Optimization and Benefit Assessment of Cold Chain Logistics

Network in Southeast Asia Based on Big Data Analysis

Ying Lin

School of Management, Yang-En University, Quanzhou, 362000, China

Keywords: Cold Chain Logistics Network Optimization; Benefit Assessment; Big Data Analysis; Ga Algorithm.

Abstract: With the rapid development of social economy, e-commerce and logistics enterprises are flourishing.

Continuously improving the optimization and benefit assessment methods of cold chain logistics network has

injected new vitality and momentum into the cold chain logistics industry in Southeast Asia. This paper

constructs a cold chain logistics network optimization and benefit assessment model in Southeast Asia based

on big data technology. At this stage, the development of fresh food e-commerce is very rapid, and the

consumption of all kinds of fresh food, dairy products and other perishable commodities is also increasing

rapidly, which leads to a huge demand for refrigerated transportation. This is a logistics industry with high

entry threshold, large market space and great potential, which is occupied by e-commerce and logistics

companies. In this paper, the objective function and constraint function are set as the parameters of GA

algorithm calculation through the variables affecting the optimization and benefits of cold chain logistics

network, and the optimization model of Southeast Asia's cold chain logistics network based on GA (Genetic

Algorithm) algorithm is constructed, and finally, the comparative analysis with the PSO algorithm shows that

the computation speed of the GA algorithm is faster than that of the PSO algorithm (the GA algorithm based

on the logistics Network Optimization based on GA algorithm has a computation time of only 2.51s, while

the model based on PSO algorithm has a computation time of 15s.).

1 INTRODUCTION

The rapid development of agriculture needs the

corresponding cold chain logistics system as a

guarantee to reduce the loss rate in picking,

transportation and storage. Fruit industry and animal

husbandry are the pillar industries of its economy,

however, there are still many constraints in the

development of cold chain logistics of agricultural

products, accurate, reasonable and efficient

evaluation will directly determine the future

development of cold chain logistics of agricultural

products. At present, most of the literature on cold

chain logistics performance evaluation adopts the

fuzzy hierarchical analysis method, because the

weights are decided by the decision makers, the

evaluation of the decision-making program lacks

objectivity. Based on this, this paper discusses the

optimization and benefit assessment of cold chain

logistics network in Southeast Asia based on GA

algorithm, and verifies the feasibility of the model

through experiments.

This paper introduces the logistics and

transportation network operation cost, GA algorithm

and cold chain logistics network optimization model

based on GA algorithm in Chapter 3, introduces the

experimental comparative analysis of cold chain

logistics network optimization model based on GA

algorithm and PSO algorithm in Chapter 4, and

finally makes a summary of the whole paper.

For logistics network optimization and benefit

assessment, there have long been related research

proposals by experts. For the longer distribution time

in the supply chain, Zhang Y adopts the mixed integer

nonlinear programming method to construct a

mathematical model and solves it by the discrete

continuous optimizer in the general algebraic

modeling system. Using the new optimization

method, the logistics cost can be effectively reduced

and the distribution time can be reduced, thus

improving the long-term operational efficiency of the

enterprise. Experiments show that the nonlinear

logistics distribution center siting problem can be

solved effectively with mixed integer nonlinear

methods (Zhang et al, 2022).Aloui A studied the

Lin, Y.

Optimization and Benefit Assessment of Cold Chain Logistics Network in Southeast Asia Based on Big Data Analysis.

DOI: 10.5220/0012826200004547

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Data Science and Engineering (ICDSE 2024), pages 497-503

ISBN: 978-989-758-690-3

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

497

integrated optimization problem of siting, inventory

and path of a two-box-box green logistics network,

and established a set of logistics integrated

optimization models based on supply chain

collaboration and evaluated them. It was found that

horizontal collaboration among manufacturers in a

supply chain can reduce the overall cost and carbon

emissions (Aloui et al, 2022). In order to identify the

inefficiencies in the supply chain network.Gupta S

considered a fuzzy objective planning based time-cost

two-tier decision making process for optimization of

product allocation sequence in supply chain network.

