Anomaly Detection in Industrial Production Products Using OPC-UA

and Deep Learning

Henry O. Velesaca

1,2

, Dom

´

enica Carrasco

1

, Dario Carpio

1

, Juan A. Holgado-Terriza

2

,

Jose M. Gutierrez-Guerrero

3

, Tonny Toscano

1

and Angel D. Sappa

1,4

1

ESPOL Polytechnic University, Escuela Superior Polit

´

ecnica del Litoral, ESPOL, Campus Gustavo Galindo Km. 30.5 V

´

ıa

Perimetral, P.O. Box 09-01-5863, Guayaquil, Ecuador

2

Software Engineering Department, University of Granada, 18014, Granada, Spain

3

Abbott Laboratories, 18004, Granada, Spain

4

Computer Vision Center, 08193-Bellaterra, Barcelona, Spain

Keywords:

Anomaly Detection, Industry 4.0, Deep Learning, OPC-UA, YOLO v8.

Abstract:

In the realm of industrial manufacturing, detecting defects in products is critical for maintaining quality. Tra-

ditional methods relying on human inspection are often error-prone and time-consuming. However, advance-

ments in automation and computer vision have led to smarter industrial control systems. This paper explores a

novel approach to identifying defects in industrial processes by integrating OPC-UA and YOLO v8. OPC-UA

provides a secure communication standard, enabling seamless data exchange between devices, while YOLO

v8 provides accurate object detection. By combining these technologies, manufacturers can monitor produc-

tion lines in near real-time, analyze defects promptly, and take corrective actions. As a result, product quality

and operational efficiency are improved. A case study involving tinplate lid defect detection demonstrates

the effectiveness of the proposed approach. The system architecture, including PLC integration, image ac-

quisition, and YOLO v8 implementation, is detailed, followed by the performance evaluation of the OPC-UA

server and YOLO v8 model integration. Results indicate efficient communication with low Round Trip Times

and End-to-End delay, highlighting the potential of this approach for defect detection. The code is available

at GitHub: https://github.com/hvelesaca/OPC-UA-YOLOv8-Lid-Anomaly-Detection, facilitating further re-

search.

1 INTRODUCTION

In the highly competitive landscape of industrial man-

ufacturing, the timely detection and correction of

defects in products are critical to maintaining high

standards of quality and operational efficiency (e.g.,

(Huang et al., 2017), (Monteiro et al., 2019)). Tra-

ditionally, this process has relied heavily on human

inspection, which can be error-prone and limited in

terms of speed and accuracy (Montgomery, 2019).

However, with advancements in automation technol-

ogy and computer vision, it has become possible

to implement smarter and more effective industrial

control systems ((Verkhivker et al., 2020), (Dey and

Agrawal, 2016)).

In recent years, advances in industrial communi-

cation protocols have transformed the way quality as-

sessments are performed in smart factories. These

protocols enable smooth data exchange and commu-

nication among various elements of the manufactur-

ing process, such as sensors, machinery, and quality

control systems (Zheng et al., 2018). By harnessing

these protocols, manufacturers can monitor produc-

tion processes in real-time, analyze them for potential

defects or anomalies, and swiftly implement correc-

tive measures to uphold product quality and regula-

tory standards (Li et al., 2018).

This article focuses on exploring an innova-

tive methodology for identifying defects in indus-

trial manufacturing, leveraging two key technolo-

gies: OPC-UA (Foundation, 2023) (Open Platform

Communications Unified Architecture) and YOLO v8

(Jocher et al., 2023) (You Only Look Once version

8). OPC-UA offers a robust and secure communica-

tion standard that facilitates interoperability between

different devices and systems in the industrial envi-

ronment. On the other hand, YOLO v8 is a cutting-

edge object detection model in the field of computer

Velesaca, H., Carrasco, D., Carpio, D., Holgado-Terriza, J., Gutierrez-Guerrero, J., Toscano, T. and Sappa, A.

Anomaly Detection in Industrial Production Products Using OPC-UA and Deep Learning.

DOI: 10.5220/0012812600003756

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 13th International Conference on Data Science, Technology and Applications (DATA 2024), pages 505-512

ISBN: 978-989-758-707-8; ISSN: 2184-285X

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

505

vision, known for its speed and accuracy in identify-

ing objects in images and videos.

In this context, we will explore how the integra-

tion of OPC-UA and YOLO v8 into industrial control

systems can significantly improve the ability to detect

and classify defects in real-time, enabling a faster and

more efficient response to any anomalies in the manu-

facturing process. In addition, this work will examine

case studies and practical applications that illustrate

the benefits and potential limitations of this method-

ology, as well as future opportunities for its develop-

ment and widespread adoption in the industry.

To address this work in detail, the manuscript is

organized as follows. Section 2 introduces some re-

lated works on the use of OPC-UA, image identifica-

tion, and the use of deep learning techniques within

industrial processes. Section 3 presents the proposed

approach to carry out the integration of OPC-UA and

deep learning techniques. Then, section 4 shows the

experimental results taking as reference a case study

for the detection of anomalies in tinplate lids. Finally,

conclusions are presented in Section 5.

2 BACKGROUND

As described previously, this paper presents an ap-

proach showing the integration of industrial control

systems using OPC-UA and deep learning techniques

as key elements. This section summarizes some of

the most relevant techniques related to the topic of

this work.

2.1 OPC-UA Overview

OPC-UA (Open Platform Communications Unified

Architecture) is a communication standard widely

used in industrial environments to facilitate interoper-

ability between different devices, systems, and soft-

ware platforms. Designed to address connectivity

challenges in modern industrial environments, OPC-

UA provides a robust and secure platform for near

real-time data exchange and heterogeneous system in-

tegration.

