The Applications of the Combinations of Deep Learning and

Blockchain Technology in Manufacturing Production Process: A

Comprehensive Investigation

Chuanhui Zhou

School of Information Science and Engineering, Zhejiang Sci-Tech University, 310018, Hangzhou, Zhejiang, China

Keywords: Deep Learning, Blockchain, Manufacturing

Abstract: In recent times, both deep learning and blockchain technology have garnered significant interest, attributed to

their respective strengths in predictive accuracy and data security enhancement. As the push towards

intelligent manufacturing gains momentum, the integration of these two technologies holds the potential to

fundamentally transform the manufacturing production process. This paper explores the applications and

significance of the combination of deep learning and blockchain technology in manufacturing production

process, discussing the benefits and areas for further improvement. Specifically, this work first briefly

introduces the related concepts of deep learning and blockchain technology. Furthermore, the possible

applications and benefits of the combination of deep learning and blockchain technology in manufacturing

are discussed. The three potential proposed applications include predictive maintenance, quality control, and

supply chain management. Finally, after discussion, this work points out that challenges such as large

computational resource requirements, large training data labeling effort and training data privacy and security

issues still need to be improved.

1 INTRODUCTION

In recent years, the convergence of deep learning and

blockchain technology has recently emerged as a

promising approach to revolutionize the

manufacturing production process. As a branch of

machine learning, deep learning has demonstrated

remarkable success in extracting meaningful

information from complex datasets, enabling accurate

predictions and decision-making. Meanwhile,

blockchain technology, originally designed for secure

and transparent transactions in cryptocurrencies, has

found diverse applications due to its decentralized

and immutable nature. By combining the strengths of

deep learning and blockchain, manufacturers can

potentially overcome significant challenges, boost

productivity, and established more robust and

efficient supply chains.

Deep learning algorithms, specifically deep

neural networks, have shown exceptional capabilities

in processing and analysing large volumes of data

generated in the manufacturing sector. By leveraging

techniques such as Convolutional Neural Networks

(CNN) and Recurrent Neural Networks (RNN),

manufacturers can learn high-level patterns, make

accurate predictions, and optimize production

processes (LeCun et al. 2015). These algorithms can

analyse sensor data from machinery, predict

equipment failures, detect anomalies in real-time, and

optimize maintenance schedules (Zhao et al. 2016).

Additionally, deep learning algorithms can be

employed to improve product quality control by

analysing image data, ensuring consistent and reliable

manufacturing standards (Soori et al. 2023).

On the other hand, blockchain technology

provides a decentralized and secure platform for

recording, sharing, and verifying data throughout the

manufacturing supply chain. The irreversibility and

transparency of blockchain records ensure

information’s integrity, making it an ideal solution for

traceability and provenance verification (Nakamoto

2008). By immutably recording data related to

production processes, quality control, and logistics on

the blockchain, manufacturers can enhance the

visibility of supply chain, reduce the risks of

counterfeit, and strengthen trust among stakeholders

(Jackson et al. 2023).

Zhou, C.

The Applications of the Combinations of Deep Learning and Blockchain Technology in Manufacturing Production Process: A Comprehensive Investigation.

DOI: 10.5220/0012821200004547

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Data Science and Engineering (ICDSE 2024), pages 281-285

ISBN: 978-989-758-690-3

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

281

The combination of deep learning and blockchain

technology offers a few potential applications in

manufacturing production process. For example,

predictive maintenance, a critical aspect of

manufacturing operations, stands to benefit greatly

from this combination. Deep learning algorithms can

predict equipment failures by analysing historical

sensor data, while the blockchain can secure and

distribute these predictions to relevant stakeholders,

enabling proactive maintenance and minimizing

downtime (Lee et al. 2020). Furthermore, supply

chain management can be improved through the

integration of deep learning and blockchain. Deep

learning models can analyse historical data to identify

patterns, optimize inventory management, forecast

demand, and identify potential bottlenecks in the

supply chain (Tadayonrad & Ndiaye 2023).

