CRANEBot: Teleoperated Crane-Suspended Robotic System

for Inspection and Manipulation in Harsh Environments

Giancarlo D’Ago

1,2 a

, Sergio Di Giovannantonio

1 b

, Luca Rosario Buonocore

1 c

and Mario Di Castro

1 d

1

European Organization for Nuclear Research, CERN, 1211 Geneva, Switzerland

2

PRISMA Lab, Department of Electrical Engineering and Information Technology,

University of Naples Federico II, Via Claudio 21, 80125 Naples, Italy

Keywords:

Robotics in Hazardous Fields, Engineering for Robotic Systems, Telerobotics and Teleoperation.

Abstract:

The need to perform operations from above has become one of the primary challenges that robotics must

address in recent times. At CERN, high-intensity hadron colliders and fixed target experiments increasingly

require robotic telemanipulation to prevent human personnel from being exposed to radioactive environments.

In this article, we propose a modular robotic system called CRANEBot, which is transported by cranes. This

system enables operations from above, allowing for extended sessions of inspection, manipulation, and remote

handling at variable heights with minimal impact on the external environment. The system operates using a

robotic framework that enables communication with its hardware components and is controlled by a teleop-

erator through a graphical interface. The proposed functionalities have been tested and validated in multiple

robotic interventions.

1 INTRODUCTION

The development and deployment of robotic technol-

ogy in hostile environments has received consider-

able attention in recent years. Key applications in-

clude space exploration, nuclear inspection and de-

commissioning, offshore energy maintenance, under-

water inspection and deep mining (Bellingham and

Rajan, 2007), (Trevelyan et al., 2016). In all these

application areas, the robot is the ideal candidate to

replace skilled personnel, both to eliminate the risk

related to human health and to increase productivity.

At the European Organization for Nuclear Research

(CERN), the world’s largest high-energy physics lab-

oratory, robotics fits exactly into this context. At

CERN there are more than 70 km of underground tun-

nels and multiple fixed target experiments, with thou-

sands of items that need to be inspected, monitored

and maintained. The radiation from particle collisions

and the high magnetic field are major risk factors for

human operators. The use of robots in CERN’s semi-

a

https://orcid.org/0000-0002-4695-7719

b

https://orcid.org/0009-0008-1871-9458

c

https://orcid.org/0000-0001-5396-2519

d

https://orcid.org/0000-0002-2513-967X

structured and unstructured environments is particu-

larly challenging (Di Castro, 2019): the specific en-

vironments in which robots have to operate led to

the need to design ad-hoc solutions with high level

of dexterity that are not available on the market.

Maintenance and inspection work at CERN can re-

quire both ground (Di Castro et al., 2017), (D’Ago

et al., 2022) and overhead operations (Di Castro et al.,

2018b), (Gamper et al., 2021), (D’Ago et al., 2024).

The necessity of conducting operations from

above is one of the primary challenges that robotics is

increasingly being called upon to address. Examples

include the inspection and maintenance of difficult-

to-access sites and structures, such as bridges (Do-

rafshan and Maguire, 2018), (Ivanovic et al., 2021),

power lines (Cacace et al., 2021), and pipe arrays in

chemical plants (Suarez et al., 2020a). A solution to

these challenges is provided by the expanding field

of Unmanned Aerial Manipulators (UAM) (Ruggiero

et al., 2018), (Ollero et al., 2021). This field combines

aerial vehicles, such as drones, with manipulators, en-

abling not only visual inspection but also the execu-

tion of manipulation tasks at significant heights and

over extended distances. Other examples of robotic

activities from above include the inspection and dis-

mantling of nuclear sites, for which the most com-

D’Ago, G., Di Giovannantonio, S., Buonocore, L. R. and Di Castro, M.

CRANEBot: Teleoperated Crane-Suspended Robotic System for Inspection and Manipulation in Harsh Environments.

DOI: 10.5220/0012892100003822

In Proceedings of the 21st International Conference on Informatics in Control, Automation and Robotics (ICINCO 2024) - Volume 2, pages 101-108

ISBN: 978-989-758-717-7; ISSN: 2184-2809

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

101

Figure 1: CRANEBot, crane-suspended robotic system in

its dual-arm configuration.

monly used solutions are once again drones (Jiang

et al., 2018) or robotic systems suspended from above

using cable systems (Yokokohji, 2021). Overhead op-

erations are also a fundamental aspect in the latest

installations for nuclear fusion research, where it is

necessary to perform remote handling operations in

highly radioactive zones. In this case, the most com-

monly used solutions consist of long-reach manipula-

tors (Ribeiro et al., 2011), or industrial manipulators

connected to telescopic structures extending from the

ceiling (Haines et al., 2014).