The results obtained show the optimal quantities to be

shipped from different sources to different

destinations, which allows managers to discover the

optimal quantities of products in a hierarchical

decision making process involving two levels (Gupta

et al, 2021). Shadkam E proposed a mixed-integer

linear programming model with fixed costs, material

flow costs, and potential transportation routing costs

as objectives. He used the cuckoo algorithm to

optimize this model and performed a sensitivity

analysis to verify the validity of the model (Shadkam,

2022). Archetti C proposed a method for optimal

allocation of goods based on multiple modes of

transportation mainly for the combination of modes of

transportation. He summarized the existing research

results in recent years and pointed out the current

research direction and future development direction

(Archetti et al, 2022). There are some defects in the

current logistics network optimization and benefit

assessment models, including that the models are

overly dependent on accurate input data resulting in

the accuracy of the model output results being

affected, and some of the models only focus on the

optimization of a single indicator, whereas the actual

logistics network involves multiple indicators and

multiple stakeholders, and requires comprehensive

consideration of multiple factors for decision-making.

To address these shortcomings, improvements can be

considered in terms of improving the data collection

and processing methods of the model, simplifying the

model structure, introducing real-time monitoring and

feedback mechanisms, strengthening the modelling of

uncertainty, and realizing multi-objective

optimization.

2 METHODS

2.1 Logistics and Transportation

Network Operating Costs

The so-called logistics network is a network structure

composed of logistics routes and logistics nodes in

logistics activities. The logistics on the route mainly

includes trunk transportation and distribution

transportation. Logistics at the nodes are mainly

packaging, loading and unloading, circulation

processing, information processing, distribution,

grouping and other activities (Rajput & Singh, 2022,

Fontaine et al, 2021). According to the components

of logistics activities, the structure of the logistics

network can be summarized as consisting of lines

performing movement tasks and nodes performing

suspension tasks. The network composed of these

two basic elements of logistics is the logistics

network. In this paper, for the real location situation

in Southeast Asia, we not only carry out the design of

the location of cold chain logistics center on

Southeast Asia, but also include the study of the

optimization of the path of the logistics and

distribution center on the sales ground (Esmizadeh &

Parast, 2021).

The optimization model of logistics and

transportation network is an extension of the existing

model. For this reason, the model takes the applied

research as the core, based on the mathematical and

physical model, combined with the basic information

data, the optimization planning of the cold chain

network cold chain service network is incorporated

into the optimization model, so that it can reflect the

actual traffic status more clearly (Anderluh et al,

2021). On this basis, the assessment model of cold

chain flow is constantly revised and improved on the

basis of mathematical statistics and according to

relevant specifications. After the initial establishment

of the optimal model, various analytical means

should also be used to carry out scientific research on

it (Tang & Meng, 2021). Firstly, it is necessary to

carry out an in-depth study of its technical process to

ensure that it matches the actual needs of cold chain

logistics; secondly, it is necessary to study its

functioning mechanism, so that the established

optimization model can essentially guarantee the

transportation quality of cold chain logistics. On this

basis, the cost analysis of the model is carried out, and

on this basis, the cost of each stage is calculated in

accordance with the requirements of the optimal

model, and the optimal plan is scientifically evaluated

on the basis of the cost (Reddy et al, 2022).

