Utilizing Data Analysis for Optimized Determination of the Current

Operational State of Heating Systems

Ahmed Qarqour

1,2,*

, Sahil-Jai Arora

1,3,* a

, Gernot Heisenberg

2b

,

Markus Rabe

3, c

and Tobias Kleinert

4d

1

Bosch Thermotechnik GmbH, Junkersstraße 20-24, 73243 Wernau (Neckar), Germany

2

Department of Information Management, TH Cologne University, Claudiusstraße 1, 50678 Köln, Germany

3

Department IT in Production and Logistics, TU Dortmund University, 44221 Dortmund, Germany

4

Department of Information and Automation Systems for Process and Material Technology,

RWTH Aachen University, Turmstraße 46, 52064 Aachen, Germany

Keywords: Heating Systems, Time Series Analysis, Air-to-Water Heat Pump System, Knowledge Discovery in Databases,

Random Forest Algorithm, Field Data, Data-Driven Analysis, Fault Prediction.

Abstract: In response to the pressing global challenge of climate change, the emphasis on sustainable energy techno-

logies has escalated, spotlighting the critical role of heat pump systems as eco-friendly alternatives for heating

and cooling. These systems stand at the forefront of efforts to reduce greenhouse gas emissions and improve

energy efficiency. The advent of Internet of Things (IoT) technology has unlocked the potential for

comprehensive data collection on the operational intricacies of heat pump systems in real-world settings,

offering precious insights into their performance and guiding technological advancements. This paper

introduces an analytical approach to optimize air-to-water heat pump systems using time series data from

Bosch Home Comfort Group's systems. Utilizing Fayyad's data-driven analysis model and the Random Forest

algorithm, the study tackles system behavior complexities. Characterized by interpretability crucial for

application, it achieves a 97.6% fault detection accuracy. The method encounters difficulties in accurately

predicting compressor control faults due to limited data quality and a lack of comprehensive system

information. The findings highlight IoT's potential to enhance system efficiency and availability, but also

point to the limitations of relying solely on data-driven models for fault prediction in field systems.

1 INTRODUCTION

In 2021, German households consumed about 670

terawatt-hours of energy, mainly for space heating, as

per the Federal Environment Agency (Icha and Lauf,

2022). Heat pumps are crucial in this regard, known

for their efficiency and ability to reduce utility costs

and emissions by leveraging renewable energy

(Chiang, 2001). However, realizing their full poten-

tial requires understanding their entire lifecycle, from

production to user operation. Key stages of this life-

cycle encompass product development, manufac-

turing, storage, transport, installation, operation, and

a

https://orcid.org/0000-0002-6877-1480

b

https://orcid.org/0000-0002-1786-8485

c

https://orcid.org/0000-0002-7190-9321

d

https://orcid.org/0000-0001-7441-4431

*These Authors contributed equally to this work

maintenance. These stages primarily generate signif-

icant data during the development and operational

phases (Wiedemann and Schnell, 2006).

The Internet of Things (IoT) has upgraded data

collection, allowing for the extensive networking of

devices and sensors with the data stored in the cloud

(Zhang et al., 2010). Analyzing these data aims to

optimize heating systems. The potential incorporation

of suppliers and service providers into this analysis

enhances system lifecycle understanding, supporting

early fault detection and refining system requirements

for future models (Wiedemann and Schnell, 2006).

Fault detection methods in systems are crucial for

200

Qarqour, A., Arora, S., Heisenberg, G., Rabe, M. and Kleinert, T.

Utilizing Data Analysis for Optimized Determination of the Current Operational State of Heating Systems.

DOI: 10.5220/0012876200003838

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 16th International Joint Conference on Knowledge Discovery, Knowledge Engineering and Knowledge Management (IC3K 2024) - Volume 1: KDIR, pages 200-209

ISBN: 978-989-758-716-0; ISSN: 2184-3228

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

improving efficiency, availability, and customer

satisfaction (Chiang, 2001). These methods include

model-based, data-based, and hybrid approaches

(Zhang and Jiang, 2008). Model-based methods simu-

late and diagnose the system behavior with

mathematical precision, but demand thorough

understanding and are complex (Venkatasubramanian

et al., 2003). Data-based strategies, leveraging machine

learning on historical data, suit complex systems, but

need high data quality and substantial resources (Chen,

1999). Hybrid approaches combine the strengths of

models and data to efficiently detect faults, providing

a balanced solution for fault diagnosis in challenging

systems (Yang and Rizzoni, 2016). Data-driven

methodologies employ structured models for

Knowledge Discovery in Databases (KDD), including

the Fayyad KDD framework (Fayyad et al., 1996).