However, the robotic solutions presented are inad-

equate when the following conditions occur simulta-

neously:

• The operating environments are unstructured, and

the height of operation is variable;

• There is a requirement to perform not only visual

inspections but also heavy remote manipulation

tasks;

• The total operation time can be considerably high;

• It is essential to minimize environmental contam-

ination, especially in areas with radioactive dust.

Furthermore, the presented systems typically suffer

from the disadvantage of having a limited workload

capacity. As a result, they are unable to perform han-

dling, installation, and dismantling tasks through a

single robotic system in one operational phase.

We propose the mechatronic design and con-

trol architecture of a modular robotic system named

CRANEBot, shown in Fig. 1, which allows opera-

tions from above and extensive inspection, manipula-

tion and remote handling sessions at varying heights

with minimal impact on the unknown external envi-

ronment.

2 RELATED WORKS

This section aims to present the state of the art in

robotic systems for inspection and manipulation from

above. Robotic systems can be categorised into

two primary classes based on their operational en-

vironments: (i) systems designed for structured or

semi-structured environments, where environmental

knowledge can be utilised to grant the robot a high

degree of autonomy, and where the robot often in-

tegrates seamlessly with its surroundings; (ii) sys-

tems intended for unstructured environments, where

the robot does not inherently integrate with its sur-

roundings from a design perspective.

The first category includes numerous robotic sys-

tems designed for operations from above, commonly

used in big science facilities. In (Di Castro et al.,

2018b), a robotic system employed at CERN, known

as the Train Inspection Monorail (TIM), is presented.

This system entails a train that moves along an over-

head monorail within the Large Hadron Collider

(LHC) tunnel, which comprises several modules in-

cluding a wagon designed for overhead manipulation,

equipped with robotic arms for handling and mea-

surement tasks from above, as illustrated in Fig. 2a.

In (Gamper, 2024), a study is presented on the devel-

opment and deployment of a robotic system within

the 100 km-long tunnel of the Future Circular Col-

lider (FCC) at CERN. This system comprises a trol-

ley mounted on a double rail, capable of bidirectional

movement. Attached to the trolley is a 9-degree-of-

freedom robotic arm, enabling inspection and manip-

ulation tasks from above. These functionalities are

crucial for reducing human intervention in such an

extensive workspace. In (Graves and Dayton, 2011)

and (Haines et al., 2014), the robotic system utilised

at the Spallation Neutron Source (SNS), a nuclear fu-

sion facility characterised by high radiation levels, is

presented. This system, depicted in Fig. 2b, is meant

to handle and place experimental samples within the

SNS instrumentation. The system is a telerobotic

dual-arm servomanipulator mounted at the end of a

vertical telescoping boom, which is in turn attached

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

102

to a traversing gantry. The system at the European

Spallation Source (ESS) (Gahl, 2015) is used instead

for remote handling within the Active Cells Facility.

It consists of a dual-arm system suspended on rails at

an approximate height of 7 meters from the ground

and connected via a telescopic boom. However, all

the presented systems are closely tied to their opera-

tional environment both in terms of functionality and

design, which limits their use in an unknown environ-

ment.

To overcome this limitation, one possibility is of-

fered by aerial platforms such as drones, which are

ideal for working in unknown and unstructured en-

vironments. These systems are capable of being

positioned throughout the whole three-dimensional

space. They are well-suited for outdoor visual

inspection (Falorca et al., 2021), and recent re-

search allows their use even in GNSS-denied environ-

ments (Mostafa et al., 2018). When interaction with

the environment is needed, manipulators can be in-

stalled underneath the aerial platform (Ollero et al.,

2021). However, the rigid coupling of manipulators

with drones may prove inadequate for maintaining a

safe distance between the rotors and the area to be

inspected. Therefore, the trend is to separate the ma-

nipulation structure from the transport structure using

rigid rods (Suarez et al., 2020b) or cables (Miyazaki

et al., 2019), (Lee et al., 2020). An example of this

type of solution is provided in Fig. 2c. Despite be-

ing an excellent solution for inspection and manipu-

lation tasks in unknown environments, these systems

encounter three significant limitations: (i) their in-

ability to execute heavy manipulation tasks (such as

screwing, sewing, bolting, etc.) due to the presence

of an unconstrained floating suspension platform; (ii)

diminished operation times due to the restricted space

for batteries within the aircraft and the energy ex-

pended in flight management; (iii) the potential dis-

persal of contaminating particles if radioactive dust is

present in the environment, facilitated by the airflow

generated by the rotors.

