Framework for Modeling the Propagation of Disturbances in Smart

Construction Sites

Ali Attajer

a

and Boubakeur Mecheri

b

Institut de Recherche, ESTP, 28 Avenue du Président Wilson, F-94230, Cachan, France

Keywords: Smart Construction Sites (SCS), Disturbances, Propagation, Resilience, Framework, Simulation.

Abstract: The construction sector is currently undergoing a paradigm shift by technological advances. This

transformation has led to the emergence of the concept of “Construction 4.0”. However, despite these

advances, improving resilience - the ability to adapt effectively to unexpected events - remains a major

challenge. In this work, we aim to bridge this scientific gap by proposing a framework to systematically

characterize and model disturbances and their propagation. We instantiate the framework in a case study using

discrete event simulation in FlexSim. In this model, we simulate a smart construction site where construction

activities are automated by intelligent and autonomous entities, such as robots, automated guided vehicles,

and autonomous cranes. Moreover, we examine two scenarios to understand how a type of disturbance, with

specific characteristics, propagates through the system and impacts the continuity of construction activities

and operations. The results provide essential insights into the impact of disturbances on work progress, project

duration, the capacities of autonomous entities, and stock levels.

1 INTRODUCTION

The construction sector is currently undergoing a

paradigm shift by integrating new practices and

cutting-edge technologies (Akanmu et al., 2021). This

transformation, characterized by the deployment of

advanced tools and methodologies such as off-site

modular construction (Wang et al., 2020), Building

Information Modeling (BIM) (Sepasgozar et al.,

2023), 3D printing, and robotics, represents a

fundamental transition for building design and

construction. These innovations are more than just

evolutions; they represent an overhaul of the

philosophy behind construction, oriented towards

greater efficiency, sustainability, and resilience

(Attajer et al., 2022). At the core of this

transformation lies the increasing complexity of

construction projects. This complexity, characterized

by a diversity of components and actors- ranging

from materials and equipment to operators,

supervisors, and engineers - requires continuous

coordination to successfully complete a project

(Muñoz-La Rivera et al., 2021). Moreover, the strong

interconnection between these elements increases the

a

https://orcid.org/0000-0002-1567-8653

b

https://orcid.org/0009-0009-3204-0107

vulnerability of construction sites to disturbances and

their propagation, whether technical, human or

logistical, underlining the need for innovative and

effective disturbance and risk management strategies

(Afzal et al., 2021). These new strategies require

continuous monitoring and anticipation throughout

the project lifecycle, particularly during the

construction phase.

The sources of disturbances are multiple and

varied, ranging from the intrinsic characteristics of

the construction project (e.g., technical

specifications, dimensions, and architectural

elements) to more operational aspects (e.g.,

equipment failures or delays in material supply)

(Kikwasi, 2012). These factors impact the continuity

of activities, risking the construction value chain and,

consequently, the successful delivery of projects

(e.g., delays, and increased cost). The fundamental

question that emerges from this issue is therefore how

these disturbances propagate through the various

elements of a construction site and what strategies can

be implemented to evaluate and mitigate their

impacts? Despite the considerable efforts made in the

literature (Love & Matthews, 2020), the dynamic

80

Attajer, A. and Mecheri, B.

Framework for Modeling the Propagation of Disturbances in Smart Construction Sites.

DOI: 10.5220/0012792400003764

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 21st International Conference on Smart Business Technologies (ICSBT 2024), pages 80-87

ISBN: 978-989-758-710-8; ISSN: 2184-772X

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

analysis of disturbances and their propagation during

project execution remains an open problem. To

address this challenge, it is essential to develop tools

and methodologies capable of acquiring and

analyzing real-time data, detecting potential

disturbances, and assessing their impact.

In this context, the concept of Smart Construction

Sites (SCS) emerges as a promising solution. By

equipping construction sites with advanced

technologies — such as Automated Guided Vehicles

(AGV) for material transport, robots dedicated to

specific tasks like painting, welding, and finishing, or

autonomous cranes offering increased precision —

construction projects benefit from increasing

automation in operation execution. Thus, the

adoption of these technologies allows for real-time

monitoring and tracking of all activities on the site

(Rao et al., 2022). This ability to collect and analyze

information continuously offers an unprecedented

opportunity to detect and assess disturbances and

their propagation as they occur on the site.

The main objective of this paper is to develop a

framework for the characterization of disturbances

and their propagation in SCS. Furthermore, we use a

discrete event simulation using FlexSim to model and

analyze a SCS process and operations. With advanced

visualization and analysis capabilities (Attajer et al.,

2021), FlexSim is used to create detailed, realistic

scenarios to assess the impact of disturbances on SCS

performance, and to test various mitigation strategies

prior to their implementation in the field. Several

works have used FlexSim software in the construction

industry, as illustrated in this review article (Dziadosz

& Kończak, 2016).