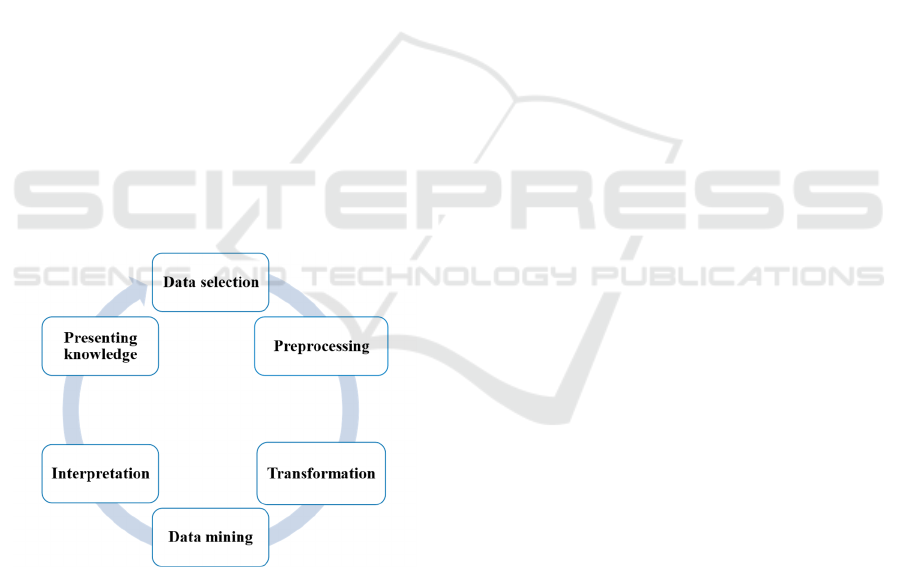

As depicted in Figure 1, this model contains cru-

cial steps for knowledge extraction from databases,

starting with the selection of relevant data, followed

by its cleaning and formatting in the preprocessing

phase. Then, the data are transformed into a format

appropriate for mining, after which mining is conduc-

ted to discover patterns (Fayyad et al., 1996). These

patterns are interpreted to determine their relevance,

and finally the extracted insights are presented. This

comprehensive process is essential for understanding

and enhancing system performance (Garcia et al.,

2015).

Figure 1: KDD process according to Fayyad.

2 RELATED WORK

2.1 Data-Based Approaches in Heating,

Ventilation, and Air Conditioning

Systems

With growing demand for efficient and reliable

heating, ventilation, and air conditioning (HVAC)

systems, the development and application of machine

learning algorithms for fault detection and diagnosis

(FDD) have become increasingly crucial (Li and

O’Neill, 2018). Pioneering work by Gharsellaoui et

al. (2020) leverages the Multiclass Support Vector

Machine (SVM) algorithm to categorize data within

smart buildings effectively. Concurrently, the

approach of Ebrahimifakhar et al. (2020) introduces a

statistical ML-based classification model using SVM

to detect faults in rooftop units by analyzing and

classifying data. Similarly, Bode et al. (2020) have

developed an innovative FDD model that combines a

big data framework with SVMs, aimed at identifying

faulty operations in HVAC terminal units through the

aggregation and evaluation of data from various

sources. Complementing these efforts, Ren et al.

(2020) have proposed a comprehensive FDD proce-

dure that merges SVM with principal component

analysis (PCA), designed to predict system behavior

under new load conditions by extracting pivotal fea-

tures from the dataset. This ensemble of models

underscores the potential and reliability of machine

learning in enhancing fault detection and diagnostic

capabilities in HVAC systems. An extensive over-

view of FDD models within the realm of building

technology, as detailed in the literature, highlights the

eclectic range of approaches and techniques that form

the foundation of this field (Li and O’Neill, 2018).

2.2 Key Challenges in Currently

Applied Approaches

Heating systems are complex and impacted by di-

verse operating conditions. The need for interpretable

models that can handle this complexity and be applied

to different systems is critical. However, challenges

arise with data-driven FDD methods developed based

on black-box models such as artificial neural net-

works (ANN) and SVM, mainly due to their lack of

interpretability (Yan et al., 2016). This limitation

makes it difficult to understand the process of fault

identification within these models. Moreover, the

effectiveness of data-driven methods largely depends

on the quality of the training data (Yang and Rizzoni,

2016). Insufficient data samples and errors in the

training data can lead to incorrect classifications.

Often the available training data do not cover the

entire spectrum of system operation, which limits the

model validity to certain conditions. Especially, very

critical situations appear only rarely in reality, leading

to a deficit of related sensor data. Without

interpretability, evaluating model reliability and

applicability becomes a challenge (Yan et al., 2016).

Utilizing Data Analysis for Optimized Determination of the Current Operational State of Heating Systems

201

2.3 Methodological Contributions

This paper outlines an application-oriented

methodology for heat systems employing the

Random Forest algorithm for extracting knowledge

from data. Central to this approach is its use of deci-

sion trees, distinguishing Random Forest by revealing

causes of faults through key parameter identification

and enhancing model transparency with decision tree

visualizations, a clarity lacking in black-box models.

Moreover, as an ensemble method, Random Forest

reduces overfitting risks by aggregating multiple

trees' predictions, ensuring applicability across varied

operational conditions (Cutler et al., 2012). This

adaptability is essential for analyzing and anticipating

system faults, evaluating system performance

through error rate analysis, and guiding potential

enhancements. Emphasizing its computability,

accuracy, and interpretability, this methodology

underscores the direct applicability of Random Forest

approaches over more complex techniques found in

explainable artificial intelligence (XAI), such as

Shapley values, ensuring the methodology's efficacy

and practical relevance (Başağaoğlu et al., 2022).

Thus, this approach provides a fault detection and

prediction solution for heating systems in the field,

making it particularly valuable for engineers and

practitioners in the domain of heating systems.