The limitations outlined are partially addressed

by solutions conceptually akin to the one devised for

the dismantling of the chimneys of Units 1/2 exhaust

stack at the Fukushima nuclear reactor (Yokokohji,

2021), as depicted in Fig. 2d. This system consists

of a large lifting beam containing all the electronics to

power and control multiple Staubli industrial manipu-

lators capable of cutting the chimney. In this scenario,

the benefits associated with the capability to operate

in an unfamiliar environment despite the absence of

inherent integration with the surroundings are facili-

tated by the option to link the system to a standard

crane. This crane then positions and lowers the sys-

Figure 2: (a) Long-reach robotic arm mounted on the Train

Inspection Monorail inside CERN’s LHC tunnel. (b) Teler-

obotic dual-arm servomanipulator mounted on a telescopic

boom at SNS

1

. (c) UAM for bird-diverter installation on

power lines, with drone and dual-arm system connected via

four ropes. (d) Multi-arm system mounted on lifting beam

hoisted by cranes for decommissioning of Fukushima nu-

clear site

2

.

tem to the desired height. Nonetheless, the system

presented is oversized for the requirements of indoor

facilities necessitating narrow spaces.

To date there is no robotic system in the literature

capable of performing both inspection tasks and time-

consuming heavy manipulation tasks in unstructured

environments (indoors and outdoors), with the need to

access narrow spaces with variable heights and with

minimal impact on the external environment.

(a) (b)

(c) (d)

3 ROBOT DESCRIPTION

This section is intended to provide the functional and

mechatronic specification of the CRANEBot robotic

platform.

3.1 Functional Specifications

This robotic system allows the execution of tasks

at considerable heights by leveraging lifting systems

(e.g. overhead and tower cranes), hence being capa-

ble of tackling all those manipulation and inspection

tasks in areas inaccessible to ground robots (wheeled

and legged). In the specific setting of CERN, where

1

Courtesy of Oak Ridge National Laboratory

2

Source: Tokyo Electric Power Company Holdings

CRANEBot: Teleoperated Crane-Suspended Robotic System for Inspection and Manipulation in Harsh Environments

103

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

sdigiova

24/05/2024

DESIGNED

1 / 1

CHECKED

APPROVED

RELEASED

A3

1 : 15

Scale

Designed:

Sheet

QAC

Revision

Number

LABEL:

CERN

24/05/2024

4

0

°

1

4

5

°

6

3

°

6

3

°

1

4

5

°

4

0

°

R950

R600

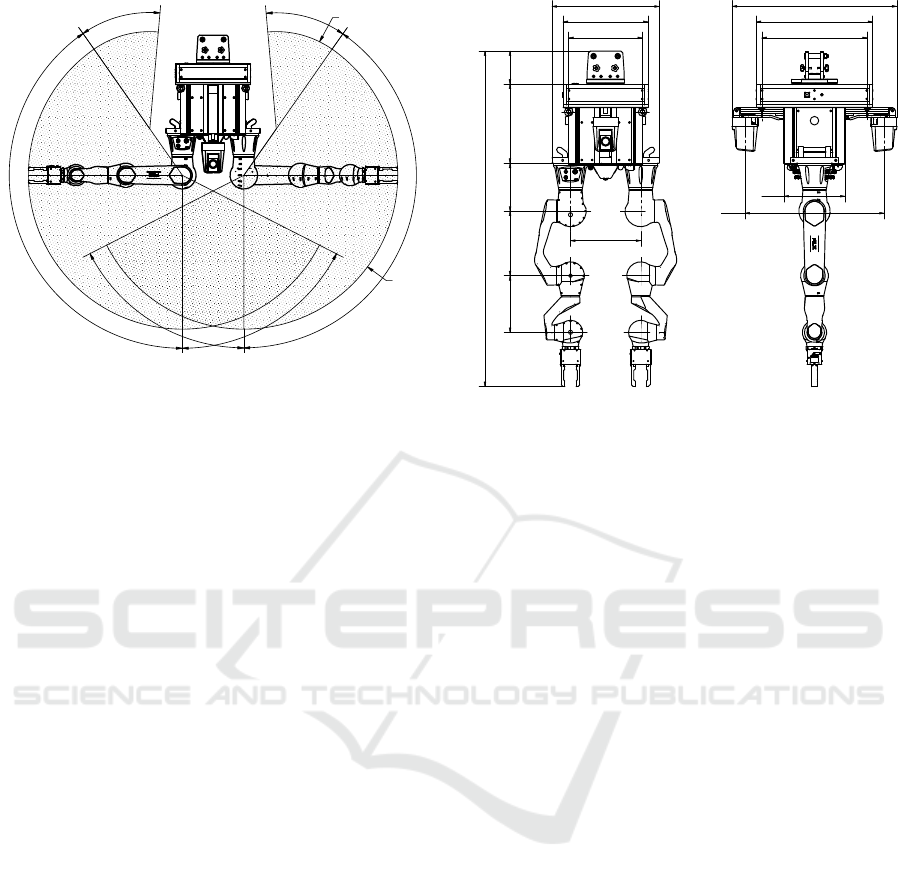

Figure 3: Robot workspace with grippers installed on the

end-effectors.

the system is currently deployed, the robot’s activities

primarily occur within hazardous areas. This hazard

stems from the radioactivity generated by the particle

accelerator, as well as the complex nature of the ma-

nipulation and inspection tasks, which pose risks to

human intervention.

