Power Quality Monitoring Device of EMU Traction Network Based

on Zynq

Jiale Zhang

1

, Zhengwei Liu

1

, Chao Guan

1

, Dalei Ha

1

and Song Xiang

2

1

CRRC Changchun Railway Vehicles Co., Ltd, Changchun, China

2

School of Physical Science and Technology, Southwest Jiaotong University,Chengdu, China

Keywords: EMU, Power Quality, Monitoring Devices, Zynq-7000, AD9251.

Abstract: Aiming at the power quality problem of traction network during the operation of moving train sets, a traction

network power quality monitoring device is designed in the paper. The device uses the XC7Z045 chip of the

Zynq-7000 series as the main control chip, and adopts a modularized design, including the signal acquisition

module, signal processing module, data transmission module and power supply module. The signal

acquisition module designs a 1000:1 large-ratio resistor-capacitor buck circuit and a current sampling circuit

with a gain of 3.9, and realizes the high-speed synchronous acquisition of network voltage and network current

based on the AD9251 chip; the signal processing module completes the high-speed processing of data by

using the built-in FPGA+ARM dual-core architecture of the main control chip; the data transmission module

uses the Ethernet chip 88E1116R and network transformer HR682430E to construct the PAC and the data

transmission module; the signal processing module uses the Zynq-7000 series XC7Z045 chip as the main

control chip. The data transmission module uses Ethernet chip 88E1116R and network transformer

HR682430E to build PHY Gigabit network circuit, which realizes high-speed and reliable data transmission;

the power supply module is based on a variety of power management chips such as TPS54560, SY8263, and

so on, and the logic of power supply architecture according to the multi-stage conversion, which improves

the power supply reliability of the hardware circuits. After test verification, the device has stable performance

and high calculation accuracy, and the calculation error of each parameter is within 0.5%.

1 INTRODUCTION

In the 21st century, the rapid development of EMU

speed and intelligence, and inevitably accompanied

by the introduction of the corresponding high-power

and nonlinear equipment, EMU asymmetric load and

other nonlinear load capacity continues to increase,

which brings a series of problems in the traction

network system voltage and current waveform

distortion, fluctuation and flicker, which seriously

affects the power quality of the power supply

system(Weiwei Li, 2020;Jianxiong Zhang, 2022;Ke

Yin, 2020;Tao Liu, 2022). Therefore, it is urgent to

conduct data monitoring on the power quality of the

traction network during the operation of EMU, and

use the data as support to trace and solve the

problems, so as to provide guarantee for the safe

operation of EMU(Liping Zhao, 2022;Guiping Cui,

China National Railway Group Corporation Science and Technology Research and Development Program(N2022J008)

2020;Zhuo Liu, 2021;He Wang, 2021;Shuang Yan,

2020).

At present, the power quality monitoring

technology is mature in the field of power system, but

because of the complex electrical coupling process of

EMU train traction network, it is not suitable for the

technical standards of power system(Guipeng Zhang,

2023). According to the survey, a unified and

standardized standard system has not been formed in

the field of EMU. The existing power quality

monitoring device of traction network have single

function, high cost, long development cycle time, and

are mostly installed in traction substations. However,

EMU trains as traction load are ignored as the

incentive source of power quality deterioration of

traction network. Therefore, the power quality of

traction network should be monitored by monitoring

the output signals of on-board voltage and current

transformer of EMU(Yifeng Su, 2021;Qiang Li,

2021;Chengyue He, 2021;Shenggao Gong, 2020).

46

Zhang, J., Liu, Z., Guan, C., Ha, D. and Xiang, S.

Power Quality Monitoring Device of EMU Traction Network Based on Zynq.

DOI: 10.5220/0012876500004536

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Data Mining, E-Learning, and Information Systems (DMEIS 2024), pages 46-52

ISBN: 978-989-758-715-3

Proceedings Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda.

In summary, the XC7Z045 chip of Zynq-7000

series is selected as the main control chip, and a

monitoring device is built with AD9251 and other

auxiliary chips to monitor the power quality of the

traction network of the EMU by monitoring and

recording the voltage transformer, secondary voltage

of current transformer and current output signals on

the EMU. At the same time, the device adopts mature

chip products for research and development, which

has the advantages of low cost, fast development

speed, perfect function and easy expansion. This

paper introduces the design principle of power quality

monitoring device, and verifies the accuracy and

stability of the system by using standard power

source.

