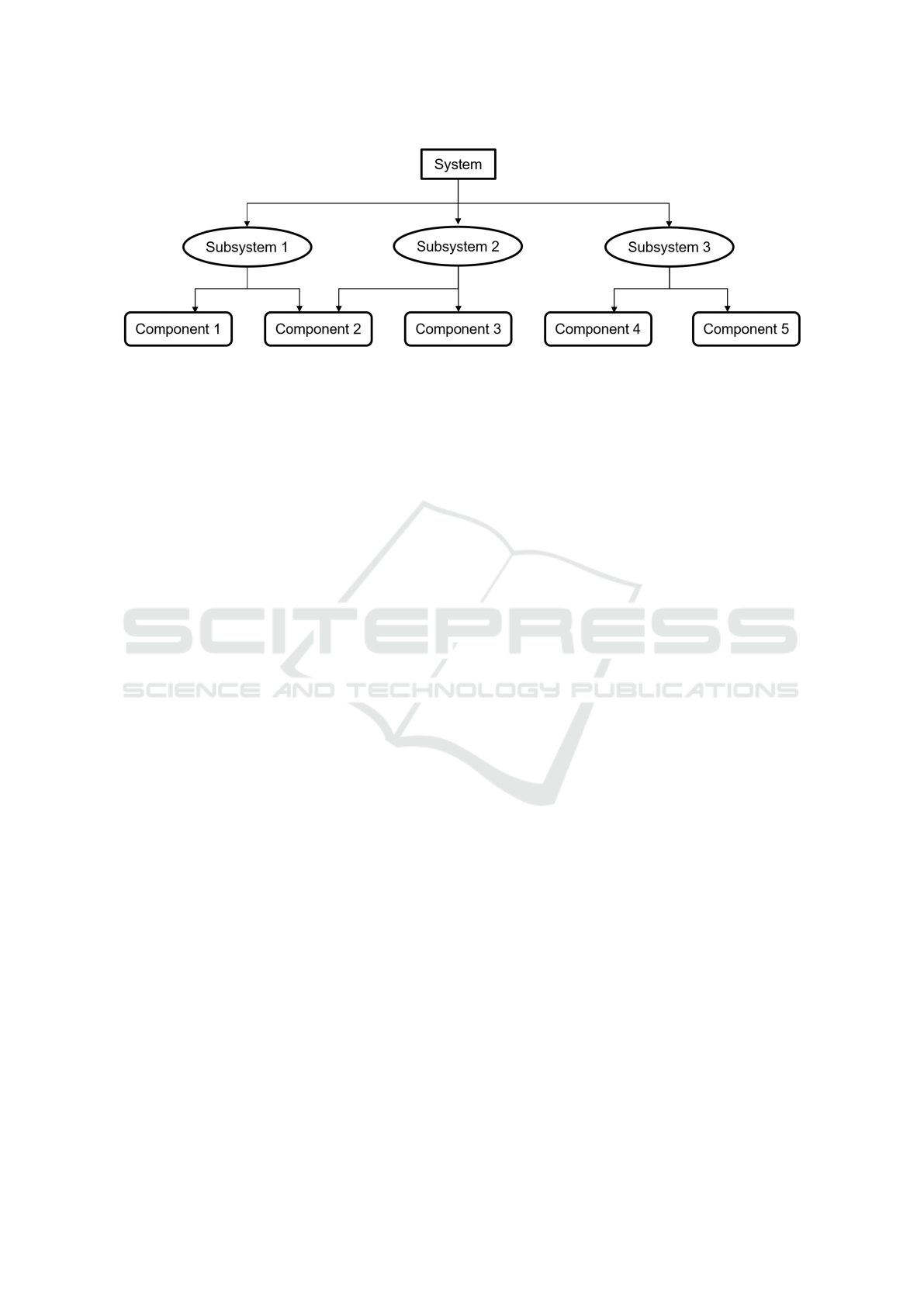

Figure 1: Example of a multilevel system’s structure.

information. It enables system administrators to take

proactive actions, thereby minimizing downtime and

optimizing system reliability (Mobley, 2002). The

proposed method is versatile and scalable. It can be

generalized to handle complex, multi-component sys-

tems, broadening its applicability in system health la-

beling.

The article is organized as follows. First, the

context of predictive maintenance and labeling is

explored in the domain of electronic maintenance.

Secondly, the proposed labeling methodology is ex-

plained, discussing the application of unsupervised

discretization methods. Then the results of labeling

are presented and discussed for a public dataset. Fi-

nally, the last part concludes and summarizes the key

findings while providing recommendations for future

research.

2 ELECTRONIC SYSTEM

MAINTENANCE

2.1 Context

As illustrated in Figure 1, the studied system con-

sists of several electronic subsystems that perform

different functions. Each subsystem is composed of

multiple components which can be part of several

subsystems. Different parameters of each subsystem

are monitored by collecting data at regular intervals.

These measurements are organized into control runs

that verify if each component is operating within its

nominal range and does not exceed any failure thresh-

old. If this threshold is reached, the component is con-

sidered as non-functioning and needs to be repaired.