The tasks encompassed by the robot include ob-

ject recognition, machinery monitoring, and defect

detection, thanks to its on-board camera system. Ad-

ditionally, manipulation, positioning, and object in-

sertion are enabled by the presence of two robotic

manipulators. Furthermore, by equipping the robotic

arms with various mechatronic tools, the robot can

undertake assembly, disassembly, screwing, centring,

measuring, and maintenance tasks. Robot’s large

workspace and overall compact dimensions, shown in

Fig. 3 and Fig. 4 respectively, make it a device capable

of accessing relatively confined spaces while ensuring

high dexterity.

Another important innovative feature is the possi-

bility of using the robot as a rotating lifting beam for

the remote transport of loads up to 300 kg. Objects to

be transported can be hooked/released using special

hooks/lifting components handled by the manipula-

tors, slung and lifted via the 4 eye nuts installed under

the platform, and eventually rotated for accurate posi-

tioning.

3.2 Mechatronic Design

The robot’s key component is its central platform, i.e.

an aluminium frame that plays a multiple role: (i) al-

lows the connection with the crane hook; (ii) offers

an additional degree of freedom allowing the robot

to rotate around a vertical axis; (iii) supports the two

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

400

580

1

8

1

5

380

4

2

8

1

7

8

2

6

0

3

5

0

3

0

7

460

754

630

570

331

891

Figure 4: CRANEBot dimensions.

robotic manipulators; (iv) incorporates the on-board

camera system; (v) contains all the essential electron-

ics for powering, actuating and controlling the con-

nected systems; (vi) plays the role of lifting beam for

remote transport of additional loads. The following

will give more details on the above-mentioned points.

In its top part the robot features an adapter de-

signed to accommodate double hooks (adhering to

DIN15402 or UNI 9470/1 standards) that serves as a

safe and solid attachment point, allowing the system

to be lifted vertically and handled by the crane (see

Fig. 6). The hook adapter comprises three plates ar-

ranged in a U-shaped configuration and affixed to the

top of the platform. Upon inserting the crane hook

between the two vertical plates, it is securely held in

place by lifting pins equipped locking nuts. Addition-

ally, four threaded knobs are provided to ensure the

hook is correctly centred and its lateral movement is

restricted. Currently a set of four adapters is available

to accommodate four different DIN15402 hook sizes:

4, 6, 8, and 10. When dealing with larger hooks, it

is necessary to harness the platform by attaching two

slings to the lifting pins. The crane hook adapter is

attached to a rotational actuated joint that allows a

360-degree rotation around a vertical axis at a speed

of 4 revolutions per minute. To utilise this capabil-

ity, it is imperative to lock the rotation of the crane

hook. Thanks to this joint it is possible to rotate the

platform, and therefore the load it carries, to enable a

precise orientation positioning.