2 OVERALL DESIGN SCHEME

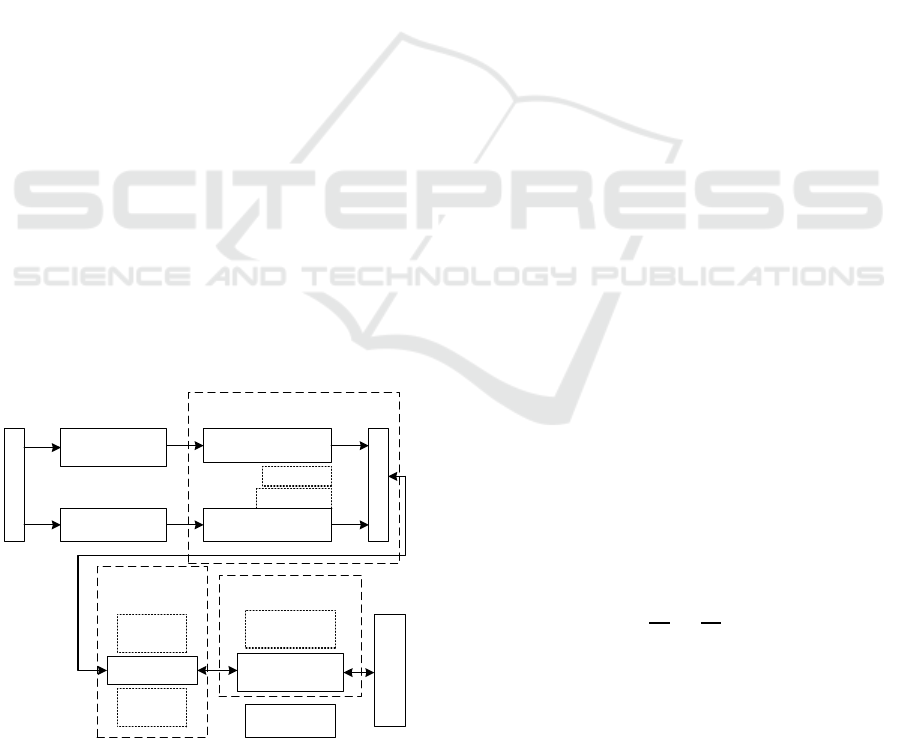

The overall structure block diagram of the monitoring

device is shown in Figure 1. It mainly includes the

following four modules: signal acquisition module,

signal processing module, data transmission module

and power module. The signal acquisition module

uses AD9251 analog-to-digital conversion chip to

realize high-speed synchronous signal acquisition;

Signal processing module uses dual-core ARM and

FPGA embedded in XC7Z045 main control chip to

realize high-speed data processing. The data

transmission module uses 88E1116R Ethernet chip to

construct gigabit network circuit to realize high-speed

data transmission. The power module uses the DC-

DC conversion chip and a series of voltage regulator

chips to realize the normal operation of the device.

Traction network

Voltage

transformer

Current

transformer

Voltage acquisition

channel

Current acquisition

channel

AD9251

XC7Z045

PHY Gigabit

network circuit

Upper computer

software

LMH6612

AD8138

QSPI

FLASH

88E1116R

HR682430E

Power supply

module

Signal acquisition

module

Signal processing

module

Data transmission

module

DDR3

(PL、PS)

Figure 1: System structure diagram.

3 MAIN MODULE DESIGN

3.1 Signal Acquisition Module

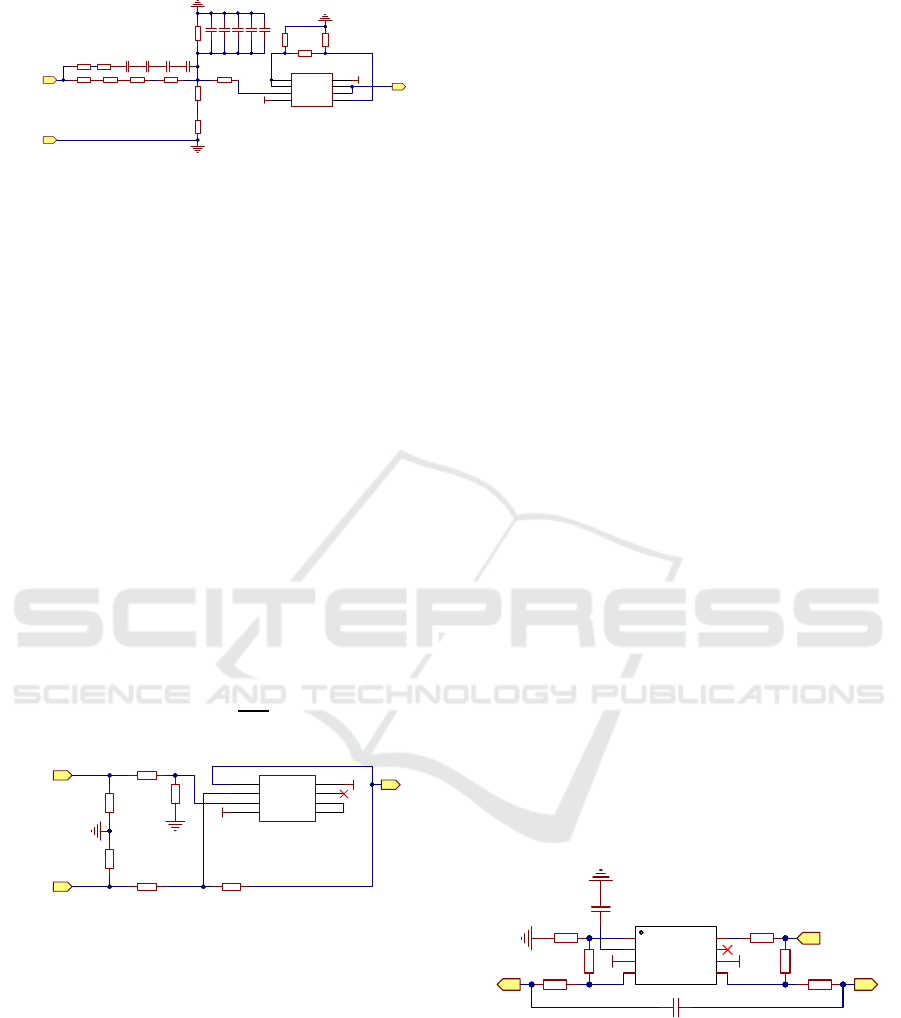

The signal acquisition module is designed based on

AD9251 analog-to-digital conversion chip. When the

train is running in steady state, the net voltage RMS

value is 17.5kV~31.5kV, and the voltage transformer

ratio is 250:1, so the secondary voltage RMS value is

70V~126V. Since overvoltage faults often occur

during train operation, and the peak value of

overvoltage is high, in order to ensure that the system

can withstand the overvoltage shock, the maximum

voltage input is considered to be ±1250V, thus the

voltage acquisition channel circuit design is carried

out. Moreover, the voltage input range of the AD9251

chip in the signal acquisition module is ±1V.