However, OPC-UA is not only a communication

protocol, but also allows other tasks to be carried

out, such as, for example, providing a specification

for Alarms (OPC-UA Part 9: Alarms and Conditions)

which is a specific part of the OPC-UA standard that

focuses on alarm and condition management in indus-

trial environments. This standard specifies the guide-

lines for modeling, triggering, managing, and moni-

toring alarms and conditions in automation and con-

trol systems. It also includes a part (OPC-UA Part 11:

Historical Access) which focuses on accessing and

retrieving historical data stored on OPC-UA servers.

This enables client applications to use historical in-

formation for analysis, reporting, trending, and other

applications in industrial environments.

The study presented by (Georgi Martinov, 2017)

demonstrates the use of the OPC-UA protocol for

monitoring equipment with different kinematics. It

highlights data acquisition from a CNC system, in-

cluding motor positions, linear encoder readings,

and electroautomatic device signals. The implemen-

tation does not require a separate adapter for the

OPC server. Additionally, OPC-UA enables effi-

cient client-side data retrieval through the ”Publisher-

Subscriber” model, allowing modifications to the

kinematic schema. However, challenges may arise

from network connectivity issues and the availabil-

ity of OPC-UA servers in unreliable network environ-

ments.

Furthermore, (Nedeljkovic and Jakovljevic, 2020)

addressed an issue in a manufacturing cycle using

a ”pick and place” system controlled by an Om-

ron CP1L-EM40DT-D PLC. The problem emerges

from components frequently entering the system in-

correctly positioned. To resolve this, communication

between the vision sensor and the handling system

was established using the OPC-UA standard. This al-

lowed the transmission of information about the parts’

orientation and signaled the sensor when the manipu-

lator was ready to receive data from the camera. Im-

plementing OPC-UA provided the advantage of eas-

ily exchanging the smart vision sensor without repro-

gramming or modifying the wiring. However, transi-

tioning from a previous OPC DA server introduced

complexities, leading to the use of OPC Expert to

adapt functionalities to the OPC-UA standard.

On the other hand, the paper presented by (Sch

¨

afer

et al., 2022) outlines an architecture for integrating

reinforcement learning (RL) into industrial environ-

ments to optimize operations and enhance decision-

making, with a key emphasis on the use of OPC-UA

for seamless and secure data exchange. The frame-

work includes real-time data collection from sensors

and IoT devices via OPC-UA, preprocessing of this

data, and training of RL models that learn optimal

strategies through continuous interaction with the en-

vironment. Once trained, these models are deployed

within the industrial control system to make real-

time decisions. The system also incorporates moni-

toring and feedback mechanisms to continuously im-

prove and retrain the models, ensuring adaptability

and scalability for various industrial applications, ul-

timately leading to more intelligent and autonomous

processes.

DATA 2024 - 13th International Conference on Data Science, Technology and Applications

506

Finally, based on object-oriented principles,

Gutierrez et al. (Gutierrez-Guerrero and Holgado-

Terriza, 2017) propose a metamodel iMMAS for

conceptualizing industrial automation systems. This

metamodel includes a concrete syntax and specific

semantics that simplify the development and deploy-

ment of manufacturing control systems. In these sys-

tems, the models can be transformed into PLC pro-

grams and OPC-UA data models.

2.2 Object Recognition

Object recognition in industrial environments has

emerged as a powerful tool to improve efficiency,

quality, and safety in a wide range of industrial ap-

plications. With the advancement of computer vision

technology and deep learning, companies are increas-

ingly leveraging the ability of machines to visually

analyze and understand their work environment. On

the other hand, object recognition in industrial envi-

ronments involves the use of machine learning algo-

rithms and models to recognize specific objects, pat-

terns, or features in images captured by cameras or

vision devices. These systems can detect product de-

fects, monitor equipment performance, perform qual-

ity inspections, and more.

For example, the paper by (Dominguez et al.,

2006) addresses the complexities of object recogni-

tion and inspection in challenging industrial environ-

ments. They use advanced computer vision tech-

niques, particularly the YOLO v8 convolutional neu-

ral network, to enhance object detection and clas-

sification in real-time. YOLO v8’s capabilities en-

able fast and accurate detection even under adverse

conditions, improving industrial inspection processes.

However, challenges such as the need for diverse

training datasets, adaptation to varying environmen-

tal conditions, and computational resource require-

ments may hinder successful implementation. Ad-

ditionally, expertise in parameter fine-tuning is cru-

cial for achieving optimal results in practical indus-

trial settings.

On the other hand, the paper by (Rocha et al.,

2014) introduces a cascade system designed for ob-

ject recognition and pose estimation in industrial set-

tings. This system comprises several stages, starting

with object detection using deep learning techniques

such as YOLO, followed by pose estimation algo-

rithms to determine object orientation. By integrat-

ing these methods, the system demonstrates robust

performance in identifying and accurately estimating

object poses, thus enhancing automation and quality

control processes in industries. However, challenges

may arise due to occlusions, lighting variations, and

complex backgrounds, potentially impacting the ac-

curacy and reliability of object recognition and pose

estimation. Moreover, the computational complexity

of the cascade system may necessitate efficient hard-

ware resources for real-time deployment in industrial

environments.

2.3 Deep Learning Within Industrial

Systems

The advancement of artificial intelligence, especially

in the field of deep learning, has opened new fron-

tiers in the optimization and automation of industrial

systems. In this context, the use of deep learning

techniques within industrial systems is gaining more

and more relevance due to its ability to process large

amounts of data, identify complex patterns, and im-

prove operational efficiency. This article explores the

impact and applications of deep neural networks in in-

dustrial environments, highlighting their potential to

improve quality, predict failures, optimize processes,

and reduce production costs.