3 DATA-DRIVEN

METHODOLOGICAL

FRAMEWORK

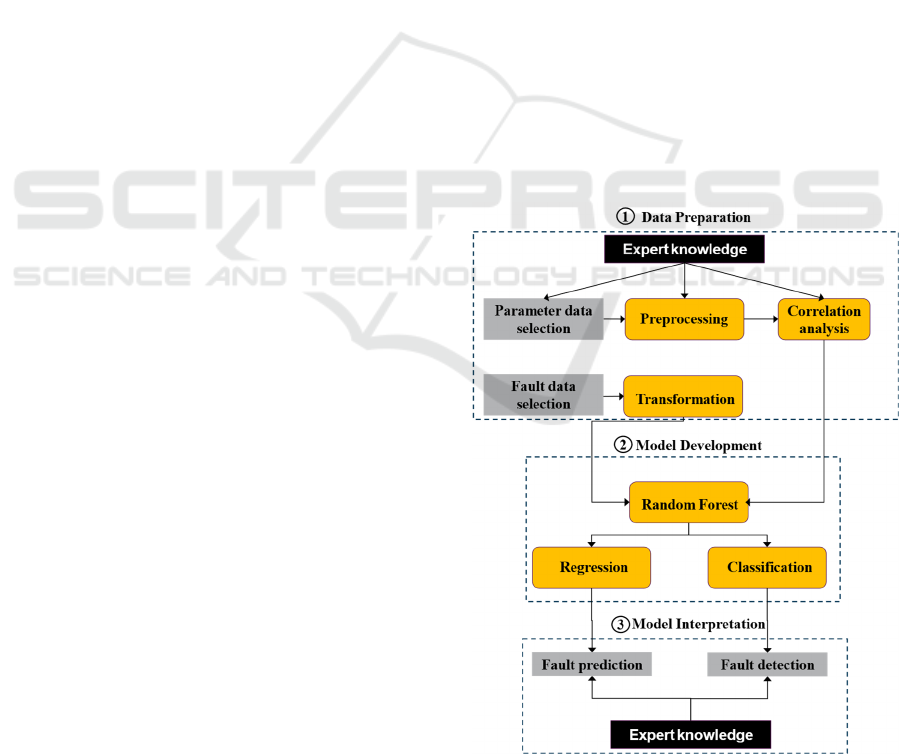

This paper presents a structured approach to analyze

and explore air-to-water heat pump systems, with a

focus 1 faults. Concurrently, the regression segment

estimates the remaining time until a fault occurs. These

models undergo testing to validate their accuracy in

assessing the system status and forecasting faults.

The Model Interpretation stage offers a deep dive

into the model's decision-making, elucidating how it

identifies the system status and predicts faults. Expert

knowledge validates the model's underlying logic.

4 APPLICATION OF

METHODOLOGY:

INTRODUCTION TO THE USE

CASE STUDY

The methodology applied in this paper focuses on an

air-to-water heat pump system with a fault in the

compressor control. Such control faults arise from

issues within the heat pump's control unit and can

impact compressor performance. This may lead to in-

efficient operation of the heat pump, adversely affect-

ing its heating and cooling capacity. Potential causes

of these faults include high ambient temperatures

around the compressor leading to sensor failures,

poor wiring, or incorrect control settings. This analy-

sis was conducted at the Bosch Home Comfort

Group. The Heat Pump Development Department

was responsible for providing the parameter data and

fault information.

The primary objective of this study is to analyze

the impact of the fault on the system and to identify

the occurrence of the fault using system data. Addi-

tionally, the research explores the potential for pre-

dicting future fault occurrences. The system data,

which describe the system's state, were collected

through the bus system. The data analysis is based on

time series data with a sampling frequency of 0.83

Hz, covering the period from February 1, 2021, to

May 1, 2022. The findings contribute to enhance

understanding of the field system's behavior. Based

on these insights, strategies to optimize the efficiency

and stability of the heat pump system can be

developed, ensuring smooth operation in the future.

Figure 2: Stages of the methodology.

KDIR 2024 - 16th International Conference on Knowledge Discovery and Information Retrieval

202

5 DATA PREPARATION

This stage is designed to achieve a structured and

complete dataset. This section outlines how each step

of the stage is executed for the investigated use case.

5.1 Data Selection

The data selection for analysis focuses on identifying

critical parameters within the heat pump's bus system,

which characterize the general state and specifically

the control faults in the compressor. This selection is

performed in close collaboration with experts in the

heat pump development team at Bosch Home Com-

fort Group to ensure that the chosen data possess the

necessary relevance and quality for the study. Verify-

ing the availability and integrity of the data in the bus

system is an essential part of this process. Finally, the

resulting parameters considered central to the analy-

sis are detailed as follows:

Power Setpoint: Targeted electrical power

consumption level for the heat pump, setting

the desired performance level for optimal

efficiency and meeting heating or cooling

demands.

Actual Power: Current electrical power

consumption of the heat pump, used to

assess energy efficiency and operational

status.

Actual Compressor Speed: Current speed

at which the compressor is operating, indica-

ting performance level and efficiency of the

heat pump.

Air Temperature at the Evaporator:

Temperature of air entering the evaporator,

helping to evaluate heat exchange efficiency

and system load.

Temperature of the Compressor: Current

temperature of the compressor, used to

monitor compressor health and prevent

overheating.

Temperature of the Hot Gas: Temperature

of the gas after compression, before conden-

sation, indicating the efficiency of the com-

pression cycle.

Evaporator Return Temperature:

Temperature of the fluid returning to the

evaporator, assisting in assessing heat

absorption efficiency.

Outdoor Temperature: Outdoor ambient

temperature, used to adjust operations for

optimal efficiency and performance.

Condenser Inlet Temperature: Tempe-

rature of the fluid entering the condenser,

providing insights into the condensing

process efficiency.

5.2 Data Preprocessing

As long as the values of these parameters remain

constant, the bus system does not report any values.

However, when any value changes, the bus system

communicates this change. In the dataset, this leads

to empty cells between these two values, which need

to be filled to complete the dataset. This is done using

the zero-order hold principle, meaning empty cells

between two known values are filled with the last

known value until a new value is registered.

To detect outliers, data have been visualized using

box plots. This decision was driven by the need for a

straightforward and visually intuitive method,

allowing experts to easily identify and assess unusual

values as potential outliers. Box plots were chosen

over other methods, because they clearly delineate the

range of typical data, making deviations apparent. In

the context of missing operational condition details,

solely data-driven outlier detection proved to be

unreliable (Xu et al., 2020). Instead, combining box

plots with expert insights and system specifications

enabled a more informed decision on whether values

were outliers or relevant variations, ensuring a

nuanced and accurate outlier elimination process.