Considering this, a resistive-capacitive (RC) voltage

divider circuit with a turns ratio of 1000:1 is designed.

This circuit reduces the high voltage signal with a

peak value of 1250V to 1.25V. To minimize the

impact introduced by the monitoring device, the input

impedance of the monitoring device needs to be

designed to be greater than 1MΩ. In order to ensure

stable turns ratio over a wide frequency range, the RC

voltage divider circuit needs to satisfy Equation 1,

where R

1

and R

2

represent the resistances of the high

and low voltage arms, and C

1

and C

2

represent the

capacitances of the high and low voltage arms. As

shown in Figure 2, the high voltage arm of the voltage

divider circuit consists of four 1MΩ resistors

connected in series. The low voltage arm is

constructed by connecting a 150KΩ resistor in series

with a 5.1KΩ resistor, and then these are connected

in parallel with a 4.3KΩ resistor. This configuration

forms a 1000:1 voltage divider circuit. After the step-

down circuit is the voltage following circuit

composed of the integrated operational amplifier

model LMH6612MA, where the 100Ω and 390Ω

resistors form a voltage divider circuit, making the

circuit gain 0.796. Thus, the large voltage signal with

the maximum peak value of 1250V is converted into

a small voltage signal with the peak value of 1V after

a series of step-down processing.

ோଵ

ோଶ

=

ଶ

ଵ

(1)

Power Quality Monitoring Device of EMU Traction Network Based on Zynq

47

R1 R2 R3

R4

R5

R6

C1

C2

C3 C4

R7

R8

R9

C5 C6

C7

C8 C9

R10

R11

R12

R13

GND

GND

GND

EX_A IN_VP

EX_AIN_VN

AIN_V

OUTA

1

-INA

2

+INA

3

V-

4

V+

8

OUTB

7

-INB

6

+INB

5

LMH6612

+5

-5

Figure 2: Voltage acquisition circuit schematic.

When the train is running in steady state, the RMS

of the network current is 480A~720A, and the

transformer ratio is 600:1, so the RMS of the

secondary side current is 0.8A~1.2A. In order to

ensure that the system current acquisition has a

certain margin, the maximum current input is

considered to be ±2.5A, so the current acquisition

channel circuit is designed. As shown in Figure 3, the

current sampling resistors are two high-precision

cryobleach 0.05Ω resistors in series to convert a

±2.5A current signal into a ±0.25V voltage signal.

Then the voltage signal of ±0.25V passes through the

integrated operation amplifier of model

LMH6612MA to form a voltage amplifier circuit with

gain of 3.9, amplifies the voltage signal of ±0.25V to

a voltage signal of ±1V, and outputs it to the rear

circuit. The gain calculation formula for the current

sensing circuit shown in Figure 3 is given by Equation

2, where R

19

= 390Ω and R

18

= 100Ω. From this, we

can calculate the gain to be 3.9.

Gain =

ோଵଽ

ோଵ଼

(2)

R14

R15

R16

R17

R18 R19

GND

+5V

-5V

EX_AIN_IP

EX_AIN_IN

AIN_I

GND

OUTA

1

-INA

2

+INA

3

V-

4

V+

8

OUTB

7

-INB

6

+INB

5

LMH6612

Figure 3: Current acquisition circuit schematic.

