Software Toolchain for Offline-Programming a Jig-Less Fiber Placement

Process Using Cooperating Robots

Michael Vistein

1 a

, Lars Brandt

1 b

, Gabriel C

ˆ

ot

´

e

2 c

, Julien-Mathieu Audet

2 d

and

Bruno Monsarrat

2 e

1

German Aerospace Center, Center for Lightweight Production Technology, Am Technologiezentrum 4, Augsburg, Germany

2

National Research Council Canada (NRC), Advanced Robotics and Mechatronic Systems (ARMS),

Aerospace Manufacturing Technology Center (AMTC), 2107 Chem. de Polytechnique, Montr

´

eal, Qu

´

ebec, Canada

Keywords:

Offline Programming, Dual Robot, Thermoplastic Composites, Automated Fiber Placement.

Abstract:

Automated Fiber Placement (AFP) is one technology that can be used to produce lightweight Carbon Fiber

Reinforced Plastic (CFRP) aircraft parts which can help in the decarbonization of the aviation industry. Usu-

ally this process requires an expensive, rigid mold into which the material is laid using a tape laying head.

By using a second industrial robot with a specialized counter-endeffector, the need for a mold can be avoided.

However, in order to be able to efficiently program two industrial robot simultaneously, an end-to-end offline-

programming (OLP) approach is needed. This paper demonstrates a software toolchain covering the whole

process from initial computer aided design (CAD) to the final robot controller programs.

1 INTRODUCTION

Decarbonization of the commercial aviation industry

is targeted to be completed in 2050. This requires

new propulsion systems, improved aerodynamics and

efficient lightweight structures. Significant reduction

in the structural weight could be achieved for long-

haul aircraft programs using Carbon Fiber Reinforced

Plastics (CFRPs) in the past. In order to transfer the

technology to high volume single-aisle aircrafts, new

joining, consolidation and recycling processes have

to be established. A particular focus is given to ther-

moplastic CFRPs, as they offer great potential for di-

rection consolidation and new welding processes en-

able additional weight reductions. The first can be

exploited using Automated Fiber Placement (AFP)

where thermoplastic prepregs are deposited as narrow

tapes layer by layer.

Traditional AFP processes use a rigid mold. This

has a big disadvantage: Producing the mold is very

cost intensive, and therefore changes to the product

are difficult since they usually require a new (expen-

a

https://orcid.org/0000-0001-6998-0017

b

https://orcid.org/0009-0007-8608-0759

c

https://orcid.org/0009-0005-7842-908X

d

https://orcid.org/0009-0007-4667-4595

e

https://orcid.org/0009-0002-4369-2986

sive) mold. In (Kochoski et al., 2022), an approach

utilizing a second robot instead of a rigid mold was

demonstrated. In this paper, a dual-robot AFP process

is shown for CF/LMPAEK (Carbon-Fiber Low-Melt

PolyArylEtherKetone) materials. The setup is quite

similar to the one described by Kochoski et al., two

KUKA 6-DoF industrial robots are used, and real-

time synchronization is achieved using KUKA’s tech-

nology package RoboTeam.

For complex processes such as AFP, offline-

programming is a key requirement. Manually “teach-

ing” hundreds or even thousands of tape tracks clearly

is no viable option. For single robot applications,

several (commercial) offline programming software

applications exist. Many robot manufacturers pro-

vide specific tools for their hardware, and there are

also vendor-independent sofware tools available such

as DELMIA

1

, Cenit FastSuite Ed2

2

, Visual Compo-

nents

3

or RoboDK

4

.

While some of these tools allow for the simul-

taneous programming of two (or more) independent

robots within a single cell, automatic programming of

cooperating robots is often not possible. An overview

of programming techniques for multi-robot applica-

1

https://www.3ds.com/products/delmia

2

https://www.fastsuite.com

3

https://www.visualcomponents.com/

4

https://www.robodk.com

Vistein, M., Brandt, L., Côté, G., Audet, J.-M. and Monsarrat, B.

Software Toolchain for Offline-Programming a Jig-Less Fiber Placement Process Using Cooperating Robots.

DOI: 10.5220/0012889700003822

In Proceedings of the 21st International Conference on Informatics in Control, Automation and Robotics (ICINCO 2024) - Volume 2, pages 379-386

ISBN: 978-989-758-717-7; ISSN: 2184-2809

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

379

tions is provided by (Gan et al., 2013). There are

some approaches that try to facilitate the program-

ming of a master/slave robot system with one robot

holding the workpiece, while the other performs the

manipulating task (e.g. (Wagner et al., 2014; Xiong

et al., 2020). In these approaches, an automated tra-

jectory generation based on the trajectory required on

the workpiece is done.