Due to the complexity of the logistics and

transportation network, which makes the operation of

the whole transportation network more and more

complicated, each logistics enterprise has not yet

formed a perfect cost management system to realize

the effective control of the operation cost of the

transportation network. Therefore, this paper

establishes a standard logistics transportation network

operation framework to analyze the operation cost of

ICDSE 2024 - International Conference on Data Science and Engineering

498

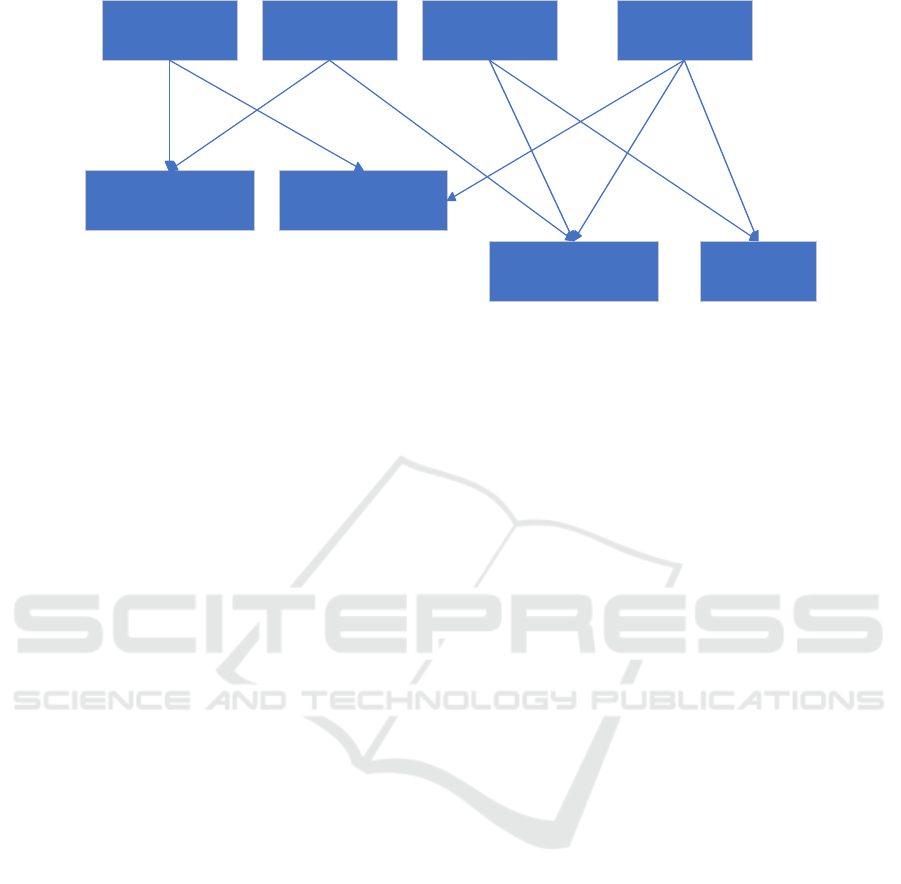

Shipping

locations

Outgoing

distribution

Destination

allocation

Delivery

locations

Network

handover process

Distribution

handover process

Select Dispatch

Figure 1: Logistics and Transportation Network Operation Framework (Picture credit: Original).

logistics transportation network, as shown in Figure 1

(Makarova et al, 2021).

As can be seen from Figure 1, the above logistics

and transportation network operation framework can

effectively complete logistics transportation, because

logistics and transportation costs are related to the

losses in the transportation, so it can be analyzed by

analyzing the various influencing factors in the

transportation to determine the logistics and

transportation costs.

2.2 GA Algorithm

Genetic algorithm is a stochastic optimization

algorithm based on the theory of genetic variation, its

idea is simple and easy to implement. The effect is

remarkable in practical application. The evolution of

animals tends to follow the universal law of "survival

of the fittest", that is, those who are best able to adapt

to the environment, tend to reproduce more offspring.

Genetic algorithms simulate the evolution of

organisms under natural conditions, which is a kind

of stochastic way to simulate the evolution of

organisms (Sohail, 2023).

In genetic algorithms, crossover, mutation is an

important generative method, new individuals can

enrich the diversity of the population and improve the

algorithm's global optimization seeking ability. At the

same time, crossover operation is also an important

feature that distinguishes genetic algorithm from

other algorithms. Crossover and mutation use random

generation method, that is, the hybrid individuals and

the hybrid position are randomly decided, the selected

hybrid individuals are truncated at the intersection

point, and then they are interchanged with the

corresponding hybrid individuals (Garud et al, 2021).

In addition, different individuals can be selected

according to different situations, in which the variant

position changes from 0 to 1, and the variant that was

originally 1 is 0. This method uses a full randomness

approach, which gives it strong global optimality

seeking ability and enables it to converge to the

global optimum (Rostami et al, 2021).

2.3 Cold Chain Logistics Network

Optimization Model based on Ga

Algorithm

For the two-layer distribution-path optimization

planning algorithm constructed in this paper, the

optimization objective of the upper-layer model is to

select suitable logistics centers from the perspective

of logistics center construction cost and distribution

of logistics centers, so as to minimize the construction

cost of logistics centers. The objective function

expression of the upper layer model is as follows.