On its left and right lateral sides, the system is

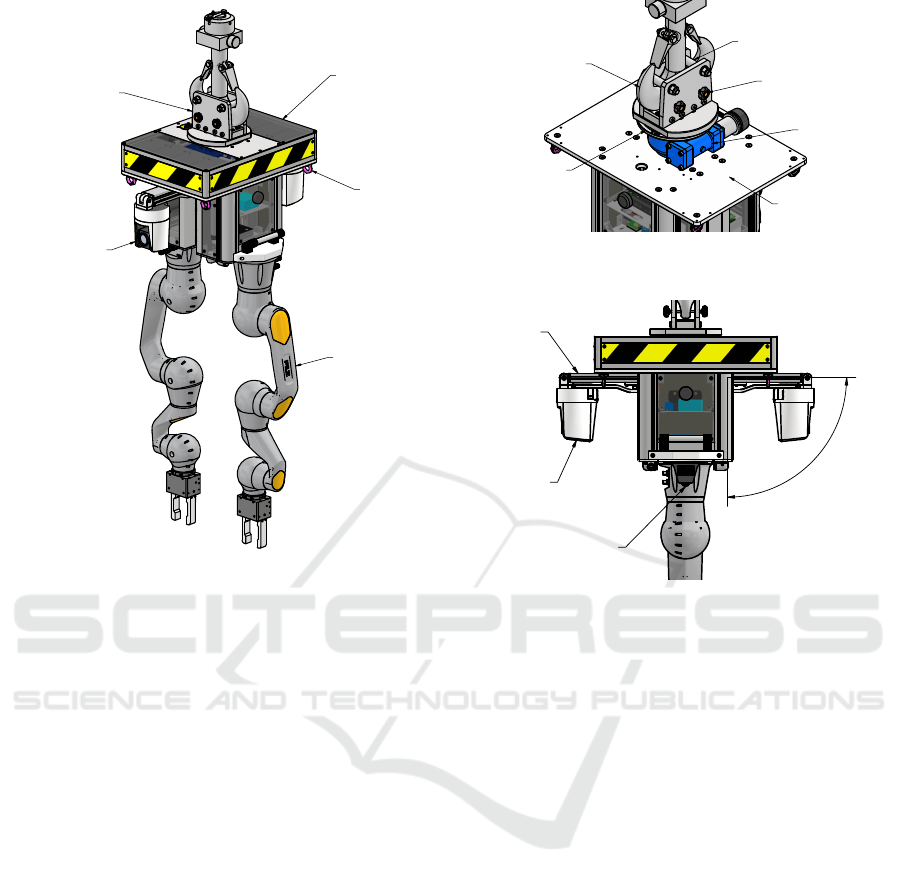

equipped with two lightweight robotic arms, as shown

in Fig. 5. Currently, the system can accommodate

two manipulator models, namely PRBT6 arms man-

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

104

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

battery pack

eye nuts

on-board

camera system

manipulators

crane hook

adapter

Figure 5: Overview of CRANEBot mechanical design.

ufactured by PILZ and LWA4P arms manufactured

by Schunk. Both models are driven by three pairs of

actuators with perpendicular axes, named ERB mod-

ules, located at the shoulder, elbow and wrist respec-

tively, for a total of 6 revolute joints. Each ERB mod-

ule is endowed with zero-backlash Harmonic Drives

which allow precise positioning of manipulator joint.

These arms are also notably lightweight (maximum

of 19 kg per arm) and compact, and have a maximum

payload of 6 kg, allowing for high versatility with re-

spect to the mentioned tasks. The arms are also pow-

ered 24 V DC power, so they do not require an ex-

ternal large inverter. The choice of this manipulator,

besides its construction characteristics, is also due to

the possibility of not necessarily having to use a pro-

prietary control system and external control box, but

of being able to write open-source code and interface

with the firmware via the CANopen protocol.

Additionally, the central platform houses the on-

board camera system, as shown in Fig. 7. This set of

vision sensors is meant to provide a visual feedback

during inspection and teleoperation. It comprises

a panoramic camera, specifically an AXIS F1035-E

Sensor Unit, located in the lower central portion of the

frame pointing down, and two Pan-Tilt-Zoom (PTZ)

cameras, denoted as AXIS V5925, positioned on the

front and back sides of the platform. Moreover, with

the aim of enhancing the operator’s perspective and

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

sdigiova

28/05/2024

DESIGNED

1 / 1

CHECKED

APPROVED

RELEASED

A3

1 : 6

Scale

Designed:

Sheet

QAC

Revision

Number

LABEL:

CERN

28/05/2024

slew drive

main

support plate

lifting pins

absolute

encoder

threaded knobs

double hook

Figure 6: Detail on the hook system and the rotational actu-

ator with vertical axis positioned below the adapter.

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

panoramic camera

9

0

°

wings

PTZ

camera

Figure 7: Detail on the camera system and the wings open-

ing/closing feature.

visibility, a wings system enables independent move-

ment of the PTZ cameras on the sides of the platform.

The system is also pre-wired for the installation of

three additional cameras, in particular AXIS F1005-E

Sensor Units, which can serve as additional points-of-

view for observing the manipulator end-effectors.

All mentioned electromechanical devices are in-

ternally connected to each other via the platform and

are powered by 8 lead-gel 24 V batteries, which guar-

antee a total operating time of up to 8 hours, in most

situations sufficient to complete a robotic task. The

central structure houses an on-board controller PC,

a Inertial Measurement Unit for on-line pose estima-

tion, and a router for connecting the robot via 4G/5G

and WiFi.

Finally, four eye nuts are available in the corners

of the central platform facing downwards, allowing

an external suspended load of up to 300 kg to be

tied to the robot and thus transport simultaneously

the robotic system and additional object via overhead

crane. The combined handling of the two systems

(robot and load) is of fundamental importance be-

cause: (i) it allows, via the robot, to have an easy vi-

sual feedback on the handling of the load suspended

by the overhead crane, which is important when, for

example, the load has to be centred with respect to

CRANEBot: Teleoperated Crane-Suspended Robotic System for Inspection and Manipulation in Harsh Environments