The structure of the paper is organized as follows:

Section 2 presents a review of the literature on the

propagation of disturbances in SCS. Section 3 details

the proposed framework for characterizing

disturbances and their propagation through the

components of SCS. Section 4 illustrates an

instantiation through a case study conducted using

simulation. Section 5 concludes the article by

suggesting future directions for research.

2 RELATED WORKS

Disturbance management represents a significant

challenge in the execution of construction projects,

given the inherent complexity of operations and the

interconnection of components (Peñaloza et al.,

2020). Understanding the propagation of disturbances

and their overall impact offers valuable insight into

the complexity of managing construction projects.

However, the lack of detailed analysis on the use of

advanced technologies to dynamically monitor and

analyze this propagation on the overall project

performance, such as delays, represents a challenge

(Meszek et al., 2019). SCS constitute a new area of

investigation for proactive and real-time disturbance

management, but this requires further exploration

(Peñaloza et al., 2020). In the literature, several works

have proposed frameworks for the classification of

disturbances. The distinction between high-impact

and low-frequency disturbances, often likened to the

"ripple effect" in the supply chain domain, and those

of low impact and high frequency, provides a first

layer of complexity in the management of

disturbances (Dolgui et al., 2020). This classification

highlights the need for a nuanced approach in the

evaluation of disturbances, where the focus is not

only on their direct impact but also on their frequency

and propagation through the project.

Additionally, previous studies have addressed

other classification criteria related to the sources of

disturbance: internal or external. For example,

(Zhang & Yu, 2021) addressed external disturbances

specific to the supply chain of off-site prefabricated

construction components. Furthermore, recent works

(Meszek et al., 2019) has highlighted the significant,

financial and temporal, impacts of internal sources of

disturbances. However, there is a lack of a more

generic approach that can carefully examine and

consider both internal and external types of

disturbances and their management in a broader

context. Many studies tend to handle disturbances in

an isolated manner, without exploring their

propagation or examining how SCS technologies can

be used to anticipate and mitigate these effects in real

time (Meszek et al., 2019). A few proactive

approaches aimed to identify the impact of

disturbances have been proposed. For example,

(Zarghami & Zwikael, 2023) suggested a

methodology focusing on assessing the probabilities

and consequences of disturbances, highlighting the

necessity of preparation and planning in risk

management. Its integration into SCS management

systems could offer effective means to predict and

respond efficiently to disturbances, leveraging

advanced analytical capabilities to optimize resource

allocation and minimize delays. At the same time, the

use of system dynamics and neural networks to

anticipate delays brings an advanced technological

dimension to disturbance management (Zhao et al.,

2022). While the reviewed research provides valuable

insights, literature highlights the lack of the capability

of SCS to manage disturbances proactively and in real

time.

Framework for Modeling the Propagation of Disturbances in Smart Construction Sites

81

3 PROPOSED FRAMEWORK

Before addressing the modelling of disturbance

propagation within SCS, it's crucial to understand and

characterize disturbances.

3.1 Characterization of Disturbances

To structure and classify disturbances in the context

of SCS, we propose a framework articulated around

four main dimensions: the impact, frequency, nature,

and source of disturbances.

Impact of Disturbances:

The impact of

disturbances on the activities of construction sites

varies considerably, directly influencing the

continuity of operations, costs, and project delay.

This dimension is detailed into three levels of impact:

high, medium, low.

High Impact: These disturbances can cause

considerable delays or significantly increase project

costs, while having a profound impact on the

organization and planning of the construction site.

For example, a major design or sizing error in the

BIM plan might require significant revisions, thereby

causing delays and additional cost.

Medium Impact: These disturbances affect the

project but can be managed or corrected with minor

adjustments. For example, a delay in the delivery of

materials can affect the schedule without necessarily

risking the overall project delay.

Low Impact: These disturbances have minimal, if

not negligible, impact on the project and can

generally be resolved without requiring significant

adjustments. An example could be a temporary

equipment breakdown, quickly repairable and need

systematic maintenance actions (Attajer et al., 2019).

Frequency of Disturbances:

The frequency of

disturbances refers to the likelihood of occurrence

within the system. Three levels of frequency are

considered in our paper: very likely, likely, unlikely.

Very Likely: These disturbances are frequent and

can be anticipated. For example, minor delays in the

delivery of materials are common, as are issues

related to the management of spare parts inventories

for equipment used during construction.

Likely: These disturbances occur occasionally

and must be considered in planning. Unfavorable

weather conditions, for example, can temporarily

affect outdoor activities and therefore require

anticipation.

Unlikely: These disturbances are rare and

unpredictable. For example, the discovery of an

archaeological site on the construction area could

require work to be paused for evaluation and taking

specific measures to preserve the historical site,

leading to a significant delay in the progress of the

construction.

Nature of Disturbances:

Before exploring the

different types of disturbances that can affect a

construction site, it's essential to understand the

nature of these disturbances. They can be classified

based on their familiarity and occurrence in previous

projects, as well as their specificity and novelty.