∈∈∈

++=

Gr

rpr

GrGr

rrrprpr

ZtZFZdCH

2

1

)(min

θ

(1)

1≥

∈Gr

r

Z

(2)

∈∈

≥

Hj

j

Gr

rr

qZQ

(3)

Where denotes the cost of

transporting goods from supplier p to logistics center

r,

rr

ZF

denotes the construction cost of logistics

center r, and

2

)(

rpr

Zt

denotes the loss of goods in

the transportation process. The first inequality of the

constraints indicates that at least one or more logistics

centers must be selected in the transportation

network, the second indicates that the amount of

rprpr

ZdC

Optimization and Benefit Assessment of Cold Chain Logistics Network in Southeast Asia Based on Big Data Analysis

499

goods that can be stored in the logistics center exceeds

the retailer's demand, and the third indicates that the

logistics center can only be selected or not selected.

1=

r

Z

denotes a logistics center at r,

1=

r

Z

denotes

no logistics center at r,

Gr ∈

.

Constraints.

1=

j

ij

X

(4)

1=

k

jk

X

(5)

max

),( jiDXd

ijij

≤

(6)

max

),( kjDXd

jkjk

≤

(7)

≤

i

H

Jij

Qq

(8)

≤

j

kkjk

QZq

(9)

=

k

jkj

i

ij

S

i

qPXq

(10)

𝑞

≥0,𝑞

≤0 (11)

𝑃

∈

0,2, ⋯ ,7

,∀𝑗 ∈ 𝐽 (12)

𝑋

,𝑋

,𝑌

,𝑍

∈

0,1

,∀𝑖 ∈ 𝐼,∀𝑖 ∈ 𝐽,∀𝑘 ∈𝐾

(13)

Where, the objective function (1) represents the

minimization of the relevant cost,, the

∑

3×C

Z

is

the leasing cost of leasing fresh produce distribution

center per quarter; and90

∑

C

∑

q

X

denotes the

total processing cost of using pre-cooling station to

process fresh produce in each quarter;

and

∑

Z

∑

Y

[(q

)×(d

C

+C

+C

)]

Indicates that each quarter from the pre-cooling

station to the distribution center of the transportation

costs and distribution centers within the cold storage,

sorting and other operations, the sum of the cost;

formula (4) that each product origin only assigned a

pre-cooling station for its services; formula (5) that a

pre-cooling station and a fresh produce distribution

center corresponds to only one; formula (6) that the

origin of the product and the pre-cooling station of the

transportation distance between the maximum

distance limit; formula (7) that the pre-cooling station

and the distribution center of fresh produce, the

maximum distance limit ) indicates that the

transportation distance between the pre-cooling

station and the fresh produce distribution center

satisfies the maximum distance limitation; Eq. (8)

indicates that the maximum processing capacity

limitation is satisfied in the centralized purchasing

cycle of the pre-cooling station; Eq. (9) indicates that

the maximum capacity limitation is satisfied within

the fresh produce distribution center; Eq.(10)

indicates that the inflow and outflow equilibrium is

satisfied at the pre-cooling station; Eq. (11) indicates

that all the decision variables are positive; and

Eq.(12) indicates that The centralized purchasing

cycle of fresh produce is maximum 7 days.

The cold chain logistics network optimization

problem belongs to the uncertain polynomial

problem, and other algorithms have difficulty in

solving the global optimum quickly during the

solving process.GA algorithm has fast convergence

speed and is a global optimization search method,

which greatly reduces the solving speed under the

same computational accuracy. For this reason, this

paper adopts an optimal logistics network

optimization method based on genetic algorithm. The

current model solving procedure is as follows:

(1) Coding. By the supplier . Manufacturers,

distribution centers composed of three-tier logistics

network, this paper adopts real number coding, with

the vector V to represent the chromosome,

),,,,,,( lrikrmjV =

indicates that the

manufacturer to transport mode r from the supplier j

to buy. Raw material m to the factory k to produce

product i ,and then distributed to the distribution

center l by transportation mode r (Palanisamy et al,

2022, Zhang et al, 2022).