Another kind of synchronization is required when

two robots share the load of a workpiece, e.g. for

transportation purposes. Rigid structures can be trans-

ported by all robots performing the same trajectory,

either by using the built-in features of the robot con-

trollers, or by planning identical motions (e.g. (Vis-

tein et al., 2019)). For flexible pieces such as textiles,

the deformation of the piece due to gravity has to be

taken into account (e.g. (Larsen et al., 2015; Larsen

et al., 2017)).

The dual robot AFP process is special with regard

to some aspects. First, there are commercial tools

available for motion planning for a single laying ma-

chine or robot. Second, while the secondary robot

needs to move on a very similar trajectory as the pri-

mary robot, the strategies used for load sharing cannot

be applied due to small differences in the trajectory

for the thickness of the part or the required (small)

fixture. Therefore, an approach which builds upon al-

ready available tools, extending them at the necessary

points, has been chosen. The work done by (Kochoski

et al., 2022) seems to follow a very similar path by ex-

tending their own MikroPlace software, although lit-

tle information about the specific implementation is

available.

The remainder of this paper is organized as fol-

lows: In section 2, the setup of the dual-robot

AFP process is described. Section 3 describes the

toolchain that is being used for offline-programming,

and in section 4 the necessary steps for robot synchro-

nization and robot code generation are explained. Fi-

nally in section 5 a conclusion is drawn and an out-

look for future extensions is provided.

2 JIG-LESS DUAL-ROBOT

AUTOMATED FIBER

PLACEMENT

For the AFP processes, a laser-assisted thermoplas-

tic layup machine provided by AFPT GmbH is used.

The laser has a rated power output of 6 kW and is sup-

plied by Laserline GmbH. The layup machine is de-

signed to deposit 3 × 1/2” prepreg tapes per track.

During layup the tape and laminate are heated over

silicone

rubber

pressure

tape

laminate

tool

nip-point

laser

tape

run -in

water-cooled

shaft

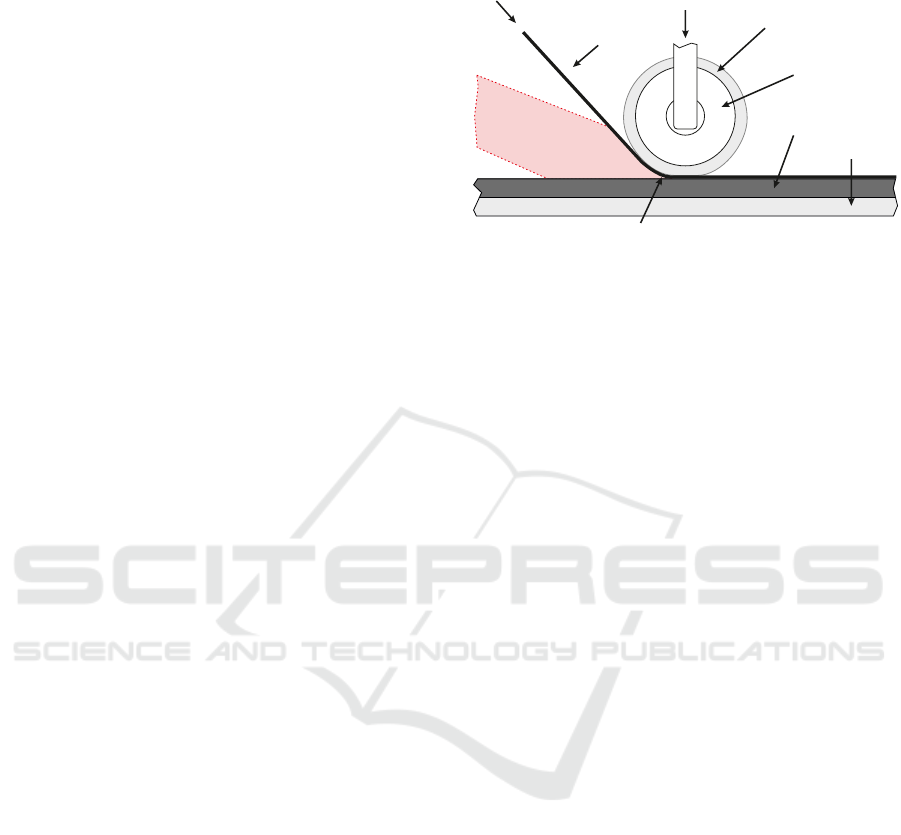

Figure 1: Process principle AFP.

melting temperature equally. In this case a con-

formable consolidation roller (refer to figure 1) is

used that forms a consolidation area under pressure.