Known & Common: These disturbances are well

identified and have been encountered in the past. Due

to the experience gained, it is often possible to

anticipate them, such as seasonal fluctuations in

productivity due to weather conditions. Moreover,

some disturbances are recurrent and common, like

noise from site activities, requiring the adoption of

measures such as time restrictions for noisy work.

Known & Specific: These disturbances refer to

identified and documented events, often related to

specific technical or organizational aspects. Due to

their predictable nature, these disturbances can be

proactively managed. Examples include delays in the

delivery of essential materials like concrete or

foundations, errors in labor scheduling, or initial

design errors.

New & Specific: Disturbances not previously

experienced can arise due to various factors such as

the introduction of new technologies, regulatory

changes, or unprecedented conditions. For example,

the Covid-19 pandemic perfectly illustrates this type

of disturbance, having forced the construction

industry to adapt its working methods and implement

strict health measures. T1hese new disturbances often

require a significant adaptation period, due to the lack

of prior experience, and can extend project durations.

Source of Disturbances:

Identifying the sources of

disturbances that affect construction sites is crucial.

In this paper, we distinguish between internal and

external disturbances.

Internal: These disturbances typically originate

from the project itself, the organization responsible

for its completion, or the construction processes and

resources involved. Changes in key personnel, such

as resignations or retirements of skilled collaborators,

can significantly influence the progress of the project.

External: These disturbances are caused by

factors outside the project and organization. The

location of the construction site in an urban area, for

example, can pose challenges to material deliveries'

accessibility, with potential delays due to traffic

constraints, parking restrictions, or congestion.

Moreover, introducing new safety or environmental

standards, may require adaptations in the planning

and execution.

ICSBT 2024 - 21st International Conference on Smart Business Technologies

82

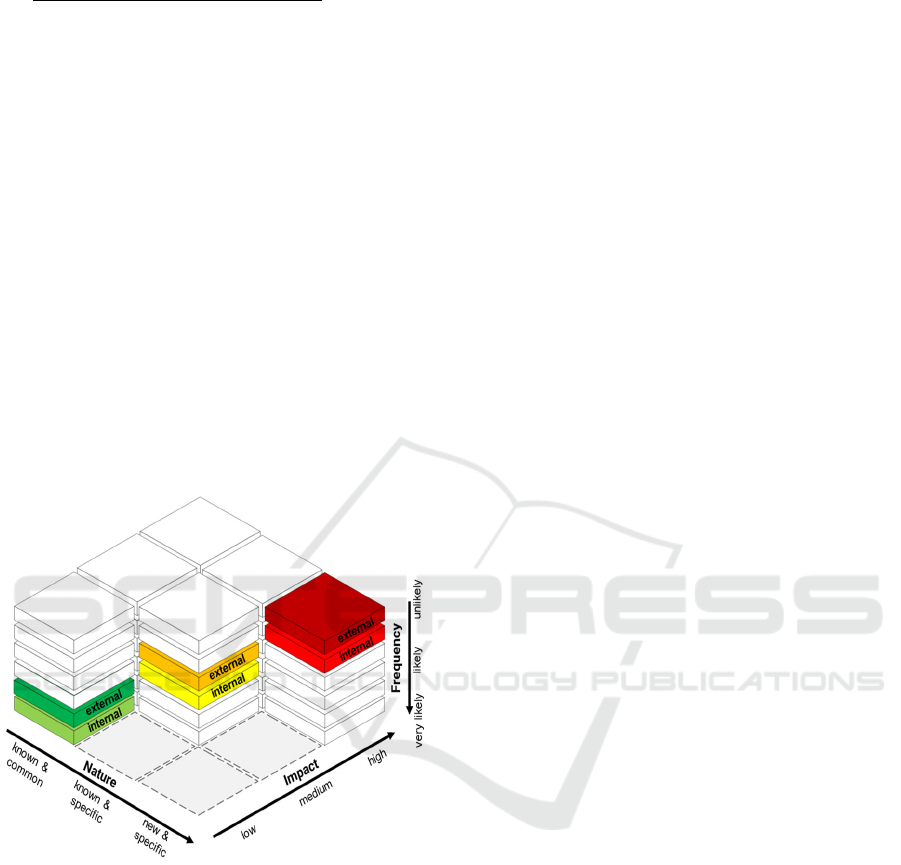

Relationships Between Dimensions: High-impact

disturbances are often unlikely and can occur as a

result of exceptional events. These disturbances can

be of a new and specific nature and originate from

either external or internal sources. In contrast, low-

impact disturbances are often high-frequency, such as

minor delays in material delivery, and are generally

well-known and can occur regularly throughout the

project. These disturbances, resulting from

predictable circumstances, often involve minor

operational adjustments and can originate from both

internal and external sources. Recognizing and

understanding the relationships between these

various types of disturbances is essential. This

understanding not only allows for anticipating events

that may affect a project but also for developing

adapted and effective management strategies, thus

optimizing the site response to disturbances. Figure 1

offers a schematic representation of the different

dimensions characterizing disturbances, as well as the

interdependent relationships between these

dimensions.