5.3 Correlation Analysis

As mentioned in the previous section, the necessity of

this step in the data preparation stage is caused by low

data quality. Correlation analysis investigates the

relationship between operational parameters to

determine how accurately the data represent these

physical interactions (Wilcox, 2001). This accurate

representation is essential to deliver valid inputs to

the model during the training phase. Therefore, the

model is enabled to understand the system's status

through the available training data and to produce

reliable predictions about the system status. To

achieve this, three sub-steps are involved: a)

assessing data normality to select an appropriate

correlation method, b) applying the chosen

correlation to the dataset, and c) validating the

correlation results against the parameters' physical

relationships through expert knowledge.

The Shapiro-Wilk test (Ghasemi and Zahediasl,

2012) initially assessed for normal distribution

revealed a non-normal distribution that necessitated

the use of Spearman's correlation method (Wilcox,

Utilizing Data Analysis for Optimized Determination of the Current Operational State of Heating Systems

203

2001) for the analysis. Experts reviewed the correla-

tion coefficients to verify their physical relevance,

ensuring that data faithfully represent the system's

physical dynamics. This step illuminates crucial

relationships between variables and affirms the data's

pertinence to the studied physical phenomena.

5.4 Transformation

Fault information is encoded into binary values, with

0 indicating no fault and 1 indicating a fault occur-

rence, to serve as the target variable for training the

Random Forest model. This conversion sets up a

classification problem, allowing the model to learn

fault detection from parameter data and target

variables.

6 MODEL DEVELOPMENT

The Random Forest model is developed to analyze

the relationship between various operational

parameters and fault occurrences in the air-to-water

heat pump system. It comprises two parts: (1)

classification model that determines the system's

status and (2) regression model predicting the time

until a fault occurs. These models were implemented

using the scikit-learn library in Python and developed

within a Jupyter Notebook.

6.1 System Status Detection

Random Forest Classifier (RFC) employs decision

trees on random data subsets, leveraging ensemble

learning for accurate classifications while mitigating

overfitting and assessing feature importance (Biau

and Scornet, 2016). The steps of the model imple-

mentation are illustrated in Figure 3. To address the

challenge of rare critical situations outlined in Section

2.2, particularly the infrequent occurrence of faults in

the compressor control, a down sampling strategy has

been implemented.

Figure 3: RFC implementation steps.

This method balances the dataset by reducing the

number of non-faulty instances to equal the number

of faulty instances, ensuring uniform representation.

A RFC with three trees (n_estimators=3) and a

random_state of 42 is chosen, targeting a balance of

model complexity and computational efficiency. The

decision to use three trees was based on performance

evaluations against a validation set, where adding

more trees resulted in only minimal improvements in

accuracy, suggesting that further increases would not

yield significant benefits. This choice reflects an

optimization between simplicity and the ability to

capture operational variability, with a random_state

of 42 ensuring result reproducibility. Default para-

meter settings are maintained as detailed in (scikit-

learn, 2024).