The signal acquisition module of the monitoring

device uses AD9251 chip for signal acquisition. The

AD9251 is a single-chip, dual-channel, 14-bit ADC

acquisition chip powered by a 1.8V analog power

supply that supports differential analog signal inputs

up to 2Vpp, with high signal-to-noise ratio (SNR),

large spury-free dynamic range (SFDR), and low

power consumption. Integrated with a high-

performance sample-and-hold circuit and an on-chip

reference voltage source, the sample-and-hold circuit

can maintain stable and excellent performance at

input frequencies up to 200MHz. The chip uses a

multistage differential pipeline architecture with

integrated error correction logic to provide 14-bit

accuracy and guarantee no code loss over the entire

operating temperature range. Since the input signal is

a differential analog signal, and the output of the

acquisition channel circuit is a single-ended signal, it

is necessary to add a single-ended to differential

circuit after the acquisition channel circuit to drive the

ADC. At the same time, because the voltage and

current acquisition channels both output voltage

signals of ±1V, the single-ended to differential ADC

driving circuits of the two channels are exactly the

same. The circuit schematic diagram is shown in

Figure 4. The low-distortion differential ADC driver

AD8138 is used to complete the circuit principle

design, and the output end is connected to the signal

input port of the AD9251. This drives the ADC for

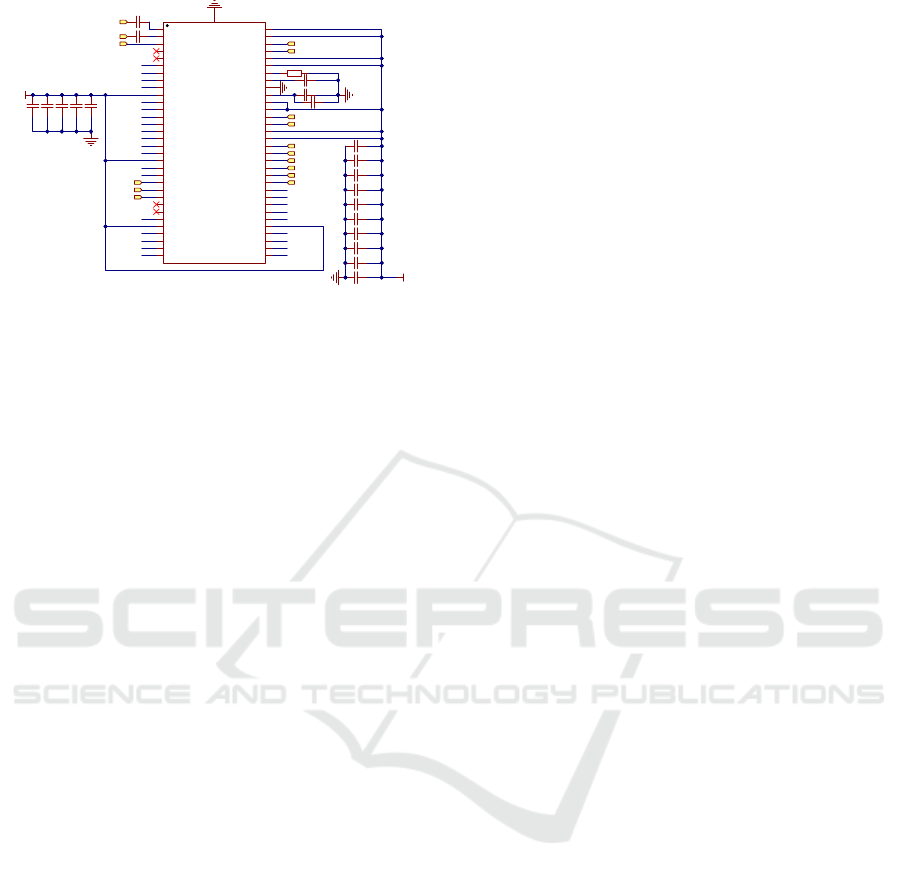

data acquisition. Figure 5 shows the schematic

diagram of the AD9521 peripheral circuit, which

mainly includes clock circuits, including external

reference clock input, clock frequency division circuit

and clock synchronization circuit. The power supply

circuit mainly includes analog power supply and

digital power supply, wherein AVDD is analog power

supply and DRVDD is digital output drive power

supply, both of which are 1.8V, in which a plurality

of 10µF large capacitors and 100nF small capacitors

are incorporated for voltage regulation filtering; The

input circuit mainly includes two differential signal

input circuits, A and B. The output end of the voltage

and current single-ended to differential circuit is

connected to the port respectively to drive the ADC

to collect voltage and current. The output circuit

mainly includes data output and clock output; The

control circuit mainly includes control SPI interface,

control register and status register, and the AD9251 is

configured and controlled through SPI interface.

R21

R20

R22

R23

R24 R25

C18

C19

GND

GND

AIN_V

V-

-IN

1

VOCM

2

V+

3

+OUT

4

-OUT

5

V-

6

NC

7

+IN

8

AD8138

+5 -5

V+

Figure 4: Single terminal to differential circuit schematic.

DMEIS 2024 - The International Conference on Data Mining, E-Learning, and Information Systems

48

CLK+

1

CLK-

2

SYNC

3

NC

4

NC

5

(LSB)D0B

6

D1B

7

D2B

8

D3B

9

DRVDD

10

D4B

11

D5B

12

D6B

13

D7B

14

D8B

15

D9B

16

D10B

17

D11B

18

DRVDD

19

D12B

20

(MSB)D13B

21

ORB

22

DCOB

23

DCOA

24

NC

25

NC

26

(LSB)D0A

27

DRVDD

28

D1A

29

D2A

30

D3A

31

D4A

32

D5A

33

D6A

34

D7A

35

D8A

36

DRVDD

37

D9A

38

D10A

39

D11A

40

D12A

41

D13A(MSB)

42

ORA

43

SDIO/DCS

44

SCLK/DFS

45

CSB

46

OEB

47

PDWN

48

AVDD

49

AVDD

50

VIN+A

51

VIN-A

52

AVDD

53

AVDD

54

VREF

55

SENSE

56

VCM

57

RBIAS

58

AVDD

59

AVDD

60

VIN-B

61

VIN+B

62

AVDD

63

AVDD

64

0

AD9251BCPZ-40

C24

C25

AD C_CLK _P

ADC_CLK_N

AD C_SYN C

ADC _DB0

ADC _DB1

ADC _DB2

ADC _DB3

AD C_DB4

AD C_DB5

AD C_DB6

AD C_DB7

AD C_DB8

AD C_DB9

ADC _DB10

ADC _DB11

ADC _DB12

ADC _DB13

AD C_ORB

C26C27C28C2 9C3 0

GND

+1.8V

AD C_DCO B

AD C_DCO A

AD C_DA 0

AD C_DA 1

AD C_DA 2

AD C_DA 3

AD C_DA 4

AD C_DA 5

AD C_DA 6

AD C_DA 7

AD C_DA 8

AD C_DA 9

AD C_DA 10

AD C_DA 11

AD C_DA 12

AD C_DA 13

ADC _ORA

AD C_SDI O

ADC _SCLK

AD C_CS B

ADC _OEB

ADC _PDWN

GND

V+( V)

V-(V)

V-(I)

V+( I)

GND

C33

C32

C31

R26

GND

C34

C35

C36

C37

C38

C39

C40

C41

C43

C42

+1.8VGND

GND

Figure 5: AD9251 peripheral circuit schematic.