The authors propose various deep learning tech-

niques for fault diagnosis in industrial environments,

emphasizing their ability to identify unique patterns

and ensure accurate, timely detection. Challenges in-

clude interpreting model results and integrating them

with existing monitoring systems. For example, the

work presented by (Surendran et al., 2022) highlight

the effectiveness of deep learning in analyzing large

data sets for early fault detection but notes the high

demand for training data and computational complex-

ity. On the other hand, the article presented by (Iqbal

et al., 2019) address fault detection and isolation, un-

derscoring the capability of deep learning models to

detect complex patterns but also recognizing the need

for extensive data and significant computational re-

sources. The work presented by (S

´

anchez Santalices

et al., 2023) demonstrate neural network implementa-

tion for tray anomaly detection, capable of identifying

irregular patterns for early problem detection. How-

ever, the need for representative training data and the

potential for false positives or negatives necessitate

careful model optimization and tuning.

3 PROPOSED APPROACH

This section details the different stages of the pro-

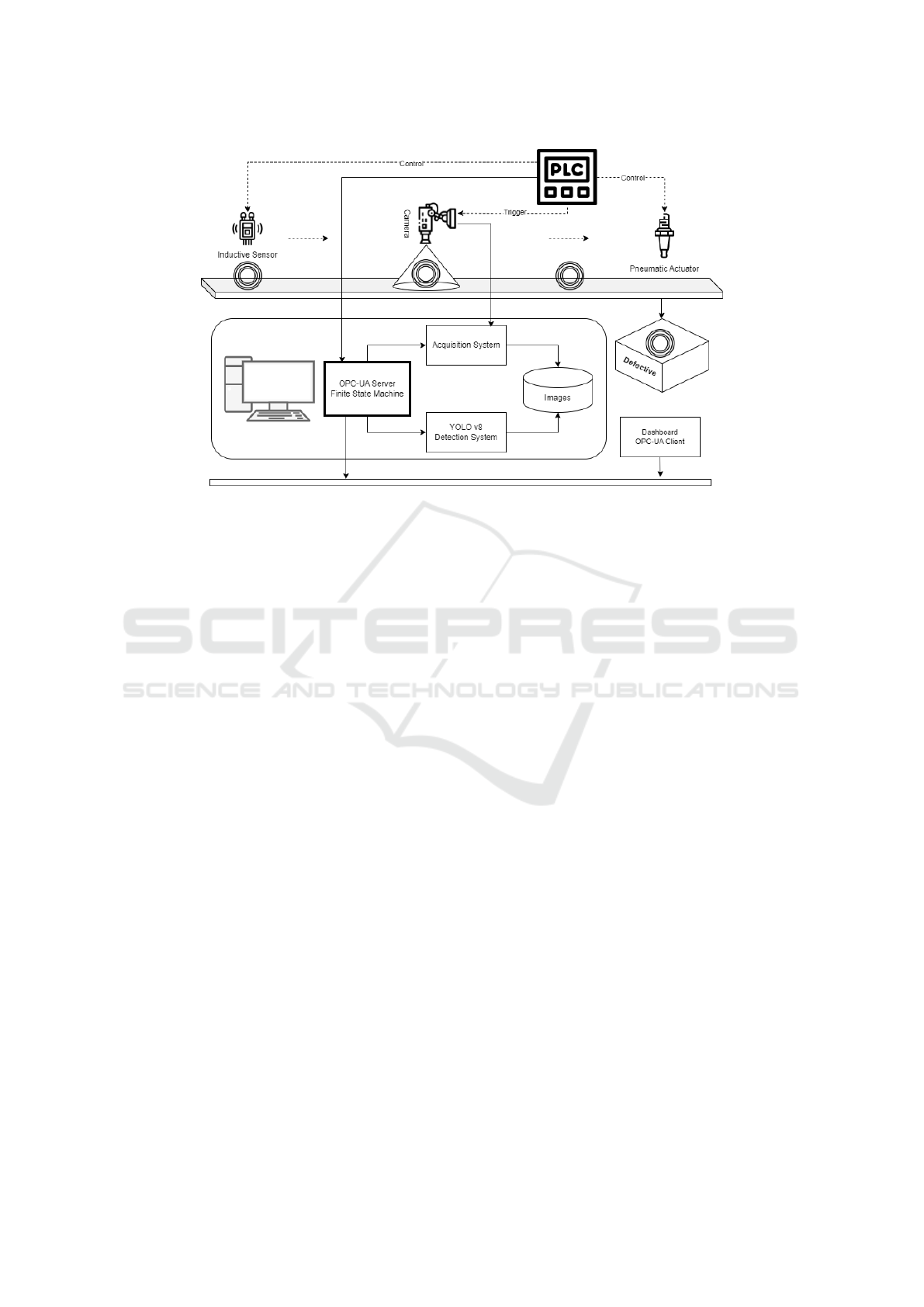

posed approach. Figure 1 shows the system architec-

ture of the proposed approach. The system architec-

ture is based on a hierarchical industrial system with

three layers: a) the control layer where the main PLC

subsystem is in charge of controlling the plant; b) the

Anomaly Detection in Industrial Production Products Using OPC-UA and Deep Learning

507

Figure 1: General outline of the proposed system architecture in this paper.

supervision layer where the main OPC-UA subsystem

is responsible for retrieving the plant status, the im-

age acquisition from the camera and the application

of anomaly detector based on a deep neural network;

and, finally, c) the visualization layer where operators

can examine the evolution of the plant using a dash-

board.