(2) Adaptation function. First set the number of

suppliers to be selected, the number of factories and

the number of distribution centers, this paper will

adaptive function is selected as the inverse of the

objective function in the model, from the model can

be seen, the program with the smallest cost is the

optimal chromosome, that is, the adaptive function is

the largest (Nikbakht et al, 2021).

(3) Selection. The selection process affects the

number of iterations and the speed of

convergence,therefore,in the initial selection

process,suppliers and distribution centers that are

close to the plant are prioritized to be used as parent

individuals. The more adaptive the parent individual

is, the higher the possibility of crossover and

mutation,and it is required that all the individuals

with high adaptability should be retained in each

offspring community (Vivekanandam, 2021).

ICDSE 2024 - International Conference on Data Science and Engineering

500

(4) Crossover. The crossover operation of genetic

algorithms refers to selecting two parent individuals

from the parent community with a certain probability

and randomly performing structural interchanges on

them to generate new offspring individuals

(Velliangiri et al, 2021, Mazaideh & Levendovszky,

2021).

(5) Mutation. Mutation in genetic algorithm refers

to the selection of different locations of the mother

individual, such as suppliers, factories, distribution

centers, etc. where random changes occur to produce

new individuals. As a general rule, the manufacturer's

logistics network is large and extensive. Therefore, in

order to reduce the number of iterations and accelerate

the convergence, this paper introduces a heuristic

algorithm, which divides the suppliers, factories and

distribution centers into several regions first, and

takes the center of the region as the reference point,

and carries out the mutation operation in the direction

of the large adaptability, so as to optimize the genetic

algorithm improvement.

Individuals in the population are binary coded to

represent each initial parameter in the multi-objective

ant colony algorithm as well as the site selection

parameters of the warehouse. The fitness function is

defined according to the two objectives in logistics

network optimization, i.e., minimizing the total cost

and minimizing the maximum one-way cost, when a

certain number of iterations is reached. The algorithm

ends, the optimal parameter set is output and used as

the initial parameters of the multi-objective algorithm

to start solving the Pareto optimal solution set.

3 RESULTS AND DISCUSSION

3.1 Experimental Preparation

Using MATLAB 7.0 Genetic Algorithm Toolbox to

run the solution, the average running time was

determined by debugging the parameters several

times,the average number of running generations to

reach the near-optimal solution was 120, and the

optimal layout of each node of the cold chain logistics

network was finally derived. In this example, Table 1

shows the distances between eight source locations

and six alternative cold storage stations. The

experiments in this paper do a comparative analysis

with the algorithm of this paper through PSO

(Particle Swarm Optimization) algorithm.

3.2 Sample Data

Table 1 also shows the average daily deliveries at

each source and the maximum daily deliveries at the

alternative pre-cooling sites. Table 2 shows the cost

per unit of travel from the eight sources to the six

alternative pre-cooling sites. The algorithm needs to

satisfy the supply demand under the constraints to

minimize the total cost associated with the cold chain

logistics activities.

Table 1: Distance from the production site to the pre-cooling station and maximum average daily purchases from the pre-

cooling station.

The source of a product Ⅰ II III IV V VI Maximum supply quantity

1 17 27 49 12 39 71 37

2 38 43 50 78 53 96 76

3 22 43 18 34 29 57 41

4 23 39 88 59 31 105 65

5 324 245 508 115 27 213 73

6 35 155 470 79 51 412 53

7 41 72 66 38 149 81 50

8 106 255 78 95 46 128 80

Maximum Purchase Volume 231 355 510 250 111 250 4910

Optimization and Benefit Assessment of Cold Chain Logistics Network in Southeast Asia Based on Big Data Analysis

501

Table 2 shows the unit distance cost, which is also

a key factor in the constraints of the GA algorithm, as

a parameter substituted into the GA algorithm.