Due to this compaction force intimate contact be-

tween laminate and tape is established and polymer

self-diffusion dissolves the interface between the ma-

terials. Water-cooling of the compaction roller en-

sures that the bonding partners are below their melt-

ing temperature after the roller even for elevated layup

velocities(Brandt et al., 2023).

To achieve a jig-less (or – at least – low-jig) solu-

tion, two additional components are required:

• A mobile counterpart that replaces the traditional

full-size jig.

• A small fixture that can be used to attach the cre-

ated piece to.

In this case study, a second robot, equipped with

a special counter-endeffector is used as counterpart.

This endeffector consists of an aluminum roller that

resembles the compaction roller, except not being

conformable. The roller is driven by a servomotor

which is synchronized to the Tool Center Point (TCP)

velocity (in rolling direction) of the second robot, i.e.

the roller surface pointing to the primary robot does

not move with respect to the world, therefore provid-

ing a surface much similar to a mold. Synchronization

of roller and robot velocity is done using the Robot

Sensor Interface (RSI) technology package providing

the robot’s current position to the Beckhoff TwinCAT

PLC driving the servo motor.

Since the part cannot be laid purely into thin air, a

small, lightweight fixture to attach each tape at the be-

ginning and the end is required. The fixture consists

of aluminum profiles for the overall frame and nu-

merous (identical) aluminum modules that form the

surface where the beginning and end of each tape is

placed. The modules are beveled on one side with the

straight side pointing to the AFP head. The setup can

be seen in figure 2.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

380

Figure 2: Setup of dual-robot AFP process.

CATIA VCP

RoboDK KRC

surfaces single robot

programs

dual robot

programs

Figure 3: Schematic flow of software toolchain for dual-

robot AFP applcation with the main type of data that is

transmitted between the steps.

3 OFFLINE PROGRAMMING

TOOLCHAIN

Since AFP requires a large number of individual

placement trajectories, manual robot programming

(“teaching”) is no viable option. Starting with the

CAD design of the desired component, an automated

path for generating the final robot programs is desired.

The overall flow is depicted in figure 3.

3.1 CATIA

For high performance CFRP components, a load-

compliant design is generated by adjusting the lam-

inate thickness and fiber orientation accordingly us-

ing computer aided design (CAD). In this work Das-

sault CATIA V5 is utilized. The design process starts

with the definition of the part surface. All ply bound-

aries are defined with reference to this surface. Most

CAD systems do not implement process driven design

changes, thus an export to a computer aided manufac-

turing (CAM) software is sensible.

3.2 VCP

Using the surface and ply boundaries, the laminate is

constructed sequentially. Each ply is first segmented

into tracks comprising the width of all tapes placed si-

multaneously. An optimization is carried out to max-

imized coverage of the ply and minimize gaps and

overlaps between the tapes. Afterwards the layup se-

quence and retraction movements of the robot are de-

fined.

Vericut Composites Programming (VCP) gener-

ates layup tracks and usually creates Numerical con-

trol (NC) programs for automated layup machines.

By using custom-made post-processors, it is possible

to create programs for other types of machines, too. In

the dual-robot use case, the NC programs are trans-

formed into KUKA Robot Language (KRL) source

files which can be executed by the KUKA KRC4 con-

troller. These source files contain the trajectory, as

well as all necessary I/O operations needed to control

the AFP head (e.g. cutting the tapes at the appropriate

locations, turning the laser source on and off).

Since the work-pieces can consist of free-form

surfaces, an approximation of the robot programs to

the ideal trajectories is necessary. A common practice

of offline-programming software is to segment the tra-

jectories into small pieces that can be connected with

either linear or circular motion blocks that are blended

into each other, or by using spline motions. The

VCP post-processor uses spline motions for approx-

imation. The layup trajectory is split into small auxil-

iary positions (with configurable maximum distances

and orientation changes) which are inserted into the

source program using the SPL motion command and

embedded into a single SPLINE motion block. The

KUKA controller uses these commands to plan a tra-

jectory which exactly passes every auxiliary position

and maintains a constant velocity as far as possible.