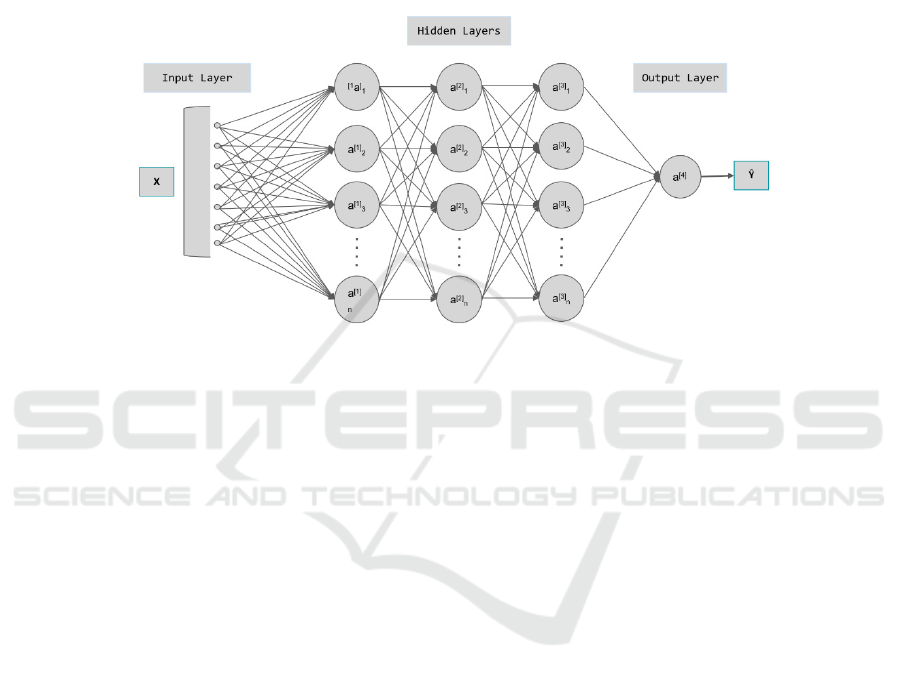

Figure 1: The architecture of the neural network (Photo/Picture credit : Original).

Given the novelty of the combination of deep

learning and blockchain in manufacturing, it is

critical to understand their potential applications in

manufacturing and the implications for production

and supply chain management. In order to gain a

deeper understanding of this field, this review paper

aims to explore the applications and significance of

the combination of deep learning and blockchain

technology in manufacturing production process.

This paper will examine the current prevalent

methods and techniques, discuss their benefits and

limitations, and identify areas for further

improvement.

2 METHOD

2.1 Introduction of Deep Learning

As a subset of machine learning, deep learning

models and understands complex patterns in datasets

with artificial neural networks which have multiple

layers, which has been widely applied in many tasks

(Chen et al. 2023, Kayalibay et al. 2017, Qiu et al.

2022). The structure of a neural network shown in

Fig. 1 consists of an input layer, one or more hidden

layers, and an output layer. And all layers contain

nodes that connect to nodes in the subsequent layer,

forming a "web" of interconnected nodes or

"neurons" (LeCun et al. 2015). The functionality of

deep learning is based on the concept of 'learning

representations from data', which means, given a set

of features, the model learns to recognize patterns and

make predictions or decisions without being

explicitly programmed to perform the task. The

learning process involves adjusting the weights and

biases of the network through a process called

backpropagation and optimization algorithms like

stochastic gradient descent (LeCun et al. 2015).

2.2 Introduction of Blockchain

Technology

Blockchain technology, as a decentralized distributed

database, enables point-to-point transactions with no

intermediaries. It utilizes encryption, consensus

algorithms, and smart contracts to enhance security,

traceability, authenticity, and collaboration (Ye et al.