Table 2: Unit distance cost per unit quality of agricultural

products from origin to alternative pre-cooling station (unit:

yuan/ton. kilometer)

The

source of

a product

Ⅰ II III IV V VI

1 7 5 5 8 2 6

2 3 9 3 7 3 6

3 6 5 1 8 10 3

4 7 3 10 3 5 2

5 4 8 7 10 8 9

6 3 6 4 2 2 1

7 6 8 4 8 7 5

8 7 2 3 2 5 3

3.3 Experimental Results

The distribution matrix for the different algorithms is

=

9826715016247

611828256424

40621378692

143148645815084

7727493017

13132117359

643844291431

2039471815

GA

A

(14)

=

120133333370

621031133918

934263597825

6610051226114

92849339

3815417911

5847784475

38301232710

PSO

A

(15)

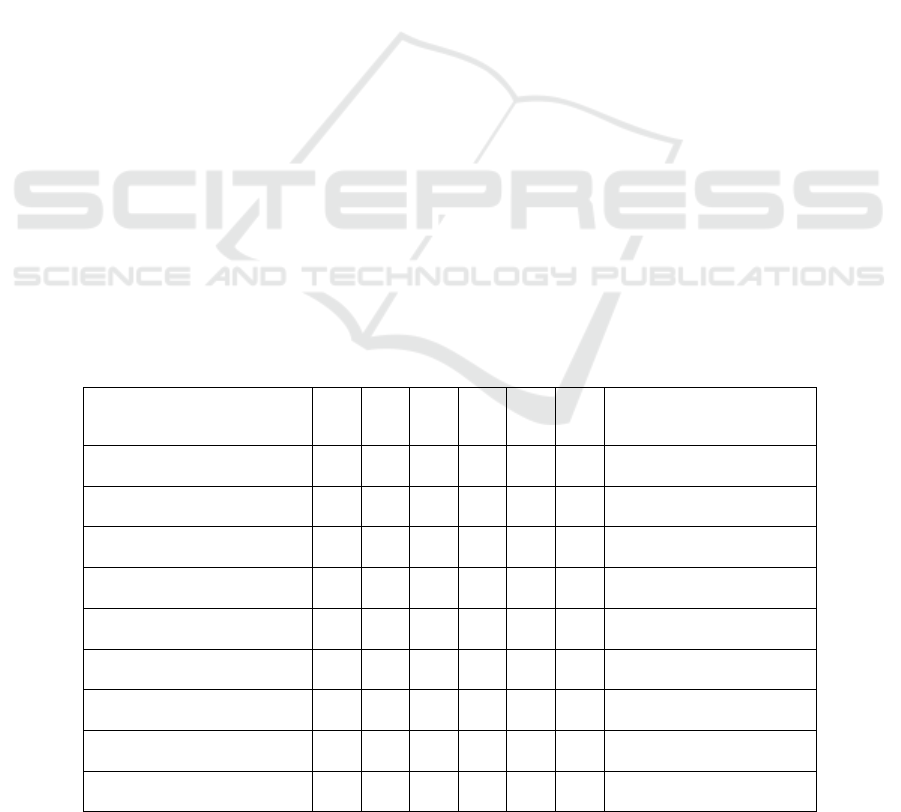

As can be seen from Figure 2, the calculation time

of logistics network optimization based on GA

algorithm is only 2.51s, while the model calculation

time based on PSO algorithm is 15s, so GA algorithm

is more able to meet the need of real-time

optimization of Southeast Asia's cold chain logistics

network. In addition to this the final cost of logistics

network construction based on the PSO algorithm is

about 23,000,000 yuan, while the cost of logistics

network construction of the GA algorithm is about

14,000,000 yuan. So no matter the optimization result

or the optimization time of the algorithm to judge, the

logistics network optimization model based on GA

algorithm is more excellent than the PSO algorithm

model. The main reason for this is that GA performs

better in dealing with complex, multi-dimensional

problems, because it can consider multiple solutions

simultaneously and perform global search through

gene crossing and mutation operations, which makes

it more likely to find the global optimal solution, and

compared with PSO, GA usually has better global

search and convergence performance, and it can find

the optimal solution or close to the optimal solution

more quickly.