3.1 System Description

The evaluation of the proposal is based on a case

study of a tinplate lid failure detection system. For

the architecture proposed in this work, a conveyor

belt, a PLC, and an inductive sensor are used to detect

the passage of the lids. In addition, a vision system

consisting of an industrial camera with a lighting sys-

tem is used. In addition, the camera is connected to

a workstation which also allows the execution of the

OPC-UA Server and the deep neural network.

3.2 OPC-UA Server

In our proposal, the integration of an OPC-UA server

in the defect detection system in industrial processes

plays a crucial role by providing a unified and secure

interface for near real-time data collection. By lever-

aging the interoperability and security capabilities of

OPC-UA, it can ensure the integrity and reliability of

data collected from different devices and systems on

the plant floor. This integration allows for continuous

and efficient process monitoring, providing a solid ba-

sis for defect detection.

3.3 YOLO v8

The neural network selected to be used in the image

identification component of the detection subsystem

is YOLO v8 (Jocher et al., 2023). It is selected for its

efficiency and speed in detecting objects in images,

which makes it suitable for real-time applications in

industrial environments where fast responses are re-

quired. Additionally, its ability to identify multiple

objects in a single pass makes it ideal for identifying

defects in industrial products with multiple irregular-

ities. YOLO v8 also offers a deep and flexible archi-

tecture that allows easy adjustment and optimization

to adapt to different lighting conditions, viewing an-

gles, and defect types. This makes it a viable option to

address the complexity and diversity of defect detec-

tion challenges in industrial environments. Finally, it

is open source and its extensive developer community

makes it easy to implement and long-term maintain

YOLO v8-based defect detection systems.

3.4 Integration of OPC-UA Server and

YOLO v8

Combining the OPC-UA server with advanced defect

detection algorithms, such as YOLO v8, the system’s

ability to identify and classify defects in near-real-

time can significantly be improved. By using accurate

and timely data provided by the OPC-UA server, de-

tection algorithms can be effectively trained and tuned

to recognize a wide range of defects with high accu-

racy. The integration of these technologies offers a

DATA 2024 - 13th International Conference on Data Science, Technology and Applications

508

comprehensive and effective approach to improving

quality and efficiency in industrial processes. This

approach simultaneously reduces downtime and pro-

duction costs.

3.5 Metric Evaluation

For the evaluation of the proposed work, Round Trip

Time (RTT) and End-to-End delay metrics will be

calculated to establish the performance of the server.

RTT is a measure of the amount of time it takes for a

data packet to travel from the source point to the desti-

nation and then return to the source. E2E refers to the

time it takes for information to travel from its source

to its destination in a networked system. These mea-

surements are important in evaluating network perfor-

mance as it directly affect the communication speed

and responsiveness of online applications and ser-

vices. Both metrics are commonly used in computer

networks to evaluate latency or network response time

(Eckhardt and M

¨

uller, 2019).

4 CASE STUDY

This section presents the case study experimental re-

sults obtained with the proposed framework. For per-

formance evaluation of the proposed approach, RTT

and E2E measurements are used.

4.1 System Implementation

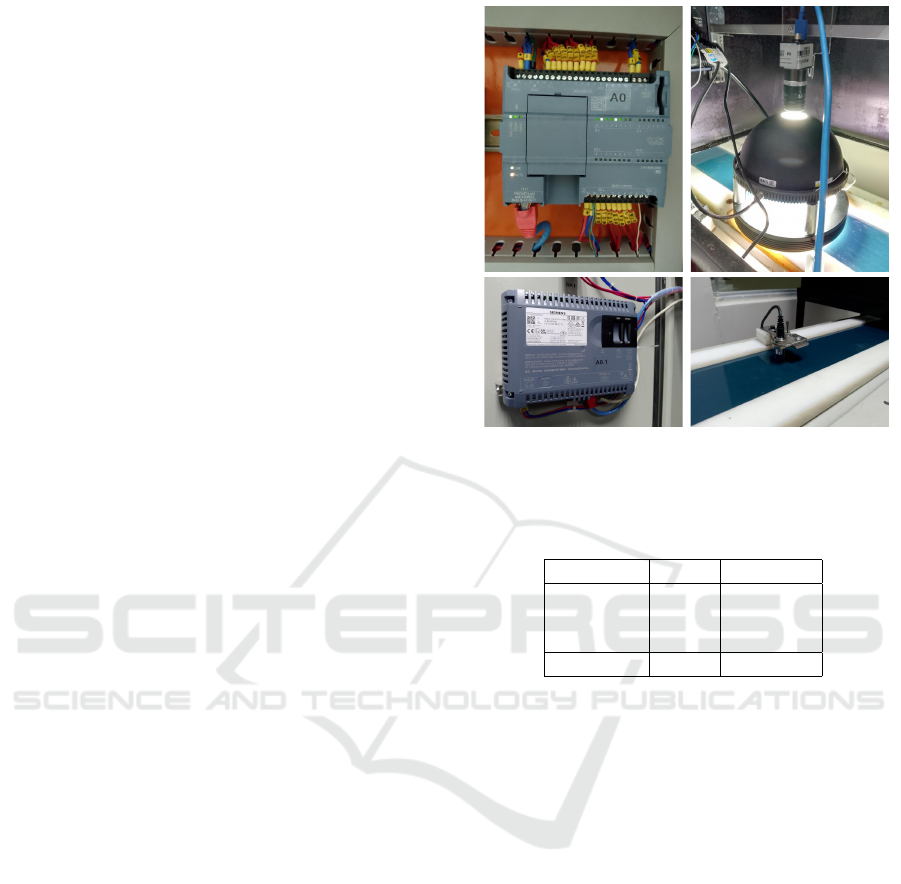

In consideration of the system architecture depicted

in Figure 1, a system implementation for the detec-

tion of manufacturing defects in tin lids within a fac-

tory is presented. As the main element, a Siemens

S7 1200 PLC is used in the control layer. Addition-

ally, a vision system consisting of an Industrial Vis-

ible Spectrum Camera is used along with a lighting

system. The system also has an Inductive Sensor used

to detect the lids on the conveyor belt. For the supervi-

sion layer, a workstation is used with an Intel Core I9

3.3GHz CPU and NVIDIA Titan XP GPU for training

and testing YOLO v8 for the identification of images.