3.3 RoboDK

The KUKA programs that are generated by VCP can

be executed directly on a single robot for a tradi-

tional fiber placement system using a rigid mold. For

a dual-robot application however, the corresponding

programs for the secondary robot still need to be gen-

erated. Several important requirements must be taken

into account:

• VCP takes the thickness of the already placed lay-

ers into account while the counter tool must be at

the position of the first layer during each run.

• The trajectory of the secondary robot must be ad-

justed for the surrounding frame that holds the

tapes which has a defined thickness.

• During the layup motion, both robots need to be

synchronized, i.e. each robot must be at the desig-

nated position at the right time.

• The approach and retract motions must be ad-

justed for the secondary robot.

Software Toolchain for Offline-Programming a Jig-Less Fiber Placement Process Using Cooperating Robots

381

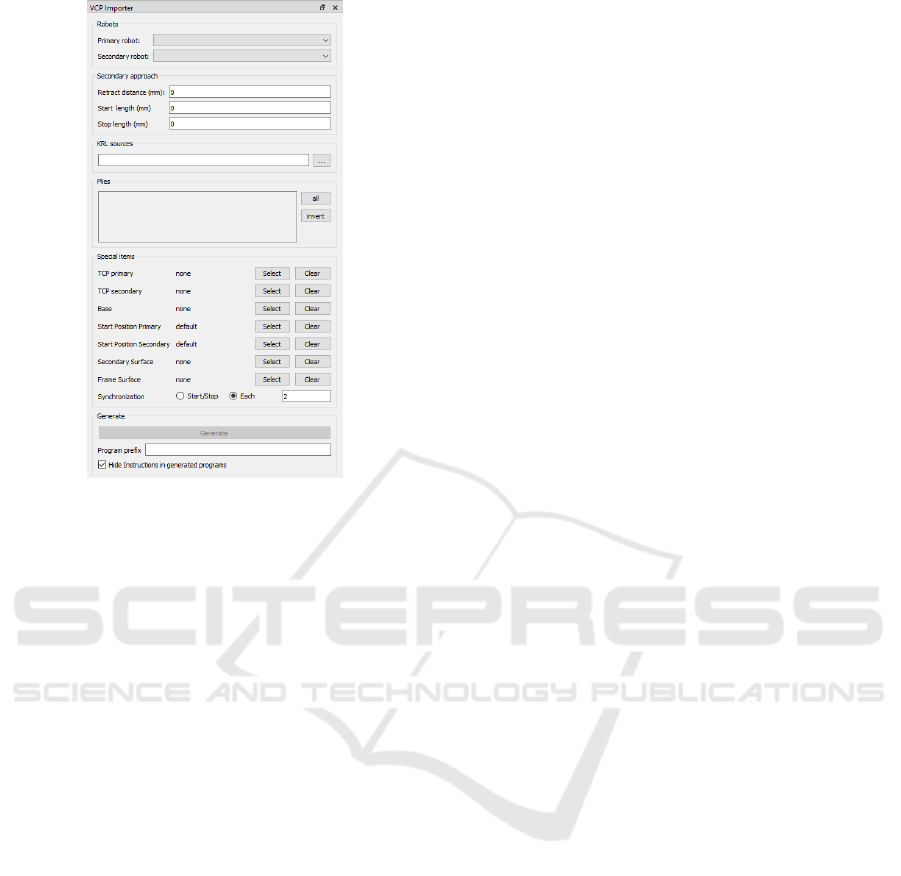

Figure 4: Graphical user interface of VCPImporter plugin

in RoboDK.

• The (initial) park-position of the secondary robot

needs to be defined (in joint coordinates or alter-

natively in Cartesian coordinates with additional

redundancy information such as status/turn).

In order to create the trajectories for the sec-

ondary robot while fulfilling all requirements, a soft-

ware solution based on the offline-programming tool

RoboDK has been created. RoboDK allows to model

a robotic work-cell and to create programs graphi-

cally. The created programs are independent of a con-

crete manufacturer or robot type that is used, but can

later be converted into manufacturer-specific program

code by adjustable post-processors. A 3D simulation

of the robot-cell and of the programs is possible. The

simulation takes specifics of the robots (such as sin-

gularities) into account and can optionally perform a

collision check based on CAD geometries. This al-

lows to preview and validate all trajectories prior to

running on the real robots.