A single threshold proves insufficient for a com-

prehensive characterization of a system’s state. In

many instances, the goal is to establish a more nu-

anced health assessment, typically manifesting as a

health indicator, health state, or Remaining Useful

Life (RUL) of the system (Lei et al., 2018a). The

health indicator represents a numerical value evalu-

ating the overall condition of the system. Similarly,

the health state, while similar to the health indica-

tor, adopts a categorical form rather than a numerical

value. On the other hand, RUL estimation is directed

towards predicting the remaining lifespan of the sys-

tem. Each of these indicators offers valuable insights

crucial for informed decision-making in maintenance

practices.

2.2 Health Diagnosis

Heath indicators are either physics-based or virtual

(Hu et al., 2012). The difference between these two

types lies in the method used for their calculations.

The physical indicator can be calculated using statis-

tical methods or signal processing techniques based

on measurements related to the equipment. It is often

the root mean square of signals (Huang et al., 2017),

but it can be calculated in many other ways depend-

ing on the data processed, such as vibrations (Soualhi

et al., 2015). The virtual indicators are based on the

fusion of multiple physical health indicators or several

signals. Principal Component Analysis is the method

generally used for this type of approach, but there are

also many methods possible to determine it (Lei et al.,

2018b). For instance, it can be estimated using unsu-

pervised ML algorithms (Kurrewar et al., 2021).

Health states are often created by dividing a health

indicator into multiple states by identifying trends in

the indicator values. A simple strategy for two-state

division involves checking if the indicator exceeds an

alarm threshold. Various methods are used to deter-

mine this threshold (Lei et al., 2018b).

When degradation trends of machinery are incon-

sistent and cannot be expressed using a single model,

multi-state division is used. This division can be

achieved through various methods such as the anal-

ysis of change points in health indicators (Hu et al.,

2016) or by applying clustering algorithms (Scanlon

Discretization Strategies for Improved Health State Labeling in Multivariable Predictive Maintenance Systems

435

et al., 2013). Machine learning classifiers can also be

applied to multi-stage division (Soualhi et al., 2015).

To conclude, health states’ labeling is a crucial step

to precisely describe the behavior of the studied sys-

tem. Yet it presents several challenges in the context

of predictive maintenance.

2.3 Challenges of Data Labeling in

Predictive Maintenance

Data labeling stands as a critical phase in supervised

machine learning, where labeled data are imperative

for training models effectively. However, in the do-

main of predictive maintenance, datasets often con-

tain only binary labels indicating normal or failure

states (Jovicic et al., 2023), unfortunately, transition

states are frequently missing. These intermediate

states represent crucial transition phases and are rele-

vant in the context of predictive maintenance. How-

ever, the same level of certainty is not easily achiev-

able when it comes to identifying transitional states

between these two conditions.

The challenge in data labeling for predictive main-

tenance increases when dealing with failure events.

The quantity of failure labels in databases is often lim-

ited due to preventive maintenance strategies, where

components are replaced before actual failure occurs.

This strategy decreases the number of recorded fail-

ures, complicating the labeling process and affecting

the model’s ability to generalize effectively.

2.4 Dataset

For this study, multiple public datasets were consid-

ered to benchmark the studied method such as popu-

lar datasets: CMAPSS (Saxena et al., 2008), bearing

dataset (Lee et al., 2007), or milling dataset (Agogino

and Goebel, 2007). However, the majority does not

provide or consider failure thresholds, which is a cru-

cial element in predictive maintenance analysis in the

presented context. For this reason, the AI4I predictive

maintenance dataset (Matzka, 2020) has been chosen

due to its feature of providing failure thresholds.

Including 10,000 data points with five features, the

dataset includes a ’machine failure’ label indicating

various failure modes. Notably, three of these modes

are threshold-dependent: Heat Dissipation Failure

(HDF), Power Failure (PWF), and Overstrain Failure

(OSF). While Tool Wear Failure (TWF) and Random

Failures (RNF) are based on random occurrences.

To enhance the dataset, modifications were made

to introduce columns specifying the defined failure

thresholds. This adjustment ensures that limits are set

for individual parameters rather than combinations,

facilitating the analysis of failure states. It is impor-

tant to highlight that, despite its robust representation

of failures, the dataset does not include explicit in-

formation on transition states. This limitation under-

scores the need for the proposed method, which fo-

cuses on addressing this gap.

The following sections of this paper will exam-

ine existing methodologies and propose new strate-

gies to enhance data labeling in the context of predic-

tive maintenance, ultimately contributing to the relia-

bility and performance of predictive maintenance sys-

tems.

3 PROPOSED LABELING

TECHNIQUES

3.1 Overview of Discretization

Approaches

Discretization is a process that transforms continuous

data into discrete categories, typically finite sets of

distinct intervals. Several methods exist for this pur-

pose, they can be classified as supervised or unsuper-

vised (Garc

´

ıa et al., 2013).