It is responsible for acquiring the images and also for

running the OPC-UA Server and YOLO v8. Figure 2

shows the main components used in the system archi-

tecture.

4.2 Image Acquisition

As a first step, the acquisition of images of tin lids in

good and defective condition is established. Among

the most common defects are scratches, dents, and

Figure 2: (top-left) Siemens S7 1200 PLC. (bottom-left)

HMI TP700 comfort. (top-right) Vision system and lighting

system. (bottom-right) Inductive Sensor.

Table 1: Distribution of data acquisition.

Task Good Defective

Training 457 588

Validation 85 112

Testing 29 36

Total 571 736

lack of rubber on the inside edge. Table 1 shows the

distribution of data used for the training, validation,

and testing stages used by YOLO v8 in a later stage.

4.3 OPC-UA Server Implementation

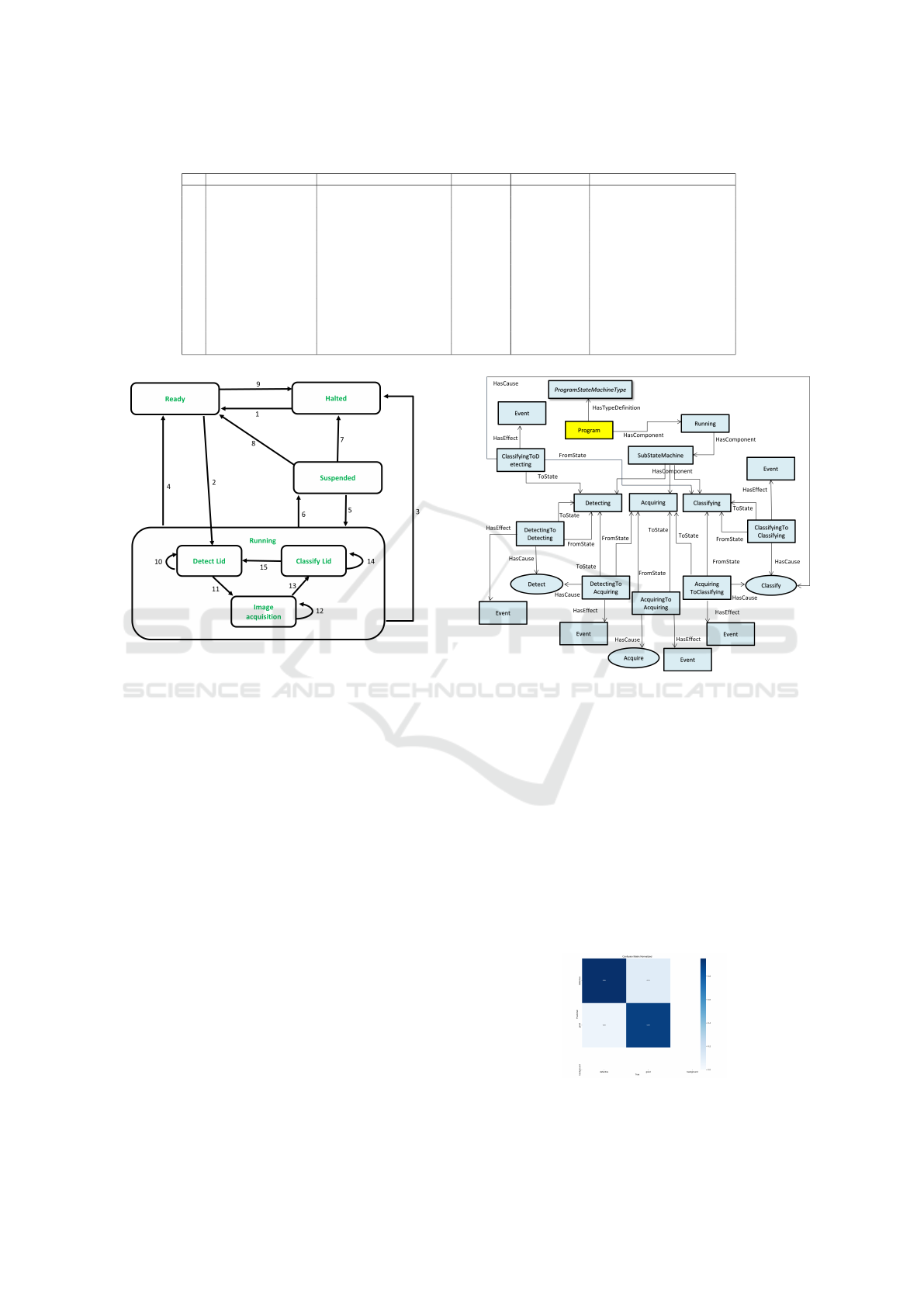

The next step is the implementation of the OPC-UA

server for which the design of the finite state ma-

chine (FSM) specified in Part 16 of OPC-UA has been

defined (see Figure 3). Also to create the OPC-UA

server, the behavior model has been defined based on

the FSM and using the methodology proposed by (Ve-

lesaca et al., 2024). Starting from the model created

in Figure 4 and with the help of the Free OPC-UA

Modeler (FreeOpcUa, 2 28), the OPC-UA server is

created in XML format.