3.2 Signal Processing Module

The XC7Z045 chip of Zynq-7000 series is the main

control chip of the monitoring device. It is an SoC

chip, which integrates the dual-core ARM Cortex-A9

processor and Xilinx 7 series FPGA. It has rich

resources and communication interfaces, which is

convenient for developers to expand and develop, and

its working frequency is up to 1GHz. Data processing

speed is fast. The monitoring device will carry out

data calculation and analysis for each cycle signal,

and package the calculated results and upload them

every 100ms. At the same time, the original data will

be packaged and uploaded at different sampling rates.

The large amount of data requires high data

processing speed of CPU. XC7Z045 is selected as the

main control chip to make full use of its high

computing speed.

The signal processing module mainly uses the

FPGA contained in the main control chip to complete

data processing, and uses the ARM contained in it to

complete the configuration management and external

communication of the device. In this paper, the

monitoring device uses 10Msps sampling rate for

original data acquisition, and 12.8K/S rate for data

extraction (256 data points per cycle) for the

calculation of power quality parameters, including

voltage and current RMS. Frequency; Active,

apparent and reactive power; Power factor; Dc offset;

Voltage deviation; Voltage fluctuation; Voltage and

current harmonics (up to 65 times); Voltage, current

waveform distortion and other parameters. Every

cycle, all parameters except harmonics and voltage

fluctuation parameters are calculated, and every

100ms (5 groups of data are averaged) are packaged

and uploaded. The harmonic parameters are

calculated every 100ms, and the data of each

harmonic component is packaged, and the voltage

fluctuation parameters are calculated every minute.

The data of each parameter is calculated and

packaged in FPGA, and then transmitted to ARM. In

ARM, network data is transmitted through TCP

protocol.

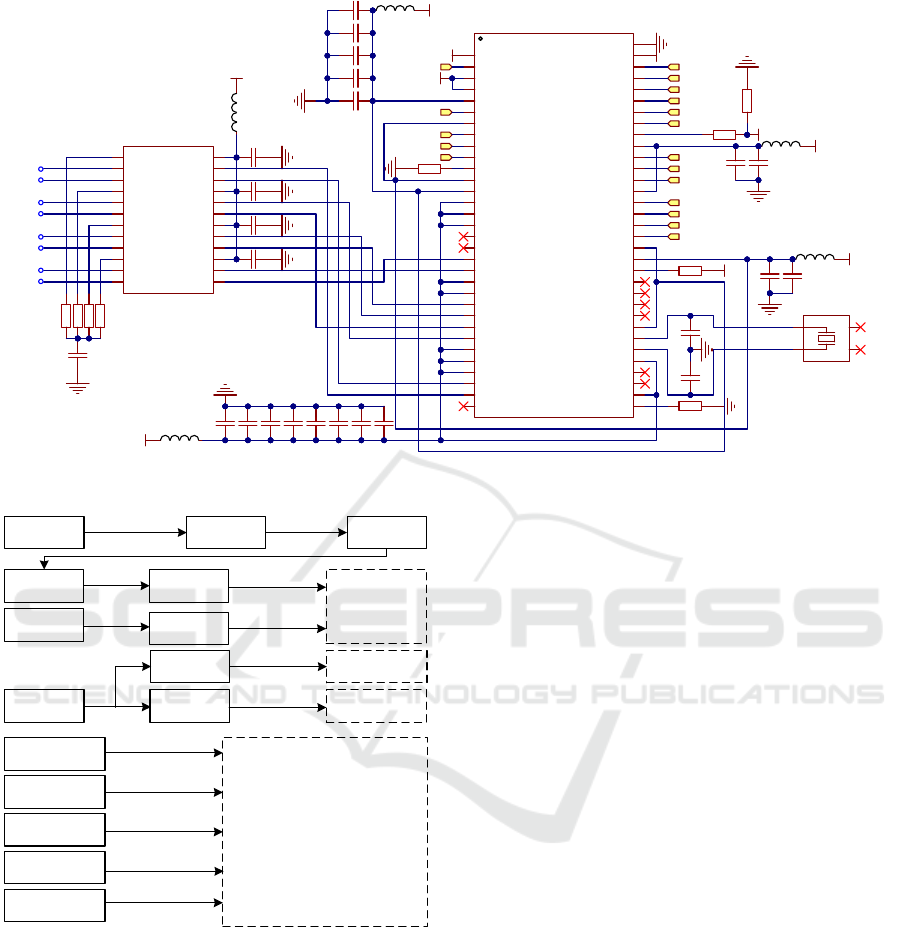

3.3 Data Transmission Module

As shown in Figure 6, this system builds gigabit

Ethernet circuit for data communication, selects

88E1116R Gigabit Ethernet chip for Ethernet circuit

construction, and HR682430E network transformer

chip for output isolation. 88E1116R chip supports

1.8V and 1.2V power supply, is a low-power

10/100/1000Mbps Ethernet chip, it integrates the

MDI interface terminal resistor, eliminates 12 passive

devices, reduces the complexity of peripheral circuits,

And its reference clock supports 25MHz±50ppm

tolerance crystal reference or oscillator input,

reducing development costs. At the same time, it also

has the following features: support for full duplex and

half duplex mode, support for IEE 802.3u adaptive

rate negotiation, support for IP\TCP\UDP uninstall

acceleration, support for MAC address filtering and

broadcast storm suppression.