Supervised methods use labeled data to guide

the process of dividing continuous features into dis-

crete categories. They generally outperform unsu-

pervised methods due to their context-specific nature

(Dougherty et al., 1995). For this reason, the most

common methods for discretization are ChiMerge

(Kerber, 1992), Minimum Description Length prin-

ciple (Rissanen, 1986), or entropy-based techniques

(Fayyad and Irani, 1993). However, they have to use

data with class information. In practical cases, man-

ual annotation of data is often used to create labeled

data before using those approaches. However, in the

case of the presented dataset (Section 2.4), labels for

discretization have not been created, so such super-

vised techniques cannot be used and unsupervised

methods are the only choice.

Unsupervised discretization methods, such as the

EW discretization method, divide the range of con-

tinuous values into a predetermined number of inter-

vals of equal width. This approach is straightforward

to implement and computationally efficient. How-

ever, it is sensitive to outliers, as extreme values can

significantly affect the width of intervals, leading to

a suboptimal representation of the data distribution

(Catlett, 1991). The EF discretization method par-

titions the data into intervals that contain approxi-

mately the same number of data points, aiming to ad-

dress the sensitivity to outliers seen in EW discretiza-

DATA 2024 - 13th International Conference on Data Science, Technology and Applications

436

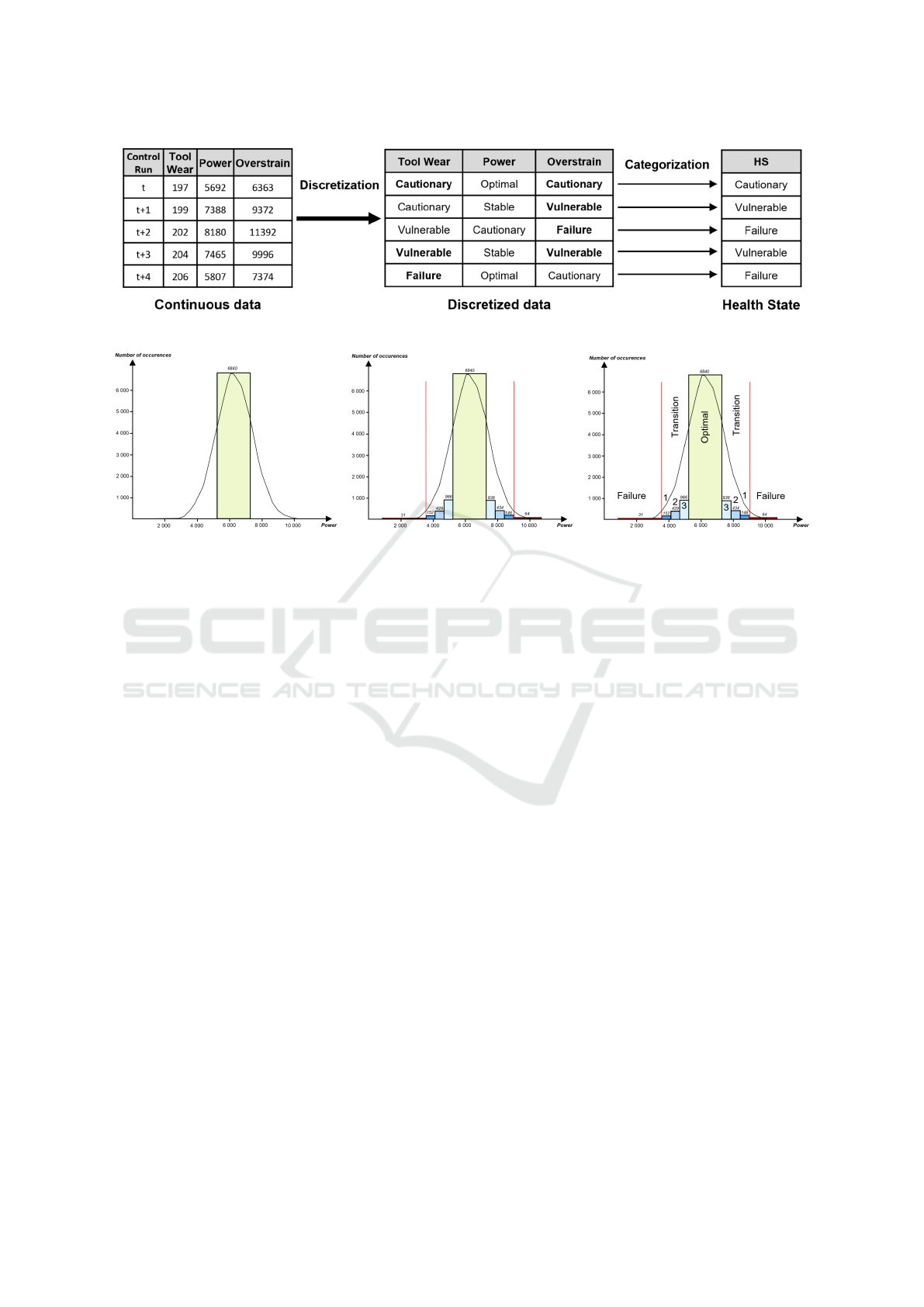

Figure 2: Labeling process by discretization.

(a) Standard deviation approach to cre-

ate the optimal state.

(b) Addition of the others categories of

health state.

(c) Labelization of the different health

states.