After obtaining the model in XML format, the

next step is deploying the server. The language

used is Python, so to carry out the deployment of

the OPC-UA server, two files are created: Server.py

and Utils.py. The file Server.py contains the general

structure of the server and defines a class that rep-

resents OPC-UA programs, specifically implements

the methods that contain the behavior of the FSM,

Anomaly Detection in Industrial Production Products Using OPC-UA and Deep Learning

509

Table 2: Finite State Machine transitions of the system.

No Name Transition Cause Origin State Destination State Effect

1 HaltedToReady Reset Method Halted Ready Report Transition 1 Event/Result

2 ReadyToRunning Start Method Ready Running Report Transition 2 Event/Result

3 RunningToHalted Halt Method or Internal (Error) Running Halted Report Transition 3 Event/Result

4 RunningToReady Internal Running Ready Report Transition 4 Event/Result

5 RunningToSuspended Suspend Method Running Suspended Report Transition 5 Event/Result

6 SuspendedToRunning Resume Method Suspended Running Report Transition 6 Event/Result

7 SuspendedToHalted Halt Method Suspended Halted Report Transition 7 Event/Result

8 SuspendedToReady Internal Suspended Ready Report Transition 8 Event/Result

9 ReadyToHalted Halt Method Ready Halted Report Transition 9 Event/Result

10 DetectingToDetecting Internal Detecting Detecting Report Transition 10 Event/Result

11 DetectingToAcquiring Internal Detecting Acquiring Report Transition 11 Event/Result

12 AcquiringToAcquiring Internal Acquiring Acquiring Report Transition 12 Event/Result

13 AcquiringToClassifying Internal Acquiring Classifying Report Transition 13 Event/Result

14 ClassifyingToClassifying Internal Classifying Classifying Report Transition 14 Event/Result

15 ClassifyingToDetecting Internal Classifying Detecting Report Transition 15 Event/Result

Figure 3: Finite State Machine for defect detection system

in tinplate lids.

and uses the semantics offered by OPC-UA to vali-

date transitions between states which are defined in

the Table 2. Utils.py file contains additional functions

for server creation. The last step is the execution of

the server.

4.4 YOLO v8 Implementation

As a first step before starting the training phase, it

is decided to increase the number of examples for

training, for which the Albumentations library is used.

This library allows for data augmentation and is com-

monly used in computer vision tasks, such as training

object detection models such as YOLO v8. Albumen-

tations offers a wide range of image transformations,

such as cropping, rotations, brightness, and contrast

changes, among others. These transformations can

be applied in a random and controlled manner dur-

ing preprocessing of the training data, generating ad-

ditional instances of the original images with realistic

variations.

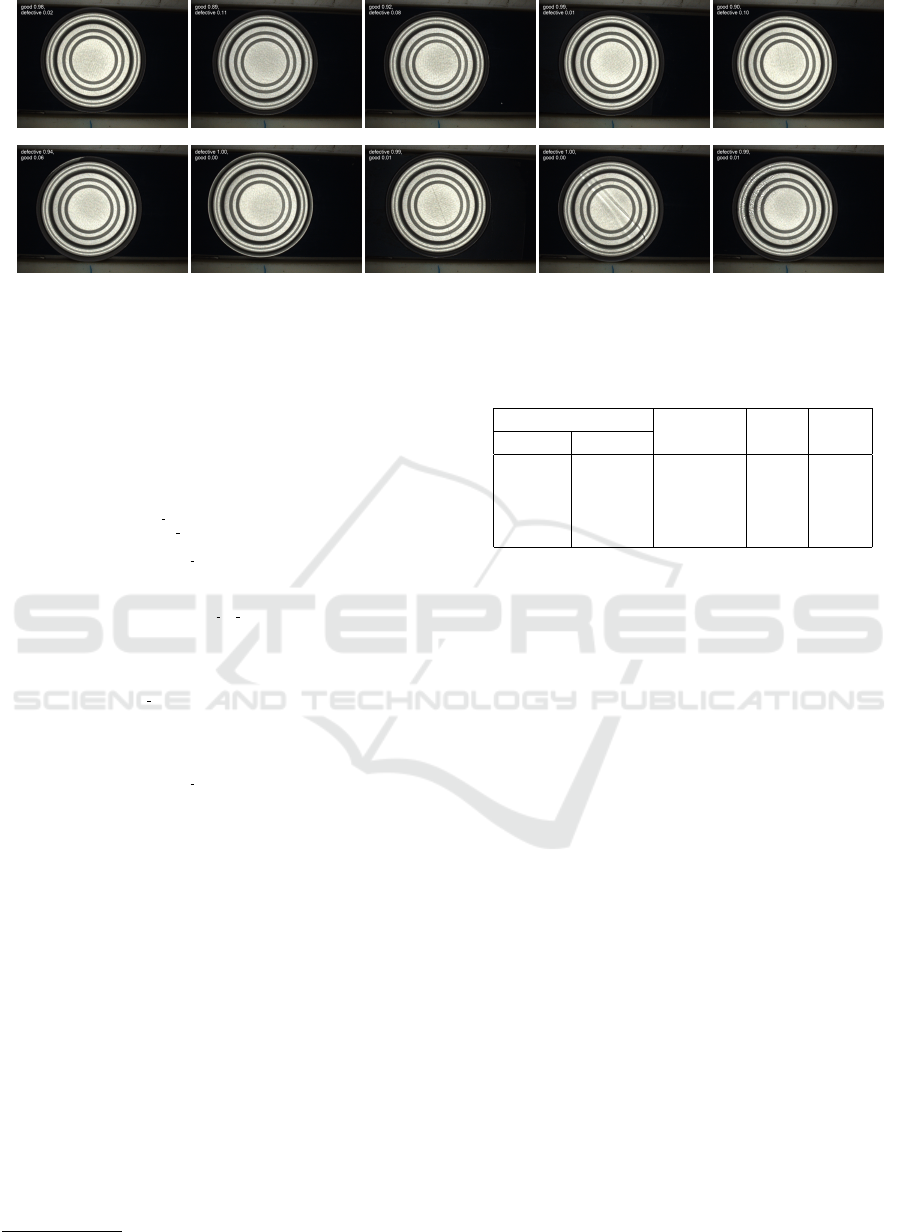

Figure 5 shows the execution code using con-

sole mode with YOLO v8 for the classification task.