3.4 Power Supply Module

The power module is responsible for the power

supply of the entire hardware system. In this paper,

the hardware system uses DC power supply for power

supply, and several power management chips are

selected to convert the voltage into the power supply

voltage required by each module chip. The power

supply logic diagram is shown in Figure 7. The

transient voltage suppression diode (TVS) of model

AMPA36CA is connected at the overall power input

end of the hardware system to protect the overvoltage

of the power supply end of the hardware system. The

operating voltage of TVS of this model is 10-36V, so

the overall power supply range of the hardware is

DC10-36V. After TVS is the model TPS54560 DC-

DC step-down chip, which is used to convert the input

DC10~36V voltage into DC8V, and then use the

power management chip to convert step by step, and

finally output the power supply voltage required by

each module.

Power Quality Monitoring Device of EMU Traction Network Based on Zynq

49

MCT1

24

MX1+

23

MX1-

22

MCT2

21

MX2+

20

MX2-

19

MCT3

18

MX3+

17

MX3-

16

MCT4

15

MX4+

14

MX4-

13

TCT1

1

TD1+

2

TD1-

3

TCT2

4

TD2+

5

TD2-

6

TCT3

7

TD3+

8

TD3-

9

TCT4

10

TD4+

11

TD4-

12

HR682430E

CONFIG[1]

1

CONFIG[2]

2

CONFIG[3]

3

COMAn

4

DVDD

5

LED[0]

6

VDDO

7

LED[1]

8

LED[2]

9

RESETn

10

TRSTn

11

DIS_REG12

12

DVDD

13

AVDDR

14

AVDDR

15

AVDDX

16

CTRL18

17

NC

18

MDIN[3]

19

MDIP[3]

20

AVDD

21

AVDD

22

MDIN[2]

23

MDIP[2]

24

MDIN[1]

25

MDIP[1]

26

AVDD

27

NC

28

AVDD

29

MDIN[0]

30

MDIP[0]

31

TSTPT

32

RSET

33

AVDDC

34

HSDACN

35

HSDACP

36

AVDDC

37

XTAL_IN

38

XTAL_OUT

39

DVDD

40

TMS

41

TCK

42

TDI

43

TDO

44

MDIO

45

VDDO

46

DVDD

47

MDC

48

RX_CTRL

49

RXD[0]

50

RXD[1]

51

VDDOR

52

RX_CLK

53

RXD[2]

54

RXD[3]

55

VDDOR

56

VREF

57

TXD[0]

58

TXD[1]

59

TX_CLK

60

TXD[2]

61

TXD[3]

62

TX_CTRL

63

CONFIG[0]

64

PAD

65

88E1116R

C54

GND

FB1

BLM15PD121SN1D

+1.8V

C55

GND

C56

GND

C57

GND

C53

GND

MX1_P

MX1_N

MX2_P

MX3_P

MX3_N

MX2_N

MX4_P

MX4_N

+1.8V

PHY_LED1

+1.8V

PHY_LE D0

PHY_LE D1

PHY_LE D2

PHY_RESETn

R67

GND

C62

C61

C60

C59

C58

FB2

BLM15PD121SN1D

+1.2V

GND

C73 C74

FB3

BLM15PD121SN1D

+1.8V

GND

C63C64C65C66C67C68C69C70

FB4

BLM21PG220 SN1D

GND

+1.8V

R70

GND

4

1 2

3

X322525MSB4SI

C75

C76

GND

R69

+1.8V

PHY_MDC

PHY_RXD0

PHY_RX_CTRL

PHY_RXD1

C71 C72

GND

FB5

BLM15PD121SN1D

+1.8V

PHY_RX_CLK

PHY_RXD2

PHY_RXD3

R68

R35

GND

-1.8V

PHY_TXD0

PHY_TXD1

PHY _TX_CLK

PHY_TXD2

PHY_TXD3

PHY_TX _CTRL

+1.8V

GND

R63

R64

R65

R66

Figure 6: Gigabit ethernet transcelver and network transformer circuits.

DC

(10-36V)

TVS

(AMPA36CA)

DCDC

(TPS54560)

DCDC

(SY8263)

LDO

(ADP7104)

DCDC

(SY8263)

LDO

(LT3094)

Analog

DCDC

(SY8263)

LDO

(MF7672)

LDO

(ADP7104)

ADC

PLL

DCDC

(HNE-12S20)

DCDC

(SY8263)

DCDC

(SY8263)

DCDC

(SY8263)

DCDC

(SY8263)

Z7_Core

Z7_MGTAVTT

Z7_VCCAUX

Z7_DDR

Z7_VCCO

ZYNQ 7Z045

+6.0VDDA

1A

+5.0VDDA

0.5A

1A

-6.0VDDA

0.5A

-5.0VDDA

+3.8V

3A

+1.8VA

0.5A

+3.3VCLK

2A

+1.0V/20A

+1.2V/3A

+1.8V/3A

+1.5V/3A

+3.3V/3A

Figure 7: Power supply logic diagram.