RoboDK offers an Application Programming In-

terface (API) for custom extension. Besides API im-

plementations for Python, C# and C++ there is also

a plugin-interface (based on C++ and Qt) which al-

lows to run custom code directly within the RoboDK

process. For the dual-robot AFP use-case, the latter

interface has been selected. The number of auxiliary

points can become very large, therefore a fast con-

nection between the custom software and RoboDK is

necessary. The plugin-interface is faster by a magni-

tude compared to the (network-based) API interface.

The created plugin (called VCPImporter) pro-

vides a graphical user interface that is embedded in

RoboDK (see figure 4). Because the programs gen-

erated by VCP are intended for a single machine,

some additional information has to be provided by the

user to allow the generation of a secondary trajectory.

These information contain:

• Retract distance: The distance the primary robot

retracts after finishing a track in order to move on

a connection link to the next track.

• Start- and stop-length: The distances the tape lay-

ing head is moving on the frame at the start and

stop of each track.

• TCPs, Base: The TCP and Base (defined within

RoboDK) that should be used for primary and sec-

ondary robot.

• Start positions: The park-positions defined in

RoboDK at which the primary and secondary

robot start each ply.

• Surfaces: The CAD objects in RoboDK which

represent the frame and the final workpiece.

The VCPImporter plugin parses the KRL source files

generated by VCP. A program consisting of all mo-

tions specified by VCP is created within RoboDK,

which immediately allows for a simulation of the tra-

jectory of the primary robot.

The VCP post processor uses a defined structure

for each generated program. Every track is placed in

its own source file, and every source file consists of

the following blocks:

• Program header

• Optional: point-to-point (PTP) motion to start po-

sition (first track of each ply)

• Optional: Motion commands for transfer from last

track to current track (connection link)

• Motion commands for the track, consisting of a

number of SPL motion commands embedded in to

a SPLINE block.

• Program footer

Each segment is clearly embedded in a FOLD struc-

ture (a source code hint that usually allows to show or

hide certain blocks within the program on the limited

screen of the programming pendant). This predictable

structure allows the VCPImporter plugin to split each

trajectory into the relevant segments, and to calculate

appropriate trajectories for the secondary robot.

Another important feature of RoboDK is the pos-

sibility for geometric calibration of the used robots.

While industrial robots usually offer a very good

repeatability, the absolute accuracy is often worse.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