Figure 1: Overview of the dimensions of disturbances and

their interactions.

3.2 Propagation of Disturbances

The links between components on a SCS are often

characterized by functional and operational

interdependencies. For example, the use of an

autonomous crane to move essential materials creates

an operational dependency between the crane and the

construction activities that require these materials. In

this interconnected system, a breakdown of the crane

can lead to significant delays in the progress of the

site. If other equipment or activities directly depend

on this crane for their operation, their productivity

could be severely affected. For instance, operators

might find themselves unable to mount prefabricated

structures or move materials to specific areas of the

site. Moreover, the malfunctioning crane could block

access to certain areas, obstructing the movement of

materials and personnel, while posing a potential

safety risk on the site. When a system (components –

links) consists of several interconnected components

through links, any disturbance in one of these

components can potentially propagate through the

network and impact other connected components.

When a component is disturbed, this can trigger a

chain reaction that propagate through the links to

adjacent components. The propagation of the

disturbance can occur in various ways depending on

the system nature and the characteristics of the

disturbance. In some cases, a disturbance may remain

isolated, affecting a single network component

without notable consequences on the entire system.

However, in other cases, an initial disturbance can

lead to cascading failures, disturbing the overall

functioning of the system. This situation is often

triggered by operational disturbances affecting the

construction process. For example, a delay in material

delivery may initially affect a single construction

process step. Nevertheless, this initial disturbance can

quickly propagate further downstream, affecting

other components that depend on the delayed

materials for their operations. This type of cascading

propagation, which reduces the performance of

affected components, is similar to the "Bullwhip"

effect observed in supply chains. Furthermore, some

disturbances have the potential to affect the entire

construction network structure, causing a critical

decrease in the overall system performance. These

major disturbances, such as natural disasters or

systemic failures of key technologies, can paralyze

the entire construction process. This phenomenon, is

similar to the "Ripple" effect in supply chains,

demonstrates the propagation of an initial disturbance

through multiple levels or components of a system,

exacerbating the overall impact on the project (Dolgui

& Ivanov, 2021).

Analyzing the modes of disturbance propagation

in SCS reveals complex dynamics influenced by its

dimensions. These elements interact to determine

how a disturbance can influence the entire

construction system. High-impact, new and specific,

and unlikely disturbances are distinguished by their

capacity to cause significant effects across the entire

construction process network, thus generating the

"Ripple" effect. Their unexpected and specific nature

means they are not easily anticipated by standard risk

management practices. When such disturbances

Framework for Modeling the Propagation of Disturbances in Smart Construction Sites

83

occur, they can rapidly propagate through the

construction network interdependencies, affecting

not only immediate operations but also the overall

project performance. In contrast, disturbances that are

very likely, of low impact, and of a known and

common nature tend to be well understood and

manageable. These disturbances, like minor delivery

delays or short and predictable work interruptions,

can be mitigated through standardized operational

procedures. Their low impact means they can be

addressed without significantly disturbing the entire

construction network. Generally, these events remain

isolated to the component or process step initially

affected, without significant propagation. Medium-

impact, medium-frequency, and known nature

disturbances can trigger the "Bullwhip" effect. This

implies a chain propagation due to the complexity of

interdependencies. A typical example could be a

cumulative delay in a project phase that, while

initially modest, amplifies through subsequent stages

due to operational adjustments. These disturbances

require careful management to limit their

amplification and minimize downstream impacts.