GA PSO

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Calculation time(s) Cost(yuan)

Algorithm

Calculation time(s)

0

1250

2500

3750

5000

6250

7500

8750

10000

11250

12500

13750

15000

16250

17500

18750

20000

21250

22500

23750

25000

26250

27500

Cost(yuan)

Figure 2: Computation time and cost of results for different

algorithms (Picture credit: Original).

3.4 Convergence Speed of Different

Algorithms

0 25 50 75 100 125 150 175 200 225 250 275 300 325 350 375 400 425 450

0

25000

50000

75000

100000

125000

150000

175000

200000

225000

250000

Minimum cost

Epoch

PSO GA

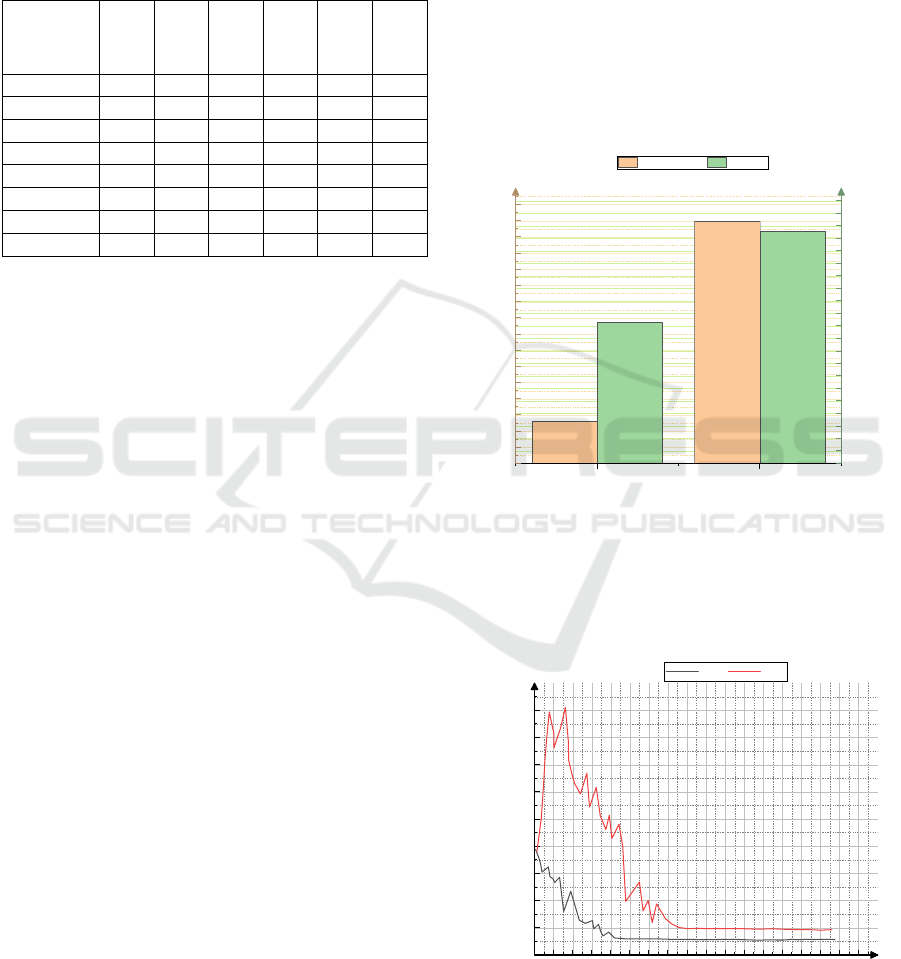

Figure 3: Iteration process of different algorithms (Picture

credit: Original).

ICDSE 2024 - International Conference on Data Science and Engineering

502

From Figure 3, it can be seen that the PSO algorithm

is close to convergence in 200 iterations, while the

GA algorithm has reached the convergence value of

minimum cost in only almost 120 iterations. The

above data just verifies that the GA algorithm in Fig.

2 is computationally faster than the PSO algorithm.

Since the GA algorithm uses crossover and mutation

operations to generate new individuals, such

operations are able to search the entire solution space

faster, thus speeding up the convergence of the

algorithm. In addition, GA algorithms are able to

process multiple individuals simultaneously in each

generation, and therefore are able to perform parallel

computations faster, which speeds up the algorithm.