2017). The key technologies of blockchain basically

include distributed ledgers, asymmetric encryption,

consensus mechanisms, and smart contracts. 1)

Distributed ledger, as decentralized data storage

technology (Ølnes et al. 2017), enables decentralized

data storage and synchronization, reducing

maintenance costs and improving efficiency (Ostern

ICDSE 2024 - International Conference on Data Science and Engineering

282

2017). It uses a network composed of multiple nodes

to realize data sharing and synchronization. 2)

Asymmetric encryption utilizes public and private

keys for secure encryption and decryption (Mofer et

al. 2017). The public key is public and used for

encryption, and the private key corresponding to the

public key is private and used for decryption. At

present, common asymmetric encryption algorithms

include hash function, Rivest-Shamir-Adleman

(RSA), Elgamal, Diffie–Hellman key exchange (D-

H) and elliptic curve encryption algorithm (Shi et al.

2021). 3) Consensus mechanisms enable the

verification and confirmation of data in the network

of each node, thus ensuring data consistency and trust

among participants (Lashkari & Musilek 2021).

Common consensus mechanisms include Proof of

Work (PoW) and Proof of Stake (PoS) (Khamar &

Patel 2020). 4) Smart contracts, as a computer

protocol, executed automatically based on predefined

conditions, can facilitate trusted transactions without

intermediaries, reducing costs and improving

efficiency (Mourouzis 2019).

2.3 Predictive Maintenance

Predictive maintenance is a crucial aspect of modern

manufacturing. Deep learning algorithms can achieve

efficient predictive maintenance by analysing sensor

data from machinery, predicting equipment failures,

and optimizing maintenance schedules. For instance,

a study by Butte et al. (2018) demonstrated the use of

machine learning including deep learning like CNN

and Deep Belief Networks (DBN) for predictive

maintenance in a semiconductor manufacturing

industry. In their study, generalized distributed linear

model, distributed random forest, Gradient Boosting

Machine, DBN and CNN were applied to analyse

sensor data and predict device failures. It combines

predictions from multiple different models based on

cross-validation. It not only reduces downtime and

increases productivity, but also reduces the risk of

high variability and low accuracy because of relying

on a single method and makes Product Data

Management (PdM) systems robust. Blockchain

technology complements this by providing a secure

and transparent platform for sharing these predictions

with relevant stakeholders, ensuring proactive

maintenance (Rachad et al. 2023).

2.4 Quality Control

Quality control is another critical application area.

Deep learning algorithms can analyse image data to

ensure consistent and reliable manufacturing

standards. The study of Villalba-Diez et al. (2019)

shows an application of deep learning on increasing

the accuracy and decrease the computational

resources requirement of industrial visual inspection

process in the process of printing. And a study by

Jianqiang et al. (2023), proposed a blockchain-based

quality control methodology. In their research,

blockchain technology and machine learning are used

to secure the safety and privacy of information

operations and managing data sets, providing a secure

platform for delivering relevant predictions and

preserving relevant data sets. Its quality control was

established based on comprehensive techniques that

accurately reflected the intricate world and

determined the actual positivity rate of the platform’s

standard control methodology.

2.5 Supply Chain Management

Supply chain management also benefits greatly from

the integration of deep learning and blockchain

technology. Deep learning models can analyse

historical data to optimize inventory management,

forecast demand, and identify potential bottlenecks in

the supply chain. A study by Henkelmann (2018)

proposed an approach based on deep learning for

supply chain management in the automobile spare

part industry. The approach used deep learning

algorithms to analyse historical sales data and

forecast demand, thereby optimizing inventory

management. Blockchain technology can improve

this process by providing a secure and transparent

platform for sharing these forecasts with relevant

stakeholders, thereby enhancing supply chain

visibility (Saberi et al. 2018).

3 DISCUSSION

The combination of deep learning and blockchain

technology holds immense potential for

revolutionizing the manufacturing production

process. One of the significant advantages of deep

learning algorithms in manufacturing is their ability

for processing and analysing large volumes of data.

Deep neural networks, such as CNN and RNN, can

extract high-level patterns from sensor data and make

accurate predictions. This capability is particularly

useful in predictive maintenance, where the

algorithms can analyse historical sensor data to detect

anomalies and predict equipment failures (Butte et al.

2018). By proactively identifying potential issues,

manufacturers can optimize maintenance schedules,

reduce downtime, and increase productivity.