Figure 4: Behavior model in OPC-UA notation (Velesaca

et al., 2024).

$ yolo classify train data="dataset/" \

model=yolov8m-cls.pt epochs=500 imgsz=640

Figure 5: Code executed to training data with YOLO v8.

The model ”yolov8m-cls.pt” and 500 training epochs

are used as execution parameters. After completing

the training/validation tasks, the normalized confu-

sion matrix shown in Figure 6 is obtained as a result.

Furthermore, an accuracy of 93% is obtained.

For the testing task, the code shown in Figure 8

is used. Additionally, the qualitative and quantitative

Figure 6: Normalized confusion matrix for the network

trained using YOLO v8.

DATA 2024 - 13th International Conference on Data Science, Technology and Applications

510

GT=Good GT=Good GT=Good GT=Good GT=Good

Defect=Missing rubber Defect=Missing rubber Defect=Interior peeling Defect=Twisted Defect=Defective paint

Figure 7: YOLO v8 prediction results. These example images are part of the testing set.

$ yolo classify predict source="test/" \

model="train/weights/best.pt"

Figure 8: Code executed to testing data with YOLO v8.

d e f ru n ( s e l f ) :

w h i l e ( Tr u e ) :

i f s e l f . s C u r I d . g e t v a l u e ( ) == s e l f . sRun . n o d e i d :

i f s e l f . s C u r I d . g e t v a l u e ( ) == s e l f . s D e t . n o d e i d :

s e l f . D e t e c t i n g ( )

e l i f s e l f . s C u r I d . g e t v a l u e ( ) == s e l f . sAcq . n o d e i d :

s e l f . A c q u i r i n g ( )

# p r e d i c t on 1 i ma g e s

r e s u l t s = m odel ( i m a g e t o p r e d i c t )

# I n d e x : d e f e c t i v e ( 0 ) , good ( 1 )

p r e d = r e s u l t s [ 0 ] . p r o b s . c p u ( ) . d e t a c h ( ) . numpy ( )

i f ( p r e d [ 0 ] > p r e d [ 1 ] ) :

d e f e c t i v e = Tr u e

a c t i v a t e a c t u a t o r ( )

p r i n t ( ” D e f e c t i v e ” )

e l s e :

d e f e c t i v e = F a l s e

p r i n t ( ”Good” )

e l i f s e l f . s C u r I d . g e t v a l u e ( ) == s e l f . s C l a s . n o d e i d :

s e l f . C l a s s i f y i n g ( )

t i m e . s l e e p ( 0 . 0 0 0 0 1 )

Figure 9: Code executed in FSM in OPC-UA server with

YOLO v8.

evaluation on a testing subset is shown in Figure 7.

4.5 Integration of OPC-UA Server and

YOLO v8

To establish communication between the PLC and the

OPC-UA server, the Snap7

1

library is used. One of

the variables configured in the PLC is a trigger signal

which captures the reading of the inductive sensor and

based on the distance from the camera determines if

it is necessary to perform a capture. Once the image

is read, it is sent to the YOLO v8 prediction system

1

https://pypi.org/project/python-snap7/

Table 3: Performance evaluation in End-to-End delay and

Round Trip Time metrics in milliseconds.

Image Size Payload E2E RTT

Width Height (kB) (ms) (ms)

1440 1080 1555200 237 275

1080 810 1166275 209 231

720 540 777450 178 189

360 270 388690 159 168

so that it can determine if the tinplate lid is defective

or good. If it is defective, the pneumatic actuator will

be activated to separate the damaged item.

The execution of the model trained in YOLO v8 is

carried out within the OPC-UA server scope, in addi-

tion, state changes are executed using the finite state

machine model. Figure 9 shows the code in the OPC-

UA server where the execution of the model trained

in YOLO v8 is carried out.

4.6 Metric Evaluation

As a last stage to evaluate the performance of the

OPC-UA server together with YOLO v8 in near real-

time two metrics are used End-to-end delay (E2E) and

Round-Trip Time (RTT). E2E refers to the time taken

for a packet to be transmitted across a network from

source to destination. It is a common term in IP net-

work monitoring and differs from RTT in that only

the path in one direction from source to destination

is measured. Additionally, 100 images are considered

for the calculation of this measure.

5 CONCLUSIONS

The article proposes a methodology to improve

anomaly detection in industrial processes by inte-

grating OPC-UA and YOLO v8. Traditional human

inspection methods are noted to be error-prone and

Anomaly Detection in Industrial Production Products Using OPC-UA and Deep Learning

511

slow, underscoring the need for more automated and

accurate solutions. The article describes in detail the

architecture of the proposed system, which includes

components such as a PLC, an industrial camera, an

OPC-UA server, and the YOLO v8 model. The in-

teraction between these components is highlighted to

achieve efficient near-real-time defect detection. Fur-

thermore, experimental results are presented, includ-

ing performance metrics such as RTT and E2E to

evaluate the system efficiency.