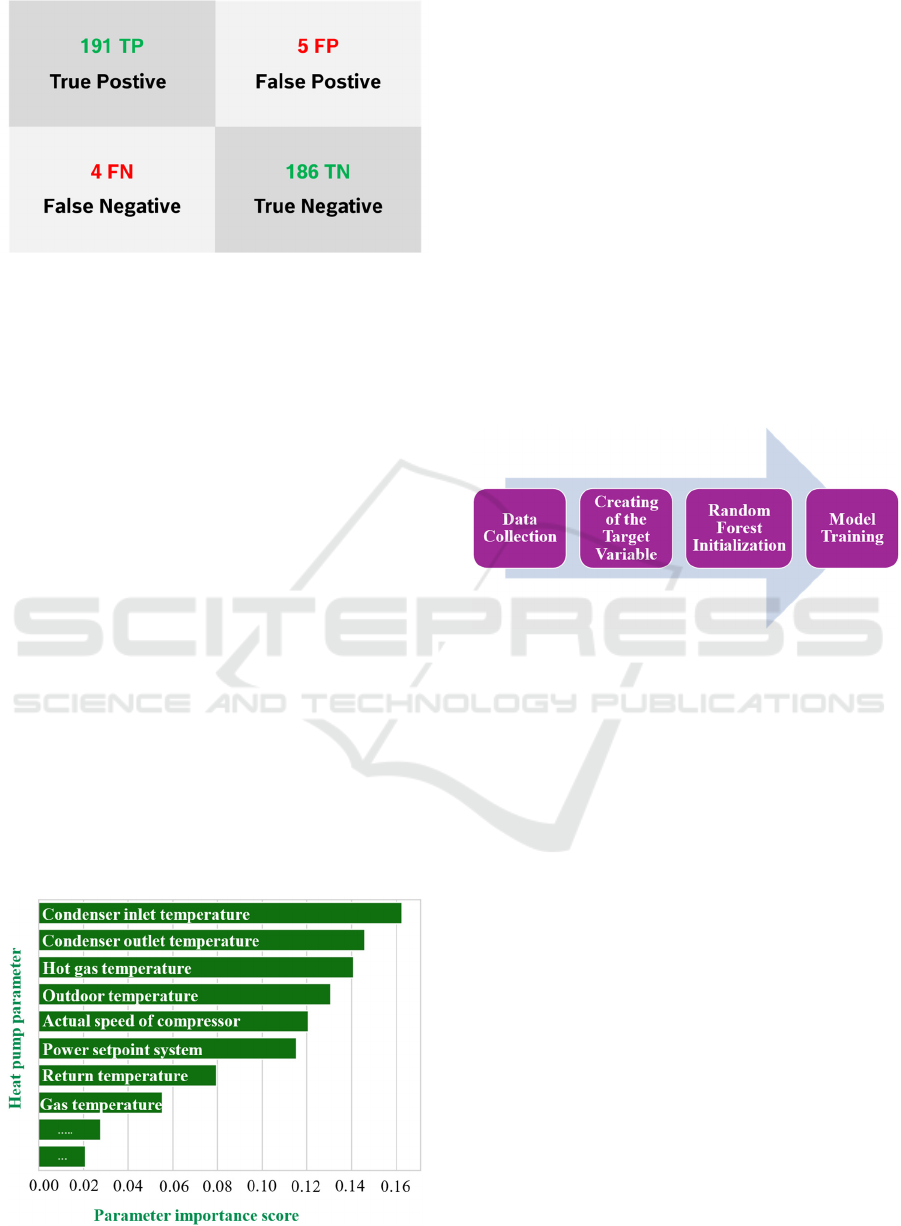

6.1.1 Evaluation of the Detection Model

The model was validated using test data to assess its

reliability in predicting on unknown data, using a

confusion matrix for evaluating accuracy and

precision. Results are illustrated in Figure 4.

This analysis revealed 191 true positives,

indicating non-faulty operation status were correctly

identified, and 181 true negatives, which means fault

status were accurately detected as such. Additionally,

the model encountered four false negatives, repre-

senting overlooked fault status, and five false posi-

tives, where faults were incorrectly identified in non-

faulty operation status. Achieving a high accuracy of

97.6% and a precision of 97.4%, the model demon-

strates efficient fault detection and classification.

Maintaining a low rate of false positives is crucial;

they not only lead to unnecessary fault correction

costs, but also could divert resources from actual

issues, potentially leaving real faults undiagnosed.

This emphasis on minimizing false positives is vital

for operational efficiency and cost management. The

results highlight the model's effective performance in

accurately identifying the operation status, balancing

accurate fault detection with the imperative to

minimize false alarms.

6.1.2 Model Interpretation

The RFC algorithm addresses the challenge of lack of

interpretability in data-driven FDD methods based on

black-box models as mentioned in Section 2.2. It

identifies key parameters through parameter

importance calculation – facilitating an

understanding of the classification processes – and

enhancing transparency while validating the model’s

outputs (Breiman, 2001). Through Python's scikit-

learn library, feature importance is determined using

KDIR 2024 - 16th International Conference on Knowledge Discovery and Information Retrieval

204

Figure 4: Confusion matrix of the test data.

the Mean Decrease in Gini (MDG) method, which

assesses how a feature reduces impurity across the

model's trees. MDG values range from 0 (no impact)

to 1 (perfect prediction capability), where higher

values indicate a stronger effect on model decisions

(Biau and Scornet, 2016). This calculation considers

the decrease in node impurity, weighted by the

probability of reaching that node, averaged over all

trees (Breiman, 2001). The key findings of the

parameter importance are illustrated in Figure 5.

It indicates that specific parameters, such as con-

denser inlet and outlet temperatures, hot gas tempera-

ture, external temperature, compressor speed, and

power setpoint are paramount in fault detection,

demonstrating nearly equal importance. Conversely,

parameters like evaporator air temperature, com-

pressor temperature, evaporator return temperature,

and current performance have a lower impact.

These insights emphasize the importance of

temperature-related measurements in detecting the

fault. Through the interpretability of the model, these

insights into model parameters can be traced back to

the faulty state of the system. The relevance of the

parameters to the faulty state are confirmed by the

experiential knowledge of experts.

Figure 5: Visualization of the importance of parameters.

This validation not only enhances the

development steps of the component to prevent the

occurrence of such faults but also expands the

knowledge of relevant factors that can lead to faults.

In the future, this approach can also be applied to

other types of faults to gain valuable insights.

6.2 System Status Prediction

This model aims to predict the remaining time until

the next fault occurs, utilizing an ensemble of

decision trees to make accurate predictions on

continuous values by averaging the outputs of all

trees in the forest. Similar to the classifier model, the

Random Forest Regressor (RFR) applies ensemble

learning, but focuses on estimating continuous

outcomes. The implementation of the RFR mirrors

that of the classifier model, as depicted in Figure 6.

Figure 6: RFR implementation steps.

The process starts with data collection represen-

ting various operational conditions, followed by crea-

ting the target variable time until the next fault, which

is hereafter referred to as "Time to Failure". This is

achieved by reverse iterating through the data to cal-

culate the time until the next fault for each data point,

producing a list of minutes until the next fault. For

this model, a RFR with ten trees (n_estimators=10)

and a random_state of 42 was selected, balancing

model complexity with computational efficiency. The

choice of more trees for the RFR compared to the

RFC reflects the increased complexity needed in

regression models to capture data variability and

nuances accurately (Corrales et al., 2018). With this

optimized tree ensemble, the RFR can more

accurately identify and predict underlying trends,

enabling precise predictions for the time to failure.

The default parameters are retained as described in

(scikit-learn, 2024).