The Applications of the Combinations of Deep Learning and Blockchain Technology in Manufacturing Production Process: A

Comprehensive Investigation

283

Additionally, deep learning algorithms can

improve quality control in manufacturing by

analysing image data. This application is evident in

the printing industry, where deep learning models

have been employed to increase the accuracy and

reduce the computational resources requirement in

industrial visual inspection processes (Villalba-Diez

et al. 2019). By automatically detecting defects and

inconsistencies, manufacturers can ensure consistent

and reliable manufacturing standards, leading to

higher product quality.

Blockchain technology complements deep

learning in several ways. Its decentralized and

immutable nature makes it an ideal solution for

traceability and provenance verification. By

recording data related to production processes,

quality control, and logistics on the blockchain,

manufacturers can enhance supply chain visibility,

reduce counterfeit risks, and strengthen trust among

stakeholders (Jackson et al. 2023). For instance, a

blockchain-based quality control methodology can

secure information operations and manage datasets,

providing a secure platform for delivering relevant

predictions and preserving data integrity (Gu et al.

2023).

Another significant application of the

combination of deep learning and blockchain is in

supply chain management. Deep learning models can

analyse historical data to optimize inventory

management, forecast demand, and identify potential

bottlenecks in the supply chain (Henkelmann 2018).

By leveraging the power of deep learning,

manufacturers can make decisions driven by data

which can save cost and improve efficiency.

Blockchain technology can further enhance this

process by providing a secure and transparent

platform for sharing forecasting data with relevant

stakeholders, ensuring trust and collaboration (Saberi

et al. 2018).

Despite the numerous benefits, there are some

limitations and challenges to consider. Deep learning

algorithms require substantial computational

resources and large amounts of labeled training data.

Acquiring and labeling such datasets can be time-

consuming and costly, especially in complicated

manufacturing environments recognizing changes in

scenarios and situations is a must when collecting and

using datasets required for training (Gu et al. 2023).

Additionally, ensuring the privacy and security of

sensitive data used in deep learning models is a

significant concern. Manufacturers need to apply

robust data protection techniques to prevent

unauthorized access and data breaches. At present,

advancements in federated learning might address

privacy concerns associated with deep learning.

Federated learning allows training models on

distributed data without sharing the raw data, thereby

preserving data privacy (Kamp et al. 2021).

Implementing federated learning in the

manufacturing sector will help enable collaborative

model training while helping ensure data security and

privacy.

4 CONCLUSION

In this work, the applications and significance of the

combination of deep learning and blockchain

technology in manufacturing production process have

been explored. The author has discussed the current

prevalent methods and techniques, their benefits,

limitations, and identified areas for further

improvement in the field of deep learning, blockchain

and their integration in the manufacturing process.

This research shows that the integration of deep

learning and blockchain has several applications in

manufacturing, including predictive maintenance,

quality control, and supply chain management.

After discussing the current related applications,

there are still some challenges to overcome in the

future, including the need for substantial

computational resources, large training data labeling

effort and training data privacy and security issues.

REFERENCES

Y. LeCun, Y. Bengio, G. Hinton. Deep learning. Nature

(2015)

G. Zhao, G. Zhang, Q. Ge, X. Liu. Research advances in

fault diagnosis and prognostic based on deep learning.

Prognostics and System Health Management

Conference (2016)

M. Soori, B. Arezoo, R. Dastres. Artificial Intelligence,

Machine Learning and Deep Learning in Advanced

Robotics, A Review. Cognitive Robotics (2023)

S. Nakamoto. Bitcoin: a peer-to-peer electronic cash system

(2008)

A. Jackson, V. Spiegler, K. Kotiadis. Exploring the

potential of blockchain-enabled lean automation in

supply chain management: a systematic literature

review, classification taxonomy, and future research

agenda. Production Planning & Control (2023)

J. Lee, J. Ni, J. Singh, B. Jiang, M. Azamfar, J. Feng.

Intelligent Maintenance Systems and Predictive

Manufacturing. Journal of Manufacturing Science and

Engineering-transactions of The Asme (2020)