Figure 3: Distribution of the power parameter (1 = Vulnerable state, 2 = Cautionary state and 3 = Stable state).

tion. However, it may struggle with uneven data dis-

tributions, where certain intervals may capture sparse

or dense regions of data. This method is particularly

useful when the goal is to ensure each category has a

comparable number of instances.

Both of those approaches can be used in the con-

text of discretization, but in the following section, the

new approach is presented using discretization tech-

niques as a way of unsupervised data labeling.

3.2 Multivariable System Labeling

Through Discretization Approach

It is common for predictive maintenance databases to

lack detailed health states, often merely indicating a

binary state of failure or non-failure. The proposed

Multivariable System Labeling through Discretiza-

tion (MSLD) approach creates these health states for

a multivariable system using unsupervised discretiza-

tion of the acquired data. This method enhances

the granularity of system health assessment, enabling

more detailed predictions and effective maintenance

strategies.

The proposed method consists of two main steps:

discretization and categorization as shown in Fig-

ure 2.

In the discretization step, each measured parame-

ter from control runs is converted into discrete values

based on its distribution. A standard deviation-based

approach has been used to identify the optimal oper-

ating range for each parameter. It corresponds to the

values that fall within plus or minus one standard de-

viation from the mean value to identify outliers.

For example, in Figure 2, the power parameter

has an average value of 6279 and a standard devia-

tion of 1067. In this case, values between 5212 and

7347 are considered optimal (Figure 3a). The size of

the optimal class is arbitrary and can be adjusted by

experts based on the stability of the studied system.

Any values outside this range are considered as non-

optimal. Furthermore, two additional categories are

also created for values that exceed the failure thresh-

olds on either side, representing a failure state for the

equipment. The failure thresholds for the power pa-

rameter are 3500 and 9000. The values between the

failure threshold and the optimal state are further di-

vided into multiple intervals using the EW discretiza-

tion method. The EW method is used to have similar

size bins to reflect the actual distribution of the data.

This way, with the example of three transition states,

values between 7347 to 7898 are categorized as the

stable state, 7898 to 8449 as the cautionary state, and

8449 to 9000 as the vulnerable state. The same type

of state is applied to the other side of the Gaussian

curve (Figure 3b). The number of transition states

on each side is determined by experts depending on

the system. In the case of this article, the choice of

Discretization Strategies for Improved Health State Labeling in Multivariable Predictive Maintenance Systems

437

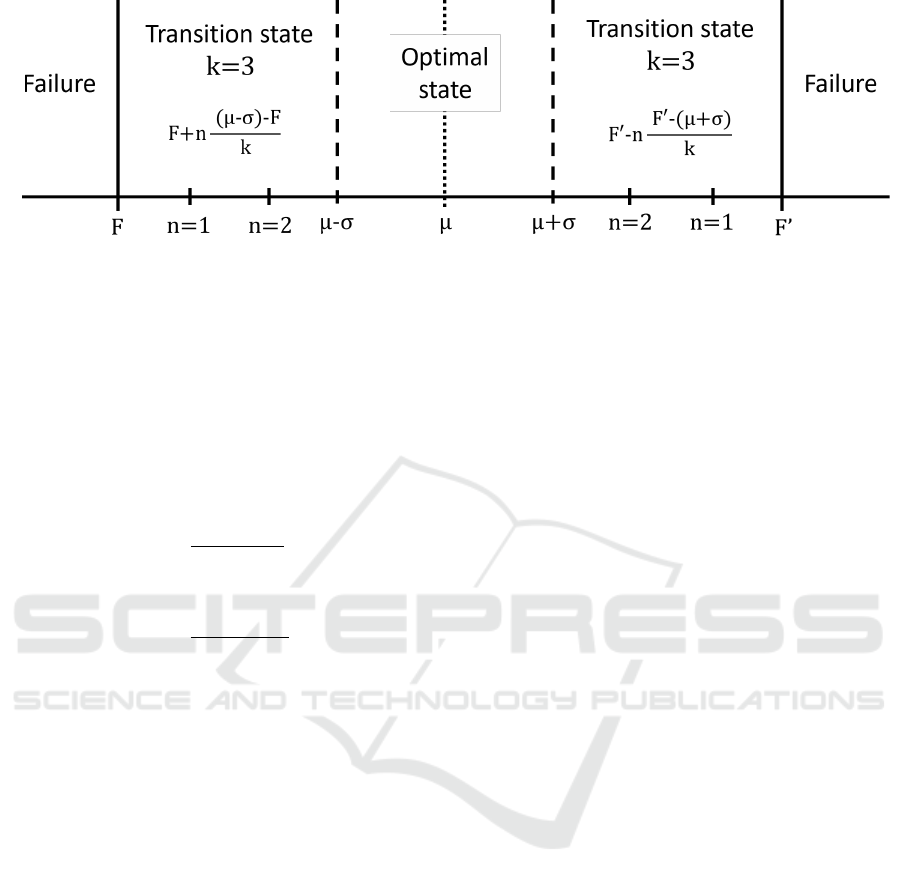

Figure 4: Labeling process by discretization.

three transition states is based on the results obtained

in Sec. 4.