105

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

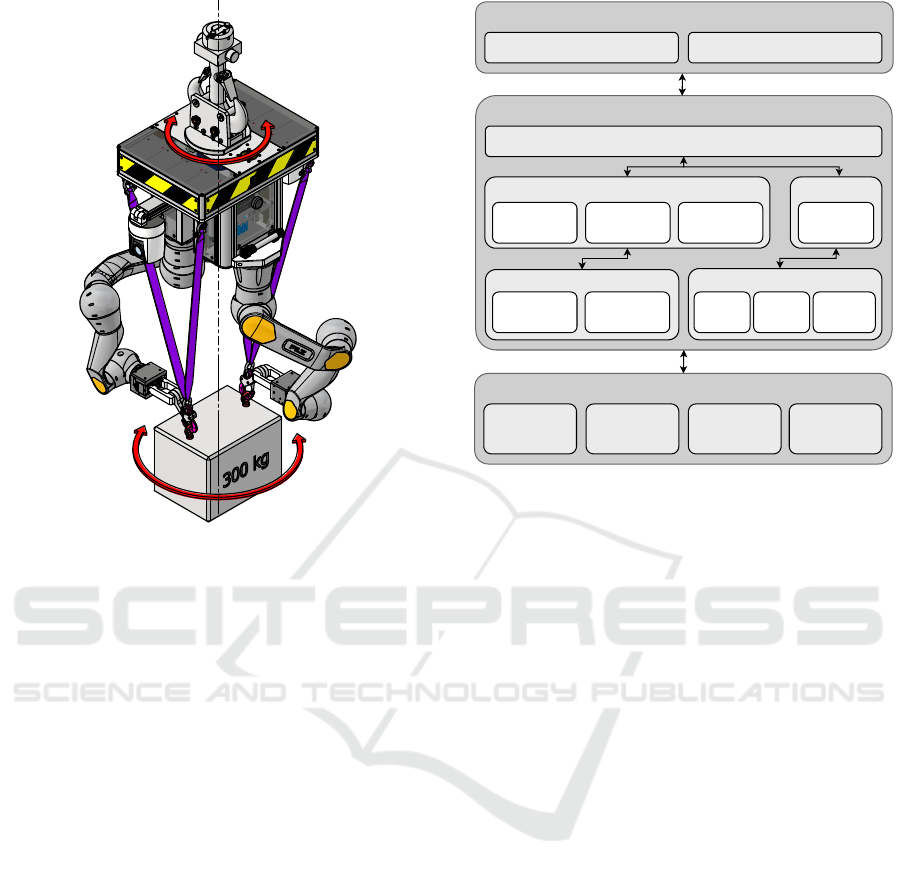

Figure 8: Robot handling an external load (max. 300 kg),

with the manipulators in the configuration to hook/release

the load.

fixed supports; (ii) once it has been positioned in the

space via the overhead crane, it allows immediate ma-

nipulation on the load (e.g. screwing it onto a sup-

port) in the same operational phase, without the need

to separate the two handling actions.

4 CONTROL

The robot operates in a remote, hazardous area, con-

trolled through its on-board computer, which inter-

faces with all physical components, including motor

drivers, cameras, and sensors. This computer runs

a robotic framework that processes sensory data and

manages both control functions and communications.

Operators interact with the robot through a Graphical

User Interface (GUI) connected over available net-

works. There are two types of interfaces developed

for use at CERN: a 2D GUI and a 3D Mixed Reality

GUI (Szczurek et al., 2023), both created with Unity

and C#. Depending on the specific setup, communi-

cation between the robot and the GUIs can occur via

a 4G network, WiFi, or a wired network connection.

Robot Base Robot Arms Tools

CRANEBot Hardware

Sensors

CERN Robotic Framework

CERN Robotic GUI

2D GUI 3D Mixed Reality GUI

CANOpen

Motor drivers

Actuators

Tools motors

Sensors

Cameras IMU

Radiation

measure

Motion control Kinematics

Control

Trajectory

generator

High level communication

Vision

Object

recognition

Figure 9: Overview of control architecture.

4.1 Control Architecture

The CERN Robotic Framework, abbreviated as

CRF (Di Castro et al., 2018a), is a modular software

architecture developed at CERN for supervised tele-

operation and autonomous inspection in hazardous

environments. It is a fully in-house solution essen-

tial for controlling CERN’s pool of robots. The CRF

covers all the software aspects required for using a

robot, ranging from low-level driver implementations,

through middleware communication, to communica-

tion with the user interface for teleoperations. The

framework is written in standard C++17 and uses

CMake as its building tool. The framework is cur-

rently ran and tested on Ubuntu 20.04 and Ubuntu

22.04 distributions. As shown in Fig. 9, the CERN

Robotic Framework decomposes into a set of in-

terconnected modules. These include modules for

low-level communication with actuators and sensors,

modules for control, kinematics management, and

trajectory generation, modules for vision algorithms,

and modules for data exchange with user interfaces.