382

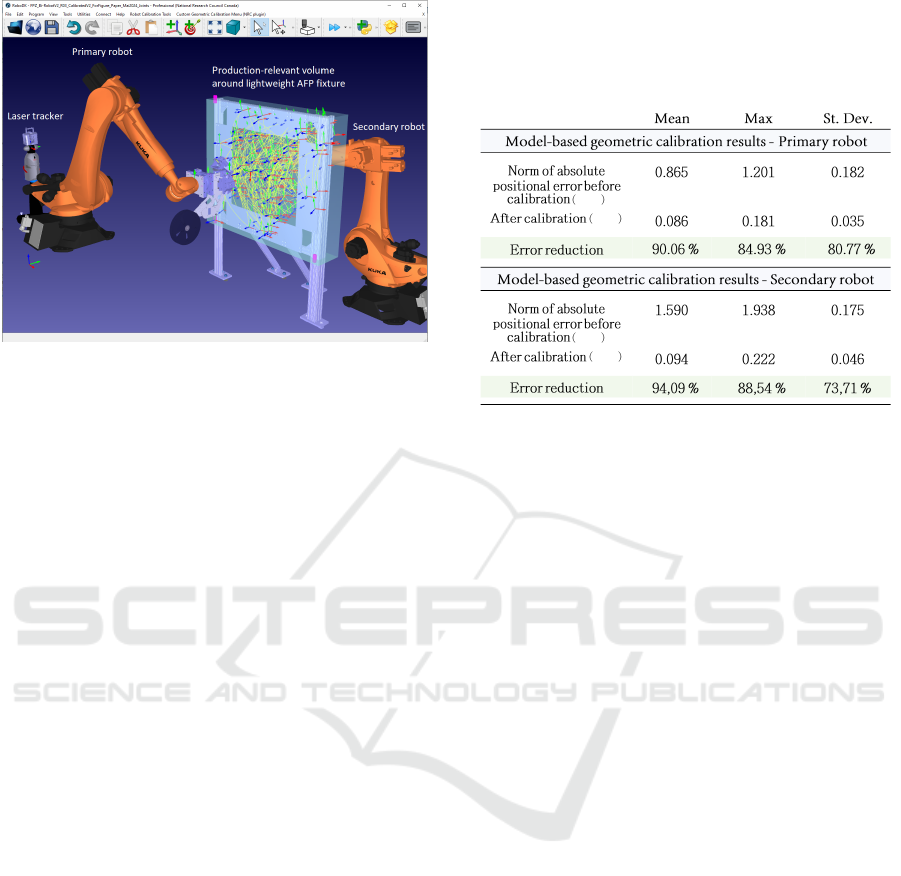

Figure 5: RoboDk interface showing the 100 test poses that

were randomly generated in the production-relevant par-

allepipedic volume located around the lightweight fixture

to verify the accuracy of the primary robot following geo-

metric calibration. After each test pose is reached, the laser

tracker measures a metrology marker located at the vicinity

of the robot tool-center-point. A similar approach was used

to verify the accuracy of the secondary robot.

RoboDK allows to calibrate the robots using a laser

tracker as an absolute reference. A model of the

deviations of the robot within its workspace is gen-

erated, and programs can be adjusted automatically

with small offsets to the desired Cartesian positions

such that the robot reaches the target more precisely.

As an illustration of the importance of geometric path

correction in the off-line programming flow, the abso-

lute accuracy of each robot has been evaluated before

and after geometric calibration using a set of 100 test

poses that were randomly generated in a production-

relevant volume of rectangular parallelepiped shape

located around the lightweight AFP fixture, as shown

in figure 5. The accuracy improvements obtained for

both the primary and secondary robots are described

in table 1.

By embedding the VCPImporter into RoboDK di-

rectly and by creating the programs within RoboDK,

the geometric calibration feature can be used without

additional effort.

3.4 Secondary Trajectory Generation

For each of the program segments described in sec-

tion 3.3, a different strategy for the generation of the

secondary trajectory is applied.

Program header and footer can be ignored,

since they will be regenerated appropriately by the

post-processor that is exporting the programs from

RoboDK (cf. section 4). The PTP motion to the start

position is simply replaced by a motion to the start

Table 1: Summary of the accuracy improvements obtained

thanks to the geometric calibration of the primary and sec-

ondary robots. For each robot, the accuracy was verified by

measuring a set of 100 test poses using a laser tracker, as

illustrated in Fig. 5.

mm

mm

mm

mm

position specified by the user for each robot. Because

this is the first motion of the final program, this will

always be a PTP motion.

The connection links that return the tool from the

end of a track to the beginning of a new track are mir-

rored. The approach and retract motions generated by

VCP consist of a single linear motion directly in the

Z-direction of the tool. All other intermediate points

of the connection link also have the same distance (in

Z-direction) from the workpiece. Therefore, the sec-

ondary trajectory is calculated by moving each frame

of the primary trajectory for twice the retract distance

along the Z-direction. The result is a trajectory mir-

rored along the work-piece. A diagram of the result-

ing trajectories can be seen in figure 6.

The layup motion itself needs to be handled differ-

ently. By using the overall track length and the length

that has been laid up to a certain point, together with

the user-specified start- and stop-lengths, it can be de-

termined whether the current track point is laid onto

the frame or in the void in the middle. If the track

point is on the frame, it is projected along the Z-axis

to the backside of the frame. If it is in the air, a pro-

jection to the closest point on the workpiece surface is

performed. In order to achieve good results, it is nec-

essary that a precise CAD model of the workpiece’s

lower surface – but without thickness – is provided.

Using either the projection to the frame or the

workpiece surface, it is ensured that the secondary tra-

jectory both takes the thickness of the frame as well

as the thickness of previously laid tracks into account.

From a 2D-perspective (like in figure 6) it seems

that the secondary trajectory (on the right) is identi-

cal for every layer since the part only grows to the

left. In order to achieve optimal part quality however,

the tracks of each layer are usually not identical to

Software Toolchain for Offline-Programming a Jig-Less Fiber Placement Process Using Cooperating Robots

383

Frame

primary

trajectory

secondary

trajectory

workpiece

retract distance retract distance

Figure 6: Schematic side display of the trajectories of the

primary robot (dashed) and the secondary robot (dotted) and

the frame that is used for support.

the previous one. Depending on the part design, they

might be shifted sideways in a way the border of two

tapes of the previous layer is covered with a tape in the

next layer, or the fiber angle might even be completely

changed e.g. for 0

◦

, ±45

◦

and 90

◦

layers. Therefore,

the secondary trajectory has to be calculated indepen-

dently for each track.