Figure 4 represents the discretization step. F and

F

′

represent the failure thresholds, µ the mean value

and σ the standard deviation. The optimal state is then

defined by the values between µ−σ and µ+σ. k is the

number of transition states and n defines the limit be-

tween the different transition states with the following

formula for value inferior to the optimal:

F + n

(µ − σ) − F

k

And for value superior the optimal:

F

′

− n

F

′

− (µ + σ)

k

In the categorization step, each control run is as-

signed a specific category. This assignment is based

on the discretized values of its parameters. The cat-

egory assigned to the control run corresponds to this

most deviated parameter. This deviation is measured

in terms of how far the parameter’s value is from its

normal range. This is based on the assumption that

the health status of the system is determined by the

state of its most degraded component. In other words,

if one component of the system is in a poor state, it

significantly affects the overall health of the system,

regardless of the state of the other components.

With the example of three transition states, the fol-

lowing states can be defined as vulnerable, cautionary,

and stable. They represent different levels between

the failure and optimal state. The vulnerable state

indicates a condition closest to the failure state, sig-

nifying a potential early warning or indication of an

impending issue. The cautionary state reflects an in-

termediate condition between the failure state and an

optimal state, suggesting a moderate level of concern.

The stable state, on the other hand, is the closest to the

optimal state, indicating a state with minimal risk or

deviation from normal system operation (Figure 3c).

These states provide a nuanced understanding of the

system’s health, with transitions between them serv-

ing as key indicators for effective predictive mainte-

nance.

This approach allows for a more detailed and com-

prehensive understanding of the system’s health. Po-

tential issues can be identified early and appropriate

corrective measures can be taken, thereby enhancing

the effectiveness of the predictive maintenance strate-

gies.

4 RESULTS AND DISCUSSION

4.1 Results

After introducing the new labeling approach, this

section will discuss the results and effectiveness of

this method. The presented results of the discretiza-

tion step are for the power parameter from the AI4I

dataset, aiming to identify distinct states of the sys-

tem. This method is applied to all parameters, leading

then to categorization. Figure 3 illustrates the distri-

bution of the power parameter, categorized into differ-

ent states with the previously described approach in

Sec. 3.2. The optimal state, denoted by the green cate-

gory, encompasses 68% of the dataset, while the tran-

sition state (blue) represents 31% and failure states

(red) constitute 1%. These categories serve as cru-

cial indicators of the system’s health, with transitions

playing a pivotal role in precise predictive mainte-

nance.

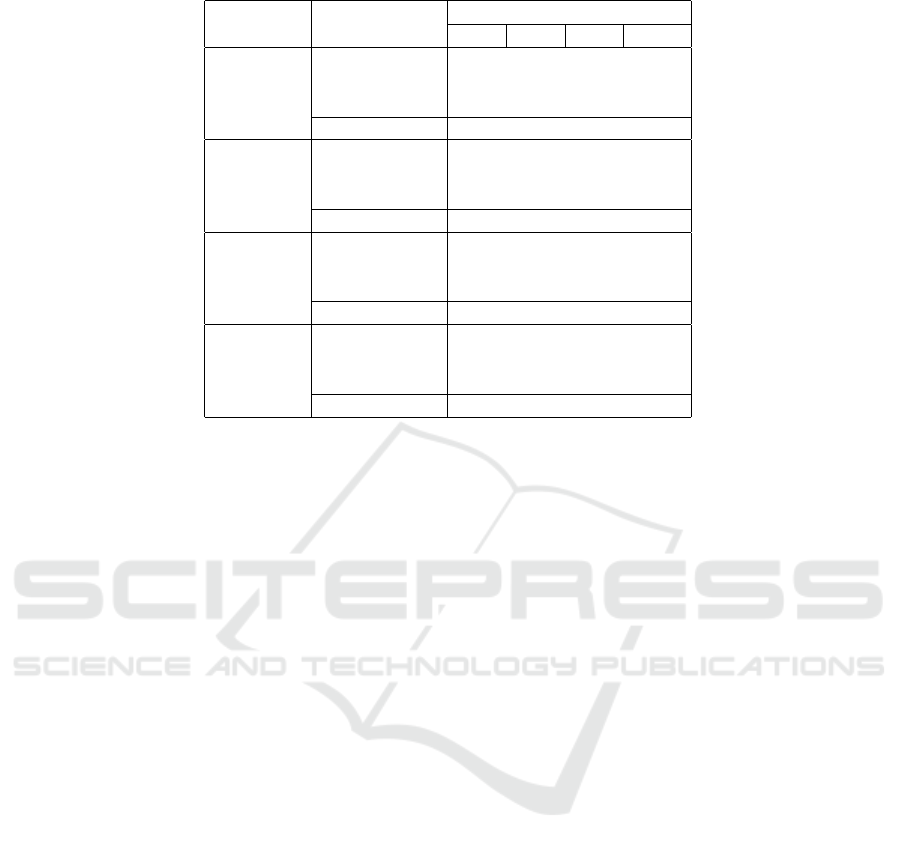

Table 1 presents the distribution of the power pa-

rameter for three different discretization techniques:

EW, EF, and MSLD. Depending on the discretization

method used, the distribution can greatly vary. Be-

cause of the way EF works, there is a high number of

values in extreme bins which leads to an unbalanced

diagnosis after categorization 2. EW and MSLD are

more adapted to discretize parameters because they

do not alter the shape of the data distribution.