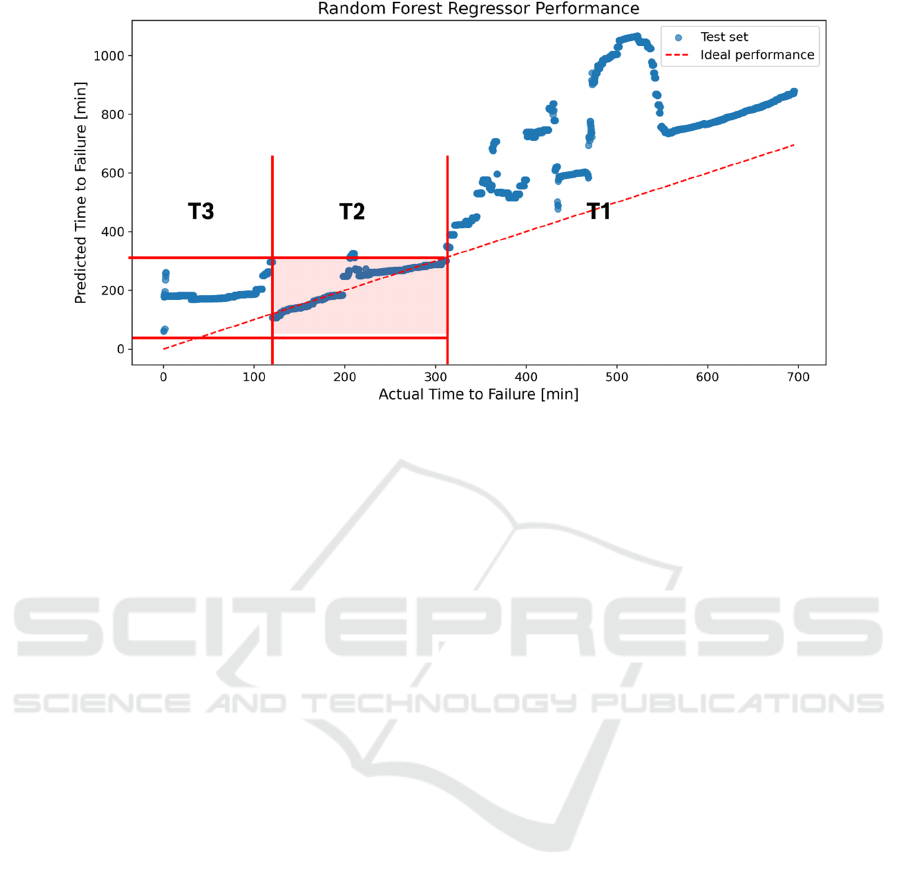

6.2.1 Evaluation of the Prediction Model

The model accuracy was validated using test data to

assess its reliability in predicting on unknown data

using the Mean Absolute Error (MAE). The test

Utilizing Data Analysis for Optimized Determination of the Current Operational State of Heating Systems

205

Figure 7: Accuracy of the model with test data.

dataset contains a fault scenario. The results were

visualized in Figure 7, where the X-axis represents

the actual values and the Y-axis the predicted values

of "Time to Failure". Ideal model performance is

achieved when data points closely align along the

ideal performance line, aiming for an MAE value of

0, indicating precise alignment between predictions

and actual events.

The accuracy evaluation of the model reveals

three key insights that provide a nuanced view of the

model's performance across different periods before a

fault event.

Phase T1: Actual Time to Failure > 320

minutes

Phase T2: 320 minutes ≥ Actual Time to

Failure ≥ 120 minutes

Phase T3: 120 minutes > Actual Time to

Failure > 0 minutes

Phase T1 describes long-term predictions, star-

ting from 320 minutes before the fault occurrence. In

this phase, it was observed that the model appears in-

capable of detecting reliable indicators of an

impending fault, resulting in a large discrepancy

between predicted and actual values. This limitation

highlights the challenges in predicting faults over an

extended period. Phase T2 describes mid-term predic-

tions, between 120 and 320 minutes before the fault

occurrence. In contrast to Phase T1, the model de-

monstrates considerably better performance with a

MAE of 18.6 minutes. During this critical period, the

model effectively analyzes and interprets operational

conditions and potential signs of an impending fault,

indicating its capability to utilize relevant information

for fault prediction. Phase T3 involves short-term

predictions made 0 to 120 minutes before a fault

occurs. In this phase, the model's accuracy decreases,

primarily due to a significant deviation of data points

from the ideal line. This reduction in accuracy can be

attributed to insufficient information density in the

parameters, leading to unreliable predictions.

However, the application of the model to other

faulty scenarios has revealed significant limitations,

primarily due to the limited availability of faulty data

and limited understanding of the underlying causes.

This problem is closely linked to the challenge of

data quality and availability, as discussed in Section

2.2. The lack of comprehensive data sets significantly

impairs the model's ability to predict under different

operating conditions. In addition, the complexity of

the heat pump system combined with a limited data

set further reduces the model’s prediction accuracy.

This is compounded by uncertain causes of failure

such as wiring or software issues, which are discussed

in more detail in Section 4. Ultimately, these

challenges emphasize the urgent need for improved

data quality and a deeper understanding of failure

mechanisms.

6.2.2 Model Interpretation

In the RFR model, evaluating parameter significance

is the key to decoding its predictive logic. This

process identifies the extent to which various features

impact the model's ability to predict the timing of a

fault. Understanding the critical features enhances the

insight into the model's operational dynamics. Dif-

fering from the RFC model, the RFR model assesses

KDIR 2024 - 16th International Conference on Knowledge Discovery and Information Retrieval

206

the feature importance via the Mean Decrease in Im-

purity (MDI). MDI reflects how each feature's

variance reduction, averaged across all trees, contri-

butes to the model's accuracy. This method highlights

the influence of specific features on enhancing the

model's precision by reducing prediction variance

through data segmentation.

This analysis reveals that the outdoor temperature

and air temperature at the evaporator exert the stron-

gest influence on prediction accuracy, with a com-

bined importance of 50%. Additionally, the conden-

ser exit temperature and the power setpoint also make

significant contributions to the forecast, both with

importance of 14%. These four parameters collec-

tively account for 78% of the predictive influence.

These results emphasize two major results: (1)

temperature-related measurements and the power

setpoint in the context of precise fault prediction are

crucial and (2) there is a need for the extension of the

knowledge about the selection of relevant parameters

for fault monitoring and the definition of the time

period in which a fault can be predicted. Despite the

limited number of fault cases in the system history,

these findings are valuable for future research and

help in the selection of time periods and relevant

parameters in the model training to reduce model

complexity.