4 ROBOT PROGRAMS

With both the primary and secondary trajectories

modeled within RoboDK, the final programs that are

run on the KUKA KRC4 controllers can be generated.

For both tools, the TCPs are defined identically, i.e.

for the first layer both TCPs usually are at the same

coordinates during layup. For the tape laying head,

the Z-axis points normal into the workpiece, while

for the counter endeffector the Z-axis points out of

the work-piece.

4.1 Synchronization

To achieve good part quality, synchronization be-

tween the tape laying head and the counter effec-

tor is required. Synchronization between the robots

is achieved using the KUKA.RoboTeam technology

package. This package establishes a real-time com-

munication channel between the robots and offers

several possibilities for synchronization:

Program Synchronization. A certain point in each

robots program is reached simultaneously, i.e. one

robot waits until the other has reached the speci-

fied point.

Motion Synchronization. One or more motions are

run simultaneously, i.e. both robots start and fin-

ish their respective motion at the same time. The

velocities and accelerations of the motions are ad-

justed as needed.

Geometric Linking. One robot is geometrically

linked to the other, i.e. it movements are relative

to the TCP of the first robot. Without any spe-

cific motions of the secondary robot, it performs

exactly the same motion as the first.

For the Dual-Robot AFP process, program and mo-

tion synchronization are used. Only the track itself

and parts of the approach and retract motions are syn-

chronized, the connection links are independent of

each other.

The first synchronization point is at the approach

motion. The primary robot may only start approach-

ing the frame once the secondary robot has completed

the approach motion and is in contact with the frame.

This is necessary, because otherwise the tape laying

head would apply the process force to the unsupported

frame and potentially cause deformation. With the

counter endeffector already in place, this force is ab-

sorbed by the secondary robot (as it is during the fol-

lowing layup).

The layup track itself consists of a large number

of SPL motions that are embedded in a single SPLINE

block. The KUKA controller calculates a single mo-

tion of this whole block. For synchronization pur-

poses, it is possible to synchronize the whole block,

as well as to specify certain points within the block

that must be reached simultaneously. In the dual robot

AFP use case, the number of intermediary points in

the spline block are identical, so it would be possi-

ble to synchronize every single point. This however

causes unnecessary load on the robot controller, and

synchronizing every third point turned out to be suf-

ficient for the tested parts. Nevertheless, this setting

can be modified by the user.

All required synchronization points are inserted

into the RoboDK program. Using the Python inter-

face of RoboDK, a rudimentary simulation of the syn-

chronized motions can be performed. Unfortunately,

this is very limited and only roughly the equivalent of

program synchronization as mentioned above, which

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

384

leads to both robot stopping at each synchronization

point.

4.2 Source Code Generation

RoboDK already provides means to generate robot

controller files from the programs. Like VCP, a post-

processor is used, which is written in Python and

can be adjusted to specific needs. RoboDK already

provides an exemplary open-source post-processor to

generate KRL programs which has been modified ac-

cording to the special requirements of the dual-robot

application.

In the dual robot AFP use case, the fixed struc-

tures of the program can be utilized once again. The

overall program structure is provided as template sep-

arately for the primary and secondary robot. The sec-

tions of the template are filled with the motions of the

RoboDK programs, and additionally synchronization

markers are inserted where indicated. As template en-

gine, Jinja2

5

is used.

The generated source files make use of TCP and

base definitions on the robot controllers, which must

be created appropriately. Both robots must share a

common world coordinate system and must both de-

fine a base coordinate system on the frame. Once

these preconditions are met, the generated programs

can be uploaded to the robot controller and executed.

5 CONCLUSION

The process for dual-robot AFP is currently still un-

der heavy development. At the current time, it is not

yet possible to manufacture a part which is ready to

go into production. An example of a double-curved

test specimen that has been produced is depicted in

figure 7. The previously described toolchain is a key

factor for successful process development, because it

allows for rapid testing of process parameters and part

designs. After changes have been made in the part

design for example, only the steps necessary for tra-

ditional AFP CAM (i.e. trajectory planning) are re-

quired, while all specifics for the dual-robot applica-

tion are generated automatically.

While the current software toolchain aimed at

both robots being synchronized as precisely as pos-

sible, a next step in the development will be the pos-

sibility for a defined offset between the primary and

secondary robot. The aim is to induce prestressing

into the material (dependent on the curvature of the

part) which helps to reach the desired form better.