The effectiveness of various discretization tech-

DATA 2024 - 13th International Conference on Data Science, Technology and Applications

438

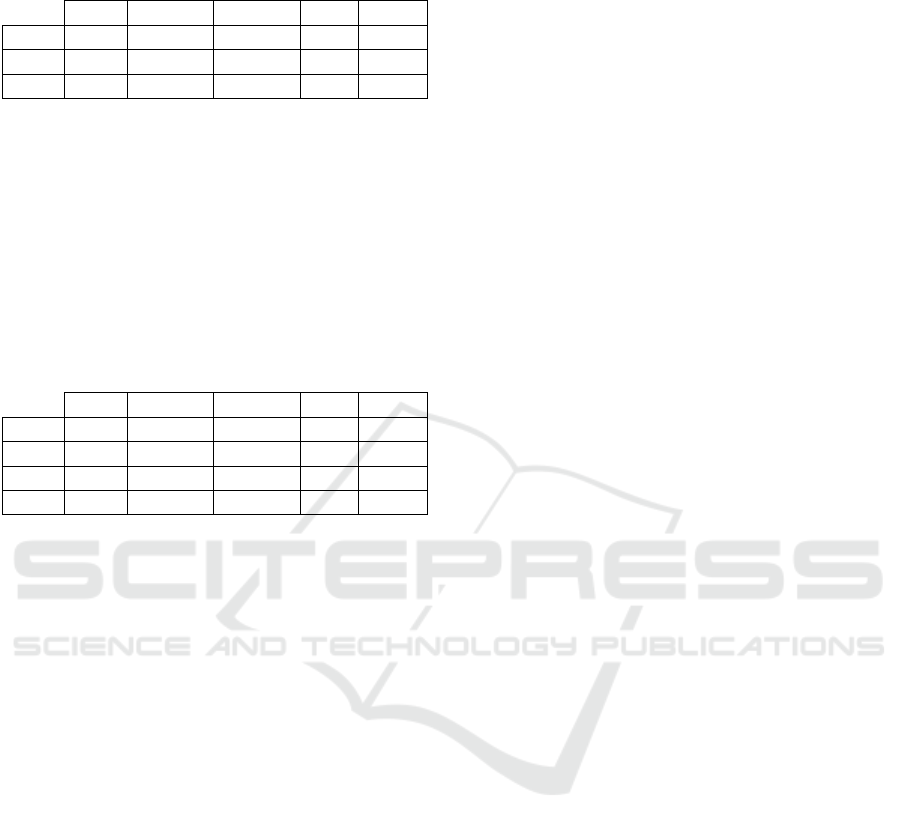

Table 1: Different distributions for the ”Power” parameter

with different discretization techniques.

Failure Vulnerable Cautionary Stable Optimal

EW 95 451 1415 3240 4799

EF 95 2453 2464 2453 2439

MSLD 95 298 863 1904 6840

niques for all parameters, when applying the same

categorization step is provided in Table 2. The out-

comes of health states after the categorization step

are heavily dependent on the discretization method.

It becomes evident that the simple EW and EF meth-

ods are suboptimal for the discretization step of the

MSLD approach. MSLD discretization step approach

provides much more details and transition states than

EW and EF methods.

Table 2: Table of the different distribution of system states

depending on the discretization technique.

Failure Vulnerable Cautionary Stable Optimal

Binary 348 0 0 0 9652

EW 348 3851 5186 615 0

EF 348 7421 1928 303 0

MSLD 348 2074 3290 3290 998

As shown in Table 2, the original binary scenario,

with only failure and non-failure states, lacks gran-

ularity. This could lead to missed opportunities for

early intervention before a system failure occurs. The

EW and EF methods provide more detailed states,

which could allow for more proactive maintenance

strategies. However, the absence of optimal states

might indicate an over-prediction of system issues,

potentially leading to unnecessary interventions. The

MSLD method seems to provide a more balanced

distribution across all states, including optimal ones.

This could offer a more nuanced understanding of

system health, allowing for targeted interventions and

efficient resource allocation.

As seen with EF and EW when obtaining the diag-

nosis from the weakest link among all parameters, the

attribution of an excessive number of values at the ex-

tremities of the binning fails to accurately depict the

actual health state of the system. The MSLD method

outperforms the others, offering a more balanced rep-

resentation of different system states with the help of

failure thresholds.

Table 3 presents the performance of different ma-

chine learning algorithms (Decision Tree (DT), Ran-

dom Forest (RF), K-Nearest Neighbours (KNN), and

XGBoost) using previous discretization methods (EF,

EW, MSLD) and the original binary states dataset.

The performance is measured by the F1 score for dif-

ferent numbers of classes.

From the table, it is evident that the performance

generally decreases as the number of classes in-

creases. This is expected as increasing the number

of classes adds complexity to the model, making it

harder to achieve high accuracy. However, the rate of

decrease varies depending on the algorithm and dis-

cretization method used.