4.2 Graphical User Interface

At the top of the control architecture is the Graphical

User Interface (GUI), which allows the teleoperator to

control all the main components of the robot and be

informed about its current status. To enable remote

operations, the user connects via 4G or WiFi to the

same network as the robot. This setup allows the ini-

tiation of the so-called communication points, which

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

106

(a) (b) (c)

Figure 10: Robotic interventions and tests conducted at CERN with CRANEBot.

are software modules developed within the CRF that

establish the connection between the robot and the

GUI. For this purpose, the Transmission Control Pro-

tocol (TCP) is used. The communication points also

initiate the control loops for the central platform and

the arms, ensuring that command signals can be trans-

mitted from the interface to the robot’s joints. In the

specific case of the CRANEBot, the teleoperator can

control the central platform, which includes the ro-

tational joint with vertical axis and the wings, the

robotic arms, and the tools. Video information from

the on-board camera system is streamed in real-time

to the interface.

The interface also provides a visualisation of a

three-dimensional model of the robot, i.e. a graphi-

cal representation of the system’s current state. This

is crucial for the operator to understand the robot’s

configuration, offering an external view that comple-

ments the on-board camera views.

5 VALIDATION: ROBOTIC

OPERATIONS

The robot’s functionalities and control architecture

have been validated in real operations within CERN

facilities, as demonstrated by the examples shown in

Fig. 10. As mentioned in Section 3.2, the robot can

be integrated with different types of cranes and can

be equipped with different types of arms and tools.

In Fig. 10a the CRANEBot is shown equipped with

Schunk LWA4P manipulators and grippers, transport-

ing a vacuum module connected to the platform via

slings. The module is to be installed on a fixed sup-

port and aligned with the beamline within the Com-

pact Muon Solenoid (CMS) experiment. The devices

required for the installation are shown in Fig. 10b,

where one of the two manipulators, in this case PILZ

PRBT6, is equipped with a screwdriver for tighten-

ing the vacuum connections. Finally, in Fig. 10c, the

robot is shown tightening a vacuum tank flange using

an impact driver.

6 CONCLUSIONS

This study presents an innovative robotic system de-

veloped at CERN, called CRANEBot, capable of

performing remote operations in harsh environments

where access from above is required. Its design al-

lows the use of different robotic arms and differ-

ent tools, making it capable of long inspection ses-

sions and heavy manipulation. Finally, the robot is

also configured as a mechanical interface, i.e., lifting

beam, with respect to another load to be transported,

allowing components to be placed and installed eas-

ily and effectively. The system has been validated in

numerous tests and robotic interventions, successfully

performing the required tasks.

REFERENCES

Bellingham, J. G. and Rajan, K. (2007). Robotics in remote

and hostile environments. science, 318(5853):1098–

1102.

CRANEBot: Teleoperated Crane-Suspended Robotic System for Inspection and Manipulation in Harsh Environments

107

Cacace, J., Orozco-Soto, S. M., Suarez, A., Caballero, A.,

Orsag, M., Bogdan, S., Vasiljevic, G., Ebeid, E., Ro-

driguez, J. A. A., and Ollero, A. (2021). Safe local

aerial manipulation for the installation of devices on

power lines: Aerial-core first year results and designs.

Applied Sciences, 11(13):6220.

D’Ago, G., Lefebvre, M., Buonocore, L. R., Ruggiero, F.,

Di Castro, M., and Lippiello, V. (2022). Modelling

and control of a variable-length flexible beam on in-

spection ground robot. In 2022 International Con-

ference on Robotics and Automation (ICRA), pages

8224–8230. IEEE.

Di Castro, M. (2019). A novel robotic framework for safe

inspection and telemanipulation in hazardous and un-

structured environments. PhD thesis, Industriales.

Di Castro, M., Buonocore, L. R., Ferre, M., Gilardoni,

S., Losito, R., Lunghi, G., Masi, A., et al. (2017).

A dual arms robotic platform control for naviga-

tion, inspection and telemanipulation. In Proceed-

ings of the 16th International Conference on Ac-

celerator and Large Experimental Control Systems

(ICALEPCS’17), Barcelona, Spain, pages 8–13.

Di Castro, M., Ferre, M., and Masi, A. (2018a). Cern-

tauro: A modular architecture for robotic inspection

and telemanipulation in harsh and semi-structured en-

vironments. IEEE Access, 6:37506–37522.

Di Castro, M., Tambutti, M. B., Ferre, M., Losito, R.,

Lunghi, G., and Masi, A. (2018b). i-tim: A

robotic system for safety, measurements, inspection

and maintenance in harsh environments. In 2018 IEEE

International Symposium on Safety, Security, and Res-

cue Robotics (SSRR), pages 1–6. IEEE.

Dorafshan, S. and Maguire, M. (2018). Bridge inspec-

tion: Human performance, unmanned aerial systems

and automation. Journal of Civil Structural Health

Monitoring, 8:443–476.

D’Ago, G., Selvaggio, M., Suarez, A., Ga

˜

n

´

an, F. J., Buono-

core, L. R., Di Castro, M., Lippiello, V., Ollero, A.,

and Ruggiero, F. (2024). Modelling and identification

methods for simulation of cable-suspended dual-arm

robotic systems. Robotics and Autonomous Systems,

175:104643.