4 SOFTWARE DESIGN

In order to visualize the data of the monitoring device

and facilitate the user's use and management, it is

necessary to develop the upper computer software. Qt

Creator is a cross-platform graphical interface

development platform that mainly supports C++ and

Python languages. At the same time, Qt has a rich

API, the library functions needed in the development

process can be found in the API, and it also provides

rich help documents, so that every developer can

quickly get started, so Qt is widely used in GUI

program development. In this paper, the host

computer chooses the Windows version of Qt for

software development, mainly realizes the data

communication with the monitoring device,

completes the configuration management, data

display and data storage functions.

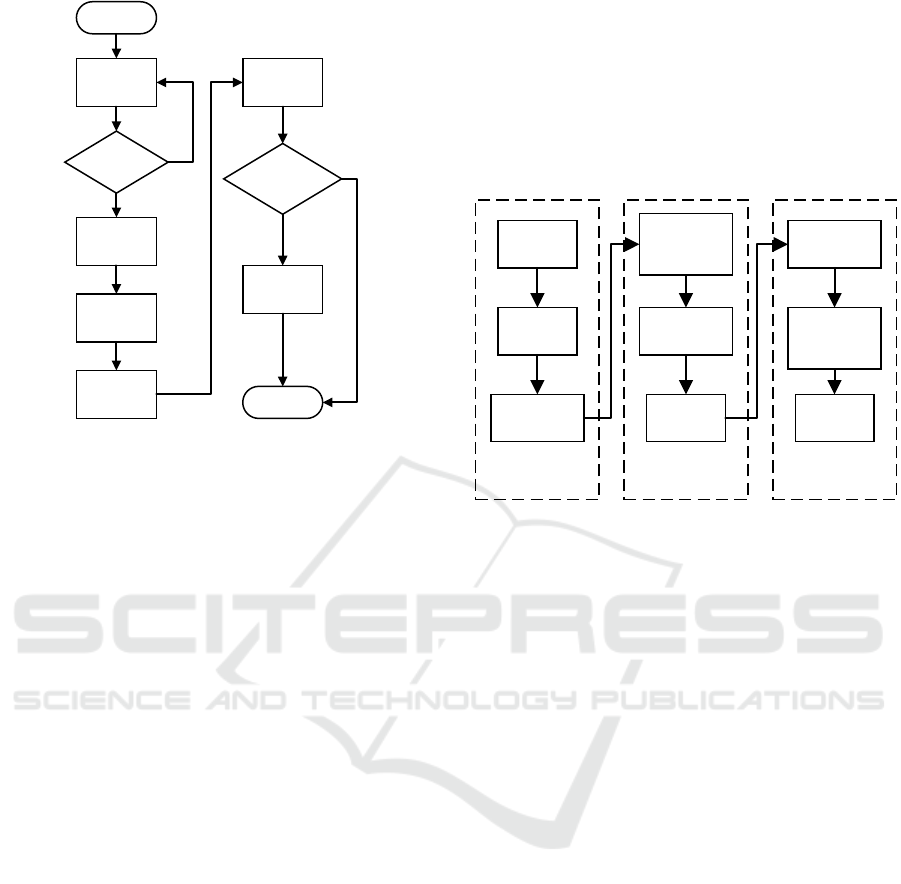

In this paper, the monitoring device and the host

computer are located in the same LAN using gigabit

network. The monitoring device is the server and the

host computer is the client. In the TCP protocol, each

server has its own IP address, and the client can only

communicate with the server after searching for and

connecting to the server's IP address. The running

process of the host computer in this paper is shown in

Figure 8. First, the UDP protocol is used to broadcast

search for the IP address of the device in the LAN,

and after searching for the IP address, it returns and

connects to the TCP network port. After connecting

the port, corresponding data is transmitted. Different

packets transmit data through different network ports.

Therefore, after the host computer successfully

connects to the acquisition card, the port data needs to

be analyzed according to the communication

protocol, and the analyzed data is filled to the

corresponding area for display. You can choose

whether to store the data as required. If yes, the data

is saved to a local folder and the file is named after

the storage time.

DMEIS 2024 - The International Conference on Data Mining, E-Learning, and Information Systems

50

Start

Search IP

address

Found a

device?

Connect

Data reception

Data

waveform

display

Data storage?

Data saved

locally

End

Yes

Yes

No

No

Da ta par sing

Figure 8: Upper computer software running flow.

In software interface design, Qt's built-in GUI

interface class functions, such as QWidget,

QGridLayout, QTableWidget, etc., and GUI

component class functions, such as QPushButton,

QLabel, QTextEdit, etc., are used to complete the

overall design of the interface. Due to the presence of

multiple ports for data transmission at the same time,

the amount of data is large, so the response and

processing speed of the upper computer software is

particularly important, the use of multithreading can

make better use of system resources, make full use of

the idle time of the CPU, and use as little time as

possible to make the system respond. Therefore, the

design of the upper computer software of this system

adopts multi-thread method for data processing. It can

be roughly divided into receiving, parsing and display

three threads, and use Qt's "signal and slot"

mechanism to complete the data communication

between threads, and the data communication process

between threads is shown in Figure 9. First of all, after

the host computer successfully connects the IP

address of the acquisition card and the corresponding

port in the data receiving thread, it uses the

"readAll()" function in the QTcpSocket class to

receive data, uses a byte stream object as the

temporary cache of data, and then transmits the

parsing signal, which will transmit the byte stream

object. The parse slot function in the parse thread is

called at this point. In the parsing slot function, the

byte stream object in the signal is first received, and

the semaphore is then released so that the parsing

thread has resources to begin parsing the data. When

the data is parsed, the data will be stored in the

QVector container class object, and then the display

signal will be transmitted, and the display signal will

also be transmitted to the corresponding container

class object. At this time, the display slot function in

the display thread will be called. In the display slot

function, the data in the container class object is first

received, and then the data is filled into the

corresponding area for display.