5

https://palletsprojects.com/p/jinja/

Figure 7: Test specimen produced by dual-robot AFP pro-

cess.

In addition, while the RoboDK model-based geo-

metrical calibration already improves the overall ab-

solute accuracy of the robots significantly (ref. ta-

ble 1), it has be shown in a recent complementary re-

search that the performance of the geometric calibra-

tion can be further improved by combining the model-

based geometric calibration of the primary and sec-

ondary robots with a cascaded calibration approach

using deep neural networks (Maghami et al., 2023).

In the later research, the mean value of the track-

ing error between the primary and secondary robots,

as well as the absolute positional accuracy of the

secondary robot could be improved by an additional

57%. Moreover, external forces that are applied to the

robot still can cause significant deviations. With dual-

robot AFP, both robots are applying the process force

of around 600 N against each other and therefore suf-

fer elastic deformation. In a joint research project, the

in-situ elastic calibrations and compensation as intro-

duced in (Monsarrat et al., 2024) has been applied to

the dual-robot AFP use-case, and in improvement in

absolute accuracy for both the primary as well as the

secondary robot could be shown.

ACKNOWLEDGMENTS

The authors wish to acknowledge the financial sup-

port of the National Program Office (NPO) of the Na-

tional Research Council Canada (NRC).

REFERENCES

Brandt, L., Vistein, M., Deden, D., Sch

¨

uhler, F., and

G

¨

answ

¨

urger, P. (2023). Towards toolless manufactur-

ing of aerospace CFRP components via thermoplastic

AFP. In Aerospace Europe Conference 2023.

Software Toolchain for Offline-Programming a Jig-Less Fiber Placement Process Using Cooperating Robots

385

Gan, Y., Dai, X., and Li, D. (2013). Off-line program-

ming techniques for multirobot cooperation system.

International Journal of Advanced Robotic Systems,

10(7):282.

Kochoski, F., Dukovski, V., Samak, S., Cvetkoska, D.,

and Petkoska, B. (2022). Manufacturing Thermoplas-

tic Composites by Laser Automatic Tape Placement

Toolless Technology with Dual Robot System. In-

ternational Journal of Engineering and Technical Re-

search, 11:238.

Larsen, L., Kaspar, M., Schuster, A., Vistein, M., Kim, J.,

and Kupke, M. (2017). Full automatic path planning

of cooperating robots in industrial applications. In

2017 13th IEEE Conference on Automation Science

and Engineering (CASE), pages 523–530.

Larsen, L., Pham, V.-L., Kim, J., and Kupke, M. (2015).

Collision-free path planning of industrial cooperating

robots for aircraft fuselage production. In 2015 IEEE

International Conference on Robotics and Automation

(ICRA), pages 2042–2047.

Maghami, A., Imbert, A., C

ˆ

ot

´

e, G., Monsarrat, B., Bir-

glen, L., and Khoshdarregi, M. (2023). Calibration

of multi-robot cooperative systems using deep neural

networks. Journal of Intelligent and Robotic Systems,

107(4):55.

Monsarrat, B., Audet, J.-M., Fortin, Y., C

ˆ

ot

´

e, G., Vistein,

M., Brandt, L., Sadek, A., and Krebs, F. (2024). In-

situ elastic calibration of robots: Minimally-invasive

technology, cover-based pose search and aerospace

case studies. Robotics and Computer-Integrated Man-

ufacturing, 89:102743.

Vistein, M., Deden, D., Gl

¨

uck, R., and Schneyer, S.

(2019). Automated production of large fibre metal

laminate aircraft structure parts. Procedia Manufac-

turing, 38:1300–1307. 29th International Conference

on Flexible Automation and Intelligent Manufacturing

(FAIM 2019), June 24-28, 2019, Limerick, Ireland,

Beyond Industry 4.0: Industrial Advances, Engineer-

ing Education and Intelligent Manufacturing.

Wagner, M., Hess, P., and Reitelshoefer, S. (2014). Auto-

mated programming of cooperating industrial robots.

In ISR/Robotik 2014; 41st International Symposium

on Robotics, pages 1–8.

Xiong, J., Fu, Z., Chen, H., Pan, J., Gao, X., and Chen, X.

(2020). Simulation and trajectory generation of dual-

robot collaborative welding for intersecting pipes.

The International Journal of Advanced Manufactur-

ing Technology, 111:2231–2241.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

386