Falorca, J. F., Miraldes, J. P., and Lanzinha, J. C. G. (2021).

New trends in visual inspection of buildings and struc-

tures: Study for the use of drones. Open Engineering,

11(1):734–743.

Gahl, T. (2015). The modular control concept of the neu-

tron scattering experiments at the european spallation

source ess. Proceedings of ICALEPCS15, pages pp–

529.

Gamper, H. (2024). A robotic system for cern’s future cir-

cular collider/submitted by dipl. ing. hannes gamper

bsc.

Gamper, H., Gattringer, H., M

¨

uller, A., and Di Castro,

M. (2021). Design optimization of a manipulator for

cern’s future circular collider (fcc). In ICINCO, pages

320–329.

Graves, V. B. and Dayton, M. J. (2011). Core vessel insert

handling robot for the spallation neutron source. Tech-

nical report, Oak Ridge National Lab.(ORNL), Oak

Ridge, TN (United States). Spallation . . . .

Haines, J., McManamy, T., Gabriel, T., Battle, R., Chipley,

K., Crabtree, J., Jacobs, L., Lousteau, D., Rennich,

M., and Riemer, B. (2014). Spallation neutron source

target station design, development, and commission-

ing. Nuclear Instruments and Methods in Physics Re-

search Section A: Accelerators, Spectrometers, Detec-

tors and Associated Equipment, 764:94–115.

Ivanovic, A., Markovic, L., Car, M., Duvnjak, I., and Orsag,

M. (2021). Towards autonomous bridge inspection:

Sensor mounting using aerial manipulators. Applied

Sciences, 11(18):8279.

Jiang, G., Voyles, R. M., and Choi, J. J. (2018). Precision

fully-actuated uav for visual and physical inspection

of structures for nuclear decommissioning and search

and rescue. In 2018 IEEE international symposium

on safety, security, and rescue robotics (SSRR), pages

1–7. IEEE.

Lee, J., Balachandran, R., Sarkisov, Y. S., De Stefano,

M., Coelho, A., Shinde, K., Kim, M. J., Triebel, R.,

and Kondak, K. (2020). Visual-inertial telepresence

for aerial manipulation. In 2020 IEEE International

Conference on Robotics and Automation, pages 1222–

1229.

Miyazaki, R., Jiang, R., Paul, H., Huang, Y., and Shi-

monomura, K. (2019). Long-reach aerial manipu-

lation employing wire-suspended hand with swing-

suppression device. IEEE Robotics and Automation

Letters, 4(3):3045–3052.

Mostafa, M., Zahran, S., Moussa, A., El-Sheimy, N., and

Sesay, A. (2018). Radar and visual odometry inte-

grated system aided navigation for uavs in gnss denied

environment. Sensors, 18(9):2776.

Ollero, A., Tognon, M., Suarez, A., Lee, D., and Franchi,

A. (2021). Past, present, and future of aerial robotic

manipulators. IEEE Transactions on Robotics.

Ribeiro, I., Damiani, C., Tesini, A., Kakudate, S., Siuko,

M., and Neri, C. (2011). The remote handling systems

for iter. Fusion Engineering and Design, 86(6-8):471–

477.

Ruggiero, F., Lippiello, V., and Ollero, A. (2018). Aerial

manipulation: A literature review. IEEE Robotics and

Automation Letters, 3(3):1957–1964.

Suarez, A., Caballero, A., Garofano, A., Sanchez-Cuevas,

P. J., Heredia, G., and Ollero, A. (2020a). Aerial ma-

nipulator with rolling base for inspection of pipe ar-

rays. IEEE Access, 8:162516–162532.

Suarez, A., Real, F., Vega, V. M., Heredia, G., Rodriguez-

Castano, A., and Ollero, A. (2020b). Compliant bi-

manual aerial manipulation: Standard and long reach

configurations. IEEE Access, 8:88844–88865.

Szczurek, K. A., Prades, R. M., Matheson, E., Rodriguez-

Nogueira, J., and Di Castro, M. (2023). Multimodal

multi-user mixed reality human–robot interface for re-

mote operations in hazardous environments. IEEE Ac-

cess, 11:17305–17333.

Trevelyan, J., Hamel, W. R., and Kang, S.-C. (2016).

Robotics in hazardous applications. Springer hand-

book of robotics, pages 1521–1548.

Yokokohji, Y. (2021). The use of robots to respond to nu-

clear accidents: Applying the lessons of the past to the

fukushima daiichi nuclear power station. Annual Re-

view of Control, Robotics, and Autonomous Systems,

4:681–710.

ICINCO 2024 - 21st International Conference on Informatics in Control, Automation and Robotics

108