Y. Tadayonrad, A. B. Ndiaye. A New Key Performance

Indicator Model for Demand Forecasting in Inventory

ICDSE 2024 - International Conference on Data Science and Engineering

284

Management Considering Supply Chain Reliability and

Seasonality. Supply Chain Analytics (2023)

H. Chen, Y. Qiu, M. Jiang, J. Lin, P. Chen. Kernel-mask

knowledge distillation for efficient and accurate

arbitrary-shaped text detection. Complex & Intelligent

Systems, 1-12 (2023)

B. Kayalibay, G. Jensen, P. van der Smagt. CNN-based

segmentation of medical imaging data. arXiv preprint

arXiv:1701.03056 (2017)

Y. Qiu, J. Wang, Z. Jin, H. Chen, M. Zhang, L. Guo. Pose-

guided matching based on deep learning for assessing

quality of action on rehabilitation training. Biomedical

Signal Processing and Control, 72, 103323 (2022)

X. Ye, Q. Shao, R. Xiao. A supply chain prototype system

based on blockchain, smart contract and internet of

things. Sci. Technol. Rev., 35, 62–69 (2017)

S. Ølnes, J. Ubacht, M. Janssen. Blockchain in government:

Benefits and implications of distributed ledger

technology for information sharing. Government

Information Quarterly (2017)

N. Ostern. Typology of Distributed Ledger Based Business

Models. Institute for Business Studies (BWL):

Darmstadt (2017)

M. Nofer, P. Gomber, O. Hinz, D. Schiereck. Blockchain.

Bus Inf Syst Eng, 59, 183–187 (2017).

L. Shi, Z. Guo, M. Xu. Bitmessage Plus: A Blockchain-

Based Communication Protocol with High Practicality.

IEEE Access, 9, 21618–21626 (2021)

B. Lashkari, P. Musilek. A Comprehensive Review of

Blockchain Consensus Mechanisms. IEEE Access, 9,

43620–43652 (2021)

J. Khamar, H. Patel. An Extensive Survey on Consensus

Mechanisms for Blockchain Technology. Data Science

and Intelligent Applications (2020)

T. Mourouzis, J. Tandon. Introduction to decentralization

and smart contracts. arXiv, arXiv:1903.04806 (2019)

S. Butte, A. R. Prashanth, S. Patil. "Machine Learning

Based Predictive Maintenance Strategy: A Super

Learning Approach with Deep Neural Networks." 2018

IEEE Workshop on Microelectronics and Electron

Devices (WMED), Boise, ID, USA, pp. 1-5, doi:

10.1109/WMED.2018.8360836 (2018)

A. Rachad, L. Gaiz, K. Bouragba, M. Ouzzif. Predictive

Maintenance-as-a-Service (PdMaaS) in Industry 4.0

using Blockchain. 2023 10th International Conference

on Wireless Networks and Mobile Communications

(WINCOM), pp. 1-6, doi:

10.1109/WINCOM59760.2023.10322922 (2023)

J. Villalba-Diez, D. Schmidt, R. Gevers, J. Ordieres-Meré,

M. Buchwitz, W. Wellbrock. Deep Learning for

Industrial Computer Vision Quality Control in the

Printing Industry 4.0. Sensors (2019)

J. Gu, L. Zhao, X. Yue, N. I. Arshad, U. H. Mohamad.

Multistage quality control in manufacturing process

using blockchain with machine learning technique.

Information Processing & Management (2023)

R. Henkelmann. A deep learning based approach for

automotive spare part demand forecasting. PHD thesis,

Otto von Guericke University (2018)

S. Saberi, M. Kouhizadeh, J. Sarkis, L. Shen. Blockchain

technology and its relationships to sustainable supply

chain management. International journal of production

research (2018)

M. Kamp, J. Fischer, J. Vreeken. Federated learning from

small datasets. arXiv preprint arXiv:2110.03469

(2021).

The Applications of the Combinations of Deep Learning and Blockchain Technology in Manufacturing Production Process: A

Comprehensive Investigation

285