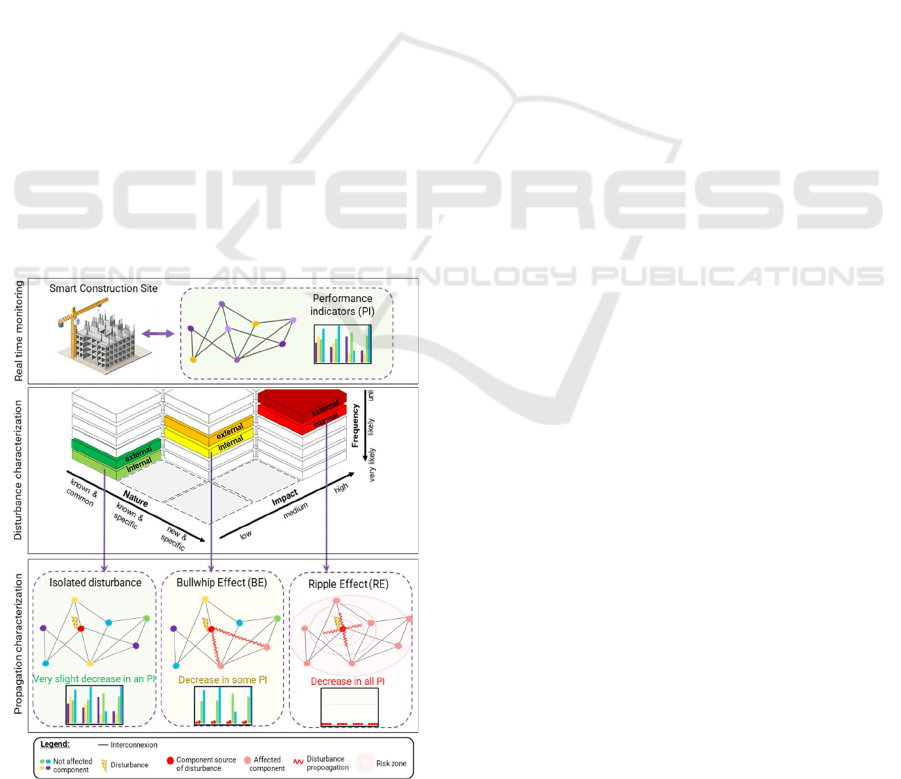

Figure 2 illustrates the conceptual framework

developed to analyze disturbance characteristics

within SCS. This model aids in identifying the nature,

impact, frequency, and source of disturbances, as well

as understanding their mode of propagation and effect

on the performance and continuity of operations in

construction sites.

Figure 2: Framework for disturbance analysis:

characterization and propagation.

4 CASE STUDY

Our case study focuses on the execution of the first

phase of construction of a building. The objective of

this phase is to construct five first-floor walls of the

building under construction. This project is modeled

in FlexSim simulation software v.24.0.1. The model

and the data are available on request. The process

begins with the arrival of bricks. Upon their arrival, a

forklift transports the bricks to a first storage area.

This initial step ensures that the necessary materials

are gathered and ready for the next operation. an

AGV transports autonomously the bricks from the

first storage area to a second zone. This latter is

positioned closer to where the construction work is

carried out, thus optimizing the process by reducing

the material transport time. An autonomous crane

uses the bricks from the second storage area to

precisely build the walls. As the crane progresses in

the construction, an autonomous robot takes over to

complete the finishing touches. Throughout this

process, an operator supervises the construction

operations. This supervisor has the capability to take

manual control of the crane in case of failure.

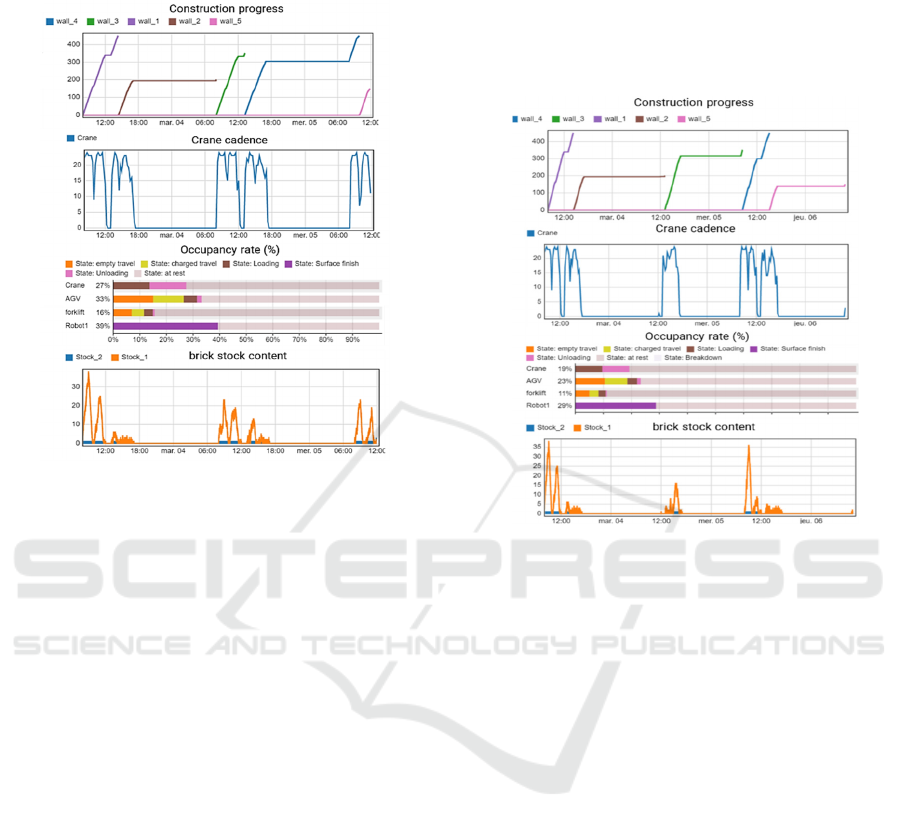

4.1 Scenario Without Disturbances

This section evaluates the model through a series of

simulations to understand how the system operates in

the absence of disturbances, and to establish a

baseline for construction performance. Figure 3

illustrates various key indicators collected during the

simulation, offering a detailed overview of the SCS

operations. The first diagram presents the work

progress. There is a linear progression during

working hours, with notable stops at break times (12-

14h) and outside working hours (17h-8h). This

observation highlights the system efficiency during

active periods, while respecting the need for breaks

for human supervisor and environmental noise-

related constraints. The second diagram shows the

operating cycle of the autonomous crane (i.e., number

of operations per hour). We notice that this indicator

drops to zero outside working hours, as expected.