For instance, the XGBoost algorithm maintains

relatively high performance across all numbers of

classes and discretization methods, with the F1 score

only slightly decreasing as the number of classes in-

creases. This suggests that XGBoost is robust to the

increase in class numbers and can handle the added

complexity well. On the other hand, the other three

algorithms, especially KNN, show a significant drop

in performance as the number of classes increases, in-

dicating that it may not be the best choice for this par-

ticular problem.

In terms of the discretization methods with XG-

Boost, EF, and EW perform similarly with MSLD

across all numbers of classes. But, as seen previ-

ously in Table 2, the distribution of system states from

MSLD is more balanced.

Considering the trade-off between performance

and the number of classes, choosing nine classes

seems to be a good balance. It corresponds to three

transition states on each side, two failure states, and

the optimal state. This choice provides more granu-

larity than the original binary states while still main-

taining relatively high performance across all algo-

rithms and discretization methods. Specifically, the

XGBoost algorithm with the more balanced MSLD

discretization method is a more robust performance

across different numbers of classes.

4.2 Discussion and Limitations

The proposed approach relies on an unsupervised

method, which means the role of the expert is impor-

tant in selecting the right number of transition states.

This choice is based on the results obtained with the

different configurations.

The number of transition states as well as the size

of the optimal state need to be configured correctly

depending on the dataset.

The MSLD approach presented here can be ap-

plied in a generalized manner to various databases

with failure thresholds, to determine transition states.

The presented approach provides a more granular

understanding of system transitions. By discretizing

data and accounting for transition states, the preci-

sion of health state labeling is enhanced. Although

this method may not necessarily yield superior pre-

diction performance compared to other approaches,

Discretization Strategies for Improved Health State Labeling in Multivariable Predictive Maintenance Systems

439

Table 3: Results with different ML algorithms, discretization methods, and number of transition classes.

Algorithm

Discretization

Method

F1Score with n classes

n=5 n=7 n=9 n=11

DT

EF 97.3 89.3 85.4 79.2

EW 97.0 92.7 77.2 75.9

MSLD 93.6 81.7 74.1 63.9

Binary 96.7

RF

EF 96.4 91.1 82.9 85.2

EW 96.7 92.0 85.5 82.7

MSLD 94.7 84.8 80.1 75.4

Binary 99.1

KNN

EF 53.6 50.2 47.2 45.4

EW 66.8 60.3 60.4 59.0

MSLD 54.1 52.6 48.9 48.1

Binary 97.3

XGBoost

EF 98.5 97.9 97.9 97.1

EW 98.2 98.3 97.4 97.5

MSLD 98.7 97.8 97.9 96.7

Binary 98.8

its strength lies in its ability to accurately classify a

wider range of health states, thereby improving de-

scriptive abilities without necessarily impacting over-

all predictive performance.

This method is limited to datasets with failure

thresholds which give context for the creation of tran-

sition states. In many cases, it restricts the use of

this method because failure thresholds are not always

present. But, if there are no failure thresholds, expert

knowledge can be used to determine them.

The discussed methods use manual tuning but

it is not always optimal nor efficient. Implement-

ing an automatic parameter optimization could en-

hance both efficiency and accuracy. Future research

will explore these techniques for their applicability in

health state labeling. This could lead to more robust

health state estimation, improving system reliability

and longevity.

5 CONCLUSION

In conclusion, the introduced methodology enhances

predictive maintenance practices by addressing the

limitations associated with binary labeling commonly

found in existing datasets. The unsupervised dis-

cretization technique, guided by data distribution and

failure thresholds, enables a nuanced classification

of multiple transitional states. It allows the experts

to rapidly decide the best discretization according to

their knowledge and experience. The research un-

derscores the versatility of the MSLD approach, em-

phasizing its applicability across diverse electronic

systems and databases. By providing a more intri-

cate understanding of a system’s health and incorpo-

rating transitional states as vital indicators, the pro-

posed method enhances anomaly detection. This con-

tribution improves decision-making in maintenance

strategies, contributing to the refinement of predictive

maintenance applications for a more accurate and in-

formed approach to system health assessment.

ACKNOWLEDGEMENTS

This work is supported by ArianeGroup SAS and the

“Agence de l’Innovation de D

´

efense” (French De-

fence Innovation Agency).

REFERENCES

Agogino, A. and Goebel, K. (2007). Milling data set.

Technical report, NASA Ames Research Cen-

ter. url https://www.nasa.gov/intelligent-systems-

division/discovery-and-systems-health/pcoe/pcoe-

data-set-repository/.

Budach, L., Feuerpfeil, M., Ihde, N., Nathansen, A., Noack,

N., Patzlaff, H., Naumann, F., and Harmouch, H.

(2022). The effects of data quality on machine learn-

ing performance. arXiv preprint arXiv:2207.14529.

Carvalho, T. P., Soares, F. A. A. M. N., Vita, R., da P. Fran-

cisco, R., Basto, J. P., and Alcal

´

a, S. G. S. (2019). A

systematic literature review of machine learning meth-

ods applied to predictive maintenance. Computers &

Industrial Engineering, 137:106024.