7 DISCUSSION OF RESULTS

The research findings, which were discussed with

engineering experts from the heat pump department

at Bosch Home Comfort Group, focus on four key

questions:

How does interpretability clarify causality

between system parameters and faults while

supporting model scalability?

Which benefits does a system status detec-

tion model offer?

How does the parameter significance de-

rived from the classification model affect

error detection logic and contribute to the

optimization of the regression model for

error prediction?

How could more diverse data improve fault

prediction, and what are the challenges?

Regarding the first aspect (interpretability),

discussions with the experts in the heat pump

department emphasize the importance of

interpretability for scaling the model to systems with

similar data deficiencies. As explained in Section

6.1.2, the interpretability of the model enables the

exact quantification of the meaning of the parameters.

This improves the understanding of how each feature

affects the predictions of the model. This insight is

crucial for accurate adjustments when applying the

model to new systems. This ensures the effectiveness

of the model in different operating environments.

This detailed interpretative analysis also helps to

adapt the model and standardize fault detection

practices across different environments.

Regarding the second aspect (benefits of a

detection model), experts highlight the significant

benefits of a system status detection model, especially

for systems that do not capture fault data. Such a

model enables an understanding of the system's

behavior in operation, identification of common

faults, and efficient resource planning, directly

contributing to the optimization of the system design.

Concerning the third aspect (parameter

significance), discussions with experts emphasize the

importance of specific parameters, such as condenser

inlet and outlet temperatures, hot gas temperature,

and outdoor temperature, identified in Section 6.1 as

crucial for detecting faults within the compressor

control. Expert opinions indicate that future research

could significantly enhance prediction accuracy by

redesigning the error detection logic to reflect

parameter relevance and optimizing the online

monitoring of these parameters. Achieving this

improvement also involves intensified collaboration

with service companies to obtain detailed fault

information, including causes of occurrences. This

collaboration forms the foundation for a more effi-

cient predictive control system, aimed at reducing

downtime and improving overall system perfor-

mance.

The last aspect discussed with the experts

involves analyzing the predictive model’s capability

to determine the precise time phase when a fault can

be anticipated within the system. The model – under

the constraints of current assumptions and data

rarity – identifies early symptoms of errors occurring

between 120 and 320 minutes. This preliminary

insight is crucial as it suggests that expanding our

dataset with a broader range of failure cases could

potentially reduce the need for extensive training data

and help avoid overfitting. Enhancing the dataset in

this manner would improve the model’s accuracy and

its applicability to similar systems.

Utilizing Data Analysis for Optimized Determination of the Current Operational State of Heating Systems

207

8 SUMMARY AND FUTURE

WORK

This paper explores the potential of time series

analysis of sensor data from heating systems in

operation for detecting and predicting errors, a critical

area complicated by the significant distance between

users and manufacturers. A procedure based on

Fayyad's model was implemented and applied to an

air-to-water heat pump system to identify and forecast

specific control faults in the compressor.

A RFC model was developed to recognize system

status and assess the impact of parameter weights on

fault detection. This model successfully determined

the status of the systems, achieving a detection accu-

racy of 97.6% and a precision of 97.4%. A key chal-

lenge was the limited dataset, which complicated the

expert validation and underscored the necessity for a

larger data foundation. The analysis underscored the

significance of certain parameters, particularly tem-

perature readings, in fault detection. Experts valida-

ted these findings, emphasizing the need for ongoing

adjustment of weight factors.

The limited availability of fault data and the lack

of system information restricts the effectiveness of

the RFR model. This limitation stems from the sys-

tem's lifecycle; after sale, third-party service and

maintenance companies oversee installation and

upkeep, while manufacturers conduct field monito-

ring for a brief period. As a result, failure data collec-

tion is primarily limited to this monitoring phase, thus

affecting the model's ability to predict accurately.

Future research directions, inspired by this work,

will explore the potential of Random Forest models

to analyze more extensive datasets with increased

error instances and assess other machine learning

algorithms for error detection and prediction in heat

pump systems. An optimized dataset, including

detailed parameter and fault information, is crucial

for developing models that accurately reflect system

reliability and behavior. Additionally, future studies

should explore the reliability of specific system

components and their impact on overall system

reliability. Future investigations should incorporate

not only existing data but also laboratory results,

simulations, and physical models. The integration of

physics-based models will be explored to establish

causal relationships between system parameters and

fault occurrences, thereby enhancing the model’s

ability to predict and diagnose faults with higher

accuracy. This approach is expected to improve the

overall effectiveness of the system, contributing to a

deeper understanding of system dynamics, and

advancing control strategies for heating systems.

REFERENCES

Arora, S.-J., & Rabe, M. (2023). Predictive maintenance:

Assessment of potentials for residential heating

systems. International Journal of Computer Integrated

Manufacturing, 1--25. https://doi.org/10.1080/

0951192X.2023.2204471.

Başağaoğlu, H., Chakraborty, D., Lago, C. D., Gutierrez,

L., Şahinli, M. A., Giacomoni, M., Furl, C., Mirchi, A.,

Moriasi, D., & Şengör, S. S. (2022). A review on

interpretable and explainable artificial intelligence in

hydroclimatic applications. Water, 14(8), 1230.

https://doi.org/10.3390/w14081230.

Biau, G., & Scornet, E. (2016). A random forest guided

tour. TEST, 25(1), 197--227. https://doi.org/

10.1007/s11749-016-0481-7.

Bode, G., Thul, S., Baranski, M., & Müller, D. (2020).