During active hours, performance fluctuations are

observed, mainly due to changes in trajectory when

moving from one wall to another, which implies a

variation in the distance between stock 2 and the wall

under construction. The third diagram illustrates

occupation status of four components: forklift, AGV,

crane, and robot. The different states of occupation

reveal that the construction site resources are not fully

utilized. The highest utilization rate observed for the

robot is 39%, indicating that activity interruptions

ICSBT 2024 - 21st International Conference on Smart Business Technologies

84

(breaks, end of the day) and the arrival of materials

limit their efficient use.

Figure 3: Key Indicators collected during the simulation

without disturbances.

This suggests that the flow of materials,

particularly the arrival of bricks, constitutes a critical

bottleneck in optimizing the construction site. The

final diagram in the Figure 3 presents the stock

analysis which reveals that storage area 2 is

frequently empty, indicating rapid use of bricks by the

crane. This observation contrasts with stock 1, where

materials may stay longer. The finding that stock 2

acts as a potential bottleneck suggests that increasing

the quantity of bricks in this area could improve the

crane utilisation and, consequently, the use of robot

and progress of construction work.

4.2 Impact of an External Disturbance

This section analyzes the impact of an external

disturbance, specifically an interruption in the brick

supply, on construction operations. This disturbance,

for 4 hours, had significant repercussions on work

progress, resource utilization, and stock levels. Figure

4 illustrates collected indicators during the simulation

with this disturbance.

Impact on work progress (First diagram in Figure

4): The effect becomes evident at the start of the

second day. Wall 2, whose construction had begun on

the first day, was only completed in the afternoon of

the second day, contrary to the normal scenario where

it was expected to be finished at the beginning of the

day. This disturbance caused a ripple effect,

impacting all components and delaying the

construction of subsequent walls and extending the

total duration of work to 73 hours and 54 minutes,

compared to 51 hours and 48 minutes in the normal

scenario without disturbances.

Figure 4: Key Indicators collected during the simulation

with the external disturbance.

Impact on the crane operation (Second diagram in

Figure 4): The operational rate followed the same

pattern as in the normal scenario, with the exception

of the inactivity observed during the morning of the

second day due to the absence of bricks (i.e.,

disturbance impacts the crane efficiency).

Furthermore, the crane was used throughout the third

day and for a short period on the fourth day, showing

an extension of the working time needed to

compensate for the delay caused by the disturbance.

Impact on the resource utilization rate (Third

diagram in Figure 4): Each component of the

construction site experienced a decrease in utilization

rate due to the half-day of inactivity and the extension

of work beyond the initial schedule. This decrease

directly reflects the impact of the disturbance on the

overall efficiency of the construction site,

highlighting the crucial role of continuous material

supply in maintaining an optimal work operation.

Impact on stock levels (Final diagram in Figure

4): Stock levels were directly affected by the supply

interruption. Stock_1 remained empty throughout the

morning of the second day, leading to complete

inactivity of the construction site during this period

and justifying the decrease of resource utilization.

Framework for Modeling the Propagation of Disturbances in Smart Construction Sites

85

This observation confirms that material availability is

a key factor for the continuity of operations.