In contrast, the PSO algorithm can usually only

handle a single individual and therefore will be

relatively slow in searching the entire solution space.

Therefore, the reason why the GA algorithm is

computationally faster than the PSO algorithm is

mainly due to its parallel computation and faster

search speed.

4 CONCLUSION

With the deepening of globalization, the cold chain

logistics industry in Southeast Asia is also attracting

increasing attention. Cold chain logistics refers to the

logistics method of transporting and storing

commodities under constant temperature conditions,

which is mainly applied to the transportation of

perishable goods such as food, medicine and

cosmetics. In Southeast Asia, the development of cold

chain logistics faces many challenges due to factors

such as hot climate and inconvenient transportation.

Therefore, how to optimize the cold chain logistics

network and evaluate its benefits through big data

analytics has become a pressing issue. The

optimization and benefit assessment of cold chain

logistics network in Southeast Asia based on big data

analysis discussed in this paper is of great

significance. Through big data analysis, the operation

of cold chain logistics network in Southeast Asia can

be better understood and grasped to provide decision

support for enterprises and promote the development

of cold chain logistics industry. Therefore, the

research and application of big data analytics should

be strengthened to continuously improve the

optimization and benefit assessment methods of cold

chain logistics networks, so as to inject new vitality

and momentum into the cold chain logistics industry

in Southeast Asia.

REFERENCES

Y.Zhang, X. Kou, Z. Song, Nonlinear Engineering, 10(1),

526-534 (2022).

A.Aloui, N. Hamani, R. Derrouiche, International Journal

of Systems Science: Operations & Logistics, 9(3), 302-

323 (2022).

S.Gupta, A. Haq, I. Ali, Complex & Intelligent Systems,

7(4), 2119-2139 (2021).

E.Shadkam, Waste Management & Research, 40(4), 458-

469 (2022)..

C. Archetti, L. Peirano L, M. G. Speranza, European

Journal of Operational Research, 299(1), 1-20 (2022)..

S. Rajput,S. P. Singh, International Journal of Logistics

Research and Applications, 25(4-5), 837-877 (2022).

P. Fontaine, T. G. Crainic, O. Jabali, European Journal of

Operational Research, 294(2), 558-570 (2021).

Y. Esmizadeh, M. Mellat Parast, International Journal of

Logistics Research and Applications, 24(2), 174-197

(2021).

A. Anderluh,P. C. Nolz, V. C. Hemmelmayr, European

Journal of Operational Research, 289(3), 940-958

(2021).

L. Tang, Y Meng, Frontiers of Engineering

Management,8(2), 157-171 (2021).

K. N. Reddy, A. Kumar, A. Choudhary, European Journal

of Operational Research, 303(2), 735-752 (2022).

I. Makarova, K. Shubenkova, P. Buyvol, FME

Transactions, 49(1), 173-185 (2021).

A. Sohail, Annals of Data Science, 10(4), 1007-1018

(2023).

K. S. Garud, S. Jayaraj, M. Y. Lee, International Journal of

Energy Research, 45(1), 6-35 (2021).

M. Rostami, K. Berahmand, S. Forouzandeh. Journal of Big

Data, 8(1), 1-27 (2021).

R. Palanisamy, V. Govindaraj, S. Siddhan, Journal of

Intelligent & Fuzzy Systems, 43(1), 1163-1176 (2022).

H. Zhang, J. Thompson, M. Gu, Acs Photonics, 8(6), 1662-

1672 (2022).

S. Nikbakht, C. Anitescu, T. Rabczuk, Journal of Zhejiang

University-Science A, 22(6), 407-426 (2021).

B. Vivekanandam, Journal of ubiquitous computing and

communication technologies, 3(2), 135-149 (2021).

K. Velliangiri, P. Karthikeyan, V. M. A. Xavier, Ain Shams

Engineering Journal, 12(1), 631-639 (2021).

M. Al Mazaideh, J. Levendovszky, Journal of

Communications and Networks, 23(2), 138-147 (2021).

Optimization and Benefit Assessment of Cold Chain Logistics Network in Southeast Asia Based on Big Data Analysis

503