Catlett, J. (1991). On changing continuous attributes into

ordered discrete attributes. In Kodratoff, Y., edi-

DATA 2024 - 13th International Conference on Data Science, Technology and Applications

440

tor, Machine Learning — EWSL-91, pages 164–178,

Berlin, Heidelberg. Springer Berlin Heidelberg.

Dougherty, J., Kohavi, R., and Sahami, M. (1995). Su-

pervised and unsupervised discretization of continu-

ous features. In Prieditis, A. and Russell, S., editors,

Machine Learning Proceedings 1995, pages 194–202.

Morgan Kaufmann, San Francisco (CA).

Fayyad, U. M. and Irani, K. B. (1993). Multi-interval dis-

cretization of continuous-valued attributes for classi-

fication learning. In Ijcai, volume 93, pages 1022–

1029.

Garc

´

ıa, S., Luengo, J., S

´

aez, J. A., L

´

opez, V., and Herrera,

F. (2013). A survey of discretization techniques: Tax-

onomy and empirical analysis in supervised learning.

IEEE Transactions on Knowledge and Data Engineer-

ing, 25(4):734–750.

Hu, C., Youn, B. D., Wang, P., and Taek Yoon, J. (2012).

Ensemble of data-driven prognostic algorithms for ro-

bust prediction of remaining useful life. Reliability

Engineering & System Safety, 103:120–135.

Hu, Y., Li, H., Liao, X., Song, E., Liu, H., and Chen, Z.

(2016). A probability evaluation method of early dete-

rioration condition for the critical components of wind

turbine generator systems. Mechanical Systems and

Signal Processing, 76-77:729–741.

Huang, Z., Xu, Z., Ke, X., Wang, W., and Sun, Y. (2017).

Remaining useful life prediction for an adaptive skew-

wiener process model. Mechanical Systems and Sig-

nal Processing, 87:294–306.

Jovicic, E., Primorac, D., Cupic, M., and Jovic, A. (2023).

Publicly available datasets for predictive maintenance

in the energy sector: A review. IEEE Access,

11:73505–73520.

Kerber, R. (1992). Chimerge: discretization of numeric

attributes. In Proceedings of the Tenth National

Conference on Artificial Intelligence, AAAI’92, page

123–128. AAAI Press.

Kurrewar, H., Bekar, E. T., Skoogh, A., and Nyqvist, P.

(2021). A machine learning based health indicator

construction in implementing predictive maintenance:

A real world industrial application from manufactur-

ing. In Advances in Production Management Systems.

Artificial Intelligence for Sustainable and Resilient

Production Systems, pages 599–608, Cham. Springer

International Publishing.

Lee, J., Qiu, H., Yu, G., Lin, J., and Services,

R. T. (2007). Bearing data set. Techni-

cal report, NASA Ames Research Center.

url https://www.nasa.gov/intelligent-systems-

division/discovery-and-systems-health/pcoe/pcoe-

data-set-repository/.

Lei, Y., Li, N., Guo, L., Li, N., Yan, T., and Lin, J. (2018a).

Machinery health prognostics: A systematic review

from data acquisition to rul prediction. Mechanical

Systems and Signal Processing, 104:799–834.

Lei, Y., Li, N., Guo, L., Li, N., Yan, T., and Lin, J. (2018b).

Machinery health prognostics: A systematic review

from data acquisition to rul prediction. Mechanical

Systems and Signal Processing.

Matzka, S. (2020). Explainable artificial intelligence for

predictive maintenance applications. In 2020 Third

International Conference on Artificial Intelligence for

Industries (AI4I), pages 69–74.

Mobley, R. K. (2002). An Introduction to Predictive Main-

tenance 2nd edition. Elsevier.

Ran, Y., Zhou, X., Lin, P., Wen, Y., and Deng, R. (2019). A

survey of predictive maintenance: Systems, purposes

and approaches. ArXiv, abs/1912.07383.

Rissanen, J. (1986). Stochastic complexity and modeling.

The annals of statistics, pages 1080–1100.

Saxena, A., Goebel, K., Simon, D., and Eklund, N. (2008).

Damage propagation modeling for aircraft engine run-

to-failure simulation. In 2008 International Confer-

ence on Prognostics and Health Management, pages

1–9.

Scanlon, P., Kavanagh, D. F., and Boland, F. M. (2013).

Residual life prediction of rotating machines using

acoustic noise signals. IEEE Transactions on Instru-

mentation and Measurement, 62(1):95–108.

Soualhi, A., Medjaher, K., and Zerhouni, N. (2015). Bear-

ing health monitoring based on hilbert–huang trans-

form, support vector machine, and regression. IEEE

Transactions on Instrumentation and Measurement,

64(1):52–62.

Tan, C. M. and Raghavan, N. (2010). Imperfect predictive

maintenance model for multi-state systems with mul-

tiple failure modes and element failure dependency.

In 2010 Prognostics and System Health Management

Conference, pages 1–12.

Discretization Strategies for Improved Health State Labeling in Multivariable Predictive Maintenance Systems

441