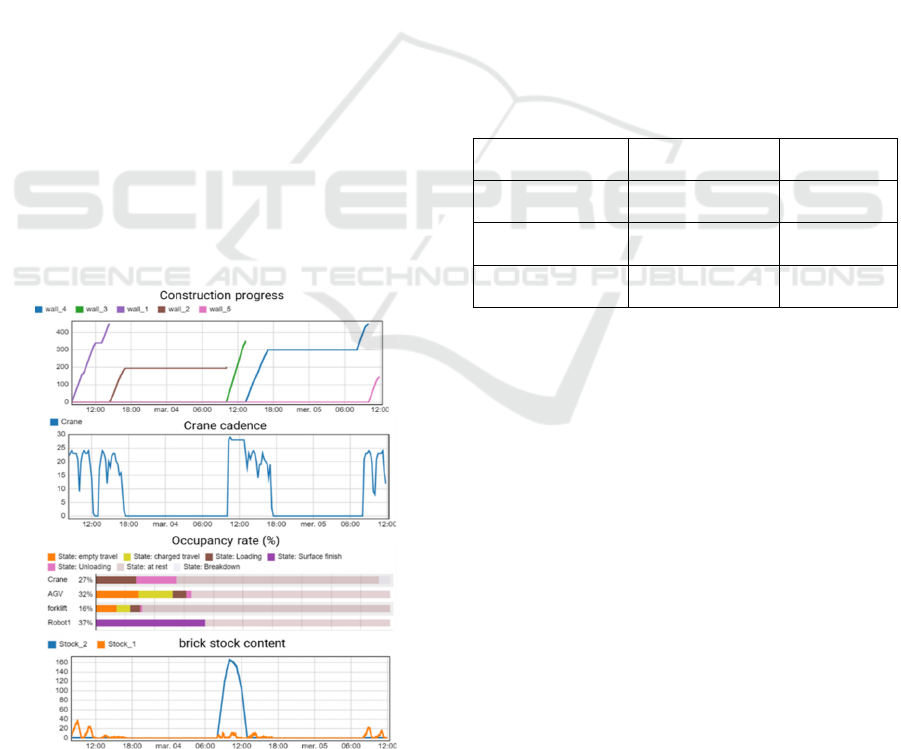

4.3 Impact of an Internal Disturbance

This section analyzes the impact of an internal

disturbance characterized by a two-hour crane

malfunction at the beginning of the second day.

Despite this disturbance, the overall progress of the

construction remained unaffected (see the first

diagram in Figure 5). The disturbance impacted the

construction of the second wall, as it occurred early

in the second day. This disturbance did not propagate

across the subsequent construction activities due to

the crane high capacity and the uninterrupted material

flow from the source to stock_2, resulting in an

accumulation of bricks in stock_2 awaiting crane

repair. Once operational, the crane high capacity

enabled it to quickly catch up on the delay, ensuring

no downstream delay in construction activities and

maintaining the project completion within the

original calendar, which is 51 hours and 48 minutes.

After the crane was repaired, its operational rate

increased notably due to the accumulated bricks in

stock_2 (see the second diagram in Figure 5),

demonstrating the crane capability to compensate for

the lost time. This scenario demonstrates that the

perturbation has an isolated nature, as it did not

significantly affect the utilization rates of other

resources (see the third diagram in Figure 5).

Figure 5: Key Indicators collected during the simulation

with the internal disturbance.

4.4 Discussion

This case study illustrates how the nature, duration,

and impact of disturbances vary their propagation

effects within SCS. In the scenario related to a

disturbance on the brick supply, this external event

propagated through the system, causing a ripple

effect. This disturbance affected not only the supply

of materials but also the operational efficiency of key

components, extending the total construction time

significantly beyond the initial schedule. In contrast,

the second disturbance, internal in nature, remained

nearly isolated to a single system component without

significant propagation. Despite temporarily

breakdown of the crane, the system inherent capacity

and uninterrupted material flow allowed for a quick

recovery. Table 1 compares the different scenarios

studied in relation to the total duration of the project

and the propagation effects. In brief, this analysis

underscores the critical role of disturbance

characteristics in determining their propagation and

impact within a SCS.

Table 1: Comparison of scenarios.

Scenario

Project total

duration

Disturbance

propagation

Normal operation

51 hours and 48

minutes

No

disturbance

External

disturbance

73 hours and 54

minutes

Ripple effect

p

ro

p

a

g

ation

Internal

disturbance

51 hours and 48

minutes

Isolated

distrubance

5 CONCLUSION

The construction industry is transforming

significantly towards Construction 4.0, integrating

innovative technologies. Our study on Smart

Construction Sites (SCS) highlights the complex

dynamics of disturbances and their propagation,

proposing a comprehensive framework. Our study on

SCS highlights the complex dynamics of disturbances

and their propagation, proposing a comprehensive

framework. Our findings show that disturbance

impact, frequency, nature, and source greatly

influence their effects. Using FlexSim, we provided

key insights into operational interdependencies and

impact of disturbances on construction operations. An

external disturbance, like a brick supply delay, caused

a ripple effect, impacting material supply and

operational efficiency, extending construction time.

In contrast, an internal disturbance, such as a crane

malfunction, remained isolated with minimal

ICSBT 2024 - 21st International Conference on Smart Business Technologies

86

propagation due to the system's quick recovery

capabilities. Several avenues for further research

emerge from this study. Firstly, we need propose

methodologies to evaluate and quantify the negative

consequences of disturbance propagation to identify

potential bottlenecks in construction operations.

Secondly, quick decision-making strategies need to

be developed, enabling just-in-time actions that can

mitigate the effects of disturbances effectively. It is

also essential to consider the technological capacity

of SCS in our reaction strategies. For example,

incorporating redundancy of critical elements or

utilizing multi-task intelligent elements can

significantly enhance the system’s capacity to

respond to disturbances. The comparison of these

reaction approaches with existing risk management

approaches in complex systems will provide valuable

insights. Finally, real construction site

implementation and experimentation are necessary to

validate the findings and refine the proposed model.