Finally, the combined use of OPC-UA and

YOLOv8 in industrial environments offers significant

benefits such as secure, standardized communica-

tion, and interoperability between devices, along with

near-real-time monitoring. OPC-UA enables seam-

less and protected data exchange, while YOLOv8 pro-

vides fast and accurate object classification, automat-

ing visual inspection and reducing human errors. Ad-

ditionally, OPC-UA’s capability to access and ana-

lyze historical data facilitates predictive maintenance

and process optimization, enhancing operational effi-

ciency and product quality.

ACKNOWLEDGEMENTS

This research has been partially supported by the

ESPOL project “Automatizaci

´

on del proceso de de-

tecci

´

on de fallas en piezas de hojalata usando visi

´

on

por computador” (CIDIS-004-2023), and by Univer-

sity of Granada.

REFERENCES

Dey, S. and Agrawal, M. K. (2016). Tinplate as a sustain-

able packaging material: Recent innovation and de-

velopments to remain environment friendly and cost

effective. Int. J. Res. IT Manag. Eng, 8:9–22.

Dominguez, E., Spinola, C., Luque, R. M., Palomo, E. J.,

and Munoz, J. (2006). Object recognition and inspec-

tion in difficult industrial environments. In Int. Conf.

on Industrial Technology, pages 989–993. IEEE.

Eckhardt, A. and M

¨

uller, S. (2019). Analysis of the round

trip time of opc ua and tsn based peer-to-peer commu-

nication. In Int. Conf. on Emerging Technologies and

Factory Automation (ETFA), pages 161–167. IEEE.

Foundation, O. (2023). OPC Unified Architecture. Ac-

cessed: December 2023.

FreeOpcUa (

´

ultimo acceso: 2024-02-28). FreeOpcUa Mod-

eler. https://github.com/FreeOpcUa/opcua-modeler.

Georgi Martinov, Roman Pushkov, S. E. (2017). Opc ua-

based smart manufacturing: System architecture, im-

plementation, and execution. IEEE.

Gutierrez-Guerrero, J. M. and Holgado-Terriza, J. A.

(2017). iMMAS an Industrial Meta-Model for Au-

tomation System Using OPC UA. Elektronika Ir Elek-

trotechnika, 23((3)):3–11.

Huang, H.-W., Wu, S.-J., Lu, J.-K., Shyu, Y.-T., and Wang,

C.-Y. (2017). Current status and future trends of high-

pressure processing in food industry. Food control,

72:1–8.

Iqbal, R., Maniak, T., Doctor, F., and Karyotis, C. (2019).

Fault detection and isolation in industrial processes

using deep learning approaches. Transactions on In-

dustrial Informatics, 15(5):3077–3084.

Jocher, G., Chaurasia, A., and Qiu, J. (2023). Ultralytics

yolov8.

Li, Q., Tang, Q., Chan, I., Wei, H., Pu, Y., Jiang, H., Li,

J., and Zhou, J. (2018). Smart manufacturing stan-

dardization: Architectures, reference models and stan-

dards framework. Computers in Industry, 101:91–

106.

Monteiro, C. A., Cannon, G., Lawrence, M.,

Costa Louzada, M. d., and Pereira Machado, P.

(2019). Ultra-processed foods, diet quality, and health

using the nova classification system. Rome: FAO, 48.

Montgomery, D. C. (2019). Introduction to statistical qual-

ity control. John wiley & sons.

Nedeljkovic, D. M. and Jakovljevic, Z. B. (2020). Integra-

tion of smart vision sensor into manipulator control

system using opc-ua. IEEE.

Rocha, L. F., Ferreira, M., Santos, V., and Moreira, A. P.

(2014). Object recognition and pose estimation for

industrial applications: A cascade system. Robotics

and Computer-Integrated Manufacturing, 30(6):605–

621.

S

´

anchez Santalices, J., Moya de la Torre, E. J., and Pon-

cela M

´

endez, A. V. (2023). Implementaci

´

on de una

red neuronal para la detecci

´

on de anomal

´

ıas en ban-

dejas. In Jornadas de Autom

´

atica, pages 873–878.

Universidade da Coru

˜

na. Servizo de Publicaci

´

ons.

Sch

¨

afer, G., Kozlica, R., Wegenkittl, S., and Huber, S.

(2022). An architecture for deploying reinforcement

learning in industrial environments. In Int. Conf.

on Computer Aided Systems Theory, pages 569–576.

Springer.

Surendran, R., Khalaf, O. I., and Tavera Romero, C. A.

(2022). Deep learning based intelligent industrial fault

diagnosis model. Computers, Materials & Continua,

70(3).

Velesaca, H. O., Holgado-Terriza, J. A., and Gutierrez-

Gutierrez, J. M. (2024). Optimizing Smart Factory

Operations: A Methodological Approach to Industrial

System Implementation based on OPC-UA. In Int.

Conf. of Applied Industrial Engineering, pages 1–15.

Verkhivker, Y., Altman, E. I., Dotsenko, N. V., and Mirosh-

nishenko, E. (2020). Commodity approach to materi-

als when manufacturing containers for foods. Iuniper

Online Journal Material Science, 6(3):555687.

Zheng, P., Wang, H., Sang, Z., Zhong, R. Y., Liu, Y., Liu,

C., Mubarok, K., Yu, S., and Xu, X. (2018). Smart

manufacturing systems for industry 4.0: Conceptual

framework, scenarios, and future perspectives. Fron-

tiers of Mechanical Engineering, 13:137–150.

DATA 2024 - 13th International Conference on Data Science, Technology and Applications

512