Real-world application of machine-learning-based fault

detection trained with experimental data. Energy, 198,

323. https://doi.org/10.1016/j.energy.2020.117323.

Breiman, L. (2001). Random forests in machine learning.

Springer, New York, NY, 5--32. https://doi.org

/10.1023/A:1010933404324.

Chen, J. (2013). Model-based fault diagnosis in dynamic

systems using identification techniques. Springer,

London, United Kingdom. ISBN: 978-1-4471-3829-7.

https://doi.org/10.1007/978-1-4471-3829-7.

Chiang, L. H. (2001). Fault detection and diagnosis in

industrial systems. Springer, London, United Kingdom.

https://doi.org/10.1088/0957-0233/12/10/706.

Corrales, D., Corrales, J., & Ledezma, A. (2018). How to

address the data quality issues in regression models: A

guided process for data cleaning. Symmetry, 10(4), 99.

https://doi.org/10.3390/sym10040099.

Cutler, A., Cutler, D. R., & Stevens, J. R. (2012). Random

forests in Ensemble Machine Learning. Springer, New

York, NY, 157--175. https://doi.org/10.1007/978-1-

4419-9326-7_5.

Dey, M., Rana, S. P., & Dudley, S. (2020). Smart building

creation in large scale HVAC environments through

automated fault detection and diagnosis. Future

Generation Computer Systems, 108, 950--966.

https://doi.org/10.1016/j.future.2018.02.019.

Ebrahimifakhar, A., Kabirikopaei, A., & Yuill, D. (2020).

Data-driven fault detection and diagnosis for packaged

rooftop units using statistical machine learning

classification methods. Energy and Buildings, 225, 318.

https://doi.org/10.1016/j.enbuild.2020.110318.

Fayyad, U., Piatetsky-Shapiro, G., & Smyth, P. (1996). The

KDD process for extracting useful knowledge from

volumes of data. Communications of the ACM, 39,

27--34. https://doi.org/10.1145/240455.240464.

García, S., Luengo, J., & Herrera, F. (2015). Data

preprocessing in data mining. Springer International

Publishing, Cham, Switzerland, 19--38.

https://doi.org/10.1007/978-3-319-10247-4.

Gharsellaoui, S., Mansouri, M., Trabelsi, M., Harkat, M.-

F., Refaat, S. S., & Messaoud, H. (2020). Interval-

valued features based machine learning technique for

fault detection and diagnosis of uncertain HVAC

KDIR 2024 - 16th International Conference on Knowledge Discovery and Information Retrieval

208

systems. IEEE Access, 8, 892--902. https://doi.

org/10.1109/ACCESS.2020.3019365.

Ghasemi, A., & Zahediasl, S. (2012). Normality tests for

statistical analysis: a guide for non-statisticians.

International Journal of Endocrinology and

Metabolism, 10(2), 486--489. https://doi.org/10.5812/

ijem.3505.

Icha, P., & Lauf, T. (2022). Entwicklung der spezifischen

Treibhausgas-Emissionen des deutschen Strommix in

den Jahren 1990–2021. Retrieved February 12, 2024,

https://www.umweltbundesamt.de/sites/default/files/m

edien/1410/publikationen/2022-04-13_cc_15-

2022_strommix_2022_fin_bf.pdf.s

Li, Y., & O’Neill, Z. (2018). A critical review of fault

modeling of HVAC systems in buildings. Building

Simulation, 11(5), 953--975. https://doi.org/10.1007/

s12273-018-0458-4.

scikit-learn. (2024).

sklearn.ensemble.RandomForestClassifier. Retrieved April

23, 2024,

https://scikitlearn.org/stable/modules/generated/sklearn.en

semble.RandomForestClassifier.html.

Venkatasubramanian, V., Rengaswamy, R., Yin, K., &

Kavuri, S. N. (2003). A review of process fault

detection and diagnosis: Part I: Quantitative model-

based methods. Computers & Chemical Engineering,

27(3), 293--311. https://doi.org/10.1016/S0098-

1354(02)00160-6.

Wiedemann, B., & Schnell, G. (2006). Bus systems in

automation and process technology. Vieweg+Teubner,

151–344. https://doi.org/10.1007/978-3-8348-9108-

2_4.

Wilcox, R. (2001). Fundamentals of modern statistical

methods. Springer, New York, NY, 67--91.

https://doi.org/10.1007/978-1-4757-3522-2.

Xu, X., Lei, Y., & Li, Z. (2020). An incorrect data detection

method for big data cleaning of machinery condition

monitoring. IEEE Transactions on Industrial

Electronics, 67, 326--336. https://doi.org/10.1109/TIE.

2019.2903774.

Yan, R., Ma, Z., Zhao, Y., & Kokogiannakis, G. (2016). A

decision tree based data-driven diagnostic strategy for

air handling units. Energy and Buildings, 133, 37--45.

https://doi.org/10.1016/j.enbuild.2016.09.039.

Yang, R., & Rizzoni, G. (2016). Comparison of model-

based vs. data-driven methods for fault detection and

isolation in engine idle speed control system. In Proc.

of PHM Conference, 8(1), Oct. 2016. https://doi.

org/10.36001/phmconf.2016.v8i1.2502.

Zhang, Q., Cheng, L., & Boutaba, R. (2010). Cloud

computing: State-of-the-art and research challenges.

Journal of Internet Services and Applications, 1(1),

7--18. https://doi.org/10.1007/s13174-010-0007-6.

Zhang, Y., & Jiang, J. (2008). Bibliographical review on

reconfigurable fault-tolerant control systems. Annual

Reviews in Control, 32(2), 229--252. https://doi.org/

10.1016/j.arcontrol.2008.03.008.

Utilizing Data Analysis for Optimized Determination of the Current Operational State of Heating Systems

209