REFERENCES

Afzal, F., Yunfei, S., Nazir, M., & Bhatti, S. M. (2021). A

review of artificial intelligence based risk assessment

methods for capturing complexity-risk

interdependencies: Cost overrun in construction

projects. International Journal of Managing Projects in

Business, 14(2), 300–328.

Akanmu, A. A., Anumba, C. J., & Ogunseiju, O. O. (2021).

Towards next generation cyber-physical systems and

digital twins for construction. Journal of Information

Technology in Construction, 26.

Attajer, A., Chaabane, S., Darmoul, S., Sallez, Y., & Riane,

F. (2022). Evaluation of Operational Resilience in

Cyber-Physical Production Systems : literature review.

IFAC-PapersOnLine, 22–27.

Attajer, A., Darmoul, S., Chaabane, S., Riane, F., & Sallez,

Y. (2021). Benchmarking Simulation Software

Capabilities Against Distributed Control Requirements:

FlexSim vs AnyLogic. In T. Borangiu, D. Trentesaux,

P. Leitão, O. Cardin, & S. Lamouri (Eds.), SOHOMA

2020: Vol. SCI 952 (pp. 520–531). Springer Nature

Switzerland AG 2021. https://doi.org/10.1007/978-3-

030-69373-2_38

Attajer, A., Darmoul, S., Riane, F., & Bouras, A. (2019).

Distributed Maintenance : A Literature Analysis and

Classification. In IFAC (Ed.), 9th IFAC Conference on

Manufacturing Modelling, Management and Control,

MIM2019. 9th IFAC Conference on Manufacturing

Modelling, Management and Control, MIM2019.

Dolgui, A., & Ivanov, D. (2021). Ripple effect and supply

chain disruption management: new trends and research

directions. International Journal of Production

Research, 59(1), 102–109.

Dolgui, A., Ivanov, D., & Rozhkov, M. (2020). Does the

ripple effect influence the bullwhip effect? An

integrated analysis of structural and operational

dynamics in the supply chain. International Journal of

Production Research, 58(5), 1285–1301.

Dziadosz, A., & Kończak, A. (2016). Review of selected

methods of supporting decision-making process in the

construction industry. Archives of Civil Engineering,

62(1), 111–126.

Kikwasi, G. (2012). Causes and effects of delays and

disruptions in construction projects in Tanzania.

Australasian Journal of Construction Economics and

Building-Conference Series, 1(2), 52–59.

Love, P. E. D., & Matthews, J. (2020). Quality, requisite

imagination and resilience: Managing risk and

uncertainty in construction. Reliability Engineering &

System Safety, 204, 107172.

Meszek, W., Rejment, M., & Dziadosz, A. (2019).

Disturbance Analysis and Their Impact on Delays in

Construction Process. IOP Conference Series:

Materials Science and Engineering, 603(5), 52002.

Muñoz-La Rivera, F., Mora-Serrano, J., Valero, I., &

Oñate, E. (2021). Methodological-technological

framework for construction 4.0. Archives of

Computational Methods in Engineering, 28, 689–711.

Peñaloza, G. A., Saurin, T. A., & Formoso, C. T. (2020).

Monitoring complexity and resilience in construction

projects: The contribution of safety performance

measurement systems. Applied Ergonomics, 82,

102978.

Rao, A. S., Radanovic, M., Liu, Y., Hu, S., Fang, Y.,

Khoshelham, K., Palaniswami, M., & Ngo, T. (2022).

Real-time monitoring of construction sites: Sensors,

methods, and applications. Automation in Construction,

136, 104099.

Sepasgozar, S. M. E., Khan, A. A., Smith, K., Romero, J.

G., Shen, X., Shirowzhan, S., Li, H., & Tahmasebinia,

F. (2023). BIM and Digital Twin for Developing

Convergence Technologies as Future of Digital

Construction. Buildings, 13(2), 441.

Wang, M., Wang, C. C., Sepasgozar, S., & Zlatanova, S.

(2020). A systematic review of digital technology

adoption in off-site construction: Current status and

future direction towards industry 4.0. Buildings, 10(11),

204.

Zarghami, S. A., & Zwikael, O. (2023). Buffer allocation in

construction projects: a disruption mitigation approach.

Engineering, Construction and Architectural

Management.

Zhang, H., & Yu, L. (2021). Resilience-cost tradeoff supply

chain planning for the prefabricated construction

project. Journal of Civil Engineering and Management,

27(1), 45–59.

Zhao, Y., Chen, W., Arashpour, M., Yang, Z., Shao, C., &

Li, C. (2022). Predicting delays in prefabricated

projects: SD-BP neural network to define effects of risk

disruption. Engineering, Construction and

Architectural Management, 29(4), 1753–1776.

Framework for Modeling the Propagation of Disturbances in Smart Construction Sites

87