Connect

readAll()

Emit parsing

signal

Calling the

parse slot

function

Release

semaphore

Parse data

Emit display

Signal

Calling the

display slot

function

Display

data

Data Receivin g

Thread

Data Pars in g

threads

Data Display

Thread

Figure 9: Data communication between threads.

5 TEST VERIFICATION

In order to verify the calculation accuracy of various

parameters of the device, a three-phase standard

power source STR3060A is used for experimental

verification. The standard power is derived from basic

parameters such as RMS value, frequency, power and

harmonics of the output voltage and current that can

be displayed in real time with a screen, with an

accuracy of 0.5, and its single-phase sinusoidal output

is connected to the monitoring system for precision

comparison and verification. Set the fundamental

voltage RMS value of 100V, the current RMS value

of 1A, the third harmonic content of 20%, the fifth

harmonic content of 5%, and the seventh harmonic

content of 5%, adjust the fundamental frequency, and

record and compare the total voltage and current

distortion rate of the STR3060A and the monitoring

device respectively. The test results are shown in

Table 1.

The experimental results show that the maximum

relative error of voltage RMS calculation is 0.15V, the

maximum error of current RMS calculation is

0.007A, the maximum error of frequency calculation

is accurate, the maximum error of total voltage

distortion rate is 0.027, the maximum error of total

current distortion rate is 0.033, and the total error is

within 0.5%. It can be verified that the power quality

Power Quality Monitoring Device of EMU Traction Network Based on Zynq

51

monitoring system designed in this paper can measure

and calculate all parameters accurately.

Table 1: Parameter test results based on standard power

sources.

U

RMS

/V I

RMS

/A f/Hz VTHD% ITHD%

STR3060A

99.998 0.999 49.5 21.206 21.219

99.998 0.999 50.0 21.213 21.214

99.998 0.999 50.5 21.218 21.206

Device

99.848 1.006 49.5 21.190 21.239

99.848 1.004 50.0 21.186 21.230

99.848 1.006 50.5 21.190 21.239

6 CONCLUSIONS

This article presents the design of a traction power

grid quality monitoring device for high-speed trains

based on ZYNQ. The device utilizes the XC7Z045

chip from the ZYNQ-7000 series as the main control

chip and is supplemented by other chips such as

AD9251 to achieve overall functional design. It can

analyze multiple power grid quality parameters.

Through experimental comparison and verification,

the device demonstrates parameter calculation errors

within 0.5%, meeting the requirements for practical

monitoring and accuracy. It also offers advantages

such as low cost, fast development, complete

functionality, and easy scalability. The device can be

applied in the field of traction power grid quality

monitoring for high-speed trains, providing reliable

data support for safe operation and maintenance of the

trains, and promoting the advancement of high-speed

train technology.

REFERENCES

Weiwei, Li., Huamin, Ai., 2020, 31(S2). Analysis of power

quality improvement measures for 27.5 kV self-use

electricity in traction station. Electrified railway.

Jianxiong, Zhang., Guo, Wang., 2022, 33(S1). Evaluation

and research on power quality of high-speed railway.

Electrified railway.

Ke, Yin., Cheng, Guo., Gengyin, Li., 2020, 31(05).

Influence of high-speed railway on power quality of

power grid. Electrified railway.

Tao, Liu., 2022. Influence of Hign-speed Railway Traction

Load on Power Quality of Power Grid and

Comprehensive Evaluation. Lanzhou Jiaotong

University.

Liping, Zhao., 2022. Interaction between High-Speed

Railway and Wind Farm and Its Influence on Power

Quality of Power Grid. North China Electric Power

University(Beijing).

Guiping, Cui., 2020. Research on Power Quality and

Braking Energy Recovery Control System of Electrified

Railway. Hunan University.

Zhuo, Liu., 2021. Research on Voltage Reconfiguration

Cascaded Power Quality Integrated Treatment Device

Based on Source Load Decoupling. North China

Electric Power University(Beijing).

He, Wang., 2021. Research on Interaction Influence

Analysis and Coordination Control of Powe Quality

Governance Devices in Distribution Network. North

China Electric Power University(Beijing).

Shuang, Yan., 2020. Research and Application of

Comprehensive Power Quality Control Technology for

Distribution Network. Shandong University.

Guipeng, Zhang., Qingfeng, Wang., Lihua, Xu., et al, 2023,

(07). Power Quality Monitoring and Analysis System of

EMU Based on LabVIEW. Instrument Technique and

Sensor.

Yifeng, Su., Yu, Zhou., Zipei, Guo., et al, 2021, 30(09).

Design and research of portable modular power quality

control device. Guangdong Science & Technology.

Qiang, Li., Liming, Wang., Changlin, Cai., et al, 2021,

21(08). Design of High-speed Data Acquisition System

Based on ZYNQ. Microcontrollers & Embedded

Systems.

Chengyue, He., Yeming, Liu., 2021, 38(12). Design of

ZYNQ Hign-speed Data Acquisition System Based on

AD8285. Application of IC.

Shenggao, Gong., Jin, Ren., 2020, (04). Design of dual-core

power quality monitoring system based on DSP and

ARM. Modern Machinery.

DMEIS 2024 - The International Conference on Data Mining, E-Learning, and Information Systems

52